Professional Documents

Culture Documents

HACCP System Requirements

Uploaded by

2011_croreOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HACCP System Requirements

Uploaded by

2011_croreCopyright:

Available Formats

HACCP System Requirements MI Specification H-02 Moody International Certification Group

MI Specification H-02

Requirements for

an Operational

HACCP System

(UKAS)

www.moody-group.com

This is the property of Moody International Certification Group. No copy of any part or all of the

content is permitted without written authorisation by Moody International.

Issue 1, Rev 0: 01/01/05 Page 1 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

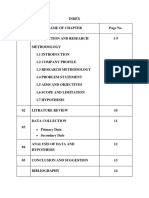

CONTENTS

Change register………………………………………………………………………………..3

0 Introduction································································································································ 4

1.0 Scope········································································································································· 4

2.0 Definitions ································································································································ 5

3.0 Prerequisite Programs ············································································································ 6

3.1 Management Assurance·······································································································6

3.2 Sanitation Standard Operating Procedures ··········································································6

3.3 Training·······························································································································6

3.4 Recall ··································································································································7

3.5 Complaints ··························································································································7

4.0 HACCP Plan Requirements··································································································· 7

4.1 General Information ············································································································7

4.1.2 Product Specification……………………………………………………………………..8

4.2 HACCP-Team ·····················································································································8

4.3 Process Flow Diagram ········································································································8

4.4 Hazard Analysis and Preventive Measures ··········································································9

4.5 Critical Control Points (CCPs) ··························································································10

4.6 Critical Limits ···················································································································10

4.7 Monitoring Procedures ······································································································10

4.8 Corrective Actions············································································································· 11

4.9 Verification Procedures ····································································································· 11

4.10 Documentation and Records····························································································12

Annex 1 HACCP Principles ······································································································· 13

Annex 2 CCP Determination Tree ····························································································· 14

Annex 3 Reference ······················································································································ 15

Issue 1, Rev 0: 01/01/05 Page 2 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

Control Register

Date Type of Change Approved

November 2004 Revised for English clarification Y

January 2005 Revised to show use with ISO 9001:200 Y

Issue 1, Rev 0: 01/01/05 Page 3 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

0 Introduction

The HACCP system is a management tool that systematically identifies specific hazards and control

measures to ensure the safety of food products. The system is recognised world-wide and accepted as an

effective system for food safety.

At present there is no recognised international standard for HACCP, Moody International recommends the

requirements of this specification (H-02) in order to facilitate the implementation of a HACCP

management system.

This specification describes the minimum requirements for an operational HACCP system.

References have been made to the principles of HACCP, Codex Guidelines for the Application of a

HACCP system (CAC), EU Council Directives, USA, Japan, China and other international relevant

regulations, etc.

1.0 Scope

The system requirements describe the key elements for the adequacy, effectiveness and the compliance of

HACCP system to ensure the hygiene and safety of foodstuffs.

The system requirements are generic and applicable to all organisations concerned with the food chain

from preparation, processing, packaging, storage and distribution until the point of customer consumption.

For the purposes of assessing the requirements of this specification in conjunction with ISO 9001:2000,

the appropriate clauses of ISO 9001 have been cross-referenced and are shown against the relevant

sections of this specification.

The organisation shall also satisfy the relevant requirements of the applicable legislation and regulations.

At present, the primary applicable legislation and regulations in force are:

Vertical: EU 93/493/EEC, 92/5/EEC, 92/46/EEC, 89/437/EEC, 91/492/EEC, USA 21 CFR Part 106, 123,

113, 114, 120, 129, 9 CFR Part 416, 417, China National Code of Quality Management for Fish

Processing, etc.

Horizontal: Codex Alimentarius Commission, Codex General Principle of Food Hygiene, Codex

Guidelines for the Application of the Hazard Analysis and Critical Control Points (HACCP) System,

CAC/RCP 1-1969, Rev. 4-2003, Council Directive 93/43/EEC, USA 21 GMP CFR Part 110, Food Act of

People's Republic of China, Food Act of Japan, The Practices of Food Act, Japan, Food Safety Act, UK

etc.

