Professional Documents

Culture Documents

Highly Crystalline Mesoporous TiO2 for Sunlight-Driven Dye Degradation

Uploaded by

patel_smitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Highly Crystalline Mesoporous TiO2 for Sunlight-Driven Dye Degradation

Uploaded by

patel_smitCopyright:

Available Formats

Self-assembled highly crystalline TiO

2

mesostructures for

sunlight-driven, pH-responsive photodegradation of dyes

Xinyi Zhang

a,b,

*, Jianfeng Yao

c

, Dan Li

c

, Xiaodong Chen

c

, Huanting Wang

c

,

Leslie. Y. Yeo

d

, James. R. Friend

b,d,

*

a

School of Chemistry, Monash University, Clayton, VIC 3800, Australia

b

Melbourne Centre for Nanofabrication, Clayton, VIC 3800, Australia

c

Department of Chemical Engineering, Monash University, Clayton, VIC 3800, Australia

d

Micro/Nanophysics Research Laboratory, RMIT University, Melbourne, VIC 3000, Australia

A R T I C L E I N F O

Article history:

Received 16 July 2013

Received in revised form 26 December 2013

Accepted 31 March 2014

Available online 04 April 2014

Keywords:

A. Semiconductor

A. Oxide

C. Transmission electron microscopy (TEM)

D. Crystal structure

D. Catalytic properties

A B S T R A C T

The development of new strategies and photocatalytic materials for practical environmental solutions

remains a great challenge, particularly due to the large energy demands associated with various

remediation processes. In this paper, we report the fabrication of self-assembled ordered mesoporous

TiO

2

with highly crystalline anatase structures as well as high surface area, and characterize their

photocatalytic performance on the degradation of three typical dyes, including anionic methyl orange,

cationic methylene blue, and neutral rhodamine B driven merely by sunlight. The results show that the

dye photodegradation strongly depends on the charging state of both mesoporous TiO

2

surface and dyes,

which can be adjusted by the pH value of the solutions. Such charge-dependent photocatalytic

functionality of mesoporous TiO

2

can thus be exploited for highly efcient and selective dye

photodegradation.

2014 Elsevier Ltd. All rights reserved.

1. Introduction

Dyes are common across many industriesincluding printing,

textile, pulp and paper, and leather processingto color products

to suit customer desires, generating substantial amounts of dye

wastewater that is harmful to the environment, hazardous to

human health, and difcult to degrade by natural means. Their use

remains problematic, an anachronism remaining among the many

chemicals produced and used via sustainable processes developed

in recent years. Numerous treatment technologies have been

developed to treat dye wastewater, from physico-chemical to

biological processes [16]. Among these, the solar energy-driven

photodegradation of dyes in aqueous solutions has gained

considerable attention due to practical and fundamental benets

alike in recognition of the impact dye-laden waste has on the

environment [710]. Semiconductor-based photocatalysis has

attracted particular attention as a suitable green technology

for this purpose because of its chemical stability and favorable

energy band structure. TiO

2

is considered to be one of the best

material candidates for photovoltaic and photocatalytic devices in

this application; its nanoparticles possess superior photocatalytic

efciency over the bulk phase and the photocatalytic activity of

such nanoparticles have been extensively investigated [1113].

However, intrinsic limitations prevent further improvement in the

photocatalytic process in TiO

2

nanoparticles. Illuminated TiO

2

nanoparticles behave as short-circuited electrodes: the interfacial

charge transfer competing with the charge recombination

between the charge carriers is a major problem in photocatalysis

and is a limiting factor in improving the photocatalytic efciency

[14]. There are further drawbacks: nanoparticles tend to aggregate,

are difcult to separate and recover from solution, and the

environmental impact of such nanoparticles remains an open

question, greatly limiting their practical use in many commercial

applications. The signicant need remains, therefore, for another

approach and alternative materials to solve these challenging

problems inherent in TiO

2

and in using them in a nanoparticle

morphology.

So far, little information is available on the reaction mecha-

nisms involved in the photocatalytic degradation of dyes and on

the identication of major transient intermediates which have

been more recently recognized as very important aspects of these

processes, especially from the viewpoint of practical application

[1517]. As the charging states of both dye and photocatalyst play

* Corresponding author. Tel.: +61 3 9902 4619; fax: +61 3 9905 4597.

E-mail addresses: xinyi.zhang@monash.edu (X. Zhang),

james.friend@rmit.edu.au (J.R. Friend).

http://dx.doi.org/10.1016/j.materresbull.2014.03.036

0025-5408/ 2014 Elsevier Ltd. All rights reserved.

Materials Research Bulletin 55 (2014) 1318

Contents lists available at ScienceDirect

Materials Research Bulletin

j our nal homepage: www. el se vi e r . com/ l ocat e/ mat r esbu

crucial roles in the photodegradation process, investigating the

prior adsorption of dyes in addition to the interactions between the

dyes and the catalyst surface is crucially important to develop

superior photocatalysts for efcient dye degradation. In compari-

son with TiO

2

nanoparticles, highly structured mesoporous TiO

2

formed using evaporation-induced self-assembly is of consider-

able interest [1820]. The advantage of this technique lies in the

possibility of tuning the symmetry of the mesostructure by

adjusting the composition of the initial solution and the

preparation condition [2123]. Further, the mesoporous morphol-

ogy avoids the myriad practical drawbacks of nanoparticles. To the

best of our knowledge, there is no study to date on the pH-

responsively selective photocatalytic activity of ordered meso-

porous TiO

2

. Here, we report the fabrication of self-assembled

highly crystalline ordered mesoporous TiO

2

and investigate the

sunlight-driven photocatalytic activity of the mesoporous TiO

2

.

