Professional Documents

Culture Documents

Mould Base

Uploaded by

BernikeFebryanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mould Base

Uploaded by

BernikeFebryanaCopyright:

Available Formats

1 | Mo u l d i n g

BAB I

PENDAHULUAN

I.1. Latar Belakang

Saat ini, terjadi pertumbuhan yang sangat pesat pada penggunaan produk plastik di

industri manufaktur karena sangat serbaguna dan memiliki nilai ekonomis yang tinggi.

Dukungan ilmu pengetahuan dan teknologi sangat diperlukan khususnya untuk pemanfaatan

dan pengolahan polimer, sehingga dapat dihasilkan produk plastik dengan kuantitas yang

cukup tinggi dan kualitas yang baik. Salah satu teknik yang cukup efektif dan banyak

dipergunakan untuk pengolahan bahan thermoplastic adalah injection molding.

Injection Molding banyak dipilih karena memiliki beberapa keuntungan diantaranya :

kapasitas produksi yang tinggi, sisa penggunaan material (useless material) sedikit dan tenaga

kerja minimal. Sedangkan kekuranganya, biaya investasi dan perawatan alat yang tinggi ,

serta perancangan produk harus mempertimbangkan untuk pembuatan disain moldingnya.

Pembuatan sebuah mould, tidaklah serumit dulu , karena telah banyak produsen yang

menjual sebuah mould base , yang dapat memudahkan operator dalam mencapai efesiensi

waktu dan memiliki kemudahan yang sangat menguntungkan.

I.2. Tujuan

Mengetahui fungsi Mould Base

Agar mengetahui standar-standar Mould Base yang ada atau tersedia di pasaran

Sarana belajar moulding

Pemenuhan tugas mata kuliah (PPK)

2 | Mo u l d i n g

BAB II

PEMBAHASAN

II.1. Pengertian Mould Base

Mould base digunakan dalam berbagai industri untuk jangka pendek dan aplikasi

pencetakan.Mould base diproduksi dengan menggunakan bahan kualitas unggul seperti baja

ringan dan baja karbon. Tersedia berbagai cetakan yang tersedia dalam berbagai ukuran,

bentuk dan dimensi yang sesuai dengan berbagai jenis die casting dies.

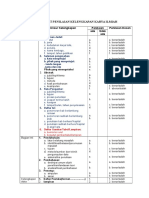

II.2. Standar Mould Base

II.2.1. Standar Mould base dari Ashna

Standar. Standar dasar Mould umumnya digunakan dalam prototipe cetakan dan

pendek berjalan. Cetakan ini menawarkan fleksibilitas untuk melakukan lebih banyak

pekerjaan bernilai tambah, dengan penurunan yang signifikan dalam biaya dasar cetakan.

Proses produksi terkonsentrasi pada penyediaan dasar cetakan berkualitas tinggi untuk

plastik.

Mould base / Mold Base

Material - C - 45 / As Per Customer requirement

S.N. 1 2 3 4 5 6 7 8 9 10 11 12

TYPE 2020 2025 2030 2035 2525 2530 2540 3030 3035 3040 4040 4045

CODE 1 AE 1 AE 1 AE 1 AE 1 AE 1 AE 1 AE 1 AE 1 AE 1 AE 1 AE 1 AE

3 | Mo u l d i n g

CODE 2 AE 2 AE 2 AE 2 AE 2 AE 2 AE 2 AE 2 AE 2 AE 2 AE 2 AE 2 AE

CODE 3 AE 3 AE 3 AE 3 AE 3 AE 3 AE 3 AE 3 AE 3 AE 3 AE 3 AE 3 AE

CODE 4 AE 4 AE 4 AE 4 AE 4 AE 4 AE 4 AE 4 AE 4 AE 4 AE 4 AE 4 AE

II.2.2. Standar Mould base dari Futaba

Specification/selection

Specification

2-plates

type

3-plates type

S series

D/E

series

F/G series H series

Standard

specification

Thickness

selection

Dimension

A

Dimension

B

4 | Mo u l d i n g

Dimension

U

Dimension

C

Mounting plate specification

Guide specification

Ejector plate specification

Support pin specification

Support pin length

Puller bolt length

Option specification

Thickness

selection

Dimension

R

Dimension

S

No screw hole for Eyebolt

No hole for Ejector rod

Material change

Plate accuracy of mold base (template, ejector plate and the other plates)

* The surface roughness sign in the above figure is arithmetic mean roughness (Ra).

Material

S50C(up to 25mm thick)

S55C(30mm thick or more)

Dimensional allowance of T

L - dimension(mm) Dimensional allowance of T (mm)

Up to 300 +0.1 to +0.2

5 | Mo u l d i n g

More than 300 and up to 600 +0.15 to +0.25

More than 600 and up to 1150 +0.2 to +0.3

Uniformity of thickness (T)

0.008 per 100mm

Flatness of both faces of T

Dimensional T (mm)

Dimensional - L (mm)

Up to 300

More than 300

and up to1150

5 or more and up to 10

More than 10 and up to 20

More than 20 up to 40

More than 40 up to 350

0.020 0.040

0.015 0.020

0.010 0.015

0.008 0.010

Squareness of reference plane

0.008 per 100mm

Spacer block

* The surface roughness sign in the above figure is arithmetic mean roughness (Ra).

Material

SS400 or more than equivalent

Uniformity of thickness of (T)

0.008 per 100mm

Variation of T in a pair of plates

0.02

6 | Mo u l d i n g

Mold base with three plates structure used for such as pin point gate

Feature Type Template size

High rigidity type which extend spacer block width High rigidity type 15182540

Standard type with extensive template sizes Standard type

11135070

Structure/Name

DA type

DD type

Ej ector pi n ej ects products.

