Professional Documents

Culture Documents

BN033521 BTEC HNs Unit 138 Composite Materials in Engineering

Uploaded by

alexandre_motta_30 ratings0% found this document useful (0 votes)

35 views5 pagesBN033521 BTEC HNs Unit 138 Composite Materials in Engineering

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBN033521 BTEC HNs Unit 138 Composite Materials in Engineering

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views5 pagesBN033521 BTEC HNs Unit 138 Composite Materials in Engineering

Uploaded by

alexandre_motta_3BN033521 BTEC HNs Unit 138 Composite Materials in Engineering

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

UNIT 138: COMPOSITE MATERIALS IN ENGINEERING

BN033521 Unit 138: Composite Materials in Engineering

Issue 1 September 2012 Pearson Education Limited 2012

1

Unit 138: Composite Materials in Engineering

Unit code: L/504/1914

QCF level: 5

Credit value: 15

Aim

The aim of this unit is to provide the learner with a knowledge and understanding of composite

materials, terminology, design, methods of production and how to select a suitable composite for

chosen applications. The range of study will include fibre-reinforced composites, metal matrix,

cermets and ceramic composite materials.

Unit abstract

Light, strong and corrosion-resistant, composites are being used in an increasing number of

products as manufacturers discover the benefits of these versatile materials.

The focus of the learning outcomes is on ensuring learners can identify, design and select

appropriate materials and manufacturing methods for components and how these materials are

being implemented into a wider range of markets.

Learning outcomes

On successful completion of this unit a learner will:

1. Understand the functions and properties of composite materials

2. Understand appropriate theories and principles in the design of composite products

3. Be able to evaluate the manufacturing methods of composite products

4. Be able to investigate applications of composites within existing and developing markets.

UNIT 138: COMPOSITE MATERIALS IN ENGINEERING

BN033521 Unit 138: Composite Materials in Engineering

Issue 1 September 2012 Pearson Education Limited 2012

2

Unit content

1 Understand the functions and properties of composite materials

Classify composites: examples under the headings: dispersion strengthened, particle

reinforced fibre reinforced and hybrids; show considerations of volume fractions, geometric

details and strengthening mechanisms

Matrix materials: functions and properties required of a matrix material

Reinforcement materials: functions and properties required of a reinforcement material;

forms of supply: filament, whisker, roving cloth, mat and pre-impregnated products

Range of composite materials: polymeric, metallic and ceramic matrix materials;

reinforcement types: glass, carbon, aramids, polythene; typical metallic and ceramics; hybrid

composites: honeycomb and foams; with reference to properties, characteristics and uses

2 Understand appropriate theories and principles in the design of composite products

Design philosophy: influence of stiffness and second moment of area; effects of subdividing a

structure; structure loading coefficient; pre-stressing; monocoque/shell structures; material

efficiency criterion

Strenthening and toughening: notch sensitivity; crack control; adhesion; work to fracture

Zirconia toughening in ceramics

Model strength and stiffness: law of mixture equation; relative strength and stiffness of matrix

and reinforcement; preferred combinations; influence of volume fraction

Effects of reinforcement: reinforcement efficiency; packing models; practical limitations;

voids; relationship between volume fraction, weight fraction and composite density;

associated design calculations

Failure mechanisms: tensile; compressive; buckling, fatigue; Griffith crack length; fracture

toughness; damage tolerance

3 Be able to evaluate manufacturing methods of composite products

Manufacturing methods: resin/fibre processing: hand-lay-up, spray-up; resin transfer

moulding; filament winding; centrifugal moulding; hot and cold press moulding; pultrusion;

appropriate terminology

Metal/ceramic matrix composite processing: isostatic pressing; sintering; reaction bonding;

powder metallurgy; squeeze casting; liquid pressure forming

Machining composites: mechanical cutting; ultrasonic; water jet; laser methods

Joining composites: fasteners; bonding; friction welding

Coatings technology: chemical and physical vapour deposition methods

UNIT 138: COMPOSITE MATERIALS IN ENGINEERING

BN033521 Unit 138: Composite Materials in Engineering

Issue 1 September 2012 Pearson Education Limited 2012

3

4 Investigate applications of composites within existing and developing markets

Viability of composites: cost analysis; processing /operating cost; computer aided design; part

