Professional Documents

Culture Documents

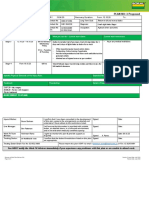

Rhombic 3D Condylar Fracture Plate

Uploaded by

ahujasurajCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rhombic 3D Condylar Fracture Plate

Uploaded by

ahujasurajCopyright:

Available Formats

Three-dimensional geometries for multilateral forces

CMF Surgery

Rhombic 3D Condylar Fracture Plate

Case image provided by courtesy of Dr. Hamid-Reza Sarajian, Red Cross Hospital (RKK) Kassel, Germany

3

I NNOVATI ON: Rhombi c 3D Condyl ar Frac t ure Pl at e

Developed in collaboration with

Prof. Dr. Dr. Gnter Lauer,

University Hospital of Dresden

Rhombic 3D Condylar Fracture Plate

Condylar fractures surely are among the greatest challenges

with which surgeons can be confronted in the region of the

craniomaxillofacial skeleton. The considerable degree of

dislocation, the lack of working space and the proximity to

vital vessels and nerve structures are inherent aspects that

make many physicians recoil from any surgical treatment of

such conditions. However, more recent studies have shown

that a generally better aesthetic and functional result can

be achieved by careful open surgery using the best possible

approach. Moreover, the range of available osteosynthesis

materials (micro- and mini-plates, meshes, resorbable

solutions, etc.) is so wide that surgeons frequently find it

hard to make their choices. With the Rhombic 3D Condylar

Fracture Plate, KLS Martin offers you a medium that is

perfectly adapted to the multilateral masticatory forces

present in this area.

Advantages

The rhombic shape of the plate takes account of the

great variety of pressure and tensile forces involved

in the masticatory process, thus ensuring rigid,

torsionresistant osteosynthesis.

Thanks to the rhomboidal lightweight design, the plate

provides a central window for perfect control of the

fracture gap after reduction.

Closely positioned screw holes in the cranial part of

the plate allow you to place the osteosynthesis screws

securely even where space is very limited.

Pattern of the tensile and pressure forces present

in the mandible. The special geometry of the

Rhombic 3D Condylar Fracture Plate ensures

optimal force transmission.

Pressure

Tension

Note

The narrow side of the implant is fixed in place

cranially (top), the wide base must be placed

caudally (bottom).

Indications

Surgical treatment of deep, medium and high

condylar fractures

Contraindications

Diacapitular fractures

Approaches

Intraoral approach and endoscopically assisted

intraoral approach

Preauricular or auricular approach, especially

in the case of high condylar fractures

Periangular approach

Retromandibular approach

Retroauricular approach

Submandibular approach

Rhombic 3D Condylar Fracture Plate

Three-dimensional geometries for multilateral forces

4

I NNOVATI ON: Rhombi c 3D Condyl ar Frac t ure Pl at e

The plates are available in two different versions:

Standard version (non-locking)

2.0-mm Mini osteosynthesis screws, non-locking

2.3-mm Fracture osteosynthesis screws, non-locking

Special gliding holes allow raising the condyle

securely to its original position

Locking version

2.0-mm ThreadLock TS locking screws (angle-stable)

2.3-mm ThreadLock TS locking screws (angle-stable)

2.0-mm Mini osteosynthesis screws, non-locking

2.3-mm Fracture osteosynthesis screws, non-locking

The locking plate (green anodization) is usually implanted with

locking (angle-stable) osteosynthesis screws from the 2.0/2.3-mm

ThreadLock TS system. This gives you a maximum lateral range

of angulation of 40 ( 20 in every direction).

The locking feature keeps the screw exactly in the chosen

angulation relative to the osteosynthesis medium. This provides

a self-supporting structure that prevents resorption caused by

pressing the bone against the plate when tightening the screws.

Alternatively, it is also possible to use non-locking screws from

the 2.0 Mini and 2.3 Fracture standard osteosynthesis product

lines. These screws offer the advantage of a significantly wider

range of lateral angulation compared to the locking screws.

Of course, the locking effect will not be available in this case.

Fixation by

Special properties

Illustrations

25-285-05-09

20 x 13 mm

= 1.0 mm

1

25-283-05-09

20 x 13 mm

= 1.0 mm

1

1

1

1

1

5

The procedure step by step

using the standard version for illustration

Fig. 1: Preoperative X-ray of the condylar

fracture

Fig. 3: Now the plate is securely fixed to

the fractured bone segment. Following intra-

operative verification of the anatomically

correct position of the condyle or proximal

fragment, this position can be secured step

by step by inserting additional screws in

the intact, distal region of the mandible.