The results show that the adsorption of dyes on the mesoporous

TiO

2

surface strongly depends on the pH value of the dye solution

in addition to the charging state of the dyes, and that these factors

in turn have a crucial effect on the photocatalytic performance of

the mesoporous TiO

2

.

2. Experimental

Mesoporous TiO

2

was synthesized by using a mixture of poly

(ethylene oxide)-b-poly(propylene oxide)-b-poly(ethylene oxide)

copolymer (P123), ethanol, concentrated HCl, and tetrabutyl

titanate (TBT) [24]. The mass ratio of P123/TBT/EtOH/HCl was

1:2.8:30:2. For a typical synthesis, 1.0 g of P123 was dissolved in

30 g of ethanol, and then 2 g of concentrated HCl was slowly added

with stirring. Then 2.8 g of TBT was added, and the solution was

stirred for 4 h. The resulting solutions were transferred into Petri

dishes and subsequently sealed and aged at room temperature for

1 week. Then the samples were calcined at 400

C in air for 2 h with

a 1

C min

1

temperature ramp to obtain the mesoporous TiO

2

thin

lms with thickness of about 2 mm. All chemical reagents used in

this study were of analytical grade and were supplied by Sigma

Aldrich (Australia). Nitrogen adsorptiondesorption experiments

were performed at 77 K with a Micromeritics ASAP 2020MC. The

samples were degassed at 300

C for 5 h prior to measurement.

The pore volume was estimated from the desorption branch of the

isotherm at P/P

o

= 0.98 assuming complete pore saturation. The

morphology and microstructure of the mesoporous TiO

2

were

investigated using an X-ray diffractometer (XRD, PW1140/90) with

CuKa radiation (25 mA and 40 kV), and a transmission electron

microscope (TEM, JEOL-2011).

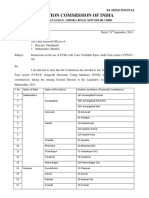

Three typical dyes including rhodamine B (RB), methyl orange

(MO), and methylene blue (MB) were studied for photodegrada-

tion. The molecule structures of the dyes are shown in Fig. 1. The

concentrations of the dye solutions were 50 mg/L. 10 mg of the

mesoporous TiO

2

samples were added into 20 mL dye solution and

the muddy solution was dispersed with an ultrasonic instrument

for 30 min, and then irradiated by sunlight. The temperature was in

the range of 2226

C and the average sunlight intensity was about

6.5 kW h m

2

. The pH of the samples was adjusted by using

0.1 mol/L HCl or 0.1 mol/L NaOH. After the photocatalytic experi-

ment, the remaining dye solutions were collected and analyzed. A

UV-240 UVvis spectrometer was used to record the change of the

absorbance of the dye solution.

3. Results and discussion

The TiO

2

mesostructures were formed using the evaporation

induced self-assembly (EISA) approach, which has been estab-

lished as an efcient process for the preparation of mesostructured

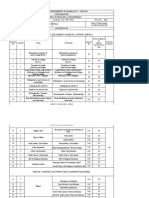

oxide with controlled morphologies [24]. The wide-angle X-ray

diffraction pattern of the sample is shown in Fig. 2a. The main

diffraction peaks correspond to the tetragonal structure of anatase

TiO

2

. Fig. 2b exhibits the small angle X-ray diffraction spectrum,

clearly showing the principle diffractional peak (10 0) and

suggesting a well-dened hexagonal mesostructure. The N

2

sorption isotherms of mesoporous TiO

2

show type-IV curves with

clear condensation steps, indicating uniform mesopores (Fig. 2c).

The Langmuir surface area which is calculated from nitrogen

sorption results to be 172.2 m

2

/g. Fig. 2d shows the derived pore

size distributions. The pore size distributions of the samples are

observed to be narrow and the corresponding peak is located at

about 4.8 nm, conrming the formation of the mesostructure [25].

The mesostructure of the TiO

2

was further investigated by

transmission electron microscopy (TEM). The TEM images of the

ordered mesoporous structure of the TiO

2

are displayed in Fig. 3. As

shown in Fig. 3a, the cross-sectional view of the mesoporous TiO

2

Fig. 1. The molecule structures of dyes.

14 X. Zhang et al. / Materials Research Bulletin 55 (2014) 1318

exhibits parallel cylindrical channels. Fig. 3b shows the plain view

of the mesoporous TiO

2

, where ordered hexagonally-organized

mesopores with pore sizes of 35 nm can be clearly observed. The

inset in Fig. 3b shows the corresponding electron diffraction (ED)

pattern and the strong and continuous rings can be indexed as the

anatase TiO

2

structure, which is in accordance with the X-ray

diffraction (XRD) analysis. The high-resolution TEM (HRTEM)

images of the mesopore wall in the mesoporous TiO

2

are displayed

in Fig. 3c and d wherein the well-recognized lattice spacings of

0.35 and 0.19nm correspond to the anatase (10 1) and (2 0 0)

20 30 40 50 60

2

0

4

2

1

3

2

1

1

1

0

5

2

0

0

1

0

3

,

0

0

4

2 theta (degree)

1

0

1

1 2 3 4 5

2theta (degree)

100

0.0 0.2 0.4 0.6 0.8 1.0

0

20

40

60

80

100

120

140

160

180

200

220

A

d

s

o

r

p

t

i

o

n

V

o

l

u

m

e

(

c

m

3

g

-

1

)

Relative Presure (P/P

o

)

0 20 40 60 80 100 120 140 160

0.00

0.01

0.02

0.03

0.04

0.05

0.06

d

V

/

d

D

(

c

m

3

g

-

1

n

m

-

1

Pore size (nm)

(a) (b)

(c) (d)

Fig. 2. (a) Wide-angle and (b) small-angle XRD spectrum. (c) The N

2

sorption isotherm and (d) pore size distribution of mesoporous TiO

2

.