Issue 1, Rev 0: 01/01/05 Page 4 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

2.0 Definitions

Corrective Action: - Actions undertaken by the organisation to clear deviations or non-conformity to

satisfy system requirements and improve effectiveness of the system.

Critical Control Point (CCP): - A step at which control can be applied and is essential to prevent or

eliminate a food safety hazard or reduce it to an acceptable level.

Critical Limit: - A criterion, which specifies the acceptability and unacceptability.

CCP Decision Tree: - A systematic sequence of questions to be considered in the process to decide

whether or not there is a CCP.

Organisation: - An Organisation providing products or services with the food chain from production

preparation, processing, packaging, storage and distribution until the point of consumption.

HACCP Plan: - A document prepared in accordance with the HACCP principles ensuring control of

hazards which are significant for food safety in the segment of the food chain under consideration.

HACCP System: - A food safety management system that identifies evaluates and controls hazards, which

are significant for food safety.

Hazard Analysis: - The process of collecting and evaluating information on hazards and conditions

leading to their presence to decide which are significant for food safety and therefore should be addressed

in the HACCP plan.

Monitoring: - To conduct a planned sequence of observations or measurements of control parameters to

assess whether the CCP’s are controlled by the food organisation.

Restricted Ingredients: - Definition.

SSOP: - Sanitation Standard Operating Procedures.

Verification: - The application of methods, procedures, tests and other evaluations, in addition to

monitoring to determine compliance with the HACCP plan.

Issue 1, Rev 0: 01/01/05 Page 5 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

3.0 Prerequisite Programs

3.1 Management Assurance (4.2.1-5.1-5.3)

Management shall make commitment to a safety management system through safety policy and employee

awareness for the implementation of an effective HACCP system.

The management has responsibilities for establishing, implementing and maintaining a HACCP system

and providing adequate resources to ensure the effective implementation of the HACCP system and its

continuous improvement.

The top management has the final responsibility for the safety of products.

Note: Resource includes manpower, infrastructure, finance, information etc.

3.2 Sanitation Standard Operation Procedures (7.1b-7.53)

The organisation must primarily comply with the general hygiene requirements of appropriate codes and

regulations. The organisation must specify and implement documented sanitation standard operation

procedures. The procedures shall include, but not be limited to the following:

Safety of water

Condition and cleanliness of food contact surfaces

Prevention of cross-contamination

Maintenance of hand washing, hand sanitising and toilet facilities

Protection of food, food packaging material, and food contact surfaces from contamination or

adulteration

Proper labelling, storage and use of toxic compounds

Control of employee health conditions

Exclusion of pests

Construction, process flow and plant layout

Waste control

The sanitation monitoring records shall be maintained and evaluated. Corrective actions must be taken in a

timely manner if sanitation is out of control.

3.3 Training (6.2.2)

The organisation shall develop, and implement a documented training procedure for all employees related

to food safety ensuring that the HACCP plan can be implemented effectively.

The following shall be addressed in the training programme:

Identification of training needs and initiation of a suitable training plan;

All employees are well trained in HACCP principles/sanitation controls and applications;

At least two persons in the organisation are trained in HACCP principles/applications, the relevant

legislation and regulations and internal audit programme;

Evaluation of training effectiveness.

Training records shall be retained.

Issue 1, Rev 0: 01/01/05 Page 6 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

3.4 Recall (8.3c)

The organisation shall establish a documented procedure for recall of the products in the event of a food

safety incident. The procedure must ensure that all products shall be properly identified and traceable.

The procedure shall include:

Product information, including the description of product, production date, lot number and other

relevant data.

In what circumstances the products would need to be recalled

All participant parties to be notified

Disposal of recalled product

Consideration for improving the existing HACCP system and product

Compliance with requirements of relevant regulation, if applicable

The recall shall be documented.

3.5 Complaints (8.5.2a)

The organisation shall establish a documented procedure to handle consumer and customer complaints,

which shall include:

Responsibility for receiving the complaints and collecting all necessary information (label, lot,

production date, etc.) for the product concerned.

Responsibility to investigate the complaint and communicate findings to the customer.

