Professional Documents

Culture Documents

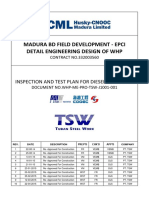

POSCO SS VN - Inspection Testing Plan - ITP

Uploaded by

Nguyen Anh TuanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

POSCO SS VN - Inspection Testing Plan - ITP

Uploaded by

Nguyen Anh TuanCopyright:

Available Formats

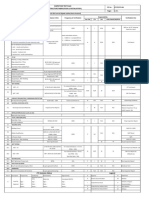

Project Name : POSCO SS VINA PROJECT

POSCO E&C-

Viet Nam

POSCO SS

VN

-

1.0

1.1 AWS D1.1 AWS D1.1 Posco SS VN accepted documents P RD

1.2 AWS D1.1 AWS D1.1 Valid certificates P RD

1.3 AWS D1.1 AWS D1.1 Posco SS VN accepted procedure P RD

1.4 AWS D1.1 AWS D1.1 Posco SS VN accepted procedure P RD

1.5 SNT-TC-1A Level II operator Valid certificates P RD

1.6 POSCO E&C-Viet NamASME Sec.II-C/Suppliers stdPosco SS VN accepted procedure P RD

1.7 POSCO E&C-Viet Nam Posco SS VN accepted procedure P RD

1.8 POSCO E&C-Viet Nam Posco SS VN accepted procedure P RD

1.9 POSCO E&C-Viet Nam ISO 1461 Posco SS VN accepted procedure P RD

2.0

2.1 ASTM,JIS, Mill certificate HP RD

2.2 ASME Sec.II, part C Test report HP RD

3.0

3.1 WPS AWS D1.1 Posco SS VN accepted documents RI RI / WP

3.2 NDE report Completed NCR HP RI / WP

4.0

4.1 AWS D1.1 sect 6 Report P RI /RD

4.2 AWS Report P RI/RD

4.3 UT procedure AWS D1.1 sect 6 Report P RI /RD

4.4 MT Procedure AWS D1.1 sect 6 Report P RI /RD

4.5 UT procedure AWS D1.1 sect 6 Report P RI /RD Butt Joint : UT 10% for total weld length

Dimensional inspection 100%

Weld preparation and fitup

Execution of (major) repairs

Testing

Visual examination 100%

UT 100% if mention in the drawing

Materials

Certification

Certification of welding consumable

NDE procedures (UT/MT)

Fabrication

Visual procedure

Non destructive testing personnel qualifications

Welding material control quality procedure

Non conformance control procedure

Weld Repair procedure

Coating procedure

Verifying document

Inspection point

Procedures & Qualifications

Preparation of WPS/PQR

Welder qualifacations

MT 10% Buildup Beam

INSPECTION AND TEST PLAN

Doc.: ITP-POSCO SS VN-01

Rev.: 0

Date: 12 JUN. 2012

RD= Review Document , RI = random Inpection , WP = Witness point, HP = Hold Point ,A=Attend point MDR= Manufacturer's Data Record, P=Performane

Number Activity Procedure Acceptance criteria

Page 1 of 4

Project Name : POSCO SS VINA PROJECT

POSCO E&C-

Viet Nam

POSCO SS

VN

-

Verifying document

Inspection point

INSPECTION AND TEST PLAN

Doc.: ITP-POSCO SS VN-01

Rev.: 0

Date: 12 JUN. 2012

RD= Review Document , RI = random Inpection , WP = Witness point, HP = Hold Point ,A=Attend point MDR= Manufacturer's Data Record, P=Performane

Number Activity Procedure Acceptance criteria

5.0

5.1 POSCO E&C-Viet Nam SSPC 10 Report P RI /RD

5.2 POSCO E&C-Viet Nam SSPC Report P RI /RD

5.3 POSCO E&C-Viet Nam SSPC Report P RI /RD

5.4 POSCO E&C-Viet Nam SSPC Report P RI /RD

5.5 POSCO E&C-Viet Nam SSPC PA2 Report P RI /RD

5.6 POSCO E&C-Viet Nam ISO-4628 Report P RI /RD

5.7 POSCO E&C-Viet Nam ASTM D4541 Report P RI /RD

6.0

6.1 Packing Procedure Packing List P RI / WP

7.0

7.1

All documents as per

approved ITP

As per the MDR index

Sheet Enclosed With

- HP RD

Documention

Final Inspection Dossiers for Submittal to client

upon completion of the job

Dry Film Thickness Check

Visual Inspection on each coat

Adhesion Test

Packing

Packing inspection

Coating

Surface Profile Testing

Air Temperature & Humidity Check

Metal Surface Temperature Check

Wet Film Thickness Check

Page 2 of 4

-

Inspection point

Remark

Doc.: ITP-POSCO SS VN-01

Rev.: 0

Date: 12 JUN. 2012

RD= Review Document , RI = random Inpection , WP = Witness point, HP = Hold Point ,A=Attend point MDR= Manufacturer's Data Record, P=Performane

