Professional Documents

Culture Documents

Air Carbon Arc Gouging Process Explained

Uploaded by

Mehmet Soysal0 ratings0% found this document useful (0 votes)

18 views3 pagesAir carbon arc gouging uses an electric arc between a carbon electrode and workpiece to melt metal, which is then blown away by a high-velocity air jet, leaving a clean groove. It can remove metal at a high rate while closely controlling the gouge profile. Disadvantages include the air jet ejecting molten metal over a large distance and high noise levels from the currents of up to 2000A and air pressures of 80-100 psi used. It is applied to remove surface defects, excess weld metal, and prepare edges for welding on a wide range of metals.

Original Description:

Job Knowledge 12

Original Title

Job Knowledge 12

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAir carbon arc gouging uses an electric arc between a carbon electrode and workpiece to melt metal, which is then blown away by a high-velocity air jet, leaving a clean groove. It can remove metal at a high rate while closely controlling the gouge profile. Disadvantages include the air jet ejecting molten metal over a large distance and high noise levels from the currents of up to 2000A and air pressures of 80-100 psi used. It is applied to remove surface defects, excess weld metal, and prepare edges for welding on a wide range of metals.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views3 pagesAir Carbon Arc Gouging Process Explained

Uploaded by

Mehmet SoysalAir carbon arc gouging uses an electric arc between a carbon electrode and workpiece to melt metal, which is then blown away by a high-velocity air jet, leaving a clean groove. It can remove metal at a high rate while closely controlling the gouge profile. Disadvantages include the air jet ejecting molten metal over a large distance and high noise levels from the currents of up to 2000A and air pressures of 80-100 psi used. It is applied to remove surface defects, excess weld metal, and prepare edges for welding on a wide range of metals.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Cutting and Gouging

Job knowledge 12:

Air Carbon Arc Gouging

The main difference between this gouging technique and the others is that a

separate air jet is used to eject molten metal from the groove.

Process description

Air carbon arc gouging works as

follows. An electric arc is generated

between the tip of a carbon

electrode and the workpiece. The

metal becomes molten and a high

velocity air jet streams down the

electrode to blow it away, thus

leaving a clean groove. The process

is simple to apply (using the same

equipment as MMA welding), has a

high metal removal rate, and

gouge profile can be closely

controlled. Disadvantages are that the air jet causes the molten metal to be

ejected over quite a large distance and, because of high currents (up to 2000A)

and high air pressures (80 to 100 psi), it can be very noisy.

Application

As air carbon arc gouging does not rely on oxidation it can be applied to a wide

range of metals. DC (electrode positive) is normally preferred for steel and

stainless steel but AC is more effective for cast iron, copper and nickel alloys.

Typical applications include back gouging, removal of surface and internal defects,

removal of excess weld metal and preparation of bevel edges for welding.

Electrode

The electrode is a graphite (carbon) rod which has

a copper coating to reduce electrode erosion.

Electrode diameter is selected according to

required depth and width of gouge. Cutting can be

precisely controlled and molten metal/dross is kept

to a minimum.

Power source

A DC power supply with electrode positive polarity

is most suitable. AC power sources which are also

constant current can be used but with special AC

type electrodes. The power source must have a constant current output

characteristic. If it does not, inadvertant touching of the electrode to the

workpiece will cause a high current surge sufficient to 'explode' the electrode tip.

This will disrupt the operation and cause carbon pick-up. As arc voltage can be

quite high (up to 50V), open circuit voltage of the power source should be over

60V.

Air supply

The gouging torch is normally operated with either a compressed air line or

separate bottled gas supply. Air supply pressure will be up to 100psi from the air

line but restricted to about 35psi from a bottled supply. Providing there is

sufficient air flow to remove molten metal, there are no advantages in using

higher pressure and flow rates.

Carbon pickup

Although carbon is picked up by the molten metal, the air stream will remove

carbon-rich metal from the groove to leave only minimal contamination of the

sidewalls. Poor gouging technique or insufficient air flow will result in carbon pick-

up with the risk of metallurgical problems, e.g high hardness and even cracking.

