Professional Documents

Culture Documents

MTU Rail GB Low PDF

Uploaded by

alvaror320Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MTU Rail GB Low PDF

Uploaded by

alvaror320Copyright:

Available Formats

A TOGNUM GROUP BRAND

Power. Passion. Partnership.

We move you.

With experience and

innovation.

Rail

Contents

I A CUSTOMER-ORIENTED

TECHNOLOGICAL LEADER

II PUTTING PROGRESS ON TRACK

8 Drive Solutions for Railcars

10 Drive Solutions for Multiple-Unit

Trains and High-Speed Trains

12 Drive Solutions for Mainline and

Multipurpose Locomotives

14 Drive Solutions for Shunting and

Industrial Locomotives

16 Drive Solutions for Special Purpose

Vehicles

III MTU POWERPACKS

AND ENGINES

20 System Expertise and System

Integration

22 MTU PowerPack

26 Series 4000

30 Repowering Solutions

IV AUTOMATION SYSTEMS

34 Powerline Managing Your Trains

Drive System

36 CaPoS Capacitor Power System

V MTU_VALUE CARE

40 MTU_Value Service

42 MTU_Value Spares

MTU_Value Exchange

44 MTU Worldwide

VI CERTIFIED QUALITY

We move you. With experience and innovation. I Rail I 3

I

1 2

3

1 Technological leader

As a supplier of high-quality, performance propulsion solutions, MTU stands

for the highest level of technological expertise.

2 Passion

MTU is passionate about fullling the needs of its customers with the utmost

professionalism and precision.

3 Partnership

MTU is a reliable and trend-setting partner which acts with foresight in

a results-oriented manner.

MTU is one of the Tognum Groups agship

brands

With its two business units Engines and

Onsite Energy and Components the Tognum

Group is one of the worlds leading suppliers of

engines, propulsion systems and distributed

energy systems. These products are based on

diesel engines up to 9100 kW (12203 bhp),

gas engines up to 2150 kW (2883 bhp) of

power and gas turbines with up to 50000 kW

(67050 bhp).

The Engines business units product range

is comprised of MTU engines and propulsion

systems for marine vessels, heavy land, rail

and military vehicles and for the oil and gas

industry.

The Onsite Energy and Components business

units product portfolio comprises MTU Onsite

Energy distributed energy systems as well as

components for engines and propulsion systems.

The energy systems consist of diesel engines

for emergency power generation, including base

and peak load, as well as cogeneration power

plants gas engines, fuel cells and gas turbines

that generate both electri city and heat.

An expert technological leader

Since its founding, MTU has set standards in

technological expertise, innovative ideas, and

customized product and systems solutions. At

MTU, research is a tradition. We concentrate

our innovation on the systematic advancement

of our core competencies in the areas of fuel

injection, turbo charging, and automation right

from the start.

A passionate engine specialist

We spend every day working with our customers

to nd the propulsion systems that best ts

their needs. Whether a standard system or a

customized solution we passionately assume

responsibility in the art of engine building.

A reliable partner

We understand the specic requirements for

diverse applications. In collaboration with our

customers we look for the propulsion solution

which is best suited to the individual require-

ments. Regardless of which propulsion system

is selected, our top-quality automation can be

completely integrated into almost any area of

application.

A customer-oriented

technological leader.

MTU supplies its customers with technologically

advanced premium products that are proven in the eld.

MTUs range of services for off-highway diesel engines is

extensive from standard to customized solutions.

We move you. With experience and innovation. I Rail I 5

II

2 1

Rail

Putting progress on track.

Over the course of their lifetime, trains cover

immeasurable distances, carry people and goods,

bring support and ensure mobility. They move us,

and we move them. Our engines and drive sy-

stems make rail transportation powerful, reliable

and safe.

Back in 1924, standard engines developed and

manufactured by MTU were already being used in

rail transportation and, since 1950, we have

supplied more than 16,500 engines as drive units

and power generation units for railcars all over

the world. Time and time again, over hundreds of

millions of kilometers of rail, they have proven

their absolute reliability, high operational availabi-

lity and exceptional economic efciency. They

also incorporate the very latest in environmental

technology and have the potential to meet future

requirements.

These many years of experience, coupled with a

unique level of expertise accumulated over de-

cades, form the basis of our innovative strength

and acknowledged systems capabilities. Loco-

motive and railcar manufacturers all over the

world rely on us as their industrial partner.

With MTU_ValueCare we offer a comprehensive

portfolio of service products that ensure the

optimum running and value retention of our drive

systems over the long term. Our service network

is at your disposal all over the world: always and

everywhere.

All our products and services continue to set new

standards. Such consistently high levels of quality

are also reected in our leading status in certi-

cations: MTU is the rst diesel engine manufac-

turer in the world to have received International

Railway Industry Standard (IRIS) certication.

1 Looking back

In 1933 our diesel engines powered the legendary

Flying Hamburger to 160 km/h, a revolutionary speed

at that time.

2 State of the art

MTU rail engines are reliable, powerful and eco-friendly

drive units found in many of todays high-speed trains

and many other rail vehicles.

Increasing demand for local public transportation brings with it an

ongoing need for modern railcars with the latest drive system tech-

nology. MTU as the experienced specialist provides the drive

systems to support eco-friendly trafc designs.

The innovative MTU Rail PowerPacks meet all the requirements of

this high-performance sector, which demands far more than simply a

powerful engine. Our extremely compact, complete systems are

congured to suit individual customer needs and can then be inte-

grated into the vehicle in a quick and easy process, using Plug&Play.

The high level of reliability of our drive systems ensures that trains

can run on time and that operations keep running smoothly a key

factor in economic success. In addition, low operating costs and fuel

consumption gures, long maintenance intervals and a maintenance-

friendly design all help keep operating costs down and further improve

efciency.

Drive Solutions for Railcars

Improvements in performance,

efciency, and trust.

All on track.

We move you. With experience and innovation. I Rail I 9

Multiple-unit trains require top-level performance over a long period,

maximum operational availa bility and uncompromising economic

efciency. For this reason manufacturers and rail operators have

depended on MTUs Series 4000 rail drive systems for many years.

For high-speed trains in particular, which are playing an increasingly

major role on national and international routes, the advantages of

MTU engines come into their own. Extremely powerful and proven in

continuous service, our drive systems demonstrate an excellent

power-to-weight ratio and outstanding operational availability, en-

abling them to deliver the reliability, punctuality and safety expected

from these high-tech trains.

