Professional Documents

Culture Documents

Log Building News Issue No 58

Uploaded by

ursindCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Log Building News Issue No 58

Uploaded by

ursindCopyright:

Available Formats

NEWS

January | February | March 2006 Number 58

Agreement Number 40707514

Log Builders Mecca

by Ingrid Boys

Le Chateau Montebellowhy

does it hold such signicance for

log builders? Perhaps it has

become a kind of reference point

to handcrafters and here we are

reminded of the essentials of our

trade pared down and stripped

of power tools and chainsaws and

jigs.

We look in amazement at this

magnicent structure built entirely

with hand tools, and we shake our

heads in wonder at the accom-

plishment of Montebello. At the

same time we are affirmed in our

builders hearts that here is an

accomplishment that we also are

capable of; we too could build a

Montebello. And so by virtue of

our craft we have a sense of own-

ership in this structurewe, unlike

all other admirers of Montebello,

know rst-hand the sweat and

skills of this endeavour.

The construction of Montebello

is not just a celebration of crafts-

men, it is also the story of busi-

ness: beginning with an idea,

backed by money, building the

right team, nding the man-

power, efficiently organizing a

huge workforce, dealing with gov-

ernment authorities, and in true

entrepreneurial fashion, assessing

the economic challenges of the

day and turning them to advan-

tage.

Montebello is therefore a venue

that suits the theme of our 33rd

AGM and Conference. As we work

towards developing further the

skills of our craft, we too are chal-

lenged by uctuating economies,

changing markets, and issues of

government authority.

The founding members of our

Association dreamed of the day

that the CLBA would be big

enough to hold our AGM at

Montebello. If we can measure

the success of the ILBA by arriving

at Montebello, then we have

arrived indeedtwice.

Our rst Montebello conference,

in 2000, was an arrival to maturity

for our Association. The name-

debate was nally settled when we

transcended national boundaries

and took a global perspective by

continued page 22

Six years ago at Le Chteau Montebello

Inside This Issue

Presidents Letterpage 2

Letter to the Editorpage 3

Helicopter Re-assembly

page 4

BhutanLand of the

Thunder Dragonpage 6

ICC Code in Second

Roundpage 7

Treasurers Reportpage 9

Dummies Can Be Smart

page 10

Advertisers in This Issue

page 11

TechTalkpage 13

ILBA Conference 2006

Telling Our Story Building

Our Futurepage 14

From the Conference Team

page 15

International Log Building

Conference in Latvia

page 16

Construction Agreements

and Procedures, Part 1

page 18

Log Building in Russia

page 20

New and Renewing

Memberspage 22

Classied Adspage 24

2 LogBuildingNews January | February | March 2006

LogBuildingNews

January | February | March 2006

Issue #58

Published four times a year

2006 International Log Builders

Association

P.O. Box 775

Lumby, British Columbia

Canada V0E 2G0

Toll-free: 800-532-2900

Phone: 250-547-8776

Fax: 250-547-8775

www.logassociation.org

Ann Miks, Administrative Assistant

ann@logassociation.org

Log Building News Editor

Robert Chambers

robert@logbuilding.org

Contributors to this issue:

Ingrid Boys

ingrid@logworks.ca

Patti LeFrancois

plefran@shaw.ca

Michael Pielorz

huskylogwork@hotmail.com

Graeme Mould

graeme@NaturalLogHomes.co.nz

Robert W. Chambers

robert@logbuilding.org

Egils Artmanis

egipapa@msn.com

Ed Shure

ed@timmerhusinc.com

Christopher Mannix

topnotch@gci.net

Rick Hall

rickhall@conveyists.com

John Boys

logworks@uniserve.com

Nick Berwian

nickberwian@gmx.de

Robrt Savignac

logbob@telus.net

Presidents Letter

by Ed Shure, President

My last letter to you (Transition Time at

the ILBA) spelled out some of the difficult

decisions that had to be made in order for

our organization to turn the corner. I am

very pleased to be able to tell you that we

are back on track, and ready to get to

work on ensuring that the ILBA will be

both scally responsible and responsive to

the needs of our members.

My mission during my term as President

is to create a more cohesive system of gov-

ernance, so that the lessons learned over

the past few years do not get lost as new

Board members (and staff) may come and

go. I will be working with the Board and

with our members on a range of projects,

from updating our bylaws, to developing a

Board handbook, and mentoring new

Board members. We will hold a forum at

Montebello to discuss how you see the

future your

organization.

In other news,

our recent elec-

tions returned

John Boys and

Jean Rodrigue to

the Board of

Directors. We

also welcome rst-timer, Todagin Hodson,

whose rst project will be to take a look at

our website with an eye towards making it

an even more valuable tool for the mem-

bership. Im sure he would welcome any

suggestions any of you might have in

making his evaluation.

The re-elected Mr. Boys has graciously

agreed to continue as Treasurer. When a

staff and a Board changes dramatically

there is always the usual due diligence at

the time of change-over. John has recently

completed an evaluation of our nancial

records, and reports thatjust as we

expectedeverything has been kept in

order, and that he nds no irregularities.

Please see Johns article, and check our

website for updates and budget details.

Thank you to outgoing director Sjoerd

Bos for his years of service on the ILBA

Board. Most recently he took the lead in

fundraising efforts that played a major part

in getting us back in the black. We will

miss him on the Board!

Robrt Savignac is representing the ILBA

on ICC log home code committee. It is an

inevitability, and if we dont get involved

there will most certainly be decisions made

that will make it difficult to make good

handcrafted buildings. An email on how to

offer amendments was recently sent to all

ILBA members. When the ICC Code-writ-

ing committee nishes its work, the ILBA

Standards Committee and ILBA Board will

review the nal draft and consider whether

to endorse it.

Cathy Hansen is still on sick leave, and

we all wish her a quick and complete

recovery. Meanwhile, Ann is doing a great

job of holding down the fort. Shes been

working on membership renewals. Sorry

for nagging, but please make Anns job a

bit easier and upgrade your individual

membership to the company level today!

The Board recently hired Patti LeFrancois

to run our Montebello conference this

Spring. She and Ingrid Boys, along with a

contingent of volunteers, are working

overtime to ensure that this conference

will be a memorable one.

Hope to see you there!

I am very pleased to be able to tell you that

we are back on track, and ready to get to

work on ensuring that the ILBA will be both

scally responsible and responsive to

the needs of our members.

MONTEBELLO FACTS

They have to be million-

aires or I dont spend my

time, attributed to Victor

Nymark, master builder of

Montebello.

Number 58 LogBuildingNews 3

Hello Robert

First, let me congratulate you on your new responsibility as edi-

tor of the Log Building News it is a worthy publication.

Second, I want to thank the LBN for your kind notice of my

80th birthday, I think I have had as long and as rewarding a

career as I could wish for.

Three, I want to take the opportunity to thank those who par-

ticipated in the birthday celebration here and also to thank those

who could not come. I was more than amazed by the effort

many people went to in attending and my only regret is that

most live too far away and I can not see them more often.

Particularly, I would like to thank Dai Ona who has, over the

years been steady, true and generous with his time, resources

and expertise. I want specially to thank Kako Hoshino, associate

of 20 years, who took the time from a busy schedule to come all

the way from Japan. In the same breath is Mr. Kim from Korea

and all his guys that came along with him as well as the group

from Japan. Closer to home, there were many old friends from

the good old days of the BAM School in Prince George, to note

Dave Rogers and Higgs Murphy.

It is also my great pleasure to extend warm, nay hot thanks

to my very kind neighbors who have welcomed me here and

provided invaluable assistance to an old codger whenever they

could make the opportunity. This is especially true of Peter

McEwen who got into the house building from day one and has

been a lifeline and good friend for the past ve years. He was

there to help move the rst small house in, helped building the

walls for Ardea, pour the footings, move the house onto the

foundation and on to the roof and nishing. Without him, I

could not be here.