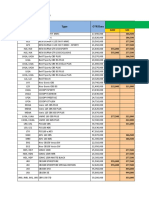

Typical operating data for air carbon arc gouging:

Gouging

dimensions Electrode

diameter (mm)

Current A

Note: DC

electrode Depth

(mm)

Width

(mm)

Carbon

electrode

consumed

(mm/min)

Gouging

speed

(mm/min)

6.4 275 6-7 9-10 120 609

8.0 350 7-8 10-11 114 711

9.5 425 9-10 12-13 100 660

Manual

13.0 550 12-13 18-19 76 508

8.0 300-400 2-9 3-8 100 1650-840

9.5 500 3-12 3-10 142 1650-635

13.0 850 3-15 3-13 82 1830-610

Automatic

16.0 1250 3-19 3-16 63 1830-710

Operation

Gouging is commenced by striking the electrode tip on to the workpiece surface to

initiate the arc. Unlike manual metal arc (MMA) welding the electrode tip is not

withdrawn to establish arc length. Molten metal directly under the electrode tip

(arc) is immediately blown away by the air stream. For effective metal removal, it

is important that the air stream is directed at the arc from behind the electrode

and sweeps under the tip of the electrode. The width of groove is determined by

the diameter of electrode, but depth is dictated by the angle of electrode to the

workpiece and rate of travel. Relatively high travel speeds are possible when a low

electrode angle is used. This produces a shallow groove: a steep angle results in a

deep groove and requires slower travel speed. Note, a steeply angled electrode

may give rise to carbon contamination.

Oscillating the electrode in a circular or restricted weave motion during gouging

can greatly increase gouging width. This is useful for removal of a weld or plate

imperfection that is wider than the electrode itself. It is important, however, that

weave width should not exceed four times the diameter of the electrode.The

groove surface should be relatively free of oxidised metal and can be considered

ready for welding without further preparation. Dressing by grinding the side-walls

of the gouge should be carried out if a carbon rich layer has been formed. Also,

dressing by grinding or another approved method will be necessary if working on

crack-sensitive material such as high strength, low alloy steel.

Information and advice from TWI and its partners are provided in good faith and based, where appropriate,

on the best engineering knowledge available at the time and incorporated into TWI's website in

accordance with TWI's ISO 9001:2000 accredited status. No warranty expressed or implied is given

regarding the results or effects of applying information or advice obtained from the website, nor is any

responsibility accepted for any consequential loss or damage.

You might also like

- Air Carbon Arc GougingDocument3 pagesAir Carbon Arc GougingMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Air Carbon Arc GougingDocument2 pagesAir Carbon Arc Gougingkevin herry100% (1)

- Air Carbon Arc GougingDocument2 pagesAir Carbon Arc GouginghariNo ratings yet

- Equipment and Circuit DiagramDocument7 pagesEquipment and Circuit DiagramRaje GunaNo ratings yet

- Air Carbon&Arc GougingDocument2 pagesAir Carbon&Arc GougingJanakiram100% (1)

- Manual Metal Arc GougingDocument2 pagesManual Metal Arc GougingMehmet SoysalNo ratings yet

- Advanced Welding Technology Ca2Document3 pagesAdvanced Welding Technology Ca2Monglafru MogNo ratings yet

- Basic Weld JointsDocument10 pagesBasic Weld JointsSham AmirNo ratings yet

- Specific Welding DetalsDocument17 pagesSpecific Welding DetalsradiantsteelNo ratings yet

- Air GougingDocument4 pagesAir GougingJose Marie Rmgrocks BatoNo ratings yet

- Air Carbon Air GougingDocument6 pagesAir Carbon Air GougingJlkKumarNo ratings yet

- Submerged Arc WeldingDocument21 pagesSubmerged Arc WeldingSACHIN A. MORENo ratings yet

- Manual Metal Arc Gouging - Job Knowledge 10Document2 pagesManual Metal Arc Gouging - Job Knowledge 10tuanNo ratings yet

- Submerged Arc Welding GuideDocument11 pagesSubmerged Arc Welding Guidemiteshpatel191No ratings yet

- Welding Lab Report. Part 1Document6 pagesWelding Lab Report. Part 1Ayuub Abdi Mahamed100% (1)

- Job Knowledge 17Document4 pagesJob Knowledge 17Mehmet SoysalNo ratings yet

- Welding BasicsDocument37 pagesWelding BasicsSnehal DeshmukhNo ratings yet

- Welding Technology: Department of Mechanical Engineering National Institute of Technology RaipurDocument66 pagesWelding Technology: Department of Mechanical Engineering National Institute of Technology RaipuryashNo ratings yet

- Common Welding ProcessDocument4 pagesCommon Welding ProcessLalit Bom MallaNo ratings yet

