Professional Documents

Culture Documents

Use of Steel in Construction: Lecturer, SCECE Ricky - Chan@rmit - Edu.au Brooklyn Bridge, NY

Uploaded by

Prashanth KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Use of Steel in Construction: Lecturer, SCECE Ricky - Chan@rmit - Edu.au Brooklyn Bridge, NY

Uploaded by

Prashanth KumarCopyright:

Available Formats

Use of steel in construction

Dr Rick Chan,

Lecturer, SCECE

ricky.chan@rmit.edu.au

Brooklyn Bridge, NY

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 2

Lecture Outline

What is steel?

Where do we use steel?

How it is made?

Advantages & disadvantages

Mechanical properties

Comparison with other construction materials

Corrosion

Welding and fire resistance

RMIT Universityyyyy School/Department/Area 3

The Colosseum in Rome,

Italy

Source: http://www.telegraph.co.uk/

The Eiffel Tower, France

Source:http://www.planetware.com/

What is steel

Steel may be defined as an alloy of iron and carbon

Tensile strength: 200-500MPa

Density: 7850kg/m

3

Youngs modulus: 200,000MPa

Shear modulus: 80,000MPa

Poissons ratio: 0.3

Coeff. thermal expansion: 12x10

-6

/K

RMIT Universityyyyy School/Department/Area 4

Southbank Footbridge

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 5

Effects of carbon content

An increase in carbon content will

Increases tensile strength

Increases hardness

Reduction in ductility

Increase difficulty in welding

Greater tendency to corrode

Steel used in construction is

generally low in carbon content to

ensure ductility

Transmission towers

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 6

Effects of carbon content

Rollason, Metallurgy for

Engineers, Butterworth-

Heinemann

El= Elongation

TS = Tensile

strength

BH = Brinell

Hardness

RMIT Universityyyyy School/Department/Area 7

Carbon content in Steel (by mass)

Low carbon steel 0.15% C

Mild Steel 0.15-0.25% C

Medium Carbon Steel 0.2-0.5% C

High Carbon Steel 0.5-1.4% C

Common in construction

Australian standards

There are several Australian Standards which governs chemical

composition, test requirement, and geometrical requirements, etc for

structural steel sections

AS/NZS 1163:2009 : Cold-formed structural steel hollow sections

AS/NZS 3679.1:2010 : Structural steel - Hot-rolled bars and sections

RMIT Universityyyyy School/Department/Area 8

Structural sections

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 9

Use of steel in construction Tall Buildings

Empire State Building, NYC

Photo: Ricky Chan

Bank of China, Hong Kong (left)

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 10

Use of steel in construction Framed buildings

A residential building in Japan

Photo by Ricky Chan

A car park in Japan

Photo by Ricky Chan

RMIT Universityyyyy School/Department/Area 11

Use of steel in construction Bridges

A plate girder bridge in Japan

Photo by Ricky Chan

A box girder bridge in Japan

Photo by Ricky Chan

RMIT Universityyyyy School/Department/Area 12

Use of steel in construction long span roofs

Hong Kong airport

Photo by Ricky Chan

Kuala Lumpur airport

Photo by Ricky Chan

Use of steel in construction long span roofs

RMIT Universityyyyy School/Department/Area 13

Osaka airport

Photo by Ricky Chan

Southern Cross Station

Photo by Ricky Chan

RMIT Universityyyyy School/Department/Area 14

Use of steel in construction reinforcement steel

Reinforcement bars in a column

Photo by Ricky Chan

Reinforcement bars in beam /

column

Photo by Ricky Chan

RMIT Universityyyyy School/Department/Area 15

Earthworks and foundations

Steel piles

Photo by Ricky Chan

Sheet piles

Photo by Ricky Chan

RMIT Universityyyyy School/Department/Area 16

Extraction of metals

Metals occurs in nature as ores, in the form of oxides, sulphides,

carbonates, etc.

