Professional Documents

Culture Documents

3935 A722-43007 - Rev00 - 01

Uploaded by

Elena CucerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3935 A722-43007 - Rev00 - 01

Uploaded by

Elena CucerCopyright:

Available Formats

NSTRUCTONS

This drawing or document, being the

property of MH, may neither be copied,

reproduced, read by any other third party

nor used for any purpose other than

designated without previous written

consent of MH, regardless of the status

of the patent, whether prior to filing,

pending, or registered.

CONFDENTAL

FOR CONSTRUCTON

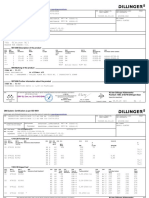

INSPECTION RECORD

FOR

RF-731-E3 LUBE OIL COOLER

OF

RF-731 REFRIGERATOR(B.05)

(MNF.: GEA REFRIGERATION ITALY)

FR No.:

FR-0126

DSTR

Document Category for Owner OWNER E

Appx. 9-2.1 3.3.1 MCC -

Appx. 9-6

CLASS A e - Sojitz -

CODE (by Owner) 1 2 3

RC E

PM -

46 SHEETS WTH COVER EM -

R

E

V

O

N

S

SM -

QA/QC *

PROCURE

COST _

SCHEDULE -

NO DATE DESCRPTON REFERENCE

APP'D APP'D APP'D PROCESS -

SECTON MACHNERY PROJECT TEAM

ORDER NO. 533820 CUSTOMER:

JSC GAZPROM NEFTEKHM SALAVAT (GNS)

EQUP -

PROJECT TEAM : RSAE PROJECT

MACHNE *

FURNACE -

APPROVED

99/*

PPNG -

-

PROJECT:

NSTRU -

MACHNERY

RSAE PROJECT

ELECT -

SECTON Plant QA Group CVL -

APPROVED

GNS DWG. NO. :

CONST *

3.3.1

- - -

- -

- -

MH DWG. NO. : REV. VENDOR -

3935 A722-43007

0

SPARE -

DRAWN DATE 8-Apr.-2014 TOTAL 0

MITSUBISHI HEAVY INDUSTRIES, LTD.

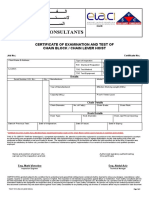

DOCUMENTAZIONE APPARECCHIO

EQUPMENT BOOK

CLIENTE N DI FABBRICA

Client GEA Refrigeration taly Serial nr. 1262

ORDINE N SIGLA

Order nr. 3314016349-1 del 12/02/2013 Item RF-731-E3

COMMESSA DISEGNO N

Job 2037/A Drawing nr. TCF-1438

INDICE

Index

CLENTE

Client GEA Refrigeration taly

N D FABBRCA

Serial nr. 1262

ORDNE N

Order nr. 3314016349-1 del 12/02/2013

SGLA

Item RF-731-E3

COMMESSA

Job 2037/A

DSEGNO N

Drawing nr. TCF-1438

SERVZO

Service LUBE OL COOLER

COLLAUDO

Inspection WORKSHOP + CLENT + GQS

Descrizione

Description

N.

N

Pagina

Page

Certificato di conformit

Certificate of conformit 1 1

Certificato di prova idraulica

!drostatic test certificate 2 3

Certificato di controllo visivo

"is#al test certificate 3 1

Certificato di controllo dimensionale

Dimensionai test certificate 4 1

Certificato di visita interna

Internal visit certificate 5 1

Certificato di controllo materiali

$aterials c%ec& certificate 6 1

Lista materiali

$aterials list 7 1

Certificati materiali

$aterial certificates 8 21

Piano ispezioni

Inspections plan 9 3

Quaderno delle saldature

'elding boo& 10 19

Qualifiche del personale CND

(#alification man forND) 11 2

Certificati di controlli non distruttivi

Non distr#ctive test certificates 12 5

Certificato di controllo lembi da saldare e puntatura

Certificate of bevels and fit*#p c%ec& 13 1

Certificati visivo dimensionali fascio tubiero

Dimensional and vis#al test certificates of t%e t#be b#ndle 14 3

Certificati complementari

Complementar certificates 15 2

Copia targa dati

Nameplate cop 16 1

Manuale d'uso e manutenzione

$an#al for operation and maintenance 17 8

Calcoli meccanici

$ec%anical calc#lations 18 104

Disegno costruttivo

Constr#ction drawing 19 1

Data

Date 05/08/2013

FrateIIi MAGNI s.a.s.

20064 GORGONZOLA (Milano) Via Parini,60

tei. 02 95.30.28.68 r.a. fax 02 95.30.00.91

C.F./P.VA FF00686490152

email : info@fratellimagni.com website : www.fratellimagm.com

Quality System Certified UN EN SO 9001 :2008 (TOM 1472/)

CERTFCATO D VERFCA

DELLA TARATURA

Spett. Ditta

D.C.D. NOX snc

VA BARCELLONA, 35

20093 COLOGNO MONZESE

NUMERO: FM/9327/12 RCHESTA: 941 del 21.11.2012

Manometro: DN 80 campo scala 0/60 bar MatricoIa: 17566

OGGETTO:

Costruttore: FRATELL MAGN CIasse precisione : 1,0 % Divisione minima: 1,0 bar

CONDIZIONI AMBIENTALI : CONDIZIONI DI TARATURA:

Temperatura ambiente: 20 +/- 1C Posizione: verticaIe

Pressione atmosferica : 1005 +/- 5 mbar FIuido: da -1 a +25 bar : aria

da +25 a+1100 bar : olio

Umidit reIativa : 65%

STRUMENTI DI RIFERIMENTO:

AEPLabDDMn309184 -1+2,5 bar g- certificato S..T n7312P del 24/01/12 - Centro Taratura n 93

Druck DP 145: n0453-97-02/490193 -1+2 barg- certificatoUKAS n 0046071 del 31/05/12 - Centro Taratura n 0221

Druck DP 145: n0453-97-02/891045 0/10 bar g- certificatoUKAS n0046071 del 31/05/12 - Centro Taratura n 0221

AEP Lab DDM n710317 0/20 bar g - certificato S..T. n K0212P del 22/06/12 - Centro Taratura n 93

Druck DP 145: n0453-97-O2/889378 0/35 bar g- certificatoUKAS n0046071de31/05/12 - Centro Taratura n 0221

AEP Lab DDM n609609 0/50 bar g - certificato S..T. n74112Pdel 16/05/12 -CentroTaratura n 93

AEPLabDDMnB02319 0/100 bar g- certificato S..T. n 9351 P del 27/06/11 - Centro Taratura n 93

Druck DP 145: n0453-97-02/1376167 0/200 bar g- certificatoUKAS n 0046071 del 31/05/12 - Centro Taratura n 0221

AEPLabDDMn121415 0/700 bar g- certificato S.LT. n7412P del 24/01/12 - Centro Taratura n 93

Bilancia Pesi S. BARNET 9189/6 - n 7031 10/1100 bar g- certificato S..T. n00.020 del 24/01/00-Centro Taratura .n 25

PRESSIONE NOMINALE (bar) 0,00 10,00 20 B0 30,00 40,00 50,00 60,00

VALORE NDCATO (bar) Salila 0,00 9,65 19,72 29,78 39,82 50,12 60,31

VALORE NDCATO (bar) Discesa 0,00 9,94 19,98 30,03 40,09 50,20

ERRORE (%) Salita 0,00 0,58 0,47 0,37 0,30 -0,20 -0,52

ERRORE (%) Discesa 0,00 0,10 0,03 -0,05 -0,15 -0,33

Max errore (massimo errore di indicazione) % f.s. = Emax = 0,58

risultali di misura riportati nella presente dichiarazione sono stati ottenuti applicando la Procedura (PR-O9-0) del Sistema Qualit Aziendale (UN

EN SO 9001:2008 certificato CM n1472/3).

NCERTEZZA DEL PROCEDMENTO D TARATURA:

ncertezza di misura del procedimento di taratura: t=p + s = 0,46% di f.s.

p = incertezza di misura dello strumento campione 0,03 % di f.s.

s = incertezza di indicazione dello strumento in taratura 0,43% di f.s.

(risoluzione) calcolata come 1/4 della divisione minima sul % f.s.

NCERTEZZA DELLO STRUMENTO N TARATURA:

Se si effettuano le opportune correzioni rispetto ad ogni punto di misura sulla base degli errori di indicazione sopra riportati, l'incertezza di misura m

dello strumento in taratura pari a quella t del procedimento di taratura.

Nel caso non si effettuino correzioni ai valori misurati, l'incertezza m di misura dello strumento in taratura, espressa come due volte lo scarto tipo,

pari

rti = incertezza di misura dello strumento in taratura lm= = 0,74 % di f.s.

I documenti reIativi ai campioni primari sono consuItabiIi presso Ia ns. sede di GorgonzoIa

DATA TECNCO RESPONSABLE QUALTA'

03/12/2012 QUADR ANGELO ENZO BRAMBLLA

CQS 155

NSPECTOR NAME

REVEWED WTNESSED

MONTORED SPOT WTNESSED

DATE 24 JUN 2013 SGNATURE

fintec

QUALTY CONTROL DEPARTEMENT

UFFCO CONTROLLO QUALTA'

date 24/6/13 ch'K

ALLEGATO 5

+ttac%ment ,

CERTIFICATO DI VISITA INTERNA

NTERNAL VST CERTFCATE

CLIENTE N DI FABBRICA

P#rc%aser GEA Refrigeration taly Serial nr. 1262

ORDINE N SIGLA

Order nr. 3314016349-1 del 12/02/2013 Item RF-731-E3

COMMESSA DISEGNO N

Job 2037/A Drawing nr. TCF-1438

Questo certificato per autenticare che Io scambiatore di caIore di cui aII'ordine sopra indicato

stato sottoposto a visita interna.

)%is is to certif t%at t%e %eat e-c%anger covered b t%e above mentioned order %as satisfactor

passed t%e internal visit.

Esito deIIe prove

.es#lt of test SATSFACTORY

Firma costruttore

$an#fact#rer signat#re

Firma ispettore

Inspector signat#re

Firma cIiente

Client signat#re

Data

Date 30/05/2013

Note

Notes

fintec

QUALTY CONTROL DEPARTEMENT

UFFCO CONTROLLO QUALTA'

date 24/6/13 ch'K

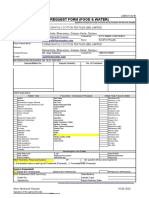

ALLEGATO 7

+ttac%ment /

CLIENTE N DI FABBRICA

P#rc%aser

GEA REFRGERATON S.p.A.

Serial nr. 1262

ORDINE N SIGLA

Order nr.

3314016349 del 12/02/2013

Item RF-731-E3

COMMESSA DISEGNO N

Job 2037/A

Drawing nr TCF-1438

Pos.