Stri pper plate ej ects produts.

No support pl ate.

7 | Mo u l d i n g

DB type

DE type

.

DC type

DF type

.

EA type

Stri pper plate ej ects products.

Stri pper plate ej ects products

by mol d openi ng movement

Ej ector pi n ej ects products.

No support pl ate.

Stri pper plate ej ects products by mol d

openi ng movement.

No support pl ate

Ej ecter pi n ej ects products.

No runner stri pper pl ate.

EA t ype is mol d base which eliminate runner stripper

pl ate from DA type.

Similarl y, each t ype of EB/EC/ED is DB/DC/DD without

runner stri pper pl ate.

8 | Mo u l d i n g

Mold base with three plates structure which usable space is extended owing to the guide

by only support pin

Feature Type Template size

High rigidity type to extend spacer block width High rigidity type 15152540

Standard type with extensive template sizes Standard type

11135070

Structure/name

9 | Mo u l d i n g

FA type

FF type

This Type is what ejector pin is stuck out.

This type is what stripper plate is stuck out by mold opening movement.

FC type

GA type

This type is what ejector pin is stuck out without backing plate.

This type is what ejector pin is stuck out without runner stripper

FE type

GC type

This type is what stripper plate is stuck out by mold opening movement.

This type is what ejector pin is stuck out without runner stripper plate.

10 | Mo u l d i n g

Mold base with three plates structure to make pins etc. arranged at the four corners

Feature Type Template size

Standard for long mold with split mold and slide mechanism

25404070

Structure/name

11 | Mo u l d i n g

HA type

HC type

This type is what ejector pin is stuck out.

This type is what ejector pin is stuck out without backing plate.

HB type

HD type

This type is what stripper plate is stuck out.

This type is what stripper plate is stuck out without backing plate.

12 | Mo u l d i n g

13 | Mo u l d i n g

II.2.3. Standar Mould base Hasco

HASCO Standard mould base (450*450~450*700)

Quick Details

Place of Origin: Guangdong, China (Mainland)

Brand Name: JSM

Model Number: 45 seriesThree Plate Type System mold base

Type: FAI~FCI, GAI~GCI,FAH-FCH,GAH-GCH

Size: 450*450~450*700

Shaping Mode: Plastic Injection Mould

Product Material: Steel

Application: Household Product or Vehicle

Raw material:1050,P20,718,718H,738,8407,1.2311,1.1730,S50C

Roughness: Ra 1.6

Thickness tolerance: +/- 0.05mm

Vertical: 0.01/100mm

Packaging & Delivery

Packaging

Details:

(1)Anti-rust oil (2)plastc film (3)white foam (4)pallet or wood

box ,according to customer's request.

Delivery

Detail:

7 days

14 | Mo u l d i n g

Specifications

1. professional manufacturers.

2. High quality, low price.

3. Advanced machinery and equipment.

4. Meet European standard.

Product's Details:

Standard: DME, HASCO, JIS, LKM

Design Software: UG, CAD

Life Time: 300,000 shots

lead Time: 7 days

Manufacture Experience: 15 years

Certification: ISO9001

Processing Machinery: CNC, Grinding, Milling, lathe, polishing

Terms Of Delivery: By sea or By air

Surface Treatment: Sparkerusion and polished

place an order: your own design or choose our design

Terdapat 3 standar, di antaranya:

I. K Standards

K 3600 / Small series mould

Order No. material No.

K3660/3670/156x156/1.1730 2048822

K3660/3670/156x156/1.2312 2048823

K3660/3670/190x246/1.1730 2048824

K3660/3670/190x246/1.2312 2048825

K3660/3670/246x296/1.1730 2048826

K3660/3670/246x296/1.2312 2048827

K3660/3670/296x396/1.1730 2048828

K3660/3670/296x396/1.2312 2048829

Ejector assembly K3660/3670

15 | Mo u l d i n g

K / round

Order No. material No.

K 15/156X 22/1.1730 11142

K 15/196X 22/1.1730 11231

K 15/246-3X 27/1.1730 114880

K 15/246X 27/1.1730 11304

Clamping plate K 15

K / square

Order No. material No.

K 10C/095X095X 22/1.1730 2009292

K 10C/095X095X 22/1.2085 2009293

K 10C/095X095X 22/1.2312 2009294

Clamping plate K 10C

K 2500 / Split Mould Kit

Order No. material No.

K 2500/100x130x 16 589546

K 2500/100x130x 20 589547

K 2500/100x130x 25 589548

K 2500/100x130x 32 589549

K 2500/100x130x 40 589550

K 2500/156x156x 20 589551

K 2500/156x156x 25 589552

Split mould kit K 2500

K 3500 / Quick-change Mould System

Quick changeable mould K 3500

Order No. material No.

K 3500/156x196x46x46/1.2085 2001233

K 3500/156x196x46x56/1.2085 2001234

K 3500/156x196x 46x 56/1.2312 589071

K 3500/156x196x 46x 46/1.2312 589070

16 | Mo u l d i n g

K 3500/156x196x56x46/1.2085 2001235

K 3500/156x196x56x56/1.2085 2001236

K 3500/156x196x 56x 46/1.2312 589072

K 5000 / Mouldbase 75x75mm

Cavity plate K 5121

Order No. material No.

