Professional Documents

Culture Documents

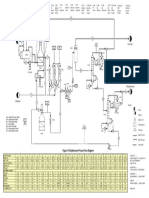

Batch Production of L-Phenylalanine and L-Aspartic Acid

Uploaded by

Siti Nurshahira0 ratings0% found this document useful (0 votes)

288 views2 pagesassignment plant design

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentassignment plant design

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

288 views2 pagesBatch Production of L-Phenylalanine and L-Aspartic Acid

Uploaded by

Siti Nurshahiraassignment plant design

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Question 1

The production of L-aspartic acid

The reaction of fumaric acid to form L-aspartic acid is an enzymatic conversion carried out using

the aspartase activity activity of bacteria Escherichia coli (E.coli) cells.

The production of L-phenylalanine

L-phenylalanine is produced via fermentation using a mutant Brevibacterium lactofermentum.

To achieve the production of L-aspartic acid and L-phenylalanine, a fermentation process need to

undergo to grow the bacteria in the presence of appropriate nutrients. The reaction of inoculation and

nutrient feed will fermented to produce fumaric acid. Then the fumaric acid will react with ammonia to

produce aspartic acid. The production of aspartic acid will react with elutant to form L-phenylalanine.

Question 2

There is one bypass stream which is at stream 28.From F-905(amino acid crystal filter) the excess of

amino acid that not crystallized were recycle back to stream 28 to undergo the process crystallization

again. In addition, there is no recycle loop involve in this production.

Question 3

Reactant to produce Aspartic acid

Aspartic acid product

Reactant to produce L-phenylalanine

L-phenylalanine acid product

Bypass stream

Reactant to produce Aspartic acid: Tactic 1 is applied to each unit operation in succession.

a) The inoculation feed of stream 1 enter F-901and stream 2 goes to fermenter R-901.

b) Ammonia feed of stream 7 and stream 8 enter fermenter R-901.

Aspartic acid product:

i. Tactic 2 is applied to each unit operation in succession.

a) Product stream 11 leaves fermenter R-901 and goes to bacteria filter F-904.

b) Product of stream 12 leaves bacteria filter F-904. It contains all the aspartic acid product.

ii. Tactic 1 is applied to each unit operation in succession.

c) Entering bacteria filter F-904 is stream 13 from fermenter R-901.It contains all the aspartic acid

product.

d) Entering slurry storage V-901 is stream 15 from bacteria filter F-904. It contains all the aspartic acid

product.

Reactant to produce L-phenylalanine: Tactic 1 is applied to each unit operation in succession.

a) Elutant feed of stream 17 enter ion exchange column T-901.

L-phenylalanine acid product: Tactic 2 is applied to each unit operation in succession.

a) Leaving ion exchange column T-901 is stream 19.

b) Entering product crystallizer CR-901 is stream 20 from the ion exchange column T-901 and amino acid

crystal filter F-905.

c) Entering amino acid crystal filter F-905 is stream 26 from product crystallizer CR-901.

d) Product of stream 27 leaves amino acid crystal filter F-905. It contains all the L-phenylalanine acid

product.

e) Apply tactic 5 at stream 28,bypass stream.

You might also like

- Baylon, Et. Al.-Solving Problems Regarding Vapor-Liquid EquilibriumDocument21 pagesBaylon, Et. Al.-Solving Problems Regarding Vapor-Liquid EquilibriumblessaNo ratings yet

- Cap 222222Document27 pagesCap 222222Paty ChiluisaNo ratings yet

- Potensiometri PDFDocument70 pagesPotensiometri PDFWira Pratiwi PinemNo ratings yet

- 4-Nonelementary Reaction KineticsDocument23 pages4-Nonelementary Reaction KineticsFajri AmrullahNo ratings yet

- HimmelblauDocument17 pagesHimmelblauadilla nitaaNo ratings yet

- Something Related To Catalysts.Document2 pagesSomething Related To Catalysts.Deepro BhattacharyaNo ratings yet

- Replacement of Gas Phase With Liquid HexamineDocument6 pagesReplacement of Gas Phase With Liquid HexaminePradhita Ramdani HNo ratings yet