POS.

Descrizione

Description

Spessore

)%ic&ness

CoIata

!eat n#mber

Costruttore

$an#fact#rer

Certificato

Certificate

Data

Date

1 CAP 9,52 41789 OFF. MEC. RGH 1600/13-SR 14/03/2013

2 CHANNEL from PPE 9,52 47858 ARCELOR MTTAL B 449/3 22/02/2013

3 MAN FLANGE 58 30222 RE-OMBA 131572/3 11/04/2013

4 TUBESHEET 38 323033 GALPERT 587 04/06/2013

5 TUBESHEET 38 323033 GALPERT 587 04/06/2013

6 STUD BOLT 3/4" L=120 CD8813 BULLONERA VLLA 130802 13/06/2013

7 NUT 3/4" 45707 BULLONERA VLLA 130802 13/06/2013

11 PPE 7,62 108037 TUBOS REUNDOS 0000304771/1 03/10/2011

12 WN FLANGE 3" 212456 DUEV 1391 06/05/2013

13 LWN FLANGE 2" 214540 MONTCELL 108-2013 11/04/2013

14 SHELL from PPE 9,52 47858 ARCELOR MTTAL B 449/3 22/02/2013

15 EXCHANGER TUBE 2,11 192720 215798 RONCON 13390 28/03/2013

21 RENF. PLATE 10 1TL589 METNVEST 254441 14/02/2012

26 RENF. PLATE 10 1TL589 METNVEST 254441 14/02/2012

Firma costruttore

$an#fact#rer signat#re

Firma cIiente

Client signat#re

Firma ispettore

Inspector signat#re

Data

Date 14/06/2013

SCHEMA STAMPGLATURE

STAMPNG OUTLNE

SGL

A

TE

M

RF-731-E3

cor

r.

JOB

2037/A

N.F.

S.N. 1262

DS.

DW

G.

TCF-1438

fintec

QUALTY CONTROL DEPARTEMENT

UFFCO CONTROLLO QUALTA'

date 14/06/13 ch'K

CQS 155

NSPECTOR NAME

REVEWED WTNESSED

MONTORED SPOT WTNESSED

DATE 24 JUN 2013 SGNATURE

//

Phone +39 0523 8617:1

Fax -+39 0523 862794

COMPANY WITH QUALITY MANAGEMENT

SYSTEM CERTIFIED BY /HEPA3BOPHHBO/

ISO 9001:2008

INSPECTION CERTIFICATE

ABNAHMEPRUFZEUGNIS

CERTIFICAT DE RECEPTION

CERTIFICATO DI ISPEZIONE

EN 10204: 2004

CERT No. 1600/13-SR

REV No. 0

x 3.1 3.2 DATE 14/03/2013

CLIENT

COMMERCIALE TUBI ACCIAIO SPA

ORDER No

LS-0OO0O69

OMR JOB No

38025

We hereby certify that the Iisted materiaIs have been manufactured in compIiance with the

above standards and order specifications if any.

ASTM A420M-10A-ASME SA420 Sect.II Part A Ed. 10 - ASME B16.9-07 - SEAMLESS

ITEM O.TY DESCRIPTION HEAT

HEAT CODE OF

THEFTGS

RAWMATERIAL STEEL MAKER RAW CERT No CLIENT ITEM rSTOCK CODE

030 40 Caps 12- STD WPL6 41789 PIate

ILSENBURGER

GROBBLECH

722889

CHEMICAL COMO!ITION H= LADLE ANALISYS P* PRODUCT ANALISYS

HEAT c% Mn% Sl% P% S% Ni% Cr% Mo% Cu% V% Ti% Nb% AL%

Ceq LF

%

C.E.

(CSA) %

Pcm

%

PREN

%

J Factor

%

41789

H 0,16 0,89 0.19 0.012 0,003 0.12 0,05 0,01 0,03 0,004 0,002 0.02 0,04 0,33

P

MECHANICAL ROERTIE! ON RAW MATERIAL ON PIECES IN FINISHED CONDITION

TEST

TENSILE STRENGHT

Hardness

Max

IMPACT TEST (CHARPY V)

Direction

YELO

STR.0.2%

U.T.S

EntongaIitin

(2")

EntongjIion

(5.65. So) YS/

U.TS.

Direction Dimension Temp. Obtained VaIues (JouIes) Average LateraI Expansion

N/mm

2

N/mm

2

HB C 1 2 3 JouIes 1 2 3

818 L 343 461 30,9 0,0 0,74 13B L 10 X 7.5 -5O 169 193 171 178 0.00 0,00 0,00

REMAR"!#

METHOD OF FABRCATON: HOT FORMNG BETWEEN 780C AND 980C

HEAT TREATMENT: NORMALZNG AT 920C PERMANENCE 1 Hr/t WTH (30' min. MNMUM) COOLNG

N STLL AR

THS MATERAL MEETS THE SPECFCATON NACE MR 01-75/2003 SO 15156

AND NACE MR 01-03/2007 WHEN USED N THE SPECFC CONDTONS DETALED N THE

STANDARDS

VSUAL AND DEMENSONAL CONTROL OF FTTNGS: SATSFACTORY RESULTS.

Ceq %=C+(Mn)/6+(Cr+Mo+V)/5+(Ni+Cu)/15

LA SOCETE' O.M.R. SPA GARANTT QUELES PRODUTS, OBJET DU PRESENT

CERTFCAT RESPECTENT EN LEUR TOTALTE' LES PRESCRTONS DE L'ARTCLE 15

DE L\ARRETE MNSTEREL DU 24 MARS 1978 MODFE'

C<=0.25-S<=0.05-P<=0.05%-Rm<700 N/mm2-A%(L=5.65Vso)>16% Long. Rm(A-2)>10500-

Rp0.2/Rm<=0.9

MANUFACTURER AUTHORIZED INSPECTOR $ PURCHASER AUTHORIZED INSPECTOR OFFICIAL DESIGNATED INSPECTOR

DATE 14/03/13 DATE DATE

THE OUAUTY MANAGEMENT SYSTEM SUPPORTS THE REQUREMENT OF ANNEX 1. SECT. 4.3 OF PEO 97/23/EC

C

u

s

to

m

e

r

:

F

N

T

E

C

S

.

R

.

L

.

T

h

is

d

o

c

u

m

e

n

t

is

r

e

p

r

o

d

u

c

e

d

b

y

a

c

o

m

p

u

t

e

r

iz

e

d

s

y

s

t

e

m

a

n

d

is

c

o

n

fo

r

m

t

o

t

h

e

o

r

ig

in

a

l

C

O

M

M

E

R

C

A

L

E

T

U

B

A

C

C

O

V

ia

le

L

id

ic

e

4

0

-

G

r

u

g

lia

s

c

o

(

T

O

)

P

.O

.

N

o

.

:

P

0

:

5

2

8

1

.

1

3

u

e

a

r

o

.

:

4

1

7

8

9

K

g

C

t

a

's

jo

b

:

O

R

0

0

0

0

3

8

7

M

t

te

m

:

D

a

te

:

0

3

/

0

4

/

2

0

1

3

P

c

s

N

o

.

:

5

Manufacturer:

ArcelorMittal Tubular Products Roman S.A.

Stefan eel Mare Str.B1.15,ScA,Parter 1

Roman,Neamt,Romania

MILL TEST CERTIFICATE

according to EN 10204/3.1/2004

Page 1/6

B 449/3

22.02.2013

Buyer: T.AX. TUB ACCAO LOMBARDA SPA

Via G. Di Vittorio. 6, Zona bd., Fiorcnzuola

D'Arda. Piace 29017, taly

SEAMLESS STEEL LNE PPES

Total weight:

20266 tons

44 679 lbs

Total Length:

274.67 meters

901.15 feets

Pieces

24

Bundles

Standard: AP 5L PSL 1/SO 3183-2007; ASTM A 333/A 333M/2011:ASME SA 333/SA 333M/201 La:TS 02 REV.OS/24.01.2012 with

devotions as per ourTO no.2/03.072012:ASME B 16.25/2007:NACE MR 0175flSO 15156-2009; NACE MR 0103-2010

Buyer's

referenc

e

PO NO.: OF-120284

Dimensions: 323.80 x 9.52 ram

12.750x0.375 inch

Schedule: - Length: 10.00-11.80 m 32.81-38.71 feet

Contract 50000837

tem tem Client HydroTest: Bar PS MPa Time(sec) Steel Grade: Gr6/X52

3 - 179 2609 17.9 5

Chemical Analysis(%)

C Mn Si S P Cr Ni Cu Al Mo V Nb Ti B

Heat

Bulletin

No.

Product

Max 020 130 035 0.010 0.020 020 0.40 030 0.060 0.12 0.080 0.020 0.040 0.0010

Min - - 0.15 - - - - - 0.015 - 0.060 - - -

47858 Heat analysis 0.14 1.20 030 0.003 0.011 0.10 0.10 0.15 0.036 0.03 0.060 0.001 0.001 0.0004

47851 Heat analysis 0.15 120 027 0.004 0.010 0.05 0.12 020 0.024 0.03 0.060 0.001 0.001 0.0004

47848 Heatanalysis 0.13 1.20 030 0.005 0.017 0.07 0.11 020 0.027 0.02 0.060 0.002 0.001 0.0005

47858 297

Product

analysis

0.13 1.21 027 0.005 0.012 0.06 0.11 0.20 0.021 0.03 0.060 0.000 0.000 0.0000

47858 297

Product

analysis

0.13 1.20 027 0.005 0.012 0.06 0.11 0.20 0.021 0.03 0.060 0.000 0.000 0.0000

47851 252

Product

analysis

0.15 1.25 028 0.005 0.011 0.05 0.10 0.18 0.030 0.02 0.060 0.000 0.000 0.0001

47S5 252

Product

analysis

0.15 1.25 028 0.005 0.011 0.05 0.10 0.18 0.030 0.02 0.060 0.000 0.000 0.0001

47848 201

Product

analysis

0.13 1.29 026 0.004 0.010 0.07 0.09 0.16 0.023 0.03 0.060 0.001 0.000 0.0001

47848 201

Product

analysis

0.13 128 026 0.005 0.010 0.07 0.09 0.15 0.023 0.03 0.060 0.001 0.000 0.0001

Manufacturer:

ArcelorMittal Tubular Products Roman S.A.

