Professional Documents

Culture Documents

GB FL Complete

Uploaded by

Luqman YusofOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GB FL Complete

Uploaded by

Luqman YusofCopyright:

Available Formats

Ref.

Calculations Output

SPECIFICATION

Slab thickness = 125 mm = 0.125 m

Unit weight of concrete = 25 kN/m

Weight of brickwork = 0 kN/m

Characteristic Actions :

Finishes etc. = 1.2 kN/m

Variable q k = 2 kN/m

Materials :

Characteristic strength of concrete,fck = 30 N/mm

Characteristic strength of concrete, fyk

= 500 N/mm

Characteristic strength of link , f yk = 500 N/mm

Nominal concrete cover = 30 mm

Assumed :

bar 1 = 16 mm

bar 2 = 12 mm

link

= 10 mm

6050

2085

W1

W2

Ref Calculations Output

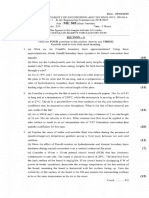

5.3.2.1 BEAM SIZE

bw = 150 mm = 0.15 m

hf = 125 mm = 0.125 m

h = 600 mm = 0.60 m

b1 = 210 mm = 0.21 m

b2 = 682.5 mm = 0.68 m

0 = 2085 mm = 2.09 m

b eff,i = 0.2b i + 0.1 0 0.2 0

0.2b 1 + 0.1 0

= 250.5 mm

0.2b 2 + 0.1 0 = 345 mm

0.2 0 = 417 mm

b eff,1 = = 250.5 mm

b eff,2 = = 345 mm

b = b 1 + b 2 +b w = 1042.5 mm

Effective flange width,

b eff = b eff,i + b w b

= b eff,1 + b eff,2 + b w = 745.5 mm

= 745.5 mm b

LOADING

Loads on slab :

Self - weight = 3.75 kN/m

Finishes etc. = 1.2 kN/m

Chac. Permanent load , g k

= 4.95 kN/m

Chac. variable load , q k = 2.00 kN/m

6050

2085

h

0

hf

bw

Ref Calculations Output

W1, Ly= 6.05 m Lx = 0.57 m

W2, Ly= 6.05 m Lx = 1.52 m

Table 3.15 Distribution of load from slabs to beam are as follows :

BS8110 W1, Ly /Lx = 10.61 > 2.0 , one-way slab.

Shear coefficient, v = 0.57

W2, Ly /Lx = 3.99 > 2.0 , one-way slab.

Shear coefficient, v = 0.50

Characteristic pemanent load :

Beam self-weight ,

w0 =

0.15 0.6 0.13 x 25 = 1.78 kN/m

w1 = vnL x = 0.57 x 4.95 x 0.57 = 1.61 kN/m

w2 = vnLx = 0.50 x 4.95 x 1.52 = 3.75 kN/m

Brickwall, w3 = 0 x 2.0 = 0 kN/m

Gk 7.14 kN/m

Characteristic variable load :

w1 = vnL x = 0.57 x 2.00 x 0.57 = 0.65 kN/m

w2 =

vnL x = 0.50 x 2.00 x 1.52 = 1.52 kN/m

Qk = 2.16 kN/m

Total design load on beam

w = 1.35 Gk + 1.5 Qk = 12.89 kN/m

Analysis

w = 12.89 kN/m

L = 2.085 m

Shear force ,

V = wL/2

= 13.43 kN

Bending Moment ,

M = wL /8

= 7.00 kNm

(

-

)

M

Ref. Calculations Output

6.1 MAIN REINFORCEMENT

Effective depth ,

d = h - C nom - link - 0.5 bar = 552 mm

MEd = 7.00 kNm

Mf = 0.567 f ck bh f (d - 0.5 h f )

