Professional Documents

Culture Documents

Weld Cost1

Uploaded by

Denis Hinojosa Zeballos0 ratings0% found this document useful (0 votes)

154 views25 pagesOriginal Title

Weld Cost1.xls

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

154 views25 pagesWeld Cost1

Uploaded by

Denis Hinojosa ZeballosCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 25

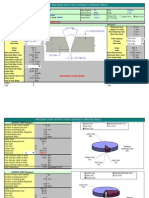

DETERMINING WELDING COST FOR A FILLET WELD

Mark Mruczek Project: Base Material: A 516 Date: 08/07/02

Welding Engineer Company: Product Form: Plate Page: 1 of 2

Subject: Welding Cost Filler Material

Welding process Used: Trade Name:

Process 1 Process 2

Leg Size (in) 0.250 Leg Size (in) 0.250

Filler material Filler material

Process Process

Gas Used Gas Used

Amps 200 Amps 200

Volts 21 Volts 21

Wire Feed (in/min) 0 Wire Feed (in/min) 190

Wire Diam. (in) 0.187 Wire Diam. (in) 0.045

Total Length of Weld(ft) 10 Total Length of Weld(ft) 10

Travel Speed (ipm) 6 Travel Speed (ipm) 8

Gas Flow Rate (cfh) 0 Gas Flow Rate (cfh) 40

Welder Efficiency 30% Welder Efficiency 50%

Cost Electrode($/lb) 1.3 Cost Electrode($/lb) 2.5

Labor Rate ($/hr) 60 Labor Rate ($/hr) 60

Cost of Gas (per bottle) $0.00 Cost of Gas (per bottle) $70.00

Weight of gas (1 bottle) (lb) 0 Weight of gas (1 bottle) (lb) 50

Power Cost ($/kilowatt-hr) $0.15 Power Cost ($/kilowatt-hr) $0.15

WELDING COST OUTPUT FOR A FILLET WELD

OUTPUT FOR PROCESS 1 SMAW (14" Stick)

Amount of weld wire needed 2.00 lb

Number of passes per joint ~ 1

Size of fillet weld** 0.290 in

Amount of shielding gas 0.00 ft^3 bottles = N/A

Actual welding time 1.80 hr

Labor Cost $108.15

Welding Wire Cost $2.60

Gas Cost $0.00

Power Cost $0.35

Initial Cost $111.10

Final Cost $127.80

Cost per ft of weld $11.11 $/ft

Cost per foot filler metal $0.26 $/ft

Cost per foot of gas $0.00 $/ft

Cost of Labor per foot $10.82 $/ft

** Size of the fillet weld is based on heat input. This information can be used to adjust your amps & volts to achieve the leg size you entered in B10

OUTPUT FOR PROCESS 2 FCAW (Gas)

Amount of weld wire needed 2.00 lb

Number of passes per joint ~ 1

Size of fillet weld** 0.251 in

Amount of shielding gas 0.00 ft^3 bottles = 1

Actual welding time 0.78 hr

Labor Cost $46.80

Welding Wire Cost $5.00

Gas Cost $2.55

Power Cost $0.25

Initial Cost $54.60

Final Cost $62.80

Cost per ft of weld $5.46 $/ft

Cost per foot filler metal $0.50 $/ft

Cost per foot of gas $0.26 $/ft

Cost of Labor per foot $4.68 $/ft

Labor Cost

98%

Welding Wire Cost

2%

Gas Cost

0%

Power Cost

0%

Labor Cost

Welding Wire Cost

Gas Cost

Power Cost

Labor Cost

86%

Welding Wire

Cost

9%

Gas Cost

5%

Power Cost

0%

Labor Cost

Welding Wire Cost

Gas Cost

Power Cost

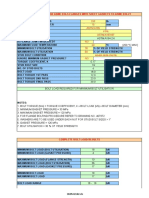

DETERMINING WELDING COST FOR A SINGLE-V GROOVE WELD

Mark Mruczek Project: Base Material: A 516 Date: 08/07/02

Welding Engineer Company: Product Form: Plate Page: 1 of 2

Subject: Welding Cost Filler Material E7018

Welding process Used: Trade Name:

