Professional Documents

Culture Documents

HST 6000 Leaflet

Uploaded by

phucgenjiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HST 6000 Leaflet

Uploaded by

phucgenjiCopyright:

Available Formats

HST-6000 Transfer Unit

Features and Benefts

4 fnger sizes

8 fnger spacing confgurations

Quick Change Fingers

Transfers containers from 40mm to 170mm

diameter

Adjustable top and bottom ware guides

Spacing reduced by 40% through transfer

Reduced job set-up time

Enhanced container stability

Reliable cross conveyor spacing

Minimal spares holding

Consistent ware handling up to 450BPM

Intermediate fngers 12 fngers and above

For optimum performance we recommend use

with Sheppee Cross Conveyor

Recommended service Intervals 12 months

Carbon or SSB insulation

UK: T: +44 1904 608 999 E: sales@sheppee.com China: T: +86 755 8222 5976 E: sales@si-ap.com www.sheppee.com

The HST-6000 Transfer unit gives a combination of a smooth fnger motion utilising a cam

profle which reduces container impact as the bottle arrives into the transfer. The fnger

spacing is reduced by 40% through the transfer curve and combined with the precise fnger

retraction, provides accurate positioning of the container onto the cross conveyor.

This fexible transfer is the ideal multi job machine with the capability of handling a large

range of container diameters.

UK: Halifax Way, Airfeld Business Park, Elvington, York, YO41 4AU

T: +44 1904 608 999 F: +44 1904 608 777

E: sales@sheppee.com

China: Sheppee-AP Sales & Support Centre, Shenzhen, China,

T: +86 755 8222 5976 E: sales@si-ap.com

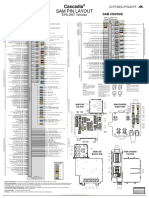

Variable and Consumable Item Identifcation Chart

Standard Finger Assembly

Part Number Description

HST-6018-01-L/R Size 01 Finger Assembly

HST-6018-03-L/R Size 03 Finger Assembly

HST-6018-EXT-L/R Extended Finger Assembly

HST-6015-L/R Intermediate Finger

HST-117-01 Size 01 Pusher Pad

HST-117-03 Size 03 Pusher Pad

HST-117-EXT Extended Pusher Pad

HST-079 Back Pad

Tall Ware Finger Assembly

Part Number Description

HST-6014-01-L/R-HW Tall Ware Finger Assembly

HST-6015-03-L/R-HW

HST-6014-EXT-L/R-HW

HST-6015-L/R-HW Intermediate Tall Ware Finger

HST-117-01 Size 01 Pusher Pad

HST-117-03 Size 03 Pusher Pad

HST-117-EXT Extended Pusher Pad

HST-079 Back Pad

Finger for 3 Spacing

Part Number Description

HST-6021-L/R Finger Assembly

HST-117-30 Pusher Pad

HST-132 Back Pad

Lower/Upper Ware

Guide

HST-140A

Lower/Upper Ware

Guide

HST-140B

Support Block

HST-006

This page folds in

HST-6000 Transfer Unit

UK: T: +44 1904 608 999 E: sales@sheppee.com China: T: +86 755 8222 5976 E: sales@si-ap.com www.sheppee.com

HST-6000 Transfer Unit

90 Chain

C262-008

www.sheppee.com

Container size limits

For Stainless Steel Braid add SSB to the part number.

Special

Chain

For all additional parts refer to assembly

drawings.

Carbon - Standard

Tall Ware

Using exactly the same chassis and principles

of the standard HST, the Tall Ware Version of the

HST was initially a customer-driven development,

designed to improve the transferring of tall bottles which

had a higher than normal centre of gravity.

By doubling the amount of support area by increasing the

fnger height and by pushing the bottle at a higher position,

greater stability on taller bottles is achieved. A full range of fnger

spacings and confgurations, capable of handling a large range of

bottle diameters is available.