I hope to work at a different pace now and stay home as

much as possible. I will miss the very many great people that I

have been privileged to work with on courses from Alaska to

Romania and especially Japan, Germany and Korea. If the air-

planes are still ying, I think I just have to go to Korea and Japan

one more time.

I hope also to attend the conference at Montebello in April

and I wish everyone connected with it the best success.

Very best regards

B. Allan Mackie

L E T T E R S T O T H E E D I T OR

MONTEBELLO FACTS

Three huge log structures amounting to

4,000,000 cubic feet are the core of

Le Chteau Montebello.

4 LogBuildingNews January | February | March 2006

We built a log shell that needed to be

delivered to a private cove near French

Pass, one of the most remote parts of

New Zealand, and not accessible by trucks

or cranes. After considering the options, a

helicopter reassembly was inevitable.

Some specs on the project: the shell

was made of 155 pieces of log totaling

2680 lineal feet of logwork in the pack-

age, and the house was 1950 square feet

on main oor. The longest logs were 14

meters (46 feet), and these weighed

about 1 metric tonne (2200 pounds)

each. From our yard in Geraldine we sent

the shell on two 40-foot at deck trailers

and one 20-foot straight truck with its

own hiab folding crane.

Each of the 155 log pieces was pre-

strapped by us in the log yardwe always

transport our logs with 2 thin straps on

each. It makes loading and unloading the

trucks easy and prevents a lot of damage

to the logs during assembly.

Some construction is done in the

Marlborough Sounds using ocean-going

barges to transport building materials. But

a helicopter was still going to be needed

to set each log, and it was faster to y

1.5km downhill with the logs, than it was

to y a few hundred meters uphill from a

barge anchored below. And by spreading

out the logs on land we were able to easi-

ly nd the next log neededon a barge,

the next log might be trapped.

The rst night found us around the

table brieng as to who was doing what

and where. This operation was only going

to work with precise coordination and

communication, as the skid site of logs

was 1.5 kms away, and out of site of the

building platform.

First: we unloaded the 3 trucks at the

only piece of not very steep ground in the

areaan exposed cattle yard area high on

the ridge about 1500 feet above the

building platform, and well out of sight.

Day 2 saw high winds, so there was no

chopper work that day, and with nothing

else to do, we opted to take small logs of

2-3 meter lengths from the skid site to the

building site in my ute, nearly a half-hour

trip each way, up and down a wet slip-

pery clay farm track.

I called in the helicopter at about 4

oclock as the wind had gone down, but

when he arrived, some 20 minutes from

Nelson, the wind again made conditions

unworkable, and I felt helpless as the

chopper ew away, as there was nothing

more we could doas massive 12 meter

(40-foot) logs made up the lower rounds

below windows. We could be sitting here

for days, I thought.

The next morning was calm at the

house site and the log site, so the pilot

from Helicopters NZ, Ricky Park, met us all

at the ridge for a brieng on helicopter

safety and told us what action he would

take if things went dramatically wrong. If

the helicopter was falling down, he told

us, he would do everything he could to

keep it from landing on us.

He also advised each man to never take

his eyes off of the load, because just the

hook alone will kill ya if it tags you in the

head. Everything at the house platform

had to be xed to the ground or

removedbecause a scrap of timber, a

hardhat, a raincoat, lunch bag, or nylon

sling could end up in the rotor, causing

disaster.

The Squirrel B2 helicopter had a lifting

capacity of 900kgs (about 2000 pounds).

Early on we had to determine if this

machine was capable of doing the job, as

a B3 that could payload 1.5 tons was

available, but it had been stripped down

to be sent to for a job in Australia later

that week. As we progressed, and with sill

logs weighing 850kg we felt this machine

was capable of most of the work.

All logs were labelled with large num-

bers so they could be seen from a dis-

tance by us at the house siteand having

big numbers on every saddle (scarf) was a

huge help. Each long log was also tted

with two12-foot tag lines, so the log

could be rotated to t its location while it

was being lowered. The chain under the

chopper was a xed length, so lowering a

log meant lowering the helicopter. There

was a lightweight 40-foot-long chain

hanging under the chopper that the two

NLH men at the log skid site hooked each

Helicopter Re-Assembly

by Graeme Mould

Number 58 LogBuildingNews 5

log to. Chain (unlike nylon rope and

slings) wont get caught in an up-draft

and end up in the rotors.

We had 5 men at the house (me, two

more NLH log builders, and 2 carpenters

supplied by the general contractor). This

assembly crew was on the building plat-

form to physically grab each log and push

it towards its proper location on the

wallthe helicopter got pulled along as

we pushed the log where we wanted it.

The pilot would hover at a constant

height (as best he could), and then he

would carefully adjust the chopper so it

stayed plumb above the log as we pushed

it around. Sometimes after a log was

placed, an updraft would take the heli-

copter up, and with it, the log right off

the wall.

The log was only forty feet below the

helicopter, so the rotor wash on the house

platform was intense. We tied the hard-

hats to our heads, and some paperwork

went west early on. It was vital the hard-

hats (and everything else) was anchored.

No loose debris allowed with all that rotor

wash.

At the house, I was the only one with

ground-to-air communications with the

pilot (big, aviator earmuffs and voice-acti-

vated microphone that HelicoptersNZ

supplied). I told Ricky which logs we

wanted next, and then he relayed the

next desired log numbers to the men up

at the skid siteour walkie-talkies were

line of sight which meant we couldnt talk

to the men at the log site.

Plus there wasnt time for me to take off

my headset and pick up the radio. As the

day progressed we got into a rhythm that

resembled a military operation. The heli-

copter delivered one log to us about every

200 seconds.

I also used the headset to tell the pilot

how high a log wasit was difficult for

him to see us, being directly under him,

even though the helicopters door was off

so he could lean out and look down on us.

When we reached the window height, a

lot of the small logs had to be placed with

the helicopter. Some corners were built of

short logs, so we assembled these corners

by hand, on the ground or the oor, and

ratched-strapped them together for a sin-

gle pick. The biggest corner-group we did

this way was 8 logs (4 pieces from each

wall). Saving 5 or 6 minutes of helicopter

time was hugeequal to a days wages

for one log builder.

After all the log walls were assembled,

the gable-end wall frames that the car-

penters had pre-built, were own into

place.

At this time in the afternoon we were all

amazed at just how far we had gotten,

And all that was left to do was lift the

long roof logs, and y down some more

packs of rafters and some lumber. Ricky

was thinking it may be prudent to return

the next day with the larger B3 Squirrel.

But with the changeable weather in this

area and the fact we were all set to go,

we pushed on and attempted these roof

log picks into precarious positions. After

one of these went well we continued until

all were in place.

Now the helicopter and its fuel truck

could head off home, and we could sit,

for the rst time all day, and reect on a

mission that went so smoothly that we

could hardly believe it. Nine hours of y-

ing (NZD$19,000 for the chopper), and a

log home shell assembled in one of the

most remote parts of New Zealand.

FAR LEFT Squirrel B2 helicopter placing

a log.

CENTRE Gable end, fully assembled.

Custom welded steel space frame

supports purlins and ridge.

RIGHT Fully assembled shell,

Marlborough Sounds, New Zealand

BELOW We would grab a log and push

it where we needed it to go. The pilots

job was to try to follow where we pulled

him.

P

h

o

t

o

s

b

y

G

r

a

e

m

e

M

o

u

l

d

a

n

d

M

i

l

a

n

B

r

o

d

i

n

a

BhutanLand of the Thunder Dragon

by Chris Mannix

6 LogBuildingNews January | February | March 2006

UPPER RIGHT Typical house. Rammed earth walls, timber frame,

bamboo ceiling on one half, boards on the other for heavy

storage. With the exception of a few skilled laborers

(carpenters) the work is done communally.

