Professional Documents

Culture Documents

Tip Comutari Ac1 - Ac15

Uploaded by

sandum1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tip Comutari Ac1 - Ac15

Uploaded by

sandum1Copyright:

Available Formats

96

T

E

C

H

N

I

C

A

L

I

N

F

O

R

M

A

T

I

O

N

Product loadability

Problematic choice of suitable relay contact for a particular load switched with a product is described below.

Mostly we experience problems with incorrect choice of load (meaning incorrect relay for a particular load) which results in permanent switching of contact (sealing) or damage on relay contact which

then results in malfunction.

What load can you use?

Detailed types of load according to standard EN 60947 are described in charts below categories of use.

Non-inductive or slightly inductive load, resistance furnace

Includes all appliances supplied by AC current with power factor (cos .) 0,95.

Examples of use: resistance furnace, industrial loads

Category of use

How can you distinguish for which load is our product (relay) designated?

Our company record this information on a products and also in our catalogue, instruction manual and other promotional and technical material (web-site etc.).

It is important to realize that it is not always possible to point out load because of lack of information about the device ( user cannot measure cos .) or it is not possible because of inconstancy of parameters

of switched device.

Manufacturer of relays record always guaranteed parameters in ideal conditions which are done by a norm (temperature, pressure, humidity, etc.) and reality can be in a lot of cases diferent.

Category of use (classifcation) of a particular relay is done by material of output contacts.

Basic types of materials which are used for production of contacts for high-performance relay are:

a)AgCd suitable for switching ohmic loads. Before of harmfulness of Cd, this type of contact is remitted.

b)AgNi designated for switching resistive loads , good quality switching and conducting (contact doesnt oxidate) small currents/voltages ,it is not designated for surge currents and loads with inductive

component

c)AgSn or AgSnO suitable for switching loads with inductive component , not suitable for switching small currents/voltages, it is more resistive to surge currents, suitable for DC voltage switching,

less suitable for switching loads of ohmic type

d)Wf (wolfram)-special contact designated for switching surge currents with inductive component

e)with gold (AgNi/Au)- it is used for improvingcontacts for low currents/ voltages , prevents oxidation.

Motors with short-circuit armature, motor switching when in operation

This category applies to switching of motors with short-circuit armature while in operation. While switching, contactor switches current which is 5 up to 7 times

rated current of motor.

Switching of electrical gas-flled lights, fuorescent lights

El. bulb switching

Enables low contact loading due to resistance of cold fber is many times smaller that the one of hot fber.

Switching of capacitors

Switching of semiconductor loads with separation transformers

Management of alternating electro-magnetic loads

This category applies to switching inductive loads with input for closed electro-magnetic circuit higher than 72 VA

Use: switching coils of contactors

Connecting and disconnecting in unloaded states

Switching resistive loads, including low loading

Switching of mixed resistive and inductive loads, including low overloading

Switching of motor loads or other high inductive loads

Non-inductive or low inductive load, resistive furnaces

Non-inductive or low inductive loads, resistive furnaces el. bulbs

Management of resistive loads and fxed loads with insulation by opto-electric element

Switching of highly inductive loads (e.g. series motors)

AC-1

AC-2

AC-3

AC-4

AC-5a

AC-5b

AC-6a

AC-6b

AC-7a

AC-7b

AC-8a

AC-8b

AC-12

AC-13

AC-14

AC-15

AC-20

AC-21

AC-22

AC-23

AC-53a

DC-1

DC-3

DC-5

DC-6

DC-12

DC-13

DC-14

DC-20a(b)

DC-21a(b)

DC-22a(b)

DC-23

EN

AC current, cos = P/S (-)

Motors with slip-ring armature, switching of

Switching low inductive loads of home appliances and similar applications

Load of motors for home appliances

Switching of hermetically sealed motors of cooling compressors with manual reset switches against overload

Hermetically sealed cooling compressors have to be placed in one box without external shaft or shaft padding and motor must operate with cooling liquid

Switching of hermetically sealed motors of cooling compressors with manual reset switches against overload

Hermetically sealed cooling compressors have to be placed in one box without external shaft or shaft padding and motor must operate with cooling liquid

Switching of semiconductor loads with separation transformers

Switching of low electro-magnetic loads (max.72 VA)