Evaluation of consumer complaints concerning product safety.

Actions to be taken, if needed. (This action will include starting the recall procedure, if necessary.)

Complaints and subsequent actions shall be fed back to HACCP system verification for corrective

actions.

All complaints and the action taken shall be documented.

4.0 HACCP Plan Requirements

4.1 General Information

4.1.1 Organisation Information

The organisation shall provide the following information in the HACCP plan:

Name of the organisation

Address, telephone/fax numbers, e-mail address, etc of key personnel.

Number of employees related to food safety

Issue 1, Rev 0: 01/01/05 Page 7 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

4.1.2 Product Specification (7.2.2-7.2.3a)

The organisation shall make following information available about the products covered by the HACCP

plan.

Full description of the products

Safety information (such as pH, Aw, etc.)

Raw materials

Ingredients (restricted ingredients and non-restricted ingredients)

Packaging (contact and non contact)

Storage conditions

Labelling

Valid shelf life data and how established

Logistics

Intended use and the target consumers

Specific methods of use by the consumer to ensure the product remains safe

4.2 HACCP-Team (5.5.1-6.2.2)

The organisation shall form a HACCP team to establish, implement and maintain the HACCP plan,

including:

Appoint a team leader who has the responsibility and authority to plan and facilitate the HACCP team

activities.

A multi-disciplinary team to establish, implement, maintain and regularly review the HACCP plan.

The HACCP team shall have sufficient knowledge and experience with regard to the organisation’s

products and process within the scope of the HACCP system.

The tasks, responsibilities and authority of HACCP team members shall be defined and documented.

The members of HACCP team shall be trained in the principles of hazard analysis.

4.3 Process Flow Diagram (4.1-7.1b)

Process flow diagrams shall be prepared which provide a complete description of all stages of

product/service realisation process from materials receipt, through preparation to finished product/service.

The Process Flow Diagrams shall include:

Details of raw material and ingredients (clearly identify restricted from the non-restricted ingredients).

The sequence of all steps in the operation, including transportation, storage and any process that has

an impact on food safety.

Packaging material

Rework opportunities

Possible delays in processing

Other information related to food safety (such as temperature, pH, etc)

Process flow diagrams shall provide adequate information for identifying the potential hazards. The

process flow diagram shall be verified on-site and documented ensuring consistency with the actual

operation.

Issue 1, Rev 0: 01/01/05 Page 8 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

4.4 Hazards Analysis and Preventive Measures (6.4-7.1-7.3)

All potential hazards (biological, chemical or physical) likely to occur, associated with the product or

process at each step from materials preparation, processing, storage and distribution until the point of

consumption, shall be identified and documented.

As a minimum the following, shall be considered in the hazard analysis:

All hazards that may reasonably occur and the severity of their adverse health effects at each step

from materials preparation until the point of consumption

A risk evaluation, including occurrence, probability, qualitative and quantitative aspects

Raw materials and ingredients

Product characteristics (e.g. Aw, pH, etc.)

Process parameters and process design

Processing facilities, equipment and layout

Storage facilities and conditions

Packing and Packaging material

Methods of distribution and use

Sanitation conditions and control procedures

The HACCP team shall validate the hazard analysis for adequacy to ensure food safety. (7.5.2)

If any changes occur, which could lead to a requirement to modify the HACCP plan, the hazard analysis

shall be repeated. Such changes include, but are not limited to:

Raw material and ingredients

The sources of raw material and ingredients

Processing methods or systems

Production volume

Packaging

Personnel

Finished product distribution

Intended use or target consumer group

The organisation shall define preventive measures for each identified hazard. (8.5.3)

The preventive measures shall include:

Product specifications (labelling, intended use, etc)

Process control (cooking, sterilising, etc.)

Storage and distribution control (environment conditions)

Sanitation control procedures

Maintenance

Training, etc.

Issue 1, Rev 0: 01/01/05 Page 9 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

4.5 Critical Control Points (CCP’s) (5.4.2-7.1-7.3)

All significant hazards shall be controlled to an acceptable level by measures established at one or more

critical control points.