Process 1 Process 2

Thickness (in) 0.438 Thickness (in) 0.625

Height of "h" (in) 0.125 Height of "h" (in) 0.063

Root Opening (in) 0.125 Root Opening (in) 0.094

Root Face(in) 0.063 Root Face(in) 0.063

Filler material Filler material

Process Process

Gas Used Gas Used

Amps 130 Amps

Volts 27 Volts

Wire Feed (in/min) 0 Wire Feed (in/min)

Wire Diam. (in) 0.1576 Wire Diam. (in)

Joint Angle 70 Joint Angle

Total Length of Weld(ft) 8.9 Total Length of Weld(ft)

Travel Speed (ipm) 6 Travel Speed (ipm)

Gas Flow Rate (cfh) 0 Gas Flow Rate (cfh)

Welder Efficiency 30% Welder Efficiency

Cost Electrode($/lb) 1.26 Cost Electrode($/lb)

Labor Rate ($/hr) 60 Labor Rate ($/hr)

Cost of Gas (per bottle) $0.00 Cost of Gas (per bottle)

Weight of gas in one bottle (lb) 0 Weight of gas in one bottle (lb)

Power Cost ($/kilowatt-hr) $0.10 Power Cost ($/kilowatt-hr)

WELDING COST OUTPUT FOR A SINGLE-V GROOVE WELD

OUTPUT FOR SMAW (12" Stick)

Amount of weld wire needed 10.70 lb

Number of passes per joint ~ 6

Amount of shielding gas 0.00 ft^3 bottles = N/A

Actual welding time 16.83 hr

Labor Cost $595.66

Welding Wire Cost $13.48

Gas Cost $0.00

Power Cost $1.77

Initial Cost $610.91

Final Cost $702.55

Cost per ft of weld $68.64 $/ft

Cost per foot filler metal $1.52 $/ft

Cost per foot of gas $0.00 $/ft

Cost of Labor per foot $66.93 $/ft

OUTPUT FOR FCAW (Gas)

Amount of weld wire needed 1197.52 lb

Number of passes per joint ~ 10

Amount of shielding gas 6897.88 ft^3 bottles = 16

Actual welding time 394.16 hr

Labor Cost $20,338.90

Welding Wire Cost $2,694.42

Gas Cost $1,189.88

Power Cost $94.60

Initial Cost $24,317.80

Final Cost 27,965.47 $

Cost per ft of weld $24.32 $/ft

Cost per foot filler metal $2.69 $/ft

Cost per foot of gas $1.19 $/ft

Cost of Labor per foot $20.34 $/ft

Labor Cost

84%

Welding Wire Cost

11%

Gas Cost

5%

Power Cost

0%

Labor Cost

Welding Wire Cost

Gas Cost

Power Cost

Labor Cost

98%

Welding Wire Cost

2%

Gas Cost

0%

Power Cost

0%

Labor Cost

Welding Wire Cost

Gas Cost

Power Cost

Process 2

200

20

225

0.05

60

1000

8

35

50%

2.25

60

$75.00

50

$0.12

Labor Cost

Welding Wire Cost

Gas Cost

Power Cost

Welding Wire Cost

Labor Cost

Welding Wire Cost

Gas Cost

Power Cost

DETERMINING WELDING COST FOR A SINGLE-BEVEL GROOVE WELD

Mark Mruczek Project: Base Material: A 516 Date: 05/22/02

Welding Engineer Company: Product Form: Plate Page: 1 of 2

Subject: Welding Cost Filler Material E7018

Welding process Used: SMAW + GMAW Trade Name: Lincoln

Process 1 Process 2

Thickness (in) 2.25 Thickness (in) 2.25

Height of "h" (in) 0.09375 Height of "h" (in) 0.09375

Root Opening (in) 0.125 Root Opening (in) 0.125

Root Face(in) 0.09375 Root Face(in) 0.09375

Filler material Filler material

Process Process

Gas Used Gas Used

Amps 200 Amps

Volts 21 Volts

Wire Feed (in/min) 225 Wire Feed (in/min)

Wire Diam. (in) 0.052 Wire Diam. (in)

Joint Angle 45 Joint Angle

Total Length of Weld(ft) 3.535 Total Length of Weld(ft)

Travel Speed (ipm) 9 Travel Speed (ipm)

