Professional Documents

Culture Documents

1 s2.0 S001600320900132X Main PDF

Uploaded by

EdwardAlbertoQuirozRojasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S001600320900132X Main PDF

Uploaded by

EdwardAlbertoQuirozRojasCopyright:

Available Formats

Journal of the Franklin Institute 348 (2011) 11631176

A new eccentricity-based simulation to generate

ultimate conned interaction diagrams for circular

concrete columns

Ahmed Abd El-Fattah, Hayder A. Rasheed

, Asad Esmaeily

Department of Civil Engineering, Kansas State University, Manhattan, KS 66506, USA

Received 31 May 2009; accepted 6 October 2009

Available online 25 October 2009

Abstract

The analysis of circular concrete columns using unconned concrete models is a well established

practice. However, there is a necessity to develop realistic analysis and design tools that predict the

extreme ultimate capacity of such columns since modern codes and standards like AASHTO LRFD

are introducing extreme load events. The increase in strength and ductility due to full axial

connement is not applicable to pure bending and bending plus axial load simply because the area of

effective conned concrete is reduced. The higher the eccentricity the smaller the compressed portion

of the conned core. Accordingly, the ultimate conned strength is gradually reduced from the fully

conned value f

cc

0

(at zero eccentricity) to the unconned value f

c

0

(at innite eccentricity) as a

function of eccentricity to diameter ratio. A numerical analysis algorithm is developed using the nite

layer procedure and the secant stiffness approach within a framework of incremental-iterative

moment of area computations. The resulting nonlinear section analysis requires radial loading in

which the eccentricity is kept constant or the axial load is proportional to the applied moment. The

results are compared with existing experimental data and the widely used Mander model to

benchmark the present predictions.

& 2009 The Franklin Institute. Published by Elsevier Ltd. All rights reserved.

Keywords: Conned concrete; Nonlinear analysis; Circular columns; Eccentric loading

www.elsevier.com/locate/jfranklin

0016-0032/$32.00 & 2009 The Franklin Institute. Published by Elsevier Ltd. All rights reserved.

doi:10.1016/j.jfranklin.2009.10.005

Corresponding author. Tel.: +1 785 532 1589; fax: +1 785 532 7717.

E-mail address: hayder@ksu.edu (H.A. Rasheed).

1. Introduction

The development of column interaction diagrams for unconned concrete is a standard

analysis procedure. However, the need to develop analysis tools for the conned ultimate

capacity of columns is evident. Modern codes and standards are introducing the need to

perform extreme event analysis [1]. In previous studies, various models were implemented

to assess the ultimate conned capacity of columns under concentric axial loads. On the

other hand, the effect of connement in case of the eccentric axial load is not investigated

in such models [2]. Therefore, it is pertinent to relate the strength and ductility of conned

concrete to the degree of connement utilization in a new model [2,3]. The more the

eccentricity, the less the connement engaged until the connement effect is reduced to a

negligible level at pure bending.

In this study, a new eccentricity based model is developed for gradual transition of the

ultimate strength and ultimate strain, of conned circular columns, in between full

connement effects based on the Mander model for concentric sections and negligible

connement effects for pure bending. The eccentricity model is incorporated in a numerical

procedure that combines radial loading, nite layer method, secant stiffness procedure and

moment of area concept to incrementally-iteratively generate the momentcurvature

response of the column up to failure using a spectrum of eccentricities that yield the

conned column interaction diagram.

2. Material model

Mander model [4] has been the model of choice in connement studies since it is well-

known, widely benchmarked and expressed in terms of a single equation that traces the

fully conned and unconned curves, Fig. 1. Accordingly, it lends itself to a relatively easy

adaptation to partial connement. The main equations describing the model are given

below:

f

c

f

cc

0

xr

r 1 x

r

1

where r=E

c

/(E

c

E

sec

), E

sec

f

cc

0

=e

cc

, x=e

c/

e

cc

, E

c

5000

f

c

0

p

where f

c

0

and E

c

are in

MPa. f

cc

0

is the strength of the fully conned concrete and e

cc

is the strain corresponding to

f

cc

0

which is dened as

e

cc

e

c

0

1 5

f

cc

0

f

c

0

1

2

cc cc c

cc

f

cc

f

c

f

cu cu

Fig. 1. Eccentricity-based stressstrain family of curves.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1164

where f

c

0

is the strength of unconned concrete and e

c

0

is the strain corresponding to f

c

0

.