Fig. 3. TEM images show (a) the cross section, and, (b) plane view and HRTEM images show (c) the cross sectional view, and, (d) the plane view of the mesoporous TiO

2

.

X. Zhang et al. / Materials Research Bulletin 55 (2014) 1318 15

atomic planes, respectively. The interpore distance is about 6 nm,

which is consistent with the lattice parameter (6 nm) of the

hexagonal mesophase of the P123 liquid crystal.

Fig. 4 shows the sunlight-driven photocatalytic degradation of

dyes on mesoporous TiO

2

in neutral solutions (pH 6.5). The

adsorption spectra of RB, MB, and MO dyes at various irradiation

times on mesoporous TiO

2

are shown in Fig. 4a, b, and c,

respectively. As illustrated in Fig. 4d, the photocatalytic degrada-

tion of different dyes on mesoporous TiO

2

is quite different

(Fig. 4d). The degradation rates of dyes are in the order of

MO < MB < RB. Among them, the highest activity with a degrada-

tion rate of around 51% was obtained for RB after 1 h of sunlight

irradiation. The degradation mechanism of dyes under sunlight

irradiation is clearly different from that under UV irradiation.

During UV irradiation, electron (e

)hole (h

+

) pairs are generated

and are capable of initiating oxidation and reduction reactions on

the surface of TiO

2

[26,27]. The dyes are aromatic compounds

containing aryl rings which have delocalized electron systems.

These are responsible for the absorption of electromagnetic

radiation of varying wavelengths; the cleavage of conjugated

chromophore structures occuring during the photodegradation

process. Under sunlight irradiation, electron transfer to the TiO

2

surface is achieved mainly through the extraction of electrons from

excited dyes to the conduction band of TiO

2

directly or photo-

generated holes from the dyes to the valence band of TiO

2

,

respectively. The dyes with labile organic functional groups are

more easily to be excited and converted to the dye radicals that

subsequently undergo degradation. The dye radicals readily react

with hydroxyl ions undergoing oxidation or interacts effectively

with O

2

.

, HO

2

.

or HO

.

species to yield intermediates that

ultimately lead to CO

2

. The mechanism of solar light-induced

photocatalytic degradation of dyes is schematically presented in

Fig. 5. In neutral solutions, the differences in the ease of formation

of the dye radical and the stability of the aryl rings should be

300 350 400 450 500 550 600

0.0

0.5

1.0

1.5

2.0

2.5

3.0

A

b

s

o

r

b

a

n

c

e

Wavelength (nm)

0 h

1 h

2 h

4 h

6 h

a

400 500 600 700 800

0.0

0.5

1.0

1.5

2.0

2.5

3.0

c

A

b

s

o

r

b

a

n

c

e

Wavelength (nm)

0 h

1 h

2 h

4 h

6 h

300 400 500 600 700 800

0

1

2

b

A

b

s

o

r

b

a

n

c

e

Wavelength (nm)

0 h

1 h

2 h

4 h

6 h

0 1 2 3 4 5 6

0

20

40

60

80

100

d

D

e

g

r

a

d

a

t

i

o

n

r

a

t

e

(

%

)

Time (h)

Rb

MB

MO

Fig. 4. The adsorption spectra of (a) RB, (b) MB, and (c) MO dyes at various irradiation times on mesoporous TiO

2

, and (d) the photocatalytic degradation rate of the dyes on

mesoporous TiO

2

as a function of irradiation time in neutral solutions.

Fig. 5. Schematic illustration of sunlight-driven photocatalytic mechanism of dye

degradation on mesoporous TiO

2

.

16 X. Zhang et al. / Materials Research Bulletin 55 (2014) 1318

mainly responsible for the difference in the degradation rates

among the dyes [28,29]. As shown in Fig. 6, the photocatalytic

performance of mesoporous TiO

2

is strongly dependent on the pH

of the dye solutions. The photodegradation rate of MO is observed

to decrease with increasing pH, whereas the photodegradation

rate of MB is seen to increase with increasing pH. In contrast, the

photodegradation rate of RB also increases with increasing pH

though its degradation rate nevertheless drops signicantly in

strong alkaline solution. The adsorption of dyes on the surface of

catalysts is indispensable for photocatalytic degradation. There-

fore, the charging state of the dyes and catalyst surface should be

taken into consideration. Fig. 7 shows the z-potential of

mesoporous TiO

2

surface in aqueous solution with different pH

values. The TiO

2

surface is positively charged at pH 8 or below and

becomes negatively charged upon increasing the pH. Since MO is

an anionic dye containing sulphonate group whereas MB is a

cationic dye containing amino groups, it can then be inferred that

the cationic dye MB prefers to adsorb on the catalyst surface at pH

above 8, while the anionic dye MO prefers to adsorb on the catalyst

surface at pH lower than 8. The charging states of both the TiO

2

and dyes change when the pH of the solution changes. The

increase of pH decreases the positive charging of the TiO

2

surface.