A worldwide service network and on-site facilities at railway depots

ensure optimum levels of support and minimum downtime.

Drive Solutions for Multiple-Unit Trains and High-Speed Trains

Travel at speed.

Arrive on time.

10 I Rail I We move you. With experience and innovation.

MTU drive systems for mainline and multipurpose locomotives

operate in a wide variety of conditions and are always custom-

made to suit their specic areas of activity.

They are in continuous use, day after day, and prove their reliability

on every continent and over thousands of kilometers. They prove

their worth in heavy goods operations just as much as at high

speeds on long-haul passenger routes.

Long maintenance intervals, maintenance-friendly design and low

specic consumption gures all contribute to keeping overall life

cycle costs low and are thus important factors in the economically

efcient running of rail vehicles.

As a system supplier, MTU is also, upon request, able to integrate

the train power supply (electricity supply, air-conditioning, lighting,

etc.) into the overall system.

MTUs worldwide service network and local railroad depots give

rail operators the highest possible level of condence: fast and

competent support minimizes unproductive downtime and ensures

uninterrupted operational availability of rolling stock.

Drive Solutions for Mainline and Multipurpose Locomotives

Reliability in motion.

We move you. With experience and innovation. I Rail I 13

Shunting and industrial locomotives are true workhorses. Their specialized area of opera-

tion involves frequent load changes in all part-load operations and long periods spent in

low-load operations. This gives rise to very specic demands on the drive system, which

MTU engines meet with ease thanks to their excellent part-load per formance and accel-

eration characteristics.

Our robust and powerful engines prove their reliability one of the key factors in all rail

applications thousands of times every day. And since the smooth running of overall

railroad operations depends to a considerable extent on the reliable functioning of

shunting and industrial locomotives, our drive systems clearly have an important eco-

nomic role to play. Long maintenance intervals and low specic fuel consumption gures

are further arguments that convince operators of the efciency of our engines.

And wherever your eet may be: were not far away. Our worldwide service network will

ensure that rolling stock powered by our engines is always ready to go and to operate

under even the toughest of conditions.

Drive Solutions for Shunting and Industrial Locomotives

Versatile power.

Reliable operation.

14 I Rail I We move you. With experience and innovation.

2

4

3

1

To keep railroad operations running smoothly at all times, a range of

special rail vehicles provides supporting services. For these special-

purpose vehicles, we provide custom-made drive solutions.

Low exhaust emissions make MTU drive systems ideal for use in a range

of special-purpose vehicles such as tunnel servicing and maintenance

locomotives used for construction or repair work in places like subway

systems. A choice of diesel-electric, diesel-mechanical and diesel-

hydraulic drive versions is available.

We also offer diesel-hydrostatic drive systems for construction-work and

other special vehicles that operate at extremely low speed.

Whichever you choose, all our engines come with the uncompromising

levels of reliability, availability and economic-efciency you need.

As an industrial specialist, we offer the complete engineering package for

every drive solution, from the project concept phase through to installa

tion. Throughout the entire operating life of our engines, our service net-

work and local rail depots will provide professional support: anytime,

anywhere.

Drive Solutions for Special Purpose Vehicles

Individual drive solutions for

extraordinary requirements.

1 Fire ghting and rescue train

2 Grinding train

3 Snow plow

4 Our experts develop the best solution for your requirements.

We move you. With experience and innovation. I Rail I 17

III

MTU PowerPacks and Engines

We move you.

With experience and innovation.

MTU railroad engines and PowerPacks set the benchmark for what

diesel drive systems must deliver in this demanding sector. Their

uncompromising operational availability ensures that railroad ope-

rations run with absolute reliability, while their excep tional efcien-

cy is a key factor in the economic success of railroad operators.

The very latest MTU emissions technologies also ensure that our

railroad engines are among the cleanest drive systems in the world.

Systems like these, that treat natural resources with respect and

already meet future emissions standards, help us ensure that we

meet our social responsibilities as an engine manufacturer.

1

2

System Expertise and System Integration

We develop the system

to deliver your success.

A conventional drive system made up of individual

components or an MTU PowerPack: as an expe-

rienced system supplier we design and deliver indi-

vi dualized complete solutions, tailor-made to suit a

specic application, a broad range of needs, and all

associated conditions and requirements.

At the heart of what we do is always the engine.

A choice of underoor or engine room installation,

low weight and compact installation dimensions

make MTU diesel engines the best solu tion for drive

systems in railroad vehicles.

The high exibility of the system conguration makes

the engines suitable for use in diesel-electric, diesel-

mechanical or diesel-hydraulic drive units. This means

that complete drive systems can be individually tted.

A wide range of accessories is also available, to suit

your requirements; and all of these meet the same

high quality standards as the engine itself. Such items

ensure simple integration at all interface points as well

as the functionality of required special features.

The high standard of our comprehensive engineering

expertise is just as convincing. During the design

phase of individual drive solutions, our Competence

Center Rail, as we call it, will provide you with a level

of expertise that is unique, anywhere in the world.

No other company can offer more experience or more

solid references. No one knows and understands your

requirements better. And no company except MTU

has been able to con sistently offer the complete

package of capabilities that is necessary for the devel-

opment of complete customer-specic solutions from

one source.

Take advantage of our expertise.

1 Conventional railroad drive systems

Comprised of a series of individual components. The foundation of each is our Series 4000 engines.

In each case we design and supply an individual system solution.

2 MTU PowerPacks

Complete, proven drive systems for your rail vehicles.

Here, too, we provide the solution that best suits your special requirements.

We move you. With experience and innovation. I Rail I 21

MTU

PowerPack

Series 1800

Engine model 6H 1800R

Cylinders 6 / in-line

Power output kW 315 335 360 390

bhp 422 449 483 523

Drive systems

1)

DM DM DM/DH DH/DE

Speed rpm 1800

Emissions certication EU IIIA / EPA Tier 3

EU IIIB / EPA Tier 4i

1)

Drive systems:

DM = diesel-mechanical

DH = diesel-hydraulic

DE = diesel-electric

We move you. With experience and innovation. I Rail I 23

1 2

1

2

3

4

5

6

7

8

9

The MTU PowerPack

:

Compact. Complete. Efcient.

