Professional Documents

Culture Documents

Howard B. - Petroleum Engineers Handbook, Part 1

Uploaded by

khanhnn81Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Howard B. - Petroleum Engineers Handbook, Part 1

Uploaded by

khanhnn81Copyright:

Available Formats

Click Here To Continue

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

.

d

o

cu-tra

c

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

.

d

o

cu-tra

c

k

.

c

o

m

Petroleum

Engineering

Handbook

Editor-in-Chief

Howard B. Bradley

Professional/Technical Training Consultant

Associate Editors

Fred W. Gipson Mohamed Mortada

Senior Engineering Professional (retired) President

Conoco Inc. Mortada Intl. Inc.

Aziz S. Odeh Lewis L. Raymer

Senior Scientist President

Mobil R&D Corp. Lewis L. Raymer Enterprises

Phillip S. Sizer Gerry L. Smith

Senior Vice President/Technical Director Engineering Consultant

Otis Engineering Corp. (deceased)

Third Printing

Society of Petroleum Engineers

Richardson, TX, U.S.A.

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

@Copyright 1987 by the Society of Petroleum Engineers. Printed in the

United States of America. All rights reserved. This book, or parts thereof,

cannot be reproduced in any form without written consent of the publisher.

Third printing, Feb. 1992, incorporating minor changes on Pages 22-3,30-3,

30-4, 33-2, and 51-52.

ISBN 1-55.563-010-3

ii

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Preface

The 1962 edition of the Petroleum Production Handbook filled a need at that time for a comprehensive compilation

of practical information and data covering production equipment and reservoir engineering. This 1987 edition updates

the original 48 chapters and adds 11 new ones. New technology, developed over the past 25 years, resulted in im-

proved equipment, materials, and methods. They are described and discussed in the revised original chapters and

in the new ones. The 11 new chapters are the following:

Chapter 7-Electric Submersible Pumps

Chapter 1 &Offshore Operations

Chapter 19-Crude-Oil Emulsions

Chapter 4%Miscible Displacement

Chapter 46-Thermal Recovery

Chapter 47-Chemical Flooding

Chapter 48-Reservoir Simulation

Chapter 5 l-Acoustic Well Logging

Chapter 52-Mud Logging

Chapter 58-SI Metric System of Units and SPE Metric Standard

Chapter 59-SPE Letter and Computer Symbols Standard

This 1987 edition, now called the Petroleum Engineering Handbook, provides a current and worthwhile addition

to the industrys literature for students and experienced professionals working in the petroleum industry.

The handbook is again divided into three sections: Sec. 1, Mathematics (one chapter); Sec. 2, Production Engineer-

ing (18 chapters); and Sec. 3, Reservoir Engineering (40 chapters). There are 57 chapters written by professionals

who are recognized as authorities in their fields of expertise. Chap. 58 is a revised version of the 1982 SI Metric

System of Units and SPE Metric Standard, and Chap. 59 is the 1986 revision of the 1984 Standard SPE Letter and

Computer Symbols for Economics, Formation Evaluation and Well Logging, Natural Gas Engineering, and Petrole-

um Reservoir Engineering.

The Mathematics section presents the basic tables and calculation procedures required by persons engaged in petro-

leum production. The Production Engineering section covers basic types of materials, methods, and tools available

for use in petroleum operations, including their capabilities and proper applications. The Reservoir Engineering sec-

tion treats gas, oil, condensate, and formation water properties and correlations; reservoir rocks and traps; primary,

secondary, and tertiary recovery data and methods; oil and gas reserves; formation evaluation, including well logging

methods; and well treating methods. The what, why, how, and now-what aspects of each topic are emphasized. Also,

at the end of the appropriate chapters, key equations are presented with SI metric units.

Special acknowledgment is due the SPE staff for their immeasurable help and advice, the associate editors for their

avid dedication to the technical-editing task, and all the authors who contributed much time and effort to provide

the timely and excellent information included within each chapter. We are much indebted to the editor-in-chief of

the 1962 edition, Thomas C. Fricke. and to the original group of authors for their arduous 3-year job of developing

the original edition of the Petro/eum Production Handbook. Special thanks are due Ed Mayer of THUMS and B.J.

Dotson of Mobil Oil Corp. (now retired) for their advice and helpful discussions on the proper use of the 1986 SPE

standard letter symbols throughout the handbook and for their editing of Chap. 59, the SPE Letter and Computer

Symbols Standard.

Our hope is that by proper application of the updated information contained within the second edition of this hand-

book, the petroleum-industry professional will be led to more efficient production and use of the worlds petroleum-

energy resources.

Howard B. Bradley

Editor-in-Chief

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Acknowledgments

The Society of Petroleum Engineers sincerely thank\ the following organizations and individuals for permission to use the

cited material.

Chap. 2

Figs. 2.1 through 2.3 and 2.6 through 2.8, from Casino, Tubi,l~, and Drill Pipe, API Spec. 5A, 38th edition. API. Dallas

(1985).

Fig. 2.9, from Line Pipe, API Spec. 5L, 35th edition. API. Dallas (1985).

Figs. 2.10A, 2.10B, 2.11, 2.12, and 2.14 through 2.18, from 7hrt&inR, &g;,lg, and 7hveud hl.~fcct;or2, API Spec, SB.

1 Ith edition, API. Dallas (1985).

Table 2.1, modified from Cusing, Tubing, and Drill Pipe, API Spec. 5A, 37th edition, API, Dallas (1984).

Tables 2.2, 2.5 through 2.7, and 2.25 through 2.27, Casing, Tubing, and Drill Pipe, Bull., USS. Pittsburgh. PA

(1972).

Tables 2.3, 2.4, and 2.24, modified from Performance Propertics of Casing, Tubing, and Drill Pipe, Apf Bu//. 5~2,

API. Dallas (1983).

Tables 2.8 through 2.11 and 2.28, from USS Seamless Casing. Tubing, and Drill Pipe, Bu//, , USS. Pittsburgh, PA

(1972).

Table 2.14, Bull. 664. National Supply Co.. Houston.

Tables 2.31 through 2.33, 2.36, and 2.37, from Line Pipe, API Spec. 5L. 34th edition. API, Dallas (1984).

Tables 2.38 through 2.43, from Formulas and Calculations for Casing, Tubing. Drill Pipe. and Lint Pipe Properties.

API Bull. 5C3, third edition with Supplement No. 1. API. Dallas (1983).

Tables 2.44 through 2.54, from Thrrudit~~. Gaging, und thread Inspection. API Spec. 5B, 10th edition with Supplement

No. 4. API. Dallas (1983).

Chap. 3

Figs, 3.1 and 3.3, and Tables 3.1 through 3.33, from Specicarionsfor Wellhcad and Chrisrtnas Tree Eyuipment. API

Spec. 6A. 14th and 15th editions, API. Dallas (April 1. 1986).

Fig. 3.2, courtesy McEvoy Co., General Catalog 58-59 (Jan. 1959).

Fig. 3.5, from Eichenberg, R., Design Consideration for AWHEM 15,000 psi Flanges, ASME Paper 57.PET-23, Sept.

22, 1957.

Figs. 3.6 through 3.17, courtesy Otis Engineering Corp.. Dallas.

Chap. 4

Figs. 4.1 through 4.11, from Patton, L.D. and Abbott, W.A.: Well Completions and Workovers: The Systems Approuth.

second edition, Energy Publications, Dallas (1985) 57-67.

Tables 4.1 and 4.2, from Pucker Culculations Handbook, Baker Oil Tool Div. (1971).

Chap. 5

Fig. 5.1, from Winkler. H.W.: How to Design a Closed Rotativc Gas Lift System-Part I: Proccdurc, World Qj/ (July

1960) 116-19.

Figs. 5.2, 5.5, 5.6, and 5.18, from Gus Lij?, Book 6 of API Vocational Training Series, revised edition. API. Dallas (1984)

65.

Fig. 5.3, from Winkler. H.W.: Heres How to Improve Your Gas Lift Installations-Part I : Pressure at Depth

Determinations. World Oil (Aug. 1959) 63-67.

Figs. 5.4 and 5.29, from Winkler. H.W. and Smith. S.S.: Cameo Gas Liji Manual, Cameo Inc.. Houston (1962) A2-001.

Fig. 5.7, from King, W.R.: Time and V 0 umc Control for Gas Intermitters, I U.S. Patent No. 2.339.487 (Jan. 1944).

Fig. 5.21, from Kirkpatrick. C.V.: Advances in Gas-Lift Technology, API Drill. and Prod. Pruc. (I 959) 24-60.

Fig. 5.25, from Gas Lt, Book 6 of API Vocational Training Series. API. Dallas (1965) 109.

Fig. 5.33, from CLlmco Cornplere Service Cuialog, Cameo Inc. (1962) 42.

Chap. 6

Figs. 6.1, 6.5, 6.7, 6.12, 6.13, 6.31, 6.40, 6.44, 6.47, 6.49, and 6.51, and Table 6.18, courtesy Trico Industries.