Switching of motors with short-circuit armature with semiconductor contactors

Note: Category AC 15 replaces formerly used category AC 11

Shunt motors: start-up, braking by backset, reversion, resistive braking

Series motor: start-up, braking by backset, reversion, resistive braking

Switching of electromagnets

Switching of electromagnetic loads in circuits with limiting resistor

Switching and breaking without load(a: frequent switching ,b: occasional switching)

Switching ohmic loads including limiting overloading (a: frequent switching ,b: occasional switching)

60947-4

60947

60947-4

60947

60947-4

60947-4

60947-4

60947-4

60947

60947

60947

60947

60947-5

60947-5-1

60947-5-1

60947-5

60947-3

60947-3

60947-3

60947-3

60947

60947-4

60947-4-1

60947-4-1

60947-4-1

60947-5-1

60947-5-1

60947-5-1

60947-3

60947-3

60947-3

60947-3

Switching of transformers

Typical use

Electro-motors with short-circuit armature: start up, braking by backset, changeover

DC current, t = L/R (s)

97

T

E

C

H

N

I

C

A

L

I

N

F

O

R

M

A

T

I

O

N

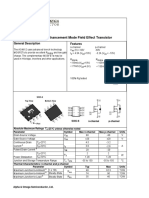

SMR-T

SMR-H

SMR-B

mW V / mA

AC1 AC3 AC15

DC1

(24/110/220 V)

DC1

(30/110/220 V)

DC1

(24/110/220 V)

DC1

(24/110/220 V)

AgSnO

2

1000 10/100

mW V / mA

AC-1 AC-15

AC-3

DC-1 R, L, C

10

AC5b AC5a AC5a AC5a AC5a

AC1 AC3 AC15 AC5b AC5a AC5a AC5a AC5a

AC1 AC3 AC15 AC5b AC5a AC5a AC5a AC5a

AC1 AC3 AC15 AC5b AC5a AC5a AC5a AC5a

10

10

10

10

AC5b AC5a AC5a AC5a AC5a

DC1

(24/110/220 V) AC1 AC3 AC15 AC5b AC5a AC5a AC5a AC5a

10

AgNi 300 5/10

AgNi

1250 VA

AgNi 500 W 2000 VA 375 VA 8 A/0.4 A/0.25 A

AgNi

1000 W 4000 VA 0.9 kW 750 VA 16 A/0.5 A/0.35 A

AgNi

500 W 2500 VA 125 VA 10 A/0.49 A/0.33 A

2000 W 1000 W 1000 W 750 W 500 W 4000 VA 0.9 kW 750 VA 16 A/0.5 A/0.35 A

AgSnO

2

500 W 0.75 A/ 240 V 5 A/0.5 A/0.3 A

LOAD

(symbols)

TYPE OF LOAD

SWITCHING MANAGEMENT

RESISTIVE

R

INDUCTIVE

L

CAPACITIVE

C

INCLINE EDGE DESCENDING EDGE

LAMP,

HALOGEN LIGHT

LOW-VOLTAGE EL.BULBS12-24V

ELECTRONICTRANSFORMERS

LOW-VOLTAGE EL.BULBS12-24V

WOUNDTRANSFORMERS

UNCOMPENSATED FLUORESCENT

LAMPS

EKONOMIC FLUORESCENT

LAMPS

ACCORDING

TO BALLAST

SWITCHING MANAGEMENT

RELAY CONTACT

MINIMUM LOAD

It is valid for foolowing products: CRM-61, SOU-2, HRN-54, HRN-54N, HRN-55, HRN-55N, HRN-56, HRN-57, HRN-57N PRI-32, PRI-51, TER-9

It is valid for foolowing products: CRM-83J, CRM-93H, PRM-92H, PRM-2H, CRM-82TO, VS308K, VS308U, TER-7

It is valid for foolowing products: CRM-4, CRM-42, SHT-1, SHT-1/2, SHT-3, SOU-1, MR-41, MR-42, VS116K, VS316, VS116U, VS316/24, VS316/230, TER-3, SMR-B