- Treybal DistDocument5 pagesTreybal DistJay CeeNo ratings yet

- CAP13Document21 pagesCAP13LIma NetoNo ratings yet

- SN Octoate - Dow PDFDocument6 pagesSN Octoate - Dow PDFAngga Tri PrasetyoNo ratings yet

- Semi-Batch Reactor Design EquationsDocument22 pagesSemi-Batch Reactor Design EquationsMelgi159100% (1)

- CSTRDocument12 pagesCSTRRuri Agung WahyuonoNo ratings yet

- CHE656 2010 Homework2 SolutionsDocument20 pagesCHE656 2010 Homework2 Solutionsdinesh1989novemberNo ratings yet

- Lab 2 HysysDocument9 pagesLab 2 HysysMuhamad AimanNo ratings yet

- Fluid Fluid Reaction KineticsDocument27 pagesFluid Fluid Reaction KineticsIlyas AzmanNo ratings yet

- Production of Hydrochloric Acid via Salt-Sulfuric Process GuideDocument2 pagesProduction of Hydrochloric Acid via Salt-Sulfuric Process GuideroxetteNo ratings yet

- Chemical Kinetics of Complex Reactions - Sample Solution - Question 2Document3 pagesChemical Kinetics of Complex Reactions - Sample Solution - Question 2Trung VõNo ratings yet

- CPE553 Thermodynamics Group Assignment - Raoult's Law ApplicationsDocument2 pagesCPE553 Thermodynamics Group Assignment - Raoult's Law ApplicationsMuhamad Hazim Zaaba0% (1)

- Quiz AnswerDocument3 pagesQuiz AnswerXenn Mar RiveraNo ratings yet

- Lab 3Document16 pagesLab 3Paen Zulkifli100% (1)

- Tugas Kelas A Termodinamika Industri KimiaDocument1 pageTugas Kelas A Termodinamika Industri KimiaayatbimaNo ratings yet

- Chapter 12 Liquid ExtractionDocument68 pagesChapter 12 Liquid ExtractionNurul AinNo ratings yet

- Bab 8Document28 pagesBab 8Mohammad Farhan S0% (1)

- Latihan Soal Packed Bed AbsorberDocument7 pagesLatihan Soal Packed Bed AbsorberAgam Duma Kalista WibowoNo ratings yet

- Thus, This Term Actually Means A in A Constant-Volume System The Measure of Reaction Rate of Component I BecomesDocument23 pagesThus, This Term Actually Means A in A Constant-Volume System The Measure of Reaction Rate of Component I Becomesalice Annabelle100% (1)

- Toluene BenzeneDocument20 pagesToluene BenzeneZarin ZahurinNo ratings yet

- Design and Control of a Methyl Acetate Process Using Carbonylation of Dimethyl EtherDocument18 pagesDesign and Control of a Methyl Acetate Process Using Carbonylation of Dimethyl Ethersheida shNo ratings yet

- ChE 822 Homework#1 Reactor SizingDocument2 pagesChE 822 Homework#1 Reactor SizingOguz KurtulanNo ratings yet

- Cellulose Acetate Uv FilmDocument7 pagesCellulose Acetate Uv FilmLara Faith AshantiNo ratings yet

- Absorption SlidesDocument39 pagesAbsorption SlidespratapNo ratings yet

- 06 Chapter 12 (Compiled) PDFDocument80 pages06 Chapter 12 (Compiled) PDFHaziq KhairiNo ratings yet

- Tute ProblemsDocument5 pagesTute Problemsralston204No ratings yet

- Journal of Chemical EquilibriumDocument11 pagesJournal of Chemical EquilibriumLina RosyidahNo ratings yet

- Reaktor Trickle BedDocument8 pagesReaktor Trickle BedAgaNo ratings yet

- Material Balance With Out RXN Example Unit3-RSDocument129 pagesMaterial Balance With Out RXN Example Unit3-RSGodolias WoldemariamNo ratings yet

- Optimal temperature progression for plug flow reactorDocument18 pagesOptimal temperature progression for plug flow reactorSarah SanchezNo ratings yet