Page 3 of 4

-

Inspection point

Remark

Doc.: ITP-POSCO SS VN-01

Rev.: 0

Date: 12 JUN. 2012

RD= Review Document , RI = random Inpection , WP = Witness point, HP = Hold Point ,A=Attend point MDR= Manufacturer's Data Record, P=Performane

Page 4 of 4

You might also like

- 30 - Painting ProcedureDocument12 pages30 - Painting ProcedureNguyen Anh TuanNo ratings yet

- Qualified Welder ListDocument6 pagesQualified Welder ListNguyen Anh TuanNo ratings yet

- 4-Welding Painting Repair-PDocument8 pages4-Welding Painting Repair-PNguyen Anh TuanNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- Saudi Aramco Dow Arabia (MFC) Project As Run Data Sheet: Sub-Contractor Welding Inspector DAELIM Welding InspectorDocument1 pageSaudi Aramco Dow Arabia (MFC) Project As Run Data Sheet: Sub-Contractor Welding Inspector DAELIM Welding InspectorSiddiqui Abdul Khaliq100% (1)

- Mau ReportDocument30 pagesMau ReportNguyễn Hoàng DũngNo ratings yet

- BS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedDocument24 pagesBS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedtienlamNo ratings yet

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCDocument1 page22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforNo ratings yet

- Paint Application Record: Condition of Surface PreperationDocument2 pagesPaint Application Record: Condition of Surface PreperationNguyen Anh TuanNo ratings yet

- Blasting &painting Pocedures MTD SOP 15 01Document1 pageBlasting &painting Pocedures MTD SOP 15 01vinothNo ratings yet

- NRP QapDocument10 pagesNRP QapKevin Mathew100% (1)

- 1method Statement For Passivation and PicklingDocument6 pages1method Statement For Passivation and PicklinggatoNo ratings yet

- Sand Blasting With Paint ApplicationDocument6 pagesSand Blasting With Paint ApplicationBidhan BaruaNo ratings yet

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoNo ratings yet

- Liquid Penetrant Testing Report SummaryDocument1 pageLiquid Penetrant Testing Report SummaryAbdul NaveedNo ratings yet

- Approved ITP 06012023 For WT6Document1 pageApproved ITP 06012023 For WT6mohamed irsath100% (1)

- Back Weld Repair Procedure QualificationDocument15 pagesBack Weld Repair Procedure QualificationFelipe Vásquez ArribasplataNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Welding Procedure Specification (WPS) & Procedure Hp-Bolir Esr0040020qmo4279a-2507 - 0BXDocument62 pagesWelding Procedure Specification (WPS) & Procedure Hp-Bolir Esr0040020qmo4279a-2507 - 0BXkingstonNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Magnetic Particle Examination Procedure: Document No.: POS-MT-01 Rev.01Document11 pagesMagnetic Particle Examination Procedure: Document No.: POS-MT-01 Rev.01Nguyen Anh TuanNo ratings yet

- ESD Flooring Audit ReportDocument11 pagesESD Flooring Audit Reportlaiju cs100% (1)

- Dimensions and Dimensional Tolerances of Straight Tees, NPS 1 - 2 To NPS 48, ASME B16Document4 pagesDimensions and Dimensional Tolerances of Straight Tees, NPS 1 - 2 To NPS 48, ASME B16groshan20No ratings yet

- Zinc Plating Reports 01Document2 pagesZinc Plating Reports 01Amandeep Singh100% (1)

- Modernization Project Inspection ReportDocument4 pagesModernization Project Inspection ReportTomasPavlovicNo ratings yet

- Welders ManagementDocument11 pagesWelders ManagementStanley AlexNo ratings yet

- NORSOK Coating System No. 1 Carbon Steel 120CDocument5 pagesNORSOK Coating System No. 1 Carbon Steel 120CSam Jose100% (1)