The special gliding hole geometry ensures

that there is still a gliding range of 2.5 mm

left for further corrections or adjustments.

Fig. 5: Postoperative X-ray

Fig. 4: The final osteosynthesis screw is

inserted as soon as the fracture has been

well repositioned. This screw neutralizes

the gliding hole effect.

Clinical images provided by courtesy of Prof. Dr. Dr. Gnter Lauer, University Hospital of Dresden

Fig. 2: Since condylar fractures are almost

always dislocated fractures, the surgeon

usually will start by placing the osteosynthesis

screw next to the fracture gap on the

fractured condyle, because this hole is easily

accessible. This is followed by inserting the

second osteosynthesis screw located

cranially to the first screw.

6

I NNOVATI ON: Rhombi c 3D Condyl ar Frac t ure Pl at e

Ordering data Icon explanations

1

Titanium

Plate profile

Items/pack

25-285-05-09

20 x 13 mm

= 1.0 mm

1 25-283-05-09

20 x 13 mm

= 1.0 mm

1

1

1

1

1

Case example: Treatment of a bilateral condylar fracture

using the locking version

Fig. 1: Preoperative X-ray

Fig. 5: Postoperative X-ray

Fig. 4: Important advantage of the

Rhombic 3D Condylar Fracture

Plate: the fracture is easily visible

through the window of the plate.

This gives the surgeon perfect

control.

Clinical images provided by courtesy of Prof. Dr. Dr. Gnter Lauer, University Hospital of Dresden

Fig. 2: Endoscopically assisted

intraoral approach to expose the

condylar fracture. The fracture is

visibly dislocated.

Fig. 3: Using a hooklet, it was

possible to raise the fractured

bone segment and restore it

to its original position, thus

correcting the dislocation.

7

References

Brochures

Osteosynthesis 2.0 Mini Osteosynthesis 2.3

Fracture and Reconstruction

ThreadLock TS

Osteosynthesis 2.0 2.7

Fracture and Reconstruction

Instruments for treating

condylar fractures

Angulus

angled screwdriver

Haim, D., et al.,

Biomechanical study of the Delta Plate

and the TriLock Delta Condyle Trauma Plate.

J Oral Maxillofac Surg, 69 (10), 2011,

S. 2619 2625

Lauer, G.,

Condylar neck fractures: Delta-shaped plate

and endoscopic approach. In:

Haerle, F., et al., Atlas of craniomaxillofacial

osteosynthesis. 2. Auflage, Thieme Verlag,

Stuttgart, New York, 2009, S. 78 84

Lauer, G., et al.,

A new 3-dimensional plate for transoral

endoscopic-assisted osteosynthesis of

condylar neck fractures.

J Oral Maxillofac Surg, 65 (5), 2007,

S. 964 971

Lauer, G., et al.,

Plate osteosynthesis of the mandibular condyle.

Ann Anat, 189 (4), 2007, S. 412 417

Lauer, G., et al.,

Transoral osteosynthesis of condylar neck

fractures using a three-dimensional plate.

Mund-Kiefer-Gesichtschir, 10 (5), 2006,

S. 335 340

Lauer, G. & Schmelzeisen, R.,

Endoscope-assisted fixation of mandibular

condylar process fractures.

J Oral Maxillofac Surg, 57 (1), 1999, S. 36 40

Schmelzeisen, R., et al.,

Endoscope-assisted fixation of condylar

fractures of the mandible.

Mund-Kiefer-Gesichtschir, 1998 May,

2 Suppl 1, S. 168 170

Schneider, M., et al.,

Surgical treatment of fractures of the mandible

condyle: a comparison of long-term results

following different approaches functional,

axiographical, and radiological findings.

J Craniomaxillofac Surg, 35 (3), 2007,

S. 151 160

05.13

.

90-811-02-04

.

Printed in Germany Copyright by Gebrder Martin GmbH & Co. KG Alle Rechte vorbehalten Technische nderungen vorbehalten

We reserve the right to make alterations Cambios tcnicos reservados Sous rserve de modifications techniques Ci riserviamo il diritto di modifiche tecniche

KLS Martin Group

Karl Leibinger Medizintechnik GmbH & Co. KG

78570 Mhlheim

.