Gas Flow Rate (cfh) 35 Gas Flow Rate (cfh)

Welder Efficiency 50% Welder Efficiency

Cost Electrode($/lb) 2.45 Cost Electrode($/lb)

Labor Rate ($/hr) 50 Labor Rate ($/hr)

Cost of Gas (per bottle) $50.00 Cost of Gas (per bottle)

Weight of gas in one bottle 50 Weight of gas in one bottle (lb)

Power Cost ($/kilowatt-hr) $0.15 Power Cost ($/kilowatt-hr)

WELDING COST OUTPUT FOR A SINGLE-BEVEL GROOVE WELD

OUTPUT FOR FCAW (Gas)

Amount of weld wire needed 38.37 lb

Number of passes per joint ~ 100

Amount of shielding gas 165.52 ft^3 bottles = 1

Actual welding time 9.46 hr

Labor Cost $406.70

Welding Wire Cost $94.01

Gas Cost $19.03

Power Cost $2.98

Initial Cost $522.72

Final Cost 601.13 $

Cost per ft of weld $147.87 $/ft

Cost per foot filler metal $26.59 $/ft

Cost per foot of gas $5.38 $/ft

Cost of Labor per foot $115.05 $/ft

OUTPUT FOR SMAW (14" Stick)

Amount of weld wire needed 54.00 lb

Number of passes per joint ~ 73

Amount of shielding gas 0.00 ft^3 bottles = N/A

Actual welding time 60.00 hr

Labor Cost $3,000.00

Welding Wire Cost $70.20

Gas Cost $0.00

Power Cost $0.28

Initial Cost $3,081.00

Final Cost 3,543.15 $

Cost per ft of weld $871.57 $/ft

Cost per foot filler metal $19.86 $/ft

Cost per foot of gas $0.00 $/ft

Cost of Labor per foot $848.66 $/ft

Labor Cost

78%

Welding Wire Cost

18%

Gas Cost

4% Power Cost

0%

Labor Cost

Welding Wire Cost

Gas Cost

Power Cost

Labor Cost

98%

Welding Wire

Cost

2%

Gas Cost

0%

Power Cost

0%

Labor Cost

Welding Wire Cost

Gas Cost

Power Cost

Process 2

175

20

0

0.188

45

3.535

5.5

0

30%

1.3

50

$0.00

0

$0.15

Labor Cost

Welding Wire Cost

Gas Cost

Power Cost

Labor Cost

Welding Wire Cost

Gas Cost

Power Cost

CALCULATIONS PROCESS 1 Single-V Groove

distance "d" = 0.375 in Process Efficiency 59% Process SMAW (12" Stick)

Distance "R" = 0.4578 in Welder Efficiency 30% Bottles of gas needed N/A

Distance c1 = 0.5252 in Arc Time 5.05 hr Radius of cap "r" 0.485202

Distance "c" = 0.6502 in Total welding time 16.83 hr Deposited Weld Metal Wt. 6

Filler Density lb/in^3 0.283 lb/in^3 Density of gas 0 lb/ft^3

Area Cap "C" 0.0557 in^2 Volume of gas in one 0.00 ft^3

Weld Metal Weight "C" 0.1893 lb/ft bottle

Area Rectangle "A" 0.0547 in^2 Total gas needed 0.00 ft^3

Weld Metal Weight "A" 0.186 lb/ft Labor Cost 595.66 $

Area of two Triangles "B" 0.0985 in^2 Gas Cost $0.00

Weld Metal Weight "B" 0.334 lb/ft Cost Electrode $13.48

Total Weld Metal Weight 0.7094 lb/ft Total Cost 610.91 $

Amount of Welding Wire 10.70 lb Final Cost 91.64 $ 702.55 $

Deposition Rate 2.12 Lb/hr Heat Input 35

Total Power Cost $1.77 Number of Passes 6

CALCULATIONS PROCESS 2 Single-V Groove

distance "d" = 0.5625 in Process Efficiency 86% Process FCAW (Gas)

Distance "R" = 0.6495 in Welder Efficiency 50% Bottles of gas needed 16

Distance c1 = 0.7451 in Arc Time 197.08 hr Radius of cap "r" 1.438578

Distance "c" = 0.8388 in Total welding time 394.16 hr Deposited Weld Metal Wt. 1029.867