Stefan eel Mare Str.B1.15,ScA,Parter 1

Roman,Neamt,Romania

MILL TEST CERTIFICATE

according to EN 10204/3.1/2004

Page 1/6

B 449/3

22.02.2013

Buyer: T.AX. TUB ACCAO LOMBARDA SPA

Via G. Di Vittorio. 6, Zona bd., Fiorcnzuola

D'Arda. Piace 29017, taly

SEAMLESS STEEL LNE PPES

Total weight:

20266 tons

44 679 lbs

Total Length:

274.67 meters

901.15 feets

Pieces

24

Bundles

Standard: AP 5L PSL 1/SO 3183-2007; ASTM A 333/A 333M/2011:ASME SA 333/SA 333M/201 La:TS 02 REV.OS/24.01.2012 with

devotions as per ourTO no.2/03.072012:ASME B 16.25/2007:NACE MR 0175flSO 15156-2009; NACE MR 0103-2010

Buyer's

referenc

e

PO NO.: OF-120284

Dimensions: 323.80 x 9.52 ram

12.750x0.375 inch

Schedule: - Length: 10.00-11.80 m 32.81-38.71 feet

Contract 50000837

tem tem Client HydroTest: Bar PS MPa Time(sec) Steel Grade: Gr6/X52

3 - 179 2609 17.9 5

Chemical Analysis(%)

Nb + V Nb+Ti+V Cr+Mo+Cu+Nb+V+Ti CE_W

T

A

L

S

P

A

-

T

H

S

D

O

C

U

M

E

N

T

S

R

E

P

R

O

D

U

C

E

D

B

Y

A

C

O

M

P

U

T

E

R

Z

E

D

S

Y

S

T

E

M

A

N

D

S

C

O

N

F

O

R

M

T

O

T

H

E

O

R

N

A

L

F

N

T

E

C

S

.

R

.

L

.

P

.

O

.

5

2

6

5

.

1

3

-

C

O

.

2

0

3

8

.

1

3

&

2

0

3

7

/

A

.

1

3

T

A

L

J

O

B

n

4

0

1

3

1

3

4

0

N

1

M

T

1

1

,

4

5

H

E

A

T

:

4

7

8

5

8

D

M

E

N

S

O

N

S

:

3

2

3

,

8

x

9

,

5

2

T

E

M

1

We state on our sole responsibility that the delivered products are in conformity with the

order requirements.

Quality Control Representative

Eng, lesami Cristian

Formular 12A. rev.9

T

A

L

S

P

A

-

T

H

S

D

O

C

U

M

E

N

T

S

R

E

P

R

O

D

U

C

E

D

B

Y

A

C

O

M

P

U

T

E

R

Z

E

D

S

Y

S

T

E

M

A

N

D

S

C

O

N

F

O

R

M

T

O

T

H

E

O

R

N

A

L

F

N

T

E

C

S

.

R

.

L

.

P

.

O

.

5

2

6

5

.

1

3

-

C

O

.

2

0

3

8

.

1

3

&

2

0

3

7

/

A

.

1

3

T

A

L

J

O

B

n

4

0

1

3

1

3

4

0

N

1

M

T

1

1

,

4

5

H

E

A

T

:

4

7

8

5

8

D

M

E

N

S

O

N

S

:

3

2

3

,

8

x

9

,

5

2

T

E

M

1

We state on our sole responsibility that the delivered products are in conformity with the

order requirements.

Quality Control Representative

Eng, lesami Cristian

Formular 12A. rev.9

Heat

Bulletin

No.

Product

Max 0.100 0.150 0.600 0.42

Min - - - -

47858 Heat analysis 0.061 0.062 0342 039

47851 Heat analysis 0.061 0.062 0342 0.40

47848 Heat analysis 0.062 0.063 0353 038

4785S 297

Product

analysis

0.060 0.060 0350 038

47858 297

Product

analysis

O.060 0.060 0350 0.38

47851 252

Product

analysis

0.060 0.060 0310 0.40

47S5 252

Product

analysis

0.060 0.060 0.310 0.40

47848 201

Product

analysis

0.061 0.061 0321 039

47848 201

Product

analysis

0.061 0.061 0311 039

CEpcm= C+Si/30+Mn/2(HCu/20+Ni/60+Cr/20+Mo/l 5+V/l 0+5B CE_S = C+Mn/ CEW = C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

Manufacturer:

ArcelorMittal Tubular Products Roman S.A.

Stefan eel Mare Str.B1.15,ScA,Parter 1

Roman,Neamt,Romania

MILL TEST CERTIFICATE

according to EN 10204/3.1/2004

Page 1/6

B 449/3

22.02.2013

Buyer: T.AX. TUB ACCAO LOMBARDA SPA

Via G. Di Vittorio. 6, Zona bd., Fiorcnzuola

D'Arda. Piace 29017, taly

SEAMLESS STEEL LNE PPES

Total weight:

20266 tons

44 679 lbs

Total Length:

274.67 meters

901.15 feets

Pieces

24

Bundles

Standard: AP 5L PSL 1/SO 3183-2007; ASTM A 333/A 333M/2011:ASME SA 333/SA 333M/201 La:TS 02 REV.OS/24.01.2012 with

devotions as per ourTO no.2/03.072012:ASME B 16.25/2007:NACE MR 0175flSO 15156-2009; NACE MR 0103-2010

Buyer's

referenc

e

PO NO.: OF-120284

Dimensions: 323.80 x 9.52 ram

12.750x0.375 inch

Schedule: - Length: 10.00-11.80 m 32.81-38.71 feet

Contract 50000837

tem tem Client HydroTest: Bar PS MPa Time(sec) Steel Grade: Gr6/X52

3 - 179 2609 17.9 5

Tensile Test

Heat Gauge

Length Width/Diameter Thickness Section

Mechanical test

Bulletin No.

YS

N/mm

2

YS

(PS:1000)

UTS

N/mm

2

UTS

(PS:1000)

E %

YS/UTS

Max:-

mm inch mm inch mm inch mm

2

inch

2

47S5S Longitudinal Flat 50.8 2 38.10 1.500 9.10 0358 346.7 13.650 404 450.00 65.27 596.00 86.44 31.00 0.76

47858 Transversal Flat 50.8 2 38.10 1.500 9.70 0382 369.6 14.550 409B 438.00 63.53 585.00 84.85 28.70 0.75

47858 Transversal Flat 50.8 2 38.10 1.500 10.30 0.406 39X4 15.450 409B 500.00 72.52 581.00 84.27 27.20 0.86

47858 Transversal Flat 50.8 2 38.10 1.500 10.00 0.394 381.0 15.000 409B 429.00 62.22 576.00 83.54 29.10 0.74

47858 Transversal Flat 50.8 2 38.10 1-500 10.40 0.409 396.2 15.600 409B 437.00 6338 592.00 85.86 28.60 0.74

47851 Longitudinal Flat 50.8 2 38.10 1300 10.10 0.398 384.8 15.150 408 429.00 62.22 591.00 85.72 3330 0.73

47851 Longitudinal Flat 50.8 2 38.10 1.500 1030 0.406 392.4 15.450 413B 419.00 60.77 567.00 82.24 3430 0.74

47851 Longitudinal Flat 50.8 2 38.10 1.500 10.00 0.394 381.0 15.000 413B 428.00 62.08 572.00 82.96 32.70 0.75

47851 Longitudinal Flat 50.8 2 38.10 1.500 10.10 0398 384.8 15.150 413B 426.00 61.79 584.00 84.70 34.00 0.73

47851 Longitudinal Flat 50.8 2 38.10 1.500 10.00 0394 381.0 15.000 413B 428.00 62.08 580.00 84.12 32.40 0.74

47848 Longitudinal Flat 50.8 2 38.10 1.500 10.20 0.402 388.6 15300 408 401.00 58.16 559.00 81.08 35.90 0.72

47848 Longitudinal Flat 50.8 2 38.10 1.500 9.90 0.390 377.2 14.850 413B 415.00 60.19 573.00 83.11 35.30 0.72

47848 Longitudinal Flat 50.8 2 38.10 1.500. 10.10 0.398 384.8 15.150 413B 414.00 60.05 569.00 82.53 34.20 0.73

mpact Test

Heat mpact Test Orientation Size (mm) Temp. ReqJC KV values (J) Req.Avr. Avr. fracture KCU min0*J/cm

0

*)*1C Share Area Lateral Expansion min.

T

A

L

S

P

A

-

T

H

S

D

O

C

U

M

E

N

T

S

R

E

P

R

O

D

U

C

E

D

B

Y

A

C

O

M

P

U

T

E

R

Z

E

D

S

Y

S

T

E

M

A

N

D

S

C

O

N

F

O

R

M

T

O

T

H

E

O

R

N

A

L

F

N

T

E

C

S

.

R

.

L

.

P

.

O

.

5

2

6

5

.

1

3

-

C

O

.

2

0

3

8

.

1

3

&

2

0

3

7

/

A

.

1

3

T

A

L

J

O

B

n

4

0

1

3

1

3

4

0

N

1

M

T

1

1

,

4

5

H

E

A

T

:

4

7

8

5

8

D

M

E

N

S

O

N

S

:

3

2

3

,

8

x

9

,

5

2

T

E

M

1

We state on our sole responsibility that the delivered products are in conformity with the

order requirements.

Quality Control Representative

Eng, lesami Cristian

Formular 12A. rev.9

Bulletin No. (C)

V

(min. J)

(min.J) energy (J) min. % mm

4785S 848 Longitudinal 10x7.5x55 -50 27 286 275 304 40 288 - - - 100 100 100 1.75 1.68 1.85

47851 848 Longitudinal 10x7.5x55 -50 27 280 288 285 40 284 - - - 100 100 100 1.71 1.76 1.75

47848 848 Longitudinal 10x7.5x55 -50 27 271 289 273 40 278 - - - 100 100 100 1.64 1.78 1.66

Manufacturer:

ArcelorMittal Tubular Products Roman S.A.

Stefan eel Mare Str.B1.15,ScA,Parter 1

Roman,Neamt,Romania

MILL TEST CERTIFICATE

according to EN 10204/3.1/2004

Page 1/6

B 449/3

22.02.2013

Buyer: T.AX. TUB ACCAO LOMBARDA SPA

Via G. Di Vittorio. 6, Zona bd., Fiorcnzuola

D'Arda. Piace 29017, taly

SEAMLESS STEEL LNE PPES

Total weight:

20266 tons

44 679 lbs

Total Length:

274.67 meters

901.15 feets

Pieces

24

Bundles

Standard: AP 5L PSL 1/SO 3183-2007; ASTM A 333/A 333M/2011:ASME SA 333/SA 333M/201 La:TS 02 REV.OS/24.01.2012 with

devotions as per ourTO no.2/03.072012:ASME B 16.25/2007:NACE MR 0175flSO 15156-2009; NACE MR 0103-2010

Buyer's

referenc

e

PO NO.: OF-120284

Dimensions: 323.80 x 9.52 ram

12.750x0.375 inch

Schedule: - Length: 10.00-11.80 m 32.81-38.71 feet

Contract 50000837

tem tem Client HydroTest: Bar PS MPa Time(sec) Steel Grade: Gr6/X52

3 - 179 2609 17.9 5

Hardness Test

Heat

Hardness Test

Bulletin No.