The MTU PowerPack is an innovative drive system that combines all

the individual system elements into a single functional unit mounted on

a supporting frame. This system is specially designed for underoor in-

stallation and is characterized by its particularly at design. We are the

only manufacturer to offer all three types of power transfer: Diesel-

electric, diesel-mechanical and diesel-hydraulic. Every MTU PowerPack

can be individually congured.

Features

Responsibility for the design and performance of the traction system

as a whole stays in one place. A single supplier is responsible for all

elements of the drive system; and a single partner is in charge of

service and logistics from the project initiation phase through to the

nal handover inspection.

Interfaces are reduced to the most extreme system limits of the Power-

Pack. This means that the complete system has been coordinated and

tested by MTU well before it is installed in the vehicle.

The Plug&Play conguration makes installation and removal of the unit

quick and easy also for maintenance purposes. Your trains are sure

to run on time.

The installation of a PowerPack makes standardization possible and

reduces complexity. This leads to better cost-effectiveness than

through the use of individual components.

The compact arrangement of the components reduces the total weight

of the PowerPack.

An electronic control system monitors, controls and regulates all

functions.

For test purposes, it is possible to run the full drive system outside of

the vehicle even under load.

The technology for eco-friendly drive systems:

We take responsibility for technology also in the interests of protec-

ting the environment: our PowerPacks meet all current legislative

requirements, while we also already have the solutions to enable us to

meet the next level of emissions standards.

We meet the international and European standards UIC II, UIC III,

EU 97/68 EC, EU Stage IIIA, and the future EU Stage IIIB, with proven

technologies, e.g. through an optimized combustion process that uses

the Miller cycle to reduce NOx emissions.

Further features of the PowerPacks are their low particulate emissions

and reduced levels of noise and vibration.

In line with the special demands made upon our PowerPacks, we are

now already in a position to meet future emissions requirements.

In this particular area we are able to use SCR technology to provide the

appropriate solution to meet Stage IIIB requirements. Selective Cata-

lytic Reduction technology (SCR) involves the targeted aftertreatment

of the exhaust gas to convert nitrogen oxides (NOx) to harmless, natu-

rally occurring air components.

The MTU PowerPack

offers:

Scope for individual conguration; exible and standardized interface

solutions

Low operating costs

High performance efciency

Lowest fuel consumption

Minimal exhaust emissions

Long service life and excellent reliability

Simple maintenance

High level of availability

Minimal resource requirement thanks to Plug & Play

1 The SAM automation module is integrated into the PowerPack

and

provides an electronic interface to the central railcar control system.

It allows for simple integration into new or, in the case of rets,

existing vehicle control systems. Thanks to an integrated safety

system, outputs are automatically adjusted or triggers an engine shut-

off. The integrated load management system automatically identies

the optimum traction setting.

2 MTU PowerPack

the highly compact, highly integrated solution

1 Frame

2 Diesel engine

3 Air conditioning compressor

4 On-board power generator

5 Brake air compressor

6 Cooling unit

7 Power shift transmission

8 Urea tank

9 Exhaust catalyst with mufer

Representation of a PowerPack 6H1800 with SCR technology

(EU Stage IIIB / EPA Tier 4i)

We have developed a series of individualized solutions involving a range of

different frames and will use our extensive experience to nd the appropriate

solution to suit the requirements of any specic vehicle.

24 I Rail I We move you. With experience and innovation. We move you. With experience and innovation. I Rail I 25

Series 4000

Series 4000

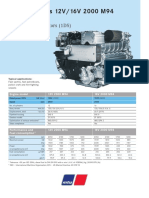

Engine model 4000 R41

Cylinders 8V 12V 16V

Power output kW 850 1100 1380 1650 1700 2200

bhp 1140 1475 1851 2213 2280 2950

Speed rpm 1500 1860

Emissions certication UIC II

Series 4000

Engine model 4000 R43

Cylinders 8V 12V 16V 20V

Power output kW 1000 1200 1500 1800 2000 2400 2700 3000

bhp 1341 1609 2012 2414 2682 3218 3621 4023

Speed rpm 1800

Emissions certication EU Stage IIIA / UIC IIIA

Series 4000

Engine model 4000 R33

Cylinders 8V 12V

Power output kW 1680 2240

bhp 2253 3004

Speed rpm 1800

Emissions certication EPA Tier 2 (40 CFR 92)

Series 4000

Engine model 4000 R64 4000 R74 4000 R84

Cylinders 12V 16V 16V 12V 16V

Power output kW 1500 2000 2200 1800 2400

bhp 2012 2682 2950 2414 3218

Speed rpm 1800

Emissions certication EU Stage IIIB / UIC IIIA

Available January 2012

Series 4000-04 engines portfolio meeting

EU Stage IIIB / UIC IIIA will be completed

with 8V / 20V models.

We move you. With experience and innovation. I Rail I 27

Series 4000:

The engine driving

your success.

The new generation Series 4000 engines comes with innovative

MTU emissions technology to meet the most stringent emission

standards, to protect the environment.

Our emissions technology of the new generation Series 4000-04

at a glance:

In-engine technologies

Exhaust gas recirculation

Common Rail injection

2-stage charging

Advanced Diesel Engine Control system (ADEC)

Aftertreatment technology

Diesel particle lter

For over 15 years, MTU Series 4000 engines have been the preferred

drive systems for modern locomotives. Over hundreds of millions of kilo-

meters of rail travel, these engines have set the benchmark for what a

high-performance railroad system needs to deliver in this day and age.

Absolute reliability. Maximum operational availability. Uncompromising

economic efciency.

Lower emissions, combined with lower weight, reduced fuel consumption

and improved overall economic efciency this is the speciality of engine

construction at MTU, developed on the basis of the very real demands of

everyday railway operations. It is a skill in engine construction that is

perfectly embodied by the Series 4000. It brings together our expertise in

all the important key technologies. It represents the mani festation of our

ambition to offer you the system solution best suited to your needs. And

with it comes as you would expect from MTU engines far more than

just a technological solution. It comes with all that you need for further

success in your particular sector. Today and in the future.