Gardena. CA,

Figs. 6.2, 6.3, 6.6, 6.8, 6.11, 6.14, 6.15, 6.19 through 6.24, 6.26 through 6.29, 6.32 through 6.39, 6.41 through 6.45,

6.48, 6.50, 6.52, 6.53, and 6.55, and Table 6.1, from National-Oilwell. Los Nietos. CA.

Fig. 6.9, courtesy Otis Engineering Corp., Dallas.

Figs. 6.17 and 6.52, and Tables 6.3, 6.12, and 6.17, courtesy Dresser Industries, Dallas.

Fig. 6.18 and Table 6.4, courtesy of Highland Pump Co. Inc.. Midland. TX.

Fig. 6.56, from Si;ing und Selecrion of Electric Submersible Pump Installations, API RP I IU, second edition, API. Dallas

(May 30, 1986).

Table 6.2, courtesy Kobe Inc., Huntington Park, CA.

Chap. 7

Figs. 7.1 through 7.18 and 7.20 through 7.32, and Table 7.1, courtesy TRW Energy Products Group, Reda Pump Div.,

Bartlesville. OK.

Chap. 8

Fig. 8.1, from Subsurface Pumps and Fitrings, API Spec. 11 AX, seventh edition, API, Dallas (June 1979).

Figs. 8.3, 8.5, and 8.7, courtesy Oilwell Div. of U.S. Steel Corp., Garland, TX.

V

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Chap. 9

Figs. 9.2 and 9.3, and Tables 9.1 through 9.4, from Sucker Rods. API Spcc. 119, 2lst editmn. API, Dallas (May 1985).

Figs. 9.5 and 9.9, and Table 9.9, from Cure und Hundling of Sucker Rod.,, API RP 1 IBR. seventh edition. API. Dallas

(May 30, 1986).

Fig. 9.10 and Tables 9.10 and 9.11, from Reir@ced Plu~fic Sucker Rods, API Spec. 1 IC, first edition. API, Dallas (Jan,

I, 1986).

Table 9.7, from Design Culrulurions for Sucker Rod P~inpini: Systems, API RP I 1 L. third edition, API, Dallas (Feb. 1977)

Chap. IO

Figs. 10.1, 10.3, 10.6, 10.7, 10.9 through 10.12, and 10.14 (pumping unit), courtesy Lufkin Industries Inc., Lufkin. TX.

Fig. 10.8, from Design Calculations for Sucker Rod Pumping Sytems (Convenrional Units), API RP 1 IL. third edition.

API. Dallas (Feb. 1977).

Figs. 10.13, 10.16 through 10.20, and 10.24 through 10.28, and Tables 10.5, 10.7, and 10.9, from Sargent Oil Well

Equipment Co., Odessa, TX.

Fig. 10.14 (engine), from Arrow Specialty Co., Tulsa, OK.

Fig. 10.15, from Waukesha Engine Div.. Dresser Industries Inc., Waukesha. WI.

Fig. 10.21, from Mom-s and Generators, MG l-1978. Natl. Electrical Manufacturers Assn.. Washington. DC (1978).

Figs. 10.29 through 10.31, from Ronk Electrical Industries Inc., Nokomis. IL.

Figs. 10.32 and 10.33, from Classijcnlion of Areas for Electrical lnstullations at Drilling Rigs and Production Facilities on

Land and on Marine Fixed and Mobile Pl at f or m, API RP 5009, second edition, API, Dallas (July 1973) 8.

Tables 10.2 and 10.3, from lnsrullation and Luhrimtim of Pumping Units, API RP 1 IG, second edition. API. Dallas (Feb.

1959) and Supplement (Jan. 1980).

Tables 10.6 and 10.10, from Motor Application and Muintenunce Hundbook, second edition, R.W. Smeaton (ed.),

McGraw-Hill Book Co. Inc.. New York City, Table 1 on Page 3-7 and Table 3 on Page I l-3.

Chap. 11

Figs. 11.1 and 11.3, from C-E Natco, Tulsa. OK.

Fig. 11.4, from Design and Fuhricution of Gulvunixd Products, American Hot Dip Galvanizer Assn. and the Zinc Inst.

(Nov. 1983).

Fig. 11.7, from CBI Industries Inc. (Chicago Bridge and Iron Co.), Oak Brook, IL.

Figs. 11.9 and 11.10, from Fenix & Scisson Inc., Tulsa. OK.

Table 11.1, from Bolted Production Tanks, API Spec. 129, 12th edition, API Div. of Production, Dallas (Jan. 1977).

Tables 11.3 and 11.4, from Venting Atmospheric cmd LowPressure Storage Tunk.7, API Std. 2000, third edition, API,

Dallas (Jan. 1982).

Chap. 12

Fig. 12.2, courtesy Jaragua S.A. Industrias Mechanicas. Sao Paula, Brazil.

Figs. 12.7 and 12.8, courtesy Fisher Controls Co., Marshalltown. IA.

Figs. 12.16 and 12.19, courtesy ACS Industries Inc., Woonsocket, RI.

Fig. 12.18, courtesy Peerless Mfg. Co., Dallas.

Fig. 12.20, courtesy Plenty Metrol. Newbury. England.

Fig. 12.21, courtesy Vortec. Inc.. Woodside. CA.

Fig. 12.22, courtesy Porta-Test Systems, Ltd., Edmonton, Alta., Canada.

Figs. 12.24, 12.26, and 12.40, courtesy C-E Natco, Tulsa, OK.

Tables 12.9 and 12.10, courtesy Cornsign Computer Program, Ellis Engineering Inc., Houston.

Tables 12.11 and 12.17, from KWIC Index of Intl. Standards, Intl. Organization for Standardization. Geneva.

Tables 12.12, 12.18, and 12.19, from ASME Boiler and Pressure Vessel Code, Sec. VIII, Div. 1, New York City (1984).

Tables 12.13 and 12.14, from Megyesy, E.F.: Pressure Vessel Handbook, Pressure Vessel Handbook Publishing Inc.,

Tulsa, OK.

Table 12.15, from Kimmell, G.O.: Stage Separation, paper 48.PET-15 presented at the ASME Annual Meeting.

Oklahoma City, Oct. 1949.

Table 12.16, Separation Flash Calculations, Process Version 0882, Simulation Sciences Inc., Houston.

Chap. 13

Fig. 13.2, courtesy The Bristol Co.

Fig. 13.3, from Orice Constunt Tub/es. American Gas Assn., Report No. 3, revised (1969). Also, ANSI/API 2530.

Fig. 13.4 and Tables 13.2a, 13.2b, and 13.4, from GPSA Engineering Dutubook, Gas Processors Suppliers Assn., Tulsa,

OK (1972).

Figs. 13.20 through 13.22, courtesy Fischer Governor Co.

Table 13.1, courtesy American Meter Co.. Inc.

Chap. 14

Fig. 14.5, from GPSA Engineering Dutuhook, ninth edition. fifth revision, Gas Processors Suppliers Assn., Tulsa, OK

(1981).

Fig. 14.14, from NGSMA Handbook.

Figs. 14.19 through 14.21, and Tables 14.1 and 14.2 from Campbell, J.M.: J.M. Campbell Gas Conditioning and

Processing. Campbell Petroleum Series, Norman, OK (1962) 2.

vi

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Chap. 15

Figs. 15.1 through 15.3, and Table 15.9, from Desl,qn and hstd/don of O&how P~C~CY;OH ~l+t~~ Pip;~ ~~~~~~~~~~~

API RP l4E, third edition, API, Dallas (1981) 22.

Figs. 15.4 through 15.6, and Tables 15.2 through 15.5, from GPSA Engineerirlg Durchx~k, @IS Processors Suppliers

Assn.. Tulsa, OK (1980).

Fig. 15.8, courtesy Paragon Engineering Services Inc.. Houston.

Fig. 15.11 and Table 15.10, courtesy Perry Equipment Co., Mineral Wells, TX.

Fig. 15.12, courtesy C-E Natco, Tulsa. OK.

Fig. 15.13, courtesy U.S. Filter. Fluid System Corp.. Whittier, CA.

Figs. 15.15 and 15.19, from Oil-Water Separator Process Design. API Manual on Disposal of Refinery Wastes. Volume

on Liquid Wastes, API. Dallas (1975) Chap. 5.

Fig. 15.20, Engineering Spccialtiea Inc.. Covington. LA.

Tables 15.6 and 15.7, from Amr~rictr~~ ~triiov7d .bmk~rd. Pip /%mgr.s arzd F/m& FirtirrRs. ANSI B26.5. ASME, New

York City (1981).

Chap. 18

Fig. 18.32, courtesy CanOcean Resources Ltd., New Westminster, B.C., Canada.

Fig. 18.36, courtesy Fluor Subsea Services. Irvine. CA.

Fig. 18.38, courtesy Hamilton Bros. Oil Co., Denver.

Fig. 18.40, from Lagers, G.H.C., Gusto, B.V., and Bell, C.R.: The Third Generation Lay Barge. Proc., Offshore

Technology Conference (1974) 1, 35-46.

Fig. 18.41, courtesy Apache, Santa Fe Intl. Corp., Alhambra. CA.

Fig. 18.43, courtesy Swan Wooster Engineering Ltd., Vancouver, B.C., Canada.