For the anionic MO dye, the increase of pH then decreases the

attraction between anionic MO molecules and the TiO

2

surface,

especially on negatively charged TiO

2

surfaces at high pH. Besides,

the increase in pH also leads to an increase in the competition

between OH

and MO during their adsorption onto the catalyst

surface. These factors then lead to the decrease of degradation

rates of MO with increasing pH. For MB, on the other hand, the

increase in pH decreases the repulsion between the cationic MB

molecules and the TiO

2

surface whilst also enhancing the base-

catalyzed demethylation of MB [30]. Therefore, the degradation

rate of MB is seen to increase with increasing pH. RB, in contrast, is

positively charged, neutral, and negatively charged in the pH range

below 6.0, 6.0 to 10.8, and above 10.8, respectively [31]. At low pH,

the situation for RB is similar to that for MB, and hence the

degradation rate of RB is very low because of the difculty of the

adsorption. An increase in pH, however, decreases the positive

charging of both the TiO

2

surface and RB. The degradation of

neutral RB molecules then suggests that the adsorption of RB can

be achieved via hydrogen bonding or van der Waals forces in

neutral solution. Conversely, both TiO

2

surface and RB molecules

are negatively charged at strong alkaline solution (pH > 10.8)

and therefore the repulsion between the TiO

2

surface and anionic

RB molecules suppresses the adsorption and hence the degrada-

tion of RB.

4. Conclusions

In conclusion, ordered mesoporous TiO

2

with highly crystalline

walls and large surface area has been prepared and characterized.

The sunlight-driven photocatalytic degradation of various dyes on

mesoporous TiO

2

and the role of pH in the photocatalytic

degradation process was then systematically investigated. We

demonstrate that the photocatalytic activity of mesoporous TiO

2

is

strongly pH-responsive, and can therefore be controlled by

adjusting the pH of the aqueous solutions. All of the dyes were

shown to be effectively photocatalytic degraded on mesoporous

TiO

2

by selecting a suitable pH range. This work therefore shows

the potential of heterogeneous photocatalysis to decontaminate

dye wastewater and opens up a new way for designing sunlight-

driven photocatalysts for environmental remediation.

Acknowledgements

This work was supported by the Australian Research Council

(ARC) (Grant No.: DP120104334) and Monash University. This work

was performed in part at the Melbourne Centre for Nano-

fabrication (MCN) in the Victorian Node of the Australian National

Fabrication Facility (ANFF).

References

[1] S.C. Yan, Z.S. Li, Z.G. Zou, Langmuir 26 (2010) 38943901.

[2] Y.F. Xie, D.Y. Qin, D.L. Wu, X.F. Ma, Chemical Engineering Journal 168 (2011)

959963.

[3] A. Zille, P. Ramalho, T. Tzanov, R. Millward, V. Aires, M.H. Cardoso, M.T.

Ramalho, G.M. Gbitz, A. Cavaco-Paulo, Biotechnology Progress 20 (2004)

15881592.

[4] Y.S. Al-Degs, M.I. El-Barghouthi, A.H. El-Sheikh, G.M. Walker, Dyes Pigments 77

(2008) 1623.

[5] N.K. Amin, Journal of Hazardous Materials 165 (2009) 5262.

[6] M. Arami, N.Y. Limaee, N.M. Mahmoodi, Journal of Colloid and Interface

Science 288 (2005) 371376.

[7] V.M. Correia, T. Stephenson, S.J. Judd, Environmental Technology 15 (1994)

917929.

2 4 6 8 10 12 14

0

20

40

60

80

100

D

e

g

r

a

d

a

t

i

o

n

r

a

t

e

pH

RB

MB

MO

a

2 4 6 8 10 12 14

0

20

40

60

80

100

pH

D

e

g

r

a

d

a

t

i

o

n

r

a

t

e

RB

MB

MO

b

Fig. 6. The sunlight-driven photocatalytic degradation of dyes on mesoporous TiO

2

as a function of pH after (a) 1 h and (b) 2 h of irradiation.

2 4 6 8 10 12 14

-30

-20

-10

0

10

20

Z

e

t

a

p

o

t

e

n

t

i

a

l

(

m

v

)

pH

Fig. 7. The z-potential of the mesoporous TiO

2

as a function of pH.

X. Zhang et al. / Materials Research Bulletin 55 (2014) 1318 17

[8] I.K. Konstantinou, T.A. Albanis, Applied Catalysis B: Environment 49 (2004) 114.

[9] A. Houas, H. Lachheb, M. Ksibi, E. Elaloui, C. Guillard, J.M. Hermann, Applied

Catalysis B: Environment 31 (2001) 145157.

[10] K. Tanaka, K. Padermpole, T. Hisanaga, Water Research 34 (2000) 327333.

[11] W. Zhao, Y.L. Sun, F.N. Castellano, Journal of the American Chemical Society 130

(2008) 1256612567.

[12] X.B. Chen, L. Liu, P.Y. Yu, S.S. Mao, Science 331 (2011) 746750.

[13] J.K. McCusker, Science 293 (2001) 15991601.

[14] W.A. Zeltner, M.A. Anderson, The use of nanoparticles in environmental

applications, in: E. Pelizzetti (Ed.), Fine Particles Science and Technology,

Kluwer Academic Publishers, Dordrecht, the Netherlands, 1996, pp. 643656.

[15] F. Zhang, J. Zhao, T. Shen, H. Hidaka, E. Pelizzetti, N. Serpone, Applied Catalysis

B: Environment 15 (1998) 147156.