K 5121/075X075X 40/1.2083 2007853

K 5121/075X075X 40/1.2085 2006804

K 5121/075X075X 40/1.2343 2006805

K 5121/075X075X 50/1.2083 2007855

K 5121/075X075X 50/1.2085 2006808

K 5121/075X075X 50/1.2343 2006809

K 5121/075X075X 60/1.2083 2007857

K 5121/075X075X 60/1.2085 2006812

K 5121/075X075X 60/1.2343 2006813

KR / Insert-Modular-System

Bloster plate KR 25

Order No. material No.

KR 25 /246X246X 36/1.1730 589902

KR 25 /246X246X 36/1.2085 589903

KR 25 /246X246X 36/1.2312 589904

KR 25 /246X246X 46/1.1730 589905

KR 25 /246X246X 46/1.2085 589906

KR 25 /246X246X 46/1.2312 589907

KR 25 /246X246X 56/1.1730 589908

KR 25 /246X246X 56/1.2085 589909

KR 25 /246X246X 56/1.2312 589910

II. P Standards

F / precision flat steel

Order No.

17 | Mo u l d i n g

K / 500 X 63 X 1000 / 1.1730

K / 500 X 50 X 1000 / 1.1730

K / 500 X 40 X 1000 / 1.1730

K / 500 X 32 X 1000 / 1.1730

K / 500 X 30 X 1000 / 1.1730

K / 500 X 25 X 1000 / 1.1730

K / 500 X 63 X 1000 / 1.1730

K / 500 X 50 X 1000 / 1.1730

Precision ground flat stell F

P / riser ring

Order No. material No.

P/ 156X098X 36/1.1730 34886

P/ 156X098X 46/1.1730 34894

P/ 156X098X 56/1.1730 34908

P/ 156X098X 76/1.1730 34916

P/ 196X132X 46/1.1730 36919

P/ 196X132X 56/1.1730 36927

P/ 196X132X 76/1.1730 36935

P/ 196X132X 96/1.1730 36943

P/ 246X168X 56/1.1730 39144

Plate P

P / riser segments

Order No. material No.

P/ 095X020X 22/1.1730 31674

P/ 095X020X 27/1.1730 31682

P/ 095X020X 36/1.1730 31690

P/ 095X020X 46/1.1730 31704

P/ 116X029X 36/1.1730 32913

P/ 116X029X 46/1.1730 32921

P/ 116X029X 56/1.1730 32930

Plate P

Order No. material No.

P/ 095X 6/1.1730 30996

P/ 095X 6/1.2162 31003

P/ 095X 6/1.2312 31011

18 | Mo u l d i n g

P/ 095X 6/1.2767 84662

P/ 095X 9/1.1730 31038

P/ 095X 9/1.2162 31046

P/ 095X 9/1.2312 31054

P/ 095X 9/1.2767 84670

P/ 095X 12/1.1730 31070

P / round

Plate P

P 1100 / square

Order No.

P 1100 / 218X296X17 / 1.2162

P 1100 / 218X296X17 / 1.2312

P 1100 / 218X296X17 / 1.2311

P 1100 / 218X296X66 / 1.2767

P 1100 / 218X296X66 / 1.2312

P 1100 / 218X296X66 / 1.2311

P 1100 / 218X296X76 / 1.2311

P 1100 / 218X296X76 / 1.2162

P 1100 / 218X296X76 / 1.2085

P 1100 / 218X296X76 / 1.1730

Machine plate P 1100

P 8000 / round steel

Order No. material No.

P 8000/006X100/1.2210 2032215

P 8000/006X200/1.2210 2032216

P 8000/006X400/1.2210 2032217

P 8000/006X500/1.2210 2032218

P 8000/006X650/1.2210 2032219

P 8000/006X800/1.2210 2032220

P 8000/008X100/1.2210 2032221

P 8000/008X200/1.2210 2032222

19 | Mo u l d i n g

P 8000/008X400/1.2210 2032223 Round steel P 8000

PR / inserts, square

Order No. material No.

PR/ 40X 50X 20/1.2767 235962

PR/ 40X 50X 20/3.4365 278262

PR/ 40X 50X 25/1.2767 235970

PR/ 40X 50X 25/3.4365 278270

PR/ 40X 50X 32/1.2767 235989

PR/ 40X 50X 32/3.4365 278289

PR/ 40X 50X 40/1.2767 235997

PR/ 40X 50X 40/3.4365 278297

PR/ 40X 70X 20/1.2767 236004

Precision insert PR

III. Z Standards

Z1 General mould Components

Order No. material No.

Z 12 /12X 40 194646

Z 12 /12X 56 194654

Z 12 /18X 45 194662

Z 12 /18X 56 194670

Z 12 /18X 71 194689

Z 12 /30X 56 194697

Z 12 /30X 75 194700

Ball guide bush Z 12

20 | Mo u l d i n g

Z2 General tool component

Arrow insert Z 484

Order No. material No.

Z 484 / 6 232009

Z 484 / 8 232017

Z 484 /12 232130

Z 484 /16 232149

Z 484 /20 232157

Z3 Ejection

Air valve Z 491

Order No. material No.

Z 491 / 8/ 6 73199

Z 491 /12/ 8 73210

Z 491 /16/10 73237

Z4 Demoulding

Adapter Z 1696

Order No. material No.

Z 1696 /22 92908

Z 1696 /25 171913

Z 1696 /32 19909

Z5 Cold runner components

21 | Mo u l d i n g

Filter cartridge Z 109

Order No. material No.

Z 109 /14 X 45/0,7 143987

Z 109 /20 X 45/1 278181

Z 109 /25 X 50/1,2 278190

Z7 measuring technology

Bracket Z 1455

Order No.

material No.

Z 1455 /20/ 6,5 383724

Z 1455 /20/ 8 383732

Z 1455 /20/ 8,2 383740

Z 1455 /20/10 557943

Z 1455 /24/12,2 383759

Z 1455 /30/18,2 383767

Z8 Cooling system

Order No. material No.