= 0.567 30 745.5 125 552 62.5

= 776 kNm

Med < Mf Neutral axis within the flange

K = Med / f ckb d

= 7.0 x10/ 30 746 552

= 0.001

z = d [ 0.5 + ( 0.25 - K / 1.134 )) = 1.00 d > 0.95 d Use : 0.95d

Area of tension reinforcement

As = Med / 0.87 fyk z

= 7.0 x10/ 0.87 500 0.95 552

= 31 mm

Use: 2H - 6

9.2.1.1 Minimum and maximum reinforcement area , 56.6 mm

A

s,min

= 0.26 (f

ctm

/ f

yk

) bd fctm = 2.9

= 0.26 2.9 500 bd

= 0.0015 bd use= 0.0013 bd

= 0.0013 150 552 = 108 mm

A

s,max

= 0.04 A

c

= 0.04 bh

= 0.04 150 600 = 3600 mm

SHEAR REINFORCEMENT

Design shear force,

V

ed

= 13.4 kN

6.2.3 Concrete strut capacity,

V

rd,max

= 0.36 b

w

d f

ck

( 1 - f

ck

/250 ) / (cot + tan )

= 0.36 150 552 30 1 30 250

( cot + tan )

= 271 kN = 22 cot = 3

= 393.5 kN = 45 cot = 1.0

V

Ed

< V

Rd.max

cot

= 2.5

V

Ed

< V

Rd.max

cot

= 1.0

x x x ( - )

( )

( x x

x

)

( ) /

x x

x x

x x x ( - / )

deg

deg

x x

Ref. Calculations Output

Therefore angle < 22

= 0.5sin ' [ Ved / 0.18 bw d fck (1- fck/250)]

= 0.5sin ' 0.98 = 1 Use :

= 22

= 22 cot = 2.5 tan = 0.4

Shear links

Asw/S = Ved/ 0.78 fyk d cot

= 0.025 mm

Try link: H16 = 56.6 mm

Spacing, s = 2264 mm Use:

H16 - 75

9.2.2(6) Max spacing = 0.75d = 414 mm (2681mm/m)

9.2.2(5) Minimum link

Asw/S = 0.08 fck bw/fyk

= 0.131 mm

Try link: H8 = 56.6 mm Use:

Spacing, s = 431 mm < 0.75d = ## mm H16 - 300

(670mm/m)

7.4 DEFLECTION

Percentage of required tension reinforcement,

p = As,req/bd = 31 82800 = 0.0004

Reference reinforcement ratio,

po = fck10x

= 0.005

Percentage of required compression reinforcement,

p' = As'req /bd = 0.000

Factor for structural system, K = 1.00

p <

po

l/d = K [( 11 + 1.5 fck (po / p)) + ( 3.2 fck (( po /p )-1)

3/2 ]

= 797.23

Modification factor for flange width, b/bw > 7 = 0.80

Modification factor for span less than 7m = 1.0

Modification factor for steel area provided, = Asprov / Asreq

= 56.6 31 = 1.84 < 1.5

Therefore allowable span-effective dept ratio,

(l/d)allowable = 797.23 0.80 1.0 1.84 = 1176.07

Actual span-effective depth

(l/d)actual

= 2085 552 = 3.78 <

(l/d)allowable

OK!

/

/

x x x

/

Ref Calculations Output

7.3 CRACKING

Table7.1N Limiting crack width, wmax = 0.3mm

Steel stress,

fs = (fyk/1.15) x [(Gk + 0.3Qk) / (1.35Gk + 1.5Qk)] x1.0

= 500 1.15 7.14 0.65 12.89 1.0

= 262.8 N/mm

Table7.3N Max. allowable clear bar spacing = 100 mm

Clear spacing,

s = (bw - 2(Cnom) - 2(link) - )

= 150 60 20 16 2

= 27 mm < 100 mm OK

DETAILING

/

x ( )

(

+

) /

x

- - - ] [ /

)

You might also like

- Skab/Skaa3613 - Hydrology & Water Resources Section 01 QUIZ 1 SEMESTER 1 2020/2021Document4 pagesSkab/Skaa3613 - Hydrology & Water Resources Section 01 QUIZ 1 SEMESTER 1 2020/2021Luqman YusofNo ratings yet