[16] F. Chen, Y. Xie, J. Zhao, G. Lu, Chemosphere 44 (2001) 11591168.

[17] G.A. Epling, C. Lin, Chemosphere 46 (2002) 561570.

[18] C.T. Kresge, M.E. Leonowicz, W.J. Roth, J.C. Vartuli, J.S. Beck, Nature 359 (1992)

710712.

[19] M.M. Turnbull, C.P. Landee, Science 298 (2002) 17231724.

[20] D. Zhao, J. Feng, Q. Huo, N. Melosh, G.H. Fredrickson, B.F. Chmelka, G.D. Stucky,

Science 279 (1998) 548552.

[21] S.S. Soni, M.J. Henderson, J.F. Bardeau, A. Gibaud, Advanced Materials 20 (2008)

14931498.

[22] P.G. Hoertz, T.E. Mallouk, Inorganic Chemistry 44 (2005) 68286840.

[23] S. Sajjad, S.A.K. Leghari, F. Chen, J.L. Zhang, European Journal of Chemistry 16

(2010) 1379513804.

[24] H.S. Yun, K. Miyazawa, H.S. Zhou, I. Honma, M. Kuwabara, Advanced Materials

13 (2001) 13771380.

[25] K. Hou, B.Z. Tian, F.Y. Li, Z.Q. Bian, D.Y. Zhao, C.H. Huang, Journal of Materials

Chemistry 15 (2005) 24142420.

[26] D. Friedmann, C. Mendive, D. Bahnemann, Applied Catalysis B: Environmental

99 (2010) 398406.

[27] A. Mills, D. Worsley, R.H. Davies, Journal of the Chemical Society, Chemical

Communications (1994) 2677.

[28] Takizawa, T. Watanabe, K. Honda, Journal of Physical Chemistry 82 (1978)

13911396.

[29] J. Oakes, P. Gratton, Journal of the Chemical Society, Perkin Transactions 2

(1998) 25632568.

[30] K. Bergmann, C.T. OKonski, Journal of Physical Chemistry 67 (1967) 21692177.

[31] Y.J. Oh, T.C. Gamble, D. Leonhardt, C.H. Chung, S.R.J. Brueck, C.F. Ivory, G.P.

Lopez, D.N. Petsev, S.M. Han, Lab on a Chip 8 (2008) 251258.

18 X. Zhang et al. / Materials Research Bulletin 55 (2014) 1318

You might also like

- Heterogeneous Nanocomposite-Photocatalysis for Water PurificationFrom EverandHeterogeneous Nanocomposite-Photocatalysis for Water PurificationNo ratings yet

- Dye DegradationDocument5 pagesDye DegradationPrasad DNo ratings yet

- Journal of Cleaner Production: SciencedirectDocument15 pagesJournal of Cleaner Production: SciencedirectCamila Andrea Chávez QuispeNo ratings yet

- Synthesis and Characterization of Cnt/Ce-Tio Nanocomposite For Phenol DegradationDocument8 pagesSynthesis and Characterization of Cnt/Ce-Tio Nanocomposite For Phenol DegradationŞebnem Gül İlarslanNo ratings yet

- 10 1002@jctb 6502Document46 pages10 1002@jctb 6502Quynh Anh NguyenNo ratings yet

- Fixed Bed Reactor Performance For Herbicide Degradation Under Solar RadiationDocument6 pagesFixed Bed Reactor Performance For Herbicide Degradation Under Solar RadiationyoussefNo ratings yet

- International Journal of Smart and Nano MaterialsDocument12 pagesInternational Journal of Smart and Nano Materialsadi_agNo ratings yet

- Synthesis by Sol-Gel of WO3 TiO2 For Solar Photocatalytic DegradationDocument6 pagesSynthesis by Sol-Gel of WO3 TiO2 For Solar Photocatalytic DegradationJosue Hernandez MrkzNo ratings yet

- Belhadjltaief 2016Document9 pagesBelhadjltaief 2016Blessing HarvestNo ratings yet

- Nanosize and Bimodal Porous Polyoxotungstate-Anatase TiO2 Composites: Preparation and Photocatalytic Degradation of Organophosphorus Pesticide Using Visible-Light ExcitationDocument9 pagesNanosize and Bimodal Porous Polyoxotungstate-Anatase TiO2 Composites: Preparation and Photocatalytic Degradation of Organophosphorus Pesticide Using Visible-Light ExcitationLenin HuertaNo ratings yet

- Zhu 2012Document8 pagesZhu 2012AlissonNo ratings yet

- Journal of Physics and Chemistry of Solids: Trung-Dung Dang, Arghya Narayan Banerjee, Quang-Tung Tran, Sudipta RoyDocument9 pagesJournal of Physics and Chemistry of Solids: Trung-Dung Dang, Arghya Narayan Banerjee, Quang-Tung Tran, Sudipta RoymadalinaAMGNo ratings yet

- 978 3 0364 0443 1 - 300Document7 pages978 3 0364 0443 1 - 300Nova SeptiNo ratings yet

- Calcination Temperature Effect on Titanium Oxide (TiO2)Document27 pagesCalcination Temperature Effect on Titanium Oxide (TiO2)SaiFunNo ratings yet

- Photocatalytic Degradation of Methyl Orange Using Tio2/Sno2 Binary Nano CompositeDocument7 pagesPhotocatalytic Degradation of Methyl Orange Using Tio2/Sno2 Binary Nano CompositeasdaNo ratings yet