The strength f

cc

0

is dened by

f

cc

0

f

c

0

1:254 2:254

1

7:94f

l

0

f

c

0

s

2

f

l

0

f

c

0

!

3

It is evident from Eqs. (2) and (3) that f

cc

0

reduces to f

c

0

and e

cc

reduces to e

c

0

when the

conning pressure f

l

0

reduces to zero. The conning pressure f

l

0

is dened as

f

l

0

1

2

k

e

r

s

f

yh

4

where r

s

4A

spiral

=d

s

s, k

e

1 s

0

=2d

s

=1 r

cc

, f

yh

is the yield strength of the

hoop reinforcement. Now, the intermediate strength of the partially conned eccentric

column f

cc

is expressed in terms of the eccentricity to diameter ratio in the new eccentricity

model:

f

cc

1

1

e

H

f

cc

0

1

1

H

e

f

c

0

5

e

cc

e

c

0

1 5

f

cc

f

c

0

1

6

here e

cc

is the strain corresponding to f

cc

. The intermediate stressstrain equation is the

same as Eq. (1) replacing f

cc

0

with f

cc

and e

cc

with e

cc

, Fig. 1.

3. Assumption for analysis

The following assumptions are made in the analysis:

1. There is perfect bond between the longitudinal reinforcing steel bars and the concrete.

2. Strains along the depth of the column section are assumed to be distributed linearly.

3. Concrete in tension is neglected after cracking.

4. The conned concrete compressive stressstrain relationship is that given by Eqs. (1),

(5) and (6) as a function of the eccentricity.

5. The axial force and bending moment are always applied at the geometric centroid (mid-

depth) of the section and then transferred to the updated inelastic centroid by statics.

6. The steel stressstrain relationship is elasticperfectly plastic. However, strain

hardening is also allowed by assuming a bilinear model, Fig. 2.

su

f

sy

y

f

su

Without strain hardening

With strain hardening

s

E

Fig. 2. Stressstrain relationship of reinforcing steel.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1165

7. The section is numerically divided into a nite number of thin layers each of which is

assumed to have a constant strain e

ci

and stress f

ci

within the layer. The layer also has a

variable width B

i

, Fig. 3.

4. Sectional properties

Considering the axial rigidity (EA) as the overall effective modulus of elasticity times the

area, the integrated form of this property is

EA

X

nlr

i1

E

ci

B

i

t

X

nbr

j1

E

sj

E

cj

A

sj

7

where E

ci

f

ci

=e

ci

, E

si

f

si

=e

si

, B

i

is the width of layer i and A

sj

is the area of rebar j. The

location of the inelastic centroid measured from the bottom of the section is based on the

ratio of the moment of axial rigidity (EAM) to the axial rigidity (EA):

Y

c

P

nlr

i1

E

ci

B

i

tY

i

P

nbr

j1

E

sj

E

cj

A

sj

Y

sj

EA

8

where Y

i

and Y

sj

are measured from the bottom of the section. The exural rigidity (EI) is

the overall effective modulus of elasticity of the section times the moment of inertia about

the inelastic centroid (Y

c

):

EI

X

nlr

i1

E

ci

B

i

tY

i

Y

c

X

nbr

j1

E

sj

E

cj

A

sj

Y

sj

Y

c

2

9

The internal axial force (F

x

) of the section and the internal bending moment about the

inelastic centroid (M

o

) are given by

F

x

X

nlr

i1

f

ci

B

i

t

X

nbr

j1

f

sj

f

cj

A

sj

10

M

o

X

nlr

i1

f

ci

B

i

tY

i

Y

c

X

nbr

j1

f

sj

f

cj

A

sj

Y

sj

Y

c

11

G

P

G

P

o

G

Y

c

Y

G

M

c

M

H

Fig. 3. Idealized section, strain distribution and applied forces.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1166

5. Numerical analysis

The section properties corresponding to any applied load step of constant eccentricity (e)

(i.e. axial force P

G

and bending moment M

G

=P

G

e) are evaluated as follows:

1. The axial force is transferred to the current inelastic centroid and the effective moment

about this centroid is calculated:

