Professional Documents

Culture Documents

Compozit1 PDF

Uploaded by

Adriana VoineaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compozit1 PDF

Uploaded by

Adriana VoineaCopyright:

Available Formats

CYOeBZCYO composites with enhanced proton conductivity:

Candidate electrolytes for low-temperature solid oxide fuel

cells

Jianbing Huang

a,

*, Li Zhang

b

, Cheng Wang

c

, Ping Zhang

b

a

State Key Laboratory of Multiphase Flow in Power Engineering, School of Energy and Power Engineering, Xian Jiaotong University,

Xian 710049, PR China

b

Faculty of Material Science and Chemical Engineering, China University of Geosciences, Wuhan 430074, PR China

c

Institute of Nuclear and New Energy Technology, Tsinghua University, Beijing 100084, PR China

a r t i c l e i n f o

Article history:

Received 20 December 2011

Received in revised form

9 May 2012

Accepted 10 May 2012

Available online 12 June 2012

Keywords:

Ce

0.8

Y

0.2

O

1.9

(CYO)

BaZr

0.1

Ce

0.7

Y

0.2

O

2.9

(BZCYO)

Composite electrolyte

Proton conductivity

Low-temperature solid oxide fuel

cells (LT-SOFCs)

a b s t r a c t

Novel composite oxide ion conductors were developed based on a uorite-type Ce

0.8

Y

0.2

O

1.9

(CYO) and a perovskite-type BaZr

0.1

Ce

0.7

Y

0.2

O

2.9

(BZCYO) synthesized by the carbonate co-

precipitation route at 700

C and the solegel process at 1000

C, respectively. When sintered

at 1400

C, CYO and BZCYO showed an ac conductivity of 1.60 10

2

S cm

1

and

1.21 10

2

S cm

1

at 600

C, respectively, in dry air and wet hydrogen. CYOeBZCYO

composites sintered at 1400

C showed much lower conductivity than CYO and BZCYO in

dry air, but they showed enhanced conductivity in wet hydrogen. The highest conductiv-

ities of 3.27 10

2

S cm

1

at 500

C and 9.40 10

3

S cm

1

at 400

C were achieved in wet

hydrogen by the composite containing 30wt.% BZCYO, which are 3e5 times higher than

those of CYO and BZCYO, making this composite material a promising candidate as an

electrolyte for low-temperature solid oxide fuel cells (LT-SOFCs).

Copyright 2012, Hydrogen Energy Publications, LLC. Published by Elsevier Ltd. All rights

reserved.

1. Introduction

To accelerate the commercialization of solid oxide fuel cell

(SOFC) technology, enormous efforts have been made to

reduce the operating temperature from a traditional high

temperature of around 1000

C down to intermediate

(600e800

C) and low (400e600

C) temperature range [1e3].

This reduced-temperature operation will allow easier cell &

stack construction, enable cheaper materials to be used, and

improve long-term cell stability and stack durability. By

reducing the operating temperature to 500

C or below, due to

its capability to start up rapidly, SOFC has the potential as

power source for electric vehicle applications in combination

with energy storage devices, e.g. rechargeable batteries or

electrochemical supercapacitors. However, electrolyte resis-

tance and electrode polarization increase greatly with the

decreasing temperature, which reduce the performance of

SOFC. Improving the electrolyte performance for low

temperature operation is achieved by reducing the electrolyte

thickness and using new electrolyte materials with high ion

(O

2

/H

) conductivity at low temperatures [4e6].

Fluorite-type ceria (CeO

2

) based oxides have been exten-

sively studied as electrolyte materials for low-temperature

solid oxide fuel cell (LT-SOFC) operating at 500e600

C and

* Corresponding author. Tel.: 86 29 82665591; fax: 86 29 82669033.

E-mail address: huangjb@mail.xjtu.edu.cn (J. Huang).

Available online at www.sciencedirect.com

j ournal homepage: www. el sevi er. com/ l ocat e/ he

i nt e r na t i ona l j o ur na l o f hy d r o g e n e ne r g y 3 7 ( 2 0 1 2 ) 1 3 0 4 4 e1 3 0 5 2

0360-3199/$ e see front matter Copyright 2012, Hydrogen Energy Publications, LLC. Published by Elsevier Ltd. All rights reserved.

doi:10.1016/j.ijhydene.2012.05.040

made much progress [7e10]. It has been reported that some

singly doped ceria, such as Ce

1x

Gd

x

O

2d

(CGO),

Ce

1x

Sm

x

O

2d

(CSO) and Ce

1x

Y

x

O

2d

(CYO) show an oxygen-

ion conductivity as high as 10

2

S cm

1

at 600

C [4], corre-

sponding to that of conventional yttria-stablized zirconia

(YSZ) at 800

C. While doped ceria exhibits mixed ionic-

electronic conducting behavior in the anodic environment

due to the reduction of Ce

4

to Ce

3

. This reduction causes

internal electronic transport in the electrolyte and expan-

sion of the lattice, resulting in signicant decrease in cell

voltage and mechanical strength. The electronic conduction

can be suppressed by lowering the operating temperature,

and doped ceria becomes a predominantly ionic conductor

below 450

C even in the fuel atmosphere [11], but its ionic

conductivity needs further improvement for LT-SOFC

application.

Oxide proton conductors are also being applied as elec-

trolytes for LT-SOFC because of their lowactivation energy for

proton conduction. Many perovskite-type oxides show high

proton conductivity in reducing and humid atmospheres at

low temperature [12]. Doped barium cerate (BaCeO

3

) such as

BaCe

0.8

Y

0.2

O

2.9

(BCYO) possesses a proton conductivity of

10

2

S cm

1

at 600

C, and it is a pure ion conductor not

suffering from the reduction at low oxygen partial pressure.