The justification of CCP determination shall be documented.

Note: It is recommended to use a CCP Determination Tree.

4.6 Critical Limits (7.3-7.52)

For every identified critical control point, the control limit that is critical for the safety of product shall be

specified and documented.

The basis of the critical limit shall be defined

The requirements of the relevant legislation and regulations

The requirements of national/international standards, experimental data, literature references, etc.

Expertise

The critical limits shall be achievable in the manufacturing facility.

4.7 Monitoring Procedures (8.2.3-8.2.4)

Monitoring procedures shall be established to ensure that the critical limits for each CCP are consistently

met. The monitoring procedures shall include a sequence of planned measurements to demonstrate that the

critical control points are under control.

The procedures shall define the following points:

What to be monitored

Monitoring method, including

- Calibration of monitoring and measuring equipment

- Identification and traceability of product

- Validation of sampling plan, if applicable

Monitoring frequency

Monitoring personnel, including dedicated personnel responsible for monitoring who are trained and

qualified

The established monitoring system shall be able to respond to any violations that may occur as specified in

4.8, Corrective Actions.

The monitoring results shall be recorded on a daily basis and signed by the personnel responsible for

monitoring and reviewing respectively.

Issue 1, Rev 0: 01/01/05 Page 10 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

4.8 Corrective Actions (8.3-8.5.2)

For each critical control point (CCP), a documented corrective action procedure shall be established and

implemented to deal with deviations when they occur.

The corrective actions shall include:

Defined personnel who have the responsibilities and authority to implement the Corrective Action;

Identification of affected products;

Correcting the cause of the non-compliance to prevent a recurrence;

Demonstrating that the CCP is back in control by means of examining the process or product at the

CCP;

Evaluation and disposition of non-conforming product (including recall procedure, if necessary);

Verifying/evaluating the effectiveness of corrective actions taken;

Modifying the process or HACCP plan, if the critical limit is repeatedly exceeded.

Corrective actions shall be signed, reviewed by authorised personnel and documented.

4.9 Verification Procedures (8.2.2-8.2.3)

The organisation shall establish, implement and maintain documented procedures to plan, specify, and

conduct all activities that verify the adequacy, compliance and effectiveness of HACCP system to ensure

the safety of the food and continuing improvement of the system.

The responsibilities, authorities, methods, frequency and assessment (internal and external audit) shall be

clearly defined in verification procedures, including the calibration of monitoring equipment and the

evaluation of consumer complaints. The personnel responsible for verification shall be trained or qualified

on HACCP principles and system audit techniques.

The HACCP system shall be updated accordingly with the development, technology and information

available.

The verification procedures shall include, but not be limited to:

a. Initial validation of the elements of the HACCP plan, such as process flow diagram, hazards analysis,

determination of CCPs, critical limits, monitoring procedures, corrective action, document/record

keeping system, etc.

b. On-going HACCP system assessment

Review of records

Observation of operations

Review of deviations and product dispositions

Confirmation that CCPs are under control

Calibration of monitoring equipment

Sampling and testing

Evaluation of consumer complaints and records concerning product safety

Issue 1, Rev 0: 01/01/05 Page 11 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

c. Verification of the overall HACCP system

Internal audit should cover all activities in the HACCP plan shall be performed at least once

every six months;

Feedback of audit data for improvement of the HACCP system

Any changes made that may affect the HACCP system

External audit

The results of the verification shall be evaluated, documented and fed back to the HACCP team for

continuous improvement. (8.5.1-5.6)

4.10 Documentation and Records Keeping System (4.2.1-4.2.3)

The organisation shall establish an efficient and effective documentation and record keeping system to

demonstrate that the product safety and compliance with the requirements of the applicable legislation and

regulations are achieved.

The system shall ensure that all necessary documents (procedures, instructions, forms, etc.) are available

where needed, and obsolete documents are promptly removed from all locations.

The documents/records shall include all the elements of the HACCP system, including:

Description of HACCP system

Hazard analysis

CCP determination

Critical Limit determination

CCP monitoring activities and results

Deviations and associated corrective actions

Training

Verification

Modifications to the HACCP system

Internal audit

Sanitation control monitoring results

Complaints

Recall

External audit

Other activities

The documentation and record control system should be set up considering of the size and nature of the

organization, its processes and products.