Halifax Way, Airfeld Business Park, Elvington, York, YO41 4AU T: +44 1904 608 999 F: +44 1904 608 777 E: sales@sheppee.com China: Sheppee-AP Sales & Support Centre, Shenzhen, China, T: +86 755 8222 5976 E: sales@si-ap.com

Contact Material Options

Stainless Steel Braid - Optional

HST-6000 Transfer Unit

UK: T: +44 1904 608 999 E: sales@sheppee.com China: T: +86 755 8222 5976 E: sales@si-ap.com www.sheppee.com

M

a

x

i

m

u

m

I

n

t

e

r

m

e

d

i

a

t

e

T

a

l

l

W

a

r

e

C

o

n

t

a

i

n

e

r

S

i

z

e

N

u

m

b

e

r

o

f

F

i

n

g

e

r

F

i

n

g

e

r

P

a

r

t

F

i

n

g

e

r

P

a

r

t

F

i

n

g

e

r

P

a

r

t

L

i

m

i

t

s

F

i

n

g

e

r

s

S

p

a

c

i

n

g

N

u

m

b

e

r

*

N

u

m

b

e

r

N

u

m

b

e

r

(S

ta

n

d

a

r

d

In

s

u

la

tio

n

)*

*

3

0

3

H

S

T

-

6

0

2

1

L

/

R

4

4

m

m

2

4

3

3

4

H

S

T

-

6

0

1

8

-

0

1

L

/

R

H

S

T

-

6

0

1

4

-

0

1

-

L

/

R

-

H

W

5

4

m

m

2

0

4

1

2

H

S

T

-

6

0

1

8

-

0

1

L

/

R

H

S

T

-

6

0

1

4

-

0

1

-

L

/

R

-

H

W

6

6

.

5

m

m

H

S

T

-

6

0

1

8

-

0

3

L

/

R

H

S

T

-

6

0

1

4

-

0

3

-

L

/

R

-

H

W

6

3

m

m

1

7

5

1

/4

H

S

T

-

6

0

1

8

-

0

3

L

/

R

*

*

*

7

5

m

m

1

5

6

H

S

T

-

6

0

1

8

-

0

1

L

/

R

7

0

m

m

H

S

T

-

6

0

1

8

-

0

3

L

/

R

H

S

T

-

6

0

1

4

-

0

3

-

L

/

R

-

H

W

8

2

m

m

1

2

7

1

2

H

S

T

-

6

0

1

8

-

0

3

L

/

R

H

S

T

-

6

0

1

5

L

/

R

H

S

T

-

6

0

1

4

-

0

3

-

L

/

R

-

H

W

1

0

6

m

m

1

0

9

H

S

T

-

6

0

1

8

-

E

X

T

H

S

T

-

6

0

1

5

L

/

R

1

2

0

m

m

6

1

5

H

S

T

-

6

0

1

8

-

E

X

T

H

S

T

-

6

0

1

5

L

/

R

1

7

0

m

m

*

F

o

r

S

S

B

(

s

t

a

in

le

s

s

s

t

e

e

l

b

r

a

id

)

o

p

t

io

n

,

a

d

d

-

S

S

B

t

o

t

h

e

e

n

d

o

f

t

h

e

p

a

r

t

n

u

m

b

e

r

.

*

*

W

h

e

n

u

s

in

g

S

S

B

in

s

u

la

t

io

n

,

c

o

n

t

a

in

e

r

s

iz

e

lim

it

s

s

h

o

u

ld

b

e

r

e

d

u

c

e

d

b

y

2

m

m

.

*

*

*

A

H

S

T

w

it

h

1

7

F

in

g

e

r

s

r

e

q

u

ir

e

s

a

s

p

e

c

ia

l

C

h

a

in

T

r

a

c

k

H

S

T

-

1

1

5

L

/

R

a

n

d

C

h

a

in

H

S

T

-

6

0

1

0

-

1

7

.