LEFT This guy is taking slabs from a sawmill and hewing

them into boards. They will be parts for the handmade

window and door frames that go into the traditional house.

CENTRE Their version of the broad axe. The business part of

the axe measures about 12" and is beveled on both sides.

RIGHT This guy is making corbels for the cornice details.

I have just returned from a trip to the King-

dom of Bhutan where, when we werent

searching for new bird species, I got a

chance to briey check out the home and

monastery building techniques that haven't

changed for centuries. Carpentry is recog-

nized as one of the country's thirteen tradi-

tional arts and crafts, and although house

and monastery design are pretty much

standardized, the level of craftsmanship

using hand tools is high. Obviously, more

square stuff than round stuff.

On another note, my wife and I went to

Bhutan to go birding. Since they have

such a huge chunk of undisturbed habitat,

ranging from tropical hardwoods in the

lowlands to spruce/hemlock in the higher

elevations, they have a lot of birds in a small

area. About six hundred species in an area

the size of Switzerland. By comparison,

North America has about 800 species.

Besides the birds, the culture is amazing,

and the monarch is enlightened. However, I

found it incredibly fascinating from the

point of craftsmanship and tradition.

ICC Code in Second Round

by Robrt Savignac, ILBA delegate representative to ICC Standards Committee

The changes made after the First Round of

Public Comments to the ICC Log Standard

are posted on the ICC website:

http://www.iccsafe.org/cs/standards/

is-log/index.html

Now there now will be a Second Round

of Comments-the due date for your com-

ments is March 6th, 2006. According to

ICC rules and procedures, your comments

must be submitted as follows:

1) You may comment only on the topics

and issues that were brought up during

the rst comment period. For example,

you cannot comment on the denition of

"Checking," since that denition was not

challenged during the rst Public com-

ment period.

2) You can submit comments on topics

and issues that were brought up in the

rst Round. For example, you can com-

ment on the Provisions for Settling in Log

Structures (Section 304) because it has

been re-written and re-organized.

You can nd out which topics are open

by reading through the submissions,

which are available as PDF les at

http://www.iccsafe.org/cs/standards/is-

log/PublicComments0805.html and you

can nd out what changes were made by

reviewing http://www.iccsafe.org/cs/stan-

dards/is-log/draft_2.html

3) Your comments must be sent directly to

the ICC in their format, and on ICC forms.

Giving your comments to a member of

the ICC Committee, or emailing them to

the ILBA will NOT bring action on your

comments, questions, and problems.

The submission form to use is

http://www.iccsafe.org/cs/standards/pdf/st

andards_public_comment_form060205

You ll out this form for each part of the

IS-LOG code you want to propose a

change to. You also must follow their pro-

cedure, which is striking out the words

you don't want, and adding in (underlin-

ing) the words you want to be added. The

ICC Committee will not take action on any

comments or suggestions unless you use

the strikeout and underline method.

4) Some topics you may want to look at:

Roof Overhangs (Section 305.1), Saddle-

Notching Floor Joists over Summer Beams

(Sec 302.2.4.1); Fire Rated Log Walls must

have long grooves that are wider than 6

inches everywhere (Section 303.2.1);

Settling (Section 304). But we suggest you

read the entire Standard, if you can.

For further information and support,

please contact the ILBA office, with ICC

Log Standard as your email subject-line.

Please be diligent in reviewing this ICC

Standard and the revisions of the second

draft, as it is intended to assist you in the

design, development, approval and con-

struction of your log structures.

Number 58 LogBuildingNews 7

ABOVE Two adults and child relax on large, hewn timbers at

Gang Teng Monastery in the Pobjikha Valley, Bhutan.

8 LogBuildingNews January | February | March 2006

Number 58 LogBuildingNews 9

Treasurers Report

by John Boys

I came onto the Board in September, 2005 to ll the vacancy

left by the resignation of Elaine Nosaka. Then, on October 21, I

accepted the position of ILBA Treasurer. This is my rst

Treasurers report to the general membership.

2005 was a challenging year for the Association. The Board

and staff struggled with nances, and expenses had been

exceeding revenue for most of 2005. The last quarter is tradi-

tionally the low point of the ILBA nancial cycle, but on-hand

cash reserves late last year dropped to a point that the Board

had to drastically cut expenses.

Cathy was on sick leave, which meant that office expenses

were down, but they were still higher than we could afford in

the short term. (Cathys ILBA wages are covered by sick-leave

insurance.) The Board discussed and decided it had to cut

expenses promptly and substantially, and so the difficult deci-

sion was made to lay off Robrt Savignac. It was a difficult deci-

sion for everyone, of course. Ann Miks has been retained to run

the office, and has a good handle on the administration.

Ingrid and I spent a couple of days in Lumby in early January.

We reviewed the books, office procedures, and year-end report-

ing requirements. On the whole things are in good shape

record-keeping has been scrupulous and thorough, with a paper

trail up every avenue we wandered. I haven't looked at every

scrap of paper, but I have every reason to think that everything

is accounted for and that the 2005 Board knew about and had

approved all major spending. We continue our due-diligence,

which is an ongoing duty of all Boards, all the more so when

there has been substantial turnover of Board and staff.

Administrative expenses have been reduced by about $8,000

per month in the short term, and we have budgeted for a small

increase to that as we head into Conference season. Each

Committee chair has reviewed ways to reduce overhead while

maintaining quality of the projects they oversee. For example,

Robert Chambers has stepped in to edit LBN, and we have

decided to return to four issues a year rather than six. We get

more meat, with fewer servings!

The Board is taking a more active role: a membership drive

brought in some much needed revenue (thank you to those

ILBA members who renewed early and upgraded to Company

level); and a Conference committee was struck and they adver-

tised to hire out the work required to organize Montebello for

us. The Board has contracted with Patti LeFrancois Consulting,

with Ingrid Boys subcontracting to Patti, for those conference-

coordination services.

Im pleased to report to you that our nancial circumstances

have taken a turn for the better. Our income has exceeded our

expenses since mid-December, and our cash-cushion in the

bank is growing daily. Montebello is shaping up as a money-

maker for the ILBA, with a full slate of sponsors supporting the

Association. For our members it has a dynamite program.

That said, we need to take a hard look at the ILBA goals and

the ILBA resources we have to provide our services and prod-

ucts. In the last couple of years the ILBA has undertaken some

costly initiatives that generate little or no revenue, such as our

participation in the International Code Councils Log Standards

Committee. The Road Trip hit its budgeted expenses but fell far

short of sponsor-revenue projections.

This is not to say that all ILBA projects must produce positive

cash-ow, of coursethat would not even be desirable.

Examples include: log-wall engineering research on seismic sta-

bility produce substantial benets to our members, even though

such worthwhile investments produce no income for the ILBA.

I see a need for regular twice-monthly nancial reporting, and

a more rigorous budgeting and cost/benet analysis for major

projects.

Editors note: Please check the ILBA website for nancial reports.

There will also be all the usual reports from the Board to ILBA

members at our AGM in Montebello.

10 LogBuildingNews January | February | March 2006

Dummies Can Be Smart

by Robert W. Chambers

I try to design roof support systems so that we can cut all the

parts on the ground, from shop drawings, without having to lift,

hold, and scribe heavy logs in awkward positions. But some roof

parts simply must be lifted up into position and scribed, and

marked for cutting. Round log valleys are on that list, and so are

log hips.

Lifting, positioning, and holding log hips and valleys in place

so they can be scribed is a time-consuming job. In fact, I get so

nervous about holding big, heavy round log valleys that some-

times I leave the crane hooked up to them, to prevent them

from slipping. Doing this costs a lot of time (and money)

because when the crane is tied up just holding, there may be

staff unable to work on other jobs.

And getting a valley log to exactly the right position to scribe

is, well, aggravating. Just when you get the top and bottom

right on the centerline, then you nd you need to raise the end

where it crosses the plate by a couple inches, and you start all

over again: left-right, back-forth, up-down, roll!