We need to extract the metals from their compounds which occurs

naturally

But metal tends to revert to their compounds, i.e. it corrodes

To extract it and keep it that way

Extraction metallurgy techniques with extracting the metals from

their compound

Unaided fire can reach about 1100-1200

o

C

Copper, lead and tin were produced in pre-historic times

RMIT Universityyyyy School/Department/Area 17

Extraction of Iron

Extraction of Iron dated back to 1200BC, the Iron Age

Iron has melting point of 1535

o

C

In 18s and 19s century, forced air blast furnaces were

able to melt iron

RMIT Universityyyyy School/Department/Area 18

Modern extraction of iron

Limestone, Iron ore and Coke are put together in blast

furnace. The following reactions occur in general

2C

(s)+

O

2(g)

2CO

(g)

Fe

2

O

3(s)

+3CO

(g)

2Fe

(l)

+ 3CO

2(g)

The limestone remove silica in the ore

CaC0

3(s)

CaO

(s)

+ CO

2(g)

CaO

(s)

+ SiO

2(s)

CaSiO

2(l)

see the making of steel from BlueScope Steel

RMIT Universityyyyy School/Department/Area 19

Effect of cooling rate

The rate of cooling of steel crystal distribution, and affects mechanical

properties of steel product

Annealing

Steel is cooled slowly in a controlled manner (usually in furnace)

Coarse-grain structure

Higher ductility, easier to machine

Lower yield strength than normalized steels

RMIT Universityyyyy School/Department/Area 20

Effect of cooling rate

Normalizing

Steel is allowed to cool in still air

Fine grain structure

Harder and Higher yield strength than annealing

Quenching

Rapid cooling rate by plugging the steel into water (or iced brine)

Intensely hard but brittle steel

RMIT Universityyyyy School/Department/Area 21

Hot working

At temperature above re-

crystallization For steel, at

temperature over 910

o

C Rolling

is a common method of forming

structural sections

Exposure to air at high

temperature causes a heavy

film of oxide layer to form on

surface

Rolling

Illston J.M. & Domone P.L.J.

Construction materials, 2001

Hot-rolled I-beams / columns

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 22

Cold working

Because of the cold ductility of metal, they can be shaped below re-

crystallization temperature

Yield strength can be increased

Metals sheets

Cold drawn wires

Cold formed steel decks

Steel deck in Westfield

Shopping Centre

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 23

Advantages of steel

High tensile strength (very high yield stress)

Long span structures made possible

Generally it is the only high tensile strength material commonly

used in construction. Recently the development of carbon fibre

based material replace some steel, but use is very limited.

High compressive strength

High shear strength

e.g. shear resistance of concrete structures relies on steel stirrups

to provide shear resistance

Youngs modulus is high (E=o/c)

Structure built with steel are resistance to deformation

E = 200GPa compares to Aluminium's E=75GPa

Ductile

Prevents sudden failure

RMIT Universityyyyy School/Department/Area 24

Advantages of steel

Durability

Resistance to wear and abrasion

Malleability

Can be rolled or shaped into various shape to enhance structural

efficiency. e.g. an I-beam is most efficient in bending

Alloying

Adding other chemical will change its properties. E.g. Stainless

steel contains chromium, nickel and molybdenum.

RMIT Universityyyyy School/Department/Area 25

Disadvantages of steel

Large amount of energy used in production (sustainability issue)

International Iron and Steel Institute research shows that the

amount of energy required to produce a tonne of steel is less than

half of what it was 35 years ago

Mining of iron ore destroys natural landscape

Slender steel member may buckle under compression

Can be avoided by engineering

Corrosion

Can be delayed by coating / galvanising

Poor fire resistivity

Can be improved by fire proofing material

RMIT Universityyyyy School/Department/Area 26

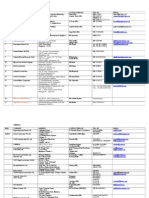

Comparison with concrete and timber

Material Youngs

Modulus

(MPa)

Working

stress

(MPa)

Density

(kg/m

3

)

Stiffness

Efficiency

Strength

efficiency

Energy of

production

(MJ/kg)

Energy of

production

(MJ/m

3

)

Energy

per unit

stress

A B C D=A/C E=B/C F G=F*C H=G/B

Steel 210,000 160 7800 27 0.02 30 234,000 1500

Concret

e

25,000 8 2400 10 0.003 0.8 1920 240

Timber 11,000 7.5 600 18 0.013 1 600 80

RMIT Universityyyyy School/Department/Area 27

Mechanical properties

We want to know what is the yield stress of

material, as we want to keep the steel

members within elastic range under design

service loads.

We are also interested in its stiffness

(resistance to deformation) and ductility.

Tensile test on coupon a small test piece is

cut from steel section and put under tensile

test. AS1391 2007 Metallic materials

Tensile testing at ambient temperature

Determine: yield stress, ultimate stress,

Youngs modulus, elongation (ductility), etc.