complexity; durability; corrosion resistance

Justify composite applications: analyse composite products; justification of material types;

design; production method

Report on adopting a composite product: investigation into the production of a component or

assembly; propose composite material design; manufacturing details to supersede an existing

product design

Current and expected developments: current/expected developments in aerospace; military

equipment; transport; motor racing; sports equipment; space; commercial products;

construction; renewable energy generation

UNIT 138: COMPOSITE MATERIALS IN ENGINEERING

BN033521 Unit 138: Composite Materials in Engineering

Issue 1 September 2012 Pearson Education Limited 2012

4

Learning outcomes and assessment criteria

Learning outcomes

On successful completion of this

unit a learner will:

Assessment criteria for pass

The learner can:

LO1 Understand the functions and

properties of composite

materials

1.1 state the classifications of composite materials

1.2 describe functions and properties of matrix materials

1.3 describe how reinforcement materials are

manufactured and supplied

1.4 investigate the range of composite materials used in

composite manufacture and products

LO2 Understand theories and

principles in the design of

composite products

2.1 explain design philosophy involved in composite

structures

2.2 describe the strengthening and toughening

mechanisms in polymeric, metallic and ceramic

composites

2.3 describe how to model strength and stiffness of fibre

reinforced composites

2.4 analyse the effects of reinforcement on composite

properties

2.5 explain typical failure mechanisms in composite

materials

LO3 Be able to evaluate

manufacturing methods of

composite products

3.1 investigate manufacturing methods of composite

products

3.2 evaluate manufacturing methods of composite

products

3.3 describe techniques for machining composite materials

3.4 explain techniques for joining composite materials

3.5 explain the technology and applications of hard ceramic

coatings

LO4 Be able to investigate

applications of composites

within existing and developing

markets

4.1 evaluate the suitability of composites compared with

conventional materials

4.2 justify the use of composite materials for particular

applications

4.3 report on adopting a composite material as a

replacement to conventional materials

4.4 demonstrate an awareness of current and predicted

developments in the use and manufacture of

composites.

UNIT 138: COMPOSITE MATERIALS IN ENGINEERING

BN033521 Unit 138: Composite Materials in Engineering

Issue 1 September 2012 Pearson Education Limited 2012

5

Guidance

Links

This unit is sufficient to standalone or could be linked to Unit 8: Engineering Design or

Unit 69: Advanced Computer-aided Design Techniques. Entry requirements for this unit are at the

discretion of the centre. However learners should have completed the appropriate BTEC National

or equivalent units and BTEC Higher National Unit 21: Materials Engineering.

Essential requirements

Access to suitable laboratory equipment and a supply of relevant materials is necessary.

Computers and CAD software will be required, dependent on the design.

Employer engagement and vocational contexts

Wherever possible, centres should provide a practical approach to learning supported by visits to

composite engineering facilities and the attendance of guest speaker(s) from relevant design and

manufacturing environments.

sb220812G:\WORDPROC\LT\PD\HIGHER NATIONALS\BN033521_BTEC_HNS_UNIT_138_ENG\BN033521_BTEC_HNS_UNIT_138_ENG.DOC.15/0

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PDF - 004E - The Beatitudes - SheffieldDocument24 pagesPDF - 004E - The Beatitudes - Sheffieldalexandre_motta_3No ratings yet

- Some Factors Affecting Viscosity in Newtonian FluidsDocument4 pagesSome Factors Affecting Viscosity in Newtonian Fluidsalexandre_motta_3No ratings yet

- Unit Specification - Fluid Mechanics NEW Unit 11Document5 pagesUnit Specification - Fluid Mechanics NEW Unit 11alexandre_motta_3No ratings yet

- Unit Specification - Fluid Mechanics NEW Unit 11Document5 pagesUnit Specification - Fluid Mechanics NEW Unit 11alexandre_motta_3No ratings yet

- Unit 4: Mechanical Principles: Lesson MP3/8B: Epicyclic Gear Trains Turns/Velocities Ratios Gear Ratios (GR)Document5 pagesUnit 4: Mechanical Principles: Lesson MP3/8B: Epicyclic Gear Trains Turns/Velocities Ratios Gear Ratios (GR)alexandre_motta_3No ratings yet