Ito et al. [13] had demonstrated the highest fuel cell perfor-

mances at 400e600

C based on a 0.7 mm thick BCYO electro-

lyte. However, BaCeO

3

is not chemically stable in an

atmosphere containing CO

2

and H

2

O, which makes it inade-

quate as electrolyte for fuel cell application, especially for use

with hydrocarbon or syngas fuels. The chemical stability can

be improved by the introduction of Zr to partially replace Ce,

but the proton conductivity is normally reduced due to its

poor sinterability [14]. BaZr

0.1

Ce

0.7

Y

0.2

O

3d

(BZCYO) achieves

high proton conductivity, as well as sufcient chemical and

thermal stability over the wide range of LT-SOFC operating

conditions, which is regarded as candidate electrolyte for LT-

SOFC [15].

Two-phase composite electrolyte based on doped ceria

phase and doped barium cerate phase has been successfully

prepared using ceramic composite technology by Zhu et al.

[16] for the rst time and excellent fuel cell performances has

been demonstrated below 600

C based on an approximately

0.3e0.5 mm thick electrolyte. It is found that doped barium

cerate phase can block the internal electron current caused by

the reduction of doped ceria phase and improve the total ion

conductivity in SOFC operation [17]. This composite effect has

been proved by some doped ceria-based composites. For

example, doped ceriaecarbonate composites show hybrid

oxygen-ion and proton conduction with extremely enhanced

ion conductivity in fuel cell environment accounting for

interfacial proton conduction [18]. In contrast, doped ceria-

doped barium cerate composites have better thermal

stability than doped ceriaecarbonate composites. However,

the study on such functional two-phase composites based on

oxide ion conductors for SOFC electrolytes is very limited. To

our knowledge, Ce

0.8

Y

0.2

O

1.9

(CYO) and BaZr

0.1

Ce

0.7

Y

0.2

O

2.9

(BZCYO) composites have never been studied. These

composites are expected to possess mixed ion conduction,

enhanced ion conductivity, suppressed electron conductivity

and improved chemical stability.

In this work, novel CYOeBZCYOcomposites were prepared

using ceramic composite technology and their electrical

conductivities under dry air and wet hydrogen (3% H

2

O)

atmospheres at 400e700

C were investigated to evaluate their

feasibility as LT-SOFC electrolytes. The phase stability of

CYOeBZCYO composites was studied to determine the sin-

tered temperature.

2. Experimental

2.1. Materials preparation

Ce

0.8

Y

0.2

O

1.9

(CYO) powders were synthesized by the

carbonate co-precipitation route. Stoichiometric amounts of

Ce(NO

3

)

3

$6H

2

O(A.R.) and Y

2

O

3

(A.R.) were dissolved in distilled

water and dilute nitric acid, respectively, then the Y(NO

3

)

3

solution was added to the Ce(NO

3

)

3

solution to form 0.5 M

metal nitrate solution. According to the molar ratio of metal

ion to carbonate ion in 1:2, a certain amount of Na

2

CO

3

was

dissolved in distilled water to form 0.5 M Na

2

CO

3

solution.

Then the metal nitrate solution was dropwise added into

Na

2

CO

3

solution under vigorous stirring to form a white

precipitate at room temperature. The precipitate was

vacuum-ltered, washed for three times with hot deionized

water and anhydrous ethanol, followed by drying at 80

C for

12 h to obtain CYOprecursor. Finally, the precursor was lightly

crushed in an agate mortar and calcined at the temperature

between 600

C and 800

C in air for 2 h to obtain pure CYO

powders.

BaZr

0.1

Ce

0.7

Y

0.2

O

2.9

(BZCYO) powders were synthesized by

the solegel process. The starting materials were Ba(NO

3

)

2

(A.R.), ZrO

2

(A.R.), Ce(NO

3

)

3

$6 H

2

O (A.R.), Y

2

O

3

(A.R.) and EDTA

(ethylenediamietetraacetic acid, A.R.). ZrO

2

and Y

2

O

3

were

dissolved in nitric acid to form 1 M solution, respectively.

Stoichiometric amounts of Ba(NO

3

)

2

and Ce(NO

3

)

3

$6H

2

O were

dissolved in distilled water, then the Zr(NO

3

)

4

and Y(NO

3

)

3

solutions were added into the above solution to form metal

precursor solution with the molar ratio of Ba

2

:Zr

4

:Ce

3

:Y

3

as 1:0.1:0.7:0.2. The molar ratio of EDTA to the total metal ion

was set at 2:1. Ammonium hydroxide (NH

3

33%) was added to

promote the dissolution of EDTA in deionized water, and

adjust the pH value to 9 when the metal precursor solution

was added dropwise to the EDTA solution. A polymeric gel

was obtained after evaporating the water at 80

C under

continuous stirring. The gel was heat-treated at 250

C in air

for 6h, and then the resultant was ground thoroughly and

calcined at the temperature between 800

C and 1200

C in air

for 4 h to obtain pure BZCYO powders.

CYOeBZCYO composite powders containing 20wt.%,

30wt.%, 50wt.% and 70wt.% BZCYO phase were prepared by

mixing pure CYO and BZCYO powders in anhydrous ethanol,

and dispersing the mixture by ultrasonic oscillation, then

grinding the suspensions thoroughly in an agate mortar, fol-

lowed by drying in an infrared oven. All composite powders

and pure CYO and BZCYO powders were uniaxially pressed

into pellets with 13 mm in diameter and 1 mm in thickness

under a pressure of 300 MPa. Then the pellets were sintered in

air at the temperature from 1200 to 1450

C for 5 h.

i nt e r na t i o na l j our na l o f hy d r og e n e ne r g y 3 7 ( 2 0 1 2 ) 1 3 0 4 4 e1 3 0 5 2 13045

2.2. Characterization measurements

The crystal structure and phase purity of calcined CYO and

BZCYO powders were characterized using an X-ray diffrac-

tometer (XRD, D8 Advance, Bruker AXS Corp., German) with

CuKa radiation (l 0.15406 nm 40 kV and 100 mA). The

densities of sintered CYO and BZCYO electrolyte pellets were

measured by the standard Archimedes method. The surface

morphology of CYO and BZCYO electrolyte pellets sintered at

different temperatures were characterized using a scanning

electron microscope (SEM, JSM-4500, JEOL, Japan). The phase

stability of sintered CYOeBZCYO composite samples was also

studied by XRD.