All relevant documents, records and data shall be maintained according to the applicable legislation,

regulations or organisation’s requirements.

Issue 1, Rev 0: 01/01/05 Page 12 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

Annex 1 HACCP Principles

HACCP is a systematic approach to the identification, evaluation, and control of food safety hazards based

on the following seven principles:

Principle 1: Hazard analysis and Preventive Measures

Potential hazards associated with a food must be identified. The hazard could be biological, such as a

microbial; chemical, such as a toxin; or physical, such as glass or metal fragments. Control measures to

prevent the occurrence of hazards must be determined accordingly.

Principle 2: Determine the critical control points (CCPs)

These are points in a food's production--from its raw state through processing and shipping to consumption

by the consumer--at which the potential hazard can be controlled or eliminated. Examples are cooking,

cooling, packaging, and metal detection.

Principle 3: Establish critical limits

The preventive measures with critical limits for each control point.

Principle 4: Establish monitoring procedures

Such monitoring procedures might include cooking time and temperature together with who is responsible

for monitoring.

Principle 5: Establish corrective actions

Those corrective actions to be taken when monitoring shows that a critical limit has not been met--for

example, reprocessing or disposing of food if the minimum cooking temperature is not met.

Principle 6: Establish verification procedures

These are procedures to verify that the system is working properly--for example, testing

time-and-temperature recording devices to verify that a cooking unit is working properly.

Principle 7: Establish record-keeping and documentation procedures

This would include records of hazards and their control methods, the monitoring of safety requirements

and action taken to correct potential problems.

Each of these principles must be backed by valid scientific knowledge.

Issue 1, Rev 0: 01/01/05 Page 13 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

Annex 2 CCP Determination Tree

(Answer questions in sequence)

#Q1: Do preventative control measures exist?

Yes No Modify steps in the process or product

Is control at this step necessary for safety? Yes

No Not a CCP Stop*

#Q2: Is the step specifically designed to eliminate or reduce the

Yes

likely occurrence of a hazard to an acceptable level?**

No

#Q3: Could contamination with identified hazard(s) occur in excess of

acceptable level(s) or increase to unacceptable levels?**

Yes No Not a CCP

#Q4: Will a subsequent step eliminate identified hazard(s) or Stop*

reduce likely occurrence to acceptable level(s)?**

Yes No Critical Control Point (CCP)

Not a CCP Stop*

* Proceed to the next identified hazard in the described process

** Acceptable and unacceptable levels need to be determined within the overall objectives in

identifying the CCPs of the HACCP plans

Issue 1, Rev 0: 01/01/05 Page 14 of 15

HACCP System Requirements MI Specification H-02 Moody International Certification Group

Annex 3 References

1. BS EN ISO 9001:2000 Quality Management Systems - Requirements

2. BS EN ISO 19011:2002 Guidelines for quality and/or environmental management systems

auditing

3. Joint FAO/WHO Codex Alimentarius Commission, Codex General Principle of Food Hygiene; Codex

Guidelines for the Application of the Hazard Analysis and Critical Control Points (HACCP) System,

1997 revision

4. Council Directive 93/43/EEC

5. US FDA 21 CFR Part123, 416, 417, 120

6. Food Act of Japan

7. The Practices of Food Act, Japan

8. FDA Guidelines - Hazard Analysis and Critical Control Point Principles and Application, Adopted

August 14, 1997

---oOo---

Moody International Certification, - a “Top 10” multi-accredited,

multi-lingual, world-wide Certification Body / Registrar.

ISO 9001 - ISO 14001 - OHSAS 18001 - HACCP - TS 16949

Notified Body ( PED) / CE Marking

IRCA REGISTERED LEAD AUDITOR TRAINING COURSES

www.moody-group.com

Moody Certification, - Your Partner in Quality

This is the property of Moody International Certification Group. No copy of any part or all of the

content is permitted without written authorisation by Moody International.