- Sound Healing Online: Mark BarnwellDocument35 pagesSound Healing Online: Mark Barnwellalexandre_motta_3No ratings yet

- Temperature & Viscosity PDFDocument17 pagesTemperature & Viscosity PDFalexandre_motta_3No ratings yet

- Manual Do Monitor H257HUDocument27 pagesManual Do Monitor H257HUalexandre_motta_3No ratings yet

- PDF - Performance Optimization of A Long Rod Penetrator Penetrating Into A Semi-Infinite Target Considering Bending Characteristics PDFDocument12 pagesPDF - Performance Optimization of A Long Rod Penetrator Penetrating Into A Semi-Infinite Target Considering Bending Characteristics PDFalexandre_motta_3No ratings yet

- Naca - Report XptyDocument11 pagesNaca - Report Xptyalexandre_motta_3No ratings yet

- Manual Do Monitor H257HUDocument27 pagesManual Do Monitor H257HUalexandre_motta_3No ratings yet

- Retaining Wall GuideDocument20 pagesRetaining Wall GuidegauraveNo ratings yet

- Manual Do Monitor H257HUDocument27 pagesManual Do Monitor H257HUalexandre_motta_3No ratings yet

- Paragon Super IIDocument10 pagesParagon Super IIalexandre_motta_3No ratings yet

- Sponsor Guide Jan 09Document5 pagesSponsor Guide Jan 09Prabakaran ThambusamyNo ratings yet

- Samsung Manual XPTODocument57 pagesSamsung Manual XPTOalexandre_motta_3No ratings yet

- Macaulay's Method Using Blocks - Big BlocksDocument2 pagesMacaulay's Method Using Blocks - Big Blocksalexandre_motta_3No ratings yet

- SIA 1 Stress ConcentrationDocument0 pagesSIA 1 Stress Concentrationjohnj_ramirezNo ratings yet

- Fluid Power PrinciplesDocument17 pagesFluid Power Principlesalexandre_motta_3No ratings yet

- Assessment GuideDocument35 pagesAssessment Guidealexandre_motta_3No ratings yet

- SIA 1 Stress ConcentrationDocument0 pagesSIA 1 Stress Concentrationjohnj_ramirezNo ratings yet

- Competence StatementsDocument5 pagesCompetence Statementsalexandre_motta_3No ratings yet

- 2015 - IEng and CEng Guidance NotesDocument26 pages2015 - IEng and CEng Guidance Notesalexandre_motta_3100% (1)

- Engtech, Ieng and Ceng: Uk Standard For Professional Engineering CompetenceDocument32 pagesEngtech, Ieng and Ceng: Uk Standard For Professional Engineering CompetencealbertofrogNo ratings yet

- Unit 50 Condition Monitoring and Fault Diagnosis - Part 02Document41 pagesUnit 50 Condition Monitoring and Fault Diagnosis - Part 02alexandre_motta_3No ratings yet

- Unit 50 Condition Monitoring and Fault Diagnosis - Part 01Document44 pagesUnit 50 Condition Monitoring and Fault Diagnosis - Part 01alexandre_motta_3No ratings yet

- Unit 50 Condition Monitoring and Fault Diagnosis - Part 03Document29 pagesUnit 50 Condition Monitoring and Fault Diagnosis - Part 03alexandre_motta_3No ratings yet

- Rules For Classification and Construction I Ship Technology: 1 Seagoing ShipsDocument20 pagesRules For Classification and Construction I Ship Technology: 1 Seagoing Shipsramlan003No ratings yet

- Outcome 01 t1Document12 pagesOutcome 01 t1alexandre_motta_3No ratings yet

- Omicron CP Line CatalogueDocument32 pagesOmicron CP Line CatalogueShirosh AyeshmanthaNo ratings yet

- Low-Loss, Broadly-Tunable Cavity Filter Operating at UHF FrequenciesDocument4 pagesLow-Loss, Broadly-Tunable Cavity Filter Operating at UHF FrequenciesDo SonNo ratings yet

- EtpPrD0ATC-1000 Quick Start GuideDocument1 pageEtpPrD0ATC-1000 Quick Start Guidedung110baclieuNo ratings yet