Youngs Modulus = 200GPa for steel

(constant)

Yield / ultimate stress vary with steel grades

Fig 14, AS1391-2007

Photo: Ricky Chan

Tensile test

RMIT Universityyyyy School/Department/Area 28

Tensile test

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 29

Stress-strain curve in tensile test

Tensile test carried out by Ricky Chan

Elastic

Plastic

Strain hardening

Elastic region

Stress is linearly proportional to strain

This is known as Hooks Law

i.e. if we can measure strain, we can calculate stress (E is material

constant)

Strain are measured by attaching strain gauges (by glue) to steels

surface. Changes in electrical resistance is converted to strain.

RMIT Universityyyyy School/Department/Area 30

Ee = o

Attaching a rosette strain

gage to surface of steel

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 31

Stress

Strain

P = Uniaxial tension

L = Length

L

0

= Initial length

A

0

= Initial cross-sectional area

e = engineering strain

o =nominal stress

Valid when strain magnitudes not exceed 0.002 (0.2%)

0

A

P

= o

0

0

L

L L

e

=

Small strain problems

Large strain problems

For large strain problems, strain should be expressed in natural strain

Total strain = elastic strain + plastic strain

For incremental strain

integration from original length to the current length

RMIT Universityyyyy School/Department/Area 32

p e

c c c + =

L

dL

d = c

} } |

|

.

|

\

|

= = =

L

L

L

L

L

dL

d

0

0

ln c c

RMIT Universityyyyy School/Department/Area 33

Creep

Time-dependent strain when a steady stress is maintained

Creep reduces with decrease in temperature

Significant strains do not normally occur at temperature below 40% of

melting point of metal in K (degree K =

o

C +273)

Creep would not be expected in ferrous metals at room temperature

But a related phenomenon called relaxation occurs in cold-worked

steel such as prestressing tendons

Prestressing tendons used in bridge

construction

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 34

The Charpy impact test

Steel becomes brittle in cold temperature

Requirement in Section 10 of AS4100 Brittle fracture based on lowest

one day mean ambient temperature.

e.g. Grade 300+ (AS/NZ3679.1 Grade 300) belongs to Steel Type 1

according to Table 10.4.4. It lowest permissible service temperature is -

10C for thickness between 6 and 12mm

Charpy impact test is a standardised test on materials toughness.

Toughness is the energy require to fracture (fail) a specimen. (area

beneath stress-strain curve of standard tensile test is toughness under

low-strain rate). Charpy impact test is a high strain rate test.

RMIT Universityyyyy School/Department/Area 35

Impact strength

Taylor G.D., Materials in Construction,

2002

RMIT Universityyyyy School/Department/Area 36

Brinell hardness test

Proposed by Swedish engineer Johan

Brinell in 1900

Correlates the diameter of an indentation

on a material test piece to a hardness

scale.

Typical tests use a 10mm dia steel ball as

an indenter with 3000kgf (29kN) force

For hard material, a tungsten carbide ball

is used.

Typical values:

Softwood: 1.6

Hardwood: 2.6 7.0

Aluminium: 15

Mild Steel: 120

RMIT Universityyyyy School/Department/Area 37

Oxidation of metal

Almost all metals are unstable in oxygen containing atmosphere,

exceptions are gold and silver

Metals release electrons and oxygen accept electrons

General equation: M + O MO

Not a major cause of corrosion in buildings as temperature is low

RMIT Universityyyyy School/Department/Area 38

Oxidation & oxide layer

Taylor G.D., Materials in Construction,

2002

RMIT Universityyyyy School/Department/Area 39

Oxidation of metal

In order for oxidation process to continue, oxygen must have access

to metallic ions below the oxide layer

Properties of oxide layer defines the rate of corrosion

Oxide layer of zinc, chromium, lead and aluminum are so tightly

bounded, oxygen cannot penetrate down and eventually corrosion will

cease

A bridge showing signs of corrosion

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 40

Electrolytic and acidic corrosion

Metals have tendency to dissolve in aqueous solution

The tendency depends on types of metals, temperature

This tendency is measured using a Standard Hydrogen Electrode

RMIT Universityyyyy School/Department/Area 41

Electrode potentials

Metal Electrode potential (Volts)

Magnesium -2.4

Aluminum -1.7

Zinc -0.76

Chromium -0.65

Iron -0.44

Nickel -0.23

Tin -0.14

Lead -0.12

Hydrogen 0.00

Copper +0.34

Silver +0.80

Gold +1.40

RMIT Universityyyyy School/Department/Area 42

Acidic Corrosion

In the presence of acid, free hydrogen ions receive electrons to give

hydrogen gas

2H

+

(aq)