Fig. 18.44, from Willits. K.L.: Well Completions in the Prudhoc Bay Field. Pet. Eng. (Feb. 1976).

Fig. 18.45, courtesy Brian Watt Assocs., Houston.

Chap. 19

Figs. 19.1, 19.3, and 19.6 through 19.8, courtesy Shell Development Co., Houston.

Figs. 19.4, 19.5, 19.9, and 19.10, courtesy Baker Performance Chemicals Inc., Santa Fe Springs, CA

Fig. 19.12, courtesy ASTM, Philadelphia. PA.

Fig. 19.17, courtesy Chemineer-Kenics. Dayton. OH.

Fig. 19.18, courtesy Modular Production Equipment Inc., Houston.

Figs. 19.19, 19.29, and 19.30, courtesy C-E Natco Inc.. Tulsa, OK.

Figs. 19.20 and 19.32, courtesy Hydrocarbon Research Inc.. Long Beach, CA.

Figs. 19.21, 19.22, and 19.28, courtesy Energy Recovery Div., Daniel Industries Inc.

Chap. 20

Figs. 20.2A and 20.3, from Katz, D.L. ef (il.: Hcr!rdhook of Nutuuu/ Gus Eng;nrcr;ng, McGraw-Hill Book Co. Inc., New

York City (1959).

Figs. 20.2B and 20.2C, from Brown, G.G. ~1 nl.: Natural Gasoline and the Volatile Hydrocarbons. Natural Gas Assn.

of America. Tulsa OK (1948).

Fig. 20.4, from Wichert, E. and Aziz. K.: Compressibility Factor for Sour Natural Gases, Cdn. J. C!zerrr. Gl,q. (1972)

49, 269-75.

Figs. 20.8 and 20.9, from Stiel. L.I. and Thodos, G.: The Viscosity of Non-Polar Gases at Normal Pressures. AICIfE J.

(1961) 7, 61 l-20.

Fig. 20.10, from Matthews, T.A.. Roland. C H.. and Katz, D.L.: High Pressure Gas Measurement. Proc~. , Natural Gas

A$sn. of America (1942) 41-51.

Fig. 20.14 and Table 20.1, from Perry. R.H. and Chilton, C.H.: C/~cwicz/ 0tgin~er.s ffmdbook. fifth edition. McGraw-

Hill Book Co Inc., New York City (1975).

Table 20.2, from GPSA Enyi~~wriufi Dorcrbonk, ninth edition. fifth revision. Gas Processors Suppliers Aasn.. Tulsa. OK,

Chau. 21

Fig. 21 .l, from Gq~~/oym/ic~ c$ C/ic,n~ic,tr/ T~~c~/tno/o,e~, The Interscicnce Encyclopedia Inc. ( 1953) 10, 1 17.

Fig. 21.3, after N&on. W.L.: Parrnlertr?~ Rc$rrrj:v ~ri,t~irt~~~ri/t~, fourth edition, McGraw-Hill Book Co Inc., New York

City (1958) 910-37.

Fig. 21.4, courtesy Hansen. D.N. and Hurd. C.O., Shell Devolopmcnt Co , Prtrd~wrn Rc$wr (Aprtl 1945).

Figs. 21.7 through 21.21, from ASTM Slcrf&rcl.c 011 Pt,/ro/c~trfi P,.oc/lrc~f.s crnd Lubricants. Part 24, ASTM, Philadelphia

( 1975) 796.

Fig. 21.22, from Matthews. T.A.. Roland. C.H.. and Katz. D.L: High Prcssurc Gas Measurements. Proc,., Natural Gas

Aasn. of America (1942) 41.

Figs. 21.23 and 21.24. from Standing. M. B. : lr~lrr/tif,/rrc, t/rid Phcrsr Brhcr~~io~ r!f Oil Fir/t/ Hwlrr,c&~orr S\stc~rns, Reinhold

Publtshing Corp.. New York City (1952).

Fig. 21.25, from Standing. M.13.: A Prcssurc-Volulnc-Tcmpcraturc Correlation for Mixtures of California Oil and Gases.

Drill. curd Prod. Pm , API ( 1937) 275.

Fig. 21.26, courtesy Calitornia Rcjcarch Corp., 1947.

Fable 2 I .7, from Nelson. W. L. : Pr~f-oic,lr!~r Rc:/iucy\ En,g;n~criyy, fourth edition, McGrawHill Book Co. Inc.. New York

City (11)5X) 910-37.

Table 21.10, from A Guide to World Export Ct-udcs. Oil & Gtrv J. (1976).

Table 21.11, courtesy Bartlcavillc Energy Technology Ccntcr. Bartlc~ville. OK.

vii

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Chau. 22

Figs. 22.1 through 22.3, from Standing, M.B.: Volumetric and Phase Behavior of Oil Field Hydrocarbon Systems, Reinhold

Publishing Corp., New York City (1952).

Fig. 22.4, from Katz, D.L.: Prediction of the Shrinkage of Crude Oils, Drill. and Prod. Prac., API (1942).

Figs. 22.5, 22.9, and 22.13, courtesy California Research Corp.

Figs. 22.19 and 22.20, from Baker, 0. and Swerdloff, W.: Finding Surface Tension of Hydrocarbon Liquids, Oil & Gas

1. (Jan. 2, 1956).

Chap. 23

Fig. 23.9 from GPSA Engineering Databook, Gas Processors Suppliers Assn.,

ninth edition, Tulsa, OK (1972).

Figs. 23.12 and 23.13 from Reamer, H.H., Fiskin, J.M., and Sage, B.H.:

Phase Equilibria in Hydrocarbon Systems,

lnd. Eng. Chem. (Dec. 1949) 41, 2871.

Chao. 24

Fig. 24.3, from Hoke, S.H. and Collins, A.G.: Mobile Wellhead Analyzerfor the Determination of Unstable Constituents in

Oil-Field Waters, ASTM STP 735 (1981) 34-48.

Fig. 24.9, from Burcik: Properties of Petroleum Reservoir Fluids, John Wiley & Sons Inc., New York City (1957).

Figs. 24.11 and 24.12, from PI-Petroleum Information,

Chap. 25

Figs. 25.3 and 25.4, from Kobayashi, R.: Vapor-Liquid Equilibria in Binary Hydrocarbon-Water Systems, PhD

dissertation, U. of Michigan, Ann Arbor (1951).

Figs. 25.5, 25.10, 25.21, 25.23, and 25.24, and Table 25.4, from Katz, D.L. et al.: Water-Hydrocarbon Systems,

Handbook of Natural Gas Engineering, McGraw-Hill Book Co. Inc., New York City (1959) 189-221.

Figs. 25.6, 25.8, and 25.33, from Kobayashi, R. and Katz, D.L.: Vapor-Liquid Equilibria for Binary Hydrocarbon-Water

Systems, Ind. Erg. Chem. (1953) 45, 440-5 1.

Fig. 25.7, from Alder, S.B. and Spencer, C.F.: Case Studies of Industrial Problems, Phase Equilibria and Fluid Properties

in the Chemical Industry, Proc., Equilibrium Fluid Properties in the Chemical Industry (1980) 465-95.

Fig. 25.14, from von Stackelberg, M.: Solid Gas Hydrates, Natunvissenschaften (1949) 36, 327-33, 359-62.

Figs. 25.17 through 25.20, from Sloan, E.D.: Phase Equilibria of Natural Gas Hydrates, paper 67f presented at the

1983 AIChE Summer Natl. Meeting, Denver, Aug. 28-31.

Fig. 25.22, from Song, K.Y. and Kobayashi, R.: Measurement and Interpretation of the Water Content of a Methane-

Propane Mixture in the Gaseous State in Equilibrium with Hydrate, Ind. Eng. Chem. Fund. (1982) 21, No. 4, 391-95.

Fig. 25.25, from Deaton, W.J. and Frost, E.M.: Gas Hydrates and Their Relation to the Operation of Natural Gas Pipe

Lines, Monograph 8, USBM, Washington, DC (1946).

Fig. 25.30, from Saito, S., Marshall, D.R., and Kobayashi, R.L: Hydrates at High Pressures: Part II. Application of

Statistical Mechanics to the Study of the Hydrates of Methane, Argon, and Nitrogen, AIChE J. (1964) 10, No. 5,

734-40.

Fig. 25.32, from Dodson, CR. and Standing, M.B.: Pressure-Volume-Temperature and Solubility Relations for Natural

Gas-Water Mixtures, Drill. and Prod. Prac., API, Dallas (1944) 173-79.

Figs. 25.34 through 25.36, from Peng, D.-Y. and Robinson, D.B.: Two- and Three-Phase Equilibrium Calculations for

Coal Gasification and Related Process, Thermodynamics of Aqueous Systems with Industrial Applications, S.A. Newman

(ed.), Symposium Series 133. ACS (1980) 393-414.

Figs. 25.37 and 25.41, from Scauzillo, F.R.: Inhibiting Hydrate Formations in Hydrocarbon Gases, Chem. Eng. Progr.

(1956) 52, No. 8, 324-28.