- L2-Arc - Welding - Process - PPTX Filename UTF-8''L2-Arc Welding ProcessDocument18 pagesL2-Arc - Welding - Process - PPTX Filename UTF-8''L2-Arc Welding Process222-020-651No ratings yet

- Chapter-4 Principle of Selected Joining and Assembling Process A Brief History of WeldingDocument12 pagesChapter-4 Principle of Selected Joining and Assembling Process A Brief History of WeldingFira tubeNo ratings yet

- TIG Welding: Job KnowledgeDocument3 pagesTIG Welding: Job KnowledgeRakesh Kumar Munda100% (1)

- GTAWDocument61 pagesGTAWIela TeoNo ratings yet

- Cutting - GougingDocument9 pagesCutting - GougingAlhaj MassoudNo ratings yet

- Stick: Arc WeldingDocument4 pagesStick: Arc WeldingmohitshuklamarsNo ratings yet

- Smaw and Tig WeldingDocument46 pagesSmaw and Tig WeldingRajesh Kumar Ravi100% (1)

- Adyapeath Annada Polytechnic CollegeDocument5 pagesAdyapeath Annada Polytechnic CollegeArunavaNo ratings yet

- Welding & Cutting ProcessDocument16 pagesWelding & Cutting ProcesscvNo ratings yet

- 3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingDocument96 pages3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingAditya KumarNo ratings yet

- Manual Metal Arc WeldingDocument13 pagesManual Metal Arc WeldingHirenNo ratings yet

- WELDINGDocument8 pagesWELDINGManibhusan MohapatroNo ratings yet

- Welding: Edge PreparationsDocument8 pagesWelding: Edge PreparationsManibhusanNo ratings yet

- Arc WeldingDocument16 pagesArc WeldingManohara BabuNo ratings yet

- UnitDocument41 pagesUnitsawravkblNo ratings yet

- Welding Process & DefectsDocument11 pagesWelding Process & DefectsAbhishek TalujaNo ratings yet

- Welding Types Procedures ParametersDocument156 pagesWelding Types Procedures ParametersVinodh Kumar YallaNo ratings yet

- Arc and Special Welding TechniquesDocument10 pagesArc and Special Welding TechniquesAvinash ChandraNo ratings yet

- Welding DictionaryDocument19 pagesWelding DictionarydrexNo ratings yet

- TIG welding process technical capabilitiesDocument2 pagesTIG welding process technical capabilitiestuanNo ratings yet

- GMAW (CO2) Welding CourseDocument129 pagesGMAW (CO2) Welding Courseanon_554333607No ratings yet

- Case Study YayaDocument6 pagesCase Study YayaYayaNo ratings yet

- Class - 5 - Baics of Arc WeldingDocument43 pagesClass - 5 - Baics of Arc WeldingroshanpateliaNo ratings yet

- Experiment 1Document16 pagesExperiment 1samayNo ratings yet

- Arc WeldingDocument33 pagesArc WeldingRakha DhaniwijayaNo ratings yet

- Electrode Converted Into TextDocument14 pagesElectrode Converted Into TextNeha NimbarkNo ratings yet

- 1 - MMAW Process - PPT (Compatibility Mode)Document44 pages1 - MMAW Process - PPT (Compatibility Mode)Kumawat Prakash100% (1)

- SMAWDocument8 pagesSMAWmostafaNo ratings yet

- Arc WeldingDocument42 pagesArc WeldingrkpnakNo ratings yet

- Submerge Arc WeldingDocument7 pagesSubmerge Arc WeldingUsman Saeed KianiNo ratings yet

- Advanced Welding Process (Welding)Document58 pagesAdvanced Welding Process (Welding)Sk SamsuddinNo ratings yet

- Arc - Welding Processes: Presented By, Radhakrishnan P Assistant Professor Toc H Institute of Science & Technology, CochinDocument5 pagesArc - Welding Processes: Presented By, Radhakrishnan P Assistant Professor Toc H Institute of Science & Technology, CochinRADHAKRISHNAN PNo ratings yet

- What Is Strip CladdingDocument6 pagesWhat Is Strip CladdingPradeep LakumNo ratings yet

- Welding ProcessDocument42 pagesWelding ProcessPankaj KumbhareNo ratings yet

- Chapter 2 Arc WeldingDocument39 pagesChapter 2 Arc WeldingAbie RexoMenNo ratings yet

- Submerged Arc Welding GuideDocument4 pagesSubmerged Arc Welding Guideরিপন মন্ডলNo ratings yet