- A Mixture Containing Equimolar Amounts of BenzeneDocument1 pageA Mixture Containing Equimolar Amounts of BenzeneFranciskus Peri0% (1)

- HW#6 Solutions Chapter 2Document14 pagesHW#6 Solutions Chapter 2Jose Mgc100% (1)

- Development of Solvay Clusters of Chemical Reactions PDFDocument11 pagesDevelopment of Solvay Clusters of Chemical Reactions PDFJordan Lopez FernandezNo ratings yet

- Physical Chemistry Question Set #19Document17 pagesPhysical Chemistry Question Set #19kimiaNo ratings yet

- Precipitation Titrimetry-221Document11 pagesPrecipitation Titrimetry-221HudzaifiNo ratings yet

- Chapter 2 - Lle EditedDocument60 pagesChapter 2 - Lle EditedSiti Nurshahira100% (1)

- ATKDocument4 pagesATKAgung SuharmantoNo ratings yet

- Gas Liquid Absorption Problems 2020Document2 pagesGas Liquid Absorption Problems 2020vikyappleNo ratings yet

- Benzene: Figure 1 Ethylbenzene Process Flow DiagramDocument1 pageBenzene: Figure 1 Ethylbenzene Process Flow DiagramOkta Abdul ChoirNo ratings yet

- Basic Integration Formulas ExercisesDocument1 pageBasic Integration Formulas ExercisesJWAN RA YA3QOBNo ratings yet

- Perpindahan MassaDocument24 pagesPerpindahan MassaJun Sumeong100% (1)

- By: Carlo Manuel A. BanquerigoDocument10 pagesBy: Carlo Manuel A. BanquerigoChristy Joy RetanalNo ratings yet

- Deshidratación y Purificación (Alcohol Absoluto)Document4 pagesDeshidratación y Purificación (Alcohol Absoluto)Jordan Venegas100% (1)

- Chemical Reaction Engineering Lecture 5bDocument42 pagesChemical Reaction Engineering Lecture 5bSói Con100% (1)

- Vapor-Liquid Equilibria. Ethylene Oxide - Acetaldehyde and Ethylene Oxide - Water SystemsDocument5 pagesVapor-Liquid Equilibria. Ethylene Oxide - Acetaldehyde and Ethylene Oxide - Water SystemsGie0% (1)

- Pyrolysis and Chlorination of Small HydrocarbonsDocument24 pagesPyrolysis and Chlorination of Small HydrocarbonssylviealNo ratings yet

- Tugas Mata Kuliah Proses TransferDocument3 pagesTugas Mata Kuliah Proses TransferYusYusup100% (1)

- Contoh Soal Heat Exchanger dan Cooling TowerDocument9 pagesContoh Soal Heat Exchanger dan Cooling TowerLuthfy AditiarNo ratings yet

- Kinetics and Mechanism of Urea FormaldehydeDocument5 pagesKinetics and Mechanism of Urea FormaldehydeDessy A. SariNo ratings yet

- Assignment 1Document3 pagesAssignment 1imtiazNo ratings yet

- Sulfuric Acid AlkylationDocument2 pagesSulfuric Acid AlkylationliafitriifNo ratings yet

- Amoxicillin 1Document18 pagesAmoxicillin 1Biswajit RoyNo ratings yet

- Dissolved Oxygen DO Titration X 10 MG/L Blank Sample Titration 079.DO Result 0.79 x10 7.9 MG/L ODocument2 pagesDissolved Oxygen DO Titration X 10 MG/L Blank Sample Titration 079.DO Result 0.79 x10 7.9 MG/L OSiti NurshahiraNo ratings yet

- Patent LicensingDocument5 pagesPatent LicensingSiti NurshahiraNo ratings yet

- Project Pid FIC 21Document14 pagesProject Pid FIC 21Siti Nurshahira100% (1)

- PFRDocument18 pagesPFRSiti NurshahiraNo ratings yet

- AdsorptionDocument56 pagesAdsorptionSiti Nurshahira100% (1)

- LAB 1 Chemical Process ControlDocument2 pagesLAB 1 Chemical Process ControlSiti NurshahiraNo ratings yet