Z 803/9x9,4 2038497

Z 803/9,4x9 2038498

Z 803/13x13,5 2038499

Z 803/13,5x13 2038500

Adapter coupling Z 803

22 | Mo u l d i n g

II.2.4. Standar Mould base LKM

23 | Mo u l d i n g

24 | Mo u l d i n g

25 | Mo u l d i n g

26 | Mo u l d i n g

II.2.5. Standarisasi Mould Base Hoppt

Mould Base & Mould Base Components

Standard, semi-complex and finishing mould bases of more than 2,000

combinations of different dimensions

Pins and bushes to support every customer's needs

We also sell various components such as:

Guide Pin, Guide Bush, Support Pin, Support Pillar, Ejector Guide Pin, Ejector Guide Bush,

Return Pin

* Steel Grade JIS S50C-Plain Carbon

Steel

* Applications: Plastic Injection Moulds

* Composition (%)

C 0.50

Si 0.25

Mn 0.70

* Equivalent:

- AISI 1050

- DIN C55W5

- WERKSTOFF 1820

- ASSAB 760

- BSS EN 43

* Our quality Mould Bases are

precision machined to close tolerance

* Material used is JIS S50C which is highly

recommended for Plastic Injection Moulds. To

cater, other materials are available upon request

* Our prices are very competitive * Quick delivery service

* "hoppt" Mould Bases are made in

Singapore

* We also accept special or customized Mould

Base orders according to customers'

specifications

All enquiries are welcomed

27 | Mo u l d i n g

28 | Mo u l d i n g

29 | Mo u l d i n g

30 | Mo u l d i n g

II.3. MOLDING PLASTIC INJECTION

Injection molding adalah proses manufaktur yang paling umum digunakan untuk

pembuatan plastik. Berbagai macam produk yang diproduksi menggunakan injection

molding, yang sangat bervariasi dalam, kompleksitas aplikasi mereka ukuran, dan. Proses

injection molding memerlukan penggunaan mesin injection molding, bahan baku plastik, dan

cetakan. Plastik meleleh di mesin injection molding dan kemudian disuntikkan ke dalam

cetakan, di mana mendingin dan membeku ke bagian akhir. Langkah-langkah dalam proses

ini dijelaskan secara lebih rinci dalam bagian berikutnya.

Injection molding

Injection molding digunakan untuk menghasilkan berdinding tipis plastik untuk berbagai macam aplikasi, salah

satu perumahan paling umum plastik yang. Perumahan plastik adalah kandang berdinding tipis, sering

membutuhkan banyak tulang rusuk dan bos pada interior. Ini perumahan digunakan dalam berbagai produk

termasuk peralatan rumah tangga, elektronik konsumen, alat-alat listrik, dan dashboard seperti otomotif. Umum

31 | Mo u l d i n g

Proses Siklus

Siklus proses untuk injection molding sangat pendek, biasanya antara 2 detik dan 2 menit,

dan terdiri dari empat tahapan sebagai berikut:

1. Clamping - Sebelum injeksi bahan ke dalam cetakan, dua bagian cetakan

pertama harus aman ditutup oleh unit klem. Setiap setengah dari cetakan terpasang

pada mesin injection molding dan satu setengah diperbolehkan untuk slide. Unit

penjepit hidrolik mendorong cetakan bagian bersama-sama dan mengerahkan

kekuatan yang cukup untuk menjaga aman cetakan tertutup sementara bahan yang

disuntikkan. Waktu yang diperlukan untuk menutup dan klem cetakan tergantung

pada mesin - mesin yang lebih besar (orang-orang dengankekuatan menjepit lebih

besar) akan membutuhkan lebih banyak waktu. Kali ini dapat diperkirakan

dari waktu siklus mesin kering.

2. I njeksi - Bahan baku plastik, biasanya dalam bentuk pelet, dimasukkan ke

dalam mesin injection molding, dan maju ke cetakan oleh unit injeksi. Selama proses

ini, bahan yang meleleh oleh panas dan tekanan. Plastik cair kemudian disuntikkan

ke dalam cetakan sangat cepat dan penumpukan kemasan tekanan dan memegang

materi. Jumlah bahan yang disuntikkan disebut sebagai tembakan. Waktu injeksi sulit

untuk menghitung secara akurat karena aliran kompleks dan berubah dari plastik cair

ke dalam cetakan. Namun, waktu injeksi dapat diperkirakan dengan volume

menembak, tekanan injeksi, dan kekuasaan injeksi.

3. Pendinginan - Plastik cair yang ada di dalam cetakan mulai dingin segera

karena membuat kontak dengan permukaan cetakan interior. Seperti plastik

mendingin, itu akan memperkuat ke dalam bentuk bagian yang diinginkan. Namun,

selama pendinginan beberapa bagianpenyusutan dapat terjadi. Kemasan bahan dalam

tahap injeksi memungkinkan material tambahan untuk mengalir ke cetakan dan

mengurangi jumlah penyusutan terlihat. Cetakan tidak dapat dibuka sampai waktu

pendinginan yang diperlukan telah berlalu. Waktu pendinginan dapat diperkirakan

dari sifat termodinamika beberapa plastik dan ketebalan dinding maksimum bagian.