+ 2e

-

(from metal) H

2(g)

Reactions occur with metal above hydrogen in the table of electrode

potentials

RMIT Universityyyyy School/Department/Area 43

Electrolytic Corrosion

Different metals in contact

e.g. Zinc in contact with copper

Electrons flow from zinc (anode) to copper (cathode)

Giving a potential difference of 0.34-(-0.76) = 1.1V

RMIT Universityyyyy School/Department/Area 44

Pitting Corrosion

Anode and cathode on the same piece of metal

Ferric oxide behaves as a cathode with respect to iron

Taylor G.D., Materials in Construction, 2002

RMIT Universityyyyy School/Department/Area 45

Pitting Corrosion

Electrolytic corrosion cells may form in a single metal in presence of

moisture

Contributes to most corrosion problems in civil structures / buildings

A heavily rusted bridge in Toronto

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 46

Effects of oxygen

In pure water, corrosion is extremely slow because water only ionizes

slightly

H

2

O H

+

+ OH

-

Fe Fe

2+

+ 2e

-

At cathode, 2H+ + 2e- H2

Fe

2+

+ 2(OH)

-

Fe(OH)

2

RMIT Universityyyyy School/Department/Area 47

Effects of oxygen

But, with oxygen in water, oxygen reacts with electrons to form

hydroxyl ions

2H

2

O + O

2

+4e

-

4(OH)

-

Steel corrode quite rapidly

RMIT Universityyyyy School/Department/Area 48

Corrosion

As a summary, corrosion takes place when the followings are present

Metal

Water (moisture)

Oxygen

Corrosion can be slowed down if either water or oxygen is eliminated.

Marine structures will require

stringent corrosion protection

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 49

Protection against corrosion

Impervious coating

By covering the metal with coating (paint, pitch, tar, etc.)

Level of protection depends on thickness of paint

Relatively cheap method

Paint must be applied immediately after manufacture

The film of paint must be intact (unbroken)

Paint workshop for structural steel

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 50

Cathodic protection

Sacrificial anodes

Simply connect the metal you want to protect to a more reactive

metal

Replacement of sacrificial metal is required

Not commonly used in construction

RMIT Universityyyyy School/Department/Area 51

Hot-dip galvanizing

A very common form of protection (but could be costly)

Prepared steel sections are dipped into molten zinc at about 450

o

C

Zinc, being more reactive than iron, act as a sacrificial anode

50m to 200m thick, 100m common

Zinc reacts with oxygen to form oxide, and because of its oxide is tightly

bounded, corrosion will cease

Galvanising factory

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 52

5 steps of hot-dip galvanizing

Pickling - Dilute solutions of either hydrochloric or sulfuric acid

remove surface rust and mill scale to provide a chemically clean

metallic surface

Fluxing - Steel is immersed in liquid flux (usually a zinc ammonium

chloride solution) to remove oxides and to prevent oxidation prior to

dipping into the molten zinc bath

Galvanizing - The article is immersed in a bath of molten zinc at

between 435-455

o

C

Finishing The galvanized item is then air-cooled or quenched in liquid.

Inspection - Coating-thickness and surface-condition inspections

complete the process

AS/NZS 4680 Hot-dip galvanized (zinc) coatings on fabricated ferrous

articles

RMIT Universityyyyy School/Department/Area 53

Welding

The material is heated locally to melting temperature, additional metal

may added to connect two metal components

Structural steel sections are often connected by arc welding

Welding should be performed by skilled workmen to ensure quality

Governed by AS1554 Structural steel welding

Welded beam / column

connection

Photo: Ricky Chan

RMIT Universityyyyy School/Department/Area 54

Types of weld

Fillet Weld Butt Weld

RMIT Universityyyyy School/Department/Area 55

Fire resistance of structural steel

At about 250

o

C, yield strength

increases

At about 400

o

C, strength

decreases rapidly

Some means of fire protection

are needed

Robinson J. T., Architecture and

construction in steel, 1993

50% strength @ 600C

RMIT Universityyyyy School/Department/Area 56

Sprayed fire proofing materials

Spray-on fire proofing materials

Photo: Ricky Chan

Further reading

Shielded metal arc welding

http://www.youtube.com/watch?v=WaDsmeB5ywM

Flux-cored arc welding

http://www.youtube.com/watch?v=Li_pAMrUWSw

Fire protection of structural steel in buildings

http://www.pfpa.com.au/docs/Steel%20Fireproofing/Rakic%20-

%20Type%20of%20Fireproofing%20materials.pdf

Galvaniser Association of Australia

http://www.gaa.com.au/

RMIT Universityyyyy School/Department/Area 57

You might also like

- Draft Consulting Agreement Sirisambedu PDFDocument27 pagesDraft Consulting Agreement Sirisambedu PDFzeddy007No ratings yet