HB max.- HV 10 niax.-

HV 10 max.- HRCmax.22

OD Midwall D End A End B

47858 362 - - - - - - - <22

47S58 362 - - - - - - - <22

47851 362 - - - - - - - <22

47851 362 - - - - - - - <22

47848 362 - - - - - - - <22

4784S 362 - - - - - - - <22

Manufacturer:

ArcelorMittal Tubular Products Roman S.A.

Stefan eel Mare Str.B1.15,ScA,Parter 1

Roman,Neamt,Romania

MILL TEST CERTIFICATE

according to EN 10204/3.1/2004

Page 1/6

B 449/3

22.02.2013

Buyer: T.AX. TUB ACCAO LOMBARDA SPA

Via G. Di Vittorio. 6, Zona bd., Fiorcnzuola

D'Arda. Piace 29017, taly

SEAMLESS STEEL LNE PPES

Total weight:

20266 tons

44 679 lbs

Total Length:

274.67 meters

901.15 feets

Pieces

24

Bundles

Standard: AP 5L PSL 1/SO 3183-2007; ASTM A 333/A 333M/2011:ASME SA 333/SA 333M/201 La:TS 02 REV.OS/24.01.2012 with

devotions as per ourTO no.2/03.072012:ASME B 16.25/2007:NACE MR 0175flSO 15156-2009; NACE MR 0103-2010

Buyer's

referenc

e

PO NO.: OF-120284

Dimensions: 323.80 x 9.52 ram

12.750x0.375 inch

Schedule: - Length: 10.00-11.80 m 32.81-38.71 feet

Contract 50000837

tem tem Client HydroTest: Bar PS MPa Time(sec) Steel Grade: Gr6/X52

3 - 179 2609 17.9 5

Technological/Microstructure Test

Heat

Flattening

Test

Bulletin No.

Flatteni

ng Test

47858 461 OK

47858 461 OK

T

A

L

S

P

A

-

T

H

S

D

O

C

U

M

E

N

T

S

R

E

P

R

O

D

U

C

E

D

B

Y

A

C

O

M

P

U

T

E

R

Z

E

D

S

Y

S

T

E

M

A

N

D

S

C

O

N

F

O

R

M

T

O

T

H

E

O

R

N

A

L

F

N

T

E

C

S

.

R

.

L

.

P

.

O

.

5

2

6

5

.

1

3

-

C

O

.

2

0

3

8

.

1

3

&

2

0

3

7

/

A

.

1

3

T

A

L

J

O

B

n

4

0

1

3

1

3

4

0

N

1

M

T

1

1

,

4

5

H

E

A

T

:

4

7

8

5

8

D

M

E

N

S

O

N

S

:

3

2

3

,

8

x

9

,

5

2

T

E

M

1

We state on our sole responsibility that the delivered products are in conformity with the

order requirements.

Quality Control Representative

Eng, lesami Cristian

Formular 12A. rev.9

T

A

L

S

P

A

-

T

H

S

D

O

C

U

M

E

N

T

S

R

E

P

R

O

D

U

C

E

D

B

Y

A

C

O

M

P

U

T

E

R

Z

E

D

S

Y

S

T

E

M

A

N

D

S

C

O

N

F

O

R

M

T

O

T

H

E

O

R

N

A

L

F

N

T

E

C

S

.

R

.

L

.

P

.

O

.

5

2

6

5

.

1

3

-

C

O

.

2

0

3

8

.

1

3

&

2

0

3

7

/

A

.

1

3

T

A

L

J

O

B

n

4

0

1

3

1

3

4

0

N

1

M

T

1

1

,

4

5

H

E

A

T

:

4

7

8

5

8

D

M

E

N

S

O

N

S

:

3

2

3

,

8

x

9

,

5

2

T

E

M

1

We state on our sole responsibility that the delivered products are in conformity with the

order requirements.

Quality Control Representative

Eng, lesami Cristian

Formular 12A. rev.9

47858 461 OK

47858 461 OK

47851 461 OK

47851 461 OK

47851 461 OK

47851 461 OK

47848 461 OK

47848 461 OK

Heat

Heat Pieces Length(m) Weight(kg)

47858 8 92.54 6827

47851 3 34.13 2519

47848 13 148.00 10920

Manufacturer:

ArcelorMittal Tubular Products Roman S.A.

Stefan eel Mare Str.B1.15,ScA,Parter 1

Roman,Neamt,Romania

MILL TEST CERTIFICATE

according to EN 10204/3.1/2004

Page 1/6

B 449/3

22.02.2013

Buyer: T.AX. TUB ACCAO LOMBARDA SPA

Via G. Di Vittorio. 6, Zona bd., Fiorcnzuola

D'Arda. Piace 29017, taly

SEAMLESS STEEL LNE PPES

Total weight:

20266 tons

44 679 lbs

Total Length:

274.67 meters

901.15 feets

Pieces

24

Bundles

Standard: AP 5L PSL 1/SO 3183-2007; ASTM A 333/A 333M/2011:ASME SA 333/SA 333M/201 La:TS 02 REV.OS/24.01.2012 with

devotions as per ourTO no.2/03.072012:ASME B 16.25/2007:NACE MR 0175flSO 15156-2009; NACE MR 0103-2010

Buyer's

referenc

e

PO NO.: OF-120284

Dimensions: 323.80 x 9.52 ram

12.750x0.375 inch

Schedule: - Length: 10.00-11.80 m 32.81-38.71 feet

Contract 50000837

tem tem Client HydroTest: Bar PS MPa Time(sec) Steel Grade: Gr6/X52

3 - 179 2609 17.9 5

Remarks PPES N COMPLANCE WTH P.E.D. 97/23/EC/29.05.1997, ANNEX 1, SECTON 4.3

Hot finished, steel is folly killed and produced by electric furnace, Arcelor Mittal Hunedoara SA- Piata ancu de Hunedoara, nr. 1 - Hunedoara.

Visual inspection and dimensional check without objection.

Steel is fully killed with a fine grain practice, size min.7.

Magnetism residual check : less than 30 Gauss.

Applied heat treatment .-normalizing with end of rolling temperature of min.880C

Hydrostatic test hold for 5 sec. no leakage noticed.

IRE- OMBA S.p.a

Cert. SO 9001

Certificato Prove MateriaIe / Test certificate

3.1 EN 10204

N -

131572/3

Rev

Cliente / Customer:

FINTEC S.R.L.

Ordine/Order:

5249.13

Collaudo/nspection: RE OMBA Comm./Job: 131572

Mater./Spec:

LF2 CL1 ASME SA350Ed.10Add.11a

Rapporto di fucinatura/Forging ratio

Processo di fabbric: Anelli fucinati + laminati

Manufactur. process: Forged + rolled rings

>= 4:1

Prova n

Test-Batch

POS

tem

Pezzi n

Pieces

est

mm

int

mm

h

mm

dentificazione / dentification HBW1 HBW2

T

A

L

S

P

A

-

T

H

S

D

O

C

U

M

E

N

T

S

R

E

P

R

O

D

U

C

E

D

B

Y

A

C

O

M

P

U

T

E

R

Z

E

D

S

Y

S

T

E

M

A

N

D

S

C

O

N

F

O

R

M

T

O

T

H

E

O

R

N

A

L

F

N

T

E

C

S

.

R

.

L

.

P

.

O

.

5

2

6

5

.

1

3

-

C

O

.

2

0

3

8

.

1

3

&

2

0

3

7

/

A

.

1

3

T

A

L

J

O

B

n

4

0

1

3

1

3

4

0

N

1

M

T

1

1

,

4

5

H

E

A

T

:

4

7

8

5

8

D

M

E

N

S

O

N

S

:

3

2

3

,

8

x

9

,

5

2

T

E

M

1

We state on our sole responsibility that the delivered products are in conformity with the

order requirements.

Quality Control Representative

Eng, lesami Cristian

Formular 12A. rev.9

60763 040 8 440 305 59

Analisi chimica / Chemical analysis %

Colata/Heat n Acciaieria/Steel mill

30222

ACC. D RUBERA - TALY- (T) Materiale calmato elaborato al forno elettrico.

Fully killed material electric furnace processed.

Cert. orig. 62849 Vacuum degassed

C

0.165

Mn

1.19

Si

0.27

P

0.006

S

0.004

Cu

0.16

Cr 0.11

Ni

0.11

Mo

0.03

Al

0.022

V

0.007

Nb

0.001

Ti

0.002

Sn

0.010

N

0.0093

H

0.00021

B

0.0005

CuNiCrMo

0.41

Cu+6Sn

0.22

Cr+Mo

0.14

Nb+V+Ti

0.01

Cea

0.411

Trattamento termico / Heat treatment

040 Normal. 900C Air

Trazione/Tension test+20C ASME SA370 0=12,5mm Lo=50mm

Valori richiesti/Required values

Rp .2%N/mm2 Rp 1%N/mm2 Rm N/mm2 A4d % A5d % z%

Senso/sense min max min max min max min max min max min max

TANG 250 485 655 22 30

Valori rilevati/Obtained values

Prova/Test n Senso/sense Rp .2% N/mm2 Rp 1%N/mm2 Rm N/mm2 A4d % A5d % z%

60763 TANG 331 513 35 71.6

ResiIienza /Impact test ASMESA370 10x10mm

Valori richiesti/Required values Valori rilevati/Obtained values

Proyaes! Senso/Sense Tipo/type TC Med./Av. Min. U.M Vali Val2 Val3 Med./Av.

60763 TANG KV -46 20 16 J 138 140 126 134.67

Durezza/Hardness test ASME SA370 / ASTM E10

Valori richiesti/Required values Valori rilevati/Obtained values

Prova/Test Min Max Tipo/Type Vah Val2

60763 197 HBW 141 148

Spec/Note

ASME PARTAEd.2010Add.11a

Data / Date (d/m/y)

11/04/13

Q.C DEPT. Pag. 1 di 1

RE - OMBA Spa Via Carlo Serassi, 14 24100 BERGAMO TALY BG Te.: 035 / 41 60 811 Fax.: 035 / 41 60 856

Marchio Produttore/Manufacture's Mar SO 9001:2008 Quality System

approved by BUREAU VERTAS

Certificate No T236970

23813 CRTENOVA (Lecco) taly

Via Provinciale, n. 20/22

Tel. +39 0341 988011 - Fax +39 0341 988012

http://www.galpertisrl.com

e-mail: quality@galpertisri.com

Certificato n1.

Certificate n.