4. Ejeksi - Setelah cukup waktu telah berlalu, bagian didinginkan dapat

dikeluarkan dari cetakan oleh sistem ejeksi, yang melekat ke bagian belakang

cetakan. Ketika cetakan dibuka, mekanisme yang digunakan untuk mendorong

bagian dari cetakan. Angkatan harus diterapkan untuk mengeluarkan bagian karena

selama pendinginan bagian menyusut dan melekat pada cetakan. Dalam rangka

memfasilitasi pengusiran bagian, agen pelepas cetakan dapat disemprotkan ke

permukaan rongga cetakan sebelum injeksi material. Waktu yang dibutuhkan untuk

membuka cetakan dan mengeluarkan bagian yang dapat diperkirakan dari waktu

siklus mesin kering dan harus mencakup waktu untuk bagian yang jatuh bebas dari

cetakan. Setelah bagian tersebut dikeluarkan, cetakan bisa menjepit ditutup

untuktembakan berikutnya untuk disuntikkan.

Setelah siklus injection molding, beberapa pengolahan pasca biasanya diperlukan. Selama

pendinginan, bahan dalam saluran cetakan akan memperkuat melekat pada bagian. Ini materi

berlebih, bersama dengan flash yang telah terjadi, harus dipangkas dari bagian, biasanya

dengan menggunakan pemotong. Untuk beberapa jenis bahan, seperti termoplastik, bahan

memo bahwa hasil dari pemangkasan dapat didaur ulang dengan ditempatkan ke dalam

penggiling plastik, juga disebut regrind mesin atau granulators, yang regrinds bahan bekas

menjadi pelet. Karena beberapa degradasi sifat material, regrind harus dicampur dengan

32 | Mo u l d i n g

bahan baku dalam rasio regrind yang tepat untuk digunakan kembali dalam proses injection

molding.

Injeksi dibentuk bagian

lainnya berdinding tipis produk meliputi berbagai jenis wadah terbuka, seperti ember. Injection

molding juga digunakan untuk memproduksi beberapa barang sehari-hari seperti sikat gigi atau

maperalatan medis, termasuk katup dan alat suntik, diproduksi menggunakan injection molding juga.

II.3.1 Injection Mould Mitsumi

Mold Related Dimensions of Plastic Injection Molding Machines (1)

Category : Standard Specifications

While a mold for plastic injection molding is used by installing it in an injection

molding machine, at present the specifications for installing the mold in the molding machine

are different for different molding machines. On the other hand, in JIS, the recommended

standard specifications have been stipulated regarding the "Mold related dimensions of

plastic injection molding machines" (JIS B 6701-1992). From now on, these standards are

considered to be referred to for the general injection molding machines manufactured in

Japan. These standards will be discussed for several courses beginning with this course.

There is only one point that has to be paid attention to and that is, in the actual design

of a mold, as the final information for judgment, giving first priority to the mold installation

specifications of the injection molding machine that is scheduled to be used. Since JIS

standards are only recommended standards, depending on the individual features of the

injection molding machine, it is possible that the contents of the standards have been

changed, and hence it is necessary to keep this point in mind.

33 | Mo u l d i n g

JIS B 6701-1992

"Mold related dimensions of plastic injection molding machines"

These specifications stipulate the mold installation dimensions, etc. of plastic

injection molding machines with a mold clamping force of 196 to 7845 kN (20 to 800 tf).

Explanation:

The names of the different parts of the injection molding machine are as shown in the

figure below. (These names are merely the names used in the explanation of this standard,

and do not indicate the shape or the structure of the different parts.)

34 | Mo u l d i n g

35 | Mo u l d i n g

In specific terms, the following items have been stipulated.

1. Spacing of the tie bar

2. Mold mounting bolt

3. Placement of the holes for mold mounting

4. Placement of the hole for the push rod (ejector rod)

5. Shape of the tip of the injection nozzle

6. Shape of the hole for the locate ring

II.3.2. Injection Machine Toshiba

Highest basic performance and achievement of high productivity and steady molding

The EC-SX series is a high performance all electric injection molding machine that

achieves"Precise aand steady molding"and"High productivity" by great improvement of the

basic performance given by newly developed mold clamping unit and injection unit. The

machine satisfies customer's various needs with "Five kinds of new technologyh"we

propose and molding technology accumulated over many years.

Product Introduction

1) New mold clamping unit (Solid Clamp)

The device transforms uniform clamping force to the mold with newly designed toggle

mechanism and improved rigidity, enabling molding by lower clamping force than

conventional device. Moreover the device achieves high speed cycle of the industry-leading

class.

1. New toggle mechanism: link line toggle + high rigidity platens

- Minimizes mold deflection and achieves uniform clamping force distribution.

- Enables molding even by clamping force lower than conventional unit and contributes to

improve product quality and mold maintenance reduction.

36 | Mo u l d i n g

2. Dynamic acceleration/deceleration control (Patent pending)

- Adopts acceleration/deceleration control to reduce shock at mold opening/closing.

- Enables maximum accelerate from an arbitrary position achieving high speed cycle

molding.

3. High response ejection

- Sharp movement shortens ejection time.

4. Grease-less tie rod

- Grease-less tie rods eliminates grease adhesion onto mold or product and maintains clean

environment.

- Standard rust proofing on hopper inlet prevents mixing of rust or refuse into product

5. SFC (high-speed mold open/close) specification (option)

- Shortens dry cycle time further and achieves molding at higher speed cycle.

6. High rigidity frame

- Level pads to facilitate installation or relocation is available as option.

7. Built-in hydraulic core puller (option)

- The unit is stored inside the machine to be installed at the clamping unit end.

2) New injection unit S-Cube (Simple, Steady, Smooth)

Takes over powerful filling performance in high speed and high pressure range and achieves

steady molding by smooth movement.

1. Friction-free drive

- Suppresses slide resistance to the utmost limit and contributes to precise and steady molding

by stable injection characteristic.