- Comment Response Sheet of Surface Preparation and Painting ProcedureDocument22 pagesComment Response Sheet of Surface Preparation and Painting ProcedureAgung PrasetyooNo ratings yet

- SC C06 Cag HBK PRC STDocument26 pagesSC C06 Cag HBK PRC STNguyen Anh Tuan100% (2)

- JIMT Visual Inspection ReportDocument1,913 pagesJIMT Visual Inspection Reportgomathyselvi100% (1)

- Thermal Power Project Weld Inspection ReportDocument1 pageThermal Power Project Weld Inspection ReportAshwani DograNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Document5 pagesA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNo ratings yet

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocument7 pagesA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNo ratings yet

- !JotTest Resist 86 TestReport Pull-OffDocument3 pages!JotTest Resist 86 TestReport Pull-OffMaricelSoledadTorrijosZuñigaNo ratings yet

- COPI - Welding Spec For Flowlines To API 1104-1999Document12 pagesCOPI - Welding Spec For Flowlines To API 1104-1999AdvisNo ratings yet

- Costing Calculations:: Date: Revision: 0 Bld-396-R1 With Canopy + Repairing PlatfarmDocument12 pagesCosting Calculations:: Date: Revision: 0 Bld-396-R1 With Canopy + Repairing PlatfarmRakesh SharmaNo ratings yet

- AWS specifications for selecting electrodes for welding various material gradesDocument1 pageAWS specifications for selecting electrodes for welding various material gradesmohammedetaNo ratings yet

- Missouri DOT Standard Inspection and Testing Plan Sections 200-300Document32 pagesMissouri DOT Standard Inspection and Testing Plan Sections 200-300mohamedamine.zemouriNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoNo ratings yet

- STS EDAC WELD REPAIR PROCEDUREDocument51 pagesSTS EDAC WELD REPAIR PROCEDUREmohd as shahiddin jafriNo ratings yet

- Client: Hindustan Petroleum Corporation Ltd. Contractor: Narmada Offshore Constructions Pvt. Ltd. Doc. No.: NOCPL/HPCL/NWOT/RK/WPS/JP/01 Rev. 00Document7 pagesClient: Hindustan Petroleum Corporation Ltd. Contractor: Narmada Offshore Constructions Pvt. Ltd. Doc. No.: NOCPL/HPCL/NWOT/RK/WPS/JP/01 Rev. 00Bhargav BbvsNo ratings yet

- Luxathane 5000 Polyurethane High Gloss Finish: Technical DataDocument3 pagesLuxathane 5000 Polyurethane High Gloss Finish: Technical DataPV AnandNo ratings yet

- Painting RecordDocument1 pagePainting RecordHimawan SetyarsoNo ratings yet

- KANSAI Tank Coating and Piping Material QuoteDocument4 pagesKANSAI Tank Coating and Piping Material QuoteTanveer Rajput EngrNo ratings yet

- CEILCOTE 505 Coroline.Document2 pagesCEILCOTE 505 Coroline.stuart3962No ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocument2 pagesMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- Daily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanDocument4 pagesDaily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanSUKhanNo ratings yet

- List of Inspection Tools (Qaqc)Document7 pagesList of Inspection Tools (Qaqc)saffririzal4237No ratings yet

- Is 4759 - 2006 - Hot-Dip Zinc Coatings On Structural Steel and Other Allied ProductsDocument9 pagesIs 4759 - 2006 - Hot-Dip Zinc Coatings On Structural Steel and Other Allied ProductsabhibmaneNo ratings yet

- Inspection certificate for Tigrod 13.23 wireDocument1 pageInspection certificate for Tigrod 13.23 wirenwoforNo ratings yet

- Bgas Paint Faults, BittinessDocument49 pagesBgas Paint Faults, BittinessslxantoNo ratings yet

- Welding Inspection Consumables PDFDocument28 pagesWelding Inspection Consumables PDFJoseph PeterNo ratings yet

- Documents - Tips TCVN Iso 90042011 Iso 90042009Document64 pagesDocuments - Tips TCVN Iso 90042011 Iso 90042009Nguyen Anh TuanNo ratings yet

- Paint Technical Specification PDFDocument3 pagesPaint Technical Specification PDFMoon SzDarkness100% (1)

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- Inspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselDocument1 pageInspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselNikki RobertsNo ratings yet

- Refractory Lining & Repair ProcedureDocument11 pagesRefractory Lining & Repair ProcedureNguyen Anh TuanNo ratings yet

- Quality Control Plan For Ducting: Project Name: TokushimaDocument4 pagesQuality Control Plan For Ducting: Project Name: TokushimaNguyen Anh TuanNo ratings yet

- Corrective Action Request (CAR) - Rev 0: Stop Here. Submit CAR To N.A.TuanDocument1 pageCorrective Action Request (CAR) - Rev 0: Stop Here. Submit CAR To N.A.TuanNguyen Anh TuanNo ratings yet

- Corrosion Management Issue119 LowresDocument36 pagesCorrosion Management Issue119 LowresNguyen Anh Tuan100% (1)

- 12414-00-1762 - Rev.0 - MT ProcedureDocument14 pages12414-00-1762 - Rev.0 - MT ProcedureNguyen Anh TuanNo ratings yet

- Quality Assurance CourseDocument63 pagesQuality Assurance CourseNguyen Anh Tuan100% (1)

- 12414-00-1761 - Rev.0 - RT ProcedureDocument39 pages12414-00-1761 - Rev.0 - RT ProcedureNguyen Anh TuanNo ratings yet

- 12414-00-1765 - Rev.0 - VT ProcedureDocument12 pages12414-00-1765 - Rev.0 - VT ProcedureNguyen Anh TuanNo ratings yet

- 12414-00-1763 - Rev.0 - PT ProcedureDocument13 pages12414-00-1763 - Rev.0 - PT ProcedureNguyen Anh TuanNo ratings yet

- 12414-00-1760 - Rev.0 - Ut ProcedureDocument22 pages12414-00-1760 - Rev.0 - Ut ProcedureNguyen Anh TuanNo ratings yet

- SC C06 Cag HBK PRC STDocument26 pagesSC C06 Cag HBK PRC STNguyen Anh Tuan100% (2)

- 2010v01 Inspection Is Not QaDocument2 pages2010v01 Inspection Is Not QaNguyen Anh TuanNo ratings yet

- Fb40rev1 Audit-Checkliste EN15085 ENGDocument14 pagesFb40rev1 Audit-Checkliste EN15085 ENGNguyen Anh TuanNo ratings yet

- E401 1000 Air Cooled CondensersDocument4 pagesE401 1000 Air Cooled CondensersNguyen Anh TuanNo ratings yet

- Global Safety Management at POSCODocument49 pagesGlobal Safety Management at POSCONguyen Anh TuanNo ratings yet

- MGT Sys Track - 1 - M Boudreaux - Risk MGTDocument33 pagesMGT Sys Track - 1 - M Boudreaux - Risk MGTVenkatesan KattappanNo ratings yet

- Regulation of Wood Packaging Material in International Trade ISPM 15Document22 pagesRegulation of Wood Packaging Material in International Trade ISPM 15erharsinghNo ratings yet

- 01 Outokumpu Portfolio Wallchart May 2015 PDFDocument4 pages01 Outokumpu Portfolio Wallchart May 2015 PDFNguyen Anh TuanNo ratings yet

- Stemming The TideDocument48 pagesStemming The TideDevika Hemalatha DeviNo ratings yet

- AISC Steel Construction Manual 14th EditionDocument2 pagesAISC Steel Construction Manual 14th EditionNguyen Anh TuanNo ratings yet

- A Training Presentation On The N7Document69 pagesA Training Presentation On The N7Nguyen Anh TuanNo ratings yet

- Iso9001 2015 Process ApprDocument7 pagesIso9001 2015 Process ApprHaitham NegmNo ratings yet

- Paint Application Record: Condition of Surface PreperationDocument2 pagesPaint Application Record: Condition of Surface PreperationNguyen Anh TuanNo ratings yet

- AWS - CMWS-2005 - Certified Welding Supervisor Manual For Quality and Productivity ImprovementDocument449 pagesAWS - CMWS-2005 - Certified Welding Supervisor Manual For Quality and Productivity ImprovementNguyen Anh Tuan94% (16)

- ElectricDocument42 pagesElectricAbd ZouhierNo ratings yet

- AISC Steel Construction Manual 14th EditionDocument2 pagesAISC Steel Construction Manual 14th EditionNguyen Anh TuanNo ratings yet

- H2FC-Materials-WS Hydrogen Embrittlement of Steels JorcinDocument40 pagesH2FC-Materials-WS Hydrogen Embrittlement of Steels JorcinNguyen Anh TuanNo ratings yet

- Documented InformationDocument5 pagesDocumented InformationbkssdgNo ratings yet

- Documents - Tips TCVN Iso 90042011 Iso 90042009Document64 pagesDocuments - Tips TCVN Iso 90042011 Iso 90042009Nguyen Anh TuanNo ratings yet

- Dies and Inserts Catalog 2018Document36 pagesDies and Inserts Catalog 2018Ahmed MohamedNo ratings yet

- Brochure Husker RollsDocument2 pagesBrochure Husker RollsEmerson OliveiraNo ratings yet

- 15 151905 Machine Design IDocument3 pages15 151905 Machine Design IPeeka Prabhakara RaoNo ratings yet

- Tutorial 7 - Kinetics - SOLUTIONSDocument5 pagesTutorial 7 - Kinetics - SOLUTIONSJustin Chuong NguyenNo ratings yet

- Tension-Weld® Strapping Tool: Downloaded From Manuals Search EngineDocument36 pagesTension-Weld® Strapping Tool: Downloaded From Manuals Search EnginePepeNo ratings yet

- Science Exam NewDocument3 pagesScience Exam NewShahani BarredoNo ratings yet

- Storing and Sanitation TechniquesDocument27 pagesStoring and Sanitation TechniquesMarjory Alga Omale100% (1)

- Ministry of Steel Presentatation On MSFDocument27 pagesMinistry of Steel Presentatation On MSFDebashis SarkarNo ratings yet

- Manual Sany Mantenimiento PDFDocument681 pagesManual Sany Mantenimiento PDFLampart100% (9)

- AIGOSTAR 300000HFA Panini Maker NoticeDocument9 pagesAIGOSTAR 300000HFA Panini Maker NoticeSYLVIENo ratings yet

- 2013 Marine Air PricebookDocument111 pages2013 Marine Air Pricebooknwmarineair2869No ratings yet

- I. Statement of The ProblemDocument5 pagesI. Statement of The ProblemFloredelNo ratings yet

- Quality Metrics For Aerospace: Tim Robertson PQA Nasa/JplDocument20 pagesQuality Metrics For Aerospace: Tim Robertson PQA Nasa/Jplnikhil jNo ratings yet

- Johnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesDocument40 pagesJohnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesMostafa Abd El AlemNo ratings yet

- Acids, Bases, Salts-IG ChemistryDocument16 pagesAcids, Bases, Salts-IG ChemistryRashi GhadiyaNo ratings yet

- Chemistry ProjectDocument16 pagesChemistry Projectgaganshishodia2No ratings yet

- GSE ElectricDocument46 pagesGSE ElectricoespanaNo ratings yet

- Steel ConstructionDocument46 pagesSteel ConstructionKhadeeja AslamNo ratings yet

- WWW - Osha.gov Pre Test Answer Key2Document3 pagesWWW - Osha.gov Pre Test Answer Key2raul_bsu100% (6)

- CanningDocument39 pagesCanningvalerieNo ratings yet

- Modification of LV Panels at Dubai International AirportDocument14 pagesModification of LV Panels at Dubai International AirportPushpakumara KarunadasaNo ratings yet

- IS-216 Queens Boiler Pit Leak RepairDocument8 pagesIS-216 Queens Boiler Pit Leak RepairShamsherHussainNo ratings yet

- Cement Additives Improve High-Performance BindersDocument7 pagesCement Additives Improve High-Performance Bindersimsurender87No ratings yet

- Explanation of NSK life calculation factors and reliability in bearing selectionDocument5 pagesExplanation of NSK life calculation factors and reliability in bearing selectionAndiniPermanaNo ratings yet

- Corporate Image enDocument8 pagesCorporate Image enDanfert PinedoNo ratings yet

- ATA24 Bombardier q400 Electrical PowerDocument85 pagesATA24 Bombardier q400 Electrical PowerAbiyot AderieNo ratings yet

- ProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Document1 pageProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Araujo Felipe AndrésNo ratings yet

- Technovate Refrigeracion y Aire AcondicionadoDocument31 pagesTechnovate Refrigeracion y Aire AcondicionadoIjazzzAli0% (1)

- Color Coding On Ships: Trainees DigestDocument2 pagesColor Coding On Ships: Trainees DigestmmakdNo ratings yet

- Chemsheets GCSE 1069 Allotropes of CarbonDocument1 pageChemsheets GCSE 1069 Allotropes of CarbonNoah KellerNo ratings yet