Professional Documents

Culture Documents

Camshaft Angle Variator

Uploaded by

NemanjaGlisicCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Camshaft Angle Variator

Uploaded by

NemanjaGlisicCopyright:

Available Formats

>

BASIC FACTS

On traditional engines, the opening and closing positions of

valves are fixed in relation to the angular position of the crank-

shaft. They are thus optimised for a given engine speed, but,

as they do not take into account the influence of the flame

face propagation velocity, they remain more approximate at

other speeds. The camshaft angle variator therefore varies the

timing of valve opening and closing as a function of the angu-

lar position of the crankshaft, according to the speed and load

of the engine

If the engine has a twin overhead camshaft, the variator can be

located either on the intake or on the exhaust. Optimisation of

the intake improves the engine output at high speed, its fuel

consumption and its exhaust emission levels, increases its

torque at full load and even substitutes for the EGR valve by

increasing the overlap between the intake and exhaust valves.

The exhaust valve reduces both consumption and exhaust

emissions under partial load. If the engine has only a single

camshaft, it is not possible to play on valve overlap. The same

shift of angular position in relation to the crankshaft is applied

to the intake and the exhaust. In addition to the fact that the

variator makes it possible to dispense with the EGR valve, it

reduces engine consumption under partial load.

IN SHORT

>>>

By adjusting the opening and closing of valves

according to engine speed and load, the camshaft

angle variator optimises the operation of the engine,

giving it more torque at low revs and more power

at high revs, at the same time as reducing polluting

emissions.

Camshaft

angle variator

Oil circuit feed

Retard

Advance

The camshaft angle variator optimises the operation of the engine at each

engine speed by modifying valve opening and closing according to the angular

position of the crankshaft. It gives the engine more torque at low revs, and more

power at high engine speeds. It also minimises fuel consumption and polluting

emissions.

>

>

M

o

b

i

l

i

t

y

>

E

n

v

i

r

o

n

m

e

n

t

>

L

i

f

e

o

n

b

o

a

r

d

>

S

a

f

e

t

y

Environment

>

Camshaft angle variator Sheet 7

R

E

N

A

U

L

T

C

O

M

M

U

N

I

C

A

T

I

O

N

(08) camvariator 1/12/05 18:08 Page 1

>

HOW DOES IT WORK?

Two types of camshaft angle variators exist. The first one is

based on a piston combined with helical teeth. This is located

on the inner face of the distribution belt pulley. In these teeth

are placed gears that are interdependent with the camshaft.

The piston allows axial movement of the gear in relation to the

helical teeth of the pulley, rather like driving down a

corkscrew. When the piston moves the gear in relation to the

helical teeth, it swivels slightly. Thus, depending on its posi-

tion, a more or less great angular shift appears between the

camshaft and the pulley and consequently between the

crankshaft and camshaft.

However, this complex device is increasingly giving way to

the paddle variator. This is still located in the camshaft pul-

ley. A rotor separates the chambers, which are cavities

arranged in the body of the pulley. By injecting oil under

pressure on one or other of the faces of the separator that

the rotor forms, the rotor tends to pivot in either one direction

or the other. There are advance and retard chambers,

depending on the direction of the shift induced on the

camshaft. It is by applying oil under pressure using a sole-

noid valve to one or other of these chambers that the com-

puter can control the camshaft shift. Depending on the

application, this operation can be carried out either in all or

nothing mode or uninterrupted. In the first case, two extreme

values of shift are available. If the system works in continu-

ous mode, the shift can then take an unspecified value

between these two extreme positions to optimise the opera-

tion of the engine still further.