M

c

M

G

P

G

Y

G

Y

c

M

G

P

G

H

2

Y

c

12

2. The section curvature and axial strain at inelastic centroid can fully dene the strain

distribution:

f

M

c

EI

; e

o

P

G

EA

13

3. For the new strain distribution, the section properties in Eqs. (7)(11) are re-calculated.

The internal moment about the geometric centroid is transferred back:

M

Go

M

o

F

x

Y

G

Y

c

14

4. Convergence to the new equilibrium position is satised when

Y

c

Y

c previous

Y

c

oY

Tol

P

G

F

x

P

G

oF

Tol

M

G

M

Go

M

G

oM

Tol

15

5. If Eq. (15) is not satised, the newly calculated Y

c

is used in Eq. (12) and steps (14) are

repeated. The rst version of the present method of analysis was presented by Rasheed

and Dinno [5] for analyzing rectangular sections with axial load and uniaxial bending.

6. Simulation results

The present simulation program is capable of generating column interaction diagrams

for standard unconned compression analysis, conned compression analysis with and

without clear cover removal as well as with and without accounting for strain hardening of

longitudinal reinforcement. For the sake of benchmarking and verifying the accuracy of

the present simulation software, the different analysis interaction diagrams are compared

with (i) experimental data, (ii) results from well-known software for unconned

compression and (iii) results from using the Mander model for the entire range of

eccentricities, which is expected to be un-conservative. The following cases of experimental

data are compared rst:

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1167

Case 1: Columns tested by Fatis and Shah [6] The rst case is two octagonal columns

examined by Fatis and Shah. The rst column has a diameter of 23.65 in, a clear cover of

0.8 in, longitudinal reinforcement of 16 # 8 bars. The concrete strength is 4.77 ksi and the

steel yield strength is 43.5 and 61.3 ksi for the longitudinal and spiral reinforcement,

respectively. The spiral diameter is 0.394 in and the spiral spacing is 2.76 in. Fig. 4 shows a

sketch of the cross section of the column.

The rst analysis graph shows three interaction diagrams as they compare with the

experimental data point. It is evident from Fig. 5 that the unconned curve is the

inner most one then the conned curve excluding the clear cover at a compression strain of

0.003 (reduced area curve) followed by the outer most one which retains the cover until the

end of the analysis (full area curve). The experimental data point proves in this case

that the three curves are accurate and conservative enough. On the other hand, if

strain hardening is considered with a secondary modulus after yielding of 5% of the

original modulus, the experimental point gets inside the conned curves with and without

concrete cover, which makes the conned analysis un-conservative in this case, Fig. 6. This

is a clear indication that the behavior prior to the failure of the column included very

minimal strain hardening effects in the longitudinal reinforcement, if any. This is

reasonable since the longitudinal reinforcement used is made of mild steel, see the material

properties above.

The second column of Fatis and Shah has the same parameters as those of the rst

column except for the slightly lower concrete strength (4.71 ksi), slightly larger spiral

spacing (2.95 in) and signicantly larger spiral diameter (0.63 in). The longitudinal steel

yield strength is the same while the spiral steel yield strength is signicantly lower (40.6 ksi).

It is important to note that the experimental point has about the same axial loadmoment

capacity as that of column 1 even though the yield strength of the spiral reinforcement is

quite different, Figs. 5 and 7. This is attributed to the location of the point on the

interaction diagram close to the balanced point that is slightly affected by this change. It is

evident from Fig. 7 that the conned curves are accurate and conservative enough with

respect to the experimental data point. On the other hand, if strain hardening is considered

with a secondary modulus of 5% of the original modulus, the experimental point gets in

between the conned curves with and without concrete cover spalling, which makes the

curve of the removed cover the realistic one to consider in analysis, Fig. 8.

Fig. 4. Fatis and Shah column cross section.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1168

Case 2: Column tested by Mander et al. [7] Case 2 presents a circular column tested by

Mander et al. in pure axial compression. The column has a diameter of 19.68 in, a clear

cover of 0.98 in, longitudinal reinforcement of 8 # 9 bars. The concrete strength is 4.49 ksi

and the steel yield strength is 42.9 ksi for longitudinal reinforcement and 49.3 ksi for spiral

reinforcement. The spiral diameter is 0.472 in and the spiral spacing is 2.04 in. The three

interaction diagrams are shown in Fig. 9. The experimental data point matches very closely

the middle curve that accounts for the cover removal in the case of neglecting strain

0

500

1000

1500

2000

2500

3000

3500

4000

0

Moment (kip.inch)

F

o

r

c

e

(

k

i

p

.