- Types of Electric WeldingDocument7 pagesTypes of Electric WeldingSUKhanNo ratings yet

- Welding: Philippine Society of Mechanical Engineers Professional Development CourseDocument30 pagesWelding: Philippine Society of Mechanical Engineers Professional Development CourseAngel Silva VicenteNo ratings yet

- Arc Welding Refers To A Group Of: SolderingDocument12 pagesArc Welding Refers To A Group Of: SolderingBhushan VermaNo ratings yet

- E1158Document4 pagesE1158Irish Manglicmot LagundinoNo ratings yet

- Yoke Brochure Issue 1Document2 pagesYoke Brochure Issue 1Mehmet SoysalNo ratings yet

- Instruction For CTS 30x Data Transmit SoftwareDocument3 pagesInstruction For CTS 30x Data Transmit SoftwareMehmet SoysalNo ratings yet

- E428 StandardDocument6 pagesE428 StandardkarthikNo ratings yet

- 4.3 WPS No.P4-GS008 & PQR No.P4-GS008.Document25 pages4.3 WPS No.P4-GS008 & PQR No.P4-GS008.Mehmet SoysalNo ratings yet

- Job Knowledge 76 CtodDocument4 pagesJob Knowledge 76 CtodmomoitachiNo ratings yet

- Vickers Hardness CoDocument8 pagesVickers Hardness CoMehmet SoysalNo ratings yet

- Job Knowledge 78Document3 pagesJob Knowledge 78Mehmet Soysal100% (1)

- Wa Series ManualDocument6 pagesWa Series ManualMehmet SoysalNo ratings yet

- Job Knowledge 74Document4 pagesJob Knowledge 74Mehmet Soysal100% (1)

- 4.1 WPS No.P1-G005 & PQR No.P1-G005Document19 pages4.1 WPS No.P1-G005 & PQR No.P1-G005Mehmet SoysalNo ratings yet

- Job Knowledge 77Document4 pagesJob Knowledge 77Mehmet Soysal100% (1)

- Job Knowledge 66Document5 pagesJob Knowledge 66Mehmet Soysal100% (1)

- Job Knowledge 73Document3 pagesJob Knowledge 73Mehmet SoysalNo ratings yet

- Mechanical Testing: Notched Bar or Impact Testing. Part IIDocument4 pagesMechanical Testing: Notched Bar or Impact Testing. Part IIMehmet Soysal100% (1)

- Job Knowledge 68Document8 pagesJob Knowledge 68Mehmet Soysal100% (1)

- Job Knowledge 75Document4 pagesJob Knowledge 75Mehmet Soysal100% (1)

- Mechanical Testing - Tensile Testing, Part 1Document4 pagesMechanical Testing - Tensile Testing, Part 1Mehmet Soysal100% (1)

- Job Knowledge 71Document4 pagesJob Knowledge 71Mehmet Soysal100% (1)

- Job Knowledge 70Document4 pagesJob Knowledge 70Mehmet SoysalNo ratings yet

- Job Knowledge 67Document5 pagesJob Knowledge 67Mehmet Soysal100% (1)

- Job Knowledge 65Document5 pagesJob Knowledge 65Mehmet SoysalNo ratings yet

- Hot Plate Welding of Plastics Moulded ComponentsDocument4 pagesHot Plate Welding of Plastics Moulded ComponentsMehmet Soysal100% (1)

- Job Knowledge 62Document5 pagesJob Knowledge 62Mehmet Soysal100% (1)

- Job Knowledge 64Document3 pagesJob Knowledge 64Mehmet SoysalNo ratings yet

- Job Knowledge 59Document5 pagesJob Knowledge 59Mehmet Soysal100% (1)

- Job Knowledge 58Document4 pagesJob Knowledge 58Mehmet SoysalNo ratings yet

- Job Knowledge 61Document4 pagesJob Knowledge 61Mehmet SoysalNo ratings yet

- Extrusion Welding of Thermoplastics IntroductionDocument4 pagesExtrusion Welding of Thermoplastics IntroductionMehmet SoysalNo ratings yet

- Job Knowledge 56Document4 pagesJob Knowledge 56Mehmet SoysalNo ratings yet

- InstructionsDocument1 pageInstructionssavinaumarNo ratings yet

- San Beda University College of Law Semester, School Year 2021-2022 Course SyllabusDocument47 pagesSan Beda University College of Law Semester, School Year 2021-2022 Course SyllabusJabezNo ratings yet