Data

Date TUV

587 04/06/2013

Codice Cliente

Customer reference

Clienfe

CIient

2ista Imballo. 3

Packing List N

Data

Date

00858 FINTEC S.r.I. PL13-00466 04/06/2013

Codice Colata

Heat Code

Colata 4ornitore

Heat Supplier

Or5gine

Oriain

Ordine

Order

$ateriale

Material

(.t6

Q.tv

Descri7ione

Description

2212537 2212537 European 5324 A/SA 350 LF2 4 DSCH SGROSS 520X40mm LF2

2212537 2212537 European 5324 A/SA 350 LF2 4 DSCH SGROSS 382X39mm LF2

310042 310042 European 5324 A/SA 350 LF2 2 DSCH SGROSS 620X48mm LF2

310042 310042 European 5324 A/SA 350 LF2 2 DSCH SGROSS 732X50mm LF2

323033 323033 European 5324 A/SA 350 LF2 4 DSCH SGROSS 440X40mm LF2

Codice Colata

Heat Code.

Analisi Chimiche / Chemical Analysis

2212537

C% 0,1500 Mn% 1,3200 Si% 0,2300 P% 0,0120 S% 0,0090 Cr% 0,0200 Ni% 0,0300 Mo% 0,0050

Ti% N% 0,0060 Cu% 0,0400 Nb% 0,0180 V% 0,0050 Al% 0,0340 Sn% 0%

Fe% H% Ca% B% Co% Pb% w% Sb%

As% Zr% CEQ 0,38

310042 C% 0,1700 Mn% 1,3200 Si% 0,2100 P% 0,0090 S% 0,0050 Cr% 0,0300 Ni% 0,0500 Mo%

Ti% 0,0020 N% 0,0050 Cu% 0,0100 Nb% 0,0040 V% 0,0530 Al% 0,0420 Sn% o%

Fe% H% 0,0002 Ca% B% Co% Pb% W% Sb%

As% Zr% CEQ 0,41

323033

V% 0,1900 Mn% 1,3200 Si% 0,2000 P% 0,0120 S% 0,0040 Cr% 0,0300 Ni% 0,0300 Mo% 0,0030

Ti% 0,0050 N% 0,0050 Cu% 0,0500 Nb% 0,0110 V% 0,0030 Al% 0,0400 Sn% o%

Fe% H% Ca% B% Co% Pb% W% Sb%

As% Zr% CEQ 0,42

Prove meccaniche / Mechanical tests

Codice Colata

Heat Code

Snervamento .ott#ra +ll#ngamento Contra7ione .esilien7a * impact Test (J) $edia D#re77a

Rp0.2%(MPa) Rm (MPa) A% - EIong. in 2" Z% - Reduct TPO TEMP C TEST1 TEST2

TEST

3

Average Hardness HB

2212S37 350 533 28,4 60 KV -50 44,00 60,00 39,00 47,67 153

310042 369 509 29,6 55,11 KV -50 86,00 79,00 79,00 81,33 153

323033 383 520 30,01 51,22 KV -50 45,00 39,00 43,00 42,33 153

TRADE MARK REDATTOLA / PRNTED BY

Galpet s.r,l.

APPROVATO DA /APPROVED BY

A.Q.M.

ENTE COLUUDATORE / NSPECTNG AGENCY

%&e ' o( )

Marchio Produttore/Manufacture's Mar

SO 9001:2008 Quality System

approved by BUREAU VERTAS

Certificate No T236970

23813 CRTENOVA (Lecco) taly

Via Provinciale, n. 20/22

Tel. +39 0341 988011 - Fax +39 0341 988012

http://www.galpertisrl.com

e-mail: quality@galpertisri.com

Certificato n1.

Certificate n.

Data

Date

TUV

587 04/06/2013

Codice Cliente

Customer reference

Cliente

CIient

2ista Imballo. 3

Packing List N

Data

Date

00858 FINTEC S.r.I. PL13-00466 04/06/2013

$ateriale

Material

)ipo di )rattamento

Material treatment

A/SA 350 LF2 Normalized

Note GeneraIi

Additional requirements:

- Satisfactory visual and dimensional check

- Steel making process:Electric Furnace

Norms applicable:

- ASTM 350 LAST EDTON

- ASME 350 LAST EDTON -EN 10204/3.1

TRADE MARK REDATTO DA /PRNTED BY APPROVATO DA'/APPROVED BY ENTE COLLAUDATORE / NSPECTNG AGENCY

Galpet s.r,l. A.Q.M.

Page 2 o( )

BULLONERIA VILLA S.

P

.A.

CAPTALE SOC. EURO 120.000 NT. VERSATO

INSPECTION CERTIFICATE

According to (EN 10204:2005) 3.1

20151 MILANO-VIA GALLARATE, 141 Nr. 130802

Ufficio vendile: - Stab.: Tel. (02) 38006529 -fax (02)3084962 ISO 9001:2008-Cert.n.3213/2 Data/Date 13/06/13

Amministrazione: Telefon (02) 38006356 - E-Mail: info@bulloneriavilla.com

www.bulloneriavina.oom

Vostro ord./Your order Ns. Bolla/Delivery note Cliente/Customer

Nr 5365.13-CO.2037/A Nr. 131145 FINTEC S.R.L.

Data/Date 20/05/2013 Data/Date 13/06/2013

VIA VERDI, 2/B

23870 CERNUSCO LOMBARDONE (LC)

Materiali e valori conformi alle norme ASTM

Materials and values in conformity with standards ASTM

Pos/item. Materiale/Materials Descrizione/Description Misure/sizes Quanti t/Quantity

1) ASTM A320/L7 TRANT / STUD BOLTS 3/4" une X 120 NR. 39

2) ASTMA194/GR.4 DAD E./HEXNUTS UN 5587 3/4" une NR. 78

TRATT./TREATMENT ZINC.HOT DIP.GALVAN. ASTM A153

ANALISI CHIMICA/CHEMICAL ANALYSIS

%C %Mn %Si %P %S %Ni %Cr %Mo %A

Req. Min 0,380 0,750 0,150 0,800 0,150

Req. Max 0,480 1,100 0,350 0,035 0,040 1,100 0,250

p/i Colata/heat

1) CD8813 0,434 0,880 0,280 0,017 0,003 1,010 0,190

Req. Min 0,400 0,700 0,150 0,200

Req. Max 0,500 0,900 0,350 0,035 0,040 0,300

2) 45707 0,420 0,820 0,270 0,020 0,015 0,230

CARATTERISTICHE MECCANICHE/MECHANICAL PROPERTIES

Required

R R 0.2 A Z HB HB* Impact test KV Proof. L=

Mpa - N/mrm Mpa - N/mrm % % Min. Max 24 h 27JMIN-101C

860 725 16 50 201

Pos/item

1) 991 813 17,1 54,8 316 30 31 29

2) 307/308 272 29 27 28 POST

Note: VSUAL DMENSONAL TEST = SATISFACTORY Heat treat. Quenched Tempered

BULLONERA VLLA S.p.A.

Quality control

We bereby certify that materials described in this certificate have been tested end compi/ with the terms of the order and of specification. * = hardness heat treatment at 540/590'Cs!

TUBOS REUNIDOS INDUSTRIAL, S.L.U

Barrio Sagarribai, 2 - 01470 AMURRO (Spain)

EN 10204:2004 /3.1

CERTIFICADO DE CALIDAD

MILL TEST CERTIFICATE

ABNAHMEPRLFZEUGNIS NACH

CERTIFI DE QUALIT

PAO. 1/3

N 0000304771/1 Rev. 000

CLIENTE:

CUSTOMER

BE8TELLER,

CUNT

EUSIDER S.P.A. PEDIDO / PARTIDA:

P.ORDER / ITEM

BESTELLER NR / POS.

N*COMMANDE / POSTE

INQ-T-11-0018/MI

PRODUCTO:

ARTICLE

PRFOEOENSTAND

FOURNITUR6

TUBERIA SIN SOLDADURA LAMINADA EN CALIENTE

HOT FINISHED SEAMLESS TUBES

REF. FABRICA:

WORK ORDER

WERKS NR.

N INTERNE

300012221

000040

EXTREMOS:

ENDS

ENDEN

EXTRMIT

BISELADOS

BEVELLED ENDS

PROTECCIN SUPERF:

EXT. COATINO

ROSTSCHUTZ

PROT. SUPERFICIEL

LACA SECA EXTERIOR

OD DRY LACQUERED

NORMA/GRADO:

APL STANDARD AND GRADE

6PECIFKATIQN/STAHL

NORME ET OUAUT

ASTM/ASME A/SA 333/A 333M-10

GR.6

PROCESO FUSION:

MELTING PROCESS

ERSCHMELZUNGSART

PROCDE FUSION

HORNO ELECTRICO

ACERO TOTALMENTE CALMADO

ELECTRIC FURNACE II FULLY KILLED

ESPJC. ADICONALES:

ADITIONAL SPECS.

ANFOROERUNOEN

SPECIFIC ADITIONNELLES

ACC.TO ASTM A999-01.

ACC. ASME SECTION II PART A

FAB. DE PALANQUILLA:

BILLETS MANUFACTURE KN0PPLFERTIOUNO

FABRICATION D E LA BILLETE

COLADA CONTINUA

CONTINUOUS CASTING

STRANOGUSS VERFAHREN

COULEE CONTINUE

DIMENSIONES:

DIMENSIONS

ABMES8UNOEN.

DIMENSIONS

88.9 X 7,62 MM. X

10-11,8 M. (

MARCAS:

MARKING

KENNZEICHNUNO

MARQUAOE

ESTAMPADO:

DIE STAMPING

POINCONAGE

POINCONNE

HN (COLADA)

PINTADO:

STENCILLED

STEMPELUNQ

MAROUAOE

TRI ASTM/ASME A/SA333 GR. 6 H.F.S. 88,90 X 7,620 MM LT -45 C HN (COLAD A)

CODIGQ COLOR:

COLOUR CODE

FARBE KENNZEICHNUNQ

COOEOECOULEUR

TRAT. TERMICO:

HEAT TREATMENT

WARMEBEHANDLUNO

TRAITEMENTTHERMJQUE

NORMALIZADO. HORNO CONTINUO. / NORMALIZED. (CONT. FURNACE). 900 C 8 MIN

AIbsran 60246761

TUBOS REUNIDOS INDUSTRIAL GARANTIZA QUE TODAS LOS TUBOS CUBIERTAS POR ESTE CERTIFICAOO CUMPLEN LOS REQUISITOS DEL PEDIDO Y CONLAS ESPECIFICACIONES ARRIBA MENCIONADAS.

TUBOS REUNIDOS INDUSTRIAL CERTIFY THAT ALL THE TUBE8 COVERED BY THIS CERTIFICATE COMPLY WITH ORDER REQUIREMENTS AND ABOVE MENTIONED SPECIFICATIONS.

TUBO* REUNIDOS INDUSTRIAI. OARANTIERT DABS ALLE ROHRE DIE BE8TEUTEN ANFORDERUNGEN UND SPEZIFIKATION6N IN OLBEM ZEUONIS ERFULiEN.

