Professional Documents

Culture Documents

What Is Hydrogen Blisteering

Uploaded by

Fathoni AhmadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is Hydrogen Blisteering

Uploaded by

Fathoni AhmadCopyright:

Available Formats

Hydrogen Blistering

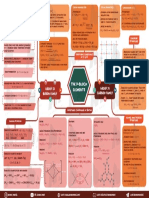

The schematic diagram below shows hydrogen diffusion, say, in a tank containing

an acid electrolyte. Hydrogen evolution occurs because of a corrosion reaction or

cathodic protection. Most of the hydrogen atoms combine to form hydrogen

molecule at the external surface.

H

a

+ H

c

2H

o

H

2

What is hydrogen blisteering?

Hydrogen Blistering (HB) refers to the formation of subsurface planar cavities, called hydrogen blisters, in a metal

resulting from excessive internal hydrogen pressure. Growth of near-surface blisters in low-strength metals usually

results in surface bulges.

Mechanisms

What causes hydrogen blistering? Hydrogen ions are reduced tohydrogen atoms that adsorb on the steel surface.

Some of the hydrogen atoms will diffuse through the steel and accumulate at hydrogen traps, typically voids around

inclusions.

When hydrogen atoms meet in a trap and

combine, they form hydrogen gas (H

2

)

molecules in the trap. The accumulation

hydrogen gas inside the extremely small cavity

will lead to the buildup of excessive

internal hydrogen pressure. At certain times,

this internal hydrogen pressure will become

sufficient to cause the steel to blister.

Blisters occur usually in low strength steels

(<80ksi yield strength) and are formed

preferentially along elongated nonmetallic

inclusions or laminations in linepipe steels.

Prevention

How to prevent hydrogen blistering? Hydrogen Blistering can be prevented through:

Control of impurity of steel.

Avoid the hydrogen source.

Baking to remove hydrogen.

The combination of some hydrogen atoms to form molecules is prevented by some

poisons like As, Bi and Sb, and the atomic hydrogen diffuses into the metal. They

diffuse in to the small voids, and surface heterogenities present in the metal. In the

void they combine to form molecular hydrogen.

Unfortunately, the molecular hydrogen does not diffuse, the concentration and

pressure of hydrogen gas with a very small void increases enormously, the

equilibrium pressure of molecular hydrogen in contact with atomic hydrogen is in

the order of several hundred thousands atmospheres, sufficient to rupture and form

blisters and cause rupture of the walls. Generally low strength steels are susceptible

to hydrogen blistering.

Hydrogen Damage

Metals and alloys may be damaged by hydrogen blistering, hydrogen

embrittlement and high temperature hydrogen attack. A classification of the three

damages is shown in Table 4.2 below. Often there is a great deal of confusion in

the three phenomena. Each of the above phenomena is presented below.

Table 4.2: Classification of Hydrogen Damages

No. Type of Attack Environments

Source of

Atomic

Hydrogen

Type of Metal

Deterioration

Method of Prevention

1. Hydrogen attack

Temperature > 230C.

H

2

Pressure >7 kg/cm

2

.

Equilibrium

dissociation of

H

2

molecules:

H

2

2H

Decarburization and

fissuring: possibly

methane blisters. Serious

loss of strength.

Use of adequately

resistant alloys.

2.

Hydrogen

blistering(Hydrogen-

Temperature 100C in

presence of moisture

Generated by

Blisters when defects are

shallow from the

Protective linings.

induced crack, HIC) and usually H

2

S.

Promoted by cyanides

corrosion:

H

+

+ e H

surface. Cracks parallel

to the surface, when

defects are deep.

Use of adequate

materials (anti-HIC

steel).

Chemical treatment of

corrosive medium with

water, polysulfides or

inhibitors

3.

Hydrogen

embrittlement

High strength steel in

environments same as

above

Same as above

Severe loss of ductility

at low strain rates and

delayed fracture

Same as hydrogen

blistering

Nearly atmospheric

temperature by rapid

cooling of high

strength equipment

operating at conditions

same as in hydrogen

attack.

Same as

hydrogen attack

Severe loss of ductility

at low strain rates and

hydrogen assisted crack

growth

Use of adequate

materials.

Hydrogen degassing.

In summary, hydrogen attack occurs in these steps

Formation of hydrogen ions (H

+

)

Reduction of hydrogen ions to H atoms

Combination of hydrogen atoms to form hydrogen molecule

Escape of hydrogen molecules from the surface (H

2

)

Diffusion of some H atoms to inside of the surface

Accumulation of hydrogen atoms in voids to form molecular hydrogen

Exertion of significant pressure on the walls of the tank

Blistering followed by rupture depending on the steel in use

Prevention

Use steels metallurgically modified to minimize voids and inclusions to prevent

hydrogen gas formation

Remove poisons like arsenic and cyanide compounds and phosphorous containing

ions. The poisons retard the formation of hydrogen molecules.

Use coatings impervious to hydrogen diffusion.

Use nickel based alloys because of their low hydrogen diffusion rates.

