Professional Documents

Culture Documents

Tensile Calculation PDF

Uploaded by

Wendimagen Meshesha Fanta0 ratings0% found this document useful (0 votes)

343 views2 pages1. This document provides a procedure to determine the tensile strength and elongation of copper foil at ambient and elevated temperatures using mechanical force testing.

2. Copper foil samples that are 10 inches by 1/2 inch are cut and tested in a tensile tester capable of pulling at varying rates. The tensile strength in PSI and elongation in percentage are calculated.

3. Samples are tested at ambient temperature at a rate of 2 inches/minute and at an elevated temperature of 180°C ±10°C at a rate of 0.050 inches/minute to determine the mechanical properties of the copper foil at different conditions.

Original Description:

Original Title

tensile calculation.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. This document provides a procedure to determine the tensile strength and elongation of copper foil at ambient and elevated temperatures using mechanical force testing.

2. Copper foil samples that are 10 inches by 1/2 inch are cut and tested in a tensile tester capable of pulling at varying rates. The tensile strength in PSI and elongation in percentage are calculated.

3. Samples are tested at ambient temperature at a rate of 2 inches/minute and at an elevated temperature of 180°C ±10°C at a rate of 0.050 inches/minute to determine the mechanical properties of the copper foil at different conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

343 views2 pagesTensile Calculation PDF

Uploaded by

Wendimagen Meshesha Fanta1. This document provides a procedure to determine the tensile strength and elongation of copper foil at ambient and elevated temperatures using mechanical force testing.

2. Copper foil samples that are 10 inches by 1/2 inch are cut and tested in a tensile tester capable of pulling at varying rates. The tensile strength in PSI and elongation in percentage are calculated.

3. Samples are tested at ambient temperature at a rate of 2 inches/minute and at an elevated temperature of 180°C ±10°C at a rate of 0.050 inches/minute to determine the mechanical properties of the copper foil at different conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

1.

0 Scope To determine the tensile strength (in PSI) and

the elongation (in percentage) of copper foil at ambient and

elevated temperatures by mechanical force testing.

2.0 Applicable Documents

ASTM-E-345 Tensile Strength

3.0 Test Specimens Copper foil sufficient in size to permit

cutting or etching of five specimens 10 inches x

1

2 inch.

Specimens must be clean cut and free of burrs and nicks.

4.0 Apparatus

4.1 Constant strain rate tensile tester capable of pulling at

rate of 0.050 and 2.0 inches/minute.

4.2 JDC #50 sample cutter

1

2 inch wide x 10 inches long.

4.3 A shear to cut 10 inches long sample to 6 inches long.

4.4 Mettler Balance type P120 or equivalent.

4.5 Elevated temperature chamber or fixture, attachable to

the tensile tester, capable of reaching and maintaining a tem-

perature of 180C 10C during sample testing.

5.0 Procedure

5.1 Preparation of Samples

5.1.1 The sample should be smooth and undistorted

(wrinkle free).

5.1.2 Use the JDC #50 to cut five tensile specimens.

5.1.3 Cut the five 10 inches long specimens to 6 inches

long.

Note: Accuracy is important in the

1

2 inch x 6 inches dimen-

sions because it is used to determine foil thickness and cross-

sectional area.

5.2 Weighing Samples

5.2.1 Weigh tensile sample to at least three places beyond

the decimal point, in grams.

5.2.2 Record the weight and calculate the mean average

cross-sectional area.

Note: The density of electrodeposited copper is 8.909 gm/cc

(16.389 cc/in

3

x 8.909 gm/cc = 146 gm/in

3

).

The density of rolled copper is 8.93 gm/cc (16.389 cc/in

3

x

8.93 gm/cc = 146.35 gm/in

3

).

Mean average thickness =

Weight of tensile sample in grams

Area of Tensile

sample in sq.

inches

X

The density

of copper in

gm/in

3

Mean avg. cross-sectional area =

Weight of tensile sample in grams

Area of Tensile

sample in sq.

inches

X

The density

of copper in

gm/in

3

5.3 General Test Information

5.3.1 If the tensile tester is equipped with an area compen-

sator, dial the mean average cross-sectional area into it. If not

then the cross-sectional area has to be used to compute the

tensile strength.