TUeOS REUNIDOS INOUSTRIAL OARANTIT QUE TOUS LES TUBES OBJECT DU PRESENT CERTIFICAR SONT CONFORMES AUX STIPULATIONS DE LA COMMANOE ET AUX SPECIFICATIONS DfiSSUS M6NTIONS

AMURRIO 03.10.2011 CONTROL DE CALIDAD DB-TUBOS REUNIDOS INDUSTRIAL

TUBOS REUNIDOS INDUSTRIAL (QUALITY CONTROL)

AIex /HEPA3BOPHHBO/

P.O:

TUBOS REUNIDOS INDUSTRIAL, S.L.U

Barrio Sagarribai, 2 - 01470 AMURRO (Spain)

EN 10204:2004/3.1

CERTFCADO DE CALDAD

MLL TEST CERTFCATE

ABNAHMEPRUFZEUGNS NACH

CERTF DE QUALT

PAG. 2/3

N 0000304771/1 Rev. 000

DESCRIPTION OF DELIVERY

ITEM FAB.

T.R. ITEM

WERKaPOB.

POSITION INTERNE

ITEM CLI.

CLIENTS ITEM

BESTELLER POS.

POSTE DU CLIENT

LONG.INDIV(M)

INDIVIDUAL LENGTH

LANGE INDMDUELL

LONGITUDE UNITAIRE

COLADA

CASTNR.

SCHME NR.

N COULE

NTUBOS

QUANTITY

STUCKZAHL

NOMBRE

LONG. TOTAL (M)

LENGTH

LANGE

LONGITUDE

PESO(KG)

WEIGHT

MASSE

POIOS

000040 10,000- 11,800 108037 80 663,890 10.260

TOTAL 80 663,890 10.260

CONTROLES NON DESTRUCTIES

ENSAY0 / TEST / PRFUNG / ESSA %CONTROL / TEST RATE(%)

%KONTROL / %COONTROLE

REQUISITOS / REQUIREMENTS

ANFORDERUNGEN/

SPECIFICATION

RESULTADO / RESULT

6RGEBNIS / RESULTAT

VSUAL Y DMENSONAL/

VSUAL 1 DMENSONAL NBP.

/eesiCHTiouNa UNO AUSMESSUNG

100% O.K.

(ASPECT ET BMENSON8

P.HDROSTATCA/ HYDROTfBT

MMSSERDRUCK VERSUCH /EPREUVE

HYDRAUUQUE

100% 2.600,0 PS fi SEC, O.K.

CORRENTESNDUCDAS/

EDDY CURRENTS /WRBELSTROMPRUFVNO /COURANTES DE

FOUCAULT

100% ASTM A999.Q4A. O.K.

TECHNOLOGIGAL AND METAL LUBRICAL TEST

APLASTADO

/FLATTENING

/RINQFALTVERSUCH

/APLATIS8EMENT

AC/A 333-OK

ANALISIS OF COLADA / CASTANALSYS/ SCHEMEL ZANALYST/ ANALYSE OF COULES

C Mn Si P S Cr N Mo Cu V C.E.

MN. 0,29 0,10

MAX. 0,24 1,35 0,026 0,026 0,43

108037 0,12 1,10 0,24 0,010 0,005 0,100 0.080 0,040 0,220 0.003 0,35

ANALISIS OF PRODUCTO / PRODUCT ANALYSIS / STUCKANALYSE / ANALYSE DE PRODUCT

C Mn S P S Cr N Mo Cu V C.E.

MN. 0,29 0,10

MAX, 0,24 1,35 0,025 0,025 0,43

108037 0,12 1,06 0,25 0,009 0,006 0,100 0,090 0,050 0,230 0.003 0,36

108037 0,12 1.07 0,23 0,00B 0,003 0,100 0.080 0,040 0,220 0,002 0,39

AMURRIO 03.10.2011

CONTROL DE CALIDAD DB-TUBOS REUNIDOS INDUSTRIAL

TUBOS REUNIDOS INDUSTRIAL (QUALITY CONTROL)

AIex /HEPA3BOPHHBO/

P.O:

TUBOS REUNIDOS INDUSTRIAL, S.L.U

Barrio Sagarribai, 2 - 01470 AMURRO (Spain)

EN 10204:2004 /3.1

CERTIFICADO DE CALIDAD

MILL TEST CERTIFICATE

ABNAHMEPRUFZEUGNIS NACH

CERTIFI DE QUALIT

PAG. 3/3

N 0000304771/1 Rev. 000

ENSAYOS DE TRACCION

TENSUF TEST / ZEGVERSUCH / ESSAL OF TRACTION

COLADA.

CAST

L/T

(1)

T/P

(2)

DMENSON

(mm)

L.ELAST.

YELD PONT

STRECKQR

L.ELASTQ.

( Mpa ) (3)

R.TRACC.

T.STRENGTH

ZUGFESTKS.

RESSTANCE

( Mpa )

ALARG.

ELONO.

DEHNUNG

ALLONG

(%)

DUREZA

HARDNESS

HARTE

DURET

( )

240 416

108037 L P 18,40 x 8,100 307 445 38

106037 L P 18,00 x 8,400 310 440 38

(1) : L=LONGTUDNAL//T=TRANSVERSAL

(2) : T=Full size tube//P=Strip specimen

(3) : yield point (0,2%)

(4) : Lo=2 (50,8 mm)

ENSAYOS DE IMPACTO - CHARPY V

IMPACT TEST / KERRSCHI AGZAHIGK / ESSAI OF RESILENCE

COLADA

CAST

L/T DMENS

(mm)

(C) RESLENCE

MPACT TEST

KERBSCHLAGZAHQK

RESLENCE

(J)

10 10,00 -45 14

18

108037 L 10 6,07 -45 200 198 202

(1) : L = LONGTUDNAL // T = TRANSVERSAL

AMURRIO 03.10.2011

CONTROL DE CALIDAD DB-TUBOS REUNIDOS INDUSTRIAL

TUBOS REUNIDOS INDUSTRIAL (QUALITY CONTROL)

AIex /HEPA3BOPHHBO/

P.O:

DUEVI

DUEV SRL

Via Albert Sabin, 15 20873 - CAVENAGO BRANZA (MB)

Tel. +39 02 95335174 r.a. Fax +39 02 95335175

Registro imp. Monza C.F./Partita VA/VAT no. T 06473230966

E-mail info@duevifornitureindustriali.it

Web www.duevifornitureindustri FLANGES AND FITTINGS

CERTFCATO D COLLAUDO EN 10204-3.1

EN 10204-3.1TEST CERTFCATE MOD.

CP_REV.2 DEL 12.03.2012

Spett.le/Messrs.

FINTEC S.R.L.

Numero Data Pagina

001391 06/05/2013 1 VA TRESTE, 42

Ns. DDT nr. Data Vs. ordine nr. Data 20064 GORGONZOLA - Ml

1403 06/05/2013 T

8 COLATA/HEAT NR. COD. NT. MAT./

MAT. NT. CODE

ACCAERA /STEEL PLANT Q.TAVQ.TY DESCRZONE/DESCRPTON

212456 LF2 VENETE 4 FL. A350LF2 WNRF A300 3" XS

ANALISI CHIMICA/ CHEMICAL ANALISYS

%C %Mn %Si %P %S %Cr %Ni %Mo %Ti %V %Cu %A %Sn %Nb %N %Fe %w %Co*

0,172 v. 1,017 0,248 0,011 0,009 0,136 0,123 0,029 0,014 0,004 0,213 0,026 0,001 0,007

%Ca %B %H %0 %Pb %Ta CE

0,398

According to nace MR01.75 Last Edition

.

| PROVE MECCANICHE/MECHANICALTESTSI

.S*9:2D

;N/mm<=>

.*):NSI2:

;N/mm?=>

:2ON@+)ION

*+,

.:DAC)ION

*+,

.:SI2I:NB+/I$P+C) ):S) ;J>

$+):.I+2: IN +CCO.DO + $+):.I+2

IN +CCO.D+NC: )O

):$P:4

;1C>

!+.DN:Si

;!C>

;D> ;=> ;E> ;F>

):S) D ):S) = ):S) E A A X X

358,6 505,0 36,0 66,0 91,00 85,00 76,00 ASTV/ASME SA/A350 LF2 -50 160-163

After tests forgins are in according with norms

CONTROLL N PRODUZONE / PRODUCTONS TESTS

MB VS ORD. N 5315/13 DEL 22/04/2013

VSVO/VSUAL

DMENSONALE/DMENSONAL

SATSFACTORY

SATSFACTORY

(1) PRODUZONE ACCAO

Steel Production

A - CALMATO ELABORATO AL FORNO ELETTRCO

Killed steel made by electric furnace

B - ELABORATO AL FORNO ELETTRCO

Made by electric furnace

(2) TRATTAMENTO TERMCO

Heat treatment

A NORMALZZATO

Normalized

B - NORMALZZATO E RNVENUTO

Normalized and tempered

C - BONFCATO

Quenched and tempered

D - SOLUBLZZATO

Solution treatment and quenched

(3) X - CERTFCATO SECONDO EN 10204/3.1

Certificate according to EN 10204/3.1

(4) X - CONTROLLO VSVO E DMENSONALE SODDSFACENTE

Satisfactory visual and dimensional test

TRADEMARK REDATT OF APPROVATO DA SPETTORE

(CE) C + Mn/6 + (Cr + Mo + V)/5 + (Ni Cu)/15 DUEV s.r.l.

FORNTURE ND..

Conforme al certificato originale rilasciato dall'acciaieria o forgiatort: imduivu iduuiauunu UJ. analisi e prove.

According to original certification issued by steel plant and relative analysis and tests laboratory.

MONTCELL MCHELE & C. S.N.C. D MONTCELL

MCHELE

23819 Pnmaluna (Lecco) - taly

Via XXV Aprile. 24

Partita .V.A T-01795330131

Tel. 0341 980404 - 980912

Fax 0341 981384

E-mail: info@monticellsnc.it

R.l. Lecco -Cod. Fise: 01795330131

R.A Lecco n 216418

N. Mecc LC 011349

Azienda con sistema di

gestione qualit certificato

Cliente / Customer

FINTEC SRL

D.D.T .IP.2N.

463

11/04/2013

UN EN 10204 3.1

"I+ @.":.DIG =/C

Certificato di Collaudo

Inspection Certificate

108-2013

11/04/2013

=EH/I C:.NASCO 2O$C+.DON: 2C I)

Acciaieria:

ABS Acciaierie

BerteIi Safau S.p.a.

Analisi Chimica

C%emical +nalsis

C Mn Si P S Cr Ni Nb V Mo Cu CEq.

0,182 0,98 0,22 0,012 0,003 0,09 0,06 0,001 0,003 0,01 0,14 0,379

Colata: Sezione: Mat / Norma $in IGII IGJI I.D, I I I I I I I I IGIID

214540

T100 SA/A350LF2CL1 $a- IGEI DGE, IGE IGIE, IGIF IGE IGF IGD= IGF IGIH IGI= IGF,

Rapporto Prova Mecc.