Figs. 25.38 through 25.40, from Gas Conditioning Fact Book, Dow Chemical Co., Midland, MI (1962) 69-71,

Table 25.5, from Dharmawardhand, P.B.: The Measurement of the Thermodynamic Parameters of the Hydrate Structure

and Application of Them in the Prediction of Natural Gas Hydrates, PhD dissertation, Colorado School of Mines,

Golden (1980).

Chap. 26

Fig. 26.1, from Fraser, H.J. and Graton, L.C.: Systematic Packing of Spheres-With Particular Relation to Porosity and

Permeability, J. Geol. (Nov.-Dec. 1935) 785-909.

Figs. 26.3 and 26.30, courtesy Core Laboratories Inc., Dallas.

Fig. 26.5, 26.24, and 26.25, from Stevens, A.B.: A Laboratory Manual for Petroleum Engineering 308, Texas A&M U.,

College Station (1954).

Fig. 26.7, from Krumbein, W.C. and Sloss, L.L.: Stratigraphy and Sedimentation, Appleton-Century-Crofts Inc., New York

City (1951) 218.

Fig. 26.27, from Klinkenberg, L.J.: The Permeability of Porous Media to Liquids and Gases, Drill. and Prod. Prac.,

API, Dallas (1941) 200-13.

Fig. 26.29, from Kennedy, H.T., VanMeter, O.E., and Jones, R.G.: Saturation Determination of Rotary Cores, Pet.

Eng. (Jan. 1954) B.52-B.64.

Chap. 27

Table 27.12, courtesy Alaska Oil & Gas Conservation Commission, Anchorage.

Tables 27.13 through 27.15 and 27.17, courtesy Core Laboratories Inc., Dallas.

Table 27.16, from European Continental shelf Guide, Oilfield Publications Ltd., Ledbury, Herefordshire, England (1982).

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Chap. 28

Figs. 28.3 and 28.4, from Rose. W.: U.S. Patent No. 4,506,542 (1985).

Fig. 28.7, from Rose. W.: Permeability and Gas Slippage Phenomena. Drill. and Prod. Pruc., API. DalIah (1948)

127-35.

Fig. 28.8, from Stone. H.L.: Probability Model for Estimating Three-Phase Relative Permeability. J. Ccl,z. P<,t. Tech.

(Oct. 1973) 53-59.

Fig. 28.12, from Panteleev. V.G. et ctl.: Influence of Carbon Dioxide on Three Phase Permeability by Oil and Water,

Nej?eprom.wlowe de10 (1973) No. 6. I l-13.

Fig. 28.16, from Ashford. F.E.: Determination of Two Phase and Multiphase Relative Permeability for Drainage and

lmbibition Cycles Based on Capillary Pressure Measurement, Revisru Tecnicu Intevep (198 1) 1, 71-94.

Fig. 28.19, from Lin, C. and Slattery. J.C.: Three-Dimensional. Randomized, Network Model for Two-Phase Flow

Through Porous Media. AlChE J. (1982) 28, No. 2, 311-24.

Chau. 29

Figs. 29.1 through 29.3, from Galloway, T.J.: Bull. 118, California Div. of Mines, Sacramento (Aug. 1957).

Fig. 29.6, from Sams. H.: Atkinson Field. Good Example of Subtle Stratigraphic Trap, Oil & Gas .I. (Aug. 12. 1974)

145-63.

Fig. 29.7, from Hoyt. W.V.: Erosional Channel in the Middle Wilcox Near Yoakum. Lavaca County. Texas, Trrlrt~.

Gulf Coast Assn. of Geological Societies (Nov. 1959) 9, 41-50.

Fig. 29.8, from Pirson, S.J.: Oil Reservoir EnRinerring, second edition, McGraw-Hill Book Co. Inc., New York City

(1958).

Figs. 29.9 and 29.10, from Occurrence of Oil and Gas in Northeast Texas, F.A. Herald (ed.). Bureau of Economic

Geology and East Texas Geological Sot. (April 1951).

Fig. 29.11, from An Infrod~rction to Gulf Cousf Oil Fields, Houston Geological Sot., Houston (1941).

Fig. 29.12, from A Guide Book, Houston Geological Sot.. Houston (1953).

Chap. 30

Tables 30.1 through 30.4, from Bergman, J.C., Gulmard, A., and Hagenar, D.S.: High Performance Pressure

Measurement Systems. Schlumberger Well Services, Houston (1980) 10.

Chao. 31

Fig. 31.1, from Clijnutu/ogicul Dutu in the United Slates. U.S. Weather Bureau, Washington, DC

Chap. 32

Fig. 32.1, from the Railroad Commission of Texas, Austin.

Figs. 32.2 and 32.3, from Calhoun, J.C. Jr.: Fundamentals of Reservoir Engineering, revised edition, U. of Oklahoma

Press. Norman (1953).

Figs. 32.10 and 32.11, from Turbine Meters, API Manual of Petroleum Measurement Standurd.T, Chap. 5. Sec. 3.

Fig. 32.12, from API Measurement of Perroleum Liquid Hydrocarbons by Positive Displuccment Meter, API Std. IlO1, first

edition (Aug. 1960).

Chap. 33

Table 33.7, from Rawlins, E.L. and Schellhardt. M.A.: Back-pressure Data on Natural Gas Wells and Their Application

to Production Practices, USBM Monograph, Washington. DC (1935).

Chap. 34

Fig. 34.2, from Moody, L.F.: Friction Factors for Pipe Flow, Trans., ASME (1944) 66, 671.

Fig. 34.3, from Brown. G.G. et al.: Nutural Gusohe and the Volatile Hydrocarbons, Natural Gas Assn. of America

(1948).

Fig. 34.4, from Nisle, R.G. and Poettmann, F.H.: Calculation of the Flow and Storage of Natural Gas in Pipe, Per Enx.

(1955) 27, No. I. D-14; No. 2, C-36; No. 3, D-37.

Figs. 34.8 and 34.9, from Griffith, P. and Wallis, G.B.: Two-Phase Slug Flow, J. Heur Transfer (Aug. 1961) 307-20:

Trans., ASME.

Figs. 34.11 and 34.12, from Poettmann, F.H. and Carpenter, P.G.: Multiphase Flow of Gas, Oil, and Water Through

Vertical Flow Strings with Application to the Design of Gas-Lift Installations, Drill. und Prod. Pruc., API (1952)

257-3 17.

Figs. 34.13 through 34.17, from Davis, G.J. and Weidner, C.R.: Investigation of the Air Lift Pump, Bull., Eng. Series,

U. of Wisconsin (191 I) 6, No. 7.

Figs. 34.23 through 34.25, from Poettmann, F.H. and Beck, R.L.: New Charts Developed to Predict Gas-Liquid Flow

Through Chokes, World Oil (March 1963) 95-101.

Table 34.7, from Rawlins, E.L. and Schellhardt, M.A.: Back-Pressure Data on Natural Gas Wells and Their Application

to Production Practices, Monograph Series, USBM (1936) 7.

Chap. 36

Fig. 36.9, from Dahm, C.G. and Graebner. R.J.: Field Development With Three-Dimensional Seismic Methods in the

Gulf of Thailand-A Case History. GeophvJics (Feb. 1982) 149-76.

ix

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Chap. 37

Fig. 37.6 and 37.7, from Tarncr, J., How Different Sire Gas Caps and Pressure Maintenance Programs Affect Amount ot

Recoverable Oil. Oil Week !\~ (June 12. 1944) 32-44.

Figs. 37.16 through 37.24, and Tables 37.1 and 37.2, from Singh. D. and Guerrero. E.T.: Material Balance Equation

Sensitivity, Oil & Gas .I. (Oct. 20. 1969) 95-102.

Figs. 37.29 and 37.30, from Cronquist, C.: Evaluating Producing Volatile Oil Reservoirs. Workl Oil (April 1979)

159-66 and 246.

Chao. 39

Figs. 39.1 through 39.3, and Table 39.1, after Eilerts. K.C. er ~1.: Phusr Rr/ution.s of Gas-Co,l~lenscite F1ui~l.s. American

Gas Assn., New York City (1957).

Figs. 39.4 through 39.6, and Tables 39.2 through 39.10, courtesy Core Laboratories Inc., Dallas (1985).

Fig. 39.7, after Marshall. D.L. and Oliver, L.R.: Some Uses and Limitations of Model Studies in Cycling. Trcrns.,

AIME (1948) 174, 67-87.

Fig. 39.8, after Stelzer, R.B.: Model Study vs. Field Performance, Cycling the Paluxy Condensate Reservoir, Drill. trrrrl

Prod. Pruc., API (1956) 336-42.

Fig. 39.9, data derived from Stelzer, R.B.: Model Study vs. Field Performance, Cycling the Paluxy Condensate

Reservoir. Drill. and Prod. Prac., API (1956) 336-42.

Table 39.12, from Miller, M.G. and Lents. M.R.: Performance of Bodcaw Reservoir, Cotton Valley Field Cycling

Project. New Methods of Predicting Gas-Condensate Reservoir Performance Under Cycling Operations. Drill. wzd Prod.

Prac., API (1946) 128849.

chap. 41

Table 41.11, courtesy Republic Bank of Dallas.