- Hydroxyl Radical RoleDocument10 pagesHydroxyl Radical RoleGRagaNo ratings yet

- Sac Ky Hat DieuDocument7 pagesSac Ky Hat DieuXuân BaNo ratings yet

- Photocatalytic Degradation of Dyes Over Cobalt DopedDocument6 pagesPhotocatalytic Degradation of Dyes Over Cobalt Dopedseranim22No ratings yet

- Journal of Photochemistry and Photobiology A: ChemistryDocument9 pagesJournal of Photochemistry and Photobiology A: ChemistryIntenNo ratings yet

- Enhanced Photodegradation of Methyl Orange With Tio2 Nanoparticles Using A Triboelectric NanogeneratorDocument7 pagesEnhanced Photodegradation of Methyl Orange With Tio2 Nanoparticles Using A Triboelectric NanogeneratorMasood KarimNo ratings yet

- Ag-doped TiO2 nanoparticles enhance photocatalysisDocument35 pagesAg-doped TiO2 nanoparticles enhance photocatalysisHugh MantaNo ratings yet

- Borges 2015Document12 pagesBorges 2015petru apopeiNo ratings yet

- Journal of Environmental Chemical Engineering: SciencedirectDocument9 pagesJournal of Environmental Chemical Engineering: SciencedirectmissaouiNo ratings yet

- Synthesis of Tio Nanoparticles by Chemical and Green Synthesis Methods and Their Multifaceted PropertiesDocument10 pagesSynthesis of Tio Nanoparticles by Chemical and Green Synthesis Methods and Their Multifaceted Propertiesastrox100zz.vnNo ratings yet

- Photocatalytic degradation of phenol using MWNT-titania compositesDocument8 pagesPhotocatalytic degradation of phenol using MWNT-titania compositesŞebnem Gül İlarslanNo ratings yet

- The Photocatalytic Application of Semiconductor STDocument10 pagesThe Photocatalytic Application of Semiconductor STShrabaniPaulNo ratings yet

- 1 s2.0 S0304389410015517 MainDocument9 pages1 s2.0 S0304389410015517 Mainpetru apopeiNo ratings yet

- Accepted Manuscript: Journal of Photochemistry and Photobiology A: ChemistryDocument39 pagesAccepted Manuscript: Journal of Photochemistry and Photobiology A: ChemistryYon tinyayaNo ratings yet

- Novel Removal of Diazinon Pesticide by AdsorptionDocument7 pagesNovel Removal of Diazinon Pesticide by AdsorptionAlissom GomesNo ratings yet

- Applsci 09 03282Document12 pagesApplsci 09 03282Rafif QuthronadaNo ratings yet

- Photocatalysis PaperDocument14 pagesPhotocatalysis PaperGoutham RNo ratings yet

- 19 - Chang2015, Photocatalytic Degradation of Acetaminophen in Aqueous Solutions byDocument8 pages19 - Chang2015, Photocatalytic Degradation of Acetaminophen in Aqueous Solutions byhellna284No ratings yet

- Beranek - 2012 - (Photo) Electrochemical Methods For The DeterminatiDocument21 pagesBeranek - 2012 - (Photo) Electrochemical Methods For The DeterminatielderwanNo ratings yet

- Kinetics of heterogeneous photocatalytic degradation of reactive dyesDocument6 pagesKinetics of heterogeneous photocatalytic degradation of reactive dyesLong HoàngNo ratings yet

- Improved Photoelectric Performance Via Fabricated Heterojunction g-C3N4 TiO2 HNTs Loaded Photocatalysts For Photodegradation of CiprofloxacinDocument45 pagesImproved Photoelectric Performance Via Fabricated Heterojunction g-C3N4 TiO2 HNTs Loaded Photocatalysts For Photodegradation of CiprofloxacinBachi NanoNo ratings yet

- Applied Catalysis B: EnvironmentalDocument6 pagesApplied Catalysis B: EnvironmentalAmir ChaNdiaNo ratings yet

- Molecules: Ffect of The Titanium Isopropoxide:AcetylacetoneDocument14 pagesMolecules: Ffect of The Titanium Isopropoxide:AcetylacetoneSasitharan MNo ratings yet

- tmp6E7F TMPDocument6 pagestmp6E7F TMPFrontiersNo ratings yet

- Falah 2016Document11 pagesFalah 2016Carlos AlarconNo ratings yet

- Synergetic Photocatalytic-Activity Enhancement of Lanthanum Doped TiO2 On Halloysite Nanocomposites For Degradation of Organic DyeDocument8 pagesSynergetic Photocatalytic-Activity Enhancement of Lanthanum Doped TiO2 On Halloysite Nanocomposites For Degradation of Organic DyeBachi NanoNo ratings yet

- Low-Temp Synthesis of Visible-Light Active BiOI/TiO2 HeterostructuresDocument8 pagesLow-Temp Synthesis of Visible-Light Active BiOI/TiO2 Heterostructuresnguyenhai2tNo ratings yet

- Journal Pre-Proof: Nano EnergyDocument33 pagesJournal Pre-Proof: Nano EnergyOussama El BouadiNo ratings yet

- Research Article: Preparation of Manganese Dioxide Nanoparticles On Laterite For Methylene Blue DegradationDocument10 pagesResearch Article: Preparation of Manganese Dioxide Nanoparticles On Laterite For Methylene Blue DegradationRamNo ratings yet

- Titanium Dioxide Film Based Photocatalytic Application For Degradation of DyesDocument21 pagesTitanium Dioxide Film Based Photocatalytic Application For Degradation of Dyes温洁胜No ratings yet