- Shell and Tube Heat ExchangerDocument36 pagesShell and Tube Heat ExchangerSiti Nurshahira67% (3)

- Standardizing NaOH and Determining Acetic Acid Concentration in VinegarDocument15 pagesStandardizing NaOH and Determining Acetic Acid Concentration in VinegarSiti NurshahiraNo ratings yet

- Chap4 AAS LectureNote DRK 111024Document19 pagesChap4 AAS LectureNote DRK 111024tokkeksemputsemputNo ratings yet

- CHE 555 Roots of PolynomialsDocument12 pagesCHE 555 Roots of PolynomialsSiti NurshahiraNo ratings yet

- Ion ExchangeDocument50 pagesIon ExchangeSiti Nurshahira100% (1)

- Stndard Electrode PotentialDocument1 pageStndard Electrode PotentialSiti NurshahiraNo ratings yet

- Introduction To Uv-VisDocument12 pagesIntroduction To Uv-VisSiti NurshahiraNo ratings yet

- Roots of Equation: Open Methods: by Lale Yurttas, Texas A&M University 1Document26 pagesRoots of Equation: Open Methods: by Lale Yurttas, Texas A&M University 1Siti NurshahiraNo ratings yet

- LleDocument18 pagesLleSiti NurshahiraNo ratings yet

- Iscosity AND THE Mechanisms OF Momentum TransportDocument24 pagesIscosity AND THE Mechanisms OF Momentum TransportSiti Nurshahira100% (1)

- Ftir IntroDocument1 pageFtir IntroSiti NurshahiraNo ratings yet

- Chap2 IR LectureNote DRK 110929Document29 pagesChap2 IR LectureNote DRK 110929farahanisiliasNo ratings yet

- Chapter 2 - Lle EditedDocument60 pagesChapter 2 - Lle EditedSiti Nurshahira100% (1)

- Source: KDI Co .LTD, 2011Document5 pagesSource: KDI Co .LTD, 2011Siti NurshahiraNo ratings yet

- Lab 7Document3 pagesLab 7Siti NurshahiraNo ratings yet

- Chapter 1 DistillationDocument110 pagesChapter 1 DistillationSiti Nurshahira80% (5)

- Chapter 2 - Lle EditedDocument60 pagesChapter 2 - Lle EditedSiti Nurshahira100% (1)

- Lab 14-Process Engineering Lab 1Document7 pagesLab 14-Process Engineering Lab 1Siti NurshahiraNo ratings yet

- T C M E T: Hermal Onductivity AND THE Echanisms OF Nergy RansportDocument15 pagesT C M E T: Hermal Onductivity AND THE Echanisms OF Nergy RansportSiti NurshahiraNo ratings yet

- 2.0 Electric Circuits: - CPE 535 Electrical TechnologyDocument20 pages2.0 Electric Circuits: - CPE 535 Electrical TechnologySiti NurshahiraNo ratings yet

- Chapter 3 - LeachingeditedDocument51 pagesChapter 3 - LeachingeditedSiti Nurshahira75% (4)

- Chapter 5-Flow MeterDocument16 pagesChapter 5-Flow MeterSiti NurshahiraNo ratings yet

- Chapter 1 DistillationDocument110 pagesChapter 1 DistillationSiti Nurshahira80% (5)

- Genetics Exp 6Document6 pagesGenetics Exp 6Ck WongNo ratings yet

- Malaria Parasite Counting: Malaria Microscopy Standard Operating Procedure - Mm-Sop-09Document5 pagesMalaria Parasite Counting: Malaria Microscopy Standard Operating Procedure - Mm-Sop-09Md. Mohidul Hasan SifatNo ratings yet

- Deleted Portions Class Xi: Biology (Code No. 044)Document5 pagesDeleted Portions Class Xi: Biology (Code No. 044)AarthiKalyanNo ratings yet

- Attachment For Week 4 Melc 5Document3 pagesAttachment For Week 4 Melc 5Caryl Ann C. SernadillaNo ratings yet