The current Series 4000 in overview:

Cylinder variants 8V, 12V, 16V, 20V

Common Rail injection system

LEAD injectors with individual reservoir

High-pressure in-line pump

Optimum charging due to MTU exhaust gas turbocharger

High charge pressures lead to increased power yield and reduced

particulate emissions

High efciency for low fuel consumption

Optimized combustion process

Reduction of NOx due to Miller cycle at optimal fuel consumption

ADEC electronics (engine control system)

Robust MTU electronics, perfectly matched to the engines

Advanced technology for environmental friendliness

the new generation: Series 4000-04

The new Series 4000 engines with our emissions technology represent

the next generation of an engine series that has been proven thousands

of times over. Designed to meet the upcoming stringent European

emission standards EU Stage IIIB that come into effect 1.1.2012, the

new generation Series 4000 is very compact, powerful and extremely

economical.

Our innovative emissions technology meeting EU Stage IIIB is based on

both in-engine and aftertreatment solutions.

In-engine technologies minimize the generation of pollutants during

combustion:

Cooled exhaust gas recirculation

LEAD

2

injection system up to 2200 bar

2-stage regulated charging, 3 turbochargers, intercooling

NOx-optimized valve control (Miller cycle)

New low-NOx, low-soot combustion process

Max. cylinder pressure 220

+10

bar

Advanced Diesel Engine Control system (ADEC) with emissions

regulation

The aftertreatment technology eliminates over 90% of particulate

emissions through use of an diesel particle lter with passive regene-

ration.

28 I Rail I We move you. With experience and innovation.

1 3

2

Our expertise as your industrial partner means that MTU will not only

provide the engines to be repowered but will also deliver a comprehen-

sive package of support services:

Design phase through implementation of the drive system; active

support and professional engineering through all stages of the re-

powering project

Supply of the very latest, extensively proven engines and PowerPacks

with the compact dimensions that make them simple to mount in the

available space, and with an excellent power-to-weight ratio that makes

the installation of higher outputs possible without permissible axle

loads being exceeded.

Following the conversion, the reduced operating costs bring the following

potential savings for the operator:

Reduction in fuel costs, also in the part-load range and at idling speed

Limited downtime thanks to high availability and high reliability

Lower investment costs through reducing reserve locomotive stock

Long maintenance intervals and minimal maintenance costs thanks to

new maintenance concept

Legal requirements are met with well-proven combustion technology;

low fuel and oil consumption lead to low pollutant emissions and thus

high regard for the environment

After reconditioning and repowering, tried and tested locomotives and rail-

cars can be a genuinely economical alternative to placing a new order

with four positive effects:

The use of a modern MTU diesel engine reduces operating and mainte-

nance costs, maximizing the economic benets to the operator.

All legally stipulated exhaust gas emission standards are met. Noise

emissions are also signicantly reduced.

The availability and reliability of the vehicles are brought up to the level

of a new vehicle.

The cost of investment is considerably lower than if a new vehicle were

purchased.

Repowering Solutions

New heart.

New life.

1 Repowering is an economical alternative for a broad variety of

rail applications.

2 We care for a smooth repowering process: with excellent

support and quality.

3 Trains repowered with MTU engines run worldwide safe

and reli able.

30 I Rail I We move you. With experience and innovation. We move you. With experience and innovation. I Rail I 31

IV

Powerful engines alone will not meet the many technical demands

made of all these many different rail vehicles. Maximizing efciency,

reliability and environmental compatibility is about more than just

power. This is why sophisticated automation systems take on the

control, regulation and monitoring of the engine functions.

MTU automation systems feature a modular design, making inte-

gration simple, and are based on intelligent data bus technology.

Automation Systems

Intelligent automation

for optimum operations.

powerline Managing Your Trains Drive System

Everything under control.

powerline MTUs automation system for train drive units represents a

step into a whole new future of technology for rail vehicles.

Even with only the basic components ADEC, POM and PAU, the

powerline automation system makes the integration of the engine into

the locomotive a simple process. POM, like ADEC, is an electronic module

mounted permanently to the engine. Control, regulation and monitoring

are all part of the package that MTU delivers. With the help of optimized

interface technology, the engine is quick and easy to install.

powerline for new locomotives or repowering

with Series 4000 R41/R43/ R04

PAU Engine (Power Automation Unit)

Module for the monitoring, control and system integration of peripheral

engine components, with the following features:

Stand-alone component with (redundant) CAN open interface to

vehicle control system

Transfer of all engine-related operational data including diagnostics to

the vehicle control system

Additional monitoring and control of peripheral engine systems

Coolant level monitoring

Charge air preheating

Fuel pump actuation

Air lter monitoring

Integrated safety functions

Data output for fuel consumption indicator

Ethernet diagnosis interface (e.g. service laptop)

Fault ring buffer

Cooling fan regulation

MDEC / ADEC engine control systems

The engine control systems

MDEC (MTU Diesel Engine Control) for Series 4000 R41

ADEC (Advanced Diesel Engine Control) for Series 4000 R43/R04

are systems that have been developed and produced by MTU specically

for use with the very latest high-performance diesel engine technology

designed not only for full control of the Common Rail technology in the

Series 4000, but above all for the management of frequent extreme loads

and sudden load changes, which can be overcome effortlessly and

smoothly using this system.

The most important features at a glance:

Component mounted on and wired into the engine

Integrated control and monitoring system

Fuel-optimized output regulation

Integrated safety and self-test system

Data bus interface

POM (Power Output Module) for Series 4000 R43/R04

Module with actuating function for the starter motor and alternator, with

the following features:

Component mounted on the engine

Starter relay and other conventional power routing not required

Optimization of start-up process; starter motor monitoring with

engaging function

Alternator function monitoring

Line break and short circuit monitoring

Battery voltage monitoring with start-up intervention plus status indi-

cation and error report function

ADEC and POM linked via CAN data bus

Fully automated start-up control with ADEC

powerline additional module for repowering of diesel-electric

locomotive drive systems

PAU Traction (Power Automation Unit)

Module for the monitoring, control, regulation and system integration of

the traction generator and rectier, with the following features:

For drive systems with direct-current series-wound engines

Optimized output regulation, congured for the diesel engine

Generator, rectier and vehicle engine monitoring

Field weakening control for vehicle engine

Wheel-slip protection

Integrated safety functions (e.g. power shut-off)

Ethernet interface (e.g. service laptop)

Internal fault ring buffer

Locomotive safety functions

Specication includes current and voltage transformers plus amplier

for generator excitation

powerline

for Series 4000

ADEC = Advanced Diesel Engine Control

MDEC = MTU Diesel Engine Control

PAU = Power Automation Unit

POM = Power Output Module

Series 4000 R41 Series 4000 R43/R04

Starter motor

Alternator

Peripheral engine

components

Fuel pump

Cooling fan

Coolant level switch

Starter motor

Alternator

MTU amplier

Generator excitation

Traction generator

MTU

Voltage transformer +

current transformer

MTU powerline PAU Engine

for new locomotives or repowering

with Series 4000 R41/R43/R04

MTU powerline PAU Traction

for repowering of diesel-electric locomotives

Cab

Vehicle control system

PAU Engine

MDEC ADEC

POM

PAU Traction

+

+

24V battery

or

MTU CaPoS

starter system

24V battery

or

MTU CaPoS

starter system

34 I Rail I We move you. With experience and innovation.

CaPoS Capacitor Power System for Series 4000

Innovation right from the start.