F

i

n

g

e

r

S

p

a

c

i

n

g

O

p

t

i

o

n

s

HST-6000 Transfer Unit

Technical Specifcations

Operating speed: Up to 450BPM

Chain length: 90

Chain pitch: 34 Duplex

Number of teeth on

drive sprocket: 24

Chain movement per

revolution of

drive shaft: 18

Installation Details and Service

Requirements

Connection to Lincoln lubrication

Can be driven by servo or synchronous motor

drive

Can work with all I.S. Machine drive systems

Transfer can be used in conjunction with a

Sheppee ITD-8000-2 Transfer Drive Unit or

STK-9284 Transfer Drive Gearbox

Chain Length Data

HST-6000 Transfer Unit

You might also like

- Sam Wall Chart Epa 07 and Epa 2010Document2 pagesSam Wall Chart Epa 07 and Epa 2010Jose Luis Calla Huanca94% (17)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Hilok Hitigue InstallationDocument16 pagesHilok Hitigue Installationtbiris0% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Hydraulic System Trainer AS-10Document13 pagesHydraulic System Trainer AS-10Tanlets Gery100% (1)

- Mach3 USB interface board manualDocument13 pagesMach3 USB interface board manualZal80% (5)

- Shurflo Product Guide - 41429Document23 pagesShurflo Product Guide - 41429senadbNo ratings yet

- 2 Gear LinkageGolf Mk1Document46 pages2 Gear LinkageGolf Mk1SteggosNo ratings yet

- R-30+B/R-30+B Mate/R-30+B Plus CONTROLLER OPERATOR'S MANUALDocument350 pagesR-30+B/R-30+B Mate/R-30+B Plus CONTROLLER OPERATOR'S MANUALSTEPHANY VANESSA LOMBANA ROJAS100% (1)

- Slickline-Tools Catalog en WebDocument57 pagesSlickline-Tools Catalog en Webneoamn100% (1)

- Crizaf Catalog 2004Document69 pagesCrizaf Catalog 2004ArmandoDias100% (1)

- Conveyor Screws PDFDocument9 pagesConveyor Screws PDFldavilaluceralNo ratings yet

- Cuña Neumatica Oil CountryDocument50 pagesCuña Neumatica Oil CountryGianna Frola100% (1)

- Excitation SystemsDocument22 pagesExcitation SystemsgprakasammNo ratings yet

- Equipo Pruebas de Presion LiquidosDocument5 pagesEquipo Pruebas de Presion Liquidosmfj79607555No ratings yet

- Coiled Tubing Introduction-Part 1Document109 pagesCoiled Tubing Introduction-Part 1qazim786100% (3)

- Handloader's Digest: The World's Greatest Handloading BookFrom EverandHandloader's Digest: The World's Greatest Handloading BookRating: 2 out of 5 stars2/5 (1)

- Axially Splitcase Pumps - HS & HST SeriesDocument12 pagesAxially Splitcase Pumps - HS & HST SeriesSuhas Natu100% (1)

- Technical Catalogue Low Voltage Air Circuit-Breakers: 1SDC200006D0204Document278 pagesTechnical Catalogue Low Voltage Air Circuit-Breakers: 1SDC200006D0204febinjohnNo ratings yet

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocument8 pagesTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4No ratings yet

- Solid Rivets ComparisonDocument3 pagesSolid Rivets ComparisonManoj ManoharanNo ratings yet

- Atopro PDFDocument6 pagesAtopro PDFgullenariNo ratings yet

- CAT Hose Assembly ToolsDocument6 pagesCAT Hose Assembly ToolsСергей ШевченкоNo ratings yet

- Heem-2,3 ManualDocument20 pagesHeem-2,3 Manualmaronnam0% (3)

- Proper Manipulation of The T-SquareDocument22 pagesProper Manipulation of The T-SquareGabrielle Yaya100% (4)

- AWT 1000 LeafletDocument6 pagesAWT 1000 Leafletphucgenji0% (1)