Filler Density lb/in^3 0.283 lb/in^3 Density of gas 0.115 lb/ft^3

Area Cap "C" 0.0351 in^2 Volume of gas in one 434.78 ft^3

Weld Metal Weight "C" 0.1192 lb/ft bottle

Area Rectangle "A" 0.0586 in^2 Total gas needed 6897.88 ft^3

Weld Metal Weight "A" 0.199 lb/ft Labor Cost 20,338.90 $

Area of two Triangles "B" 0.2096 in^2 Gas Cost $1,189.88

Weld Metal Weight "B" 0.712 lb/ft Cost Electrode $2,694.42

Total Weld Metal Weight 1.0299 lb/ft Total Cost 24,317.80 $

Amount of Welding Wire 1197.52 lb Final Cost 3,647.67 $ 27,965.47 $

Deposition Rate 6.08 Lb/hr Heat Input 30

Total Power Cost $94.60 Number of Passes 10

CALCULATIONS PROCESS 1 Single-Bevel Groove

distance "d" = 2.15625 in Process Efficiency 86% Process FCAW (Gas)

Distance "R" = 3.0494 in Welder Efficiency 50% Bottles of gas needed 1

Distance c1 = 2.1563 in Arc Time 4.73 hr Radius of cap "r" 6.986

Distance "c" = 2.2813 in Total welding time 9.46 hr Beta 45

Filler Density lb/in^3 0.283 lb/in^3 Density of gas 0.115 lb/ft^3 Deposited Weld Metal Wt. 33.00

Area Cap "C" 0.1428 in^2 Volume of gas in one 434.78 ft^3

Weld Metal Weight "C" 0.4848 lb/ft bottle

Area Rectangle "A" 0.2813 in^2 Total gas needed 165.52 ft^3

Weld Metal Weight "A" 0.955 lb/ft Labor Cost 406.70 $

Area of two Triangles "B" 2.3247 in^2 Gas Cost $19.03

Weld Metal Weight "B" 7.895 lb/ft Cost Electrode $94.01

Total Weld Metal Weight 9.335 lb/ft Total Cost 522.72 $

Amount of Welding Wire 38.37 lb Final Cost 78.41 $ 601.13 $

Deposition Rate 8.11 Lb/hr Heat Input 28

Total Power Cost $2.98 Number of Passes 100

CALCULATIONS PROCESS 2 Single-Bevel Groove

distance "d" = 2.15625 in Process Efficiency 62% Process SMAW (14" Stick)

Distance "R" = 3.0494 in Welder Efficiency 30% Bottles of gas needed N/A

Distance c1 = 2.1563 in Arc Time 18.00 hr Radius of cap "r" 6.986

Distance "c" = 2.2813 in Total welding time 60.00 hr Beta 45

Filler Density lb/in^3 0.283 lb/in^3 Density of gas 0 lb/ft^3 Deposited Weld Metal Wt. 33.00