- Holly Million Super Producer Client Referral PDFDocument4 pagesHolly Million Super Producer Client Referral PDFPrashanth KumarNo ratings yet

- Pharma & Biotech EditedDocument36 pagesPharma & Biotech EditedPrashanth KumarNo ratings yet

- Compare Zoho CRM Editions.: Starter Standard Professional EnterpriseDocument10 pagesCompare Zoho CRM Editions.: Starter Standard Professional EnterprisePrashanth KumarNo ratings yet

- ON Supplier Registration FormDocument8 pagesON Supplier Registration FormPrashanth KumarNo ratings yet

- Holly Million Super Producer Client Referral PDFDocument4 pagesHolly Million Super Producer Client Referral PDFPrashanth KumarNo ratings yet

- CH 2Document50 pagesCH 2Prashanth KumarNo ratings yet

- List of Allotment Files PDFDocument63 pagesList of Allotment Files PDFPrashanth KumarNo ratings yet

- Estimate: Bill ToDocument2 pagesEstimate: Bill ToPrashanth KumarNo ratings yet

- 15 F Q Plus Extended ReportDocument20 pages15 F Q Plus Extended ReportPrashanth KumarNo ratings yet

- List of Allotment Files PDFDocument63 pagesList of Allotment Files PDFPrashanth KumarNo ratings yet

- Anand ChristopherDocument4 pagesAnand ChristopherPrashanth KumarNo ratings yet

- Documents - Pub - List of Distributors at Srobangalore List of Distributors at SrobangaloreDocument38 pagesDocuments - Pub - List of Distributors at Srobangalore List of Distributors at SrobangalorePrashanth KumarNo ratings yet

- Civil CompaniesDocument3 pagesCivil CompanieskinananthaNo ratings yet

- Extreme Escalation PresentationDocument74 pagesExtreme Escalation PresentationPrashanth KumarNo ratings yet

- Proposal For CGCCDocument22 pagesProposal For CGCCPrashanth KumarNo ratings yet

- Greenovation PDFDocument12 pagesGreenovation PDFPrashanth KumarNo ratings yet

- Fly Ash BricksDocument29 pagesFly Ash BricksSashankPsNo ratings yet

- EGME571 Peer Evaluation SampleDocument1 pageEGME571 Peer Evaluation SamplePrashanth KumarNo ratings yet

- Business Incubators SystemDocument31 pagesBusiness Incubators SystemPrashanth KumarNo ratings yet

- Solar Energy Development An Opportunity or Challange Draft FinalDocument11 pagesSolar Energy Development An Opportunity or Challange Draft FinalPrashanth KumarNo ratings yet

- Ts 4900 Schematic PDFDocument7 pagesTs 4900 Schematic PDFPrashanth KumarNo ratings yet

- Startup PolicyDocument15 pagesStartup PolicyPrashanth KumarNo ratings yet

- Tariff Schedule 2012-13 - 30-03-2012Document8 pagesTariff Schedule 2012-13 - 30-03-2012Asgar ShariefNo ratings yet

- EGME 571 Presentation OrderDocument1 pageEGME 571 Presentation OrderPrashanth KumarNo ratings yet

- Homework From Chapter 12, Due Mon, April 7, 2014Document1 pageHomework From Chapter 12, Due Mon, April 7, 2014Prashanth KumarNo ratings yet

- Homework From Chapter 11Document1 pageHomework From Chapter 11Prashanth KumarNo ratings yet

- Assignment 1Document3 pagesAssignment 1Prashanth KumarNo ratings yet

- Homework From Chapter 11Document1 pageHomework From Chapter 11Prashanth KumarNo ratings yet

- Homework From Chapter 15: Problems: 15.21 & 15.26Document1 pageHomework From Chapter 15: Problems: 15.21 & 15.26Prashanth KumarNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SS 400Document2 pagesSS 400Jigar M. Upadhyay100% (1)