Note:

Tensile Strength

in lbs/in

2

=

Load used to break sample in lbs.

Mean average crosssectional area

If Tensile Tester is equipped with area compensator after the

test is complete, the Tensile Strength can be read directly

from the chart.

5.3.2 Ambient Temperature Testing

5.3.2.1 Select load range.

5.3.2.2 Place the sample in the jaws of the Tensile Tester

The Institute for Interconnecting and Packaging Electronic Circuits

2215 Sanders Road Northbrook, IL 60062-6135

IPC-TM-650

TEST METHODS MANUAL

Number

2.4.18

Subject

Tensile Strength and Elongation, Copper Foil

Date

8/80

Revision

B

Originating Task Group

Printed Board Test Methods (7-11d)

Material in this Test Methods Manual was voluntarily established by Technical Committees of the IPC. This material is advisory only

and its use or adaptation is entirely voluntary. IPC disclaims all liability of any kind as to the use, application, or adaptation of this

material. Users are also wholly responsible for protecting themselves against all claims or liabilities for patent infringement.

Equipment referenced is for the convenience of the user and does not imply endorsement by the IPC.

Page 1 of 2

being careful that it is properly centered and the axis aligned

with the jaws.

5.3.2.3 Test Conditions

(1) Gage length 2.0 inches

(2) Crosshead speed 2.0 inches/min.

(3) Chart speed 20 inches/min.

Note: At a chart speed of 20 inches/min., a gage length of

2.0 inches and a crosshead speed of 2.0 inches/min. each

one inch of chart paper equals 5.0% linear elongation.

5.3.3 Elevated Temperature Testing

5.3.3.1 Select load range.

5.3.3.2 Bring temperature chamber or fixture up to 180C

10C.

5.3.3.3 Open temperature chamber and clamp foil sample

between tensile jaws. (Note: Caution must be exercised to

avoid excessive clamping pressures and to provide good

sample alignment for testing.)

5.3.3.4 Close temperature chamber and monitor sample

temperature with a thermocouple. Permit foil sample to dwell

at 180C temperature for 5 minutes prior to tensile test. Maxi-

mum time at temperature should not exceed 10 minutes.

5.3.3.5 Test Conditions

(1) Gage length 2.0 inches

(2) Crosshead speed 0.050 inches/min.

(3) Chart speed 20 inches/min.

Note: At a chart speed of 20 inches/min., a gage length of

2.0 inches and a crosshead speed of 0.050 inches/min., each

one inch of chart paper equals 0.125% linear elongation.

Note: Temperature chamber contains normal ambient air.

Inert gas atmosphere is not necessary, but may be used.

5.4 Evaluation

5.4.1 Activate crosshead to break sample and make calcu-

lations of tensile strength in pounds/in

2

and elongation in %.

5.4.2 Percent elongation may be determined by fitting the

ends of the fractured specimen together carefully and mea-

suring the distance between the original gage marks to the

nearest 0.01 inch. Elongation is the increase in length of the

gage length, expressed as a percentage of the original gage

length.

Percent elongation =

length at break original gage length X 100

original gage length

5.4.3 Average all five elongation readings.

6.0 Notes

6.1 For guidance, typical values for tensile strength and

elongation are:

TENSILE STRENGTH

Oz/ft

2

Electrodeposited

Standard or high ductility As rolled

Light cold

rolled Annealed

lb/in

2

lb/in

2

lb/in

2

lb/in

2

1/2 15,000 50,000 15,000

1 30,000 50,000 25,000

2 & over 30,000 50,000 25,000 25,000

ELONGATION

Oz/ft

2

Electrodeposited

As rolled

Light cold

rolled Annealed Standard High ductility

percent percent min. percent min. percent min. percent

1/2 2 5 1/2 5

1 3 10 1/2 10

2 3 15 1 5 20

IPC-TM-650

Number

2.4.18

Subject

Tensile Strength and Elongation, Copper Foil

Date

8/80

Revision

B

Page 2 of 2

You might also like

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Conectores, Morseteria y Aisladores - Playa 132-33-13.2kv-Modk (EloDocument2 pagesConectores, Morseteria y Aisladores - Playa 132-33-13.2kv-Modk (EloSRGNo ratings yet