- Pushbar LeafletDocument4 pagesPushbar LeafletphucgenjiNo ratings yet

- SWT 2000 LeafletDocument4 pagesSWT 2000 LeafletphucgenjiNo ratings yet

- VFT 1000 LeafletDocument4 pagesVFT 1000 LeafletphucgenjiNo ratings yet

- RssDocument1 pageRssgenial72No ratings yet

- Mustang Series M115-7 (Globe), M1115-7 (Angle) Specification SheetDocument8 pagesMustang Series M115-7 (Globe), M1115-7 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetDocument7 pagesMustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetWattsNo ratings yet

- AWTS-1000 Transfer Unit: Features and BenefitsDocument4 pagesAWTS-1000 Transfer Unit: Features and BenefitsphucgenjiNo ratings yet

- Spray Nozzle CatalogueDocument3 pagesSpray Nozzle CataloguetdpomodoroNo ratings yet

- G-N60 choke parts and specificationsHSP art N um be rV- T C P - 1 0 2 0SSV- T C P - 1 0 2 2S S /T CV- T C P - 1 0 2 4HSV- T C P - 1 0 2 6Document7 pagesG-N60 choke parts and specificationsHSP art N um be rV- T C P - 1 0 2 0SSV- T C P - 1 0 2 2S S /T CV- T C P - 1 0 2 4HSV- T C P - 1 0 2 6Esteban Reyes100% (1)

- EnerpacDocument10 pagesEnerpacRaul CostiniucNo ratings yet

- Resolve Family Drainage CatetherDocument16 pagesResolve Family Drainage CatetherradeonunNo ratings yet

- Hilti enkuru tehnika - izvēle un pielietojumsDocument29 pagesHilti enkuru tehnika - izvēle un pielietojumsTom WinterNo ratings yet

- FM-CR CaraDocument4 pagesFM-CR Caraadirocks89No ratings yet

- Thomson Roundrail 1VC Continuously Supported SpecsheetDocument2 pagesThomson Roundrail 1VC Continuously Supported SpecsheetElectromateNo ratings yet

- 008 Choke ValveDocument3 pages008 Choke Valveyukos100% (1)

- Use With AX and BXX Hoses. Visual Index: Catalog 4400Document15 pagesUse With AX and BXX Hoses. Visual Index: Catalog 4400PartsGopher.comNo ratings yet

- 003 Casing & Tubing Hanger PDFDocument4 pages003 Casing & Tubing Hanger PDFalaliali88No ratings yet

- Jastram Model H Helm Pumps: Engineered For Life at SeaDocument2 pagesJastram Model H Helm Pumps: Engineered For Life at SeaingdanilocfNo ratings yet

- 2007 Kochek Catalog NCDocument55 pages2007 Kochek Catalog NCRené Mora-CasalNo ratings yet

- HDPEDocument14 pagesHDPEThiruThirunavukkarasuNo ratings yet

- PRH04-300 FLG PDFDocument5 pagesPRH04-300 FLG PDFengp3077No ratings yet

- PRH 04Document6 pagesPRH 04Heny MarthaNo ratings yet

- Mustang Series M115-3 (Globe), M1115-3 (Angle) Specification SheetDocument7 pagesMustang Series M115-3 (Globe), M1115-3 (Angle) Specification SheetWattsNo ratings yet

- Strippers JU y JU HDocument5 pagesStrippers JU y JU HEd CalheNo ratings yet

- MAK and S-MAK Mini Access KitsDocument12 pagesMAK and S-MAK Mini Access KitsradeonunNo ratings yet

- HiP Gen CatDocument144 pagesHiP Gen CatÁlvaro Conti FilhoNo ratings yet

- Spir Star Valves & Fittings PDFDocument26 pagesSpir Star Valves & Fittings PDFMidfiild CosminNo ratings yet

- Distribution Manifolds FINALDocument8 pagesDistribution Manifolds FINALSrta IncognitaNo ratings yet

- Wellheads Xmas Trees ValvesDocument29 pagesWellheads Xmas Trees ValvesAbdul Hameed OmarNo ratings yet