Table 41.14. from Wilson. W.W. and Boyd. W.L.: Simplified Calculations Determine Loan Payout. World Oil (May

1958).

Chao. 44

Figs. 44.6 through 44.8 and Table 44.2, from Craft, B.C. and Hawkins, M.J. Jr.: Applied Pc~troleum Reservoir

Engineering, Prentice-Hall Inc., Englewood Cliffs, NJ (1959) 107, 357, 412-13.

Figs. 44.58 through 44.61, from Guerrero. E.T. and Earlougher, R.C.: Analysis and Comparison of Five Methods Used

to Predict Waterflooding Reserves and Performance, Drill. and Prod. Prac., API, Dallas (I 961) 78-95.

Fig. 44.62, from Higgins, R.V. and Leighton. A.J.: Computer Techniques for Predicting Three-Phase Flow in Five-Spot

Waterfloods, RI 7011. USBM (Aug. 1967).

Chap. 45

Fig. 45.4, from Brown, G.G. et al.: Natural Gasoline and the Volatile Hydrocarbons, Natural Gasoline Assn. of

America (1948).

Fig. 45.5, from Hutchinson, C.A. Jr. and Braun, P.H.: Phase Relations of Miscible Displacement in Oil Recovery.

AIChE J. (1961) 7, 64.

Fig. 45.7, modified from Slobod, R.L. and Koch, H.A. Jr.: High Pressure Gas Injection-Mechanism of Recovery

Increase, Drill. and Prod. Prac., API, Dallas (1953) 82.

Fig. 45.8, modified from Sage B.H and Lacey, W.N.: Some Properties of the Lighter Hydrocarbons, Hydrogen Suljde, and

Carbon Dioxide, Monograph Research Project 37, API, Dallas (1955).

Chap. 46

Fig. 46.1, from Farouq Ali, S.M.: Steam Injection, Secondary and Tertiary Oil Recovery Processes, Interstate Oil

Compact Commission, Oklahoma City (Sept. 1974) 148.

Fig. 46.2, from McNeil, M.S. and Moss, J.T.: Oil Recovery by In-Situ Combustion, Pet. Eng. (July 1958) B-29-B-42.

Fig. 46.5, from Smith, R.W. and Perkins. T.K.: Experimental and Numerical Simulation Studies of the Wet Combustion

Recovery Process, J. Cdn. Pet. Tech. (July-Sept. 1973) 44454.

Fig. 46.34, from Mace. C.: Deepest Combustion Project Proceeding Successfully, Oil & Gus J. (Nov. 17, 1975) 74-81.

Fig. 46.59, from Poettmann. F.H. and Mayland, B.J.: Equilibrium Constants for High Boiling Hydrocarbon Fractures of

Varying Characterization Factors, Pet. Refiner (July 1949) 101ll2.

Tables 46.1 through 46.6, from Steam Dominates Enhanced Oil Recovery, Oil & Gas J. (April 5, 1982) 139-59.

Table 46.31, from 1967 ASTM Steam Tables, ASME. New York City (1967).

Chap. 47

Figs. 47.1, 47.12, and 47.26, from U.S. DOE: drawing by J. Lindley, Bartlesville, OK.

Fig. 47.3, from Mungan, N.: Rev. Inst. Fr. Pet., Editions Technip, Paris (1969) 24, 232.

Fig. 47.4, from Tsaur, K.: A Study of PolymeriSurfactant Interactions for Micellar/Polymer Flooding Applications, MS

thesis. U. of Texas, Austin (1978).

Fig. 47.5, from Martin, F.D., Donaruma, L.G., and Hatch, M.J.: Development of Improved Mobility Control Agents for

SurfactantiPolymer Flooding, second annual report, Contract No. DOEiBCiOCO013, U.S. DOE (Oct. 1980).

Fig. 47.8, from Overbeck, J.Th.G.: Colloids and Surface Chemistry. A Self-Study Subject Guide. Part 2, Lyophobic

Colloids, Bull., Center for Advanced Engineering, Massachusetts Inst. of Technology, Cambridge, MA (1972).

Fig. 47.9, from Khan. S.A.: The Flow of Foam Through Porous Media, MS thesis, Stanford U., Stanford, CA (1965).

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Fig. 47.19, from Recd. R.L. and Healy, R.N.: Some Physico-Chemical Aspects of Microemulsion Flooding: A Review.

Improved Oil Recovery by Sutjticttmt and Polwner Flooding, D.O. Shah and R.S. Schechter (eds.), Academic Press, New

York City (1977) 383-438.

Fig. 47.20, from Harwell. J.H.: Surfactant Adsorption and Chromatographic Movement with Application in Enhanced Oil

Recovery. PhD dissertation, U. of Texas, Austin (1983).

Fig. 47.23, from Lake, L.W. and Pope, G.A.: Status of Micellar-Polymer Field Tests, Pet. Eng. Intl. (Nov. 1979) 51,

38-60.

Fig. 47.27, from Minssieux, L.: Waterflood Improvement by Means of Alkaline Water, Enhunced Oil Recovery by

Displacement wifh Saline Solutions, Kogan Page Ltd., London (1979) 75-90; courtesy BP Trading Co. Ltd.

Table 47.1, from Manning, R.K., Pope, G.A., and Lake, L.W.: A Technical Survey of Polymer Flooding Projects,

Contract No. DOE/BETC/l0327-19, U.S. DOE (Sept. 1983).

Table 47.2, from Akstinat, M.H.: Surfactants for WOR Process in High-salinity Systems: Product selection and

evaluation, Enhanced Oi/ Recovery, Elsevier Scientific Publishing Co., New York City (1981).

Chap. 49

Figs. 49.9, 49.10, 49.19 through 49.22, 49.25 through 49.30, and 49.34, from Log Interpretation Principles, Vol. 1,

Schlumberger Well Services, Houston.

Figs. 49.42 through 49.44 and Table 49.2, from Calver, J:C.. Rau, R., and Wells, L.: Electromagnetic Propagation-A

New Dimension in Logging, Schlumberger Well Services, Houston.

Figs. 49.46 and 49.47, from Best, D.L., Gardner. J.S., and Dumanoir, J.L.: A Computer-Processed Wellsite Log

Computation, paper presented at the 1978 SPWLA Annual Logging Symposium, June 13-16.

Fig. 49.48, from Coates, G.R., Schulze, R.P., and Throop, W.H.: VOLAN*-An Advanced Computational Log

Analysis, paper presented at the 1982 SPWLA Annual Logging Symposium, July 6-9.

Tables 49.1 and 49.3 through 49.6, from Bateman. R.M., Log Qunlir?, Control, IHRDC, Boston, 1984.

Chap. 50

Figs. 50.5 and 50.6, from Evans, R.D.: 7he Aromic Nucleus, McGraw-Hill Book Co. Inc., New York City (1967) 426-38.

Figs. 50.9, 50.21, 50.30, 50.32 through 50.34, 50.40, 50.43, 50.50, and 50.51, courtesy Schlumberger Well Services.

Houston.

Fig. 50.18, from Tidman, J.: Geophysical Well Logging. excerpts from Methods in Experimental Phyic.\: Physics,

Academic Press (1986) 24.

Figs. 50.22 and 50.36, from Schlumberger Log Interpretation Charts, Schlumberger Well Services, Houston. 1984.

Figs. 50.23, 50.24, and 50.26, from Edmundson, H. and Raymer, L.L.: Radioactive Logging Parameters for Common

Minerals. paper presented at the 1979 SPWLA Annual Logging Symposium, Tulsa, June 3-h.

Fig. 50.29, from Hertzog, R.C. and Plasek, R.E.: Neutron-Excited Gamma-Ray Spectrometry for Well Logging. IEEE

Trms. NM. Sti. (Feb. 1979) NS-26, No. 1,

Fig. 50.46, Arnold, D.M. and Smith, H.D. Jr.: Experimental Determination of Environmental Corrections for a Dual-

Spaced Neutron Porosity Log, paper W presented at the 1981 SPWLA Annual Logging Symposium, Mexico City, June

23-26.

Fig. 50.47, from Schlumbergcr Chart Book, Schlumberger Well Services, Houston (1977).

Table 50.3, from Bcrtuzzi. W., Ellis. D.V., and Wahl. J.S.: The Physical Foundation of Formation Lithology Logging

with Gamma Rays, Geophy.siu (Oct. 1981) 46, No. 10.

Chap. 51

Fig. 51.2, from Sears, F.W. and Zemansky, M.W.: Unirwsi@ Physics, Addison-Wesley Publishing Co. Inc., Reading. MA

(1955) 1031.

Figs. 51.3 and 51.4, from Krautkramer, J. and Krautkramer, H.: Ultrasonic Testing ofA4ateriais, Springer-Verlag. New

York City (1969) 521.

Figs. 51.6 and 51.71, from Timur. A.: Rock Physics, The Arabian J. Sri. Eng. Special Issue (1978) 5-30.

Figs. 51.7 and 51.15, from Timur. A.: Temperature Dependence of Compressional and Shear Wave Velocities in Rocks,

Groph~sics (1977) 42, 950-56.