The electrical conductivity of CYOeBZCYO composite

electrolytes as well as pure CYO and BZCYO electrolytes was

measured in dry air and wet hydrogen (3% H

2

O), respectively,

using the standard two-probe ac impedance spectroscopy

(IM6E, Zahner, Germany). Silver paste was painted onto either

side of the electrolyte pellets and red at 600

C for 1 h to act as

electrodes. Impedance data were taken from 700

C to 400

C

(50

C at intervals) and a frequency range of 0.1 Hze1 MHz

using an excitation voltage of 10 mV.

3. Results and discussion

3.1. Calcination of CYO and BZCYO powders

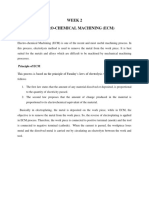

Fig. 1 shows the XRDpatterns of CYO powders calcined at 600,

700, and 800

C, respectively. These patterns conrm the

formation of the cubic uorite structure for all three samples.

The degree of XRD peak broadening decreased with the

increasing calcination temperature from 600 to 800

C, which

indicates the increase of the crystallite size. The crystallite

sizes of the particles are calculated from FWHM data for (111)

crystal face using Scherrer formula D 0.9l/bcosq, where D is

the crystallite size in nm, l the radiation wavelength

(0.15406 nm in present case, Cu target), q the diffraction angle,

and b is the corrected line widthat half peak intensity, b canbe

calculated using the formula b

2

b

2

m

b

2

s

, where b

m

is the

measured FWHM and b

s

(taken as 0.1704) is the FWHM of

a standard silicon sample. The calculated particle sizes of CYO

powders calcined at 600, 700 and 800

C are 18, 30, and 57 nm,

respectively. Here, CYO powder calcined at 700

C for 2 h was

chosen as one constituent phase for CYOeBZCYOcomposites.

Fig. 2 shows the XRD patterns of BZCYO powders calcined

at 800, 1000 and 1200

C, respectively. As evidence from the

patterns, BaCO

3

phase and uorite phase were detected in

BZCYO powder after calcination at 800

C. As the calcination

temperature increased up to 1000

C, XRD showed pure

BaCeO

3

with orthorhombic perovskite structure as a result of

the solid solution formation with Ce, Zr and Y statistically

distributed in the lattice. It indicates that solegel process is

effective to lower the phase formation temperature of BZCYO,

compared with conventional solid-state reaction method [19].

The crystallite sizes of BZCYO particles are also calculated

from FWHM data for (002) crystal face using Scherrer formula.

The calculated particle sizes of BZCYO powders calcined at

800, 1000 and 1200

C are 15, 20, and 23 nm, respectively. Here,

BZCYO powder calcined at 1000

C for 4 h was selected as the

second phase for CYOeBZCYO composites.

3.2. Sintering of CYO and BZCYO electrolytes

The surface microstructures of CYO electrolytes prepared

fromCYOpowder calcined at 700

C and sintered at 1200, 1300

and 1400

C for 5 h, respectively, were observed by SEM, as

shown in Fig. 3aec. Seen fromFig. 3a, the sintering necks were

born at 1200

C between the neighboring particles, and the

grain sizes ranged from about 0.2 to 1 mm. In the meantime,

many small pores were distributed in the grain boundaries.

When the sintered temperature increased to 1300

C (Fig. 3b),

the grain sizes grew up to about 0.5e1.5 mm, and the pore size

and number decreased signicantly. The grain sizes increased

to about 1.5e3 mm at the sintered temperature of 1400

C, and

the surface structure became rather dense with the formation

of isolated close pores. In general, large grain sized material

showed a high conductivity, due to a signicant increase in

10 20 30 40 50 60 70

(

4

0

0

)

(

2

2

2

)

(

3

1

1

)

(

2

2

0

)

(

2

0

0

)

(

1

1

1

)

800

o

C

700

o

C

600

o

C

I

n

t

e

n

s

i

t

y

(

a

.

u

.

)

2 (degree)

Fig. 1 e XRD patterns of CYO powders after being calcined

at 600, 700, and 800

C for 2 h.

Fig. 2 e XRD patterns of BZCYO powders after being

calcined at 800, 1000 and 1200

C for 5 h.

i nt e r na t i ona l j o ur na l o f hy d r o g e n e ne r g y 3 7 ( 2 0 1 2 ) 1 3 0 4 4 e1 3 0 5 2 13046

grain boundary conductivity (s

gb

), but a small decrease in

grain interior conductivity (s

gi

) [20]. Thus, CYO electrolyte

should be sintered at high temperatures to promote grain

growth and reduce the number of defects and pores along

grain boundaries in order to minimize grain boundary

resistance.

Shown in Fig. 3def are the surface views of BZCYO elec-

trolytes prepared from BZCYO powder calcined at 1000

C and

sintered at 1300, 1400, and 1450

C for 5 h, respectively. It can

be observed in the micrograph (Fig. 3d) that the sample sin-

tered at 1300

C was not fully dense. The grain size is esti-

mated to be about 0.3 mm showing uniform distribution in the

sintered body. With the increasing of sintered temperature,

the grains grew up gradually due to the diffusion and transfer

of cations, and the connected open pores were compressed

and deformed to isolated close pores. At the sintering

temperature of 1450

C (Fig. 3f), the number of pores on the

surface of the sample decreased evidently, and the contact

between adjacent particles became much tighter resulting in

an average grain size of about 1 mm. But the sample sintered at

1450

C was still not fully densied.