RELAY CONTACT

16 A

RELAY CONTACT

8 A

RELAY CONTACT

8 A

RELAY CONTACT

16 A

LOAD

RELAY CONTACT

MINIMUM LOAD

It is valid for foolowing products: CRM-81J, CRM-91H, PRM-91H, CRM-91HE, CRM-2HE, CRM-2H, CRM-2T, PDR-2/A, PDR-2/B, SJR-2, HRH-2, HRN-33, HRN-34, HRN-35, HRN-37, HRN-41, HRN-42,

HRN-43, HRN-43N, HRN-63, HRN-64, HRN-67, PRI-41, PRI-42, HRH-1, COS-1, TER-4, TEV-1, TEV-2, TEV-3, Thermo

SYMBOLS

lamp,

halogen light

uncompensated

fuorescent lamps

compensated

fuorescent lamps

in series

ekonomic

fuorescent lamps

Controllingof

alternative

electro-magnetic

loads

Squirrel-cage

motors, switching

of motors in

operation

Non-inductive or

low-inductive loads,

resistive

furnance

Product loadability

It is valid for foolowing products: CRM-2T/480

RELAY CONTACT

3 A

LOAD

compensated

fuorescent lamps

in parallel

COMMENTS

Dimmer withdef ned

load: R- resistive

L- inductive

C- capacitive

Non-inductive or

low-inductive loads,

resistive furnances

LOAD

LOAD

LOAD

ACCORDING

TO BALLAST

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Multiple Choice Question (MCQ) of Induction MotorsDocument18 pagesMultiple Choice Question (MCQ) of Induction Motorskibrom atsbha75% (4)

- PIP-MAX Manual 20200908Document77 pagesPIP-MAX Manual 20200908sandum1100% (1)

- Alarm Sound Script1Document1 pageAlarm Sound Script1sandum1No ratings yet

- Improved Universal Motor Drive-CD00003829Document10 pagesImproved Universal Motor Drive-CD00003829Dan EsentherNo ratings yet

- Hmi Basic Panels 2nd Generation Operating Instructions en-USDocument116 pagesHmi Basic Panels 2nd Generation Operating Instructions en-USgeorgel1605No ratings yet

- Ammonia AbsorptionDocument5 pagesAmmonia Absorptionfarzad100% (1)

- Gas Detector Manual Instructions for Alarm Levels, Functions and InstallationDocument8 pagesGas Detector Manual Instructions for Alarm Levels, Functions and Installationsandum1No ratings yet

- Hydrogen - Understanding Fuel CellsDocument4 pagesHydrogen - Understanding Fuel Cellssandum1No ratings yet

- Build Your Own VAWT by David MussellDocument17 pagesBuild Your Own VAWT by David MussellMr Void100% (9)

- ME 262 Fusesection - 03Document1 pageME 262 Fusesection - 03Patricio LorcaNo ratings yet

- Gas Detector Manual Instructions for Alarm Levels, Functions and InstallationDocument8 pagesGas Detector Manual Instructions for Alarm Levels, Functions and Installationsandum1No ratings yet

- Danfoss FC 102 ManualDocument94 pagesDanfoss FC 102 Manualsandum1No ratings yet

- Lecture 3Document33 pagesLecture 3Deniisa AlexaNo ratings yet

- Okp PDFDocument1 pageOkp PDFbaqwasmailNo ratings yet

- 9820 3582 05 User Guide MKIV Ethernet-IP 03Document50 pages9820 3582 05 User Guide MKIV Ethernet-IP 03StevenNo ratings yet

- Catalogue 10 EURO NH3Document32 pagesCatalogue 10 EURO NH3sandum1No ratings yet

- New Microsoft Office Word DocumentDocument1 pageNew Microsoft Office Word Documentsandum1No ratings yet

- 02-Orc VanslambrouckDocument26 pages02-Orc Vanslambroucksandum1No ratings yet

- 3tier 5km Global Wind SpeedDocument1 page3tier 5km Global Wind Speedsandum1No ratings yet

- Ap5101 SensorsDocument1 pageAp5101 SensorsJasmine KNo ratings yet

- Types of Motors Used in RoboticsDocument24 pagesTypes of Motors Used in RoboticsNehul PatilNo ratings yet