- 4 VFDBRDocument84 pages4 VFDBRLuqman YusofNo ratings yet

- Company Registration FormDocument3 pagesCompany Registration FormLuqman YusofNo ratings yet

- 2 FGSDFVFGDocument19 pages2 FGSDFVFGLuqman YusofNo ratings yet

- VFTDGNFDGVFDDocument76 pagesVFTDGNFDGVFDLuqman YusofNo ratings yet

- Pad Footing DesignDocument19 pagesPad Footing DesignLuqman YusofNo ratings yet

- Kuiz 2 Skaa3613 Sem 1 20202021Document3 pagesKuiz 2 Skaa3613 Sem 1 20202021Luqman YusofNo ratings yet

- GfmjtdgndesrtgDocument90 pagesGfmjtdgndesrtgLuqman YusofNo ratings yet

- FdjkryfkjhdsgDocument14 pagesFdjkryfkjhdsgLuqman YusofNo ratings yet

- TyhfvwacdsDocument6 pagesTyhfvwacdsLuqman YusofNo ratings yet

- HMTHDBRFBDocument21 pagesHMTHDBRFBLuqman YusofNo ratings yet

- DHRSJDSGVEDocument39 pagesDHRSJDSGVELuqman YusofNo ratings yet

- FdjkryfkjhdsgDocument14 pagesFdjkryfkjhdsgLuqman YusofNo ratings yet

- UlouykrdyhrDocument67 pagesUlouykrdyhrLuqman YusofNo ratings yet

- AsdgyfdgjtDocument158 pagesAsdgyfdgjtLuqman YusofNo ratings yet

- PuhgfhewDocument72 pagesPuhgfhewLuqman YusofNo ratings yet

- IhjmdhtfdDocument501 pagesIhjmdhtfdLuqman YusofNo ratings yet

- Road Asset Management SystemDocument214 pagesRoad Asset Management SystemLuqman YusofNo ratings yet

- Wet GHRTDocument144 pagesWet GHRTLuqman YusofNo ratings yet

- SahbtgfikghDocument24 pagesSahbtgfikghLuqman YusofNo ratings yet

- MsdfvwqefDocument78 pagesMsdfvwqefLuqman YusofNo ratings yet

- FhbftgiujDocument83 pagesFhbftgiujLuqman YusofNo ratings yet

- MsdfvwqefDocument1 pageMsdfvwqefLuqman YusofNo ratings yet

- JbniherdyghDocument9 pagesJbniherdyghLuqman YusofNo ratings yet

- GHJKLDocument67 pagesGHJKLLuqman YusofNo ratings yet

- LKJHGFDocument23 pagesLKJHGFLuqman YusofNo ratings yet

- FDHRWSHDocument80 pagesFDHRWSHLuqman YusofNo ratings yet

- EdgffdDocument80 pagesEdgffdLuqman YusofNo ratings yet

- MNVCXZXDocument49 pagesMNVCXZXLuqman YusofNo ratings yet

- POIUYDocument61 pagesPOIUYLuqman YusofNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- BEARING NSK Trang 1 109 Trang 55 109Document55 pagesBEARING NSK Trang 1 109 Trang 55 109conggiang91No ratings yet

- Physics For Scientists and Engineers, 6e: Chapter 15 - Oscillatory MotionDocument19 pagesPhysics For Scientists and Engineers, 6e: Chapter 15 - Oscillatory Motionaisyah syazwaniNo ratings yet

- Lateral Support For Tier Building FramesDocument4 pagesLateral Support For Tier Building Framesuhu_plus6482No ratings yet

- AISI - Direct Strength Method (DSM) Design GuideDocument184 pagesAISI - Direct Strength Method (DSM) Design GuidePaul KohanNo ratings yet

- Finite Element Surface Analysis of Cosmetic Finishing Applications - Shot PeeningDocument56 pagesFinite Element Surface Analysis of Cosmetic Finishing Applications - Shot PeeningShahzada Shahzeb BaigNo ratings yet

- Force in TrussDocument4 pagesForce in TrussFatin Amira Abd Manan100% (1)