Environment

>

Camshaft angle variator Sheet 7

(08) camvariator 1/12/05 18:08 Page 2

You might also like

- Seven-Speed Dual-Clutch Gearbox 0B5/S TronicDocument11 pagesSeven-Speed Dual-Clutch Gearbox 0B5/S TronicChristian Pach100% (1)

- 4JH1 Gestión ElectrónicaDocument79 pages4JH1 Gestión ElectrónicaAna Lorca89% (19)

- VT2214BDocument2 pagesVT2214BAlberto Valenzuela Urzúa67% (3)

- 600 Forms Editing! 2Document570 pages600 Forms Editing! 2widodo dp96% (24)

- 2013 Fork Rockshox Service ManualDocument83 pages2013 Fork Rockshox Service ManualXc Cristi0% (1)

- 11 - Reversing of Two Stroke EngineDocument13 pages11 - Reversing of Two Stroke EngineAisha Zaheer90% (29)

- Teaching Aids Torque Converter - ModuleDocument16 pagesTeaching Aids Torque Converter - ModuleMohd HaikalNo ratings yet

- Caterpillar Torque Curves PDFDocument11 pagesCaterpillar Torque Curves PDFAlberto Pila Alonso100% (2)

- Workshop Manual: Sisudiesel 320 420 620 634Document116 pagesWorkshop Manual: Sisudiesel 320 420 620 634Ramón ManglesNo ratings yet

- Mazda5: Training ManualDocument140 pagesMazda5: Training ManualPablo De Miguel GonzálezNo ratings yet

- Study of Variable Valve Timing System (VVTDocument16 pagesStudy of Variable Valve Timing System (VVTSadanand SontakkeNo ratings yet

- Automatic TransmissionsDocument1 pageAutomatic Transmissionspkjhan1353No ratings yet

- Torque Curves: Roduct NformationDocument11 pagesTorque Curves: Roduct NformationCandiano PopescuNo ratings yet

- Engine Performance With Variable Valve TimingDocument4 pagesEngine Performance With Variable Valve TimingWilliam KibbeNo ratings yet

- Automatic Transmission ComponentsDocument12 pagesAutomatic Transmission ComponentsRizqy Fadry LazimNo ratings yet

- Variable Geometry Turbochargers (VGTS) Are A Family ofDocument19 pagesVariable Geometry Turbochargers (VGTS) Are A Family ofdevhxNo ratings yet

- Hydraulic CouplingDocument44 pagesHydraulic Couplingsen_subhasis_58100% (1)

- Unit 17 - 02 - Starting & ManoeuvringDocument16 pagesUnit 17 - 02 - Starting & ManoeuvringAisha ZaheerNo ratings yet

- Gearboxes ClassDocument35 pagesGearboxes ClassNaveen Vachipalli100% (1)

- VVT (Variable Valve Timing)Document26 pagesVVT (Variable Valve Timing)PramodPradhan100% (1)

- Advancements of Automatic Gear Transmission SystemsDocument21 pagesAdvancements of Automatic Gear Transmission SystemsKavindu UmayangaNo ratings yet

- Automatic Transmission ComponentsDocument14 pagesAutomatic Transmission ComponentsAbdul Salam ASNo ratings yet

- Automatic Transmission Basics PDFDocument34 pagesAutomatic Transmission Basics PDFtambache69100% (1)

- Automatic Transmission BasicsDocument238 pagesAutomatic Transmission BasicsSílvio Santos100% (2)

- Choosing The Perfect Performance CamshaftDocument9 pagesChoosing The Perfect Performance CamshaftDesotoJoe100% (1)

- Torque ConverterDocument6 pagesTorque ConverterPaachu GNo ratings yet

- AutomaticDocument13 pagesAutomaticabdullah8508No ratings yet

- Ad Dit LC B Ti E I Advanced Internal Combustion Engines Mae 589V (Spring 2009)Document15 pagesAd Dit LC B Ti E I Advanced Internal Combustion Engines Mae 589V (Spring 2009)snmathad2No ratings yet

- Sleeve Metering Fuel SystemDocument6 pagesSleeve Metering Fuel SystemJosephNo ratings yet