Figs. 51.8 and 51.9 and Table 51.2, from Jones, S.B., Thompson, D.D., and Timur. A.: A Unified Investigation of

Elastic Wave Propagation in Crustal Rocks, paper presented at the Rock Mechanics Conference, Vail, CO (1976).

Fig. 51.10, from Johnston. D.H., Toksoz. M.N., and Timur, A.: Attenuation of Seismic Waves in Dry and Saturated

Rocks: Part II: Theoretical Models and Mechanism. Grophvsics ( 1979) 44, 69 l-7 1 I

Fig. 51.11, from Wyllie, M.R.J.. Gardner, G.H.F., and Gregory, A.R.: Studies of Elastic Wave Attenuation in Porous

Media. Geophysics (1962) 27, 269.

Figs. 51.12 through 51.14, from Gardner. G.H.F., Gardner, L.W.R., and Gregory, A.R.: Formation Velocity and

Density-The Diagnostic Basics for Stratigraphic Traps, Geophysics (1974) 39, 770-80.

Fig. 51.16, from Timur, A.: Velocities of Compressional Waves in Porous Media at Permafrost Temperatures,

Geophysics (1968) 33, 584-96.

Figs. 51.17, 51.19, and 51.21, from Toksoz, M.N., Cheng. C.H., and Timur, A.: Velocities of Seismic Waves in Porous

Rocks, Geoph?sirs ( 1976) 41, 62 l-45.

Fig. 51.17, from King, M.S.: Wave Velocities in Rocks as a Function of Changes in Overburden Pressure and Pore Fluid

Saturants. Geophysics (1966) 31, 50-73.

Fig. 51.18, Gregory, A.R.: Fluid Saturation Effect\ on Dynamic Elastic Properties of Sedimentary Rocks. Geophysics

(1976) 41, 895-921.

Fig. 51.20, from Timur. A.. Hempkins. W.B., and Weinbrandt. R.M.: Scanning Electron Microscope Study of Pore

Systems in Rocks. J. Geophy. Res. (1971) 76, No. 20, 4932-48.

xi

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Figs. 51.22, 51.37, 51.50, and 51.94, from Gcycr. R.L. and Myung, J.I.: The 3-D Velocity Log: a Tool for In-Situ

Determination of the Elastic Moduli of Rocks. Dynamic Rock Mechanics, Proc., Twelfth Symposium on Rock

Mechanics (1971) 71-107.

Figs. 51.23 and 51.24, from Minear, J.W. and Fletcher, C.R.: Full-Wave Acoustic Logging, Tr0n.c.) SPWLA (1983)

paper EE.

Fig. 51.25, from Cheng. C.H. and Toksoz, M.N.: Elastic Wave Propagation in a Fluid-Filled Borchole and Synthetic

Acoustic Logs, Geophysics (1981) 46, 1042-S3.

Fig. 51.26, from Cheng. C.H. and Toksoz. M.N.: Generation, Propagation and Analysis of Tube Waves in a Borehole,

Trans., SPWLA (1982) paper P.

Figs. 51.27, 51.28, 51.31, and 51.46, from Thomas, D.H.: Seismic Applications of Sonic Logs, The Log Analwt (Jan.-

Feb. 1977) 23-32.

Figs. 51.29 and 51.33, from Lynch, E.J.: Forrnutiorz Evu/uurwn, Harper and Row, New York City (1962) 422.

Figs. 51.36 and 51.77, from Ausburn, J.R.: Well Log Editing in Support of Detailed Seismic Studies, Trans., SPWLA

(1977) paper F.

Figs. 51.39 and 51.42, from Goetz, J.F., Dupal. L., and Bowler, J.: An Investigation into Discrepancies Between Sonic

Log and Seismic Check Shot Velocities, Part I, APEA J. (1979) 19, 131-41.

Fig. 51.40, from Ransom, R.C.: Methods Based on Density and Neutron Well-Logging Responses to Distinguish

Characteristics of Shaly Sandstone Reservoir Rock, The Log Analyst (May-June 1977) 18, 47-62.

Figs. 51.41, 51.43, 51.44, and 51.48, from The Long Spaciflg So&, Schlumberger technical pamphlet (1980).

Fig. 51.45, from Misk, A. ef a/.: Effects of Hole Conditions on Log Measurements and Formation Evaluation, SAID,

Third Annual Logging Symposium (June 1976).

Figs. 51.47 and 51.49, from The Long Spacing Sonic, Schlumberger technical pamphlet (1982).

Fig. 51.56, from Parks. T.W., McClellan, J.H., and Morris. C.F.: Algorithms for Full-Waveform Sonic Logging, paper

presented at the 1983 IEEE-ASSP Workshop on Spectral Estimation.

Fig. 51.58, from Wiley. R.: Borehole Televiewer-Revisited. Trans., SPWLA (1980) 21, paper HH.

Fig. 51.60, from Seisviewer Logging, Birdwell, Div. of Seismograph Service Corp.. technical pamphlet (1981).

Fig. 51.61, from Broding, R.A.: Volumetric Scanning Well Logging, Trans., SPWLA (1981) 22, paper B.

Fig. 51.63, from Log Interpretation Charts. Schlumberger (1979).

Fig. 51.65, from Evaluaci6n de Formaciones en la Argentina, Schlumberger (1973) 9455.

Fig. 51.66, from Raymer, L.L.. Hunt, E.R., and Gardner, J-S.: An Improved Sonic Transit Time-To-Porosity

Transform. Trms., SPWLA (1980) paper P.

Fig. 51.67, from Hartley. K.B.: Factors Affecting Sandstone Acoustic Compressional Velocities and An Examination of

Empirical Correlations Between Velocities and Porosities, Tram, SPWLA (1981) paper PP.

Figs. 51.70 and 51.72, from Nations, J.F.: Lithology and Porosity from Acoustic Shear and Comprcssional Wave Transit

Time Relationships, Trms., SPWLA 18th Annual Logging Symposium (June 1974).

Fig. 51.73 and 51.74, from Gardner. G.H.F. and Harris, M.H.: Velocity and Attenuation of Elastic Waves in Sands.

Trans.. SPWLA (1968) 9, paper M.

Fig. 51.75, from Arditty. P.C.. Ahrens, G., and Staron, Ph.: EVA: A Long Spacing Sonic Tool for Evaluation of

Velocities and Attenuation. paper presented at the 1981 SEG Annual Meeting, Los Angeles.

Fig. 51.76, from Domenico. S.N.: Effect of Brine-Gas Mixture on Velocity in an Unconsolidated Sand Reservoir. Thr

Log A~~nl~st (1977) 18, 38-46.

Figs. 51.78 and 51.79, from Kithas. B.A.: Lithology, Gas Detection, and Rock Properties from Acoustic Logging

Systems, Trcrns., SPWLA (1976) 17, paper R.

Figs. 51.80 and 51.81, from Laws. W.R.. Edwards. C.A.M., and Wichmann, P.A.: A Study of the Acoustic and Density

Changes Associated with High-Amplitude Events on Seismic Data. Trans., SPWLA (1974) 15, paper D.

Figs. 51.83 and 51.84, from Herring, E.A.: North Sea Abnormal Pressures Determined from Logs, Per. Eng. (1973)

45, 72-84.

Figs. 51.85 through 51.89, from Acoustic Cement Bond Log, Dresser Atlas technical pamphlet (I 979) 20.

Figs. 51.90 and 51.92, from Cement Bond Evaluation in Cased Holes Through 3-D Velocity Logging, Birdwell technical

pamphlet (1978) 12.

Fig. 51.91, from Cement Evaluation Tool, Schlumberger technical pamphlet (1983).

Fig. 51.96, from Walker. T.: Acoustic Character of Unconsolidated Sand, Welcx paper (1971).

Fig. 51.97, from Myung. J.I. and Baltosser. R.W.: Fracture Evaluation by the Borehole Logging Method. Stuhi& Rock

Sloprs. Thirteenth Symposium on Rock Mechanics (1972) 31-56.

Figs. 51.98 and 51.99, from Taylor, T.J.: Interpretation and Application of Borehole Televicwer Surveys. Tram.,

SPWLA (1983) 24, paper QQ.

Fig. 51.100, from Williams. D.M. et (II.: The Long Spacing Acoustic Logging Tool, Trans., SPWLA (1984) 25,

paper T.

Table 51.1, from Timur. A.: Application of Acoustic Wave Propagation Methods to Evaluation and Production of

Hydrocarbon Rcscrvoirs, Pm-, IEEE Ultrasonic Symposium, Dallas (1984).

Table 51.3, from Guyod. H. and Shane. L.E.: Geophysical Well Logging, Hubert Guyod, Houston (1969) I, 256; and

Wyllic, M.R.J.. Gregory, A.R.. and Gardner. G.H.F.: Elastic Wave Velocities in Heterogeneous and Porous Media,

Geophysic~s (1956) 21, 41-70.

Chap. 52

Figs. 52.1 and 52.2, from MS-196, Exploration Logging Inc., Sacramento, CA (1979).

Figs. 52.3 through 52.12 and 52.22 and Table 52.1, courtesy Exploration Logging Inc., Sacramento, CA.