Log ridges and purlins are, in comparison, easy to position

and hold in place to scribe because they are almost always level.

But hips and valleys want to slide off the roof!

Round log hips and valleys really have to be lifted up, posi-

tioned, held, and scribed. But if the logs have been reduced to

rectangles at their ends (necked down), or if you are using

timbers for hips and valleys, like this job, then I have a shortcut

for you to try.

Dummies

Here is a technique that can make some hips and valleys easier

and safer, and doesnt tie up the crane. I call these jigs dum-

mies. The idea at the heart of a dummy is a simple. Make a

replica of the timber, leave the real timber (or the necked log)

on the ground, and scribe the replica to the log wall and ridge

(Figure 1).

Dummies are short, but full-dimension (1:1 scale) replicas of

the timber you are going to use for the hip or valley. The photos

from now on will describe a job where we used a dummy for

two valleys, but remember that you can use dummies for hips,

jack purlins, jack rafters, and for any log that you have necked

down to a rectangular shapelike oor joists, or summer

beams.

Decide What Size Timber To Use

The engineer or architect will have told you what the dimen-

sions and species, and perhaps grade, the valleys will be. Fully

dress the timber, or at least know what size it will be before you

go any further. (Its bad if you dress the timber last, and then

nd out its too small to t into the mortise youve already cut in

the log walls.)

Make a Dummy

Use MDF, or your favorite jig material, and make a replica of the

end of the valley. The length of the dummy doesnt matter

much2 feet (60cm) is often enough. Make the dummy square

and stiff, but light enough that one man can easily carry it. In

Figure 3 you can see we left a hole in one end to make it easier

to carry and hold for positioning.

I draw the parts of the dummy to scale on my computer

because even my simple drafting program makes it easy to use

MDF sheets efficiently, and make angles accurately.

Speaking of angles, I dont own a protractor that I really like

or trust, so if I need to draw a 55 angle I start with my comput-

er. On screen, and to scale, I draw a 48 by 96 rectangle (4 by

8 sheet of MDF). From one corner I drew a line at a 55angle so

that it hits the opposite edge of the rectangle. One leg of this

triangle is, of course, 48 long. Switch to the applications meas-

uring tool, and measure how long the other leg isits 68-

9/16. (Numbers apply to this house, not every job!)

Wander over to the real sheet of MDF, measure along one

edge 68-9/16 and use a straightedge to connect that point to

the opposite corner. That line is extremely close to 55. This is

more accurate than any protractor, and all I needed was a tape

measure and a straightedge. No math was neededI let the

computer do the calculations.

Lay out and then cut the parts on a table saw, being as accu-

rate as necessary. Screw and glue it together.

Layout Lines

On the dummy, draw important layout lines like: ceiling line

(the plane that is the top of purlins); backing angles; centerlines

of the valley and also down the bottom face of the dummy (we

often use the centerline that is on the bottom of the dummy

because it can be easier to stretch a string under the dummy

than above the dummy, see Figure 3). Sometimes its nice to

have a plumb line or two.

1

Number 58 LogBuildingNews 11

Advertisers in This Issue

Accutech . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CBR Products . . . . . . . . . . . . . . . . . . . . . . . . 23

Cowls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Dietrichs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Emseal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Good Shepherd Wool Insulation . . . . . . . . . . 26

GRK Fasteners . . . . . . . . . . . . . . . . . . . . . . . . 19

Insulspan Corporation . . . . . . . . . . . . . . . . . . . 7

J. Rouleau & Associates . . . . . . . . . . . . . . . . . 26

Log Home Design Ideas/Log Home Living . . 28

Log Home Store . . . . . . . . . . . . . . . . . . . . . . 26

Nicola Log Works . . . . . . . . . . . . . . . . . . . . . . 8

Pat Wolfe Log Building . . . . . . . . . . . . . . . . . 26

Perma-Chink Systems Inc. . . . . . . . . . . . . . . . 17

RCM Cad Design & Drafting . . . . . . . . . . . . 26

Schroeder Log Home Supply . . . . . . . . . . . . . 9

Streamline Design . . . . . . . . . . . . . . . . . . . . . 23

Summer Beam Books . . . . . . . . . . . . . . . . . . 26

The Continental Products Company . . . . . 4/11

The Sansin Corporation . . . . . . . . . . . . . . . . . . 3

Timber Framers Guild . . . . . . . . . . . . . . . . . . 26

Wayside Press . . . . . . . . . . . . . . . . . . . . . . . . 26

Preparations

Find the spot on the plate log (wall top-log) where the center of

the valley will be, and mark it, and do the same at the ridge.

Stretch a string line from ridge to plate log to indicate the cen-

terline of the valley. This string line does not have to be at the

correct valley slope because it is used only to position the

dummy correctly in plan view (looking straight down). It can be

at any slope, as long it is in the center of the valley.

An easy way to attach the dummy to the plate log is with a

strap hinge. I prefer using methods of holding that restrict

movement in only one direction, not all directions, because it is

easy to get the dummy in the correct place step by step. This

approach really reduces job stress! A strap hinge to connect the

dummy to the plate log gets that one end of the dummy in

exactly the right place, without having to worry about whether

the dummys high end is centered on the string, or whether the

dummy is at the right slope.

In Figures 1 and 3 you can see we used a couple scraps of

wood to act as legs to support the high end of the dummy. One

scrap leg is attached to the dummy, again, with a strap hinge.

Bungy cord a digital level to the top of the dummy and lift the

dummy to the proper slope of the valley. (The valley slope is not

the same as the slope the roof, of course. See my book, the Log

Construction Manual, pp. 213-220 for how to nd the slope of

continued next page

1 Dummy in place on plate log. Note backing angles

on end of dummy, strap hinge, and scrap braces.

2 Closer to the dummy. Point B is the bottom of the

backing angles, and the elevation of B after

scribing and notching should be equal to the ceiling

line.

3 Scribing the dummy onto the plate log. String line

(center of valley in plan) has been pushed out of the

way; centerline of valley can be seen on bottom

surface of dummy. Note the hole we left in the end of

dummy to make it lighter and easier to hold.

F

i

g

u

r

e

6

p

h

o

t

o

b

y

G

r

a

e

m

e

M

o

u

l

d

.

A

l

l

o

t

h

e

r

p

h

o

t

o

s

b

y

R

o

b

e

r

t

W

.

C

h

a

m

b

e

r

s

2

0

0

6

.

2 3

12 LogBuildingNews January | February | March 2006

a valley. This valley was 35 from horizontal, which is 55 from

plumb.) Make sure the centerline on the bottom of the valley is

on the string, and screw in the nal brace.

Scribing

The end grain of the dummy shows the backing angle cuts,

and in Figure 2, Point B show the bottom center of the valley,

where the two backing cuts meet. You need to scribe the

dummy down a distance that puts Point B at the same height

as the actual ceiling line of the roof (Log Construction Manual,

pp.155-162). If you install valleys differently, then go ahead and

determine the scriber-setting as you normally would.

Cutting

Repeat for the ridge-end of the valley and score and cut out the

notches (mortises) youve scribed. Measure between the two

mortises to gure out how long the valley log or timber needs

to be. Double check, and then transfer this length to the actual

valley and cut it to length.

At this stage I dont usually even lift the valley onto the roof,

unless I needed it for jack rafters or jack purlins. As I said, I try to

lay out and cut all roof parts on the ground, without ever lifting

them up until we get to the owners foundation. And after

dozens of homes, I cannot remember a serious problem during

re-set because of this.

Two Comments

In this building, the valleys did not extend outside the walls

they stopped in the log wall. Of course, a valley that goes

through a log wall and outside should be scribed from a

dummy that is longer than the one shown here.