- TiO2/PET nanofibres for efficient photocatalytic degradationDocument6 pagesTiO2/PET nanofibres for efficient photocatalytic degradationedcr23No ratings yet

- UnknownDocument11 pagesUnknownradioactivepotatoNo ratings yet

- Photocatalytic and Electrochemical Combined Treatment of Textile Wash WaterDocument8 pagesPhotocatalytic and Electrochemical Combined Treatment of Textile Wash Waterapi-3828788No ratings yet

- Applsci 07 00049Document9 pagesApplsci 07 00049Thu Trang NguyenNo ratings yet

- Article: Dye Degradation Enhanced by Coupling Electrochemical Process and Heterogeneous PhotocatalysisDocument7 pagesArticle: Dye Degradation Enhanced by Coupling Electrochemical Process and Heterogeneous PhotocatalysisMariane Silva LopesNo ratings yet

- Photocatalytic Degradation of Methylene Blue Using Tio - Natural Zeolite As A PhotocatalystDocument8 pagesPhotocatalytic Degradation of Methylene Blue Using Tio - Natural Zeolite As A PhotocatalystVona Riski RamadaniNo ratings yet

- 607 SanjeevDocument13 pages607 SanjeevRITWIsNo ratings yet

- Catalysis Today: Raffaele Molinari, Angela Caruso, Teresa PoerioDocument6 pagesCatalysis Today: Raffaele Molinari, Angela Caruso, Teresa PoerioĐại HảiNo ratings yet

- Catalysts 03 00189 PDFDocument30 pagesCatalysts 03 00189 PDFKarel Sanchez HernandezNo ratings yet

- 1 s2.0 S0022286022011541 MainDocument14 pages1 s2.0 S0022286022011541 MainGUO YUNo ratings yet

- Crystals: The Investigation For Coating Method of Titanium Dioxide Layer in Perovskite Solar CellsDocument9 pagesCrystals: The Investigation For Coating Method of Titanium Dioxide Layer in Perovskite Solar CellsThanakrit SintiamNo ratings yet

- Quang XTDocument8 pagesQuang XTnguyengiaohungNo ratings yet

- 1-s2.0-S0926860X05003054-mainDocument11 pages1-s2.0-S0926860X05003054-mainŞebnem İlarslanNo ratings yet

- Effect of Doping Methods on Ag2O-TiO2 Nanofibers' PropertiesDocument5 pagesEffect of Doping Methods on Ag2O-TiO2 Nanofibers' PropertiesChemist.AlchemistNo ratings yet

- Pesticide 1Document6 pagesPesticide 1narenNo ratings yet

- Preparation and Integration of Nanostructured Titanium DioxideDocument7 pagesPreparation and Integration of Nanostructured Titanium DioxideriteshgajareNo ratings yet

- 08-05-2019 PDFDocument4 pages08-05-2019 PDFpatel_smitNo ratings yet

- Substitution SummeryDocument2 pagesSubstitution SummerySiddarth SinghNo ratings yet

- 1 2041 1 20-11-2019-Gad PDFDocument3 pages1 2041 1 20-11-2019-Gad PDFpatel_smitNo ratings yet

- 5 ...Document2 pages5 ...patel_smitNo ratings yet

- Paper-1 (CHN 401) Inorganic ChemistryDocument1 pagePaper-1 (CHN 401) Inorganic Chemistrypatel_smitNo ratings yet

- Compendium Prohibition RegulationsDocument8 pagesCompendium Prohibition RegulationsChakkara VarthyNo ratings yet

- CH 11 Solutions Meissler PDFDocument12 pagesCH 11 Solutions Meissler PDFFerdinand Tamayo Cayabyab Jr.0% (1)

- Quality ImprovementDocument4 pagesQuality Improvementpatel_smitNo ratings yet

- 001 Shrimad Bhagwat Geeta Arth Sahit GujratiDocument101 pages001 Shrimad Bhagwat Geeta Arth Sahit Gujratipatel_smitNo ratings yet

- MF3010 QRG Multi R PDFDocument2 pagesMF3010 QRG Multi R PDFpatel_smitNo ratings yet

- VVPAT Inst 24092014Document16 pagesVVPAT Inst 24092014patel_smitNo ratings yet

- Group Theory, Spectroscopy Methods for ChemistryDocument2 pagesGroup Theory, Spectroscopy Methods for Chemistrypatel_smitNo ratings yet

- Food Categorization CodeDocument7 pagesFood Categorization CodeKalai Ponmani Kalaimughilan100% (1)

- Handbook FOR Presiding Officers: (For The Conduct of Panchayat Elections)Document55 pagesHandbook FOR Presiding Officers: (For The Conduct of Panchayat Elections)patel_smitNo ratings yet

- Mf-Inst EngDocument20 pagesMf-Inst EngthathaishaNo ratings yet

- 1 s2.0 S1877042815004656 MainDocument5 pages1 s2.0 S1877042815004656 Mainpatel_smitNo ratings yet

- Photocatalytic Degradation of Monoazo and Diazo Dyes in WastewaterDocument20 pagesPhotocatalytic Degradation of Monoazo and Diazo Dyes in Wastewaterpatel_smitNo ratings yet

- Gujarat Right To Information Rules-2010-GujaratiDocument11 pagesGujarat Right To Information Rules-2010-GujaratidrmanwishNo ratings yet