- Smoothes leading response of injection and improves charging stability.

- Reduces variation among molding machines.

2. Control accuracy improvement in injection pressure and back pressure

- Absorbs inherent characteristic of pressure detector by linearize correction control, to lose

machine difference to the utmost limit. This improves control accuracy of injection pressure

and back pressure and achieves one up steady molding.

3. Space-saving injection unit

- The structure of the injection unit was optimized to shorten the overall length of the

machine.

4. Hold pressure strength improvement

- Hold pressure strength was improved to enable heavy load injection molding.

5. 2-stage charge deceleration device: high torque and medium rotation (option)

- Handles high viscosity resin

3) High performance controller (INJECTVISOR-V50)

Achieves high productivity and precise stability by great improvement in control

performance.

1. High performance HMI (Human-Machine Interface)

- 15-inch large-scale panel facilitates visualization and improves operability. *Takes over the

function of INJECTVISOR-V30.

- Enables data browsing or printing on the personal computer by means of USB thumb drive

or iPAQET LiTE.

37 | Mo u l d i n g

2. Wide split screen

- Displays information necessary for the process on a split screen independent of the setting

screen. This minimizes the changing of setting screen.

3. Signal customizing function

- Enables arbitrary selection of output signal to peripheral equipment.

- Allows each selection of output condition or output form.

4. Remote monitor/managerial system "iPAQET"

- Monitors and manages multiple molding machines in real time by using LAN line. Enables

centralized management on wide range of information including the monitoring of

operational condition of the machine and resin lot in addition to the monitoring of production

state or the accumulation analysis function of product quality data.

5. Enables plug-in of peripheral and rationalization equipments and facilitates integrated

management including rationalization equipments.

4) Molding control (DST: Dynamic Self Tuning)

Automatic correction function is added to molding control. This contributes to reproducibility

of high-precision molding and long-term steady molding.

1. DST-Press (clamping force correction)

- Does not generate sink mark or short shot (influence of gas vent) as a result of clamping

force fluctuation.

- Automatic correction made during molding does not influence operation cycle while

maintaining steadybr molding.

2. DST-Fill (molding condition correction)

- Conducts automatic change of molding conditions and maintains steady molding, against

the variation of molded product quality that takes place in a long period of operation as a

result of resin lot change, crushed material ratio change or molding environment change.

3. Abundant molding controls

- A variety of function are installed, such as VHI (virtual hydraulic injection) circuit, high

sensitivity mold protection and ejection torque monitor.

5) Screw variation

Screw variation matched to diversified resin types is available.

Screw name Resin

DBG screw (standard) General purpose

SDB screw For olefin series resin

DBC screw Hard vinyl chloride

6) Package specification

Satisfies customer's various needs.

o Vented-barrel injection molding machine

38 | Mo u l d i n g

o Vinyl chloride spec/fluorine spec/core back and injection compression/gas injection/light

guide plate spec/MuCell spec

II.3.3. Injection Molding Machine (MZ1180F)

Basic Info.

Model NO.:MZ1180F

Type:Injection Blow Molding

Export Markets:Global

Additional Info.

HS Code:8477101090

Production Capacity:30/Month

Product Description

Injection molding machine

1. Two oil tanks, one tank for cycle the injection part, another tank for cycle the clamping

part. In this case, the oil temperature will not increase too much when oil press through the

valves. Machine is more stable and longlife.

2. Three safety protector(hydraulic, mechanic, electric)

3. Adopt bearing in the moving platen. The connection between the surface and the bearing is

only one touchable line, so it is more quick response than normal block design.

4. Machine clamping force is bigger than the model name. So you don't afraid of reach high

peak of this machine

5. Machine has the auto-back-pressure setting in the PLC. Whatever you want to adjust the

backpressure for different products and material, just click the keyboard, very convenience.

6. Machine is more stronger design with thick platen. All the material we'r using is endurable.

SPECIFICATION TABLE

SPECIFICATION MZ1180F

INJECTION UNIT A B C

screw diameter mm 110 120 130

screw l/d ratio L/D 24 22 20

shot volume cm 3 5037 5994 7035

injection weight g 4634 5515 6472

injection pressure Mpa 181 152 129

injection rate g/sec 647 770 904

screw speed rpm 105

39 | Mo u l d i n g

CALMPING UNIT

clamp tonnage KN 11800

toggle stroke mm 1250

min mold height mm 450

max mold height mm 1200

space between tie brs mm 1220*1220

ejector tonnage KN 240

ejector stroke mm 350

ejector number pc 21

OTHERS

max pump pressure Mpa 16

heater power kw 60

motor power kw 45+45

oil box volume L 2000

machine dimension(L*W*H) M 12.3*2.6*307

machine weight T 60

40 | Mo u l d i n g

BAB III

KESIMPULAN

Dipasaran banyak sekali macam-macam jenis dan harga dari berbagai produsen

mouldbase,kita dapat membeli atau menyesuaikan harga dan tujuan yang kita inginkan

dengan tersedianya bnyak variasi di pasaran.

Mould base digunakan dalam berbagai industri untuk jangka pendek dan aplikasi

pencetakan.Mould base diproduksi dengan menggunakan bahan kualitas unggul seperti baja

ringan dan baja karbon. Tersedia berbagai cetakan yang tersedia dalam berbagai ukuran,

bentuk dan dimensi yang sesuai dengan berbagai jenis die casting dies.

Dalam membuat sebuah moulding , ada beberapa aspek penting yang harus

diperhatikan , diantaranya adalah biaya, wkatu, dan pengefesiensian alat-alat yang ada. Hal,

ini akan berpengaruh dalam ketertarikan konsumen dalam memesan hasil produksi kita.