- SOP - 0001 - Carlsberg Flask Preparation For PropagationDocument7 pagesSOP - 0001 - Carlsberg Flask Preparation For PropagationMilosStojanovicNo ratings yet

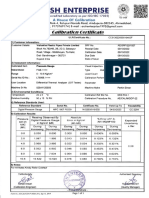

- Calibration Procedure of Metal Detection MachineDocument1 pageCalibration Procedure of Metal Detection MachineJobaer0% (1)

- Jointing Manual: Insulated Straight Through Joint For 230kV Single Core 1400 XLPE CablesDocument28 pagesJointing Manual: Insulated Straight Through Joint For 230kV Single Core 1400 XLPE CablesGustavo OliveiraNo ratings yet

- 29-Stop Watch Calibration CartificateDocument1 page29-Stop Watch Calibration CartificateCustomer SupportNo ratings yet

- FEM GHG Emission Factors FEM 2021Document13 pagesFEM GHG Emission Factors FEM 2021Emdad YusufNo ratings yet

- Inventory Techniques of BoschDocument7 pagesInventory Techniques of BoschAbimanyu ShenilNo ratings yet

- Calibration Details With Sample Certificate and Website LinksDocument9 pagesCalibration Details With Sample Certificate and Website LinksAkash RajanNo ratings yet

- Work Instruction of Stranding MachineDocument2 pagesWork Instruction of Stranding MachineWendimagen Meshesha Fanta100% (1)

- Summer Project REPORTDocument20 pagesSummer Project REPORTMrdev25555No ratings yet

- Six Sigma Control PDFDocument74 pagesSix Sigma Control PDFnaacha457No ratings yet

- Stop Watch-ID-23 - 24 To 25Document2 pagesStop Watch-ID-23 - 24 To 25monwar hosenNo ratings yet

- Enameled Copper Wire Supplier XinyuDocument5 pagesEnameled Copper Wire Supplier XinyucopperwirexinyuNo ratings yet

- Chromatography Solution: 5S AuditDocument3 pagesChromatography Solution: 5S Auditabhijit612No ratings yet

- Analytical Balance SOPDocument2 pagesAnalytical Balance SOPdivine productionNo ratings yet

- 54-Pressure Gauge OIT Calibration CartificateDocument1 page54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- 1-A-TSM Level 1 5S Campaign 02 SR TRDocument18 pages1-A-TSM Level 1 5S Campaign 02 SR TRtimazaNo ratings yet

- 02-Calibration & Control of Measuring & Monitoring DevicesDocument1 page02-Calibration & Control of Measuring & Monitoring DeviceskitekNo ratings yet

- LSS Tools 2020Document6 pagesLSS Tools 2020Varun KumarNo ratings yet

- Customer Quality KPI's: No of Defective Parts (-) X 1 Million No of Parts SuppliedDocument4 pagesCustomer Quality KPI's: No of Defective Parts (-) X 1 Million No of Parts Suppliedmohamed kaboshNo ratings yet

- Work Instruction FOR: Spectro AnalysisDocument3 pagesWork Instruction FOR: Spectro AnalysismahendraNo ratings yet

- Tai Sao CL Quan TrongDocument21 pagesTai Sao CL Quan Trongthuy doNo ratings yet

- Cost Monitoring SystemDocument18 pagesCost Monitoring SystemsatishyadavalliNo ratings yet

- JH Step-1 & 2activitiesDocument34 pagesJH Step-1 & 2activitiesGREENEXE BUSINESS CONSULTANTNo ratings yet

- Electrical Schematics - Cargo Vocacionais 2014Document39 pagesElectrical Schematics - Cargo Vocacionais 2014MarcioMartinhoFerreiraNo ratings yet

- Aj D-Prod-01 Preventive Maintenace PlanDocument5 pagesAj D-Prod-01 Preventive Maintenace PlanMANAGEMENT REPRESENTATIVENo ratings yet

- TPM Presentation Material M5 EN 200508 00918728001139491042aDocument3 pagesTPM Presentation Material M5 EN 200508 00918728001139491042ahwhhadiNo ratings yet

- Structure of The TPM Concept: Module I: Elimination of Root CausesDocument16 pagesStructure of The TPM Concept: Module I: Elimination of Root CauseshwhhadiNo ratings yet

- 가시관리표준 (개정) EnglishDocument61 pages가시관리표준 (개정) Englishomer_kuzgun3769No ratings yet

- GR&R Variable October 2019 Check - As FoundDocument5 pagesGR&R Variable October 2019 Check - As FoundxharpreetxNo ratings yet

- JH PPT 18.12.20Document46 pagesJH PPT 18.12.20MAngesh Gade0% (1)

- Measurement System Analysis (MSA)Document125 pagesMeasurement System Analysis (MSA)Vikram BillalNo ratings yet

- Value Stream Mapping, 5S& Visual ManagementDocument58 pagesValue Stream Mapping, 5S& Visual ManagementShrishti GuptaNo ratings yet

- Work Instruction Manual Front PageDocument1 pageWork Instruction Manual Front PageShreya Test HouseNo ratings yet

- Calibration ProcedureDocument5 pagesCalibration ProcedureManu SharmaNo ratings yet

- NMS FT 78 Calibration Certificate Format SoundDocument1 pageNMS FT 78 Calibration Certificate Format SoundYeswe calNo ratings yet

- Kaizen PDFDocument74 pagesKaizen PDFKaushik BiswasNo ratings yet

- 1 NablDocument11 pages1 NablNeha SharmaNo ratings yet

- Importance of Process Safety Testing For Identifying Chemical Reactions HazardsDocument60 pagesImportance of Process Safety Testing For Identifying Chemical Reactions HazardsSarsuhNo ratings yet

- For Receving Gauges - Master Sample: Gauge Callibration Work InstructionsDocument1 pageFor Receving Gauges - Master Sample: Gauge Callibration Work InstructionsAnkur Gupta100% (1)

- 080523-Safety Test (2pag)Document2 pages080523-Safety Test (2pag)Gonzalo MazaNo ratings yet

- Iacs of Metals N SolderDocument1 pageIacs of Metals N Soldersmallik3No ratings yet

- Calb 4Document1 pageCalb 4ranjt53No ratings yet

- SPC Course MaterialDocument116 pagesSPC Course MaterialPurushothama Nanje GowdaNo ratings yet

- 18.in House Calibration ProcedureDocument1 page18.in House Calibration ProcedureSAKTHIVEL ANo ratings yet

- Kaizen Idea Sheet: CountermeasureDocument1 pageKaizen Idea Sheet: CountermeasurerahulNo ratings yet

- V10 Mes PDFDocument5 pagesV10 Mes PDFBrian MelNo ratings yet

- Control Plan: FG 260 As Per IS 210: 2009Document24 pagesControl Plan: FG 260 As Per IS 210: 2009Suraj RawatNo ratings yet

- Lean ProductionDocument17 pagesLean ProductionTahir Naeem JattNo ratings yet

- Kaizen 5W 1H PDFDocument20 pagesKaizen 5W 1H PDFSUBA NANTINI A/P M.SUBRAMANIAMNo ratings yet

- Customer Special CharacteristicsDocument1 pageCustomer Special Characteristicspundhir12898No ratings yet

- Cab Basic Details: National Accreditation Board For Testing and Calibration LaboratoriesDocument6 pagesCab Basic Details: National Accreditation Board For Testing and Calibration LaboratorieskrlalitNo ratings yet

- Rework ProcedureDocument4 pagesRework ProcedureVijay RajaindranNo ratings yet

- 16 LossesDocument26 pages16 LossesAbhijit Bhattacherjee100% (1)

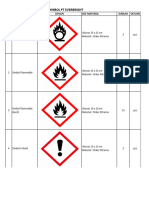

- Safety Sign & Hazard SymbolDocument4 pagesSafety Sign & Hazard SymbolRonald Abadi TariganNo ratings yet

- Mssl-Cqa Presents E - Module On "7 QC Tools"Document10 pagesMssl-Cqa Presents E - Module On "7 QC Tools"Sourabh pathakNo ratings yet

- 6W2H For Side Wrinkles MY17 - RearDocument4 pages6W2H For Side Wrinkles MY17 - RearVishvendra Pratap SinghNo ratings yet

- Operation BreakdownDocument21 pagesOperation BreakdownNikita JainNo ratings yet

- MIL-W-22759 Rev E - Part23Document1 pageMIL-W-22759 Rev E - Part23David WongNo ratings yet

- OPerationDocument84 pagesOPerationWendimagen Meshesha FantaNo ratings yet

- UntitledDocument10 pagesUntitledWendimagen Meshesha FantaNo ratings yet

- UntitledDocument48 pagesUntitledWendimagen Meshesha FantaNo ratings yet

- Departmental Manual FOR Engineering& Maintenance Dept.: Based On ISO 9001:2015 StandardDocument40 pagesDepartmental Manual FOR Engineering& Maintenance Dept.: Based On ISO 9001:2015 StandardWendimagen Meshesha FantaNo ratings yet

- Chapter 3 CPV Latest For Non-FinMgrs - PPDocument61 pagesChapter 3 CPV Latest For Non-FinMgrs - PPWendimagen Meshesha FantaNo ratings yet

- Time Management: By: Daniel Beyera Tujo (MA and Mba)Document79 pagesTime Management: By: Daniel Beyera Tujo (MA and Mba)Wendimagen Meshesha FantaNo ratings yet

- Entrepreneurship & CreativityDocument70 pagesEntrepreneurship & CreativityWendimagen Meshesha FantaNo ratings yet

- Research Methodology Sample For Social RDocument5 pagesResearch Methodology Sample For Social RWendimagen Meshesha FantaNo ratings yet

- Relationship Between Product Quality and Customer SatisfactionDocument183 pagesRelationship Between Product Quality and Customer SatisfactionCobraCMMNo ratings yet

- 4 Sample Industry AnalysisDocument18 pages4 Sample Industry AnalysisWendimagen Meshesha FantaNo ratings yet

- Competitor Analysis Unit-04Document27 pagesCompetitor Analysis Unit-04Wendimagen Meshesha FantaNo ratings yet

- Working Capital Practicesin Manufacturing IndustriesDocument37 pagesWorking Capital Practicesin Manufacturing IndustriesWendimagen Meshesha FantaNo ratings yet

- Development of Non-Financial Measures As Contemporary Performance Measurement ToolsDocument31 pagesDevelopment of Non-Financial Measures As Contemporary Performance Measurement ToolsWendimagen Meshesha FantaNo ratings yet

- Manufacturing Business PlanDocument21 pagesManufacturing Business PlanWendimagen Meshesha Fanta100% (1)

- Marketing and Sales ManualDocument17 pagesMarketing and Sales ManualWendimagen Meshesha Fanta89% (9)

- Hd1600j TechDocument1 pageHd1600j TechWendimagen Meshesha FantaNo ratings yet

- Specifications: Provide Affordable, Reliable Machines and Molds For PET Bottle Production LineDocument1 pageSpecifications: Provide Affordable, Reliable Machines and Molds For PET Bottle Production LineWendimagen Meshesha FantaNo ratings yet

- My Family (Speaking Cards)Document1 pageMy Family (Speaking Cards)Maria Marynuch100% (1)

- HorticultureDocument168 pagesHorticultureagni sahanaNo ratings yet

- Power SupplyDocument79 pagesPower SupplySharad KumbharanaNo ratings yet

- Opti Turn Tu 2004 V ManualDocument80 pagesOpti Turn Tu 2004 V ManualCharu NavneetNo ratings yet

- Vanilla Farming: The Way Forward: July 2019Document6 pagesVanilla Farming: The Way Forward: July 2019mituNo ratings yet

- IPC-S-816 SMT Process Guideline ChecklistDocument4 pagesIPC-S-816 SMT Process Guideline Checklistmigant23uNo ratings yet

- Aoc f22sDocument43 pagesAoc f22sJoao Jose Santos NetoNo ratings yet

- Titanvene ll0209sr Product Data SheetpdfDocument1 pageTitanvene ll0209sr Product Data SheetpdfHanry WRNo ratings yet

- Text 5Document7 pagesText 5santoshkumarray490No ratings yet

- KRC1 Start-Up PDFDocument29 pagesKRC1 Start-Up PDFRafael50% (2)

- 2019 BMS1021 Practice Questions Answers PDFDocument12 pages2019 BMS1021 Practice Questions Answers PDFaskldhfdasjkNo ratings yet

- Drainage BasinsDocument4 pagesDrainage BasinsDannySP10100% (1)

- Cigarettes and AlcoholDocument1 pageCigarettes and AlcoholHye Jin KimNo ratings yet

- 19 Free Amigurumi Crochet Patterns: MaterialsDocument4 pages19 Free Amigurumi Crochet Patterns: MaterialsLucica Diaconu100% (1)

- (Nano and Energy) Gavin Buxton - Alternative Energy Technologies - An Introduction With Computer Simulations-CRC Press (2014) PDFDocument302 pages(Nano and Energy) Gavin Buxton - Alternative Energy Technologies - An Introduction With Computer Simulations-CRC Press (2014) PDFmarcosNo ratings yet

- MS 005 For DUCT FABRICATION - INSULATION & INSTALLATION REV-1Document21 pagesMS 005 For DUCT FABRICATION - INSULATION & INSTALLATION REV-1vusal huseynli100% (2)

- Analisis Keterampilan Berpikir Kritis Mahasiswa Pada Materi KinematikaDocument11 pagesAnalisis Keterampilan Berpikir Kritis Mahasiswa Pada Materi KinematikaTrisnaNo ratings yet

- Yoga ProjectDocument5 pagesYoga ProjectSouri Rajan CaNo ratings yet

- Here Is Why Skincare Is ImportantDocument3 pagesHere Is Why Skincare Is ImportantKevin OkunguNo ratings yet

- User Instructions For WRC1021DDocument15 pagesUser Instructions For WRC1021DjfcNo ratings yet

- Evaluation of Global Research Trends in The Area of Food Waste D - 2020 - Food CDocument10 pagesEvaluation of Global Research Trends in The Area of Food Waste D - 2020 - Food CAliNo ratings yet

- Beauty Therapy Thesis SampleDocument8 pagesBeauty Therapy Thesis Samplerachelvalenzuelaglendale100% (2)

- L23 - Axial Flow CompressorDocument17 pagesL23 - Axial Flow CompressorRohan GuptaNo ratings yet

- Integration of Phodi Process With Mutation in Bhoomi (Simultaneous Approval of Phodi and The Mutation)Document19 pagesIntegration of Phodi Process With Mutation in Bhoomi (Simultaneous Approval of Phodi and The Mutation)seshadrimn seshadrimnNo ratings yet

- A-ZKD-13 (ZKD-59 (A) ) : Mechanical ParameterDocument1 pageA-ZKD-13 (ZKD-59 (A) ) : Mechanical Parameterwissam zaatuorNo ratings yet

- Classic Plan: Dog/Cat BedDocument3 pagesClassic Plan: Dog/Cat BedRobson DiasNo ratings yet

- School: Grade Level: Teacher: Section Teaching Dates and Time: QuarterDocument3 pagesSchool: Grade Level: Teacher: Section Teaching Dates and Time: QuarterZeny Aquino DomingoNo ratings yet

- Qualitest Canada BrochureDocument7 pagesQualitest Canada BrochureBala SingamNo ratings yet

- IJETR022563Document5 pagesIJETR022563erpublicationNo ratings yet

- RadarDocument65 pagesRadarAsifa LiaqatNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Electric Motor Control: DC, AC, and BLDC MotorsFrom EverandElectric Motor Control: DC, AC, and BLDC MotorsRating: 4.5 out of 5 stars4.5/5 (19)

- Real Life: Construction Management Guide from A-ZFrom EverandReal Life: Construction Management Guide from A-ZRating: 4.5 out of 5 stars4.5/5 (4)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationFrom EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettRating: 4 out of 5 stars4/5 (1)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesFrom EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Estimating Construction Profitably: Developing a System for Residential EstimatingFrom EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNo ratings yet

- Sustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsFrom EverandSustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsNo ratings yet

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingFrom EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNo ratings yet

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyFrom EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyRating: 4 out of 5 stars4/5 (1)