CaPoS is an innovative UltraCap voltage supply system which obviates the need for conventional starter batteries in

railroad applications.

CaPoS uses capacitor technology to optimize startup behavior. The number of UltraCap modules to be used depends on the

type of engine involved and its breakaway torque. CaPoS may be used autonomously or in conjunction with the powerline

automation system.

The most important features at a glance:

Autonomous and modular construction

Maintenance-free system

Signicant reductions in weight and volume compared with conventional starter batteries

Optimized cold-starting properties

Low life-cycle costs

No voltage interruption during start-up

On-board voltage of 16V 154V possible

Integrated self-monitoring system with interface to vehicle control system

Series 4000 R41 Series 4000 R43/R04

CaPoS

for new locomotives or repowering

Cab

Vehicle control system

Loksteuerung

MDEC ADEC

POM Starter motor Starter motor

On-Board

battery

Voltage transformer

(DC/DC)

UltraCap

module

1

UltraCap

module

4

CaPoS

CaPoS

for Series 4000

Depending on engine, use of between

1 to 4 UltraCap modules

CaPoS for the 12V 4000

We move you. With experience and innovation. I Rail I 37

V

MTU_ValueCare

Superior service for

long engine life

and top performance.

Purchasing an MTU engine or system pays off in many ways: not just by

its performance and reliability, but also because of the security you will

get from our superior service MTU_ValueCare.

We are committed to offering the best services

and maintenance solutions. With that as our

goal, we offer you a portfolio of services above

and beyond the technology itself. They are

per fectly developed for your MTU engines and

systems, helping to maximize their availa bility

and efciency.

MTU_ValueCare is an unparalleled portfolio

of value-enhancing products and services indi -

vidually tailored to your specications.

Leave it to us to care.

The three main product lines of

MTU_ValueCare are:

MTU_ValueService

Professional maintenance, training, docu-

mentation and repair solutions from the

global MTU service network.

MTU_ValueSpares

Genuine MTU spare parts and top quality

consumables to ensure the continued peak

performance of your MTU engines and

systems.

MTU_ValueExchange

Remanufactured engines and parts with the

appearance, performance and life expect-

ancy of new goods, meeting the same

performance requirements and enjoying

warranties similar or identical to equivalent

new goods.

Your partner for the long term

Our commitment to you doesnt end with the

commissioning of your MTU engines and

systems. As a service partner, we will remain at

your side for as long as you continue to use our

product. The long term, optimized management

of your engines by MTU guarantees high availa-

bility and reliability, and with that, the efciency

you need.

Benets of our product line:

Experienced engine and electronics specia-

lists help during installation, commissioning

and any other time.

MTU service on location, around the world

Flexible preventive and customized mainte-

nance solutions.

MTU Overhaul service is available and can be

completed at one of our many locations

around the world .

Quick, reliable and global supply of genuine

MTU spare parts, maintenance products and

tools.

We move you. With experience and innovation. I Rail I 39

1

MTU_ValueService

Greater performance.

Greater value. Greater success.

MTU_ValueService encompasses solutions for

maintenance, training, documentation and

repairs, all tailored by MTUs global service

network to meet your needs.

Maintenance solutions

MTU offers professional maintenance solutions

to meet your requirements.

The reliability and skilled expertise behind

MTU_ValueService is an essential part of being

able to maintain the performance of your MTU

engines and systems at a consistently high level

around the globe, around the clock. MTU is

your service partner, offering you maintenance

solutions to meet your very special require-

ments, wherever you are in the world.

MTU Customized Care maintenance and

repair services make it possible to plan the

necessary maintenance work as well as your

budget throughout the operational life of your

engines. You have the choice of entering into

a full maintenance contract, which includes

both preventive and corrective maintenance,

or you may decide to go for a straightforward

preventive maintenance contract.

Selecting one of these options will help safe-

guard the maximum availability of your drive

system.

Details, conditions and intervals of each MTU

Customized Care product are adapted to suit

your requirements.

MTU Extended Coverage (EC) is a service

specially tailored to your needs, offering

added protection for your vehicle or your

entire eet. It extends the standard warranty

period to provide corrective maintenance.

MTU Extended Coverage is available for

MTU_ValueExchange remanufactured,

MTU overhauled and new MTU Series 4000

engines as well as MTU PowerPacks.

MTU Annual Check comprises an annual

professional check of your drive system and

specialist advice from the MTU experts. They

will evaluate the maintenance condition of

your drive system and advise if any additional

maintenance or repair work is required.

The MTU Annual Check is available for all

MTU engine series.

Diagnosis solutions

With Remote Services, MTU will now be

able to offer you a powerful reporting and

diagnosis tool. Remote Service will give you

direct access to all your MTU engines and

systems, from any location. Relevant engine

data and information required for analysis

purposes can be very simply and straightfor-

wardly accessed via an internet connection.

You can use this data, at a time to suit you,

as a means of monitoring that your systems

are running as they should be and of imme-

diately identifying any malfunctions so that

unproductive downtime can be avoided.

Further services

We additionaly offer a further comprehensive

service that includes:

Technical documentation

Training

RAMS-LCC analysis

Workshop and test bench solutions

Individual maintenance and repair

Ask your local MTU Service Center for more details on all MTU_ValueCare products.

1 Our service professionals give you advice and support to ensure the

optimal operation of your rail vehicles.

2 With remote services, you always have direct access to your MTU

engines. You can get current data easily at any time and any place.

2

40 I Rail I We move you. With experience and innovation.

2

1

MTU_ValueSpares

As genuine as your MTU engines.