Use inhibitors in closed systems because they prevent hydrogen attacks.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Fuel Oil CombustionDocument35 pagesFuel Oil Combustionchaiya sonwongNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- RBBDocument4 pagesRBBFathoni AhmadNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Design and Characterization of Selectively FunctiDocument143 pagesDesign and Characterization of Selectively FunctiFathoni AhmadNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Micro HardnessDocument25 pagesMicro HardnessFathoni AhmadNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Studi Case Process Analysis of Hydrogen Blistering in NGL Fractionation UnitDocument6 pagesStudi Case Process Analysis of Hydrogen Blistering in NGL Fractionation UnitFathoni AhmadNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Global WarmingDocument1 pageGlobal Warmingsimplyrenuyadav4649No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Description PrambananDocument1 pageDescription PrambananFathoni AhmadNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Global WarmingDocument1 pageGlobal Warmingsimplyrenuyadav4649No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Test 2 CHM572 June 2024Document3 pagesTest 2 CHM572 June 2024NUR AINA SYAHMINA MOHD AMRANNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Whiskers The Root Cause of Spontaneous Short Circuits - PCIC - 2006Document5 pagesWhiskers The Root Cause of Spontaneous Short Circuits - PCIC - 2006wy6279No ratings yet

- Formulating elixirs and calculating alcohol contentDocument16 pagesFormulating elixirs and calculating alcohol contentMikaela LaoNo ratings yet

- Experiment 3 KineticsDocument20 pagesExperiment 3 KineticsNItha100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- PAH Degradation PathwaysDocument339 pagesPAH Degradation PathwaysNoor Ul NaeemNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Study On The Compressive Strength and Water Absorption of Fired Soda Ash Infused Clay BricksDocument30 pagesA Study On The Compressive Strength and Water Absorption of Fired Soda Ash Infused Clay BricksNicole Andrei BaldozaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Energy: Haifeng Liu, Xin Wang, Zunqing Zheng, Jingbo Gu, Hu Wang, Mingfa YaoDocument12 pagesEnergy: Haifeng Liu, Xin Wang, Zunqing Zheng, Jingbo Gu, Hu Wang, Mingfa YaoBắc Phạm LêNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Study On Spinel Formation PDFDocument5 pagesA Study On Spinel Formation PDFBagas Prasetyawan Adi NugrohoNo ratings yet

- Organic Chemistry Some Basic Principles and Techniques - WatermarkDocument29 pagesOrganic Chemistry Some Basic Principles and Techniques - WatermarkPrathviraj SinghNo ratings yet

- Shape Memory AlloysDocument16 pagesShape Memory AlloysginejonathanNo ratings yet

- The Effectiveness of Cassava Starch As A Component of Biodegradable PlasticDocument43 pagesThe Effectiveness of Cassava Starch As A Component of Biodegradable PlasticRhea Danica AngusNo ratings yet

- Coa - Argan Oil Organic PDFDocument1 pageCoa - Argan Oil Organic PDFDhaval SoniNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Complexometrictitration-Ppt Part III A 2Document21 pagesComplexometrictitration-Ppt Part III A 2Anand NanavatyNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Future of Composites in Gas Turbine EnginesDocument4 pagesThe Future of Composites in Gas Turbine EnginessenthilNo ratings yet

- Ammonia: Valves For Ammonia ServiceDocument2 pagesAmmonia: Valves For Ammonia ServiceArun Babu0% (1)

- Murex Tig Poster 2008 PDFDocument1 pageMurex Tig Poster 2008 PDFPCNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Chap4 CALCULATIONS USED IN ANALYTICAL CHEMISTRYDocument20 pagesChap4 CALCULATIONS USED IN ANALYTICAL CHEMISTRYDave Marimon100% (1)

- 3.2.2 Reaction Rates QPDocument17 pages3.2.2 Reaction Rates QPjasmeet kahlonNo ratings yet

- Properties of Carbon Monoxide, Silicon Dioxide and CarbondioxideDocument1 pageProperties of Carbon Monoxide, Silicon Dioxide and CarbondioxidePuppika DogNo ratings yet

- Balinit Tisaflex Machining Difficult-To-Cut Materials at The Highest LevelDocument4 pagesBalinit Tisaflex Machining Difficult-To-Cut Materials at The Highest Levelnhirpara1No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Organic Chemistry Question and AnswerDocument53 pagesOrganic Chemistry Question and Answergoi_pin100% (1)

- Chemistry Btech Experiment A Laboratory Experiment in Crystals and Crystal Model BuildingDocument7 pagesChemistry Btech Experiment A Laboratory Experiment in Crystals and Crystal Model BuildingrajaaNo ratings yet

- Grades of Stainless Steel CoilsDocument9 pagesGrades of Stainless Steel CoilsSonic SteelsNo ratings yet

- Manufacturing Processes: by Premchand Kumar Deoghar (Jharkhand)Document49 pagesManufacturing Processes: by Premchand Kumar Deoghar (Jharkhand)PremKumarNo ratings yet

- CHM2201 - LECTURE 2 METHODSDocument31 pagesCHM2201 - LECTURE 2 METHODSAcidri Abdulkarim100% (1)

- Carbohydrate ChemistryDocument78 pagesCarbohydrate ChemistryNikhil NathNo ratings yet

- 2011 Prep Problems With Solutions 110215Document115 pages2011 Prep Problems With Solutions 110215RSLNo ratings yet

- Solutions Suspensions and ColloidsDocument10 pagesSolutions Suspensions and ColloidsAfesha DanielNo ratings yet

- Periodic TableDocument3 pagesPeriodic Tablenada_izyanNo ratings yet

- Welding MachinesDocument53 pagesWelding MachinesDeepak Kumar Kant Kesri100% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)