- Photocatalytic Degradation of Monoazo and Diazo Dyes in WastewaterDocument20 pagesPhotocatalytic Degradation of Monoazo and Diazo Dyes in Wastewaterpatel_smitNo ratings yet

- RTO Gujarati 08-06-2014 Question PaperDocument6 pagesRTO Gujarati 08-06-2014 Question Paperpatel_smitNo ratings yet

- Gujarat Right To Information Rules-2010-GujaratiDocument11 pagesGujarat Right To Information Rules-2010-GujaratidrmanwishNo ratings yet

- Science Exhibition Planning 1Document3 pagesScience Exhibition Planning 1patel_smitNo ratings yet

- Alankar ChhandDocument7 pagesAlankar Chhandpatel_smitNo ratings yet

- How To Write Your PHD ProposalDocument5 pagesHow To Write Your PHD Proposalcukey13No ratings yet

- ChaosDocument7 pagesChaospatel_smitNo ratings yet

- 63Document9 pages63patel_smitNo ratings yet

- 50 Math IdeasDocument1 page50 Math IdeasAdrian Cervantes LomelíNo ratings yet

- Introduction To ACD Version 12 NMR SoftwareDocument13 pagesIntroduction To ACD Version 12 NMR Softwarepatel_smitNo ratings yet

- CourseDocument3 pagesCoursepatel_smitNo ratings yet

- Additive Manufacturing For 3-Dimensional (3D) Structures: (Emphasis On 3D Printing)Document153 pagesAdditive Manufacturing For 3-Dimensional (3D) Structures: (Emphasis On 3D Printing)mohammadmehrabi9640No ratings yet

- Mp-Filtri Low and Medium Pressure Filters Hydraulic-Filters en Low-Medium Pressure 10-2017Document156 pagesMp-Filtri Low and Medium Pressure Filters Hydraulic-Filters en Low-Medium Pressure 10-2017Sergiy SydorenkoNo ratings yet

- Mastertop 1230i M 12-04Document3 pagesMastertop 1230i M 12-04djrote4No ratings yet

- GATIC Galvanised Mild Steel GMS Grating Data SheetDocument3 pagesGATIC Galvanised Mild Steel GMS Grating Data Sheetiask5275No ratings yet

- Drying Shrinkage of ConcreteDocument6 pagesDrying Shrinkage of Concretecrownguard100% (1)

- GBDocument6 pagesGBNandor KermeciNo ratings yet

- Gold AlloysDocument16 pagesGold AlloyscoldmailhotmailNo ratings yet

- MSDS G12Document4 pagesMSDS G12JayNo ratings yet

- Materials Question PackDocument20 pagesMaterials Question PackSuper Dila12No ratings yet

- Sno Pro Diagnostic Troubleshooting Guide 72 520 1Document72 pagesSno Pro Diagnostic Troubleshooting Guide 72 520 1papamatt100% (1)

- YOKOGAWA Exa Fc400g (Ing)Document91 pagesYOKOGAWA Exa Fc400g (Ing)biotech666No ratings yet

- Song Chuan - 201191911194279049-1203708Document7 pagesSong Chuan - 201191911194279049-1203708Braian Cabañas Visca BarçaNo ratings yet

- 3M Prestige 70 Exterior PBDocument3 pages3M Prestige 70 Exterior PBDiego Ramirez FuentesNo ratings yet

- PIPE Elements 4 NIDocument88 pagesPIPE Elements 4 NIJd MagtibayNo ratings yet

- Retrofilling Aging Transformers With Natural Ester Based Dielectric Coolant For Safety and Life ExtensionDocument7 pagesRetrofilling Aging Transformers With Natural Ester Based Dielectric Coolant For Safety and Life Extension王阳No ratings yet

- 5-Speed Manual Transmission Parts and SpecificationsDocument24 pages5-Speed Manual Transmission Parts and SpecificationsAhmad Taha ZakiNo ratings yet

- TDS - Superfloc A-100 - ENDocument2 pagesTDS - Superfloc A-100 - ENFrank George Sandoval ParedesNo ratings yet

- Food Process EngineeringDocument9 pagesFood Process Engineeringvineeth vipparthiNo ratings yet

- Basement ConstructionDocument12 pagesBasement Constructionfgfghhffgh100% (2)

- QIS College Engineering & Tech Session Plan Metal CuttingDocument13 pagesQIS College Engineering & Tech Session Plan Metal CuttingKalai ArasanNo ratings yet

- DistillationDocument15 pagesDistillationRahul PalsNo ratings yet

- Brochure Steam AccumulatorDocument2 pagesBrochure Steam AccumulatorFrank HuNo ratings yet

- Guide To The Layout Requirements For A Commercial Laundry Room PDFDocument11 pagesGuide To The Layout Requirements For A Commercial Laundry Room PDFTueNo ratings yet

- Phase Transitions: Lectures in Physical Chemistry 4Document8 pagesPhase Transitions: Lectures in Physical Chemistry 4Farah AnjumNo ratings yet

- Properties of SteamDocument27 pagesProperties of SteamVishal DhimanNo ratings yet

- ASHRAE Recommend 2 PDFDocument6 pagesASHRAE Recommend 2 PDFAhmed LabibNo ratings yet

- Material SpecificationDocument9 pagesMaterial SpecificationMuthu GaneshNo ratings yet

- VT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & CirculatorsDocument4 pagesVT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & Circulatorshamdi gshNo ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Perfume Engineering: Design, Performance and ClassificationFrom EverandPerfume Engineering: Design, Performance and ClassificationRating: 4 out of 5 stars4/5 (5)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisFrom EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet