Professional Documents

Culture Documents

New Rules For Crude Oil Tanks

Uploaded by

Senol SeidaliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Rules For Crude Oil Tanks

Uploaded by

Senol SeidaliCopyright:

Available Formats

New Rules for Crude Oil Tanks

Guiding you through the changes

We have established a dedicated team of experienced people, committed to guide you through

the IMO PSPC implementation phase and are well placed to provide owners and shipyards with

sound guidance in the future.

For further information please contact:

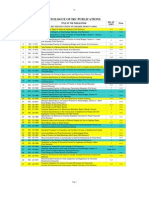

Region Name Job title Email address

Europe, Middle East, Africa Andrew Maidment Technical Service Support Manager andrew.maidment@akzonobel.com

Americas John Kelly Technical Manager john.kelly@akzonobel.com

India, South East Asia, China Khiew Lee Yen Technical Operations Executive leeyen.khiew@akzonobel.com

Japan, Australasia, Korea JongJin Jung Technical Manager jongjin.jung@akzonobel.com

International Paint Ltd,

Stoneygate Lane, Felling

Gateshead, NE10 0JY

United Kingdom

Call: +44 (0)191 469 6111

Fax: +44 (0)191 495 2003

Send an email:

marine.communication@akzonobel.com

Visit our website:

www.international-marine.com/pspc

Sign up to keep up to date with our latest news visit

www.international-marine.com/signup

Important Notes:

All representations and statements concerning the product(s) in this publication are accurate to the best

of our knowledge. Statements made in this publication are advisory only and are not intended to be specic

recommendations or warranties of any product, combination of products or tness for any particular purpose.

To the extent permitted by law, we do not accept any liability to any person for any loss or damage (direct

or indirect) that may arise from any use or reliance on any of the methods or information contained in this

publication for any purpose.

Unless otherwise agreed in writing, all products supplied and technical advice or recommendations given

are subject to the Conditions of Sale of our supplying company. Any warranties, if given, are contained in

those standard Conditions of Sale and are the only ones made with respect to any products we sell to you

or advice or recommendations we give to you.

We hereby disclaim any warranties or representations, expressed or implied, by operation of law or otherwise,

including, without limitation, any implied warranty of merchantability or tness for a particular purpose.

For each of our products the relevant Product Data Sheet, Material Safety Data Sheet and package labelling

comprise an integral information system about the product in question. Copies of our Product Data Sheets

and Material Safety Data Sheets are available on request or from our website: www.international-marine.com

and International and all products mentioned in this publication are trademarks of, or are licensed to,

AkzoNobel. AkzoNobel, 2012

International Paint Ltd is part of AkzoNobel,

the Netherlands based company serving

customers throughout the world with

coatings and chemicals.

This brochure is:

Have a smartphone?

Download a QR code

reader App and scan the

QR code above to view

more information online.

When you have nished

with this brochure, pass it

on to a colleague or recycle

NO SMOKING

Aggressive

components

in crude oil

(sludge)

Corrosion

of deck

head plating

CO

H

O SOX

H

S

60C

THERMAL

CYCLING

25C

Condensation

Inert

Gas

Inert

Gas

Inert

Gas

Inert

Gas

Inert

Gas

Inert

Gas

Loaded -

Corrosion potential

from thermal cycling

Loaded - Corrosion potential from thermal cycling

NO SMOKING

Pitting and rust staining

of the tank top

STEEL

PLATE

DRAIN WATER

OIL COAT

Pitting

(Anode)

Sludge

(Cathode)

H

S INERT

GAS

INERT

GAS

Unloaded -

Corrosion potential from

pitting in tank bottom

Unloaded - Corrosion potential from pitting in tank bottom

* Note

1) Dimension A to be from upper most PMA height to upper deck height

0

.3

m

SIDE C.O.TANK

UPPER DECK

W.B.TKS

W.B.TKS CENTER C.O.TANK

First tripping bracket

Detail (typ. ) for BHD

Shaded areas only to be painted

C

L

A

Bulkhead

Trans. Web.

O

U

T

E

R

L

O

N

G

L

B

H

D

S

ID

E

S

H

E

L

L

IN

N

E

R

L

O

N

G

L

B

H

D

Typical section of V.L.C.C

* Note

1) Dimension A to be from upper most PMA height to upper deck height

0

.3

m

SIDE C.O.TANK

UPPER DECK

W.B.TKS

W.B.TKS CENTER C.O.TANK

First tripping bracket

Detail (typ. ) for BHD

Shaded areas only to be painted

C

L

A

Bulkhead

Trans. Web.