Figs. 52.13, 52.14, 52.16, 52.17, and 52.19 through 52.21, from MS-156, Exploration Logging Inc.. Sacramento, CA

(1981).

Figs. 52.15 and 52.18, from AV-6. Exploration Logging Inc.. Sacramento. CA (1980).

Fig. 52.23, from AV-13. Exploration Logging Inc.. Sacramento. CA (1982).

xii

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Chap. 53

Fig. 53.3, from Measurement While Drilling, Technical Specifications. Anadrill Logging Unit, Schlumherger.

Fig. 53.7 and Table 53.2, from Log Qualify Conrrol Munurri. Vizilog Inc., Houston.

Figs. 53.9 through 53.11, from Dipme/er InferpretLltion~Vol. I, Fundamentals, Schlumberger, Houston (1981).

Fig. 53.12 and 53.15, from Gilbreath. J.A.: Dipmeter Interpretation Rules, Schlumberger Offshore Services, New

Orleans.

Figs. 53.13 and 53.14, from Open Hole Log Analysis and Formation Evaluation. Vizilog Inc.. Houston.

Figs. 53.16 through 53.18, from 7k Lox Analyst (March-April 1979) 20.

Fig. 53.20, from Well Evaluation Developments Schlumherger, Houston (1982).

Fig. 53.23 through 53.25, from Dresser Atlas Production Senlices Catalog, Dresser Atlas.

Fig. 53.26, from The &IR Analyst (March-April 1984) 25-28.

Fig. 53.27 through 53.32, from Well Evaluation Developments 1982, Schlumherger.

Table 53.1 and Fig. 53.5, from EXLOG Flyer GA 817-A. EXLOG (June 1983).

Table 53.3 and Figs. 53.21 and 53.22, from Dia-Log flyer, The Dia-Log Co., Houston.

Chap. 54

Figs. 54.6 through 54.9, courtesy Dowell Schlumherger Technical Brochure TSL-2038, Acidizing-State-of-the-Art,

Tulsa, OK (1981).

Chap. 56

Figs. 56.1 through 56.8, courtesy Dowell Schlumberger Technical Brochure TSL45 19, Dowell Sand Control Techniques

and Equipment Catalog (Sept. 1982). Tulsa. OK.

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Acknowledgments . . . . . . . . . . . . . . . . . . ..~......................___.____._. v

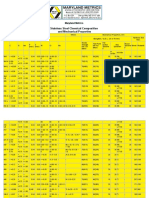

1. Mathematical Tables and Units and Systems of Weights and Measures

Mathematical Tables . .

Units and Systems of Weights and Measures . . .

............... 1-2

............... 1-68

2. Casing, Tubing, and Line Pipe

Casing.. .............................................................................. 2-1

Tubing ................................................................................ 2-38

Line Pipe .............................................................................. 2-46

Equations for Calculating Performance Properties of Casing, Tubing, and Line Pipe ............... 2-46

API Threading Data ..................................................................... 2-64

3. Wellhead Equipment and Flow Control Devices

Introduction .

API Flanged or Clamped Wellhead Equipment.

Flow Control Devices: Safety Shut-In Systems

Other Flow-Control Devices

Corrosion

Special Application.

Independent Screwed Wellhead.

4. Production Packers

Production Packers Classification and Objectives ............... 4-l

Tubing-to-Packer Connections. ............... 4-l

Packer Utilization and Constraints ............... 4-l

Considerations for Packer Selection ............... 4-4

Tubing/Packer System ............... 4-6

Tubing Response Characteristics. ............... 4-8

Combination Tubing/Packer Systems ............... 4-11

Tubing/Packer Forces on Intermediate Packers ............... 4-l I

5. Gas Lift

Introduction...................................................

Gas Fundamentals as Applied to Gas Lift .

Gas Lift Valve Mechanics

Continuous-Flow Gas Lift

Intermittent Gas Lift .

Unloading Procedures and Proper Adjustment of Injection Gas Rate

6. Hydraulic Pumping

Introduction

Downhole Pumps

Principles of Operation-Reciprocating Pumps

Jet Pumps

Surface Equipment

Appendix A-Fluid Properties

Appendix B-Friction Relationships

7. Electric Submersible Pumps

Introduction

ESP System.

Application5

ESP System Components.

Selection Data and Methods

Handling, Installation. and Operation

Troubleshooting

............... 3-l

............... 3-l

............... 3-18

............... 3-34

............... 3-35

............... 3-36

............... 3-39

.

5-l

S-3

5-12

5-21

5-38

5-53

6-1

6-2

6-8

6-34

6-49

6-66

6-69

7-l

7-l

7-l

7-3

7-9

7-12

7-14

xv

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

8. Subsurface Sucker-Rod Pumps

Introduction ...................

Pump Selection ................

Plungers ......................

Slippage Past Plungers. .........

Soft-Packed Plungers ...........

Balls and Seats ................

Double Valves ................

Bottom-Discharge Valve ........

Three-Tube Pump. .............

Gas Anchors ..................

Special Pumps. ................

Corrosion ....................

Effect of Gases and Vapors. .....

Conclusions ...................

9. Sucker Rods

Introduction ...................

Steel Sucker Rods ............

Fiberglass Sucker Rods .........

.

.

..,................,..

10. Pumping Units and Prime Movers for Pumping Units: Part l-Pumping Units

Introduction ............................................................

Pumping Units .........................................................

Component Parts .......................................................

Pumping Unit Loading ...................................................

Counterbalance .........................................................

Sizing .................................................................

Installation .............................................................

Lubrication ............................................................

Changing the Oil .......................................................

8-l

8-2

8-4

8-5

8-6

8-7

8-7

8-8

8-8

8-9

8-9

8-9

8-10

8-10

9-l

9-l

9-10

IO-I

IO-I

IO-4

IO-5

IO-6

IO-7

IO-7

IO-12

IO-13

Pumping Units and Prime Movers for Pumping Units: Part 2-Prime Movers for Pumping Units

Introduction ............................................................................ lo-14

Internal-Combustion Engines .............................................................. IO-14

Electric Motors for Oilwell Pumping ....................................................... IO-19

11. Oil Storage

Types of Storage Tanks ................................

Tank Corrosion Protection .............................

Appurtenances ........................................

Venting Atmospheric and Low-Pressure Storage Tanks ......

Materials of Construction ..............................

Production Equipment .................................

Vapor Losses ........................................

Vapor Control and Gravity Conservation With Storage Tanks

Underground Storage ..................................

12. Oil and Gas Separators

Summary.. ...........................................

Introduction ...........................................

Primary Functions of Oil and Gas Separators ...............

Secondary Functions of Oil and Gas Separators .............

Special Problems in Oil and Gas Separation ................

Methods Used To Remove Oil From Gas in Separators ......

Mist Extractors Used in Oil and Gas Separators ............

Methods Used To Remove Gas From Oil in Separators ......

Estimated Quality of Separated Fluids .....................

Classification of Oil and Gas Separators ...................

Centrifugal Oil and Gas Separators and Gas Scrubbers .......

Illustrations of Oil and Gas Separators ....................

Comparison of Oil and Gas Separators ....................

Estimating the Sizes and Capacities of Oil and Gas Separators.

xvi

. .

11-l

1 l-4

11-6

11-6

1 l-9

11-9

11-11

I l-12

11-13

12-l

12-l

. 12-3

12-4

12-6

12-8

12-l I

12-13

12-13

12-16

12-20

12-21

12-21

12-21

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

Computer Sizing of Oil and Gas Separators ............................. 12-25

Capacity Curves for Vertical and Horizontal Oil and Gas Separators ........ 12-27

Practical Considerations in Sizing Oil and Gas Separators ................. 12-32

Stage Separation of Oil and Gas. ...................................... 12-32

Selection and Application of Separators and Scrubbers .................... 12-35

Construction Codes for Oil and Gas Separators .......................... 12-38

Controls, Valves, Accessories, and Safety Features for Oil and Gas Separators 12-39

Operation and Maintenance Considerations for Oil and Gas Separators ....... 12-40

13. Gas Measurement and Regulation

Introduction ............................................

Gas Measurement. ......................................

Regulation.. ...........................................

14. Lease-Operated Hydrocarbon Recovery Systems

Introduction...............................................

Low-Temperature Separation (LTS) Systems . . . . . . . . .

Gas-Treating Systems for Removal of Water Vapor, CO,, and H,S

15. Surface Facilities for Waterflooding and Saltwater Disposal

Introduction ............................................

Piping System Design ...................................

Selecting Pumps and Drivers .............................

Separating Suspended Solids From Heater. ..................

Treating Hydrocarbons From Water. .......................

Dissolved Gas Removal ..................................

Dissolved Solids Removal ................................

Removing Hydrocarbons From Solids ......................

Process Selection and Project Management ..................

Project Control .........................................

16. Automation of Lease Equipment

Introduction ...........................................

Automatic Production-Control Equipment ..................

Production Safety Controls ..............................

Automatic Quantitative Measurement ......................

Gas Measurement ......................................

Temperature Measurement ..............................

Automatic Sampler. ....................................