41 | Mo u l d i n g

BAB IV

DAFTAR PUSTAKA

http://lathif-cyber.blogspot.com/2011/12/molding-plastic-injection.html

http://id.scribd.com/doc/62973859/Injection-Moulding-2011

http://digilib.mercubuana.ac.id/manager/file_artikel_abstrak/Isi_Artikel_853167162630.pdf

You might also like

- Design Molding InjectionDocument183 pagesDesign Molding InjectionPutra Umar Said100% (1)

- Vacuum Forming MoldingDocument19 pagesVacuum Forming MoldingYayan SupriantoNo ratings yet

- Cetakan Mesin Injeksi PlastikDocument11 pagesCetakan Mesin Injeksi Plastiksyamsud dianNo ratings yet

- OPTIMASI INJEKSIDocument36 pagesOPTIMASI INJEKSIDeby Delima DewiNo ratings yet

- MoldingDocument12 pagesMoldingAbdul MalikNo ratings yet

- Injection Molding ProsesDocument13 pagesInjection Molding ProsesCharis Arif100% (1)

- B Injection Molding Proses MHSLDocument55 pagesB Injection Molding Proses MHSLBillyRadianNo ratings yet

- Mold DesainDocument5 pagesMold DesainfiannandaNo ratings yet

- FORGING PROSESDocument6 pagesFORGING PROSESFahmi PratamaNo ratings yet

- Cara Kerja Mesin Injection Moulding PlastikDocument9 pagesCara Kerja Mesin Injection Moulding PlastikYusron Bachtiar ArdhiNo ratings yet

- Kontruksi MoldDocument6 pagesKontruksi Moldmuhamad rizkiNo ratings yet

- Proses Injeksi PlastikDocument31 pagesProses Injeksi PlastikRsmooth100% (1)

- Stamping ProsesDocument7 pagesStamping Prosesputra_sodik6364No ratings yet

- Mesin Injeksi Plastik (Moulding)Document24 pagesMesin Injeksi Plastik (Moulding)Mufti NaufalNo ratings yet

- Tugas Injection & MoldDocument41 pagesTugas Injection & MoldFauzi Adha SofwanaNo ratings yet

- Injection Molding Dan Jenis-Jenis PlastikDocument9 pagesInjection Molding Dan Jenis-Jenis PlastikHisyam AkmalNo ratings yet

- Plastik MoldingDocument39 pagesPlastik MoldingsyarifNo ratings yet

- Laporan Progressive ToolDocument26 pagesLaporan Progressive Toolisti aneNo ratings yet

- MOLD DAN PRODUKDocument4 pagesMOLD DAN PRODUKTri LarasatiNo ratings yet

- Dasar Clamping dan WorkholdingDocument21 pagesDasar Clamping dan WorkholdingILva Anwar NatsirNo ratings yet

- Cold Working ProcessDocument15 pagesCold Working ProcessRoni lembangNo ratings yet

- Teknik PenyambunganDocument21 pagesTeknik PenyambunganAnwar Fuadi100% (3)

- Modul 1 - Perancangan Produk PlastikDocument15 pagesModul 1 - Perancangan Produk Plastikisna wafiqNo ratings yet

- AssemblingDocument10 pagesAssemblingSansan JensandriNo ratings yet

- Gambar Teknik Mesin Menggambar Bagian Mesin Secara TerperinciDocument123 pagesGambar Teknik Mesin Menggambar Bagian Mesin Secara TerperinciDaniel SaragihNo ratings yet

- Bab IiiDocument38 pagesBab IiiAzies Saputra100% (2)

- Proses ManufakturDocument54 pagesProses ManufakturAhmad Amril Nurman100% (1)

- Blow MoldingDocument11 pagesBlow MoldingFebry Handika100% (1)

- Jenis Pahat, Ulir Dan Bubut Tirus'Document5 pagesJenis Pahat, Ulir Dan Bubut Tirus'Satriya HerlambangNo ratings yet

- EkstrusiDocument9 pagesEkstrusiペブリヤナ サンディNo ratings yet

- Makalah Molding Dan ForgingDocument18 pagesMakalah Molding Dan ForgingGilang YandezaNo ratings yet

- LPDC vs HPDC perbedaan proses die castingDocument1 pageLPDC vs HPDC perbedaan proses die castingRiski Winner Lorenzo WinnerNo ratings yet

- Pengertian Press ToolDocument17 pagesPengertian Press ToolEdIz Feehily Sirait100% (1)

- Makalah Termoset Dan TermoplastikDocument16 pagesMakalah Termoset Dan TermoplastikAngga Pangestu PutraNo ratings yet

- Perancangan Alat Pembantu ProduksiDocument25 pagesPerancangan Alat Pembantu ProduksiAndry Al Ezechiel100% (3)

- Metalurgi SerbukDocument14 pagesMetalurgi SerbukWaHyu SantosoNo ratings yet

- Teknik lost foam castingDocument3 pagesTeknik lost foam castingTyna NNo ratings yet

- Laporan PlastikDocument19 pagesLaporan PlastikAgathaPutri0% (1)

- Perancangan Mur Dan BautDocument19 pagesPerancangan Mur Dan Bautponi kioNo ratings yet

- 3 Komponen Jaringan DistribusiDocument84 pages3 Komponen Jaringan DistribusiTeguh PrasetyoNo ratings yet

- Pola Dan IntiDocument13 pagesPola Dan Intiharris aqil widigdoNo ratings yet

- Makalah Moulding MaterialDocument14 pagesMakalah Moulding MaterialIntan Kurniawan100% (1)