Area Cap "C" 0.1428 in^2 Volume of gas in one 0.00 ft^3

Weld Metal Weight "C" 0.4848 lb/ft bottle

Area Rectangle "A" 0.2813 in^2 Total gas needed 0.00 ft^3

Weld Metal Weight "A" 0.955 lb/ft Labor Cost 3,000.00 $

Area of two Triangles "B" 2.3247 in^2 Gas Cost $0.00

Weld Metal Weight "B" 7.895 lb/ft Cost Electrode $70.20

Total Weld Metal Weight 9.335 lb/ft Total Cost 3,081.00 $

Amount of Welding Wire 54.00 lb Final Cost 3,543.15 $

Deposition Rate 3.000 Lb/hr Heat Input 38.18181818

Total Power Cost $10.80 Number of Passes 73

CALCULATIONS PROCESS 1 Fillet Weld

Area of Fillet Weld 0.0313 in

2

Process Efficiency 62%

Volume of Weld Metal 3.750 in

3

Welder Efficiency 30%

Filler Density lb/in

3

0.283 lb/in

3

Arc Time 0.541 hr

Total Weld Metal Weight 0.106 lb/ft Total welding time 1.802 hr

Amount of Welding Wire 2.000 lb Heat Input 42 kJ/in

Deposition Rate 3.700 lb/hr Fillet Weld Size 0.290 in

Density of gas 0 lb/ft

3

Number of Passes 1

Volume of gas in one 0 ft

3

Labor Cost $108.15

bottle Gas Cost $0.00

Total gas needed 0 ft

3

Cost Electrode $2.60

Bottles of gas needed N/A Total Power Cost $0.35

Process SMAW (14" Stick) Total Cost $111.10

Final Cost $127.80

CALCULATIONS PROCESS 2 Fillet Weld

Area of Fillet Weld 0.0313 in

2

Process Efficiency 86%

Volume of Weld Metal 3.750 in

3

Welder Efficiency 50%

Filler Density lb/in

3

0.283 lb/in

3

Arc Time 0.390 hr

Total Weld Metal Weight 0.106 lb/ft Total welding time 0.780 hr

Amount of Welding Wire 2.000 lb Heat Input 31.5 kJ/in

Deposition Rate 5.1310494 lb/hr Fillet Weld Size 0.251 in

Density of gas 0.116 lb/ft

3

Number of Passes 1

Volume of gas in one 431.034483 ft

3

Labor Cost $46.80

bottle Gas Cost $2.55

Total gas needed 15.5913525 ft

3

Cost Electrode $5.00

Bottles of gas needed 1 Total Power Cost $0.25

Process FCAW (Gas) Total Cost $54.60

Final Cost $62.80

SMAW (12" Stick)

in

lb

FCAW (Gas)

in

lb

FCAW (Gas)

in

lb

SMAW (14" Stick)

in

lb

GAS Densities

Carbon Steel 0.283 SAW 99% 70% N/A 0

Stainless Steel 0.29 GMAW (98Ar-2O2) 98% 50% Ar 0.111

Nickel Alloy 0.31 GMAW (75Ar-25CO2) 96% 50% Co2 0.116

GMAW CO2 93% 50% C25 0.115

1 1 FCAW (Gas) 86% 50% 1 4 Single V

1 1 FCAW (Self Shield) 78% 50% 4 1 Single Bev

1 1 SMAW (12" Stick) 59% 30% 1 3 Fillet

SMAW (14" Stick) 0.62 30%

SMAW (18" Stick) 66% 30%

7 5 Sing-V

5 8 Sing-Bev

8 5 Fillet

Interpolation of Deposit Single_V Interpolation of Deposit

Rate Process 1 5 Deposition Rates SMAW 7 Rate Process 1

0.000 0 110 1.8 0 0.000

0.000 0 125 2 125 2.120

0.000 0 150 2.6 0 0.000

0.000 0 175 3 0 0.000

6.076 200 200 3.7 0 0.000

0.000 0 225 4.2 0 0.000

0.000 0 275 7 0 0.000

0.000 0 325 9 0 0.000

6.076 400 10 2.120

Weld Size

0.125 Interpolation of Deposit Single Bevel Interpolation of Deposit

0.1875 Rate Process 1 8 Deposition Rates SMAW 5 Rate Process 1

0.250 0.000 0 110 1.8 0 0.000

0.313 0.000 0 125 2 0 0.000

0.375 0.000 0 150 2.6 0 0.000

0.438 3.000 175 175 3 0 0.000

0.500 0.000 0 200 3.7 200 8.114

0.5625 0.000 0 225 4.2 0 0.000

0.625 0.000 0 275 7 0 0.000

0.688 0.000 0 325 9 0 0.000

0.750 3.000 400 10 8.114

0.8125

0.875 Interpolation of Deposit Fillet Weld Interpolation of Deposit

0.938 Rate Process 1 8 Deposition Rates SMAW 5 Rate Process 1

Alloy Density Process&Welder Eff (%)