2012/6954/PM

Trattamento Termico

NormaIizzazione

Propriet Meccaniche

$ec%anical Properties

RM RP0.2 Allung. Contr. Resilienza D#re77a HB

MPa MPa

% %

1C Joule Min Max

494 324 32,8 68,4 u46 61 78 87 140 143

$in

$a-

I-e. De/0123-2on M%-e12%4 He%- T1e%-.en- 56-7 O1de1 N16

LAVLW 300 RF125/250 2" L=229 SA/A350LF2CL1 NormaIizzazione 6 N.5257.13-07/03/13

NOTE:

MonticeIIi MicheIe S.n.c.

mod 25 rev0 TLMService S.a.s. - 2011 Certificato0 '89:)8'; ' d2 '

RONCONI SpA

CERTFCATO PROVE MATERAL

Mod. MDCQ01 BS

REPARTO COLLAUDO

CQ

Num. Cert. 13390 Foglio 1/1

Sheet BIaII

COLD DRAWN STEClTUBES

=II9I OP:.+ ;$I> * "ia 2swbmG9*I)+29

www.ronconi.com K L#alltMmnconl.com

MateriaI Test CefIIticaIe-AbnahmBprurzeugnIs

EN 10204: 2006 3.1

InspecIIane Oept.

-AbnahmeabteIIung

Data 28/03/2013

Data - Datum

Cliente FINTEC SRL

Customer- Kunde

Ordine num. 5226.13 Data 14/02/2013 Ns. Commessa 33 11 12 207/1 Data 25/02/2013

Order -BesteIIunn Data-Datum Our order Unsera BesIeIIung DaIe-Datum

Descrizione TUB SS TRAFLAT A FREDDO

Trattamento termico NormaIized

Description - BeschreIbung Heet treatment WarmebehandIung

Norma e Acciaio ASME SA334 Gr.6

Norm and StooI Grado - Norm und SIahIgCiIe

Pezzi 154+265+1715 Peso kg. 7310

Quantity - AnzahI Weight - GawIchI

Dimensioni

15,88 x 2.11MW x 2960/3440/4900 mm

Sizes-Abmessungsn

Valori

richiesti

Requirements Anfordarungen

Rs Rm

A2 Ap5 HRB

min min max min min min max min med min

240 415 30 90

Provino (L)

Specimen (L)

Probeslab (L)

Snervamento

Yield point

Streckgrenze

Rottura

Tensile strength

Zugfestlgkelt

Allungamento

Elongation

Bnjchdehnung

Durezza

Hardness

Haerte

Resilienza

Notch mpact

Karbschlagarbalt

Prova a caldo

Hat test

Waarmapraefung

N Sez Lo RisuItati Ottenuti (ResuIIa -ErgBbnIssa)

mm

=

mm N/mm= N/mm= N N J O N/PP

=

1 94 50 324 457 40 74

2 94 50 321 454 40 73

3 94 50 318 452 42 73

4 94 50 316 449 42 72

5 Prova di Schiacciamento eseguila con esito positivo - Flattening test sallfaclory Autwellvarsuch zufrledanslellend durchgefuhrt OK

6 Prava di Allargamento eseguila con esita positivo - Flaring test satisfactory RlngfailverBUClt zufriedenslallend tfurdigofuhrt OK

7

8

9

10

11

12

13

14

15

16

17

18

S certifica che stato eseguito con esito positivo il:

We here by certIIy that we succesfuHy run:

WIr garantIaren, dass foIgendan PrOfungen zufrIedenBIeIIend

durchgaIuhrt wurden:

Controllo (100%) Eddy current secondo norma /

Eddy current test (100%) aceto WIrbeIsIromprufung (1QQ%> pe1ans

Controllo (100%) Ultrasuoni secondo norma

UItrasonic tasi (100%) accia - UItraschaIIprfung (100%) nemSss

Controllo PM (100%)

PMI Iesi (100%) -PMK1D0%)

ASMESA 016 25.8.2.1

l controllo visivo e dimensionale dei tubi stato eseguito con esilo positivo

The visuaI and dimensionaI Iest has been performed with satisfactory resuIt - Dia vIsueIIen und dImansIonaIen KantroIIan wurden miI zufrfedensIaIIenden EmebnIssan durchqefDhrI

Analisi chimica

ChemicaI anaIysis - ChamIscJie AnaIyse

Acciaio calmato ed elaborato al forno elettrico, degasato a vuoto

SteeI eIaborated in eIectric furnace, fuIIy kiIIed and vacuum degassed - BeruhIgIar EIekIro Vakuum enIgaDt StahI

Colata N.

Heat Ne -Schmelze Nr

C

N

SI

N

$n

N

P

N

S

%

Cr

N

$o

N

Ni

N

Cu

%

V

N

Nb

+l

N

N

N

Sn

N

Ti

%

+s.

N

Sb

%

21579B 0,135 0,200 0,83 0,011 0,004

Prod.Anal.215798 0,130 0,210 0,81 0,010 0,005

192720 0,140 0,195 0,82 0,009 0,003

Prod.Anal.192720 0,15 0,1B 0,79 0,009 0,004

Marcatura (Marking-Markiamng)RONCON/TALY/SA334/GR.6/CD/SS/COUTA/15,8BX2,11/MW

Note Nates - Anmerkungen

Test n" 1-2-5-6 colata n 215798: 804 tubi.

Test n 3-4-5-6 colata n 192720: 1330 tubi.

l Capo reparto

Chief of DapL - AbteIIungscher

CND II Lev. ET-UT Cert. n. FQ1748

RONCON S.P.A.

QUALTY CONTROL

Ente collaudatore

Inspected by - Abnahmabeamter

Certificalo in accordo alla PED 97/23/EC APPENDCE 1 Par.4.3 e AD ZOOB-Merkblatt W0 Cert N 01 202 l/Q 05-185B TOV RhBlnland

Cartlfcate n accordance to PED B7/23/EC ANNEX 1 Par.4.3 and AD 200.D-Merkblalt W0 Cart N* 01 202 l/Q 05-185B TOV Rhelnland

Abnahmaprufzaugnls gomaess PED 97/23/EC ANHANG 1 Par.4.3 und AD2uC0-MerNlelt W0 Cert N' 01 202 l/Q 0S-1B59 TOV Rhelnland

prodotti forniti sano conformi al requisiti d'ardlne-Tha supplied products are n compliance with the order requlramanls-Dle gallaferten Erzaugnlssa sllmman mil den Anforderungen des Auftrages Oberein

CERTFCATO D CONTROLLO 3.1 / NSPFXTON CERTFCATE 3.1. - EN 10204:2004

A0-1/A05 (A) PROCESSO D ELABORAZONE / STEELMAKNG PROCESS: E = ELECTRC ; 80 * BASC OXYTGEN

(B) STATO Di FORNTURA / DELVERY CONDTON: AR=GREZZO D LAMNAZONE / AS ROLLED;

N* = LAMNAZONE ATEMPERATURA CONTROLLATA/ NORMALZNG ROLLNG;

N = NORMALZZATO / NORMALZED at 910C, 1,5 min/mm; ARA CALMA / STLL AR;

R = RCOTTO / ANNEALED;

N+R=NORMALZZATO+RNVENUTO / NORMALZED+ANNEALED

(C) TRATTAMENTO RERMCO DEL CAMPONE / HEAT TREATMENT OF SAMPLE;

N = 910C, 1,5 min/mm; ARA CALMA / STLL AR

R = 650C, 1,5 min/mm; ARA CALMA / STLL AR

(D) Ceq_1=C+Mn/6; Ceq_2=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15;

Pcm=C+Sl/30+(Mn+Cu+Cr)/20+N/50+Mo/15+V/10+B*5

(1) POSZONE / LOCATON: 1=TESTA/TOP; 2=PEDE/BOTTOM

(2) POSZONE / LOCATON: C=CUORE/1/2 THCKNESS; P=PELE/SURFACE; D=1/4 SPESSORE/THCKNESS

(3) DREZONE / DERECTON: L=LONGTUDNALE/LONGTUDNAL; T=TRASVERSALE/TRANSVERSE

(4) FORMA DEL PROVNO / SHAPE OF TEST PECE: P=PRESMATCO/PRSMATC; C=CLNDRCO/CYLNDRCAL

(5) ESTO PROVAD PEGA / RESULT: OK=COMPLYNG; NO=NOT COMPLYNG

METNVEST

Metinvest Trametal spa.

Societ per azioni con socio unico - soggetta a direzione e coordlnameRto di Metlnvest B.V.

STABLMENTO: 33058 S. GORGO D NOGARO (UD) VA E. FERM, 14

TEL. 0431/629989 (RC. AUT.) - FAX 0431/62S985 (RC. AUT.)

SEDE LEGALE: 16121 GENOVA- VA X OTTOBRE, 3 6 PANO

Capitale sodale C 300.120,000,001.V. - R.E.A, Genova n. 437720

C.F., P. va e scr. Reg. mp. Genova n, 05956630965

N Certificato / Certificate no. Data / Date Cliente / Customer

254441 14/02/2012

SOCET' TALANA ACCA TUBS SPA

Via dei Cavallari, 37 15077 PREDOSA

N Ordine Trametal / Works order N Ordine cliente / Customer's order

31200184 1.4

DDT del / date

31202667 13/02/2012

Pratica / File no.

del / date Marcatura di prodotto / Marklna of the product

LAMERA/ORDNE/N

0

NFORNAMENTO/DMENSON/QUALK/MARCHO DEL PRODUTTORE PLATE/ORDER/NTERNAL

N7DMENSONS/STEEL GRADE/MANUFACTURER'S MARK prodotto / Product Lamiere / Hot rolled .plates

Steel grade SA516GR70MT/LTV

Specification ASME

B07 B07 B07 B09/B11 B12 B07

C7

0

B04 C00 B05 C00 B05 PWHT C00 B05 Q+T

I

F

E

M

L

A

M

I

E

R

A

P

L

A

T

E

N

I

N

F

O

R

N

.

IN

T

E

R

N

A

L

N

U

M

B

E

R

D

IM

E

N

S

IO

N

I

[

m

m

]

D

I

M

E

N

S

I

O

N

S

P

E

S

O

T

E

O

R

IC

O

[

t

]

T

H

E

O

R

IC

A

L

W

E

IG

H

T

L

O

T

T

O

B

A

T

C

H

N

O

.

P

R

O

C

E

S

S

O

E

L

A

B

.

(

A

)

S

T

E

E

L

M

A

K

IN

G

P

R

O

C

E

S

S

S

T

A

T

O

F

O

R

N

IT

U

R

A

L

A

M

I

E

R

A

(

B

)

D

E

L

IV

E

R

Y

C

O

N

D

IT

IO

N

C

A

M

P

IO

N

E

S

A

M

P

L

E

T

R

A

T

T

.