This valley is a little different than typical. The engineer had

specied a valley timber that was deeper (taller) than I wanted

to useit was going to hang down below the ridge, and look

funny. So I scribed the valley down so that its bottom surface

was where I wanted it to be at the ridge, and which left the rest

of the valley to stick up into the 2x roof system.

This explains why the jack purlins in Figures 5 and 6 are

below the top of the valley. This also explains why the backing

angles on the dummy are not at the top edge (Figure 2). Of

course, we never cut the backing angles out on this valley,

because they were not used to hold the ceilingin fact the

backing angles wouldnt have held anything. Doing it this way

made me happy, and the engineer too.

4 5

6

4 The actual timber valley test-tted into its notch in plate

log.

5 Roof system assembled. House is T-shaped, and there are

two ridges and two valleys.

6 Looking up the valley. Jack purlins on each side are at the

ceiling heightcompare with the ceiling line on the side of

dummy in Figure 2. Extra timber height of the valley

above the ceiling line wont be seenits in the rafter space.

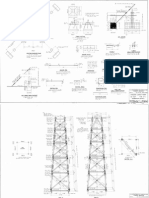

No Crane? No Problem!

By Michael Pielorz

About 10 years ago I sold a small log shell to a

group of Alaskan mountain climbers who were

willing to reassemble the shell at a remote site

with the help of a few of their friends. Because

the building had purlins and a ridgepole on

posts, it was a challenge to set the roof logs

onto the posts without a crane.

These climbers came up with a simple and

innovative solution. They built a lifting system

made out of 2 pulleys, 2 long ropes and a hand-

ful of long 2x8s. After setting by hand the 2

posts for the ridge, they nailed long 2x8s rafter-

like on each side of the posts, with two A-frame-

like constructions with the pulleys attached just

above the top of the posts (Figure 3).

The pulleys were high enough above the

posts to have room for the ridge pole, with

some extra space to maneuver into position

(Figure 2). All that was left was to tie the ropes

to the ridge pole near the location of the log

posts and then through the pulleys. The 2x8s

work as a sliding ramp to pull the ridgepole up.

The workers raised the ridge log all the way

by pulling equally on the ropes to keep it level

while on the ramps. Once it was hanging above the posts, it

could be repositioned and lowered onto the posts (Figure 1).

I have a lot of respect for those guys, who incidentally run a

well known climbing and guiding business in St. Elias Park: Bob

Jacobs of St. Elias Alpine Guides in McCarthy, Alaska. Perhaps

somebody else will be in a similar situation one day and this

idea might come in handy.

Number 58 LogBuildingNews 13

TechTalk

A CRANELES S S I TE

T

E

C

H

T

A

L

K

T

E

A

R

O

U

T

F

O

R

Y

O

U

R

J

I

G

B

O

O

K

1 The end of the joblog ridge in place on top of posts.

2 2x8 ramps and pully mounted to a log post.

3 Close-up of 2x and rigging.

1

2 3

MONTEBELLO FACTS

10,000 seasoned Western red cedar trees were

used on the rst three buildings. Despite the

need for speed, the highest standards of log

work were rigidly enforced from beginning to

end of the project.

The construction of Montebello took from

start to nish an amazing four months!

14 LogBuildingNews January | February | March 2006

33rd Annual Conference and AGM

Le Chateau Montebello April 6-9, 2006

I LBA CONFERENCE 2 0 0 6

The theme of our confer-

ence this year has two

parts. First, we tell our

story, explore our past

not just for the pleasure of a nostalgic walk down memory lane,

but to add lessons to our toolbox as we prepare to build our

future in a rapidly changing world.

Building our future, our second theme, means being ready

and prepared to take care of upcoming challenges and interests.

The expanding market for log homes brings us new kinds of cus-

tomers. Technology brings opportunity, and claims to save us

time. We hold fast to our built-by-hand tradition while we

explore new building techniques and time-saving tools.

On the horizon we will face many changes and decisions.

There is no one right way to deal with changebut it is impor-

tant to anticipate change and to develop plans that t our busi-

ness goals, as well as our personal goals and lifestyle choices.

The membership of the ILBA now spans three generations of

log builders. Some of us are just starting out, others are up-sizing

or working towards lateral growth in their companies, and a few

of us would like to develop a retirement plan. Our conference

this year helps you face the issues that we all confront, and

breakout sessions and pre-conference workshops are tailored

very specically to the interests and challenges we face individu-

ally.

The hands-on workshops and sessions will help you improve or

expand your building techniques. As our customers move

towards chateaus and away from cabins, we need to keep pace

with their vision, or we will be left behind.

Just look at our pre-Conference workshops. Learn advanced

roof layout with Will Beemer of the Timbers Framers Guild dur-

ing a full-day workshop. Also scheduled for pre-conference is a

Dietrichs software workshop presented by Wil Dancey. You will

learn how to quickly generate a house model and take-offs for

accurate quoting, saving you both time and money.

Our ILBA two-day pre-conference project this year brings

together all the elements you want in a learning environment.

Cool tools, high production, new methods, and best of all leaves

you time for a beer at the end of the day.

What could follow such appetizing starters? Wait until you see

the menu for the Conference itself! Yoshito Dai Ona and John

Boys are introducing Log Builder Helperan interactive pricing

program developed by log builders, for log builders. This well-

thought-out program is easily learned and will save you hours of

time.

For those who love to explore alternate building methods,

Chris Dancey is offering a hands-on course demonstrating hemp-

inll. Saving time while building mitered-trusses? Pat Clark shows

you his layout technique French Scribe meets the laser beam.

Further on layout, if you missed his presentation at Kananaskis

you can take in Advance Sill Layout, with Robert Chambers.

For members who are growing their business we can recom-

mend: How did you do it? Ask your experienced and success-

ful colleagues in the industrydiscover what has worked for a

diverse group of log builders.

Dont miss Protecting your Investment, a session giving you

the heads-up on why you dont want to keep your head down.

Further along those lines we explore doing business on a hand-

shake, and why you want to have a good contract in your other

hand. Rick Hall logbuilder/lawyer explains whats in a good con-

tract and how it ts into your Business Standards.

Higgs Murphy makes the sawdust y with a medley of layout

and building techniques in a project-focused 4-hour marathon.

Want to know more about the building of Montebello? See origi-

nal construction documents and get behind the scenes when

you join us for an intimate tour of the complex.

Many of us are close to making the leap into computerized

design and drafting. There are many products to choose from

and you will have the opportunity to consider very seriously

which design software is the most compatible for you.

On another track, Ed Shure shows what we can do to ensure

that Aging is a Myth. Twenty years of log building got your

body down? Eds practical session involves real-work situations

and how to train your body to work better, and feel better.

Still struggling with marketing? Join Jerry Rouleau for a

Marketing on a Shoestring specially tailored for the hand-

crafted industry. Bring your laptop and let Jerry build the founda-

tion of a PowerPoint presentation for your company.

While the Conference is focused on developing skills, we like

to have some fun too. Our auction is shaping up to knock your

socks off! You can look forward to choice Makita tools as well as

a ne selection from Gary of Timber Tools I know these tools

will get you salivating. Schroeders Log Home Supply will also be

with us this year and you-all know you like what they have to

offer!

Drafting and design software has been generously donated by

hsbCAD (and it includes 4 days of training and has a retail value

of USD$17,000), Graphisoft is donating an ArchiCAD software

package, and Deitrichs NA is also giving you the opportunity to

bid their product and raise funds for the ILBA. This is the year to

Telling Our Story Building Our Future

by Ingrid Boys

Number 58 LogBuildingNews 15

The Montebello Conference 2006 is just around the corner, and

those of you who have been calling the ILBA office for daily con-

ference updates will be pleased to nally see our conference

schedule and costs nalized.

We had a slow start as we muddled around trying to ll the

shoes of Cathy and Robrt, but they left a well-marked trail, and

when we picked up the scent we were able to gain ground as

we work towards this landmark conference.