Germany

Tel. +49 7463 838-0

info@klsmartin.com

KLS Martin GmbH + Co. KG

79224 Umkirch

.

Germany

Tel. +49 7665 98 02-0

info@klsmartin.com

Stuckenbrock Medizintechnik GmbH

78532 Tuttlingen

.

Germany

Tel. +49 7461 16 58 80

verwaltung@stuckenbrock.de

Rudolf Buck GmbH

78570 Mhlheim

.

Germany

Tel. +49 74 63 99 516-30

info@klsmartin.com

KLS Martin France SARL

68200 Mulhouse

.

France

Tel. +33 3 89 51 3150

france@klsmartin.com

Martin Italia S.r.l.

20871 Vimercate (MB)

.

Italy

Tel. +39 039 605 6731

italia@klsmartin.com

Nippon Martin K.K.

Osaka 541-0046

.

Japan

Tel. +81 6 62 28 9075

nippon@klsmartin.com

Martin Nederland/Marned B.V.

1271 AG Huizen

.

The Netherlands

Tel. +31 35 523 45 38

nederland@klsmartin.com

KLS Martin UK Ltd.

Reading RG1 3EU United Kingdom

Tel. +44 1189 000 570

uk@klsmartin.com

KLS Martin L.P.

Jacksonville, Fl 32246

.

USA

Tel. +1 904 641 77 46

usa@klsmartin.com

Gebrder Martin GmbH & Co. KG

Representative Office

121471 Moscow

.

Russia

Tel. +7 499 792-76-19

russia@klsmartin.com

Gebrder Martin GmbH & Co. KG

Representative Office

201203 Shanghai

.

China

Tel. +86 21 2898 6611

china@klsmartin.com

Gebrder Martin GmbH & Co. KG

Representative Office

Dubai

.

United Arab Emirates

Tel. +971 4 454 16 55

middleeast@klsmartin.com

Gebrder Martin GmbH & Co. KG

A company of the KLS Martin Group

KLS Martin Platz 1 78532 Tuttlingen Germany

Postfach 60 78501 Tuttlingen Germany

Tel. +49 7461 706-0 Fax +49 7461 706-193

info@klsmartin.com www.klsmartin.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Arthroscopy of TMJ PDFDocument44 pagesArthroscopy of TMJ PDFahujasurajNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Management of Medically Compromised PatientsDocument93 pagesManagement of Medically Compromised PatientsahujasurajNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Modified Rhomboid Flap For Facial ReconstructionDocument3 pagesModified Rhomboid Flap For Facial ReconstructionahujasurajNo ratings yet

- Dental Health Attitude in Indian SocietyDocument4 pagesDental Health Attitude in Indian SocietyahujasurajNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Large and Rapidly Expanding Odontogenic Myxoma of The MandibleDocument5 pagesA Large and Rapidly Expanding Odontogenic Myxoma of The MandibleahujasurajNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Clinical Use of Botulinum PDFDocument11 pagesClinical Use of Botulinum PDFkapilmalik2007No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Concepts in Local Flap Design and ClassificationDocument11 pagesConcepts in Local Flap Design and ClassificationahujasurajNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Clinical Outcome Following Use of Transconjunctival Approach in Reducing Orbitozygomaticomaxillary Complex Fractures PDFDocument7 pagesClinical Outcome Following Use of Transconjunctival Approach in Reducing Orbitozygomaticomaxillary Complex Fractures PDFahujasurajNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Bone Grafts in Craniofacial SurgeryDocument10 pagesBone Grafts in Craniofacial SurgeryahujasurajNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Reimplantation 9.2.2.2 PDFDocument4 pagesReimplantation 9.2.2.2 PDFGowri ShankarNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- MO CBDMP Cleft Lip Cleft Palate FactsDocument2 pagesMO CBDMP Cleft Lip Cleft Palate FactsahujasurajNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- AnaphylaxisDocument8 pagesAnaphylaxisahujasurajNo ratings yet