The effect of sintered temperature on the density of the

CYO and BZCYO specimens from the corresponding powders

calcined at 700

C and 1000

C, respectively, is illustrated in

Table 1. The relative densities of CYO and BZCYO electrolytes

were calculated according to the theoretical densities derived

from the XRD data referring to the corresponding crystal

structures and the densities measured by Archimedes

method. As the sintered temperature increased, all sintered

samples became increasingly dense. It is noted that a relative

density of 95.1% was obtained by the CYO sample sintered at

1400

C, which is about 200

C lower than that by conventional

solid-state reaction method [21]. Low sintered temperature of

electrolyte facilitates the selection of electrode materials for

SOFC application and the reduction of cell fabrication cost.

However, the BZCYO sample had comparatively low relative

density, below90%at 1450

C, due to lowrates of graingrowth.

The poor sinterablity of BZCYO electrolyte will inevitably

affect grain boundary resistance and gas permeability, which

restricts its application in SOFC.

3.3. Electrical conductivity of sintered CYO and BZCYO

electrolytes

Fig. 4 shows the Arrhenius plot of the electrical conductivity in

dry air for CYO electrolyte pellets from the powder calcined at

700

C sintered at 1200, 1300 and 1400

C for 5 h, respectively.

An almost linear relationship is found in the measured

temperature range of 400e700

C for each sample. It can be

seen that the electrical conductivity of CYO electrolyte

increases with the measured temperature studied. This trend

is consistent with the behavior of ion conductors. Therefore,

CYO electrolyte pellets sintered at different temperatures are

proposed to be oxygen-ion conductors in air via the migration

Fig. 3 e SEM micrographs of the surface views of the CYO pellets sintered at (a) 1200

C, (b) 1300

C and (c) 1400

C, and the

BZCYO pellets sintered at (d) 1300

C, (e) 1400

C, and (f) 1450

C for 5 h.

Table 1 e The relative densities of the CYO and BZCYO

pellets sintered at different temperatures.

Sample Relative density (%)

1200

C 1300

C 1400

C 1450

C

CYO 69.8 85.3 95.1

BZCYO 66.1 80.7 89.3

i nt e r na t i o na l j our na l o f hy d r og e n e ne r g y 3 7 ( 2 0 1 2 ) 1 3 0 4 4 e1 3 0 5 2 13047

of oxygen vacancies. These vacancies are produced from the

defect reaction (1) using Kro gereVink notation as follows:

Y

2

O

3

!

CeO

2

2Y

0

Ce

3O

O

V

O

(1)

Fig. 4 also exhibits an increase in the oxygen-ion conduc-

tivity withthe sintered temperature. The CYOsample sintered

at 1400

C shows the highest oxygen-ion conductivity,

0.016 S cm

1

at 600

C, which is much higher than that of the

CYO pellet prepared by the oxalate co-precipitation route and

sintered at 1500

C for 5 h [20]. The increase in electrical

conductivity with sintered temperature from1200 to 1400

C is

attributed to the increase in the grain size (Fig. 3aec) resulting

in the decrease of grain boundary resistance. The activation

energies for oxygen-ion conduction in CYO electrolytes sin-

tered at different temperatures are calculated from the

Arrhenius equation s A/Texp(E

a

/kT ). It is seen from Fig. 4

that the activation energy (E

a

) for oxygen-ion conduction

decreases from 0.943 eV for CYO sample sintered at 1200

C to

0.873 eV at 1400

C, indicating that sintering at 1400

C is

benecial for ion conduction at much lower temperature.

Note that the CYO sample sintered at 1400

C shows compa-

rable activation energy with the CYO samples prepared by

citric acidenitrate combustionprocess [22], but the former has

higher oxygen-ion conductivity than the latter.

Fig. 5 shows the Arrhenius plot of the electrical conduc-

tivity in wet hydrogen (3% H

2

O) for BZCYO electrolytes from

the powder calcined at 1000

C sintered at 1300, 1400 and

1450

C, respectively. An approximately linear relationship is

also found in the measured temperature range for each

BZCYO sample and the electrical conductivity increases with

the measured temperature, indicating that the sintered

BZCYO electrolyte pellets are pure proton conductors in wet

hydrogen atmosphere. As to A

O

3

perovskite-type oxides,

oxygen vacancies are introduced into the perovskite structure

by aliovalent doping. The doping reaction for an acceptor Y on

the B site of BaCeO

3

in dry atmospheres during the synthesis

process can be written as follows:

Y

2

O

3

2BaO!

CeO

2

2Ba

Ba

2Y

0

Ce

5O

O

V

O

(2)

When the sample is sintered under oxygen-containing

atmospheres the reaction (3) may occur

V

O

1

2

O

2

g5O

O

2h

(3)

In dry hydrogen, the proton can be produced in the form of

hydroxyl according to the reaction (4)

H

2

2O

O

2h

52OH

O

(4)

In wet hydrogen, the proton conduction may appear due to

incorporation of water into the sample to form hydroxyl

species according to the reactions (5) and (6)

H

2

Og 2O

O

2h

52OH

1

2

O

2

g (5)

H

2

Og O

O

V

O

52OH

O

(6)

It is believed that protons can migrate by hopping from the

OH

O

site to O

O

site nearby causing this material to exhibit the

proton conductivity. From Fig. 5, it is seen that the proton

conductivity of BZCYO samples increases with the sintered

temperature from1300

C to 1450

C. This agrees with the SEM

analysis (Fig. 3def) that showed an increasing grain size with

increasing sintered temperature. A larger grain size leads to

a smaller grain boundary surface, resulting in higher electrical

conductivity for the samples with increasing sintered

temperature. At 600

C, the proton conductivity values were

measured at 7.89 10

3

S cm

1

for the sample sintered at

1300

C, increasing up to 1.21 10

2

S cm

1

at 1400

C and

1.28 10

2

S cm

1

at 1450

C. Fromthe tted Arrhenius curves

1.0 1.1 1.2 1.3 1.4 1.5

-2

-1

0

1

2

3

4

750 700 650 600 550 500 450 400

t (

o

C)

1200

o

C

1300

o

C

1400

o

C

l

n

(

T

)

(

S

c

m

-

1

K

)

1000/T (K

-1

)

0.873eV

0.916eV

0.943eV

Dry air

Fig. 4 e Arrhenius plot of the electrical conductivity in dry

air for CYO electrolyte pellets from the powder calcined at

700

C sintered at 1200, 1300 and 1400

C for 5 h,

respectively.