- Definisi FabrikasiDocument11 pagesDefinisi Fabrikasimuhammad rizkiNo ratings yet

- MakalahDocument15 pagesMakalahIntan KurniawanNo ratings yet

- Lipped Channel Produk SpesifikasiDocument38 pagesLipped Channel Produk SpesifikasiBagus Ririh100% (1)

- Sambungan BautDocument31 pagesSambungan BautMuhammad Yuda100% (1)

- Laporan PolaDocument11 pagesLaporan PolaNugroho Faris SudrajatNo ratings yet

- ULIRDocument55 pagesULIRAri KurniawanNo ratings yet

- Makalah Cetakan MoldingDocument16 pagesMakalah Cetakan MoldingNurulAnnisaAuliaNo ratings yet

- Perkakas Potong TrainingDocument51 pagesPerkakas Potong TrainingPaskalis Catur LamarianNo ratings yet

- OPTIMASI TOLERANSI DAN SUAIANDocument34 pagesOPTIMASI TOLERANSI DAN SUAIANMochammad Gama AdriansyahNo ratings yet

- BAB 13 PROSES PENGECORAN LOGAMDocument54 pagesBAB 13 PROSES PENGECORAN LOGAMbimatheNo ratings yet

- DELI Kwalitas SNIDocument35 pagesDELI Kwalitas SNIRajinda BintangNo ratings yet

- Metode Pembuatan Stem Angle ValveDocument6 pagesMetode Pembuatan Stem Angle ValveHirwan SyahputraNo ratings yet

- SMART POTONGANDocument21 pagesSMART POTONGANVans UwUNo ratings yet

- Alat Pengupas Dan Pengiris SingkongDocument11 pagesAlat Pengupas Dan Pengiris SingkongFikryNineDheRangerzzNo ratings yet

- Tabel Berat Baja Gunung GarudaDocument37 pagesTabel Berat Baja Gunung GarudaWisman Wiharna100% (3)

- PolaDocument39 pagesPoladjancoookNo ratings yet

- Perform Basic Mould Assembly ProcessDocument24 pagesPerform Basic Mould Assembly ProcessNazri100% (2)

- Pemilihan Bahan Dan Proses Velg City CarDocument9 pagesPemilihan Bahan Dan Proses Velg City Carsatriaz90rocketmail.comNo ratings yet

- Hafidz 216411914 REVDocument8 pagesHafidz 216411914 REVBernikeFebryanaNo ratings yet

- 14 Diagram Sudut Pengantar Katup Motor 4 TakDocument6 pages14 Diagram Sudut Pengantar Katup Motor 4 TakBernikeFebryanaNo ratings yet

- Form Penilaian Ilmiah 2010Document2 pagesForm Penilaian Ilmiah 2010BernikeFebryanaNo ratings yet

- MATEMATIKA Kelas III Semester 1Document2 pagesMATEMATIKA Kelas III Semester 1Anik IndrawatiNo ratings yet

- Teknologi Hydraulic Ram Pump Atau Yang Dikenal Dengan HydramDocument1 pageTeknologi Hydraulic Ram Pump Atau Yang Dikenal Dengan HydramBernikeFebryanaNo ratings yet

- Bab IDocument7 pagesBab IBernikeFebryanaNo ratings yet

- Analisis Struktur Organisasi Perusahaan PTDocument8 pagesAnalisis Struktur Organisasi Perusahaan PTBernikeFebryanaNo ratings yet

- YogaDocument7 pagesYogaBernikeFebryanaNo ratings yet

- StatistikDocument8 pagesStatistikBernikeFebryanaNo ratings yet

- Contoh Karya TulisDocument3 pagesContoh Karya TulisBernikeFebryanaNo ratings yet

- Paper Peng PlastikDocument10 pagesPaper Peng PlastikBernikeFebryanaNo ratings yet

- Laporan Prakarya RahelDocument4 pagesLaporan Prakarya RahelBernikeFebryanaNo ratings yet

- Materi Bahasa InggrisDocument7 pagesMateri Bahasa InggrisBernikeFebryanaNo ratings yet

- Poros EngkoolDocument10 pagesPoros EngkoolBernikeFebryanaNo ratings yet

- PBHHHDocument29 pagesPBHHHBernikeFebryanaNo ratings yet

- PBHHHDocument29 pagesPBHHHBernikeFebryanaNo ratings yet

- 04 Potongan Edit PDFDocument15 pages04 Potongan Edit PDFBernikeFebryanaNo ratings yet

- Makalah Tentang PorosDocument10 pagesMakalah Tentang Porosniko andrianoNo ratings yet

- Mesin Gerinda Datar dan SilindrisDocument27 pagesMesin Gerinda Datar dan SilindrisBernikeFebryanaNo ratings yet

- Contoh Pelanggaran HukumDocument5 pagesContoh Pelanggaran HukumBernikeFebryanaNo ratings yet

- Lagu Natal dan PerayaanDocument6 pagesLagu Natal dan PerayaanBernikeFebryanaNo ratings yet

- Contoh Susunan Acara NatalDocument2 pagesContoh Susunan Acara NatalBernikeFebryana33% (3)

- PBHHHDocument29 pagesPBHHHBernikeFebryanaNo ratings yet

- Lampiran PenangguanDocument3 pagesLampiran PenangguanBernikeFebryanaNo ratings yet

- Daftar AnggotaDocument1 pageDaftar AnggotaBernikeFebryanaNo ratings yet

- Cover MKLHDocument1 pageCover MKLHBernikeFebryanaNo ratings yet

- Contoh Pelanggaran HukumDocument5 pagesContoh Pelanggaran HukumBernikeFebryanaNo ratings yet