Professional Documents

Culture Documents

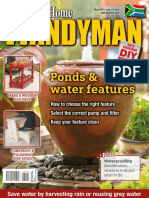

The Home Handyman - January 2014

Uploaded by

George VdovicencuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Home Handyman - January 2014

Uploaded by

George VdovicencuCopyright:

Available Formats

Enter the Maktec/Makita Make a Kitchen Gadget Competition

The Home

January 2014 Vol 21 No 1

R32.00 (incl VAT)

Construction options

Pumps and lters

Step-by-step guide

R

S

A

R

3

2

.

0

0

i

n

c

l

.

V

A

T

O

t

h

e

r

c

o

u

n

t

r

i

e

s

R

2

8

.

0

7

e

x

c

l

.

t

a

x

e

x

c

l

.

p

o

s

t

a

g

e

&

p

a

c

k

a

g

i

n

g

LIGHT UP YOUR HOME

INSTALL NEW GUTTERS

Beautiful

ponds

+

Planning to build?

All the important facts

before you start any

building alterations

plus

S

A

S

O

R

I

G

I

N

A

L

Enter the Maktec/Makita Make a Kitchen Gadget Competition

THE HOME HANDYMAN JANUARY 2014 111

The Home Handyman is published by Home Handyman

Publishing cc ck2000/036356/23

PO Box 650484, Benmore 2010

10 Cypress Avenue, Bryanston Ext. 3, RSA

email: editorial@homehandyman.co.za

Tel: 011-462-5645

Fax: 011-704-3962

Publisher: Allan Swart

Associate publisher: Michelle Funke

Editor: Johann Stadler

Assistant editor: Roelof Strydom

Sub-editors: Lynne Yates, Loren Shirley-Carr

Feature writers: Gina Hartoog, Andre Gous,

Lynne Yates, Loren Shirley-Carr

Editorial consultants: Sharl Bennie, Denis Lock,

Bruwer Leykauf

Photography: Loren Shirley-Carr

Layout & design: Rosemary Johnston-Fitch

HOW TO CONTACT US:

Editorial enquiries:

Tel: 011-462-5645 / 5796 / 5924

Fax: 011-704-3962

email: editorial@homehandyman.co.za

Advertising representatives:

Shelagh Page

Tel: 011-723-9000 / Cell: 082-822-5959

email: shelagh@homehandyman.co.za

Debbie Heard

Tel: 011-465-4265 / Cell: 083-302-7493

email: debbie@homehandyman.co.za

HOW TO SUBSCRIBE:

By email: sarah@homehandyman.co.za

By hotline phone: 011-462-5645

By fax: 011-704-3962

Online: www.homehandyman.co.za

Subscriptions manager: Sarah Moodley

Subscription enquiries:

Tel: 011-462-5645 / 5796 / 5924

email: sarah@homehandyman.co.za

Subscription rates:

SA: R296.00 (incl VAT) for 12 issues

Reproduction: AstraGraphics

Printing: CTP Web, cnr Electron Avenue

and Industry Road, Isando

Distribution: Republican News Agency

The views expressed in this publication are not necessarily those of the publisher

or its agents. While every effort has been made to ensure the accuracy of its

contents, neither the editor nor the publisher can be held responsible for any

omissions or errors. Every care has been taken to ensure that all the information

and projects presented in this publication are accurate, reliable and safe. It should

be noted, however, that the ideas for designs and product use are presented as

suggestions only. The editor strongly advises that the reader check local by-laws

and consult a qualified professional before undertaking any project and cannot

be held responsible for any loss, damage, injury or death resulting from any

information contained here.

The Home Handyman, 1994. All rights reserved. No part of this magazine may be

reproduced or transmitted in any form or by any means, electronic or mechanical,

including photocopying, recording, or any information storage or retrieval system

without prior permission from the publisher.

www.homehandyman.co.za

Johann Stadler, Editor Roelo Strydom,

Asiant Editor

I

t is a new year and although I wrote this before many of us went away, I

am hopeful you are all well rested and ready for 2014 and the challenges it

might throw at you.

I dont know about you, but last year really flew by for me. I was just

getting into the groove of things and suddenly we were talking 2014 in the

boardroom and what do you know here it is!

I want to take this opportunity to bring you the good news that our

assistant editor Roelof Strydom was recently married to a lovely lady, Alta.

Their wedding was particularly good fun unfortunately I have no pictures

to share of him or his bride dancing on a table as that didnt happen but to

them from The Home Handyman team (see picture on p57), may this be the

start of only good things.

On a more formal note, a few things will change in the magazine this

year. We have planned a few interactive competitions and lots of prize

giveaways for starters. Please visit our website too as it was recently

renovated to make it more user friendly with added articles and other

benefits.

Also remember to enter the Maktec/Makita Make a Kitchen Gadget

competition. Once again, Maktec/Makita has sponsored many prizes not

only are there two R10 000 tool vouchers up for grabs, but lots of other tools

and goodies too. Find more details on page 17.

Enjoy the first issue of The Home Handyman for 2014 and once again,

Happy New Year!

EDITORS NOTE

Happy New Year!

JANUARY 2014 THE HOME HANDYMAN 2

CONTENTS

FEATURES

Competitions & giveaways

12 Natural beauty

Turn your garden into a haven for wildlife by creating your own natural pond

18 Making plans

Before you can build on to your home, you need to have plans drawn up. Heres

what to consider

22 Building blocks

Choose the right bricks for your building project

26 Why paint fails prematurely

Find out why paint fails and how to fix and prevent it

30 Tool talk

A look at six circular saws that will turn any sheet of wood into usable pieces

in no time

32 The Home Handyman 2013 index

Looking for a particular feature covered in 2013? This handy reference will guide

you to the right issue

34 Decking pleasure

What to consider when planning a deck as well as maintenance tips for new and

existing decks

38 Look on the bright side

Light up your home effectively and efficiently

42 Replacing your gutters

Advice on choosing the right gutters for your home

46 Table restoration

Willie Koekemoer gives an old battered dining room table a new lease on life

50 Woodworkers diary

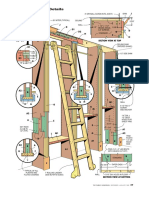

Denis Lock describes how to cut a finger joint

WIN a Makita GA9020K Angle Grinder ............................7

WIN a Bosch PSR 14.4V Li-2 Toolbox .............................11

WIN a 32-piece 3-12mm tap and die set ................... 49

18

42

34

26

Cover

Garden designed by Karen Gardelli

THE HOME HANDYMAN JANUARY 2014 3

REGULARS

4 Off the shelf

All the latest products for the DIYer

6 Voice your views

Your chance to air an opinion

8 DIY matters

News, views and reviews from around the globe

10 Ask our experts

Your DIY queries answered by our panel of experts

49 Bright ideas

Readers share their DIY ideas and projects

54 Woodworkers corner

A look at events in the woodworking calendar and an opportunity

for readers to showcase their work

62 Subscriptions

Save by subscribing to The Home Handyman and win great prizes

64 Tailpiece

Reuben the Screwman tries to build a fish pond

22

46 30

38

12

JANUARY 2014 THE HOME HANDYMAN

OFF THE SHELF Your guide to the latest products in the world of do-it-yourself

Lighting the way

The Energizer HDL33A Headlight is the perfect hands-free light

provider for camping trips or even for when your electricity

provider decides it is time for the lights to go out.

Bright Nichia LED technology, 18 lumens

Lifetime LED bulbs practically never

need replacing

Three LED bulbs: Two white and

one red

Two light modes: Night vision

and flood

Hands-free: Light where you

need it without having to

hold it

Swivel and tilt adjustment

aims light

Comfortable elastic head strap

Slide button on/off switch

Runtime is approximately

30 hours on flood, per set

of batteries

Clean it up

Norton recently

launched the Beartex

2-pack in South Africa

a shrink-wrapped pack of

two Beartex hand-sized

abrasive pads. The green

pad is used for cleaning and

scouring metal surfaces, such

as pots and pans. The maroon

pad can be used for removing

old polish and cleaning metals,

as well as for removing old paint

flaking off metal or wood surfaces

and cleaning surface rust

from metal surfaces. Both

the pads are washable

and reusable.

For more information

Visit: www.norton.eu

Tel: 011-961-2000

Strong bond

A new addition to Pratleys adhesive range

is Pratley Powda Bond. This DIY adhesive is

an instant repair system that can be used

as either a two-component or a single

adhesive. It cures very fast and can be

used to build up thick sections or fill gaps

on repair jobs.

The kit contains a special-grade,

liquid adhesive and specially formulated

black and white powder fillers. The bond

cures within seconds and its formulation

ensures good penetration of the adhesive

through the powder filler and onto

the substrate. A great way to see the

products good powder penetration is

by adhering an item to a transparent

substrate like Perspex.

Once cured, Powda Bond can be painted, sanded or filed and

can be exposed to water. It also performs well on certain difficult

plastics. Some suggested Powda Bond repairs include damaged

car bumpers, cracked

pipes, damaged television

remotes and swimming

pool pump valves.

For more information

Visit: www.pratley.com

Tel: 011-955-2190

Drill, drive, done!

The Kreg Pocket Hole Jig allows you to quickly and easily make

wooden joints. The system works with your own drill to bore

out pocket holes in your workpiece. Because only one of the two

pieces is machined, there is no need for measuring. The stainless

steel collets are positioned at the optimal angle to guarantee

the strength of the join. Once your pocket holes are cut, simply

position the two pieces of wood to be joined. By using your drill

again, the Kreg self-tapping screws are driven into position to

complete the join. No need for

time-consuming clamping or

the frustrating wait for glue

to set.

For more information

Visit: www.vermontsales.co.za

Tel: 011-314-7711

For more information

Visit: www.vermontsales.co.za

Tel: 011-314-7711

4

THE HOME HANDYMAN JANUARY 2014

Specifications

Model: DS 200

Motor induction: 230V, 50Hz

Input: 80W

Grinding wheel : Diamond

Weight approx: 2kg

No-load speed: 17 000rpm

Sharpening capacity: 1.5-13mm

Price R820

Super sharp

The Woodster Diamond Drill Sharpener

DS 200 is ideal for the professional DIY

user, small contractor and workshop. It is

easy to use and requires very little skill to

sharpen drill bits. It comes with a complete

kit with spare diamond wheel, as well as

a cleaning kit. It has a diamond wheel for

accuracy and longer life. The sharpener is

only for HSS and masonry drill bits.

Early detection

Before drilling into a wall at home, use

the advanced Bosch PMD 10 Detector

to swiftly and accurately identify power

cables, metals and drywall constructions

thereby eliminating the risk of

personal injury or damaging important

infrastructure features such as water

pipes and power cables.

The detection depth of the tool is

10cm for ferrous metals, 8cm for non-

ferrous metals, 5cm for power cables

and 2.5cm for wooden and drywall

substructures.

The user-friendly detector has an

integrated handle that enables the user

to comfortably guide the tool over the desired drill position

before alerting the user to a positive search result by emitting

an audible signal and

changing the colour of

its luminous ring. The

detection result can be

read graphically on the

illuminated display.

For more information

Visit: www.bosch-do-it.co.za

Tel: 011-651-9600

For more information

Visit: www.newcopowertools.co.za

Tel: 011-315-1504

Lock damp away

A. Shak Damploc is a waterproof coating used for combating the effects of rising and penetrating

damp on interior and exterior surfaces. It is suitable for use on concrete brick and cement-based

plaster, but not for use on gypsum-based plasters.

Follow these tips:

Apply Damploc to a clean surface; the surface can be damp, but not wet.

Remove all old paint from the surface and sand down any hard, impervious surfaces

to form a key.

Wash the surface with a sugar soap or degreaser before

applying Damploc and rinse well with clean water.

Remove any soft plaster or brick and repair or replaster.

Prime any cracks with Damploc before repairing.

For more information

Visit: www.ashak.co.za

Tel: 0861-127-425

Reduce chlorine consumption

Clinobrite is a direct substitute

for pool filter sand that saves

you money by scavenging

unwanted ammonia from

pool water, thereby reducing

your swimming pool chlorine

consumption. It is a filter

medium with both ion

exchange and superior micro-

filtration properties.

Unlike ordinary filter sand,

the surfaces of Clinobrite grains

are not smooth. Clinobrite

grains attract and trap

extremely fine dirt particles

and algae on their rough

surfaces and not just between the grains like ordinary sand. In

practise, a Clinobrite pool filter can remove 40-50% more physical

dirt than sand filtration. It can also filter out much smaller particle

sizes than sand. This greatly

improves the clarity of your

pool water and gives much

longer service cycles between

backwash operations.

For more information

Visit: www.clinobrite.co.za

Tel: 011-955-2190

5

VOICE YOUR VIEWS Do you have any thoughts or comments on issues of DIY?

When lightning strikes

Dear The Home Handyman, I read your articles with interest, especially the ones on

renewable energy. I see there is a lot of investment going into wind and solar energy. This

made me think: Why dont the guys in white coats invest their energy (excuse the pun) in

ways to harvest electricity from lightning?

Christo du Toit, Port Elizabeth

Ed replies: Although we have never thought of this topic as an idea for an article,

it is a very interesting question and it got me curious too. So I read up a bit

and, in short, this should answer your question:

Most places receive lightning very infrequently, but have a steady demand for

electrical energy. The smaller the area you look at, the fewer the lightning strikes that

hit within that area per unit time.

Secondly, lightning has a high voltage, but not a huge amount of current.

Controlled sources of electrical energy typically need it the other way around lots of

current at lower voltages. Consumers can use 120VAC, and they want a steady supply

of it. Voltage and phase should not drift over time. Lightning can give you tens of

thousands of volts over a few milliseconds and then be gone.

Source: Department of Physics, University of Illinois

I bought an old house in Warden with wooden

floors, which I decided to lift and tile over

a period of time. This past weekend I

decided it was the kitchens turn.

On Friday night I pulled out all

the nails to make life easier the

next day for my two helpers.

Early on Saturday

morning they arrived and

got ready to start lifting

the floorboards. Now I had

already removed four or

so boards in my eagerness

to start. Little did I realise that

the method they use is for one

to stand inside the hole, already

there, and one to stand with

legs spread over the board to be

removed. They would both then

jerk the board up to pull it out, nails

and all.

I watched them getting ready, completely forgetting

I had already removed the nails. They gave the first

board one huge jerk and as there were no nails, no

resistance, the board flew up nailing the guy on top

in a place where no cricketer wants to be bowled. His

eyes grew bigger and bigger, and as hard as he tried

not to, tears started flowing down his face. The one in

the hole let go some Zulu words I do not know, but they

did not sound like kind words. The guy standing on top

slowly fell over forward into the hole where the boards

had already been removed by me, leaving only his feet

sticking out.

My wife, hearing all this commotion, turned up,

gave everything one look and chased me out. About

half an hour later she came to me laughing like crazy.

When I disgustingly enquired what was so funny, she

remarked that they wanted danger pay or they would

leave. I declined and they left. As Warden is a small town

and news spreads fast, I could not find any more help

in town, leaving me to do it all by myself. Needless to

say, the project is going to take much longer now and I

have decided to get a contractor to do it for me until the

stage where the floor is filled, has a cement slab and

is tiled.

AC Muller, Warden

Winning letter

This months winning letter

comes from AC Muller who

wins a Makita 5704RK

Circular Saw

He nailed it!

WINNING

LETTER

JANUARY 2014 THE HOME HANDYMAN 6

Share your

opinion

Send us your views, ideas and opinions addressed to

The Home Handyman:

Email: editorial@homehandyman.co.za

Fax: 011-704-3962

By mail: PO Box 650484, Benmore 2010

Letters may be edited for length and clarity

A Makita GA9020K Angle Grinder

Please note: Winners prizes

may take up to six weeks for

delivery once the issue is on

the shelf.

A

W

IN

!

Tool conundrum

I have been buying The Home Handyman magazine since I was

about 16 years old. I have seen a lot of different projects and

articles in the magazine and have experienced a lot of joy out of

reading it.

These days there are so many new tools and machines

on the market and I would love to see an article where you

compare tools and then have a section on where we can buy

these tools. Yes, I know that you have had articles in the past

that compare tools, but they dont really tell me which one to

buy. There are, of course, factors such as the tools features and

its price, but if you could tell me which power tool is the best

value for my money, it would be a great help. I have bought a

few tools and thought I was buying the best for my money, but

later found out there is a better one. This is not limited to tools;

the same goes for wood glues, sealers, varnish, hand tools etc.

I would also like a comparison between the different models

of the same manufacturer; for example, Makita has so many 18V

cordless drills, but which one is the best? We read the magazine

to make informed decisions. Articles like this would give us an

idea about what to buy. I can then decide what is best for me.

Currently I have to guess and hope it is the right one.

A couple of years back I wanted a router. The two options I

could afford were from Bosch and Black & Decker. I bought the

Black & Decker one, but found it not as good as it is very plastic.

If Id had an experts opinion on which one to buy, I would not

have bought the wrong one and would have bought the Bosch,

or saved another month and bought a Metabo.

Another thing to consider is where these tools can be

bought. I usually go to Game, which does not supply a variety

of brands, and then buy a Black & Decker because I think it is

the best, but around the corner at Builders Express, there is a

Makita. I know that this is not an easy task, but it could be two

pages in each issue.

Grant Watson, via email

Ed replies: Starting with the January 2014 issue, we have a new

article called Tool talk, which looks at various power tools. The

first article in the series looks at circular saws from different

manufacturers. It is a bit difficult for us to say which tool is the

best as that would not be impartial on our side. We do, however,

provide each tools specifications to enable you to compare

them with each other and then try and make an informed

decision based on that. I hope you enjoy these articles and that

they help you.

THE HOME HANDYMAN JANUARY 2014 7

JANUARY 2014 THE HOME HANDYMAN 8

The children of Bambi Nursery School in Pretoria jumped for joy

when they heard the news that the winner of the Lonza Wood

Protection and Mintroad Saw Mills Jungle Gym Competition had

nominated them as the prize recipient. Johann van Loggerenberg,

the original winner, decided to donate his prize to the nursery

school after he heard that their jungle gym was damaged and no

longer safe to play on.

Lonza marketing manager, Gerard Busse, says, Tanalised E

wood preservative-treated poles and sawn timber were used in

the construction of the jungle gym to ensure its longevity. A high

pressure vacuum treatment with Tanalith E, which is a copper

azole-based wood preservative, will provide protection against

wood destroying organisms, such as termites and wood borer, by

rendering the treated wood fibre unsuitable as a food source, and

also provides protection against fungal decay.

Browsers Garden & Home Centre, a retail outlet of Mintroad

Saw Mills, undertook the construction of the approximately 20m

2

jungle gym. It features a sliding pole, a swing, a climbing net, stair

stringers, a slide and a sheltered platform with securely bolted

protective railing. The jungle gym had to be installed in two

separate units due to space constraints and, once safely installed,

the children did not waste any time playing on it.

Owner of Mintroad Saw Mills, Roy Smith, says, Jungle gyms

are an essential form of early childhood development so we were

thrilled to be a part of this competition with Lonza.

For further information, visit the website at www.tanalised.co.za.

DIY MATTERS News, views and reviews from around the globe

Corobriks performance last year was

pleasing, notwithstanding the setbacks

caused by the Marikana incident and

civil unrest on the building industry.

Despite these destabilising factors the

building industry is bouncing up off

its low base, albeit at fairly low levels.

Overall we see prospects improving,

buoyed by government spending on

infrastructure and raising expectations

that 2014 will be a better year than 2013,

according to Dirk Meyer, managing

director of Corobrik.

Architects are reportedly busier

than previously and the qualitative and

quantitative indicators show a general

recovery in the building industry. The

number of commercial building plans

being passed appears on a gradual

upward trend and government spending

on low cost housing and new or

extended schools is also picking up.

Dirk went on to say that the middle

and upper end of the residential market

was also on a slight upward trend,

with property prices recovering. The

middle end of the residential market is

slowly coming back off its low base and

there has been small growth in home

improvements.

Jungle gym competition

promotes early

childhood development

Building industry recovers

Do you have any DIY industry news or views to share?

Email: editorial@homehandyman.co.za

The children of Bambi Nursery School

enjoying quality time outdoors

playing on their new jungle gym

THE HOME HANDYMAN JANUARY 2014 9

The Kopano Day Care Centre, which caters

for 50 local children aged between six

months and six years of age, was officially

re-opened on 25 November 2013 with

several high profile guests in attendance,

including Bosch South Africas managing

director Steffen Hoffmann, Primavera

representative Helmut Schwarz and

Bakgatla Ba Mmakau Traditional Council

chief Motsepe.

Following the devastating fire in March

2012, the Kopano Day Care Centre issued

a plea for help from the local business

community. Multinational engineering and

electronics company Robert Bosch GmbH

stepped up to the plate by offering to assist

with the construction of a completely new

building for the crche, through funding

from Primavera, a global fundraising

organisation whose administrative costs

are paid by Bosch.

In addition to financial assistance,

Bosch has donated, amongst other

things, numerous electrical appliances,

kitchen appliances, solar geysers,

solar panels and replica Bosch toys

to the centre. Responsible corporate

citizenship is one of our core values,

especially in supporting communities

from which we draw employees and

conduct our business, says Steffen.

The temporary structure of the

centre was made of corrugated iron,

which was cold in winter and hot

in summer. As a result, Bosch Home

Appliances Division, Bosch Thermal

Technology and Bosch Solar Energy,

contributed much needed products to

improve the comfort of the children.

The site where the new home has been

built belongs to the Bakgatla Ba Mmakau

Traditional Council under the chieftainship

of Chief Motsepe. According to the building

contractor, the high content of clay in the

soil at the building site posed the largest

challenge in building the new centre.

Osram ran a Halogen Eco sms

competition in participating retail stores

from 18 May to 18 August 2013.

And, with much excitement, Andr

and Hannalie Breytenbach received their

grand prize from Osram at the Makro

Alberton Store in November 2013. The

grand prize was a boat cruise for two to

the Portuguese Islands.

Shoppers had to spot the difference

between the old incandescent lamp and

the new halogen Eco lamp on a display

in-store.

This was to emphasise that you can

save energy without having to change

what your lamp looks like by going with

Osrams new halogen eco technology.

The Osram halogen eco lamp

has the same look and feel as the

old incandescent household lamp,

but you can save up to 30% energy,

and theyre dimmable. The ban on

incandescent lamps (due to their high

energy consumption) has already been

enforced in Europe. There is talk in

South Africa about the banning and

when it will take effect locally, although

nothing is confirmed as yet. Osram has

taken the first step in phasing out the

incandescent technology and replacing

it with its new halogen eco range.

Osram turned 60% of their GLS

business into halogen eco with this

promotion, creating and contributing to

great energy savings.

Five runner-up winners walked away

with a R5 000 shopping voucher.

Osram would like to thank the

winners and other shoppers for their

valued continuous support, and we

wish Mr and Mrs Breytenbach a

splendid trip.

Osrams cruise of success

Childrens day care reopens

its doors after fire

Bosch South Africa managing director

Steffen Hoffmann and Primavera

representative Helmut Schwarz cut the

red ribbon

Kopano Day Care Centre student Thapelo

(aged 5) with his mom at the re-opening of

the centre. Thapelo says he would one day

like to be a pilot

ASK OUR EXPERTS Our panel of experts answer your questions on DIY problems

Built-in-braai

problem

We recently moved into a new house and

the previous owner had a gas braai built

into the braai opening. The first thing I did

was remove it and build a metal braai grid

to braai properly.

The problem I now have is that the smoke comes out the front and into our lapa

instead of going out the chimney. The braai opening is 138mm wide, 105mm high

(bottom to top) and 80mm deep. The chimney tapers and I installed a Whirlybird to

assist with drawing the smoke up and out of the chimney. Please advise what the

relation between the braai opening and chimney should be? I would like to keep the

opening as big as it is, if possible.

Heino Jakob, Windhoek, Namibia

Darryl Smith, customer service manager at Jetmaster, advises: There are technical

formulas to follow regarding the relation between the size of your unit and the

size of the flue. For example: A Jetmaster 1050 Universal fireplace has an opening

of 0,675m x 1.05m; this equals 0.70875 m

2

The minimum size flue area you can use is 0.07 m

2

. The Jetmaster 1050

Square is 0.2m X 0.4m. This gives you an opening area of 0.08 m

2

A simpler example is if you take our 1500 Super Deluxe unit as an example

as it is the closest size we have to your opening. With this unit, the flue size we

use is 350 x 500mm, and this is more than adequate to channel the smoke up

the chimney. Also, the Whirlybird you have installed will definitely assist with the

draw of your smoke.

I hope this assists you in resolving your current issue.

For further information speak to Darryl Smith at Jetmaster on 011-764-4632.

Kitchen island plan

I am a 64-year-old woman and have taken up woodworking

and am enjoying it tremendously. I would like to make a kitchen

island and am looking for a plan that is not too difficult. Does

anyone have such a plan to share? I have selected copies of The

Home Handyman from 2005, but none have featured a

kitchen island.

Sandry Piek, Nelspruit

Ed replies: It is great to hear that you have taken

up woodworking and are having fun learning new

woodworking skills. We have not featured a kitchen

island project in the magazine before. It is definitely a

project that we should feature in the future, so watch this space!

In the meantime, if any of our readers have made one,

perhaps they could share the plan with us.

Otherwise I suggest that you contact Viv Martin at Hardware

Centre on 011-791-0844 or visit

www.hardwarecentre.co.za as they have several books on

kitchen cabinets. Hardware Centre is a specialist

woodworking store and offers a delivery

service countrywide.

Ed replies: I am told that

the DIY Divas courses are

suitable for the layman, but

have not personally attended

any of them. Contact Janice

Anderssen on 011-475-6096

to find out what is covered in

these courses and whether

they are suitable for you.

Winning query

This months winning query

comes from Sandry Piek who

wins a Bosch PFS 105 E Wall

Paint Spray System

DIY courses

I want to know how an absolute layman can

acquire the skills needed to do all the routine

maintenance around the house himself. Ive

come across the DIY Divas workshops, but I dont

know how appropriate they are for a man.

Manfred Swanepoel, by email

W

IN

N

IN

G

Q

U

E

R

Y

JANUARY 2014 THE HOME HANDYMAN 10

11

A Bosch Cordless PSR 14.4 Li-2 Toolbox

Ask our experts

Send us your DIY queries and you could win! Send to:

The Home Handyman DIY Queries,

PO Box 650484, Benmore 2010.

Fax: 011-704-3962.

Email: editorial@homehandyman.co.za

Remember to include your physical address

and telephone number during office hours.

Broken roof tile corners

W

IN

!

Please note: Queries will be

answered in the magazine.

Winners prizes may take up

to six weeks for delivery once

the issue is on the shelf.

I recently checked my roof before the rainy season really set in and

noticed that quite a few tiles were broken on the front corners.

Is this problem related to the tile, is it typical of expansion of

overlapping joints or is it related to the way the tiles have been

mounted on the trusses?

Kindly advise on possible cause and corrective actions.

Basil Evdemon, by email

Sharl Bennie, our building expert, replies: This is very common

these days with modern tiles and I am not sure exactly what

causes the corners to chip away on roof tiles, but have always put

it down to people walking on the roof or hail damage. This does

not cause any major problems with the waterproofing of the roof,

but it does affect the aesthetics of the roof tiles. Perhaps we can

ask the manufacturers of the tiles what their take is on this and if

any preventative action can be taken. As it does not cause the roof

to leak and is commonly seen on most roofs that I have worked on,

I have put it down to the tiles being very hard and brittle.

Ed replies: We contacted Willem Grove at Coverland for a

manufacturers perspective. This is a typical complaint with all

roof tiles. The problem that causes the corner breakage is known

as splay, which is a result of incorrect knife settings during the

production process. If the tiles are pushed together, the corners

can break. The same can happen when the tiles are walked on

and due to thermal expansion between summer and winter. It is

also probable that the tile was already damaged during the laying

process and the broken piece just slipped away in wind or rain.

It is easy to repair simply by removing the broken tiles and replacing them

with new tiles. To avoid colour differences between old and new tiles in obvious

areas, take some tiles from a part of the roof that is less visible and use them

for the repair and place the new ones where they are not that obvious. For more

information contact Willem on 011-222-7406.

Ed suggests: Use RoofFix to fix broken tiles. The product is manufactured by

A.Shak and is available at most hardware and building outlets.

For more information contact A.Shak on 0861-127-425.

Orbital sanders spares

I have two older orbital sanders a Black & Decker and a

Startel. Can I replace the Velcro on the older Black & Decker

sander? If so, where can I buy it? All outlets only sell the

machine itself and not the parts.

Also, the four vibration rubbers on the Startel sander are

broken. Can I buy the rubbers only; if so, where?

Toekie Snyman, Nelspruit

Ed replies: Startel is no longer represented in South Africa;

however, Double Ring Trading (DRT), a multi brand service

centre for power tools, may be able to assist with a compatible

spare for your orbital sander. Contact Jean at DRT on

012-333-6369.

Black & Decker do carry spares for your model, the BD 190E.

There are service centres or agencies countrywide that should

be able to supply you. Contact Deon or Albert at Stanley Black

& Decker on 011-472-0454.

THE HOME HANDYMAN JANUARY 2014 11

JANUARY 2014 THE HOME HANDYMAN 12

GARDEN POND

Natural

beauty

Turn your garden into a haven for

wildlife, and create a heartening

focal point, by creating your own

natural pond

By Loren Shirley-Carr

Rocks of different sizes and plants

around the margins give this pond a

natural look

THE HOME HANDYMAN JANUARY 2014 13

A

sk any landscaper and they will tell

you the same thing: Water is a vital

component of a beautiful garden.

It makes for an attractive focal point, and

the sound soothes the soul and disguises

ambient traffic noise (not to mention noisy

neighbours!). A pool of water also creates a

popular spot for visiting local wildlife, such

as birds and lizards, and creates a haven for

water lovers, such as frogs.

Contrary to popular belief, you dont

need a lot of space, time or money to bring

water into your garden. A small DIY garden

pond can be created in the smallest of

spaces by the most inexperienced of DIYers

as long as you have the inclination and

the energy.

Choose a site

Your pond should ideally be sited where it can be enjoyed both by you and

your gardens wildlife. Consider a spot near your patio or alongside a pathway,

preferably alongside some dense shrubbery where birds and other wildlife

can seek refuge. For a natural look, find the lowest point in your garden where

water would naturally accumulate.

A pond also needs some direct sunlight (about six hours per day) so

avoid positioning it in dense shade. Also be aware that fallen leaves can be

bothersome to clean, so you may want to avoid areas below deciduous trees.

If you have pets or children who may fall into the pond, consider a safety

net or steel grid.

If you use bricks and cement

to make your pond you need

to make sure it is completely

waterproof

Pic courtesy of The Friendly Plant

JANUARY 2014 THE HOME HANDYMAN 14

GARDEN POND

Pumps and filters

Decide whether you want

a still or moving pond.

A pump is not needed

for a still pond, but

a filtration system

is recommended

to keep the

water clean and

oxygenated,

especially if you

want to keep

fish in your pond.

Excess nutrients in

the water caused

by fish dung and

decomposing plant

material can cause

algae to appear, which

turns the water cloudy

and makes it unhealthy. One

way to keep your pond clean

is by using a bio-filter, a natural

way to clean the water. A bio-filter

provides a habitat for bacteria that digest

all the excess nutrients in the water. The

result is a clear pond that is no longer a

suitable habitat for algae.

Alternatively, you can create a natural

ecosystem with moving water using a

pond pump and water plants. By ensuring

that at least half of your ponds surface

area is covered with plants, you will reduce

sunlight levels and limit the growth of

algae. A moving pond will reward you

with the sound of splashing water, and

small waterfalls, streams and fountains

help to keep the pond water aerated, also

preventing the formation of algae. Just

make sure that you choose a pump with

the appropriate strength for what you

want to achieve.

Pond surrounds

Once your pond is in,

you will need to adorn

the edges with natural

materials to create a

water garden. Your pond

should slope gradually

towards the edges so

that wildlife can climb

out or stand in the shallow

water. Consider placing

rocks, pebbles and driftwood

and old logs around the edges

to create a natural look. These

materials will also help to hold

down the edges of the flexible and

waterproof material to line your pond.

Soften the whole look with marginal

water plants, which should be planted in

the shallow water around the edges of

your pond. Choose water-loving plants

like arums, reeds and dwarf papyrus

(Cyperus prolifer).

Water plants

Bring your pond to life with water plants.

You can anchor these plants at the

bottom of your pond using pots, however

most water plants at nurseries come in

specially designed aquatic baskets. Plants

to include in your pond are water lilies

(Nymphaea capensis), waterblommetjie

(Aponogeton distachyos) and yellow water

lily (Nymphoides thunbergiana).

Choose water-loving plants

like arums

A water lily

(Nymphaea capensis)

Dwarf papyrus

(Cyperus prolifer)

Turn your garden into

a haven for wildlife and

create a scenic focal point

by installing your own

natural pond

THE HOME HANDYMAN JANUARY 2014 15

Types of ponds

Your pond can be created by using a

preformed rigid plastic or fibreglass

mould, by using a flexible

plastic waterproof liner, or by

using bricks and cement,

a more time-consuming

option. If you use bricks

and cement, you will

need to make sure it is

completely waterproof

by using cement-based

adhesive to seal the

pond or an outdoor

silicone sealer.

A pre-formed

pond is easy to

install, but using

a liner offers more

flexibility with regards

to size and shape, and is

also easy to install.

A waterfall keeps a pond

aerated, which prevents the

growth of algae

A preformed rigid

plastic mould for a pond

Step-by-step guide

How to create your own water garden

using a flexible plastic liner:

Step 1: Once you have found the perfect

spot, mark out the shape of your pond

with either a hosepipe or a trail of flour.

Step 2: Start digging your hole, making

sure that you have a shallow edge that

gently slopes in towards the middle of

pond. This shallow area is important for

wildlife such as frogs and birds to feel

safe. The deep end of your pond should be

about 75cm-100cm deep.

Step 3: If you want to include a

waterfall, dig out a little ledge

this will be covered by the

waterproof liner along with

the rest of the pond.

Step 4: Line the hole

with a little river sand

to smooth out the

contours.

Step 5: Position the

plastic liner to cover

the hole, smoothing

it out and making

sure it overlaps the

edge of the pond. Anchor it with rocks

and pebbles.

Step 6: Fill to about halfway with water.

This is to make sure that the liner fits

snugly into its place before placing rocks

and pebbles around the pond.

Step 7: Position your rocks, pebbles and

logs. Also place rocks on the waterfall, if

you made one. You may want to grout

between the rocks on the waterfall to

keep them together use cement and

building sand mix.

Step 8: Place the pump in the pond and

hide the hose from the pump to the

waterfall behind some rocks.

Step 9: Fill your pond.

Step 10: Plant water-loving plants, such

as arums, ornamental grasses and

papyrus, around the edges of the pond,

and fill the pond with water lilies and

waterblommetjies to create a natural

water garden.

JANUARY 2014 THE HOME HANDYMAN 16

GARDEN POND

A small DIY garden pond can be created

by the most inexperienced of DIYers

THE HOME HANDYMAN JANUARY 2014 17

Design brief:

Readers are invited to design and construct a useful kitchen gadget it must be functional but there is no restriction on

creativity. Let your imagination run wild or play it safe, thats up to you. Ideas include pot stands, spice racks, recipe bookstand,

paper towel holders, salt and pepper shakers, breadbin, bread board but the list is endless.

The kitchen gadget can be made from any type of wood, man-made boards (i.e. medium density breboard) and/or metal. Use

any materials for the accessories and the nish which will enhance the aesthetics of your handiwork!

The kitchen item should not exceed 500mm (w) x 500mm (h) x 500mm (d).

Judging criteria

The kitchen gadget will be judged in two categories Innovation and Craftsmanship with three winners in each category.

Innovation will look at creativity, taking into account, imagination, originality, resourcefulness and functionality.

Craftsmanship will be judged according to: Quality of craftsmanship Degree of difficulty Joinery Overall finish

The Home Handyman

magazine will sponsor

supplementary prizes

of gift vouchers,

storage binders and

subscriptions

Entry Form:

Name:

Address:

Tel No:

Cell:

Email:

Declaration: I hereby declare that the entry submitted for this

competition is entirely my own work and that I adhered to all the

rules of the competition as stipulated.

Signed:

Date:

How to enter

This competition is open to all South African citizens except employees of Home Handyman

Publishing, Rutherford and its associated brands and their immediate families.

The entries must be constructed between 30 September 2013 and 25 February 2014.

No items made before this date or shop-bought items will be accepted.

Two entries per participant allowed.

Closing date for entries is Tuesday 25 Feb 2014 (expect for entries delivered in Cape Town or

Durban. To make allowances for shipment to Johannesburg, these entries must be delivered

ONLY on Tuesday 18 Feb 2013 between 9am and 4.30pm).

Prizes cannot be extended, transferred or exchanged for cash or other product.

All entries must be accompanied by a completed entry form which is on this page or use the

form on www.homehandyman.co.za or www.makita.co.za.

Delivery of entries

Entries must be securely packaged to avoid damage in transit.

Remember to attach the entry form with your full contact details on it. Please write

Make a Kitchen Gadget clearly on the packaging item.

Post to: The Home Handyman magazine, P O Box 650484, Benmore, 2010.

Or hand deliver to: The Home Handyman, 10 Cypress Ave, Bryanston Ext 3, Randburg, 2191

OR 87 Linksfield Road, Dowerglen, Edenvale 1609. (Hand deliveries weekdays between 8am

5pm only) OR Rutherford/Makita/Maktec branches in Cape Town and Durban.

(Deliveries ONLY accepted on Tuesday 18 Feb 2014 between 9am and 4.30pm).

Rutherford Cape Town Branch: Cnr. Van Riebeeck and Jan Smuts, Beaconvale, Parow.

Tel: 021 932 0568

Rutherford KZN Branch: 12 Halifax Road, Pinetown, KZN. Tel: 031 717 6400

Judging

Judging will take place at the publishers offices in Randburg on Monday 3 March 2014

and all entries including the winning entries will be displayed at Hobby-X, Coca-Cola Dome,

Randburg which is on 6 9 March 2014.

The judges decision is final and no correspondence will be entered into. Winners will be

notified telephonically before 6 March 2014 and arrangements will be made for receipt of

prizes. Winning entries will be featured in the magazine.

For further info go to www.homehandyman.co.za or contact Tel: 011-462-5645 or Email: editorial@homehandyman.co.za

General

Entries and prizes can be collected at Hobby-X, ONLY on Sunday 9 March 2013

or from the address you delivered your entries to. Entries via Rutherford/Makita/

Maktec branches will be returned to respective branches for your collection on

Tuesday 25 March 2014 between 9am and 4.30am ONLY.

By signing the entry form you agree to having your entry photographed for

publication in The Home Handyman magazine.

Whilst everything possible will be done to ensure safe handling of all entries,

please note that neither The Home Handyman nor Rutherford nor any of their

employees will be held responsible for damage or loss of the entries.

JANUARY 2014 THE HOME HANDYMAN 18

S

o youve made the big decision. You

need a larger home, but you cant

face moving, so youre going to

build on. Once the decision is made, youll

probably want to get cracking as soon as

possible. Before you fly head first into your

new project, there are some important

things you should know.

Yes, you do need plans

A friend or family member may have told

you that you dont need plans for this or

that, but the reality is that you probably do

need to get new plans drawn up! Plans are

required for any fixed structures erected on

your property and you need plans approved

if you are going to break down walls or

build new walls inside your home. You

need plans to put in a pool, add a garage or

granny flat or build a lapa or steel carport.

Any changes to sewerage or plumbing

fixtures within the home also require

approved plans. Shade ports are excluded.

First things first

If you dont have a copy of the existing

plans of the house, get a copy from your

council. You can obtain a copy at the

ALTERATIONS

Making plans

Building on to your

home can be exciting,

but before you start

digging the foundations,

youll need to have plans

drawn up

By Gina Hartoog

THE HOME HANDYMAN JANUARY 2014 19

building office of your local municipality.

Once you have a copy of the last approved

plans for your home, you can make final

decisions regarding your addition and look

for someone to draw up the new plans.

Choosing a draughtsman

or architect

Depending on the size and type

of alteration you want to make, a

draughtsman or architect can be hired to

draw up the plans. You will need to make

an appointment with the person for a

meeting at your home. While you may

have a basic idea of what you want, ask

the architect or draughtsman for advice

on the project. Once s/he has inspected

your home and has a good idea of what

changes are required, s/he may be able to

offer professional advice that could save

you money.

Plans need to be drawn up according

to National Building Regulation Standards.

Check that the draughtsman or architect

you choose is registered with a relevant

registration body, such as the South African

Council for the Architectural Profession

(SACAP) or the South African Institute of

Architectural Technologists (SAIAT). Plans

should be completed within a month, but

this also depends on the existing plans and

work required.

SANS legislation

New building regulations, which came

into effect in November 2011, do impact

alterations to existing homes. Only the

portions of the building that are being

extended or altered are subject to these

regulations.

If you are adding a bathroom or

kitchen, you are required to install a solar

water heater or heat pump. Also, the

size of the windows in the new building

may not be more than 15% of the net

floor space. Bigger windows require low

emissivity glass. Calculations are required

to determine which window frame and

glazing will be most energy efficient.

SANS calculations must be included

on the plans. These include fenestration

calculations for glazing and frames to be

JANUARY 2014 THE HOME HANDYMAN 20

ALTERATIONS

used and roof calculations for the thickness

of insulation required. The draughtsman

will also need to calculate that the hot

water usage falls within the parameters set

out in the National Building Regulations

(NBR). Lighting calculations determine

if the number of lights proposed in the

alteration also fall within these parameters.

Architects and draughtsmen must attend

a course in order to learn how to do these

calculations.

The draughtsman or architect is

required to fill in a SANS 10400-A form,

which is a 19-page document that must

be submitted with the plans. The first

two sections of the form are completed

by the draughtsman or architect and

the third section is completed by an

engineer. The fourth section of the form

is for the approval of an engineer. The

draughtsman or architect should be able to

recommend an engineer to sign the plans

and documents. You will also need to sign

various sections of the form as the owner

of the property. The SACAP Architectural

Certificate of Compliance certificate must

be completed by the architect and included

in the plan pack.

Other documentation

Once the plans and documents are

complete, the draughtsman or architect

will fill in a building plans submission form

if required by the relevant council. Two

copies of each page of the plans will go to

the council one in colour and the other

in black and white. Once plans have been

approved, the homeowner will receive the

colour copy back and the black and white

copy is kept by the council.

Check that the

draughtsman

or architect you

choose is registered

with a relevant

registration body

THE HOME HANDYMAN JANUARY 2014 21

Choosing a contractor

A home builder legally needs to be

registered with the National Home Builders

Registration Council (NHBRC).

Master Builders Associations are active in

most regions; although this is a voluntary

registration the companies are vetted to

ensure that they have all the required legal

registration with SARS, UIF, active bank

accounts and other requirements.

Request that the contractor provide you

with a Letter of Good Standing this

may be provided by the Compensation

Commissioner or Federated Employers

Mutual Assurance Company. The letter

must be current check for the expiry date.

This will ensure the builders employees are

covered for any work-related injuries that

may occur while on the property.

Never sign anything without reading it

first! Everything must be in black and white

avoid verbal agreements.

Dont automatically accept the

lowest quote. The contractor may be

inexperienced at quoting, or accidentally or

purposefully forgotten to add something

which you may be liable for later.

Do not let any work begin before a Joint

Building Contracts Committee (JBCC)

contract or similar is signed.

Arrange a regular site inspection with the

builder (daily if possible) to ensure the

work is progressing as agreed. If there are

quality issues, sort them out immediately.

Source: Master Builders Association North

The homeowner also needs to supply a copy of their current water

and lights account as well as a copy of the title deed of the property. If

your property is bonded, ask your bank for a copy.

If your new structure will be built over the property building line

allowed by your council, you will need approval to have it relaxed.

This form can be obtained from the town planning department. All

neighbours on the relevant boundaries (even those across the street)

must be asked to give their approval for the relaxation. If you are adding

rooms or a living area to your home, a certificate of occupancy form must

be filled in.

Fees payable on submission of your documents and plans are

calculated according to the square metres of the addition on your home.

Draughtsmen and architects generally use runners to submit plans to

council. This saves on their time and yours. Should you prefer to submit

your own plans, you are able to do so.

Waiting game

The plans take between two to three months to be approved, depending

on the council. Should you want to begin your building project before the

plans are approved, you will need to apply for pre-approval. While you are

waiting for pre-approval or approval, start looking for a contractor (see

box) and get quotes in for your project.

Information courtesy of draughtsman Alan Zerff of F3 Designs

[owner: Greg Viadana (SAIAT)].

JANUARY 2014 THE HOME HANDYMAN 22

A

brick is just a brick, right? Wrong! In this feature we look

at the classification of clay and cement bricks and well

as other building blocks that can be used in various

applications in the home.

Bricks are rectangular blocks used for building and they have

been around for centuries. The most common bricks we know

today are clay and cement bricks. Bricks and blocks are generally

laid in mortar to build walls or other fixed structures inside and

outside the home. In South Africa, the brick braai is a popular DIY

project for the garden.

Bricks are a durable choice of building material as they are

able to withstand severe weather conditions and high winds.

Cement blocks are often used to construct retainer walls in

the garden.

Colour, texture and size

Cement stock bricks are grey in colour. They are suitable for

building work which is going to be plastered. Clay face bricks

are available in myriad different colours to suit every taste and

application. In most cases the colour of the brick is determined by

the raw materials used and their mineral content, as well as any

additives. Colour can also be changed during the manufacturing

process - a long firing time results in a darker coloured brick.

MASONRY

Building

blocks

If you are planning a building

project, one of the first steps

is choosing the right bricks or

blocks for the job.

By Gina Hartoog

Pic courtesy of Corobrik

THE HOME HANDYMAN JANUARY 2014 23

Face bricks also have different textures

which add to the completed projects

aesthetic appeal. A plain-coloured brick can

look very different with the addition of a

texture to the brick face. Three common

textures for face bricks are satin, travertine

and rock face. Satin bricks have a smooth

finish, while travertine is more textured.

Rock face bricks have a rough, stone-like

face. Corobrik also includes a coral and

rustic texture in their range.

Cement and clay pavers are used to

pave driveways, paths, patios and areas

around the swimming pool.

Brick strength is measured in

megapascals (MPa). SABS approved

masonry units are 7 MPa 14 MPa bricks

sold with a valid SABS Certificate, while

SABS specification masonry units are sold

as 7 MPa, without valid certification. Brick

strength also depends on how long bricks

are given to mature after production. They

longer they mature, the stronger they are.

An imperial or standard size brick measures

222mm x 106mm x 73mm.

73mm

222mm

106mm

Bricks are a durable

choice of building

material as they are

able to withstand severe

weather conditions and

high winds

Glass bricks allow light into a

room without compromising

on privacy

Sentinel Retainer blocks are

dry-stacked and lock into each

other to form an attractive

retaining wall that is part of

the garden layout

Pic courtesy of DSM

JANUARY 2014 THE HOME HANDYMAN 24

MASONRY

Types of bricks

Face brick extra (FBX)

These are clay face bricks selected

or produced for their durability and

highest degree of uniformity of size,

shape and colour. FBX is the golden

standard of bricks. They can be

used for both exterior and interior

building projects where a high

degree of perfection is required.

Non-facing plastered (NFP)

NFP clay bricks are suitable for

general building work that will

be plastered. These bricks are also

known as stock or plaster bricks.

Non-facing extras (NFX) are clay

bricks suitable for use, plastered

or unplastered, in general building

work where durability rather than

aesthetics is the key selection

criteria, for example, below a

damp-proof course or under damp

conditions or below ground level.

Face brick standard (FBS)

FBS bricks are durable clay face

bricks that are uniform in size

and shape. They can be used for

all general masonry projects.

Tolerances are not as strict as with

FBX bricks but the brick is still of a

high quality.

Clay pavers (PA)

Clay PA pavers are

paving bricks selected or

produced for their durability and for

a high degree of uniformity in size

and shape, and that have dimensions

such that the ratio of work size length

to work size width is approximately

1:1, 2:1 or 3:1. Most PA pavers have a

bevelled edge.

Face brick aesthetic (FBA)

These clay face bricks are selected

or produced for their durability and

aesthetic effect, which is derived

from non-uniformity of size, shape or

colour of the brick. Wider tolerances

are allowed on FBA bricks (also called

semi-face bricks). They are a popular

choice where a rough or more rustic

look is required.

Clay pavers (PB)

Clay PB pavers are selected or

produced for their durability

and for their uniformity in size

and shape.

The Great Wall of China was

constructed by the first emperor of

the Qin Dynasty around 210 BC and

is made up of nearly four billion

individual bricks.

Did you know?

Clay pavers (PA)

Clay PA pavers are

THE HOME HANDYMAN JANUARY 2014 25

Aluglass Bautech 0861-258 452;

www.aluglass.co.za

Clay Brick Association www.claybrick.org

Corobrik 011 871 8600; www.corobrik.co.za

Decorative Stone Masonry SA

011 964 2995; www.dsm-sa.co.za

Gauteng Brickyard www.gautengbrickyard.co.za

Contacts

Special-shaped bricks

These are any bricks that are not

rectangular in shape. They may be

single or double bullnose bricks,

angle and cant bricks, arch bricks,

capping, plinth bricks and spiral

bricks. They are available in the

same colours and textures as the

range of FBX, FBS and FBA bricks.

Glass bricks

Glass bricks can be used to construct

sections of interior and exterior walls

and allow light to enter the home

without compromising on privacy. They

are a popular choice in bathrooms, on

stairwells and in other focal areas in the

home. Glass bricks provide a solution

for an area with an unsightly view while

still allowing light inside the home.

They also have a higher insulating

factor than regular window glass. They

are easy to clean and come in a wide

range of colours, styles and designs.

Cement blocks

Cement blocks can

be used to construct

exterior walls, boundary

walls and, when used with re-enforcing,

can be used for load-bearing walls.

The holes in concrete blocks are

called cores. They aid in insulation

and lower the weight of the block.

Steel bars can also be inserted into

the cores for added strength during

construction. A variety of colours, sizes,

shapes and textures are now available,

including interlocking concrete blocks.

Compressive strength for blocks varies

between 3.5 MPa and 7 MPa.

Decorative retainer blocks

Retainer blocks are used to

build retaining walls, level a

steep slope or enclose a section

of the garden. Retaining walls

are becoming more popular in

landscaping and are no longer

designed to blend into the

background. Decorative retainer

blocks can be used to create a

retaining wall that is both eye-

catching and functional. They

are available in various colours

to suit your homes style and

colouring.

blocks

blocks can

to construct

walls, boundary

Cement pavers and

interlocking pavers

These come in a range of different

colours and textures. They are

durable and able to withstand

severe weather. Interlocking pavers

can be used on driveways or for

commercial applications where

there is heavy traffic.

Cement pavers and

Cement stock brick

Commonly called a mampara brick

in South African building lingo, the

cement stock brick is often selected

as a cheaper building option for walls

that will be plastered. Cement stocks

are manufactured to the standard

brick size, but most manufacturers

also offer a maxi size option. Bricks at

7 MPa are suitable for a single storey

building or boundary walls, and 10

MPa bricks for both single

and double storey.

g

an and double storey.

JANUARY 2014 THE HOME HANDYMAN 26

PAINTING

Find out why paint fails how

you can fix the problem and

prevent it altogether

P

aint is probably the most common

exterior finish used on wood, metal

and walls, says Herman Rabe, technical

service consultant at Prominent Paints. When

paint is properly applied to the appropriate

substrate, it can give a service life of up to

10 years. Herman explains that all too often,

problems occur during the application of the

paint and the paint coat fails to achieve the

expected lifespan.

Why does paint fail

prematurely?

Herman says, There are two main factors

contributing to early paint failure and we

only have control over one of these. The first

is the weather and the second is application

related. The weather is the primary reason

for paint failing and unfortunately this

is completely out of our control. Herman

explains that the suns ultraviolet rays cause

paint pigments to fade. Radiation from the

sun eventually breaks down the paint film,

which leads to chalking. The biggest enemy,

however, is moisture and temperature

changes which cause buildings to expand

and contract. These movements stress the

paint, weakening the bond between the

paint and the substrate ,which leads to

hairline cracks that quickly get bigger.

Moisture is a major problem, especially

on exterior walls, as paint is porous and

moisture can penetrate it. Its the most

Why paint fails

prematurely

By Roelof Strydom

THE HOME HANDYMAN JANUARY 2014 27

common cause of premature paint failure

on wood, metal and plastered walls, says

Herman. The paint on exterior walls is

subject to wetting by various means such

as rain and dew. Before painting its also

important to clean areas that are protected

from sunlight, like porches, eaves and walls

covered by overhangs. Herman explains

that dirty areas like these interfere with the

adhesion of the new paint.

Paint also fails due to human error.

This is when its applied incorrectly or the

incorrect paint is applied; eventually leading

to failure. It comes down to the paint not

adhering properly to the surface because

the surface has not been treated, primed or

prepared properly before applying the top

coat of paint, says Bennum van Jaarsveld,

communications manager at Dulux. Any

raw surface requires a primer. Use plaster

primer in the case of plaster or concrete,

wood needs wood primer to seal and

protect it, while metal requires a metal

primer. If there are specific problems, like

damp, these need to be addressed before

any primer and topcoat can be applied.

Other problems include the application

of too few coats, meaning the application is

too thin, or when paint is applied over dirty

or already peeling paint, which prevents

the new paint from adhering properly.

A third problem relates to the choice of

paint, such as using oil-based paint when

acrylic should be used or vice versa. People

also often choose cheap paint, for obvious

reasons, but then pay the price later as

cheap paints have inferior binders and

pigments, leading to early failure.

Fixing the problem

Always prepare the surface properly by

removing all the loose and flaky paint

from the surface, says Herman.

Wash the surface with a solution of one

part Progold General Purpose Cleaner to

10 parts water. Where fungus is present,

wash the area with Progold Fungal Wash

at a ratio of 1: 6 and allow for a reaction

time of three hours. After three hours,

scrub the area with a nylon brush or

abrasive pad and finally rinse the surface

with clean water.

Allow the surface to dry properly,

especially if it is a wood or cement

surface, before proceeding with any

paint application.

When the correct paint is properly

applied to the surface it can give a

service life of up to 10 years

Always clean and prepare the

surface before applying any

primers and topcoats

Avoid using cheap

paints because they

have inferior binders

and pigments which

can lead to early

failure of the paint

JANUARY 2014 THE HOME HANDYMAN 28

Make sure you are using the correct

primer for the surface as not all primers

are the same.

In the case of rising damp or other

moisture problems, use a reputable

waterproofing company to first correct

the waterproofing before starting with

the painting.

Always apply the primer and topcoats

according to the product specification on

the container. The product spreading rates

are printed on the back of the container

as a guideline and are there to guide

you in applying the product to standard,

ensuring the correct product performance.

When painting parapet walls, apply two

coats of Prominent Fibre Seal to the top

of parapet walls before painting.

Dont stop at one coat of your selected

topcoat. The second coat will provide a far

superior paint performance and is required

for the paint to perform as intended.

Preventing the problem

Bennum explains that you should rather

spend a bit more time preparing and

priming the surface before applying the

topcoat to make sure its protected against

moisture, dirt and rust.

Remember to adhere to the recoating

time on the container. Herman explains

that it is essential to waterproof parapet

walls and house wall areas beneath the

damp protective course. It is especially

necessary on houses where the damp

protective course is higher than the exterior

ground level. He also notes that prevention

is better than cure when it comes to the

building of a new house. It will save you a

lot of money in the long run.

Sources

Dulux, www.dulux.co.za

Plascon, www.plascon.co.za

Prominent Paints, www.prominentpaints.co.za

PAINTING

The surface must be properly

prepared before applying

paint. Metal objects require

a metal primer

Remove all loose and flaky

paint from the surface

THE HOME HANDYMAN JANUARY 2014 29

Troubleshooting paint problems

Chalking

This is when a fine powder forms on the painted surface and will present itself when

you wipe your hand over the surface. Possible causes may be the use of low grade and

highly pigmented paint or using interior paint for exterior application.

The solution is to remove as much of the powder residue as possible using a stiff

bristle brush or even a pressure washer on exterior surfaces. After the surface is clean

and dry, apply a solvent- or water-based primer and then paint the surface with a

topcoat.

Blistering

These bubbles usually indicate a loss of adhesion in areas and the subsequent lifting

of the paint film from the underlying surface. Possible causes may be that a solvent-

based paint was applied over a damp or wet surface, moisture has penetrated the

home through the exterior walls or the paint was exposed to high humidity and

moisture shortly after it had dried.

If the blisters dont extend all the way down, the solution is to remove the blisters

by means of scraping and sanding and then repaint the surface with a water-based

paint. If the blisters do extend all the way to the base material, you first need to locate

and remove the moisture source. Next, remove the blisters by means of scraping and

sanding, followed by an appropriate primer and then at least two coats of topcoat.

Crocodiling or alligatoring

This refers to patterned cracks in the surface of the paint film that resemble the

scales of a crocodile. The application of an extremely hard coating like a solvent-based

enamel over a more flexible coating like a water-based primer could be a possible

cause. Another reason for crocodiling could be that the topcoat was applied before the

undercoat was dry.

To solve this problem, the old paint needs to be completely removed. You can use

a heat gun to speed up the process. After the old paint has been removed, prime the

surface with a water- or solvent-based primer. Once the primer has dried, apply two

coats of water-based paint.

Foaming or cratering

These are tiny bubbles that form when the paint is applied. As the paint dries, these

bubbles then pop and leave small depressions, known as cratering. Shaking a partially

filled tin of paint could be a possible cause as well as applying paint too rapidly,

especially with a roller, or even applying a gloss or satin paint over a porous surface.

To prevent this from happening, buy good quality paint. All paint will foam to

some degree, but good quality paints are formulated in such a way that the bubbles

pop while the paint is still wet. Also avoid excessive rolling or brushing when applying

the paint.

Fading

Premature or excessive lightening of paint can occur on surfaces that are regularly

exposed to sunlight. Causes may be the use of paint that is vulnerable to UV radiation,

such as bright reds, blues and yellows. The use of interior paint on an exterior surface

can also lead to this problem.

Solve this problem by using quality exterior paint in colours that are

recommended for exterior use.

Chalking

Blistering

Alligatoring

Fading

Foaming/

cratering

JANUARY 2014 THE HOME HANDYMAN 30

TOOL TALK

Cut above

the rest

A circular saw is an indispensable

power tool for making long straight

cuts. Heres a look at six saws thatll

turn any sheet of wood into usable

pieces in no time

By Roelof Strydom

Available from: www.dewaltpowertools.co.za

Weight: 5.1kg

Recommended

retail price:

R1 995

Available from: www.bosch-do-it.com/za

Weight: 3.9kg

Recommended

retail price:

R1 199

This is a compact,

yet powerful 1 150W

saw with a 184mm

blade diameter and

no-load speed of

5 000rpm. It is able

to reach a cutting

depth of 65mm at

0 and has a maximum

bevel capacity of 50. The

blade bore is 16mm and it has

an efficient dust extraction port to

minimise airborne dust.

This Bosch circular saw

has an ergonomic

design with a

comfortable soft

grip and weighs

only 3.9kg. It

has a 1 200W