1.000 0.000 0 110 1.8 0 0

1.125 0.000 0 125 2 0 0

1.25 0.000 0 150 2.6 0 0

1.375 0.00 0 175 3 0 0

1.5 3.700 200 200 3.7 200 5.131

1.5625 0.000 0 225 4.2 0 0

1.625 0.000 0 275 7 0 0

1.75 0.000 0 325 9 0 0

1.8125 3.700 400 10 5.131

1.875

2

2.125

2.25

2.375

2.5

2.5625

2.625

2.75

2.8125

2.875

3

3.125

3.25

3.375

3.5

3.5625

3.625

3.75

3.8125

Single V 6 9

Single Bevel 27 27

Fillet Weld 3 3

Cap Hieght

0

0.03125

0.063

0.094

0.125

0.25

0.375

4 4

3 2

3 2

3 3

4 4

3 3

Interpolation of Deposit

Rate Process 1

Interpolation of Deposit

Rate Process 1

You might also like

- Welding Calculations For Base PlateDocument116 pagesWelding Calculations For Base PlateSyedZainAli100% (2)

- 564 D 2160 Welding CalculationsDocument58 pages564 D 2160 Welding CalculationsSyedZainAliNo ratings yet

- Asme Viii D Table 2aDocument16 pagesAsme Viii D Table 2aJohakim974100% (1)

- Tank Specification - Fiberglass Tanks 0408Document13 pagesTank Specification - Fiberglass Tanks 0408shankarkl100% (2)

- Welding CalculationsDocument14 pagesWelding Calculationsjitulpatil100% (6)

- Weld Metal CalculationDocument20 pagesWeld Metal CalculationJegan Thiyagarajan100% (1)

- Determinacion de Los Costos de Soldadura para Union de FileteDocument26 pagesDeterminacion de Los Costos de Soldadura para Union de FiletejavierNo ratings yet

- Welding CalculatorDocument10 pagesWelding Calculatorneel0% (2)

- Weld Cost Calc XLDocument63 pagesWeld Cost Calc XLRobert WhitakerNo ratings yet

- Lifting TrunionDocument1 pageLifting TrunionRUDHRA DHANASEKAR0% (1)

- Weldment Strength Excel CalculationsDocument38 pagesWeldment Strength Excel CalculationsRAMSINGH CHAUHAN100% (4)

- Determining The Cost of WeldingDocument22 pagesDetermining The Cost of WeldingSanjay J NNo ratings yet

- QAQC References 2Document138 pagesQAQC References 2Mohd SharainiNo ratings yet

- Welding Cost Estimation For 12 Joints in 8 NPS Sch. 80Document1 pageWelding Cost Estimation For 12 Joints in 8 NPS Sch. 80WeldPulse100% (2)

- Weld Cost CalculationDocument27 pagesWeld Cost Calculation-Abdul Khodir Van Java-100% (7)

- Imperial Piping Weight Load Calculation WorkbookDocument13 pagesImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Weld CostsDocument2 pagesWeld CostsJina Chandran100% (1)

- PV Elite Heat Exchanger CalculationsDocument99 pagesPV Elite Heat Exchanger CalculationscbousmuNo ratings yet

- Bolt Torques For ASME B16.5 Flanges With Sheet Gaskets To ASME B16.21Document30 pagesBolt Torques For ASME B16.5 Flanges With Sheet Gaskets To ASME B16.21huangjlNo ratings yet

- Weld Cost CalculationDocument30 pagesWeld Cost CalculationDenial BasanovicNo ratings yet

- Weld Cost CalculationDocument15 pagesWeld Cost CalculationMustafa KaramürselNo ratings yet

- Weld Metal Calculation 1Document6 pagesWeld Metal Calculation 1Nabihah NurulhudaNo ratings yet

- AWSPipeWeld - American Welding SocietyDocument2 pagesAWSPipeWeld - American Welding Societybarukomkss100% (1)

- Weld Cost Calc XL1.3.2mmDocument3 pagesWeld Cost Calc XL1.3.2mmVipin JoseNo ratings yet

- HILTI Typical Plumbing ApplicationsDocument140 pagesHILTI Typical Plumbing ApplicationskuraimundNo ratings yet

- ASME 31 - 8mDocument1 pageASME 31 - 8mMarcoAlbaNo ratings yet

- Weld Metal CalculationDocument1 pageWeld Metal CalculationKiukStaksNo ratings yet

- WeldkgDocument5 pagesWeldkgalokbdasNo ratings yet

- ASME B31.8 Riser CalcDocument23 pagesASME B31.8 Riser Calcisrar khan100% (2)

- Dummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMDocument4 pagesDummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMashish shrivastav50% (2)