1.0 1.1 1.2 1.3 1.4 1.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

750 700 650 600 550 500 450 400

0.381eV

0.391eV

l

n

(

T

)

(

S

c

m

-

1

K

)

1000/T (K

-1

)

1300

o

C

1400

o

C

1450

o

C

0.378eV

Wet hydrogen (3% H

2

O)

t (

o

C)

Fig. 5 e Arrhenius plot of the electrical conductivity in wet

hydrogen (3% H

2

O) for BZCYO electrolyte pellets from the

powder calcined at 700

C sintered at 1300, 1400 and

1450

C for 5 h, respectively.

i nt e r na t i ona l j o ur na l o f hy d r o g e n e ne r g y 3 7 ( 2 0 1 2 ) 1 3 0 4 4 e1 3 0 5 2 13048

shown in Fig. 5, the activation energies are 0.378 eV, 0.381 eV,

and 0.391 eV, respectively when the sintered temperature of

BZCYO electrolyte increases from 1300

C to 1450

C. The

proton conductivity for BZCYO sample sintered at 1400

C in

this study are much higher than that for BZCYO samples

prepared by gel-casting and sintered at 1550

C [23] in the

measured temperature range of 400e700

C, and the activa-

tion energy for the former is much lower than that for the

latter, although the relative density of the former (80.7%) is

lower than that for the latter (95%).

3.4. Phase stability of CYOeBZCYO composite

electrolytes

Fig. 6 shows the XRD patterns of CYOeBZCYO composite

electrolytes containing 20wt.% BZCYO sintered at 1300, 1400,

and 1450

C for 5 h, respectively. The diffraction pattern of the

composite sample sintered at 1300

C consisted of two phases:

the pure uorite phase from CYO and the pure perovskite

phase fromBZCYO. After sintered at 1400

C for 5 h, a minor of

additional Ba

2

YZrO

6

phase (JCPDS Card Number 47-0385) and

Ba

2

ZrO

4

$2.15H

2

O phase (JCPDS Card Number 43-0653) is

detected, indicating that phase segregation and interdiffusion

arose in the two-phase system during high temperature sin-

tering and hygroscopic absorption occurred when exposed in

ambient atmosphere. When the sintered temperature

increased to 1450

C, the proportion of Ba

2

YZrO

6

cubic phase

in the composite electrolyte increased signicantly, in

contrast, the proportions of CeO

2

uorite phase and BaCeO

3

perovskite phase decreased.

3.5. Electrical conductivity of CYOeBZCYO composite

electrolytes

Fig. 7 presents the Arrhenius plots of the electrical conduc-

tivity in dry air for CYOeBZCYO composite electrolytes con-

taining 20wt.% BZCYO sintered at 1300, 1400 and 1450

C,

respectively. It is obvious that all the tted Arrhenius curves

can be separated into two straight lines at about 500

C for

each sample sintered from 1300

C to 1450

C, indicating that

the conduction mechanism of the composite alters at this

temperature. Ceria phase exhibits pure oxygen-ion conduc-

tion in dry air. For doped barium cerate in dry air, oxygen-ion

conductivity is suggested to be dominant at lowtemperatures,

while electron hole conductivity is suggested to be dominant

at elevated temperatures [24]. Thereby, the composite acts as

oxygen-ion conductor at lower temperatures and mixed

oxygen-ion and electron hole conductor at higher tempera-

tures in dry air.

It can be seen in Fig. 7 that the composite electrolyte sin-

tered at 1400

C showed the highest electrical conductivity

compared with the samples sintered at 1300

C and 1450

C in

the measured temperature range, which can be attributed to

the comprehensive effect of grainsizes and impurities. Onone

hand, the grain sizes of both CYOphase and BZCYOphase will

increase with increasing sintered temperature, leading to

higher electrical conductivity. On the other hand, the

increasing content of impurities including Ba

2

YZrO

6

and

Ba

2

ZrO

4

may cause the deterioration of ion conduction espe-

cially in the interfacial regions.

Fig. 8 shows the Arrhenius plots of the electrical conduc-

tivity in wet hydrogen (3% H

2

O) for CYOeBZCYO composite

electrolytes containing 20wt.% BZCYO sintered at 1300, 1400

and 1450

C, respectively. It is evident that the conduction

mechanism alters at about 600

C in wet hydrogen atmo-

sphere. It is well known that electron conduction can be

introduced into doped ceria at low oxygen partial pressure

and high temperature according to the reaction (7).

O

O

52e

0

V

O

1

2

O

2

(7)

In wet hydrogen environment, ceria phase exhibits a mixed

oxygen-ion, proton and electron conduction [25], and barium

cerate phase exhibits pure proton conduction. At lower

Fig. 6 e XRD patterns of CYOeBZCYO composite

electrolytes containing 20wt.% BZCYO sintered at 1300,

1400, and 1450

C for 5 h, respectively.