- MELC 3 Employ The Appropriate Communicative Styles For Various Situations (Intimate, Casual, Conversational, Consultative, Frozen)Document2 pagesMELC 3 Employ The Appropriate Communicative Styles For Various Situations (Intimate, Casual, Conversational, Consultative, Frozen)Mar Sebastian82% (11)

- HPE BOM Import Config for MSL2024 Storage SolutionDocument2 pagesHPE BOM Import Config for MSL2024 Storage SolutionBertrand FotueNo ratings yet

- Project ReportDocument61 pagesProject Reportlove goyal100% (2)

- Cinnamomum Cassia - Twig: 1. ScopeDocument3 pagesCinnamomum Cassia - Twig: 1. ScopeTaufik HidayatullohNo ratings yet

- Approaches To Archaeological Ceramics PDFDocument127 pagesApproaches To Archaeological Ceramics PDFMariacarmela Montesanto100% (6)

- DFA and DOLE Not Liable for Repatriation Costs of Undocumented OFWDocument80 pagesDFA and DOLE Not Liable for Repatriation Costs of Undocumented OFWdhanty20No ratings yet

- PTC Creo Elements/Direct Modeling ExpressDocument5 pagesPTC Creo Elements/Direct Modeling ExpressladydaladyNo ratings yet

- Service Manual: NSX-SZ80 NSX-SZ83 NSX-AJ80 NSX-SZ80EDocument47 pagesService Manual: NSX-SZ80 NSX-SZ83 NSX-AJ80 NSX-SZ80EDjalma MotaNo ratings yet

- Manual For Renewal of Dog LicenseDocument12 pagesManual For Renewal of Dog Licensescibs123456No ratings yet

- DepEd Camarines Norte Daily Lesson PlanDocument5 pagesDepEd Camarines Norte Daily Lesson PlanjuriearlNo ratings yet

- Modulen 2 Newtons 2nd Law of Motion Upload 2 v2Document71 pagesModulen 2 Newtons 2nd Law of Motion Upload 2 v2Dyas FerNo ratings yet

- Chapter 26 STAINING OF MUSCLE AND BONE - Group3Document6 pagesChapter 26 STAINING OF MUSCLE AND BONE - Group3Krizelle Vine RosalNo ratings yet

- Potch Girls' Newsletter 1 2015Document5 pagesPotch Girls' Newsletter 1 2015The High School for Girls PotchefstroomNo ratings yet

- Caterpillar: Undercarriage Repair ManualDocument24 pagesCaterpillar: Undercarriage Repair ManualfrenkiNo ratings yet

- Classified2020 1 16770965Document2 pagesClassified2020 1 16770965Mohamed MaharNo ratings yet

- Cantarell SihilDocument41 pagesCantarell SihilSalvadorSuazo100% (3)

- Socio-Economic and Government Impact On Business: Lesson 4.4Document18 pagesSocio-Economic and Government Impact On Business: Lesson 4.4racelNo ratings yet

- PVR CinemasDocument16 pagesPVR CinemasSajal9971265875No ratings yet

- Semi-Log Analysis: Well Test Interpretation MethodologyDocument31 pagesSemi-Log Analysis: Well Test Interpretation MethodologyAshraf SeragNo ratings yet

- Test General Product Support Assessment (MOSL1)Document21 pagesTest General Product Support Assessment (MOSL1)Romeo67% (3)

- Prosedur Penggajian: Payroll ProcedureDocument5 pagesProsedur Penggajian: Payroll ProcedureVira TrianaNo ratings yet

- Non-Ferrous Metal SmeltingDocument47 pagesNon-Ferrous Metal SmeltinggtdomboNo ratings yet

- Investor Presentation (Company Update)Document48 pagesInvestor Presentation (Company Update)Shyam SunderNo ratings yet

- Flyht Case SolutionDocument2 pagesFlyht Case SolutionkarthikawarrierNo ratings yet

- Asmo Kilo - PL Area BPP Juni 2023 v1.0 - OKDocument52 pagesAsmo Kilo - PL Area BPP Juni 2023 v1.0 - OKasrulNo ratings yet

- Slab Sample ScheduleDocument1 pageSlab Sample ScheduleJohn Rhey Almojallas BenedictoNo ratings yet

- Overview of Co-Operative BankingDocument14 pagesOverview of Co-Operative BankingDr. Meghna DangiNo ratings yet