MTU_ValueExchange

The smart alternative.

With MTU_ValueExchange products, you will

continue to enjoy robust, reliable performance

from your MTU engines and systems with tre-

mendous savings. In the MTU_ValueExchange

process, used products and assemblies are fully

disassembled, cleaned and inspected, then re-

assembled with all genuine, new wear parts

from MTU.

Since our products have the appear ance,

performance and life expectancy of new goods,

they meet the same performance re quirements

and enjoy warranties similar or identical to

equivalent new goods.

Because our MTU_ValueExchange products

incorporate the latest updates in materials and

design, they can be better than the products

they replace.

Our global MTU Service network provides

comprehensive support for all MTU_Value

Exchange products.

Parts

All MTU_ValueExchange parts meet the same

standards as new parts in terms of perform-

ance, operational life and warranty terms.

Engines

The MTU_ValueExchange engine program

offers an inexpensive alternative to a full engine

overhaul. MTU_ValueExchange engines

represent the very best standard in recondi-

tioned drive systems.

May be combined with any MTU_ValueCare

product, e.g. Extended Coverage.

Engine overhaul

Our complete overhaul program uses genuine

MTU or MTU_ValueExchange parts and pro -

cesses to ensure that your overhauled engine

delivers the same performance, guarantee and

quality standards as a brand-new engine.

Power Packs

Railcar operators have the opportunity to

exchange their MTU PowerPack for a fully

overhauled MTU_ValueExchange PowerPack

that is as good as new. This comes with the

same level of warranty as a new PowerPack.

Ask your local MTU Service Center for more details on all MTU_ValueCare products.

The MTU_ValueSpares program offers genuine

parts and consumables to ensure the continued

peak performance of your MTU engines and

systems. We provide everything required for

maintenance and repair from a single source.

To ensure quality, MTU_ValueSpares parts and

consumables are designed, tested and approved

specically for MTU engines, and include the

latest updates.

Spare Parts

Genuine MTU_ValueSpares replacement parts

are designed for optimal performance of your

vehicle.

Replacement part programs can be tailored to

your specic requirements.

Consumables

MTU_ValueSpares consumables protect your

investment and help retain its value.

We offer a full line of lubricants, coolants and

lters.

1 Only genuine spare parts and consumables

guarantee that your MTU engines will deliver

performance you can count on over the long term.

2 Modern warehouses and professional logistics

ensure that MTU_ValueSpares parts are available

quickly and reliably all over the world, at any

time, day or night.

We move you. With experience and innovation. I Rail I 43

MTU Worldwide

We are everywhere

where you are.

Trains are used all over the world, on every continent;

in urban areas as much as in more remote regions.

So just like the rail network, our service network spans

the globe. We know that the absolute reliability and

availability of your systems are key to your success and

competitive position. Thats why our specialists can be

on the scene very quickly, bringing expert support.

No restriction, anywhere in the world.

Wherever and whenever you need us.

Local support. Worldwide.

We ensure that you receive individualized support from our global network

of more than 1,200 service centers anywhere, anytime.

Head Ofce

Regional Service Center

Sales and Customer Service Center

VI

Certied Quality

MTU quality is something

you can measure and feel.

Leading in quality and certication

MTU is the rst diesel engine manufacturer in the world to receive certication

according to the International Railway Industry Standard (IRIS).

Certication awarded by further renowned certication bodies demonstrates

clearly the uncompromising way in which we apply our quality philosophy across

all products and processes.

We have set the standard by successfully retaining our

ISO 9001 certication for many years now, and have

so proven time and time over how our capabilities can

benet our customers.

Yet what we have already achieved is not enough for

us it is just a basis and gives us the momentum for

our further development and continuous improve-

ment.

To add to all this, we have now received a further seal

of approval. We are the rst diesel engine manufactur-

er in the world to receive the Inter national Railway

Industry Standard (IRIS) certication, putting us a step

ahead of the competition.

The high quality standards we set ourselves, plus

motivated and well-qualied employees who constant-

ly think ahead and take anticipatory action where

necessary, have enabled us to fulll the demanding

requirements of IRIS.

Further certication awards, such as UIC type

approval for the Series 4000, environmental

management certicate ISO 14001 and Deutsche

Bahn Q1 supplier (awarded by the German national

railroad company) speak for themselves and for the

high level of quality and customer satisfaction that

MTU offers.

A TOGNUM GROUP BRAND

S

u

b

j

e

c

t

t

o

c

h

a

n

g

e

.

|

3

0

6

1

7

1

1

|

1

/

1

1

I

V

M

C

2

0

1

1

-

0

6

B

|

P

r

i

n

t

e

d

o

n

c

h

l

o

r

i

n

e

-

f

r

e

e

b

l

e

a

c

h

e

d

p

a

p

e

r

.

Europe I Middle East I Africa I Latin America, MTU Friedrichshafen GmbH, 88040 Friedrichshafen, Germany, T +49-7541-90-7004, F +49-7541-90-7084,

railregion1@mtu-online.com, www.mtu-online.com I Asia I Australia I Pacic, MTU Asia Pte. Ltd., 1 Benoi Place, Singapore 629923, Republic of Singapore,

T +65-6861-5922, F +65-6861-3615, railregion2@mtu-online.com, www.mtu-online.com.sg I USA I Canada I Mexico, MTU Detroit Diesel, Inc., 13400 Outer Drive

West, Detroit, Michigan 48239, USA, T +1-435-773-6720, F +1-435-773-6721, railregion3@mtu-online.com, www.mtudetroitdiesel.com

You might also like

- MTU Rail SalesProgramDocument37 pagesMTU Rail SalesProgramRoyenNo ratings yet

- MTU Brochure GendriveDocument11 pagesMTU Brochure GendrivevicNo ratings yet

- MTU Marine DefenseDocument27 pagesMTU Marine DefenseAizat DakNavyNo ratings yet

- Training Program Singapore, Asia: ValuecareDocument13 pagesTraining Program Singapore, Asia: Valuecareguichen wangNo ratings yet

- MTU Diesel Engines For LocomotivesDocument8 pagesMTU Diesel Engines For LocomotivesCosty Trans100% (1)

- MTU EngineDocument4 pagesMTU EngineChristian Dhani100% (2)

- MTU White Paper Electronic Engine ManagementDocument4 pagesMTU White Paper Electronic Engine ManagementStefan LyamovNo ratings yet