Issue 1, Rev 0: 01/01/05 Page 15 of 15

You might also like

- Questions and Answers About The FSSC 22000 CertificationDocument4 pagesQuestions and Answers About The FSSC 22000 CertificationediasianagriNo ratings yet

- FSSC 22000: Foundation For Food Safety CertificationDocument14 pagesFSSC 22000: Foundation For Food Safety CertificationAhmedElSayedNo ratings yet

- ISO 22000 - Operational Prerequisite Programs - Design and ImplementationDocument5 pagesISO 22000 - Operational Prerequisite Programs - Design and ImplementationzyrtylNo ratings yet

- Processed Meats HACCP GuideDocument118 pagesProcessed Meats HACCP GuideArkham KhollyshulNo ratings yet

- FOOD SAFETY MANAGEMENT SYSTEM MANUALDocument44 pagesFOOD SAFETY MANAGEMENT SYSTEM MANUALYoneto Yasuhiko78% (23)

- Get FSSC 22000 Certified in 40 StepsDocument14 pagesGet FSSC 22000 Certified in 40 StepsFelix MwandukaNo ratings yet

- When Recognition Matters - Difference between HACCP and ISO 22000Document5 pagesWhen Recognition Matters - Difference between HACCP and ISO 22000madmaxjune17557100% (1)

- Sac Haccp Doc 2 - Sep05 (Amdt6 - 1dec10)Document13 pagesSac Haccp Doc 2 - Sep05 (Amdt6 - 1dec10)Jeremiah WayneNo ratings yet

- Lecture 9 ISO 22000Document44 pagesLecture 9 ISO 22000ch videosNo ratings yet

- Audit Checklist TemplateDocument16 pagesAudit Checklist TemplateManasa Ravi100% (3)

- IndiaHACCP Certification Criteria Oct 2017Document13 pagesIndiaHACCP Certification Criteria Oct 2017ANKUSHNo ratings yet

- HACCP audit checklistDocument15 pagesHACCP audit checklistMuse ManiaNo ratings yet

- Training On ISO-TS 22003 Part 1 of 2Document50 pagesTraining On ISO-TS 22003 Part 1 of 2Ariv - GRNo ratings yet

- S-9.4 Applying HACCP AssessmentDocument33 pagesS-9.4 Applying HACCP AssessmentLinda Setya WatiNo ratings yet

- audit_checklist_templateDocument16 pagesaudit_checklist_templateAsif HabibNo ratings yet

- Risk-Based Qualification Approach for Pharma EquipmentDocument6 pagesRisk-Based Qualification Approach for Pharma EquipmentJorge Humberto Herrera100% (9)

- The New Requirements For Equipment Management in FSSC 22000 V.6 - LinkedInDocument8 pagesThe New Requirements For Equipment Management in FSSC 22000 V.6 - LinkedInNoé Amargo BarbosaNo ratings yet

- SAMPLE ISO 22000 Manual PDFDocument84 pagesSAMPLE ISO 22000 Manual PDFnasonex91100% (2)

- Key Changes in ISO 22000Document4 pagesKey Changes in ISO 22000miz baigNo ratings yet

- Drugs and Health Products: Validation Guidelines For Pharmaceutical Dosage Forms (GUIDE-0029)Document12 pagesDrugs and Health Products: Validation Guidelines For Pharmaceutical Dosage Forms (GUIDE-0029)upadhyayparag01No ratings yet

- 4 FSMS OverviewDocument14 pages4 FSMS Overviewjamil voraNo ratings yet

- The Pharma Professionals Interview Guide PDFDocument48 pagesThe Pharma Professionals Interview Guide PDFAjit Lonkar100% (1)

- Pharmaceutical Quality Management System (QMS) Questions and AnswersFrom EverandPharmaceutical Quality Management System (QMS) Questions and AnswersNo ratings yet

- FSCC 22000 Version 5 and Other RequirementsDocument29 pagesFSCC 22000 Version 5 and Other Requirementskrishan100% (1)