- Weld Metal Cost Calculator 3Document1 pageWeld Metal Cost Calculator 3Naresh Tammineedi100% (1)

- Welding Rod Cal (1) .Document7 pagesWelding Rod Cal (1) .hakr5100% (1)

- 6 Slickline OperationsDocument302 pages6 Slickline OperationsAntonio Bevilacqua100% (4)

- Electrodes CalculatorDocument2 pagesElectrodes CalculatorAsebaho Badr100% (1)

- Yield Strength 01Document2 pagesYield Strength 01bakellyNo ratings yet

- Frequency Analysis Vibration Spectrum Analysis Steve GoldmanDocument9 pagesFrequency Analysis Vibration Spectrum Analysis Steve GoldmantylerdurdaneNo ratings yet

- Weld CalculatorDocument6 pagesWeld Calculatorshahid khanNo ratings yet

- Weld Consumable Calculator ComDocument7 pagesWeld Consumable Calculator Comchetan85No ratings yet

- A Course in Robust Control Theory PDFDocument380 pagesA Course in Robust Control Theory PDFDenis Hinojosa ZeballosNo ratings yet

- A Course in Robust Control Theory PDFDocument380 pagesA Course in Robust Control Theory PDFDenis Hinojosa ZeballosNo ratings yet

- Ricardo R4105ZD-61kW Genset Spec SheetDocument2 pagesRicardo R4105ZD-61kW Genset Spec SheetRonald Booc100% (3)

- Welding Prcesses Estimation RecordDocument5 pagesWelding Prcesses Estimation RecorddineshshankarNo ratings yet

- Tutorial of WRC 107 For Lifting LugsDocument20 pagesTutorial of WRC 107 For Lifting LugsAlvin Smith100% (1)

- Determinacion de Los Costos de Soldadura para Union de FileteDocument26 pagesDeterminacion de Los Costos de Soldadura para Union de Filetegraci2828No ratings yet

- Calculation of Electrode ConsumptionDocument4 pagesCalculation of Electrode ConsumptionhgolestaniNo ratings yet

- Electrode CalculationDocument2 pagesElectrode CalculationTejas PatelNo ratings yet

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan PanchalNo ratings yet

- Weld CalculationsDocument12 pagesWeld Calculationshakr5100% (1)

- Weld CalculationDocument7 pagesWeld CalculationDenny Syamsuddin100% (1)

- Group 7 - Mumhdsakjbai Monorail - Project Management ReportDocument21 pagesGroup 7 - Mumhdsakjbai Monorail - Project Management ReportYogesh Parate100% (1)

- Calculation Software of WeldingDocument1 pageCalculation Software of WeldinghaharameshNo ratings yet

- Asme Sec 1 (Boiler)Document15 pagesAsme Sec 1 (Boiler)Arie MahendraNo ratings yet

- TM 9-792 M21 AMMUNITION TRAILERDocument128 pagesTM 9-792 M21 AMMUNITION TRAILERAdvocate100% (1)

- Calculation of Pipe Reinforcement ASME B31 3Document5 pagesCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- Design Office: Sanken Lanka (PVT) LTDDocument2 pagesDesign Office: Sanken Lanka (PVT) LTDUmesh ChamaraNo ratings yet

- Company Profile Metro GoldrichDocument29 pagesCompany Profile Metro GoldrichBids and Awards CommitteeNo ratings yet

- SAP Workflow Interview Questions - MindmajixDocument25 pagesSAP Workflow Interview Questions - MindmajixsudhNo ratings yet

- Weld Cost Calc XL1.3.2mmDocument3 pagesWeld Cost Calc XL1.3.2mmAdrian DavidNo ratings yet

- Asme b16.5Document246 pagesAsme b16.5hugo_siqueira_11No ratings yet

- Chemical Engineering May 2013Document90 pagesChemical Engineering May 2013Fausto RivasNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Bolt Torque ASME B16 5 Flanges Sheet Gaskets 02Document17 pagesBolt Torque ASME B16 5 Flanges Sheet Gaskets 02pirataenriqueNo ratings yet

- S.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMDocument12 pagesS.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMRajiv DamodarNo ratings yet

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDocument3 pagesASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyNo ratings yet