- Belt Conveyor Manufacturers - Ultimation IndustriesDocument2 pagesBelt Conveyor Manufacturers - Ultimation IndustriesUltimationNo ratings yet

- Refco ToolsDocument28 pagesRefco ToolsTinosNo ratings yet

- Thermostat System Controller OptionsDocument62 pagesThermostat System Controller OptionsJokanoe LertNo ratings yet

- Section 31Document13 pagesSection 31Fabian LopezNo ratings yet

- Vectra VX-FT Single Swivel Pulley PL PDFDocument7 pagesVectra VX-FT Single Swivel Pulley PL PDFEdivaldo Santos LimaNo ratings yet

- Promocion BGS TECHIC 2016 2 / Bgs Aktion 02 2016 enDocument44 pagesPromocion BGS TECHIC 2016 2 / Bgs Aktion 02 2016 enHERRAPRONo ratings yet

- Technical Information General Description Series 6F: 3300-Colorflow - Indd, DDPDocument2 pagesTechnical Information General Description Series 6F: 3300-Colorflow - Indd, DDPPartsGopher.comNo ratings yet

- HIP на 30000-60000 psiDocument15 pagesHIP на 30000-60000 psitoxa0707No ratings yet

- LSC SeriesDocument4 pagesLSC SeriesshadowmastrNo ratings yet

- Relief Valves (RH4 Series) : Catalog 4131-RH Revised, April 2001Document6 pagesRelief Valves (RH4 Series) : Catalog 4131-RH Revised, April 2001Azhar AhmadNo ratings yet

- Classic Series F115-74 (Globe), F1115-74 (Angle) Specification SheetDocument7 pagesClassic Series F115-74 (Globe), F1115-74 (Angle) Specification SheetWattsNo ratings yet

- Air Valve CatalogDocument58 pagesAir Valve CatalogJohn Holding100% (2)

- Reg RedQ Specialy Regulators PDFDocument20 pagesReg RedQ Specialy Regulators PDFDavid SaldarriagaNo ratings yet

- DP70 Universal Input Indicator ManualDocument17 pagesDP70 Universal Input Indicator ManualphucgenjiNo ratings yet

- Triflex 3axis LeafletDocument4 pagesTriflex 3axis LeafletphucgenjiNo ratings yet

- Ware Steady-Upgrade KitDocument1 pageWare Steady-Upgrade KitphucgenjiNo ratings yet

- T2 3axis LeafletDocument4 pagesT2 3axis LeafletphucgenjiNo ratings yet

- Sheppee FolderDocument5 pagesSheppee FolderphucgenjiNo ratings yet

- T2 3axisDocument1 pageT2 3axisphucgenjiNo ratings yet

- Shear Blades LeafletDocument4 pagesShear Blades LeafletphucgenjiNo ratings yet

- Table Ware Drive LeafletDocument2 pagesTable Ware Drive LeafletphucgenjiNo ratings yet

- StainlessSteelBraid (SSB)Document2 pagesStainlessSteelBraid (SSB)phucgenjiNo ratings yet

- MRS-9000 2axis LeafletDocument4 pagesMRS-9000 2axis LeafletphucgenjiNo ratings yet

- Customer Support LeafletDocument4 pagesCustomer Support LeafletphucgenjiNo ratings yet

- FT 7000 LeafletDocument6 pagesFT 7000 LeafletphucgenjiNo ratings yet

- ITD 8000 2 LeafletDocument2 pagesITD 8000 2 LeafletphucgenjiNo ratings yet

- Tai nghe chống ồnDocument11 pagesTai nghe chống ồnphucgenjiNo ratings yet

- CCA 1200 LeafletDocument4 pagesCCA 1200 Leafletphucgenji100% (1)

- INT ABB Emax Power BreakersDocument63 pagesINT ABB Emax Power Breakerscarlos vidalNo ratings yet

- AWTS-1000 Transfer Unit: Features and BenefitsDocument4 pagesAWTS-1000 Transfer Unit: Features and BenefitsphucgenjiNo ratings yet