Your 2006 Conference Planning Team is Ann Miks, Patti

LeFrancois and Ingrid Boys. We are working under the direction

of the Conference Committee with Linda Bourdage and Brian

Lloyd the co-chairs, and Jean Rodrigue our man on the ground

in Quebec.

You all know Ann at the Association office the voice of the

ILBA. Ann does much more than great phone, she is the grease

that keeps the wheels moving at the office, the resource who

knows whos who, whats what and where to get whatever it is

that needs gettin. Without Ann, we would not be WOO-ing or

HOO-ing right now.

Patti is a dynamo who caught the log building and home-

steading bug in the mid 70s. Patti has peeled her share of logs

and she nished her rst log home in 1980. Since then she has

worked extensively in the forest industry and has been specializ-

ing in the log building industry for the past 11 years.

Patti is a former director and treasurer of the BC Builders

Association; was the lead writer for the BC Log Builder

Apprenticeship program, and assisted with the development of

the BC Log Building Occupational Health and Safety Program.

And she has developed and delivered an array of personnel

development and human resource management seminars.

Despite all of these credentials, Patti is also a great deal of fun; I

know you will all enjoy getting to know her at Montebello.

I make up the 3rd corner of this teammy credentials?

Married into log building, one of the benets of matrimony was

getting the ILBA as an in-law. In my pre-log-building life I worked

in tourism, hospitality and event planning.

Enough about us our Montebello Conference is all about

you, and it is shaping up to be an event of record attendance.

This is the year to re-unite with colleagues we havent seen for

many a year. It is also the year to make new contacts and to

redene the identity and purpose of the ILBA. And, of course, the

time we learn whats new in our old craft.

I LBA CONFERENCE 2 0 0 6

From the Conference Team: WOO HOO!

by Ingrid Boys

MONTEBELLO FACTS

In order to bring materials to the wilderness

setting of Montebello, a spur line 3,700' long

was built from the Canadian Pacic Railway

to a temporary construction village.

take the leap and start building your future with these time-sav-

ing tools that whose rendering abilities have marketing advan-

tage written all over them.

Were calling our auction Tools and Jewels (Tools n Jools);

this way you can assuage your guilt at going on a tool binge by

bidding for your bride at the same time. We encourage you to

think about what you will bring!

We all look forward to Tech Talk. This year it opens with the

Higgy Jigger, presented by none other than Higgs Murphy, our

log-builder-turned-timber-framer-with-a-log-builders-soul. Higgs

will show you how to turn your band-mill into a round-log post

& beam processing machine (the poor-mans Hundegger).

Reviews of new tools will also be featured, including two new-to-

North America tools from Makita. (You can expect some dyna-

mite show specials from the folks at Makita, so start building

your wish list now).

The call has gone out for your vintage photos, we want to see

your memories in our review of the past dont let history pass

you bytell your story, and start planning for the project expo,

sort your images for the slide show and practicing your skills for

Log Builder Games. While youre at it donate an auction item

and bring your newest discovery or invention to Tech Talk.

Above allbring yourselves! Fill in the enclosed sign-up forms,

and book your ights. Get ready to get together with the rest of

the best.

ABOVE The Chateau Montebello

16 LogBuildingNews January | February | March 2006

A big thank you to Vilnis Kazaks, President of the Latvian

Chamber of Crafts, for his efforts in making the conference a

possibility. And of course thank you to all the sponsors as well.

The conference had about 150 participants from 15 different

countries. (ILBA members from Finland, Denmark, Germany,

Sweden, Norway, Estonia, Latvia, the USA, New Zealand, and

Great Britain were at this conferenceeditor.)

We were spoiled by beautiful weather, which is often unpre-

dictable in October. Riga, which is the capital of Latvia, is the

cultural center of Latvia and a major open port of the Baltic Sea.

I enjoyed translating and hope everyone was able to experience

a least a taste of my heritage.

A synopsis of the four-day event

First day bus tours to log projects of leading Latvian log build-

ing companies in different parts of Latvia. After a long day of

touring many recent projects, we all met for a late dinner at the

Lido Restaurant, which is the largest log structure in Latvia.

Second day the sessions were dedicated to Latvian specialists.

There were some speakers whose topics were not relevant to the

actual craft of log building. The most interesting presentations in

my opinion, were architect Raitis Jelevics about the soul of log

buildings, Rihards Vidzickis architectural sign work blending into

natural landscape within park zones and Karlis Apinis who is

involved in consulting and quality inspections of handcrafted log

structures shared his experience about difficulties and common

problems. And also Janis Dolacis with the topic: Healthy House

in the Energy Grid of Earth.

Third day was dedicated

to international specialists.

Different countries, different

cultures, and different prob-

lems made it quite interest-

ing. It would be difficult to

mention everybody and

again I would like to just

outline some key topics.

Janne Jokelainen spoke

about traditional Finnish log

architecture, Jari Heikila

about development of mod-

ern log architecture in

Finland. Robert Chambers

spoke about the future of

handcrafted log building,

recent advances in tech-

niques, and accelerated log

building. George Fuller pre-

sented about Norwegian log building standards and some

recent problems with log homes imported into Norway. This list

is longer and sorry for not mentioning each and everyone. The

discussions became lively at the end of the day about the issue

of log building standards. This was a key issue for debates the

next morning.

Fourth day The decision was made to create a draft of

basic standards, (within the next six months), and regional stan-

dards. Regional standards address the cultural and geographical

differences of the area. And the last event was visiting the

Latvian Open-Air museum, which was quite interesting (visit

www.muzejs.lv/en/ for the best log museum website I have

seeneditor). The open-air museum characterizes the tradition

of Latvian log building and has a collection of hundreds of his-

toric log structures on 220 acres on the outskirts of Riga. Karlis

Apinis has dedicated a big part of his life to the preservation of

the original log structures. Every time I walk through the outdoor

museum with Karlis I have a new discovery.

Latvia may be hosting the second international conference in

June, 2007 during the annual Crafts Fair at the Riga Open Air

Museum. In closing, I am certain that the experienced gained

from this conference will be invaluable in creating future

events.

International Log Building Conference in Latvia

by Egils Artmanis

The rst international log building conference in Europe took a place in Riga,

Latvia from October 5th to 8th 2005. It turned out to be a good Conference and

hopefully the start of log building activity coordination in Europe. It wasnt easy

for the organizers however, as there were obstacles and uncertainties to overcome

in planning and holding the conference, which was the rst of its kind in Europe.

Number 58 LogBuildingNews 17

LOWER LEFT Egils Artmanis and Harald Ludwig discuss log

restoration.

UPPER LEFT Inside of lavish new log home.

ABOVE Swimming hall with log

framing, on tour.

PHOTOS ROBERT W. CHAMBERS

UPPER RIGHT New log home with

thatch roof on home tour.

RIGHT Karlis Apinis in animated

discussion at Open Air Museum.

BELOW Huge Lido Restaurant in

Riga.

PHOTOS EGILS ARTMANIS

18 LogBuildingNews January | February | March 2006

BUS I NES S S TANDARDS

Construction Agreements and Procedures, PART 1

by Rick A. Hall, Attorney at Law

What happens if you disregard the Log

Building Standards and put a severe left-hand

spiral grain log in the upper courses of a log

wall, or allow for no settling space above

doors and windows? We all know, of course,

that building a log home disregarding the

Standards on spiral grain logs and settling

space would create problems in the building resulting in an

unhappy homeowner when the logs begin to shrink and settle

and maybe even conicts that could lead to litigation.

And, just as the Log Building Standards are based on the

nature of wood and weather, builders also need to follow sound

business standards because there are characteristics of each proj-

ect and of people that also must be understood when you are

building a good business relationship with a customer. In the

end, we want a happy homeowner and a builder who has made

his expected prot.

Lets take some time to explore the nature of sound business

standards.