- Haccp 2.Document11 pagesHaccp 2.sadbad6No ratings yet

- FSSC 22000 Version 5 Quick Start Guide PDFDocument27 pagesFSSC 22000 Version 5 Quick Start Guide PDFFLed NguyenNo ratings yet

- China GB-T 27341-2009 Hazard Analysis and Critica-Control Point (HACCP) System-General Requirements For Food ProcesDocument19 pagesChina GB-T 27341-2009 Hazard Analysis and Critica-Control Point (HACCP) System-General Requirements For Food ProcesNgọc Hân Phạm ThịNo ratings yet

- Non-Sterile Process Validation GuidelinesDocument12 pagesNon-Sterile Process Validation GuidelinesmaikaNo ratings yet

- What Is A Validation Master Plan (VMP) and How Do You Write OneDocument12 pagesWhat Is A Validation Master Plan (VMP) and How Do You Write One王仁宏No ratings yet

- Sample Audit Checklist For HACCPDocument16 pagesSample Audit Checklist For HACCPAprilJoyBascosNo ratings yet

- Validation QAS 055 Rev2combinedDocument77 pagesValidation QAS 055 Rev2combinedVijay Vikas100% (3)

- Audit Checklist TemplateDocument18 pagesAudit Checklist TemplateDesi AgustiniNo ratings yet

- HACCP Safety PlanDocument55 pagesHACCP Safety Plancysauts100% (1)

- Quality ControlDocument15 pagesQuality Controlحسام الدين الحيفيNo ratings yet

- China HACCP General Requirements For Food Processing Plants (GBT27341-2009)Document24 pagesChina HACCP General Requirements For Food Processing Plants (GBT27341-2009)andikaprakosoNo ratings yet

- Practical HACCP BookDocument127 pagesPractical HACCP Bookanil rautNo ratings yet

- HACCP Manual GuideDocument31 pagesHACCP Manual Guidegrsridhar71% (7)

- Sample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorDocument16 pagesSample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorMonica SinghNo ratings yet

- NBE HACCP Certification SchemeDocument47 pagesNBE HACCP Certification SchemereachrainbowNo ratings yet

- Procedure For HACCP PlanDocument25 pagesProcedure For HACCP PlanSyed Mujtaba Ali Bukhari67% (3)

- fssc22000 Part1 v3.2 2015Document15 pagesfssc22000 Part1 v3.2 2015Jose Lopez100% (1)

- Requirements HACCP Versie 3 PDFDocument41 pagesRequirements HACCP Versie 3 PDFsyed zia ul hassanNo ratings yet

- Validation Master PlanDocument33 pagesValidation Master PlanisralmayoorNo ratings yet

- Final Quality AssuranceDocument39 pagesFinal Quality AssuranceSaeed MahmoodNo ratings yet

- IFSQN ISO 22000 Food Safety Management System Product InformationDocument23 pagesIFSQN ISO 22000 Food Safety Management System Product Informationgareth1190% (1)

- Non-Aviation Fuel Quality ManualDocument142 pagesNon-Aviation Fuel Quality Manualraj dasNo ratings yet

- Kementerian Kesihatan Malaysia: Malaysian Certification Scheme (MCS) For Hazard Analysis andDocument29 pagesKementerian Kesihatan Malaysia: Malaysian Certification Scheme (MCS) For Hazard Analysis andCheahNo ratings yet

- DUTCH-Option A Requirements For An HACCPDocument48 pagesDUTCH-Option A Requirements For An HACCPravindrapkadam9423No ratings yet

- GMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsFrom EverandGMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsRating: 5 out of 5 stars5/5 (2)

- Practical Approaches to Method Validation and Essential Instrument QualificationFrom EverandPractical Approaches to Method Validation and Essential Instrument QualificationNo ratings yet

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionFrom EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionRating: 4.5 out of 5 stars4.5/5 (10)

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Food Safety in Shrimp Processing: A Handbook for Shrimp Processors, Importers, Exporters and RetailersFrom EverandFood Safety in Shrimp Processing: A Handbook for Shrimp Processors, Importers, Exporters and RetailersNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- On LuxDocument41 pagesOn Luxsabista25100% (1)