- Camless EnginesDocument18 pagesCamless EnginesJamadagniParitiNo ratings yet

- Retarder Auxiliary Brake Systems ExplainedDocument5 pagesRetarder Auxiliary Brake Systems ExplainedahmedNo ratings yet

- Pplant Lec 2Document6 pagesPplant Lec 2Alyssa SisonNo ratings yet

- Transmission SystemDocument71 pagesTransmission Systemrijorijorijo100% (1)

- VT2214B Eng 01 953694 PDFDocument2 pagesVT2214B Eng 01 953694 PDFAlberto Valenzuela UrzúaNo ratings yet

- Variable Valve TimingDocument3 pagesVariable Valve Timingsandesh ganigaNo ratings yet

- PT2606 Eng 03 303855078Document2 pagesPT2606 Eng 03 303855078Shane LinNo ratings yet

- MIVECDocument14 pagesMIVECsyamz5429No ratings yet

- How Torque Converters Work - HowStuffWorksDocument7 pagesHow Torque Converters Work - HowStuffWorksKrishanu ModakNo ratings yet

- ThethreeoperationalpahsesDocument5 pagesThethreeoperationalpahsesBirhan Menberu AbiyNo ratings yet

- 2 Variable Valve TimingDocument30 pages2 Variable Valve TimingAlex Mariei100% (1)

- Continuously Variable TransmissionDocument11 pagesContinuously Variable TransmissionsonirocksNo ratings yet

- The Operation of Hydraulic Coupling and Torque ConverterDocument10 pagesThe Operation of Hydraulic Coupling and Torque Convertergold pornNo ratings yet

- How Does The VNT Works?Document3 pagesHow Does The VNT Works?mebarki aberraoufNo ratings yet

- How Does The VNT WorksDocument3 pagesHow Does The VNT WorksAyman Al ShabanahNo ratings yet

- 2 Variable Valve TimingDocument30 pages2 Variable Valve Timingadibazmi93100% (1)

- Nissan CVTCS Continuous Valve Timing Control SystemsDocument4 pagesNissan CVTCS Continuous Valve Timing Control SystemsSecarianu Florentin RazvanNo ratings yet

- Valve Gear and Valve TimingDocument20 pagesValve Gear and Valve TimingAmmi AdemNo ratings yet

- AT6501 QBDocument8 pagesAT6501 QBSahayaraj GabrielNo ratings yet

- Torque ConverterDocument6 pagesTorque ConverterMohan Preeth100% (1)

- How Does Torque Converter WorkDocument6 pagesHow Does Torque Converter WorkJZM GulfNo ratings yet

- Starting and ReversingDocument55 pagesStarting and ReversingMeghanath AdkonkarNo ratings yet

- 5tech EnginDocument20 pages5tech EngintravelnammamysoreNo ratings yet

- PSG Princible of OperationDocument4 pagesPSG Princible of Operationmehdi kamaliNo ratings yet

- Torque Converter2 BuldozerDocument25 pagesTorque Converter2 BuldozerHelver Alonso MancipeNo ratings yet

- Meng422 Valves and Valve Mechanisms 2 Fall 2017Document11 pagesMeng422 Valves and Valve Mechanisms 2 Fall 2017Sergen SerinNo ratings yet

- Valve Operating MechansmsDocument18 pagesValve Operating MechansmsRahul GajjeNo ratings yet

- Cam Less EngineDocument10 pagesCam Less EngineSridhar DineshNo ratings yet

- Fluid Coupling &torque ConverterDocument5 pagesFluid Coupling &torque ConverterArsh Gautam UD100% (1)

- Amte 116Document2 pagesAmte 116school.chaimepnceNo ratings yet

- Gear Boxes in Automobiles PresentationDocument24 pagesGear Boxes in Automobiles PresentationHada NanuNo ratings yet

- 0B5 Etails About The SevenDocument19 pages0B5 Etails About The SevenLili100% (3)