- Sales Program Oil Gas Industry MTU ShopDocument83 pagesSales Program Oil Gas Industry MTU ShopBogdan ApostolNo ratings yet

- 2011 Engine Tech Review MWMDocument2 pages2011 Engine Tech Review MWMGrietekeNo ratings yet

- MTU 12V4000 Diesel EngineDocument2 pagesMTU 12V4000 Diesel Enginenastyn-1No ratings yet

- MTU CI Ag Mining SalesProgramDocument37 pagesMTU CI Ag Mining SalesProgramMarcial MilitanteNo ratings yet

- Tender Starter Marine - CatalogueDocument100 pagesTender Starter Marine - CatalogueGivan IsmailNo ratings yet

- 360°dclounge FUTURE MTU PDFDocument17 pages360°dclounge FUTURE MTU PDFguichen wangNo ratings yet

- Here: Mtu Technical Project Guide PDFDocument4 pagesHere: Mtu Technical Project Guide PDFhadi0% (1)

- 3 Optics Fibres Can Bus Repeater MN67XXXYYY ENGDocument28 pages3 Optics Fibres Can Bus Repeater MN67XXXYYY ENGGiang DoNo ratings yet

- OE Flyer Genset A5 01 16 LowDocument33 pagesOE Flyer Genset A5 01 16 LowCecep NanuNo ratings yet

- Solution Guide: Oil & Gas IndustryDocument59 pagesSolution Guide: Oil & Gas IndustryPerezPedroNo ratings yet

- Monitoring and Remote Control For MTU Ship Propulsion SystemsDocument8 pagesMonitoring and Remote Control For MTU Ship Propulsion SystemsThiha BoBo100% (1)

- MTU General WhitePaper EngineManagement 2014Document4 pagesMTU General WhitePaper EngineManagement 2014Pankaj KambleNo ratings yet

- MTU 16V 2000 M93 Brochure SpecificationDocument2 pagesMTU 16V 2000 M93 Brochure SpecificationPedro Mas0% (1)

- MTU 4000 With MIP v1.8Document23 pagesMTU 4000 With MIP v1.8Aurelio Serrano100% (2)

- Wartsila 2007Document120 pagesWartsila 2007Atandho Gama MagwasyarNo ratings yet

- Understanding Generator Set RatingsDocument48 pagesUnderstanding Generator Set RatingsdaneNo ratings yet

- Baudouin Brochure PDFDocument5 pagesBaudouin Brochure PDFVăn Tuấn NguyễnNo ratings yet

- 20v4000enDocument266 pages20v4000enMario MartinezNo ratings yet

- Rolls Royce TUG LNG - 2012Document72 pagesRolls Royce TUG LNG - 2012Maurizio BernasconiNo ratings yet

- Series 8000 Diesel Engines For Marine ApplicationsDocument3 pagesSeries 8000 Diesel Engines For Marine ApplicationsMaurizioNo ratings yet

- Sokratherm 40 400 KW Eng 2011Document6 pagesSokratherm 40 400 KW Eng 2011silvercristiNo ratings yet

- Mtu 16v4000 m53&m63 PDFDocument2 pagesMtu 16v4000 m53&m63 PDFJoan Manuel Rivas SantandreuNo ratings yet

- Presentation DIESELWORXDocument12 pagesPresentation DIESELWORXovidiuserbanNo ratings yet

- Catalogo MahleDocument96 pagesCatalogo MahlejavierNo ratings yet

- Wartsila o e W 50df PG PDFDocument182 pagesWartsila o e W 50df PG PDFRio WawoNo ratings yet

- S4000M05-N Gas Mobile Marine Workshop On Modernisation of Danube Vessels FleetDocument43 pagesS4000M05-N Gas Mobile Marine Workshop On Modernisation of Danube Vessels FleetbbssNo ratings yet

- MWM DEUTZ Natural Gas Generator 63Document1 pageMWM DEUTZ Natural Gas Generator 63Pankaj KambleNo ratings yet

- Series 4000 Diesel Engines: For Stationary Power GenerationDocument6 pagesSeries 4000 Diesel Engines: For Stationary Power GenerationNelitza Wuilmary Arellano RojasNo ratings yet

- Injector CE RingsDocument1 pageInjector CE RingsRonald AcostaNo ratings yet

- Mtu 12v&16v2000m94Document2 pagesMtu 12v&16v2000m94ozakyus50% (2)

- Himsen H46 60VDocument4 pagesHimsen H46 60VairtupasNo ratings yet

- Propulsion Solutions For Large High Speed VesselsDocument29 pagesPropulsion Solutions For Large High Speed VesselshaujesNo ratings yet

- MTU Diesel Genset Global BrochureDocument24 pagesMTU Diesel Genset Global BrochureghostshotNo ratings yet

- GAC Product Application GuideDocument247 pagesGAC Product Application GuideRaeedNo ratings yet

- Series 2000 For Power GenerationDocument6 pagesSeries 2000 For Power GenerationBarham Gen Barham100% (1)

- Bosch Parts in Marine & Power Generation EnginesDocument4 pagesBosch Parts in Marine & Power Generation EnginesNeoteric IndustrialNo ratings yet

- Aksa Global Rental Power CatalogueDocument24 pagesAksa Global Rental Power CatalogueThato Merapelo PuleNo ratings yet

- X52907500070 - Vto-G279p36s2 L Orange Diesel InjectorDocument1 pageX52907500070 - Vto-G279p36s2 L Orange Diesel InjectoraurelghitaNo ratings yet

- Spec Sheet Mtu 12v4000 Ds1750 NeaDocument6 pagesSpec Sheet Mtu 12v4000 Ds1750 NeaTri Hudami WibowoNo ratings yet

- Dieselfacts 2014-3 WebDocument12 pagesDieselfacts 2014-3 WebTapas ChaudhuriNo ratings yet

- MEX Special ShippandOffshore 6 2010Document14 pagesMEX Special ShippandOffshore 6 2010hany mohamedNo ratings yet

- Colt Pielstick PA6B Data SheetDocument2 pagesColt Pielstick PA6B Data SheetRot Tor FedecaNo ratings yet

- MTU Marine SalesProgramDocument49 pagesMTU Marine SalesProgramselleriverket100% (1)

- Navitron NT920 RAI - LeafletDocument1 pageNavitron NT920 RAI - LeafletUFUKKK50% (2)