- BestSub 2019 CatalogDocument186 pagesBestSub 2019 CatalogAlex Burența100% (1)

- Haldiram Marketing Strategy AnalysisDocument17 pagesHaldiram Marketing Strategy Analysispratibha bawankuleNo ratings yet

- Benz Packaging Solutions (P) LTDDocument21 pagesBenz Packaging Solutions (P) LTDManan ChopraNo ratings yet

- For LudhianaDocument2 pagesFor Ludhianayaman raoNo ratings yet

- Classified Trade Leviable Fee (RS) New Trade CodeDocument9 pagesClassified Trade Leviable Fee (RS) New Trade CodeRajesh BoodhooNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument8 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- Industrial Report (Naveena Textile)Document6 pagesIndustrial Report (Naveena Textile)YES UCETianNo ratings yet

- X - Butyl Halobutyl For Tire Inner Liners: Product PropertiesDocument2 pagesX - Butyl Halobutyl For Tire Inner Liners: Product PropertiesDebal BaishyaNo ratings yet

- Cosumar ReportDocument31 pagesCosumar ReportHajar JehouNo ratings yet

- Exhibitor List Heimtextil 2020Document166 pagesExhibitor List Heimtextil 2020Abhay JainNo ratings yet

- Easy Day: An Introduction to the Indian Retail BrandDocument11 pagesEasy Day: An Introduction to the Indian Retail BrandVikas SharmaNo ratings yet

- Strategic Management Cia 1 Component 1: Submitted By: Hrithik Agrawal 1720614 5 Bba FDocument5 pagesStrategic Management Cia 1 Component 1: Submitted By: Hrithik Agrawal 1720614 5 Bba FSAHILNo ratings yet

- 90 Questions of Garments Washing & Dyeing.Document26 pages90 Questions of Garments Washing & Dyeing.Ferdous Khan RubelNo ratings yet

- Latihan UtsDocument8 pagesLatihan UtsFadhli Aulia SNo ratings yet

- Pulp and Paper ProductionDocument17 pagesPulp and Paper ProductionJohn Eduard BernabeNo ratings yet

- Corrugated Boxes: Profile No.: 73 NIC Code: 17022Document8 pagesCorrugated Boxes: Profile No.: 73 NIC Code: 17022arpit85No ratings yet

- Hershey Packaging Supplier Quality Expectations ManualDocument26 pagesHershey Packaging Supplier Quality Expectations Manualkhassandra dumaguinNo ratings yet

- Awz 410Document2 pagesAwz 410vukelic79No ratings yet

- Fredrix 2014 Product GuideDocument48 pagesFredrix 2014 Product GuidefredrixartistcanvasNo ratings yet

- Financial Feasibility StudyDocument316 pagesFinancial Feasibility Studyronavanessa0% (1)

- TBA250E SpecificationDocument4 pagesTBA250E Specificationmashuri72100% (1)

- Internship Project - Thushara MK (2016-2018)Document43 pagesInternship Project - Thushara MK (2016-2018)Thushara MKNo ratings yet

- Capstone Literature ReviewDocument5 pagesCapstone Literature ReviewNirav PatelNo ratings yet

- Solutions For Ketchup Production Lines - tcm11-41731Document16 pagesSolutions For Ketchup Production Lines - tcm11-41731Faheem AkramNo ratings yet

- Experienced Asst. Sourcing Manager Seeks New OpportunityDocument3 pagesExperienced Asst. Sourcing Manager Seeks New OpportunityVikas DhandNo ratings yet

- Tyndall Furniture Company (B) EnglishDocument2 pagesTyndall Furniture Company (B) EnglishProcusto LNo ratings yet

- Chipole FinalDocument26 pagesChipole FinalVân Anh Phan100% (3)

- External Factor Evaluation (EFE) Matrix, Internal Factor Evaluation (IFE) MatrixDocument5 pagesExternal Factor Evaluation (EFE) Matrix, Internal Factor Evaluation (IFE) MatrixBaby Joy Bautista100% (1)

- GPL Corporate PresentationDocument20 pagesGPL Corporate PresentationPreeti AgarwalNo ratings yet