- 3D Vector Control During Alveolar Ridge Augmentation Using Distraction Osteogenesis and Temporary Anchorage DevicesDocument3 pages3D Vector Control During Alveolar Ridge Augmentation Using Distraction Osteogenesis and Temporary Anchorage DevicesahujasurajNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Endoscopic-Assisted Reduction and Fixation of A Mandibular Subcondylar Fracture Report of A CaseDocument4 pagesEndoscopic-Assisted Reduction and Fixation of A Mandibular Subcondylar Fracture Report of A CaseahujasurajNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- An Accident With A Gates Glidden Drill in Endodontic PracticeDocument2 pagesAn Accident With A Gates Glidden Drill in Endodontic PracticeahujasurajNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Planning and EvaluationDocument1 pagePlanning and EvaluationahujasurajNo ratings yet

- AnaphylaxisDocument8 pagesAnaphylaxisahujasurajNo ratings yet

- Mandibular FX 961127Document35 pagesMandibular FX 961127Azal HadiNo ratings yet

- Diabetic Emergencies NewDocument44 pagesDiabetic Emergencies NewahujasurajNo ratings yet

- 6Document13 pages6Гулпе АлексейNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Complications of Diabetes: Pennington Biomedical Research Center Division of EducationDocument39 pagesComplications of Diabetes: Pennington Biomedical Research Center Division of EducationahujasurajNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Hemostasis PDFDocument6 pagesHemostasis PDFahujasurajNo ratings yet

- Facial and Mandibular FracturesDocument24 pagesFacial and Mandibular FracturesahujasurajNo ratings yet

- Sports EquipmentsDocument1 pageSports EquipmentsahujasurajNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Eur J Orthod 2005 Van Loenen 258 62Document5 pagesEur J Orthod 2005 Van Loenen 258 62ahujasurajNo ratings yet

- Anti Diabetic DrugsDocument58 pagesAnti Diabetic DrugsDaniel WangNo ratings yet

- Complications of Diabetes: Pennington Biomedical Research Center Division of EducationDocument39 pagesComplications of Diabetes: Pennington Biomedical Research Center Division of EducationahujasurajNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Soft Tissue ReconstructionDocument5 pagesSoft Tissue ReconstructionahujasurajNo ratings yet

- Hemostasis PDFDocument6 pagesHemostasis PDFahujasurajNo ratings yet

- PSM Concept BookDocument569 pagesPSM Concept Bookram dheer100% (1)

- Cleft Lip/Palate - Nursing InterventionsDocument2 pagesCleft Lip/Palate - Nursing Interventionsalexander abasNo ratings yet

- College of Nursing Pharmacy and Allied Health SciencesDocument2 pagesCollege of Nursing Pharmacy and Allied Health SciencesLadyfair TanticoNo ratings yet

- Malassezia: A Case of Coexisting Pityriasis Versicolor and Malassezia FolliculitisDocument1 pageMalassezia: A Case of Coexisting Pityriasis Versicolor and Malassezia Folliculitishannah khumairahNo ratings yet

- Laporan Lb1 Puskesmas Berdasarkan Icd-10: Kelompok Usia B L B L B NO Urut PEN Yaki TDocument36 pagesLaporan Lb1 Puskesmas Berdasarkan Icd-10: Kelompok Usia B L B L B NO Urut PEN Yaki TTogi Rut Marlita MarbunNo ratings yet

- Acute Complicated Urinary Tract Infection (Including Pyelonephritis) in Adults - UpToDateDocument39 pagesAcute Complicated Urinary Tract Infection (Including Pyelonephritis) in Adults - UpToDateLaís FialhoNo ratings yet

- Nasal Congestion Relief with OxymetazolineDocument3 pagesNasal Congestion Relief with OxymetazolineAnonymous la2t9oAvKNo ratings yet

- Challenges, Constraints and Opportunities in Herbal MedicinesDocument4 pagesChallenges, Constraints and Opportunities in Herbal MedicinesGregory KalonaNo ratings yet

- Methylene Blue Therapy of Viral DiseaseDocument15 pagesMethylene Blue Therapy of Viral DiseaseEstevam Dimas100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Nursing Practice II - Community Health Nursing and Care of The Mother and ChildDocument54 pagesNursing Practice II - Community Health Nursing and Care of The Mother and Childanon_840592833No ratings yet

- Recover at Work Plan 5 ProposedDocument2 pagesRecover at Work Plan 5 ProposedSiosiana DenhamNo ratings yet

- A Review of The Treatment of Male Pattern Hair LossDocument11 pagesA Review of The Treatment of Male Pattern Hair LossigorfragaNo ratings yet