BS&W Monitor .......................................

Net-Oil Computer. .....................................

Supervisory Control and Data Acquisition (SCADA) Systems .

Typical Automatic-Control Installations ....................

Automatic Well Testing .................................

LACT ...............................................

17. Measuring, Sampling, and Testing Crude Oil

Introduction ............................................

Procedure for Typical Measuring, Sampling, and Testing ......

Abstract of API Manual .................................

18. Offshore Operations

Introduction ...............................

Historical Review ..........................

Offshore Drilling ..........................

Field Operations ...........................

Special Considerations ......................

Structures ................................

Offshore Production Operations ..............

Arctic ....................................

Electrica:, Instrumentation and Control Systems

Control of Subsea Production Facilities ........

.

.

. .

. .

.

. .

13-l

13-l

13-49

14-l

14-l

14-17

5-l

5-l

5-14

5-18

5-2 I

15-28

15-29

1.5-30

15-30

1.5-32

16-1

16-2

16-4

16-5

16-6

16-7

16-7

16-7

16-7

16-8

16-10

16-12

16-12

17-l

17-l

17-3

18-I

18-l

18-3

18-17

18-20

18-22

18-27

18-38

18-43

. 18-48

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

19. Crude Oil Emulsions

Introduction............................................. 19-I

Theories of Emulsions 19-I

Sampling and Analyzing Crude Oil Emulsions . 19-6

Methods Used in Treating Crude Oil Emulsions, 19-6

Emulsion-Treating Equipment and Systems . . 19-15

Description of Equipment Used in Treating Crude Oil Emulsions 19-16

Operational Considerations for Emulsion-Treating Equipment. . 19-28

Economics of Treating Crude Oil Emulsions . . 19-32

20. Gas Properties and Correlations

Molecular Weight. . . . .

Ideal Gas . .

21.

. .

Critical Temperature and Pressure .

Specific Gravity (Relative Density) . . .

Mole Fraction and Apparent Molecular Weight of Gas Mixtures

Specific Gravity of Gas Mixtures . . . .

Daltons Law . . . . . . . . .

Amagats Law.

Real Gases . . .

Principle of Corresponding States.

Equations of State . . . . .

Van der Waals Equation. . . .

Viscosity . . . . .

Viscosity Correlations . . .

Natural Gasoline Content of Gas . . .

Formation Volume Factor . .

Coefficient of Isothermal Compressibility

Vapor Pressure . . .

Cox Chart

Calingeart and Davis Equation .

Lee-Kesler ............................

Example Problems .....................

Crude Oil Properties and Condensate Properties and Correlations

Introduction ..................................................

BaseofCrudeOil ............................................

Physical Properties ............................................

True-Boiling-Point Crude-Oil Analyses ...........................

Bubblepoint-Pressure Correlations ...............................

Dewpoint-Pressure Correlations .................................

Sage and Olds Correlation .....................................

Total Formation Volume Correlations ............................

22. Oil System Correlations

Introduction . . . . . . .

Oil Density Determination. . .

Bubblepoint-Pressure Correlations

Solution GOR for Saturated Oils .

Oil FVF Correlations . . .

Total FVFs

Oil Viscosity Correlations .

Gas/Oil IFT . . .

Glossary . . . . .

23. Phase Diagrams

Introduction . .

Single-Component Phase Diagrams

Phase Rule . . . . .

Types of Diagrams. . .

Calculation of Phase Compositions. . .

.

.

.

.

. . . .

. .

. .

. . . .

. .

. .

. . . .

. .

.

.

.

.

. .

.

. .

.

. .

.

. .

.

.

. .

.

. . .

. . . I

. . .

. .

.

.

. .

20-I

20-l

20-2

20-4

20-4

20-4

20-4

20-4

20-4

20-4

20-6

20-7

20-9

20-9

20-10

20-I 1

20-11

20-11

20-12

20-13

20-13

20-13

21-I

21-l

21-3

21-8

21-9

21-10

2llll

21-15

22-l

22-2

22-5

22-9

22-10

22-13

22-13

22-16

22-20

23-l

23-l

23-2

23-2

23-10

XVIII

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

24. Properties of Produced Waters

Introduction and History

Sampling . . . . . . .

Analysis Methods for Oilfield Waters . . .

Chemical Properties of Oilfield Waters . . .

Inorganic Constituents . . . . .

Physical Properties of Oilfield Waters

Interpretation of Chemical Analyses . .

Occurrence, Origin, and Evolution of Oilfield Waters

Recovery of Minerals From Brines . . . . . .

. .

. .

. . . .

25. Phase Behavior of Water/Hydrocarbon Systems

Introduction ...........................................................................

General Hydrocarbon/Water Phase Diagrams and Equilibrium Data Sources .....................

Hydrate Stability Conditions .............................................................

Determining the Water Content of Gas (or Hydrocarbon-Rich Liquid) in Equilibrium With Hydrates

Definition of the Saturated Water Content of Natural Gases in Equilibrium With Aqueous Phases ...

Quantitative Prediction of Water Content in Light Hydrocarbon Systems ........................

Quantitative Predictions of Solute Concentrations in the Aqueous Phase .........................

Sour Water Stripper Correlations .........................................................

Oil and Gas Reservoirs That Exist in the Gas Hydrate Region .................................

Hydrate Inhibition .....................................................................

26. Properties of Reservoir Rocks

Introduction . .

Porosity . . . . . . . . . . . . . . . . . . . . .

Permeability . .

Fluid Saturations. .

Electrical Conductivity of Fluid-Saturated Rocks

Empirical Correlation of Electrical Properties.

27. Typical Core Analysis of Different Formations

Introduction ...............................

Porosity ..................................

Permeability ..............................

Liquid Saturations .........................

Percussion Sidewall Core Data ...............

Data From U.S. Areas .....................

Data From Non-U.S. Areas .................

28. Relative Permeability

Introduction . . . . 28-l

Historical Background . 28-2

Framework Ideas . . 28-2

Measurement Methodologies . 28-3

Recent Literature 28-9

Critique of Recent Work . . . . . 28-10

Ramifications Needing Attention. 28-12

Conclusions . . 28-13

29. Petroleum Reservoir Traps

Introduction .............. ..........

Trap Classification ...................

Characteristics of Reservoir Rocks. ......

Glossary ................ ..........

30. Bottomhole Pressures

Introduction

BHP Instruments . .

Pressure Transducer Technology

Calculated BHP .

Application of BHP .

. .

.

,.,,.,.....,

. .

.

. .

24-l

24-3

24-5

24-5

24-9

24-12

24-18

24-19

24-20

25-l

25-1

25-4

25-10

25-11

25-16

25-16

25-17

25-18

25-19

26-l

26-l

26-10

26-20

26-27

26-29

27-l

27-1

27-l

27-8

27-9

27-9

27-9 . . .

.

. . . . . . . . . .

29-l

29- 1

29-6

29-8

30-l

30-l

. 30-6

30-7

30-8

xix

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

C

l

i

c

k

t

o

b

u

y

N

O

W

! P

D

F

-

X

C

hange V

ie

w

e

r

w

w

w

. d

o

cu-trac

k

.

c

o

m

31. Temperature in Wells

Introduction ...........

Thermometers .........

Thcrmometry .........

Summary .............

32. Potential Tests of Oil Wells

Texas Allowable Rule ....................

Productivity Index (PI) ...................

Specific PI. .............................

Theoretical PI ...........................

Pseudosteady-State Flow ..................

Stock-Tank Measurement. .................

Portable Well Testers, ....................

GOR ..................................

GOR as a Criterion of Reservoir Performance

....... 31-l

....... 31-I

....... 31-2

....... 31-7

....... 32-1

....... 32-2

....... 32-4

....... 32-4

....... 32-5

....... 32-6

....... 32-7

....... 32-14

....... 32-15

.

. .

33. Open Flow of Gas Wells

Introduction .. ........................

Pitot-Tube Gauging of Low-Pressure Wells

Backpressure Testing ..... ........................

Gas Well Inflow Equation. Pseudosteady State .........

Multipoint Test and Example .......................

Isochronal Test and Example .......................

Comparison of Multipoint With Isochronal Test ........

Gas Measurement ... ............... .............

Calculation of Subsurface Pressures ..................

Application of Backpressure Tests to Producing Problems

Production Rate .................... .............

Causes of Deterioration in Performance .............

Examples of Remedial Operations ..... .............

....... 33-l

....... 33-1

....... 33-3

....... 33-5

....... 33-7

....... 33-10

33-l 1 ........

....... 33-13

....... 33-13

....... 33-20

....... 13-20 _

....... 33-20

....... 33-22

. . .

.

. .

34. Wellbore Hydraulics

Introduction

Theoretical Basis

Producing Wells .

Injection Wells

Oil Wells

Multiphase Flow.

Flow Through Chokes

Liquid Loading in Wells

....... 34- 1

....... 34- 1

....... 34-3

....... 34-28

....... 34-30

....... 34-35

....... 34-45

....... 34-46

.

.

. .

. .

. .

.

35. Well Performance Equations

Introduction. ...............

Diffusivity Equation .........

Multiphase Flow. ...........