)

0

2000

4000

6000

8000

10000

12000

14000

16000

0

Moment (kN)

F

o

r

c

e

(

k

N

)

Full Area

Reduced Area

Experimental Point

Unconfined Concrete

200 400 600 800 1000 1200

2000 4000 6000 8000 10000 12000

Fig. 5. Interaction diagrams of column 1 without strain hardening.

0

500

1000

1500

2000

2500

3000

3500

4000

4500

0

Moment (kip.inch)

F

o

r

c

e

(

k

i

p

.

)

0

5000

10000

15000

20000

0

Moment (kN.m)

F

o

r

c

e

(

k

N

)

Full Area

Reduced Area

Experimental Point

Unconfined Concrete

200 400 600 800 1000 1200 1400

2000 4000 6000 8000 10000 12000 14000

Fig. 6. Interaction diagrams of column 1 with strain hardening.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1169

hardening. Fig. 10, on the other hand, shows that the three diagrams are spaced out a little

further, when accounting for strain hardening, while the experimental data point still very

closely matches the middle curve. This example shows once again that the cover removal

curve is the one to be used in conned analysis.

0

500

1000

1500

2000

2500

3000

3500

0

Moment (Kip.inch)

F

o

r

c

e

(

K

i

p

.

)

0

2000

4000

6000

8000

10000

12000

14000

0

Moment (KN.m)

F

o

r

c

e

(

k

N

)

Full Area

Reduced Area

Experimental Point

Unconfined Concrete

1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

200 400 600 800 1000

Fig. 7. Interaction diagrams of column 2 without strain hardening.

0

500

1000

1500

2000

2500

3000

3500

0

Moment (kip.inch)

F

o

r

c

e

(

k

i

p

.

)

0

2000

4000

6000

8000

10000

12000

14000

Moment (kN.m)

F

o

r

c

e

(

k

N

)

Full Area

Reduced Area

Experimental Point

Unconfined Concrete

2000 4000 6000 8000 10000 12000

0 200 400 600 800 1000 1200

Fig. 8. Interaction diagrams of column 2 with strain hardening.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1170

Case 3: Columns tested by Dodd and Cooke [8]: Case 3 illustrates circular columns

investigated by Dodd and Cooke, one almost in pure bending and two in combined

bending and axial load. The column has a diameter of 7.87 in, a clear cover of 0.43 in,

0

500

1000

1500

2000

2500

3000

0

Moment (kip.inch)

F

o

r

c

e

(

k

i

p

.

)

0

2000

4000

6000

8000

10000

12000

Moment (kN.m)

F

o

r

c

e

(

k

N

)

Full Area

Reduced Area

Experimental Point

Unconfined Concrete

1000 2000 3000 4000 5000 6000

0 100 200 300 400 500 600

Fig. 9. Interaction diagrams of case 2 without strain hardening.

0

500

1000

1500

2000

2500

3000

0

Moment (kip.inch)

F

o

r

c

e

(

k

i

p

.

)

0

2000

4000

6000

8000

10000

12000

0

Moment (kN.m)

F

o

r

c

e

(

k

N

)

Full Area

Reduced Area

Experimental Point

Unconfined Concrete

1000 2000 3000 4000 5000 6000 7000

100 200 300

400 500

600

700

Fig. 10. Interaction diagrams of case 2 with strain hardening.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1171

longitudinal reinforcement of 18 bars of 0.236 in diameter. The concrete strength is 5.07 ksi

and the steel yield strength is 65.2 ksi for longitudinal reinforcement and 36.25 ksi for spiral

reinforcement. The spiral diameter is 0.157 in and the spiral spacing is 1.1 in. It is expected

that the connement effect is less pronounced than the previous cases since the spiral

diameter is signicantly smaller despite the tight spiral spacing. The three interaction

diagrams are shown, in Fig. 11, to be relatively close to each other and the experimental

data point matches very closely all curves in pure bending. The second and third points, on

the other hand, yield all curves accurate and conservative. Fig. 12 shows no signicant

difference, when accounting for strain hardening, with the experimental data points still

closely comparing to all three curves in a similar fashion.