- Assessment Subjective: "Apat Na Araw Na SiyangDocument2 pagesAssessment Subjective: "Apat Na Araw Na Siyangmarlon_taycoNo ratings yet

- World Health Organization Dimensions of Adherence.9Document7 pagesWorld Health Organization Dimensions of Adherence.9Lucky Radja PonoNo ratings yet

- Bijender Sindhu, DR - Manoj Sharma, DR - Raj K Biraynia. Comparison of Clinic and Home Based Exercise Programs After Total Knee Arthroplasty A Pilot StudyDocument12 pagesBijender Sindhu, DR - Manoj Sharma, DR - Raj K Biraynia. Comparison of Clinic and Home Based Exercise Programs After Total Knee Arthroplasty A Pilot StudyDr. Krishna N. SharmaNo ratings yet

- Course of Instruction Third Year B.Sc. Nursing Theory Sr. No. Subject Class Lab Practical Hrs. HrsDocument3 pagesCourse of Instruction Third Year B.Sc. Nursing Theory Sr. No. Subject Class Lab Practical Hrs. HrsSimran JosanNo ratings yet

- MASTITE GANGRENOSA BOVINA POR Clostridium Perfring - Amandio Steffen NetoDocument5 pagesMASTITE GANGRENOSA BOVINA POR Clostridium Perfring - Amandio Steffen NetoAmandio Steffen NetoNo ratings yet

- Ears Lecture GuideDocument56 pagesEars Lecture GuidemajNo ratings yet

- Executive Director Research Development in Boston MA Resume Paul HallenbeckDocument5 pagesExecutive Director Research Development in Boston MA Resume Paul HallenbeckPaulHallenbeckNo ratings yet

- Wolfe - Understanding and Treating Anxiety Disorders An Integrative Approach To Healing The Wounded Self (2005)Document300 pagesWolfe - Understanding and Treating Anxiety Disorders An Integrative Approach To Healing The Wounded Self (2005)Ruxandra Pop100% (5)

- IV Admixture CalculationsDocument20 pagesIV Admixture CalculationsudinNo ratings yet

- Pas Poster FinalDocument1 pagePas Poster Finalapi-256316098No ratings yet

- Toxicology and Applied Pharmacology: Marina A. Dobrovolskaia, Michael Shurin, Anna A. ShvedovaDocument12 pagesToxicology and Applied Pharmacology: Marina A. Dobrovolskaia, Michael Shurin, Anna A. ShvedovaKarina EndoNo ratings yet

- High Blood Pressure Thesis StatementDocument8 pagesHigh Blood Pressure Thesis StatementCheapestPaperWritingServiceCanada100% (1)

- Curofy Best ECG CasesDocument26 pagesCurofy Best ECG Casescnshariff@gmail.comNo ratings yet

- FORMAT FOR UNIT PLAN-converted-1Document2 pagesFORMAT FOR UNIT PLAN-converted-1Delphy VargheseNo ratings yet

- A History of Surgery in The Instrument Tray: Eponymous Tools Used in Hand SurgeryDocument12 pagesA History of Surgery in The Instrument Tray: Eponymous Tools Used in Hand SurgeryMade SuryaNo ratings yet

- Medical Surgical Nursing 50 ItemsDocument34 pagesMedical Surgical Nursing 50 ItemsNiceniadas CaraballeNo ratings yet

- Acute Renal Failure Lecture 1 Critical Care NursingDocument52 pagesAcute Renal Failure Lecture 1 Critical Care NursingDina Rasmita100% (2)

- Corona-Fehlalarm - Anhang-Immunitaet - ENGLISHDocument20 pagesCorona-Fehlalarm - Anhang-Immunitaet - ENGLISHMarcus100% (1)

- The Age of Magical Overthinking: Notes on Modern IrrationalityFrom EverandThe Age of Magical Overthinking: Notes on Modern IrrationalityRating: 4 out of 5 stars4/5 (19)

- Why We Die: The New Science of Aging and the Quest for ImmortalityFrom EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityRating: 4 out of 5 stars4/5 (3)

- Summary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedFrom EverandSummary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedRating: 5 out of 5 stars5/5 (78)

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 4 out of 5 stars4/5 (5)

- By the Time You Read This: The Space between Cheslie's Smile and Mental Illness—Her Story in Her Own WordsFrom EverandBy the Time You Read This: The Space between Cheslie's Smile and Mental Illness—Her Story in Her Own WordsNo ratings yet