- Camless Engine: Working of Push Rod EngineDocument14 pagesCamless Engine: Working of Push Rod EngineAkshay Kumar pn AkshayNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Installation Recommendations NSXDocument11 pagesInstallation Recommendations NSXNemanjaGlisicNo ratings yet

- 12) Formulae Student UK 2013Document4 pages12) Formulae Student UK 2013Amir RasyadanNo ratings yet

- Practical TPM Chpt2Document18 pagesPractical TPM Chpt2NemanjaGlisicNo ratings yet

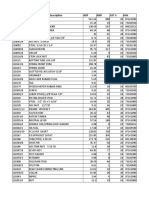

- FSC13 Scoring Total All 01Document1 pageFSC13 Scoring Total All 01NemanjaGlisicNo ratings yet

- LinMot Data Book e RecentDocument580 pagesLinMot Data Book e RecentNemanjaGlisicNo ratings yet

- FLENDERDocument79 pagesFLENDERekin100% (4)

- IRSCDocument8 pagesIRSCNemanjaGlisicNo ratings yet

- Laval NozzleDocument4 pagesLaval NozzleNemanjaGlisicNo ratings yet

- Speed Guide ExplanationDocument7 pagesSpeed Guide ExplanationNemanjaGlisicNo ratings yet

- Wireless Pressure Sensors For Optimized Sail TrimmingDocument1 pageWireless Pressure Sensors For Optimized Sail TrimmingNemanjaGlisicNo ratings yet

- 2011 Vivid Air Technical ManualDocument27 pages2011 Vivid Air Technical ManualNemanjaGlisicNo ratings yet

- 2011 Rockshox Fork Oil ChartDocument2 pages2011 Rockshox Fork Oil ChartchichetasNo ratings yet

- This Is Neither A Simple Nor A Straightforward Computation ProcessDocument4 pagesThis Is Neither A Simple Nor A Straightforward Computation ProcessNemanjaGlisicNo ratings yet

- Fuel Injectors NozzlesDocument110 pagesFuel Injectors NozzlesNemanjaGlisicNo ratings yet

- FSAE Racecar Brake DesignDocument41 pagesFSAE Racecar Brake DesignJonathan WallerNo ratings yet

- Aeromotive Manual RailDocument13 pagesAeromotive Manual RailNemanjaGlisicNo ratings yet

- Idle ValvesDocument13 pagesIdle ValvesNemanjaGlisicNo ratings yet

- FormulaStuden RaceCar EngineDocument18 pagesFormulaStuden RaceCar EngineNemanjaGlisicNo ratings yet

- Paddle SPaddle ShifterhifterDocument32 pagesPaddle SPaddle ShifterhifterNemanjaGlisicNo ratings yet

- AEROCOM-Roll Cage Info Sheet (Aug-2012) (1) InchesDocument2 pagesAEROCOM-Roll Cage Info Sheet (Aug-2012) (1) InchesNemanjaGlisicNo ratings yet

- FSAE Aero Initial Performance Predictions - MonashDocument10 pagesFSAE Aero Initial Performance Predictions - MonashPedro BarataNo ratings yet

- 2011 Fsae MQPDocument92 pages2011 Fsae MQPBrijesh GautamNo ratings yet

- Chain Noise Excitation in Combustion Engines - Numerical Simulation and Verification of Different Chain TypesDocument15 pagesChain Noise Excitation in Combustion Engines - Numerical Simulation and Verification of Different Chain TypesNemanjaGlisicNo ratings yet

- Redesign of The Intake Cams of A Formula StudentDocument8 pagesRedesign of The Intake Cams of A Formula StudentNemanjaGlisic100% (1)

- Valve TimingDocument11 pagesValve TimingAmanda HayesNo ratings yet

- Cam BookDocument69 pagesCam BookMarco Bissoli100% (3)

- SE EFI Installation ManualDocument58 pagesSE EFI Installation ManualNemanjaGlisicNo ratings yet

- Rear Frame Wiring: Electrical System D9T Track-Type TractorDocument4 pagesRear Frame Wiring: Electrical System D9T Track-Type TractorCris Lozoya100% (1)