1.0 1.1 1.2 1.3 1.4 1.5

-2

-1

0

1

2

3

4

t (

o

C)

1300

o

C

1400

o

C

1450

o

C

l

n

(

T

)

(

S

c

m

-

1

K

)

1000/T (K

-1

)

Dry air

0.772eV

0.718eV

0.752eV

0.672eV

0.751eV

0.631eV

750 700 650 600 550 500 450 400

Fig. 7 e Arrhenius plots of the electrical conductivity in dry

air for CYOeBZCYO composite electrolytes containing

20wt.% BZCYO sintered at 1300, 1400 and 1450

C,

respectively.

i nt e r na t i o na l j our na l o f hy d r og e n e ne r g y 3 7 ( 2 0 1 2 ) 1 3 0 4 4 e1 3 0 5 2 13049

temperatures (below 600

C), the electron conduction of CYO

phase is not signicant and it can be blocked by the pure

proton conductor BZCYO, thus CYOeBZCYO composite con-

taining 20wt.% BZCYO shows hybrid oxygen-ion and proton

conduction in this condition. The composite sample sintered

at 1400

C has the lowest activation energy 0.756 eV below

600

C, which is higher than that of pure BZCYO in wet

hydrogen atmosphere. At higher temperature (above 600

C),

the electron conduction becomes innegligible, thus the

composite is a mixed ion-electron conductor. Among the

three composite samples, the sample sintered at 1400

C still

exhibits the highest electrical conductivity in wet hydrogen.

This conrms that the presence of impurities will deteriorate

the electrical conductivity of the composite. Hence, the

appropriate sintered temperature is set at 1400

C for

CYOeBZCYO composite electrolytes.

It is seem from Figs. 7 and 8 that the composite sample

shows much higher electrical conductivities in wet hydrogen

than in dry air at the measured temperature range of

400e700

C. In dry air, the conductivity is only 1.03 10

2

and

7.0 10

4

S cm

1

at 600

C and 400

C, respectively; while it

increases to 8.49 10

2

and 5.9 10

3

S cm

1

in wet hydrogen

at the sametemperatures, respectively. Similar result has been

reported by Sun et al. [26] for the BaCe

0.8

Sm

0.2

O

3d

eCe

0.8

Sm

0.2

O

2d

composite (weight ratio 1:1); however, this

compositeelectrolyteshows muchlower conductivitythanthe

BaZr

0.1

Ce

0.7

Y

0.2

O

3d

eCe

0.8

Y

0.2

O

2d

composite (weight ratio 1:4)

in this study either in dry air or in wet hydrogen atmosphere.

Fig. 9 shows the electrical conductivity measured in dry air

as a function of temperature for CYOeBZCYO composite

electrolytes with different compositions sintered at 1400

Cfor

5 h. It is clear from Fig. 9 that the activation energies decrease

gradually with the increase of BZCYO content in the

CYOeBZCYO system, but the conductivities of CYOeBZCYO

composite electrolytes are muchlower thanthose of pure CYO

and BZCYOelectrolytes at elevated temperatures. This may be

caused by the increasing amount of impurities including

Ba

2

YZrO

6

and Ba

2

ZrO

4

in the composites with increasing

BZCYO content. For the composites containing 20wt.% and

30wt.% BZCYO, both CYO phase and BZCYO phase can

conduct oxygen-ion via oxygen vacancies. Moreover, consec-

utive two-phase interfaces can be formed in the matrix of CYO

phase which facilitates the interfacial conduction, despite of

the presence of small amount of impurities.

1.0 1.1 1.2 1.3 1.4 1.5

-1

0

1

2

3

4

5

6

750 700 650 600 550 500 450 400

1450

o

C

1400

o

C

1300

o

C

l

n

(

T

)

(

S

c

m

-

1

K

)

1000/T (K

-1

)

t (

o

C)

0.439eV

0.462eV

0.756eV

Wet hydrogen (3% H

2

O)

0.853eV

0.580eV

0.930eV

Fig. 8 e Arrhenius plots of the electrical conductivity in wet

hydrogen (3% H

2

O) for CYOeBZCYO composite electrolytes

containing 20wt.% BZCYO sintered at 1300, 1400 and

1450

C, respectively.

1.0 1.1 1.2 1.3 1.4 1.5

-6

-5

-4

-3

-2

-1

0

1

2

3

4

750 700 650 600 550 500 450 400

t (

o

C)

x =0wt.%

x =20wt.%

x =30wt.%

x =50wt.%

x =70wt.%

x =100wt.%

l

n

(

T

)

(

S

c

m

-

1

K

)

1000/T (K

-1

)

(1-x)CYO-xBZCYO

Dry air

0.873eV

0.416eV

0.756eV

0.705eV

0.652eV

0.607eV

0.580eV

Fig. 9 e Electrical conductivity measured in dry air as

a function of temperature for CYOeBZCYO composite

electrolytes with different compositions sintered at 1400

C

for 5 h.

1.0 1.1 1.2 1.3 1.4 1.5

-6

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

750 700 650 600 550 500 450 400

0.414eV

0.711eV

t (

o

C)

Wet hydrogen (3% H

2

O)

l

n

(

T

)

(

S

c

m

-

1

K

)

1000/T (K

-1

)

x =0wt.%

x =20wt.%

x =30wt.%

x =50wt.%

x =70wt.%

x =100wt.%

(1-x)CYO-xBZCYO

0.579eV

0.756eV

0.525eV

0.381eV

0.399eV

0.895eV

0.439eV

Fig. 10 e Electrical conductivity measured in wet hydrogen

(3% H

2

O) as a function of temperature for CYOeBZCYO

composite electrolytes with different compositions

sintered at 1400

C for 5 h.

i nt e r na t i ona l j o ur na l o f hy d r o g e n e ne r g y 3 7 ( 2 0 1 2 ) 1 3 0 4 4 e1 3 0 5 2 13050