- 37-SDMS-02 - CosaDocument5 pages37-SDMS-02 - CosaAWNo ratings yet

- OKI PULP & PAPER MILL PROJECT SUMMARY WEEKLYDocument4 pagesOKI PULP & PAPER MILL PROJECT SUMMARY WEEKLYKusnadi AnginNo ratings yet

- Lighting Lighting: Essential Smartbright LEDDocument2 pagesLighting Lighting: Essential Smartbright LEDAndi RamaNo ratings yet

- Service Manual: XS-G3 XS-G4 XS-G5Document49 pagesService Manual: XS-G3 XS-G4 XS-G5ferdelvastoNo ratings yet

- Sucofeed RF Cables H&SDocument12 pagesSucofeed RF Cables H&SRahul GoudNo ratings yet

- Power 1 Form A: Features Typical ApplicationsDocument8 pagesPower 1 Form A: Features Typical ApplicationsShainameNo ratings yet

- Siemens LW39-16B Cam Switch technical specsDocument17 pagesSiemens LW39-16B Cam Switch technical specsfahad pirzadaNo ratings yet

- Crystal Tester: Presented By-Sudesha Basu Majumder (19BEE0228) Parichay Singh (19BEE0229)Document16 pagesCrystal Tester: Presented By-Sudesha Basu Majumder (19BEE0228) Parichay Singh (19BEE0229)Sudesha BasuNo ratings yet

- MCCB Schneider EZC100F3100 PDFDocument2 pagesMCCB Schneider EZC100F3100 PDFragunatharaoNo ratings yet

- A Modern GDO - The "Gate" Dip OscillatorDocument5 pagesA Modern GDO - The "Gate" Dip Oscillatorhoteloscar100% (1)

- LED CLASSIC Meet 2020Document1 pageLED CLASSIC Meet 2020FafahMukhamadNo ratings yet

- 30 3001 837 B Link Installation InstructionsDocument2 pages30 3001 837 B Link Installation InstructionsMark Izsm AmersonNo ratings yet

- Eppb1014 / Eeeb113: Circuit Analysis 1 Semester 1, 2021/2022Document7 pagesEppb1014 / Eeeb113: Circuit Analysis 1 Semester 1, 2021/2022WilfredNo ratings yet

- General Notes and Specifications A Legends and Symbols BDocument1 pageGeneral Notes and Specifications A Legends and Symbols BRonan RojasNo ratings yet

- 60V Complementary Enhancement Mode FET FeaturesDocument9 pages60V Complementary Enhancement Mode FET FeaturesAhmad MaufiqNo ratings yet

- Multi-range digital timer for electronics equipmentDocument2 pagesMulti-range digital timer for electronics equipmentjoelsNo ratings yet

- Soft-Error-Aware Read-Stability-Enhanced Low-Power 12T SRAM With Multi-Node Upset Recoverability For Aerospace ApplicationsDocument11 pagesSoft-Error-Aware Read-Stability-Enhanced Low-Power 12T SRAM With Multi-Node Upset Recoverability For Aerospace ApplicationsZhongpeng LiangNo ratings yet

- G13 Sirena Con Luz Estroboscopica - FikeDocument4 pagesG13 Sirena Con Luz Estroboscopica - Fikefreddy vargasNo ratings yet

- Project 5 MiniAmp p78-82Document5 pagesProject 5 MiniAmp p78-82Engkiong GoNo ratings yet

- General Check List - ElectricalDocument2 pagesGeneral Check List - ElectricalSanthoshNo ratings yet

- National Cables Price ListDocument8 pagesNational Cables Price ListAbdul JabbarNo ratings yet

- NHXMH J o CableDocument3 pagesNHXMH J o CableharmlesdragonNo ratings yet

- Sta733 AukDocument3 pagesSta733 AukJhon Arenas100% (1)

- En User Guide Dell P2417HDocument13 pagesEn User Guide Dell P2417Hsupriyo110No ratings yet

- Cimre2ss8 24 OmDocument2 pagesCimre2ss8 24 OmCHINo ratings yet

- ZVS Boost Converter With A Flyback Snubber CircuitDocument8 pagesZVS Boost Converter With A Flyback Snubber Circuitmishranamit2211No ratings yet

- Cat Lovato ATL20Document6 pagesCat Lovato ATL20Luis FloresNo ratings yet