- BSE SoSDocument2 pagesBSE SoSALI AHMADNo ratings yet

- $outputDocument4 pages$outputQamar AbbasNo ratings yet

- 96-8000R English Mill - Haas PDFDocument217 pages96-8000R English Mill - Haas PDFPranjal JangidNo ratings yet

- (IJCST-V8I5P3) : Gajendra R. WaniDocument4 pages(IJCST-V8I5P3) : Gajendra R. WaniEighthSenseGroupNo ratings yet

- Chapter 2. Information Seekers and Electronic EnvironmentsDocument17 pagesChapter 2. Information Seekers and Electronic EnvironmentsCatalina Echeverri GalloNo ratings yet

- Web Engineering Lec 04Document26 pagesWeb Engineering Lec 04RamshaNo ratings yet

- IRM IT Knowledge Topic - RPADocument9 pagesIRM IT Knowledge Topic - RPAJoel Colquepisco EspinozaNo ratings yet

- Résumé: 120 "Shri Ram Kutir", Udhna, Pandesara, Surat-394210Document4 pagesRésumé: 120 "Shri Ram Kutir", Udhna, Pandesara, Surat-394210Raj AryanNo ratings yet

- CourseDocument11 pagesCourseIvan ElisioNo ratings yet

- ANA Content Marketing Maturity ModelDocument2 pagesANA Content Marketing Maturity ModelDemand Metric100% (1)

- Dataprep Cheat SheetDocument1 pageDataprep Cheat Sheetgaston_russo87No ratings yet

- Shore ApproachDocument5 pagesShore Approachvpandya1981No ratings yet

- Dissertation Adoption of Enterprise Resource Planning Erp in VietnamDocument30 pagesDissertation Adoption of Enterprise Resource Planning Erp in VietnamAr Puneet AroraNo ratings yet

- Arnold Schwarzenegger - The New Encyclopedia of ... - ScribdDocument1 pageArnold Schwarzenegger - The New Encyclopedia of ... - ScribdvklNo ratings yet

- 6 Months / 6 Weeks Industrial / Institutional Training Daily DairyDocument11 pages6 Months / 6 Weeks Industrial / Institutional Training Daily DairyRahul ThakurNo ratings yet

- Contoh PPT Sidang SkripsiDocument16 pagesContoh PPT Sidang Skripsi018Kenny ShaniaRNo ratings yet

- 1574158341-Resume AjayLanjewar QA 8YrsExp1Document7 pages1574158341-Resume AjayLanjewar QA 8YrsExp1ragunath90No ratings yet

- Final EXamDocument3 pagesFinal EXamRodrigo CalapanNo ratings yet

- Internet Access Via Cable TV NetworkDocument15 pagesInternet Access Via Cable TV Networkankur_desai100% (1)

- Lab 3 X Term.Document9 pagesLab 3 X Term.LINDER ARCE INGANo ratings yet

- Mobile Telephone History PhilippinesDocument29 pagesMobile Telephone History PhilippinesKyou Chan100% (1)

- CHAPTER 2 3.0 Power in AC Circuits With SolutionDocument20 pagesCHAPTER 2 3.0 Power in AC Circuits With SolutionMUHAMMAD ALIFF DANIAL RAZMINo ratings yet

- Interview With DR Lawrence MaysDocument6 pagesInterview With DR Lawrence Maysapi-332371318No ratings yet

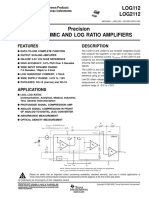

- LOG112Document21 pagesLOG112Otto Lambertus0% (1)

- V.K FITNESS J SERIES PDFDocument4 pagesV.K FITNESS J SERIES PDFavik mukherjeeNo ratings yet

- Product Manual: Manufacturer of Marine Doors and Windows Since 1943Document40 pagesProduct Manual: Manufacturer of Marine Doors and Windows Since 1943Begad MohamedNo ratings yet

- DS-2CD3743G1-IZUHK 4 MP IR Varifocal Dome Network Camera: Key FeaturesDocument4 pagesDS-2CD3743G1-IZUHK 4 MP IR Varifocal Dome Network Camera: Key FeaturesSecurity STSNo ratings yet