- Types of Toggle ClampDocument7 pagesTypes of Toggle ClamptoggleclampNo ratings yet

- Engineering Encyclopedia: Structural Steel Codes and StandardsDocument27 pagesEngineering Encyclopedia: Structural Steel Codes and Standardsbth8320100% (1)

- Sulfidic Corrosion in Refineries - A ReviewDocument13 pagesSulfidic Corrosion in Refineries - A Reviewrogerh44No ratings yet

- 2010 Agenda Package - MMDocument255 pages2010 Agenda Package - MMCarlos SYNo ratings yet

- Inspection and Heat Treatment SummaryDocument1 pageInspection and Heat Treatment SummaryJoelCristobalNo ratings yet

- TgrsetgreDocument5 pagesTgrsetgreHoff FrenchNo ratings yet

- Reduction of Mill Scale by Carbon PDFDocument5 pagesReduction of Mill Scale by Carbon PDFDeni Shidqi KhaerudiniNo ratings yet

- Book-Friction Stir WeldingDocument239 pagesBook-Friction Stir WeldingHUỲNH HOÀNG TÚNo ratings yet

- Diamondspark S 55 HP: Seamless Basic Cored Wire With Interesting Potential To Increase Submerged Arc Welding ProductivityDocument2 pagesDiamondspark S 55 HP: Seamless Basic Cored Wire With Interesting Potential To Increase Submerged Arc Welding ProductivityRMNo ratings yet

- Material Selection - Tip Speeds For MaterialsDocument1 pageMaterial Selection - Tip Speeds For Materialsjohan diazNo ratings yet

- AWTI Calendar 23-24 - MergedDocument17 pagesAWTI Calendar 23-24 - MergedArnel MagbojosNo ratings yet

- Copper-Nickel - Seawater System Design - GuidelinesDocument15 pagesCopper-Nickel - Seawater System Design - GuidelinesVidyasenNo ratings yet

- Prirucka UTP AJDocument487 pagesPrirucka UTP AJnebojsa70No ratings yet

- Introduction To Cost EstimatingDocument22 pagesIntroduction To Cost EstimatingArwa HusseinNo ratings yet

- CIM WB 2017023 - Rev.00Document12 pagesCIM WB 2017023 - Rev.00Suryana MamanNo ratings yet

- Vilniaus Gedimino Technikos UniversitetasDocument65 pagesVilniaus Gedimino Technikos UniversitetasmariliaNo ratings yet

- Alloying Elements Effects On MartensiteDocument3 pagesAlloying Elements Effects On MartensiteMalcNo ratings yet

- Wheatley Series 822 Check Valves FlyerDocument2 pagesWheatley Series 822 Check Valves FlyerLorena DávilaNo ratings yet

- SAE J411-1997 Carbon and Alloy SteelsDocument10 pagesSAE J411-1997 Carbon and Alloy Steelsflavio82pn0% (1)

- BP SP107Document1 pageBP SP107shashank sharmaNo ratings yet

- Heat Resistant Alloy Welding PDFDocument39 pagesHeat Resistant Alloy Welding PDFmimi_chan_17No ratings yet

- Internal Corrosion StudyDocument9 pagesInternal Corrosion StudyOmar WardehNo ratings yet

- Consumable and Welding of Modified 9 Cr-1M0 Steel PDFDocument4 pagesConsumable and Welding of Modified 9 Cr-1M0 Steel PDFmahmoud_allam3No ratings yet

- Livros Lista MetalurgiaDocument11 pagesLivros Lista MetalurgiaEder TheoNo ratings yet

- Corrosion MonitorDocument79 pagesCorrosion Monitorantony nirmalaNo ratings yet

- Hot-Rolled Steel Strip For Welded Tubes and Pipes - SpecificationDocument9 pagesHot-Rolled Steel Strip For Welded Tubes and Pipes - SpecificationDip Jyoti SatiarNo ratings yet

- No. Trainer TVI Name: Angela E. CervantesDocument6 pagesNo. Trainer TVI Name: Angela E. CervantesVictor De Jesus Lpt33% (3)

- Rodrigo L. Solomon: Address: San Marcos, Camaligan, Camarines Sur Contact Number: 09489259111Document2 pagesRodrigo L. Solomon: Address: San Marcos, Camaligan, Camarines Sur Contact Number: 09489259111Ally CanaveralNo ratings yet

- RV-RVR: Technical CatalogueDocument24 pagesRV-RVR: Technical CatalogueBruno ReisNo ratings yet