Good Communication

Based on my experience with builders one of the most neglected

parts of a project is the communication between builder and

customer and ultimately the writing of a well-drafted construc-

tion agreement with all the relevant issues identied and

resolved with all the risks for both builder and owner allocated.

Over the years I have represented a number of large and small

residential building companies. I have learned that people and

projects vary, but the issues and types of disputes and problems

surrounding construction projects do not. If the log home builder

discusses with their customer the potential problem areas in the

project and then drafts an agreement which incorporates how

they and the owner will resolve these potential issues if they arise,

then the builder will greatly reduce conicts, litigation expenses

and increase the chance of a successful project for everyone.

Happy homeowners will refer you to family and friends.

Unhappy ones won't, and many times homeowners are unhappy

because of issues that have nothing to do with the beautiful log-

work you delivered. Projects are not guaranteed to go smoothly

from start to nish just because you are an honest and capable

log home builder.

When the builder and owner are nally ready to proceed

beyond the talking stage: money has been discussed in

approximate amounts and the structure to be built has been

discussed only from a rough drawings basis, then it is time to

address not only the exact amount of money you need and the

exact scope of log work involved, but it is also time to address

the potential problem areas of the future business relationship

and propose resolutions.

Knowing where typical disputes and misunderstandings come

from, and then working to avoid or resolve them, will help you

draft a good agreement. And a good agreement addresses the

potential problems, it does not ignore them.

Typical Problems

Some of the potential problem areas that need discussion

between the customer are: (1) inadequate plans and/or speci-

cations, (2) contradictions between the plans and specications,

(3) plans not approved by the appropriate engineer(s), (4)

change order issues, (5) permitting issues, (6) delays in work and

delays in payment of money, (7) conicts with other tradesmen

at the reassembly site, (8) schedule and dates for payment of

money, and what happens if the customer fails to pay on time,

(9) insurance issues, (10) warranty issues, (11) building standards

for log work, (12) inaccessibility to reassembly site, (13) inspec-

tions, (14) damage to log work during transportation, (15) date

of completion of log work, (16) clean-up at reassembly site, (17)

potential damage to private roads from heavy equipment, and

(18) notices, certicates, releases and waivers expected to be

delivered and signed by either the builder or customer.

In the commentary to the ILBAs construction contract, Tom

Stonecipher, an attorney in Bozeman, Montana, states that in his

experience ...more than half of all disputes typically arise

because of uncertainties or incorrect expectations that are

formed at the time a change order is requested and agreed to.

His excellent commentary gives a number of examples of the

importance of paying heed to the potential problems areas in a

builder/owner relationship and of using a well-drafted contract

to manage those problems areas before you are faced with the

problem itself.

One-Sided Contracts

Builders who have been burned tend to jump to an extreme of

having a lawyer draft a contract that is entirely one-sided to their

benet, either neglecting to address any concerns of the cus-

tomers, or if they do address customers concerns, they put

onerous requirements on them. In the U.S., these are called

"contracts of adhesion" or "take-it-or-leave-it contracts," and

courts will interpret the entire contract with a heavy bias against

the builder. Some provisions may not even be legally enforceable

in such contracts.

Talk First, then Sign Some builders, mainly small builders, are

reluctant or even afraid to talk about anything "negative" to a

potential client for fear of chasing them away before they sign. I

have found the opposite is true: when builders talk to their

clients before the agreement is presented about the potential

problem areas, then it does not cause a crisis in the relationship

and it has not caused the client to jump to another builder

unless the proposals were actually unfair to the customer.

Number 58 LogBuildingNews 19

I nd that talking about these potential problems increases

the condence a client has in the builder because it makes the

builder look more professional and thorough. Presenting one-

sided contracts to customers, and failing to address the problem

areas, are extremes that you must avoid.

Tailor the Agreement Builders should also realize that one

construction agreement form does not t all transactions. The

particular state, province, and country where the log work is to

be delivered and assembled may also require mandatory lan-

guage to be in the agreement.

Certain states in the U.S., for example, require disclosure to

buyers concerning their risks under mechanics (builders) lien

laws in the agreement and they have very specic language.

Some locations require certain font sizes and all CAPITAL

LETTERS for arbitration clauses or warranties. There are many

such examples of different government requirements for con-

struction agreements.

Business Standards

Just as the characteristics of wood and logs in a log building are

at the heart of the Log Building Standards, Business Standards

arise out of the characteristics of a project and its people. Each

project is going to be different, and bring its own different

issues. If builders would realize that following the Standards for

good business practice are just as important as following the

Log Building Standards in building the log home, then the log

builder will have a much greater chance of being successful and

protable.

If a builder fails to follow the Business Standards even if they

have absolutely perfect log work, they expose themselves to

needless stress, frustration, potential conict and, at worst, liti-

gation, when dealing with the people side of the business.

Over the next few issues I am going to talk about the

Business Standards in detail with a discussion about the charac-

teristics of projects and of people that form the basis of Business

Standards. Ill attempt to use as many examples as space allows.

I would enjoy hearing any comments or questions from any

ILBA members about this column. You can reach me by e-mail

at rickhall@conveyists.com or by telephone at (402) 502-9999

ext 203.

Rick is a lawyer licensed in Washington and Nebraska, and is a

past student of Del Radomskes.

MONTEBELLO FACTS

The Chateau Montebello was built at the

beginning of the depression as a private

members club, and was the dream of H.M.

Saddlemire, a Swiss-American. He called his

dream Lucerne-in-Quebec.

20 LogBuildingNews January | February | March 2006

April 6 9, 2006

ILBA 33rd AGM

and Conference

Montebello, Quebec

www.logassociation.org

April 6 9, 2006

ILBA 33rd AGM

and Conference

Montebello, Quebec

www.logassociation.org

Log

Building

in Russia

Photos by Nick Berwian

Norwegian-style log notching, built in

Russia.

A bomb-proof Russian scriber. Note

screw adjustment for setting, and the

vice-lock.

RIGHT Nick Berwian sent this

photo of a 3-story log home

being built in Karelia, Russia

Number 58 LogBuildingNews 21

Russian yard, full-scribe saddle notch in

Canadian style. Nick Berwian photo.

Nick Berwian sent this photo of a large "Norwegian style" hewn-log house being

built in a log construction yard outside St. Petersburg, Russia. (It has been stitched

together from 2 photos, so the log walls do not exactly line up).

MONTEBELLO FACTS

Referring to the construction of the roof system:it was at once

a challenge and an opportunity,attributed to architect Harold

Lawson.

22 LogBuildingNews January | February | March 2006

WELCOME!

NEW COMPANY

MEMBERS

Atlantic Log Works Ltd.

Professional Investigative Engineers Inc.

Scott Hay Handcrafted Log Homes Inc.

Shuswap Log Homes International

Summit Handcrafted & Milled Log

Homes, Inc.

RENEWI NG COMPANY

MEMBERS

Accelerated Log Building, Inc.

Ackerman Handcrafted Log Homes

BC Log & Timber Building Industry

Association

BC Wood

Beaudette Consulting Engineers, Inc

Blockhausbau Porrenga GmbH

Brian Moore Log Homes

Cannon Chainsaw Bars

Chilliwack Mountain Log Homes Ltd.

Classic Log Designs

Construction EN Bois Rond Amishk Inc.

Cowls Lumber and Sawmill

Davidson Log & Timber Artisans Inc.

Dietrich's North America

Eagleridge Log Homes

Emseal Corporation

FINNHOLZ Wohnblockhuser und

Zimmerei

Fearless Engineers PLLC

Frontier Builders Inc.

Frye Custom Log Homes, Inc

Gabriels Carpentry

Gresham Post & Beam

GRK Fasteners

Hojgaard Tommerhuse APS

hsb-Cad Canada/Struc-soft Inc.

Insulspan Corporation

Jean Steinbrecher Architects

Jeffery Sharpe PE

Koski Log Homes

Laverty Log Homes

Lloyd Ventures

Log Builders' Association New Zealand

Log Cabin Homes Ltd.