- Weld Deposite CalculationsDocument2 pagesWeld Deposite CalculationsMohammad ElhedabyNo ratings yet

- VESSELDocument350 pagesVESSELRavindra S. JivaniNo ratings yet

- Torispherical Head TolvaDocument1 pageTorispherical Head TolvaFabio Augusto Hincapie HenaoNo ratings yet

- How To Calculate Filler MetalDocument3 pagesHow To Calculate Filler MetalEdgar Coavas PérezNo ratings yet

- MRCB Piepeline: Pipe Wall Thickness Checking (T)Document5 pagesMRCB Piepeline: Pipe Wall Thickness Checking (T)amirthraj74No ratings yet

- Costing of Joining Methods - Arc Welding CostsDocument27 pagesCosting of Joining Methods - Arc Welding CostsTasmanijskaNemaNo ratings yet

- Demo Weld Cost Calc XLDocument10 pagesDemo Weld Cost Calc XLKhalid Ahmod ShibleeNo ratings yet

- Abi Feed Water Inlet Nozzle No:1 Material CostDocument1 pageAbi Feed Water Inlet Nozzle No:1 Material CostKarthimeena MeenaNo ratings yet

- Data Rates Gate Works 6Document21 pagesData Rates Gate Works 6vpmohammedNo ratings yet

- Reservoir SimulationDocument24 pagesReservoir SimulationDenis Hinojosa ZeballosNo ratings yet

- Acornejo Southmayd ProfileDocument11 pagesAcornejo Southmayd Profileapi-242543114No ratings yet

- Renderoc RsxtraDocument4 pagesRenderoc RsxtraBalasubramanian AnanthNo ratings yet

- Reduced Vertical Separation Minimum - RVSM: IVAO HQ Training DepartmentDocument4 pagesReduced Vertical Separation Minimum - RVSM: IVAO HQ Training DepartmentjesusNo ratings yet

- VLSI Design FlowDocument20 pagesVLSI Design FlowPranav DarganNo ratings yet

- Et154 PDFDocument6 pagesEt154 PDFbytecNo ratings yet

- Fundamentals of Petroleum Engineering BookDocument10 pagesFundamentals of Petroleum Engineering BookRizwan FaridNo ratings yet

- SFTP Certificate Handling in BISDocument18 pagesSFTP Certificate Handling in BISkemoT1990TM100% (1)

- 1082-Adding New Replication From Sybase To OracleDocument4 pages1082-Adding New Replication From Sybase To Oraclegirish10670No ratings yet

- Installation Operation Maintenance 7200CB en USDocument140 pagesInstallation Operation Maintenance 7200CB en USEleno RibeiroNo ratings yet

- Three-Phase Induction Motor Dynamic Mathematical ModelDocument3 pagesThree-Phase Induction Motor Dynamic Mathematical Modelsajs201100% (3)

- QlikView Sviluppo Progettuale enDocument5 pagesQlikView Sviluppo Progettuale enEleazar BrionesNo ratings yet

- Cansat2017 5235 CDR v02Document185 pagesCansat2017 5235 CDR v02tom2susanNo ratings yet

- AS9104 2A Form-CDocument3 pagesAS9104 2A Form-C44abcNo ratings yet

- ABB REL5xx RIOConverterDocument10 pagesABB REL5xx RIOConverterzinab90100% (1)

- CHAPTER 2 Eff Comm ModelsDocument9 pagesCHAPTER 2 Eff Comm ModelsSubhash SoniNo ratings yet

- Iare WCN Tutorial Question BankDocument7 pagesIare WCN Tutorial Question BankVigneshNo ratings yet

- Growth of Escherichia Coli in A 5 Litre Batch Fermentation VesselDocument15 pagesGrowth of Escherichia Coli in A 5 Litre Batch Fermentation VesselAs'ad Mughal100% (2)

- Tutorial 2 What Is The Output of The Below Program?Document2 pagesTutorial 2 What Is The Output of The Below Program?Sunitha BabuNo ratings yet

- Lewmar Marine Equipment Guide Ed 14Document224 pagesLewmar Marine Equipment Guide Ed 14Renato Fonseca100% (1)

- BLTouch Setup ManualDocument7 pagesBLTouch Setup ManualBobbyNo ratings yet