To benchmark the unconned compression analysis against widely-used software, three

cases are compared against the corresponding results of CSI-Section Builder. The

parameters of the rst case are as follows: A column diameter of 36 in, a clear cover of

1.5 in, longitudinal reinforcement of 13 # 11 bars. The concrete strength is 4.0 ksi and the

steel yield strength is 60 ksi for longitudinal and spiral reinforcement. The spiral

reinforcement is #5 bars. The second case has a smaller column diameter with the

following parameters: A column diameter of 25 in, a clear cover of 1 in, longitudinal

reinforcement of 12 # 10 bars. The concrete strength is 4.0 ksi and the steel yield strength is

60 ksi for longitudinal and spiral reinforcement. The spiral reinforcement is #4 bars. The

third case has yet a smaller diameter of column with the following parameters: A column

diameter of 20 in, a clear cover of 1 in, longitudinal reinforcement of 10 # 8 bars. The

0

50

100

150

200

250

300

350

400

0

Moment (kip.inch)

F

o

r

c

e

(

k

i

p

.

)

0

200

400

600

800

1000

1200

1400

1600

0

Moment (kN.m)

F

o

r

c

e

(

k

N

)

Full Area

Reduced Area

Experimental Points

Unconfined Concrete

50 100 150 200 250 300 350 400 450 500

10 20 30 40 50

Fig. 11. Interaction diagrams of case 3 without strain hardening.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1172

0

50

100

150

200

250

300

350

400

450

0

0

Moment (kip.Inch)

F

o

r

c

e

(

k

i

p

.

)

0

500

1000

1500

2000

Moment (kN.m)

F

o

r

c

e

(

k

N

)

Full Area

Reduced Area

Experimental Points

Unconfined Concrete

50

50

100

10

150 200

20

250 300

30

350 400

40

450 500

Fig. 12. Interaction diagrams of case 3 with strain hardening.

0

1000

2000

3000

4000

5000

6000

0

Moment (kip-in)

L

o

a

d

(

K

i

p

)

0

4448

8896

13344

17792

22240

26688

0

Moment (kN.m)

L

o

a

d

(

k

N

)

5000 10000 15000 20000 25000

564.9 1129.8 1694.7 2259.6 2824.5

case 1

CSI case 1

Case 2

CSI case 2

CSI case 3

Case 3

Fig. 13. Comparison of unconned analysis with CSI-Section Builder.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1173

concrete strength is 4.0 ksi and the steel yield strength is 60 ksi for longitudinal and spiral

reinforcement. The spiral reinforcement is #4 bars. The comparison for the three

interaction diagrams of the three columns between the present program results and those

of Section Builder is excellent, as shown in Fig. 13.

To compare the predictions of the present analysis against the well-known and widely-

used Mander model [4], the complete interaction diagram is generated using the Mander

model, which is known to be valid for pure axial compression only, relative to that of the

present procedure. The parameters of the column examined are as follows: A column

diameter of 23.65 in, a clear cover of 0.8 in, longitudinal reinforcement of 16 # 8 bars. The

concrete strength is 3.857 ksi and the steel yield strength is 43.5 ksi for both spiral and

longitudinal reinforcement. The spiral diameter is 0.394 in and the spiral spacing is 1.97 in.

It is evident from this comparison, Fig. 14, that the present analysis is very accurate and

just conservative enough compared with the experimental point. On the other hand, the

Mander model is shown to be accurate as well but not conservative enough relative to the

experimental point.

To show this comparison when the connement is more pronounced, another example

column is analyzed by the two procedures. The parameters in this example are: A column

diameter of 12 in, a clear cover of 1 in, longitudinal reinforcement of 8 # 7 bars. The

concrete strength is 4.0 ksi and the steel yield strength is 60 ksi for longitudinal and spiral

reinforcement. The spiral reinforcement is #5 bars and the spiral spacing is 1 in.

It is evident from Fig. 15 that the present analysis is signicantly more conservative than

that of the Mander model which indicates that the eccentricity based simulation is

necessary especially in connement-critical columns.

0

500

1000

1500

2000

2500

3000

0

Moment (kip.inch)

F

o

r

c

e

(

k

i

p

.