Log Home Living & Log Home Design

Ideas

Makita Canada Inc.

Montana Dry Log & Lumber

Mountain High Log Homes

Mountain Living

Mountain Logworks

Nortek CopperWorks

Ojibwa Log Homes

Old Style Log Works, Inc.

Pacic Log Homes Ltd.

REB Properties LLC

Sansin Corporation

Sitka Log Homes Inc.

Sperlich Log Construction Inc

Streamline Design Group

Sun Valley Log Homes

Swiss Mountain Log Homes

The Wooden House Co.

Timber Framers Guild

Timberwize Construction Services

Corp.

Twin Butte Log Homes Ltd.

Wiens Log Homes Inc.

NEW I NDI VI DUAL

MEMBERS

Jacque Yves Blanchet

Douglas K. Fowler

Ole Getz

Patrice Graffand

Steve Grand

Jay Gutenkauf

Simon Hirsh

Dwight Martin

Peter Michael (Mick) Peat

Marcel Pihowich

Ed Rogers

Ueli Wittwer

RENEWI NG I NDI VI DUAL

MEMBERS

Stuart Adrian

Franz Ambichl

Egils Artmanis

Thomas Bembridge

Tom Blackburn

Richard Bloomeld

Stephan Bolduc

David Carradine

Jim Christensen

Keith Coppernoll

Ricci Durfeld

Steven Estola

Paul F. Figueroa

George Fuller

Peter Gott

David Gray

Ken Guest

Tom Hahney, BS Engr.

Louis A. Hansen

Vic Janzen

Kathrina Koelbel

Pekka Laine

Rick Lambert

Tim Lawton

Dave Levanger

B. Allan Mackie

Mary Mackie

L. D. (Doc) McKay

Herb Meeker

Eric Menard

Graeme Mould

Mark J. Mueller PE

Neil Norgaard

Hannes Oppelmayer

Donald Ouellet

Steven Racer

Nabil Taha

Kym Terry

Robert Ullmer

Peter F. Watson

Howard Williamson

Uwe Ziegler

CASH DONATI ONS

TO THE I LBA

Skip Ackerman

Brant Schreiber

New and Renewing Members Since Our Last Issue

representing all our members under the banner of the

International Log Builders Association.

Now, six years later, we return to the Mecca of Montebello. In

the future, when we look back at our 2006 Conference, what

attributes will we attach to this stage of our growth? Perhaps it

will be the beginning of wisdom.

This year we are look back at the story of our Association and

its evolution, but the focus of our seminars and presentation

deal with building our future. As always, we will explore new

tools and work methods; both hands-on, and those of a more

cerebral nature. We have also spiced-up the program with pre-

sentations about attitudes, mindsets, and choices that can

enhance the lifestyle of log building.

Make sure you plan a bit of free time around all the confer-

ence activities. Le Chateau Montebello is a world-class resort

with facilities and services that are second-to-none. Bring your

swimming suit, and move the meeting into the pool; break the

habit of a lifetime and go to the spa; or take some time out to

wander down to the Ottawa River.

For more information about the Chateau Montebello, check

out the web site: www.chateaumontebello.com to acquaint

yourself with the activities and historical attractions of this very

special destination.

Log Builders Mecca

from page 1

For more info: 1-866-202-2345 or www.accutechinnovations.com

Cut upto 70 angles. + or - 1/4 accuracy

Convert any size chainsaw into a

portable saw mill

Achieve a level of accuracy never

seen with a chainsaw

Transport or store all your chainsaw mills

PRECISION PORTABLE CHAINSAW MILLS

Number 58 LogBuildingNews 23

Founders of CLBA: Fergus OConnor, Bernie Legault, B. Allan

Mackie, Ed Campbell, Art Long, Vic Janzen; not shown: Mary

Mackie. PHOTO COURTESY THE CANADIAN LOG HOUSE

1977 Conference in Banff, Alberta. The members of the CLBA

completed this log shell in just three days.

24 LogBuildingNews January | February | March 2006

FOR S ALE FOR S ALE HELP WANTED

C L A S S I F I E D A D S

LOG BUILDING TOOLS STARRETT &

MACKIE scribers; heavy duty drawknives up to

30"; peeling spuds; chopping & nishing axes;

broadaxes; adzes; GRANSFORS axes; ENGLISH

slicks; ROBERT SORBY, HENRY TAYLOR, FOOT-

PRINT & PHEIL chisels and gouges; JAPANESE

slicks, chisels, saws, ink lines & ex squares;

hand-forged Flarens, shovel gouges, at & scarf

slicks, drawknives & draw-gouges; BARR

Specialty Tools; peavies; cant hooks; lifting tongs;

log dogs & cleats; log horses; water stones;

Diamond whetstones; NORTHWEST calipers,

tenon cutters & long auger bits; ship augers;

chainsaw mills & attachments; MAKITA &

MAFELL planers, saws & chain mortisers; MACKIE

log building books & videos. FREE 32-page

catalogue

MAGARD VENTURES LTD, 8365 Domagala Road,

Prince George, BC, Canada V2K 5R1

Tel: 250-962-9057 Fax: 250-962-9157

Attn: Maurice Gardy

Awesome Boom Truck for Sale All-wheel

drive Oshkosh with turbocharged International

DT466 diesel, big oat tires up front, 5 speed

with 3 speed transfer case & full power steering.

Tube steel bed custom built for hauling logs,

custom made loader. Lemco with 26ft. squirt

boom & stainless steel jawed continuous rotation

bucket. Used as all around yard machine for

unloading trucks & shell building, and delivering

and assembling cabins in mountain sites.

Grapple allows safe one man operation. Had over

$40,000 invested in new engine set up, loader

and bed. $17,500 includes fresh batteries & tires.

Call Bryan or Ed

303-449-1336 or email ed@timmerhusinc.com

1999 Heartwood Band Sawmill Model

310 Electric Never been used 6 inch Double-

Cut (cutting travel speed up to 3 feet per

second). Requires 600 V. 3 Phase Power. Eighty-

eight feet of track. Operator travels with mill

head along track. Numerous track-mounted

hydraulic log handing systems and full

programmable computer controlled set works.

(We purchased 2 and only set one up for use.)

When purchased in 1999 value exceeded

$80,000.00 Canadian. Asking $65,000.00

Canadian. Moose Mountain Log Homes Inc.

Please arrange for an appointment to see the

twin unit in operation. Link to this model at

Heartwood Saw: http://www.heart

woodsaw.com/Model_310.html

Toll free 1-877-932-3992

One 1979 S688 Bantam 20 Ton Rough

Terrain Crane for sale, $30,000 Canadian or

$21,500 US. Presently stationed in Illinois. Very

Good Condition, 60 foot hydraulic boom or 80

foot with jib. Very fuel efficient 453 Detroit.

Should provide many years of trouble free

service. Call 1-877-932-3992.

We have for sale beetle kill, dead

standing, Lodgepole Pine house logs, saw

logs, big dead timber and rewood. D-log kits, 2

sided log kits, and peeled logs also available. We

can deliver to almost anywhere in the U.S. Please

call for more info and a price list. Willow Creek

Logging 970-887-2396 or email

dPetras8angels@yahoo.com

For Sale: Diamond Willow pieces range in

size from 3"-6" diameter and 3'-7' in length.

Great for crafting unique railings, posts, and

furniture. Cost $8.00/LF + (size and character

dependent). Call Peter at Sperlich Log

Construction Inc. 250-838-7455 or email

sales@canadianloghouse.com

1975 S-588 Bantam 18 Ton Rough

Terrain Crane Very good condition, 72 foot

hydraulic boom or 92 foot with jib. Is rated to lift

1610 lbs. at an 85 foot radius or 4700 lbs at a

50 foot radius. Very fuel efficient 453 Detroit.

Should provide many years of trouble free