- Kubota Diesel 3.6L Engine: PART NO. 4053146 0600 SRM 1579Document112 pagesKubota Diesel 3.6L Engine: PART NO. 4053146 0600 SRM 1579Gabriela PurcenaNo ratings yet

- Approved CAR 147 Maintenance Training Organization (Capability List)Document3 pagesApproved CAR 147 Maintenance Training Organization (Capability List)Abhishek Kumar SinghNo ratings yet

- PDF 236Document2 pagesPDF 236Cesar CastroNo ratings yet

- Air Standard CycleDocument6 pagesAir Standard CycleBishOy NasrNo ratings yet

- SPC V15 & V12 BS Iv Rev 07 Sept 17Document85 pagesSPC V15 & V12 BS Iv Rev 07 Sept 17muheetNo ratings yet

- A Supercharger On A King AirDocument6 pagesA Supercharger On A King AirH100% (1)

- CPI Cheetah XS Service Manual 2tDocument46 pagesCPI Cheetah XS Service Manual 2tKlara PataiNo ratings yet

- Valve Adjustment PDFDocument34 pagesValve Adjustment PDFlilo6romeroNo ratings yet

- C18 Generator Set With EMCP II, EMCP II +and EMCP 3 - Electrical System - RENR7934-01 - March 2006 - CATERPILLAR PDFDocument6 pagesC18 Generator Set With EMCP II, EMCP II +and EMCP 3 - Electrical System - RENR7934-01 - March 2006 - CATERPILLAR PDFpevare100% (3)

- 02EN0780 Yd25 PDFDocument2 pages02EN0780 Yd25 PDFKevin TtitoNo ratings yet

- Fuel System Pressure - Test: Shutdown SIS Previous ScreenDocument7 pagesFuel System Pressure - Test: Shutdown SIS Previous ScreenmohamedNo ratings yet

- Civic IdleDocument4 pagesCivic IdlexmariachiNo ratings yet

- Sistema de Operacion 14G HidraulicaDocument25 pagesSistema de Operacion 14G Hidraulicayeison100% (3)

- Sil99 2Document28 pagesSil99 2Christian100% (1)

- Model: Frequency: Fuel Type: kVA Rating: C3300 D5 (2660 DQLB) 50 Diesel 3000 Data Center ContinuousDocument3 pagesModel: Frequency: Fuel Type: kVA Rating: C3300 D5 (2660 DQLB) 50 Diesel 3000 Data Center Continuousmohsen_cumminsNo ratings yet

- RE Prise ListDocument168 pagesRE Prise ListSaikumar Sai KumarNo ratings yet

- Manual de Taller Xterra-2008 vq40Document144 pagesManual de Taller Xterra-2008 vq40eduardo rubiNo ratings yet

- Raider R150Document74 pagesRaider R150GAYLE GONo ratings yet

- DM360Document2 pagesDM360Yeison Camilo Zapata DavidNo ratings yet

- Parts List Catalog Kubota L295DTDocument219 pagesParts List Catalog Kubota L295DTNik AncaNo ratings yet

- Lubricating System - Primera P11Document42 pagesLubricating System - Primera P11Ishmael WoolooNo ratings yet

- How To Fill The Coolant System 1100 PDFDocument1 pageHow To Fill The Coolant System 1100 PDFBelghennou Hadj AliNo ratings yet

- Engin Airflow Calculation GuideDocument9 pagesEngin Airflow Calculation GuideRodolfo Perez100% (3)

- PC200-7 PartbookDocument481 pagesPC200-7 PartbookNguyễn Ngọc BáchNo ratings yet

- Cat 314Document905 pagesCat 314Anderson Freitas0% (1)

- Manual Servicio 1TN - 3,5TN R Series PDFDocument98 pagesManual Servicio 1TN - 3,5TN R Series PDFRicardo BilbaoNo ratings yet