- Engineering Silence: Active Noise Cancellation: Michael Benoit Christopher Camastra Melissa KennyDocument12 pagesEngineering Silence: Active Noise Cancellation: Michael Benoit Christopher Camastra Melissa KennyxongassilvaNo ratings yet

- May Cat ABBDocument177 pagesMay Cat ABBHùng NguyenNo ratings yet

- ABB Circuit Breakers For DC ApplicationDocument100 pagesABB Circuit Breakers For DC ApplicationRelief_EngineerNo ratings yet

- Bai Giang Giao Tiep May TinhDocument6 pagesBai Giang Giao Tiep May TinhphucgenjiNo ratings yet

- User's Manual: 6 Channel Mixing ConsoleDocument18 pagesUser's Manual: 6 Channel Mixing ConsoleFrancisco J Rojas GNo ratings yet

- Hydraulic Gear Shift (HGS) Systems: Made by Kongsberg AutomotiveDocument4 pagesHydraulic Gear Shift (HGS) Systems: Made by Kongsberg AutomotiveFrancis QuarshieNo ratings yet

- 3 BSDocument23 pages3 BShaidahusinNo ratings yet

- S&S Cycle (E&G) Carb Twincam88Engines 51 1013Document4 pagesS&S Cycle (E&G) Carb Twincam88Engines 51 1013Jonathan BanksNo ratings yet

- 31 PDFDocument6 pages31 PDFAlejandro NarvaezNo ratings yet

- Mercedes-Benz C-Class Sedan 2014 4d Hybrid EN 205.14v2.0Document2 pagesMercedes-Benz C-Class Sedan 2014 4d Hybrid EN 205.14v2.0Ricardo Santo AntonioNo ratings yet

- VEHICLE MAINTENANCE TIPSDocument89 pagesVEHICLE MAINTENANCE TIPSjalda srikaranNo ratings yet

- Jszv8-12r Voltage Transformer - Shenzhen Chuangyin Co., LTD - Option 1Document2 pagesJszv8-12r Voltage Transformer - Shenzhen Chuangyin Co., LTD - Option 1redaNo ratings yet

- Working Principle of TransformerDocument4 pagesWorking Principle of TransformerMylz MendozaNo ratings yet

- ID-N-CG-YY4-PRT-PL-25-0002 - Constructability Review ReportDocument16 pagesID-N-CG-YY4-PRT-PL-25-0002 - Constructability Review ReportadjiNo ratings yet

- Scaffolding Definition Types Parts Design Materials and Hazards of Scaffolding PDFDocument6 pagesScaffolding Definition Types Parts Design Materials and Hazards of Scaffolding PDFRahmanNo ratings yet

- Display TechnologyDocument63 pagesDisplay Technologyanalog changeNo ratings yet

- Mine Master Production Master 2.3 RigDocument2 pagesMine Master Production Master 2.3 RigAlokNo ratings yet

- Reduce RsDocument73 pagesReduce RsbangpaiNo ratings yet

- GC30 assembly instructionsDocument5 pagesGC30 assembly instructionsDalibor DanevskiNo ratings yet

- Manual Do HAD4006 (6880101W80-B)Document8 pagesManual Do HAD4006 (6880101W80-B)Cheiston FigueiredoNo ratings yet

- AT400T41T M.Y. 2013 Cursor 13 Euro ViDocument16 pagesAT400T41T M.Y. 2013 Cursor 13 Euro ViCesar MartinezNo ratings yet

- MZ TuningDocument24 pagesMZ TuningJawaCz100% (2)

- Angle Gauges PDFDocument2 pagesAngle Gauges PDFpankajdharmadhikariNo ratings yet

- Problem Set 6 SolutionsDocument5 pagesProblem Set 6 SolutionsKrupali ShahNo ratings yet

- Bill of Materials - Sheet1Document1 pageBill of Materials - Sheet1api-598103816No ratings yet