Fig. 10 shows the electrical conductivity measured in wet

hydrogen (3% H

2

O) as a function of temperature for

CYOeBZCYO composite electrolytes with different composi-

tions sintered at 1400

C for 5h. At lowtemperatures (<600

C),

the activation energies decrease gradually with the increasing

of BZCYO content, but at high temperatures (600

C), the

difference in activation energy for the CYOeBZCYOcomposite

electrolytes is not marked. Composition dependences of

conductivity measured in wet hydrogen for the CYOeBZCYO

system are also illustrated in Fig. 10. With increasing amount

of BZCYO, the conductivity of the composite electrolytes

rstly increases to a maximum value then decreases sharply

especially when the BZCYO content exceeds 50wt.%. The

minimum conductivity is obtained by the composite electro-

lyte containing 70wt.% BZCYO, and the maximum conduc-

tivities are achieved by the composite electrolyte containing

20wt.% BZCYO at 550e700

C and the composite electrolyte

containing 30wt.% BZCYO at 400e500

C. Comparing the

composite electrolyte containing 30wt.% BZCYO with pure

BZCYO, the conductivity is greatly enhanced at low temper-

atures. The highest conductivities of 3.27 10

2

S cm

1

and

9.40 10

3

S cm

1

are achieved at 500

C and 400

C, respec-

tively, which are about 3e5 times higher than those of pure

CYO and BZCYO, implying the composite effect is functioned

in the CYOeBZCYO system. The composite effect can be

ascribed to the interfacial proton conduction via oxygen

vacancy or/and electron hole. Further studies will be carried

out to explore the detailed conduction mechanism in the

CYOeBZCYO system.

4. Conclusion

Novel composite electrolytes were developed based on a uo-

rite-type CYO synthesized by the carbonate co-precipitation

route at 700

C and a perovskite-type BZCYO synthesized by

the solegel process at 1000

C. The appropriate sintered

temperature for the composite electrolyte should not exceed

1400

C to maintain phase stability and high conductivity.

Compared with CYO and BZCYO, the composite electrolytes

showed much lower conductivity in dry air, however, they

showed greatly enhanced conductivity in wet hydrogen (3%

H

2

O). The highest conductivities of 3.27 10

2

S cm

1

and

9.40 10

3

S cm

1

were achieved at 500

C and 400

C in wet

hydrogen by the composite containing 30wt.% BZCYO, indi-

cating that this highly proton-conductive composite is

a promising candidate as electrolyte for LT-SOFCs.

Acknowledgments

This work was nancially supported by the National Natural

Science Foundation (NSFC) of China (No. 50902083), the NSFC

Fund for Creative Research Groups (No. 50821064), the

National Basic Research Program of China (No. 2012CB215401)

and the fundamental research funds for the central

universities.

r e f e r e n c e s

[1] Steele BCH, Heinzel A. Materials for fuel-cell technologies.

Nature 2001;414(6861):345e52.

[2] Wachsman ED, Lee KT. Lowering the temperature of solid

oxide fuel cells. Science 2011;334(6058):935e9.

[3] Huang JB, Xie FC, Wang C, Mao ZQ. Development of solid

oxide fuel cell materials for intermediate-to-low

temperature operation. Int J Hydrogen Energy 2012;37(1):

877e83.

[4] Steele BCH. Appraisal of Ce

1y

Gd

y

O

2y/2

electrolytes for

ITSOFC operation at 500

C. Solid State Ionics 2000;129(1e4):

95e110.

[5] Ishihara T. Development of new fast oxide ion conductor and

application for intermediate temperature solid oxide fuel

cells. B Chem Soc Jpn 2006;79(8):1155e66.

[6] Pergolesi D, Fabbri E, D Epifanio A, Bartolomeo ED, Tebano A,

Sanna S, et al. High proton conduction in grain-boundary-

free yttrium-doped barium zirconate lms grown by pulsed

laser deposition. Nat Mater 2010;9(10):846e52.

[7] Shao ZP, Haile SM. A high-performance cathode for the next

generation of solid-oxide fuel cells. Nature 2004;431(7005):

170e3.

[8] Zhan ZL, Barnett SA. An octane-fueled solid oxide fuel cell.

Science 2005;308(5723):844e7.

[9] Suzuki T, Funahashi Y, Yamaguchi T, Fujishiro Y, Awano M.

New stack design of micro-tubular SOFCs for portable power

sources. Fuel Cells 2008;8(6):381e4.

[10] Zuo N, Zhang M, Xie F, Wang C, Liu Z, Mao Z. Fabrication and

characterization of anode support low-temperature solid

oxide fuel cell based on the samaria-doped ceria electrolyte.

Int J Hydrogen Energy 2012;37(1):797e801.

[11] Doshi R, Richards VL, Carter JD, Wang XP, Krumpelt M.

Development of solid-oxide fuel cells that operate at 500

C.

J Electrochem Soc 1999;146(4):1273e8.

[12] Kreuer KD. Proton-conducting oxides. Annu Rev Mater Res

2003;33:333e59.

[13] Ito N, Iijima M, Kimura K, Iguchi S. New intermediate

temperature fuel cell with ultra-thin proton conductor

electrolyte. J Power Source 2005;152(1):200e3.

[14] Ryu KH, Haile SM. Chemical stability and proton conductivity

of doped BaCeO

3

eBaZrO

3

solid solutions. Solid State Ionics

1999;125(1e4):355e67.

[15] Zuo CD, Zha SW, Liu ML, Hatano M, Uchiyama M.

Ba(Zr

0.1

Ce

0.7

Y

0.2

)O

3d

as an electrolyte for low-temperature

solid-oxide fuel cells. Adv Mater 2006;18(24):3318e20.

[16] Zhu B, Liu XR, Schober T. Novel hybrid conductors based on

doped ceria and BCY20 for ITSOFC applications. Electrochem

Commun 2004;6(4):378e83.

[17] Khadelwal M, Venkatasubramanian A, Prasanna TRS,

gopalan P. Correlation between microstructure and electrical

conductivity in composite electrolytes containing Gd-doped

ceria and Gd-doped barium cerate. J Eur Ceram Soc 2011;

31(4):559e68.

[18] Wang XD, Ma Y, Li SH, Kashyout AH, Zhu B, Muhammed M.

Ceria-based nanocomposite with simultaneous proton and

oxygen ion conductivity for low-temperature solid oxide fuel

cells. J Power Sources 2011;196(5):2754e8.

[19] Ricote S, Caboche G, Estournes C, Bonanos N. Synthesis,

sintering, and electrical properties of BaCe

0.9x

Zr

x

Y

0.1

O

3d

.