O

U

T

E

R

L

O

N

G

L

B

H

D

S

ID

E

S

H

E

L

L

IN

N

E

R

L

O

N

G

L

B

H

D

Typical section of V.L.C.C

* Note

1) Dimension A to be from upper most PMA height to upper deck height

0

.3

m

SIDE C.O.TANK

UPPER DECK

W.B.TKS

W.B.TKS CENTER C.O.TANK

First tripping bracket

Detail (typ. ) for BHD

Shaded areas only to be painted

C

L

A

Bulkhead

Trans. Web.

O

U

T

E

R

L

O

N

G

L

B

H

D

S

ID

E

S

H

E

L

L

IN

N

E

R

L

O

N

G

L

B

H

D

Typical section of V.L.C.C

Why is there the need for the new performance standard?

The change from single hull to the introduction of

double hull structural arrangements for crude oil

tankers has revealed a number of double hull tankers

suffering from accelerated corrosion in areas of their

cargo tanks due to a thermal barrier which promoted

a more aggressive corrosive environment.

It has become common practice for many leading

owners and shipyards to use sound protective

coatings in the upper and lower areas of cargo tank

spaces. Now, these new regulations mean that

certain areas of cargo tanks must be suitably coated

for all new crude oil tankers above 5000 dwt.

The new IMO PSPC COT performance standard

A new set of SOLAS regulations, approved at MSC87 in May 2010, are effective for new crude oil

tankers from 1st January 2013 under the IMO Performance Standard for Protective Coatings of

Cargo Oil Tanks (IMO PSPC COT).

Just like IMO PSPC for water ballast tanks, the new

standard, designed to ensure longevity of cargo

oil tank coatings, stipulates that coatings must

remain in good condition for a minimum of 15

years - as dened by the International Association

of Classication Societies (IACS).

For a cargo oil tank coating to comply, all coatings

must have a Type Approval Certicate (TAC) which

means that the product has demonstrated the

expected performance, the quality of the supplied

material is assured and that the supply location has

met the requirements of the body issuing the TAC.

All coatings used within the cargo oil tanks must

now comply with PSPC regulations for crude oil

tanks on vessels greater than 5000 dwt at new

building, where:

The building contract is placed on or after 1st

January 2013 or, in the absence of a building

contract,

The keels of which are laid or which are at a

similar stage of construction on or after 1st July

2013,

Or the delivery of which is on or after 1st

January 2016.

What areas are affected by the new regulations?

The following areas are the minimum areas that shall be protected according to the standard:

Key coating requirements of IMO PSPC COT

Coating target useful life of 15 years for which it is

intended to be in GOOD condition

Epoxy coatings, to be applied as a multi-coat

system with a light top colour to aid inspection

The nominal dry flm thickness judged according

to the 90/10 rule to be 320 m

Zinc silicate shop primer inhibitor free, or

equivalent accepted

A Type Approval Certifcate (TAC) demonstrating

the expected coating performance and quality is

to be issued by a third party, independent of the

coating manufacturer

Surface preparation and coating application

throughout the coating process is to be inspected

to ensure compliance with this standard

Inspection results to be recorded in the ships

coating technical le.

Protecting your assets

For the foreseeable future, crude oil tankers will be

exposed to a corrosive environment. However, in

conjunction with the existing compulsory requirement

to coat ballast tanks, the new PSPC requirement

to coat the crude oil cargo tanks on new tankers

means that the basis for a long service life with limited

corrosion of essential structures should now be

possible.

For todays tanker operators, high quality protective

coatings offer a real cost-effective and practical route

to protection of crude oil cargo tanks from corrosion.

The choice of anticorrosive can have a major impact

on shipyard production and on-board operating

costs. Choose carefully; coatings must provide the

correct balance of properties to optimise the return

on investment for tanker owners / operators and

shipyards.

Deckhead with complete internal structure,

including brackets connecting to longitudinal and

transverse bulkheads.

Longitudinal and transverse bulkheads to be

coated to the uppermost means of access level.

On cargo tank bulkheads without an uppermost

means of access the coating to extend to 10% of

the tanks height at centreline but need not extend

more than 3 m down from the deck.

Flat inner bottom and all structure to height of

0.3 m above inner bottom to be coated.

KEY

W.B. TKS = Water ballast tanks

OUTER LONGL BHD =

Outer longitudinal bulkhead

INNER LONGL BHD =

Inner longitudinal bulkhead

C.O. TANK = Cargo oil tank

Detail (typ.) for BHD =

Detail (typical) for bulkhead

Trans. Web. = Transverse web frame

PMA = Permanent Means of Access

Shaded areas only to be painted

You might also like

- Pressure Gauge Cocks Pressure Gauge CocksDocument1 pagePressure Gauge Cocks Pressure Gauge CocksSenol SeidaliNo ratings yet

- Catalogue Card: Piston Type Steering GearsDocument10 pagesCatalogue Card: Piston Type Steering GearsSenol SeidaliNo ratings yet

- TW Three-Port Self-Acting Control Valve For Liquid Systems: DescriptionDocument2 pagesTW Three-Port Self-Acting Control Valve For Liquid Systems: DescriptionSenol SeidaliNo ratings yet

- SS 4010Document4 pagesSS 4010Senol SeidaliNo ratings yet

- Flat Type Level GaugeDocument4 pagesFlat Type Level GaugeSenol SeidaliNo ratings yet

- Brochure 51 60DFDocument8 pagesBrochure 51 60DFSenol Seidali100% (1)

- Yak FightersDocument60 pagesYak FightersSenol Seidali100% (5)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Load Chart Manual For Rt60 Rough Terrain Crane: Downloaded From Manuals Search EngineDocument47 pagesLoad Chart Manual For Rt60 Rough Terrain Crane: Downloaded From Manuals Search EngineRomario OliveiraNo ratings yet

- TestingDocument116 pagesTestingAkarsh LNo ratings yet

- School Action Plan in IctDocument1 pageSchool Action Plan in IctMcDaryl Mateo100% (3)

- Mock MU-BAAT Final Version Set 1Document8 pagesMock MU-BAAT Final Version Set 1Priyanshu SinghNo ratings yet

- IRC CodesDocument23 pagesIRC CodesabhijithavalNo ratings yet

- IC Hotel Revenue Projection Template 10708Document3 pagesIC Hotel Revenue Projection Template 10708carolisdwi permanaNo ratings yet

- 34 / Architecture: Form, Space, & OrderDocument5 pages34 / Architecture: Form, Space, & Ordersusmita waghmareNo ratings yet

- Fields and Galois Theory: J.S. MilneDocument138 pagesFields and Galois Theory: J.S. MilneUzoma Nnaemeka TeflondonNo ratings yet

- Training Wall Height On Convergent Stepped SpillwaysDocument10 pagesTraining Wall Height On Convergent Stepped Spillwayschutton681No ratings yet

- Lab 05Document6 pagesLab 05AbdullahNo ratings yet

- Death There Mirth Way The Noisy Merit.Document2 pagesDeath There Mirth Way The Noisy Merit.Kristen DukeNo ratings yet

- Agriculture SectorDocument66 pagesAgriculture SectorAyesha KhanNo ratings yet

- Pancreas: Anatomy & Physiology: Sanjay Munireddy Sinai Hospital 11/21/2006Document35 pagesPancreas: Anatomy & Physiology: Sanjay Munireddy Sinai Hospital 11/21/2006pedros43No ratings yet

- Megawatt Station Inverter PVS800 1 To 1.25MW-ABBDocument4 pagesMegawatt Station Inverter PVS800 1 To 1.25MW-ABBkimscribd66No ratings yet

- Gas Rating Summary 2010Document2 pagesGas Rating Summary 2010ahmadhadraniNo ratings yet

- Perak and The Malays: Sarong and KrisDocument504 pagesPerak and The Malays: Sarong and KrisIbrahim Nawawi100% (2)

- Odisha PWD Registration in CDMSDocument2 pagesOdisha PWD Registration in CDMSSabyasachi Naik (Zico)No ratings yet

- Conan The Shadow of The SorcererDocument220 pagesConan The Shadow of The SorcererPierre Dupont100% (10)

- 6 5 Nerves Hormones and HomeostasisDocument19 pages6 5 Nerves Hormones and Homeostasisapi-235355872No ratings yet

- Father William - Poem by Lewis CarrollDocument1 pageFather William - Poem by Lewis CarrollRachid AfrznaneNo ratings yet

- The Sparrow: Srijani Bhowmick Class VDocument12 pagesThe Sparrow: Srijani Bhowmick Class VsgphycoNo ratings yet

- Function List of Car BrainDocument39 pagesFunction List of Car BrainBogdan PopNo ratings yet

- Test 1 AbsenteesDocument6 pagesTest 1 AbsenteesHamza AhmedNo ratings yet

- PPL EmailDocument4 pagesPPL EmailArmando SolanoNo ratings yet

- Soa Sample ResumeDocument5 pagesSoa Sample Resumesam jessieNo ratings yet

- Doors & People ManualDocument32 pagesDoors & People ManualOscar Ayala100% (1)

- Revenue Growth Management The Time Is NowDocument6 pagesRevenue Growth Management The Time Is NowAbdel AzizNo ratings yet

- LeasePlanIndia-GSTUpdate-June2017.pdf - Filename - UTF-8''LeasePlanIndia-GSTUpdate-June2017 PDFDocument2 pagesLeasePlanIndia-GSTUpdate-June2017.pdf - Filename - UTF-8''LeasePlanIndia-GSTUpdate-June2017 PDFyogiprathmeshNo ratings yet

- Inorganic Chemistry MatriculationDocument46 pagesInorganic Chemistry MatriculationShinta Novita Sari100% (1)

- Price List YOM 2019Document1 pagePrice List YOM 2019Felix DjuliNo ratings yet