- Super 20 Ch-7 Control & Coordination Class 10 Science (2) YeahhhhhDocument2 pagesSuper 20 Ch-7 Control & Coordination Class 10 Science (2) Yeahhhhhkamalkandpal4848No ratings yet

- 12 Vertebrate Zoology 70-4-2020 Townsend Et AlDocument26 pages12 Vertebrate Zoology 70-4-2020 Townsend Et AlLuis HerreraNo ratings yet

- Chapter 1Document75 pagesChapter 1크리스틴No ratings yet

- The Internet Journal of Veterinary Medicine 2009Document10 pagesThe Internet Journal of Veterinary Medicine 2009gnpobsNo ratings yet

- A Review of Inclusion Body Hepatitis-Hydropericardium Syndrome (Document24 pagesA Review of Inclusion Body Hepatitis-Hydropericardium Syndrome (Dr.Kedar Karki ,M.V.Sc.Preventive Vet.Medicine CLSU PhilippinesNo ratings yet

- Insulin and Insulin ResistanceDocument21 pagesInsulin and Insulin ResistanceFisiologiaUFCG100% (1)

- Formative Lab Report Based On Practical 2: Introduction To Histological StainingDocument3 pagesFormative Lab Report Based On Practical 2: Introduction To Histological StainingjarvineNo ratings yet

- Biotechnol LettDocument8 pagesBiotechnol LettAkbar ArifNo ratings yet

- Molecular Biology Questions and Answers - Site-Directed Mutagenesis & Overview of RecombinationDocument4 pagesMolecular Biology Questions and Answers - Site-Directed Mutagenesis & Overview of Recombinationmwesige ronaldNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument14 pagesCambridge International General Certificate of Secondary EducationValentina RumhizhaNo ratings yet

- Chapter 5 Biochemistry and Clinical Pathology Complete Notes by Noteskarts Acc To ER20Document5 pagesChapter 5 Biochemistry and Clinical Pathology Complete Notes by Noteskarts Acc To ER20prat.medbooksNo ratings yet

- Biodiversity: Made By: Roll No.: ClassDocument19 pagesBiodiversity: Made By: Roll No.: ClassChiranjiv KarkeraNo ratings yet

- STPM Trial 2010 Bio 2 KelantanDocument8 pagesSTPM Trial 2010 Bio 2 Kelantanone kilometerNo ratings yet

- Fermentation Lab ReportDocument4 pagesFermentation Lab ReportJulia StephenNo ratings yet

- Multiple Choice Questions: BiotechnologyDocument98 pagesMultiple Choice Questions: BiotechnologyJing Li100% (1)

- Interdisciplinary Approaches To Nonlinear Complex SystemsDocument243 pagesInterdisciplinary Approaches To Nonlinear Complex SystemsBolaybalamNo ratings yet

- Biosecurity Application in AquacultureDocument8 pagesBiosecurity Application in AquacultureAlberto SaenzNo ratings yet

- WARRIER-Some Important Medicinal Plants of The Western Ghats, India, A Profile (2001) PDFDocument408 pagesWARRIER-Some Important Medicinal Plants of The Western Ghats, India, A Profile (2001) PDFJuanManuelAmaroLuisNo ratings yet

- ISAAA Vs GreenpeaceDocument1 pageISAAA Vs GreenpeaceVince Llamazares Lupango100% (1)

- Micro ToolkitDocument3 pagesMicro ToolkitinaquitoNo ratings yet

- December 1966: Published by TheDocument82 pagesDecember 1966: Published by TheMAURICIO ARMANDO PAEZ SANTOSNo ratings yet

- Test 2 - Carbohydrates, Lipids, Proteins and Nucleic AcidsDocument7 pagesTest 2 - Carbohydrates, Lipids, Proteins and Nucleic AcidsChrisNo ratings yet

- ArtemisininDocument24 pagesArtemisininSajin SaliNo ratings yet

- Henrys - ThalassemiaDocument8 pagesHenrys - ThalassemiaJovie Anne CabangalNo ratings yet

- Introduction To BotanyDocument4 pagesIntroduction To BotanyJulianaNo ratings yet

- Biology Ia IbdpDocument10 pagesBiology Ia Ibdpzain ahmedNo ratings yet