C

A

M

P

IO

N

E

(

C

)

H

E

A

T

T

R

E

A

T

M

E

N

T

C

A

M

P

I

O

N

E

P

W

H

T

S

A

M

P

L

E

T

E

M

P

E

R

A

T

U

R

A

I

N

IZ

IO

C

B

E

G

IN

N

IN

G

T

E

M

P

E

R

A

T

U

R

E

V

E

L

O

C

IT

A

'

R

IS

C

A

L

D

O

C

/

h

H

E

A

T

IN

G

R

A

T

E

T

E

M

P

E

R

A

T

U

R

A

T

R

A

T

T

A

M

E

N

T

O

C

T

E

M

P

E

R

A

T

U

R

E

T

R

E

A

T

M

E

N

T

P

E

R

M

A

N

E

N

Z

A

M

i

n

H

O

L

D

IN

G

T

IM

E

V

E

L

O

C

IT

A

'

R

A

F

F

R

E

D

D

A

M

E

N

T

O

C

/

h

C

O

O

U

N

G

R

A

T

E

T

E

M

P

E

R

A

T

U

R

A

F

IN

E

C

E

N

D

T

E

M

P

E

R

A

T

U

R

E

N

C

IC

L

I

/

C

Y

C

L

E

S

C

A

M

P

I

O

N

E

Q

+

T

S

A

M

P

L

E

T

E

M

P

E

R

A

T

U

R

A

(

Q

)

C

T

E

M

P

E

R

A

T

U

R

E

P

E

R

M

A

N

E

N

Z

A

(

Q

)

M

i

n

H

O

L

D

IN

G

T

IM

E

R

A

F

F

R

E

D

D

A

M

E

N

T

O

C

O

O

U

N

G

T

E

M

P

E

R

A

T

U

R

A

(

T

)

C

T

E

M

P

E

R

A

T

U

R

E

P

E

R

M

A

N

E

N

Z

A

(

T

)

M

i

n

H

O

L

D

IN

G

T

IM

E

R

A

F

F

R

E

D

D

A

M

E

N

T

O

C

O

O

U

N

G

2 1TL58903028 901001 10.00X3000X12000 2,83 314964 B N GZ607

2 1TL5910903A 900989 10.00X3000X12000 2,83 314952 B N GZ598

2 1TL5910904A 900985 10.00X3000X12000 2,83 314953 B N GZ599

5 1NL7150203A 901174 15.00X2500X12000 3,53 314942 B N GZ590

1NL7150203B 901174 15.00X2500X12000 3,53 314942 B N GZ590

92 COMPOSZONE CHMCA D COLATA / HEAT CHEMCAL ANALYSS

307 C71 C72 C73 C74 C75 C76 C77 C78 C79 C80 C81 C82 C83 C84 C85 C86 C87 C88 C89 C90 C91

COLATA

HEAT

C Mn Si P S Cu N Cr Mo Al V Nb Ti Sn Ca N B H Ceq1 Ceq2 Pcm

% % % % % % % % % % % % % % % % % % % (D) % (D) % (D)

Ordine Mln

2

0,00 0,00 0,00 0,000 0,000 0,000 0,000 0,000 0,00 0,000 0,000 0,000 0,000 0,000 0,0000 0,0000 0,0000 0,00 0,00 0,00

Ordine Max

2

0,18 0,00 0,00 0,000 0,006 0,000 0,000 0,000 0,00 0,000 0,030 0,040 0,000 0,000 0,0000 0,0000 0,0000 0,00 0,43 0,00

Ordine Mln

5

0,00 0,00 0,00 0,000 0,000 0,000 0,000 0,000 0,00 0,000 0,000 0,000 0,000 0,000 0,0000 0,0000 0,0000 0,00 0,00 0,00

Ordine Max

5

0,18 0,00 0,00 0,000 0,006 0,000 0,000 0,000 0,00 0,000 0,030 0,040 0,000 0,000 0,0000 0,0000 0,0000 0,00 0,43 0,00

SA51670LTV Min

0.00-12.50

0,85 0,15

SA51670LTV Max

0.00 - 12.50

0,27 1,20 0,40 0,035 0,035

SA51670LTV Mln

12,60 - 50.00

0,85 0,15

SA51670LTV Max

12.60 - 50.00

0,28 1,20 0,40 0,035 0,035

1NL715 0,16 1,45 0,25. 0,010 0,003 0,030 0,020 0,030 0,00 0,027 0,000 0,023 0,000 0,000 0,0000 0,0070 0,0000 0,0003 0,40 0,41 0,24

1TL589 0,14 1,35 0,27 0,010 0,002 0,050 0,030 0,030 0,00 0,044 0,000 0,000 0,000 0,000 0,0000 0,0070 0,0000 0,0002 0,37 0,38 0,22

1TL591 0,14 1,40 0,25 0,012 0,001 0,030 0,040 0,040 0,00 0,032 0,000 0,000 0,000 0,000 0,0000 0,0060 0,0000 0,0001 0,37 0,39 0,22

Order N31200184-Customer Order N1.4 - DDT N 31202667 - Certificate N 254441 -1 / 3

PROVADI TRAZIONE TENSILE TEST

PROVADI RESILIENZA

IMPACT TEST - CHARPY V-NOTCH

TEST

PROVADI PIEGA

BEND TEST

PROVADI DUREZZA

HARDNESS TEST

PROVADI

STRIZIONE

Z% TEST

C00 C01 C01 C02 C03 C11 C12 C13 C14 C10 C41 C02 C03 C01 C42 C43 C02 C51 C52 C50 C01 C30 C31 C32 C53 C54

CAMPIONE

SAMPLE

S

P

E

S

S

O

R

E

L

A

M

I

E

R

A

P

L

A

T

E

T

H

IC

K

N

E

S

S

P

O

S

IZ

IO

N

E

(

1

)

L

O

C

A

T

IO

N

P

O

S

IZ

I

O

N

E

(

2

)

L

O

C

A

T

IO

N

D

IR

E

Z

IO

N

E

(

3

)

O

R

I

E

N

T

A

T

IO

N

T

E

M

P

E

R

A

T

U

R

A

[

C

]

T

E

S

T

T

E

M

P

E

R

A

T

U

R

E

R

e

H

[

M

p

a

]

Y

IE

L

D

S

T

R

E

N

G

T

H

R

m

[

M

p

a

]

T

E

N

S

IL

E

S

T

R

E

N

G

T

H

R

e

H

/

R

r

a

A

8

"

E

L

O

N

G

A

T

IO

N

R

p

0

.2

[

M

p

a

]

P

R

O

O

F

S

T

R

E

N

G

T

H

F

O

R

M

A

P

R

O

V

IN

O

(

4

)

S

H

A

P

E

O

F

T

E

S

T

P

IE

C

E

L

A

R

G

H

E

Z

Z

A

[

m

m

]

W

ID

T

H

D

IR

E

Z

IO

N

E

(

3

)

O

R

I

E

N

T

A

T

IO

N

T

E

M

P

E

R

A

T

U

R

A

[

C

]

T

E

S

T

T

E

M

P

E

R

A

T

U

R

E

P

O

S

IZ

IO

N

E

(

Z

)

L

O

C

A

T

IO

N

S

I

N

G

O

L

E

V

A

L

O

R

I

[

J

]

I

N

D

I

V

ID

U

A

L

V

A

L

U

E

S

M

E

D

I

A

[

J

]

M

E

A

N

V

A

L

V

E

D

IR

E

Z

IO

N

E

(

3

)

O

R

I

E

N

T

A

T

IO

N

M

A

N

D

R

IN

O

[

m

m

]

M

A

N

D

R

E

L

A

N

G

O

L

O

[

]

A

N

G

L

E

E

S

IT

O

(

5

)

R

E

S

U

L

T

P

O

S

IZ

IO

N

E

(

2

)

L

O

C

A

T

IO

N

M

E

T

O

D

O

T

E

S

T

M

E

T

H

O

D

S

I

N

G

O

L

I

V

A

L

O

R

I

I

N

D

I

V

ID

U

A

L

V

A

L

U

E

S

M

E

D

I

A

M

E

A

N

V

A

L

U

E

Z

%

S

I

N

G

O

L

I

V

A

L

O

R

I

Z

%

I

N

D

I

V

ID

U

A

L

V

A

L

U

E

S

Z

%

V

A

L

O

R

E

M

E

D

I

O

Z

%

M

E

A

N

V

A

L

U

E

ORDINE Min

2

L -46 16 20

ORDINE Min

5

L -46 16 20

SA51670LTV Min

0.00 - 20.00

20 405 21,0

SA51670LTV Max

0.00 - 20.00

20 620

SA51670LTV Min

0.00 - 25.00

L -46 20 0

GZ590 15,00 2 P T 20 523 38,1 376 P 10,00 T -50 P 109 104 109

GZ590 15,00 2 10,00 L -46 P 175 195 169 180

GZ590 15,00 2 10,00 T -20 P 132 140 140 137

GZ598 10,00 2 P T 20 513 35,4 398 P 7,50 T -50 P 118 121101 113

GZ598 10,00 2 7,50 L -46 P 163 185 170 173

GZ598 10,00 2 7,50 T -20 P 149 147 131 143

GZ599 10,00 2 P T 20 525 33,2 379 P 7,50 T -50 P 102 101 82 95

GZ599 10,00 2 P T 300 27B C 7,50 L -46 P 163 170 158 164

GZ599 10,00 2 7,50 T -20- P 140 126 134 133

GZ607 10,00 2 P T 20 522 34,7 397 p 7,50 T -50 P 112 104 101 106

GZ607 10,00 2 7,50 L -46 P 167 151155 158

GZ607 10,00 2 7,50 T -20 P 121 137 139 132

C10

ME SA-370 FIG. 3 AND FIG, 10 (FIG. 11 b 5x10mm) - SAMPLE TAKEN AFTER PLATE HEAT TREATMENT

D02-D50 CONTROLLO ULTRASONORO / ULTRASONC EXAMNATON

D02 D03 D04 D05 D06 D07

APPARECCHATURA

EQUPMENT

N SERE 5ERAL NO CONDZON SUPERFCAL

SURFACE CONDTONS

ACCOPPANTE COUPLANT MODALT OPERATVE

PROCEDURE

TARATURA CALBRATON

GILARDONI RDG450 RDG450-4S0-140156TC GREZZO DI LAMINAZIONE

AS ROLLED

ACQUA WATER IN ACCORDO ALLA SPECIFICA

ACCORDING TO SPECIFICATION

IN ACCORDO ALLA

SPECIFICA ACCORDING TO

SPECIFICATION

B07 B08 D09 D10 D11 D12 D13 D14 D15 D16 D17

LAMIERA