)

0

2224

4448

6672

8896

11120

13344

0

Moment (kN.m)

F

o

r

c

e

(

k

N

)

Experimental Point

Mander Model

Eccentricity Model

1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

112.97 225.94 338.91 451.88 564.85 677.82 790.79 903.76 1016.73 1129.7

Fig. 14. Interaction diagrams by the present and Mander model.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1174

7. Conclusions

In this study, a new eccentricity-based model was developed to generate realistic

simulations for the behavior of conned concrete circular columns subjected to combined

axial force and uniaxial bending moment. The analysis takes into account the well-known

Mander model for the two extreme cases of pure axial compression (fully conned section)

and pure bending moment (fully unconned section) and generates a family of curves

for the eccentric cases in the transition in between. A nite layer numerical procedure is

extended to circular columns in which the secant stiffness approach is formulated within

a framework of incremental-iterative computations using the moment of area concept.

The conned analysis results are benchmarked against experimental data for a wide

spectrum of points ranging from pure axial compression to pure bending and passing

by the balanced point. The unconned analysis results were successfully compared with

the interaction diagrams generated by the widely-used software CSI-Section Builder.

Finally, the present conned analysis was compared against the widely-used Mander

model for the full range of eccentricities within the same framework of incremental-

iterative computations. It is concluded from this comparison that the present procedure is

accurate and more conservative than that of the Mander model. Accordingly, the present

procedure represents advancement to the state of the art in the area of conned concrete

analysis.

0

200

400

600

800

1000

1200

1400

0

Moment (kip.inch)

F

o

r

c

e

(

k

i

p

.

)

0

889.6

1779.2

2668.8

3558.4

4448

5337.6

6227.2

0

Moment (kN.m)

F

o

r

c

e

(

k

N

)

Mander Model

Eccentricity Model

200 400 600 800 1000 1200 1400 1600 1800 2000

22.75 45.5 68.25 91 113.75 136.5 159.25 182 204.75 227.5

Fig. 15. Comparison between the present and Mander model.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1175

Acknowledgement

This work was developed under a research project KSU 07-21 funded by the Kansas

Department of Transportation. The encouragement and support of Kenneth Hurst and

John Jones is highly acknowledged.

References

[1] AASHTO AASHTO LRFD Bridge Design Specications, American Association of State Highway and

Transportation Ofcials, third ed., SI Units, 2004, ISBN 1-56051-251-2.

[2] A. Esmaeily, K. Lucio, Analytical performance of reinforced concrete columns using various analytical

models, in: Y. Xiao, S. Kunnath, W. Yi (Eds.), International Symposium of Conned Concrete, American

Concrete Institute, SP 238-6, 2002, pp. 95110.

[3] K. Fam, A. Flisak, B. Rizkalla, S. Experimental, Analytical modeling of concrete-lled ber reinforced

polymer tubes subjected to combined bending axial loads, ACI Structural Journal 100 (4) (2003) 529539.

[4] J.B. Mander, M.J.N. Priestley, R. Park, Theoretical stressstrain model for conned concrete, ASCE Journal

of Structural Engineering 114 (8) (1988) 18041826.

[5] H.A. Rasheed, K.S. Dinno, An efcient nonlinear analysis of R.C. sections, Computers and Structures,

International Journal 53 (3) (1994) 613623.

[6] A. Fatis, S.P. Shah, Predictions of ultimate behavior of conned columns subjected to large deformations,

ACI Journal 82 (4) (1985) 423433.

[7] J.B. Mander, M.J.N. Priestley, R. Park, Observed stressstrain behavior of conned concrete, ASCE Journal

of Structural Engineering 114 (8) (1988) 18271849.

[8] L.L. Dodd, N. Cooke, Capacity of circular bridge columns subjected to base excitation, ACI Journal 97 (2)

(2000) 297308.