- TMP - 28983-PHYSICS 202LAB - Handouts Aug 2016198621344Document36 pagesTMP - 28983-PHYSICS 202LAB - Handouts Aug 2016198621344Erwin CabangalNo ratings yet

- Eccentrically Loaded Weld Group Analysis: Company Name Sample Calculations YP and Address 8/1/21 C-Shape WeldDocument9 pagesEccentrically Loaded Weld Group Analysis: Company Name Sample Calculations YP and Address 8/1/21 C-Shape WeldDesign explorer olomizanaNo ratings yet

- Lessons Learned of ANSYS v1.3 Part 1Document46 pagesLessons Learned of ANSYS v1.3 Part 1Murthy MandalikaNo ratings yet

- Answer 1 (B) (2011)Document27 pagesAnswer 1 (B) (2011)Siti Hajar Ghazali0% (1)

- B.Tech. I /II Semester (Common To All Branches) Met-103 Manufacturing ProcessesDocument144 pagesB.Tech. I /II Semester (Common To All Branches) Met-103 Manufacturing ProcessesSiddarth WadhwaNo ratings yet

- 29 - Design and Behavior of Zipper Braced FramesDocument10 pages29 - Design and Behavior of Zipper Braced FramesYami YugiNo ratings yet

- Tennis Kinematics Transient Analysis A Ball Spin Racket Collision DescriptionDocument53 pagesTennis Kinematics Transient Analysis A Ball Spin Racket Collision DescriptionIoan-Alexandru CodarceaNo ratings yet

- ES224 01 Spring 2018 CourseContentDocument1 pageES224 01 Spring 2018 CourseContentIskandar IskandarovNo ratings yet

- Mode ShapeDocument2 pagesMode ShapezcvzxNo ratings yet

- Handbook of Fluid Dynamics and Fluid Machinery - Vol-1 - Fundamentals of Fluid Dynamics - J.A.Schetz - A.E.Fuhs - 1996 - Wiley - 958pg PDFDocument958 pagesHandbook of Fluid Dynamics and Fluid Machinery - Vol-1 - Fundamentals of Fluid Dynamics - J.A.Schetz - A.E.Fuhs - 1996 - Wiley - 958pg PDFEDWAR CAMILO FLOREZ100% (1)

- A Comprehensive Comparison of Two-Fluid Model, Discrete ElementDocument23 pagesA Comprehensive Comparison of Two-Fluid Model, Discrete Elementเดชา อินทร์โท่โล่No ratings yet

- Design LocomotionDocument36 pagesDesign LocomotionsherlockmsNo ratings yet

- Main Girder-FullDocument7 pagesMain Girder-FullSatyajeet BeheraNo ratings yet

- Material Properties in Tension LAB REPORTDocument6 pagesMaterial Properties in Tension LAB REPORTDylan BlackshearNo ratings yet

- EMI NotesDocument13 pagesEMI Notesdfgh athtNo ratings yet

- Ma8353 TpdeDocument2 pagesMa8353 TpdeSrini MuktiNo ratings yet

- Teacher Notes - Activity 20: Projectile Motion-Initial Speed and Time of FlightDocument2 pagesTeacher Notes - Activity 20: Projectile Motion-Initial Speed and Time of FlightAlbert Alcantara BernardoNo ratings yet

- PowerPoint P, ResentationDocument3 pagesPowerPoint P, ResentationlaNo ratings yet

- APL100Document2 pagesAPL100Kuldeep Mal0% (1)

- Lecture No.7 - Bridge BearingsDocument39 pagesLecture No.7 - Bridge BearingsHarold Jackson Mtyana100% (2)

- 3 1 Last Year QueDocument24 pages3 1 Last Year QueSAnNo ratings yet

- Flow Meter Orifice CalculationDocument27 pagesFlow Meter Orifice CalculationLaksono BudiNo ratings yet

- M1 January 2006 Mark SchemeDocument5 pagesM1 January 2006 Mark Schemesahiltourani5992No ratings yet