- MTU General WhitePaper Bi-Fuel 2014Document2 pagesMTU General WhitePaper Bi-Fuel 2014selleriverketNo ratings yet

- 15 18 104 0F - Notice - 6M26.2 - GEB - ENDocument132 pages15 18 104 0F - Notice - 6M26.2 - GEB - ENsxturbo100% (1)

- Faraz Ahmed C.VDocument3 pagesFaraz Ahmed C.Vfaraz24No ratings yet

- PrintDocument13 pagesPrintKieron Ivan Mendoza GutierrezNo ratings yet

- ENGLISH - 170059 PR Corporate Brochure - FinalDocument60 pagesENGLISH - 170059 PR Corporate Brochure - FinalUjang KasepNo ratings yet

- Revista de Leopart PDFDocument13 pagesRevista de Leopart PDFJose Fernandez100% (3)

- MTU. Your Partner For Unrivaled Solutions.: Land DefenseDocument13 pagesMTU. Your Partner For Unrivaled Solutions.: Land DefenseOsorio Luis100% (1)

- MTU Navy Brochure 1 14Document29 pagesMTU Navy Brochure 1 14m_najmanNo ratings yet

- Training ReportDocument60 pagesTraining ReportNitish ChauhanNo ratings yet

- POSEICO ShortFormCatalogue20132014Document52 pagesPOSEICO ShortFormCatalogue20132014alvaror320No ratings yet

- Energies 13 00963Document16 pagesEnergies 13 00963alvaror320No ratings yet

- Velaro D PDFDocument4 pagesVelaro D PDFalvaror320No ratings yet

- Acronyms and Abbreviations in Avionics PDFDocument17 pagesAcronyms and Abbreviations in Avionics PDFalvaror320No ratings yet

- Seacor Maya: Main Particulars Electronics & ControlsDocument2 pagesSeacor Maya: Main Particulars Electronics & ControlsarnoldbusaNo ratings yet

- Engine Room Simulator (Ers 4000)Document7 pagesEngine Room Simulator (Ers 4000)youngfp80% (5)

- 3 - Western Technology and Soviet Economic Development 1945-1965 (1973)Document513 pages3 - Western Technology and Soviet Economic Development 1945-1965 (1973)Andeman0% (1)

- Sub: Maintenance of The NO Record Book of Engine ParametersDocument6 pagesSub: Maintenance of The NO Record Book of Engine ParametersSatyabrat GaanNo ratings yet

- EEDI Guidance NotesDocument22 pagesEEDI Guidance NotesJeff Martin0% (1)

- Propulsion Ancillary Systems and Gas TurDocument4 pagesPropulsion Ancillary Systems and Gas TurJerico Reanzares ObandoNo ratings yet

- Hybrid Shaft Generator Drive (Standalone Version) : The Main BenefitsDocument2 pagesHybrid Shaft Generator Drive (Standalone Version) : The Main BenefitsAbburi KarthikNo ratings yet

- ZF Product Selection Guide 2014 enDocument123 pagesZF Product Selection Guide 2014 enMadalina Oprea75% (4)

- Diesel Facts 2016-2Document12 pagesDiesel Facts 2016-2kaushal upadhyayNo ratings yet

- Alternative Fuels For Marine ApplicationDocument108 pagesAlternative Fuels For Marine Applicationamirlng100% (1)

- Marine Engine: IMO Tier LL Programme 3rd Edition 2011Document140 pagesMarine Engine: IMO Tier LL Programme 3rd Edition 2011vran77100% (8)

- Marine Boiler Notes.: Introduction To Marine BoilersDocument60 pagesMarine Boiler Notes.: Introduction To Marine BoilersRachitNo ratings yet

- Iww Danube Ship Design Final December 2009 PDFDocument121 pagesIww Danube Ship Design Final December 2009 PDFMohamed FouadNo ratings yet

- MaK VM32C Low Emission Engine 32305Document12 pagesMaK VM32C Low Emission Engine 32305abuzer1981100% (1)

- Propeller Design PDFDocument8 pagesPropeller Design PDFwasita wadari100% (1)

- Marine Propulsion: 974 MHP (960 BHP) 716 BKWDocument6 pagesMarine Propulsion: 974 MHP (960 BHP) 716 BKWRobert Robertt100% (1)

- 11 Diesel and Gas Turbine Worldwide 38TH Power Generation Odrer Survey 2014 PDFDocument5 pages11 Diesel and Gas Turbine Worldwide 38TH Power Generation Odrer Survey 2014 PDFaegean227100% (1)

- The Propulsion of A 12 500TEU Container Ship: JS Carlton, Lloyd's Register, LondonDocument15 pagesThe Propulsion of A 12 500TEU Container Ship: JS Carlton, Lloyd's Register, LondonŞansal DikmenerNo ratings yet

- Engines For Planing BoatsDocument16 pagesEngines For Planing BoatsAlex MarcusNo ratings yet

- Machinery MaerskDocument370 pagesMachinery Maerskgopu thalikunnath100% (6)

- AT2000 PCS Instruction ManualDocument108 pagesAT2000 PCS Instruction ManualВладимир СидоровNo ratings yet

- RFP 20-006 Equipment Installtion For Marine Repower Project FINAL1 PDFDocument52 pagesRFP 20-006 Equipment Installtion For Marine Repower Project FINAL1 PDFMouayed ZeadanNo ratings yet

- Azipod PresentationDocument18 pagesAzipod Presentationkhaihui100% (1)

- Glossary of Woodward ControlsDocument20 pagesGlossary of Woodward Controlsvv_muthukumar100% (3)

- Hamilton InstructionsDocument198 pagesHamilton InstructionsPatrick100% (1)

- Introduction To Submarine DesignDocument6 pagesIntroduction To Submarine DesignArjun S Rana50% (4)

- Report Internship HSLDocument19 pagesReport Internship HSLNandhini ShanmugamNo ratings yet

- MSS Mar 1000001073 008Document3 pagesMSS Mar 1000001073 008Mohammad Saiful Islam SujonNo ratings yet

- 06 Modu rcn3Document16 pages06 Modu rcn3djodje1No ratings yet

- Lunar Lander and Return Propulsion System Trade StudyDocument322 pagesLunar Lander and Return Propulsion System Trade Studyjakub_gramolNo ratings yet