A. Abd El-Fattah et al. / Journal of the Franklin Institute 348 (2011) 11631176 1176

You might also like

- 1 s2.0 S2352710215300292 MainDocument15 pages1 s2.0 S2352710215300292 MainEdwardAlbertoQuirozRojasNo ratings yet

- Documento 1Document22 pagesDocumento 1EdwardAlbertoQuirozRojasNo ratings yet

- 1 s2.0 S0141029611004901 MainDocument10 pages1 s2.0 S0141029611004901 MainEdwardAlbertoQuirozRojasNo ratings yet

- 1 s2.0 S0141029606003269 MainDocument20 pages1 s2.0 S0141029606003269 MainEdwardAlbertoQuirozRojasNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HomeDocument199 pagesHomevijaykumarlambaNo ratings yet

- Mini ProjectDocument13 pagesMini Project20-119 KATRAVATH HARINo ratings yet

- 1sifat Fisik Mekanik Dan Kuat Tarik Batuan UtuhDocument13 pages1sifat Fisik Mekanik Dan Kuat Tarik Batuan UtuhChrlakhyarNo ratings yet

- Chapter 13Document67 pagesChapter 13sanrorobbyNo ratings yet

- Hard Chrome 105 Plating ProcesDocument3 pagesHard Chrome 105 Plating ProcesKishora BhatNo ratings yet

- RCC Design PhilosophyDocument24 pagesRCC Design Philosophymahesh shankarNo ratings yet

- Circular Steel Tank Design CalculationDocument9 pagesCircular Steel Tank Design CalculationNitesh SinghNo ratings yet

- Piled Raft Case Study in MalaysiaDocument6 pagesPiled Raft Case Study in Malaysiasuman33No ratings yet

- Vol57 4overview1Document16 pagesVol57 4overview1Indra Chandra SetiawanNo ratings yet

- 2001 - Creep Crack Growth in A SGF RF PP CompositeDocument5 pages2001 - Creep Crack Growth in A SGF RF PP CompositeSubramani PichandiNo ratings yet

- Jis G3458Document14 pagesJis G3458riky nurgiantoroNo ratings yet

- RC 83 1027-Libre PDFDocument35 pagesRC 83 1027-Libre PDFBuluc GheorgheNo ratings yet

- Fracture Mechanics of Early Age Concrete PDFDocument5 pagesFracture Mechanics of Early Age Concrete PDFErkan ŞamhalNo ratings yet

- TextDocument2 pagesTextAbdallah GhannamNo ratings yet

- Polyethylene Encasement For Ductile Iron Pipe For Water or Other LiquidsDocument7 pagesPolyethylene Encasement For Ductile Iron Pipe For Water or Other LiquidsTamil funNo ratings yet

- Styron 686E: High Heat Crystal PolystyreneDocument2 pagesStyron 686E: High Heat Crystal PolystyreneMarwin PilayNo ratings yet

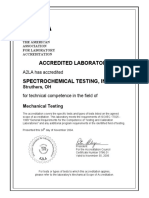

- Accredited Laboratory: A2LA Has AccreditedDocument2 pagesAccredited Laboratory: A2LA Has AccreditedRene Alfonso BeltranNo ratings yet

- Temperature Distribution Along A Constant Cross Sectional Area FinDocument7 pagesTemperature Distribution Along A Constant Cross Sectional Area FinFawaz PartoNo ratings yet

- Steel Design 1Document26 pagesSteel Design 1Gracielle NebresNo ratings yet

- FEA Report Piping Saddle PDFDocument7 pagesFEA Report Piping Saddle PDFalprieto2003No ratings yet

- HMT Unit 2Document22 pagesHMT Unit 2Muthuvel MNo ratings yet

- 45 700 ManualDocument68 pages45 700 ManualZia Ur RehmanNo ratings yet

- J.D. Tytler School: SuperconductorsDocument22 pagesJ.D. Tytler School: SuperconductorsManish SharmaNo ratings yet

- Coupling Beam SAP2000Document4 pagesCoupling Beam SAP2000Rafa SouzaNo ratings yet

- COMSOL Cohesive Zone DebondingDocument22 pagesCOMSOL Cohesive Zone DebondingAaqib AliNo ratings yet

- Seismic Design of Retaining WallsDocument23 pagesSeismic Design of Retaining WallsRutvik ShethNo ratings yet

- EE8251 Circuit Theory NotesDocument147 pagesEE8251 Circuit Theory Notessaravanakmar vNo ratings yet

- Chap 13 Conceptual QuestionsDocument4 pagesChap 13 Conceptual Questionsnouman100% (1)

- ES202 Solid Mechanics - Equation SheetDocument8 pagesES202 Solid Mechanics - Equation SheetJesus TakeTheWheelNo ratings yet