J Nanomater; 2008. doi:10.1155/2008/354258.

[20] Gu YF, Li G, Meng GY, Peng DK. Sintering and electrical

properties of coprecipitation prepared Ce

0.8

Y

0.2

O

1.9

ceramics.

Mater Res Bull 2000;35(2):297e304.

[21] Rey JFQ, Muccillo ENS. Lattice parameters of yttria-doped

ceria solid electrolytes. J Eur Ceram Soc 2004;24(6):1287e90.

i nt e r na t i o na l j our na l o f hy d r og e n e ne r g y 3 7 ( 2 0 1 2 ) 1 3 0 4 4 e1 3 0 5 2 13051

[22] Xu HM, Yan HG, Chen ZH. Sintering and electrical properties

of Ce

0.8

Y

0.2

O

1.9

powders prepared by citric acidenitrate low-

temperature combustion process. J Power Sources 2006;

163(1):409e14.

[23] Fabbri E, DEpifanio A, Bartolomeo ED, Licoccia S, Traversa E.

Tailoring the chemical stability of Ba(Ce

0.8x

Zr

x

)Y

0.2

O

3d

protonic conductors for intermediate temperature solid

oxide fuel cells (IT-SOFCs). Solid State Ionics 2008;179(15e16):

558e64.

[24] Suksamai W, Metcalfe IS. Measurement of proton and oxide

ion uxes in a working Y-doped BaCeO

3

SOFC. Solid State

Ionics 2007;178(7e10):627e34.

[25] ZhuB, AlbinssonI, Mellander BE. Electrical propertiesandproton

conductionof gadoliniumdopedceria. Ionics 1998;4(3e4):261e6.

[26] Sun WP, Jiang YZ, Wang YF, Fang SM, Zhu ZW, Liu W. A

novel electronic current-blocked stable mixed ionic

conductor for solid oxide fuel cells. J Power Sources 2011;

196(1):62e8.

i nt e r na t i ona l j o ur na l o f hy d r o g e n e ne r g y 3 7 ( 2 0 1 2 ) 1 3 0 4 4 e1 3 0 5 2 13052

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Expansion Calculations and Loop SizingDocument2 pagesExpansion Calculations and Loop Sizingzshehadeh0% (1)

- HVAC Case Study PPT ChanduDocument72 pagesHVAC Case Study PPT Chanduprasahnthrk0775% (4)

- Group Presentation: Quantum TunnellingDocument14 pagesGroup Presentation: Quantum TunnellingdeepakNo ratings yet

- Rheology ModifiersDocument35 pagesRheology Modifierssbttbs67% (3)

- The Role of Polymers in Water Treatment Applications and Criteria For Comparing AlternativesDocument42 pagesThe Role of Polymers in Water Treatment Applications and Criteria For Comparing AlternativesmnasiroleslamiNo ratings yet

- J Phys Condens Matter 18 (2006) 165Document16 pagesJ Phys Condens Matter 18 (2006) 165Balakrishnaiah RNo ratings yet

- Fall 2021 Department of Chemistry and Earth Sciences Arts and Sciences 3Document9 pagesFall 2021 Department of Chemistry and Earth Sciences Arts and Sciences 3DABAB DABABNo ratings yet

- Refex 134a SpecDocument15 pagesRefex 134a SpecSami ThirunavukkarasuNo ratings yet

- Determination of Activity and Activity Coefficient From Cell Emf 2Document7 pagesDetermination of Activity and Activity Coefficient From Cell Emf 2Khrystin Jean Berdos100% (2)

- Types of BondingDocument7 pagesTypes of Bondingukpics7No ratings yet

- Notes Air CompositionDocument4 pagesNotes Air CompositionOkami :]No ratings yet

- PhotometryDocument2 pagesPhotometryHugo WNo ratings yet

- ACT Thrissur Plus Two Easy QuestionsDocument23 pagesACT Thrissur Plus Two Easy QuestionsAbin PmNo ratings yet

- Principles of Physical ChemistryDocument28 pagesPrinciples of Physical Chemistryqwerty1298No ratings yet

- Lab Report 7Document2 pagesLab Report 7bjddjkNo ratings yet

- Week 3 - Reactive DyesDocument7 pagesWeek 3 - Reactive DyesRR TNo ratings yet

- Cambridge O Level: Chemistry 5070/11Document16 pagesCambridge O Level: Chemistry 5070/11Jack DoeNo ratings yet

- Logic PuzzleufhfgDocument1 pageLogic Puzzleufhfgkjj77600% (2)

- Cooling Tower PowerpointDocument17 pagesCooling Tower PowerpointAnonymous fQAeGFNo ratings yet

- 03 Naproxen SodiumDocument10 pages03 Naproxen SodiumSadi SamanNo ratings yet

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- Sample PaperDocument10 pagesSample PaperAbdul ZahirNo ratings yet

- ESE - Miscellaneous Treatments of WaterDocument13 pagesESE - Miscellaneous Treatments of WaterRoshan NayakNo ratings yet

- Expt 9Document3 pagesExpt 9Elaine P.No ratings yet

- FLR - Performance of A Tubular CondenserDocument12 pagesFLR - Performance of A Tubular CondenserNazario Emil LintagNo ratings yet

- Tobbala2020 PDFDocument16 pagesTobbala2020 PDFSaber AlsidNo ratings yet

- wch15 01 Rms 20240118Document38 pageswch15 01 Rms 20240118John WongNo ratings yet

- EHB Sunoco Marcus HookDocument78 pagesEHB Sunoco Marcus HookEmily ScottNo ratings yet

- AM Week 2 ECM NOTESDocument19 pagesAM Week 2 ECM NOTESa38659158No ratings yet

- Sodium Hydride 60 Percent in OilDocument3 pagesSodium Hydride 60 Percent in Oilbhawanisr@gmail.comNo ratings yet