Professional Documents

Culture Documents

Recent Advances in Materials For Use in Permanent Magnet Machines - A Review

Uploaded by

vishiwizardOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Recent Advances in Materials For Use in Permanent Magnet Machines - A Review

Uploaded by

vishiwizardCopyright:

Available Formats

Recent Advances in Materials for use in Permanent Magnet Machines - A Review

Uday S. Deshpande

Black & Decker (US.), Inc.

701 East Joppa Road

Towson, MD 21286

Abshuct - A review of the statwf-theart in materials used

io permanent magnet machines is presented. On-going research

lor new materials is also discussed. Io the end, the impact of

these and the upcoming materials on motor design ls disenssed.

I. INTRODUCTION

With the increasing use of motors in the automotive sectors

and the wide variety of applications that are involved, the

demands on the materials have changed. In the automotive

industry today, there is an increasing trend towardsa more

electric car. Increasing numbers of features in the modem

automobile are being motorized. It is said that there are an

average of 30 electric motors per car today with the number

likely to increase to over 100 by the end of this decade. The

applications runthe gamut fromwindow-lift actuators, power

seats, power doors, antilock brakes, electric power steering,

integral starter-altemator to the main traction motor in

electric vehicles. In meeting the various performance and

cost requirements, the materials used in the motors need to

evolve as well.

This paper reviews the recent developments in materials

for use in permanent magnet machines. In patticular,

permanent magnet materials and soft magnetic materials are

discussed

The permanent magnets are broadly classified as

ferrites, AlNiCo, or rare earths (including Samarium Cobalt

(SmCo) and Neodymium-Iron-Boron (NdFeB)). This paper

ignores AlNiCo and only briefly looks at SmCo because of

their very limited use in automotive applications. The typical

range of properties for ferrite and %eo grades is shown in

Fig. 1.

Femta are typically Barium Femte or Strontium

Femte and can be made by injection or compression molding

or sintering with the properties typically increasing to

remnant flux density B, of 4kG, intrinsic coercivity H, of

4kOe and maximum energy product BH- of - 5MGOe.

These magnets have poor low temperature properties and a

reasonably high Curie temperature of - 450C. The magnets

are low cost and the technology is well established.

Rare-earth magnets (NdFeB) can similarly be made by

injection or compression molding or sintering. This broadly

classifies themas %bonded neo or sintered neo magnets.

The bonded neo magnets have typical properties of 6.8kG

(B3, 15kOe (HJ and -10 MGOe ((BH)-). They have

poorer properties at higher temperatures but perform well at

lower temperatures compared to the ferrite magnets. Sintered

0 5 10 15 20 25 30

Hci W)

Fig. I - Range ofpmpcrtics of the diffeml -el grades

ne0 magnets have typical properties of 12kG (BJ, 20kOe

(HJ and - 30MGOe ((BH)-) and like the bonded neo types

have poorer properties at higher temperatures. They typically

can handle temperahues higher than the bonded ne0 magnets

but are limited by the relatively lower Curie temperature of

-320OC. Neo magnets are more expensive than the ferrite

magnets.

Note: It may be a little misleading to list the typical

properties as above because of the range that these magnets

cover as is evident fromFig. 1.

Soft magnetic materials have been fairly unchanged over the

years. Cold rolled magnetic lamination ( C W ) is still

widely used, as is silicon-based iron with the various

additives. These are characterized primarily by core loss

(Wkg) and permeability. Typical properties are - SWkg for

core loss and a permeability of - 2000 at 15kG and 50/60 Hz.

II. NEW DEVELOP-

In the opinion of the author, most of the major

developments in recent times have been in permanent

magnets. Soft magnetic materials have seen improvements in

processing for ease of manufacturing and corrosion resistance

but tittle has changed at the fundamental property levels.

(Materials like Co-Fe and Vanadium Permandur are not

considered due to their lack of use in automotive

applications). One change is in Soft Magnetic Composites

(SMC) and this will be discussed shortly.

0-7803-78 17-2/03/1,17.W 02003 IEEE 509

Authorized licensed use limited to: INDIAN INSTITUTE OF TECHNOLOGY DELHI. Downloaded on October 10, 2008 at 08:48 from IEEE Xplore. Restrictions apply.

A. Permanent Magnets

FromFig. 1 we see that there is a gap between ferrite and

bonded ne0 magnets and again between bonded ne0 and

sintered neo magnets. Femte magnets are the lowest cost but

also have the lowest properties of the magnets under

consideration here. Bonded ne0 magnets address some of the

concems of femtes but are more expensive and are limited at

higher temperahues. Sintered neo have highest properties as

well as cost and are also limited by temperature. Ne0

magnets are also affected by corrosion, which necessitates

special corrosion resistant coating prior to use. Most of the

development has been to bridge these gaps.

I. Ferrite Magnets

The low cost ferrite magnets have been the ones

primarily used in automotive applications but bonded ne0

magnets are making in-roads intot hi s domain by focusing on

enhancing their higb temperature pmpenies and lowering

cost The main issue with ferrite magnets has been the

relatively lower properties (B,, a,, and BH& and the

tendency to face demagnetization at lower temperatures.

This last feature is a concern in automotive applications

where operation at -40C is routinely required. In response,

the femte magnet developers have focused on increasing

magnet strength and low temperature capabilities. One

approach has been the use of additives such as Cobalt (CO)

and Lanthanum-Cobalt (LatCo) to the base powder.

Addition of CO essentially increases B, while maintaining H,

while the addition of La +CO increases both B, and H,. This

is typically done for sintered femtes. Fig. 2a shows range of

ferrite magnets fiom Groupe Carbonne LorraineilJgimag.

The figure shows the grade where only CO is added and the

grades where both La- is added. The sintered femtes with

CO or LaKo additives reach a B, of 4300 - 4500 Gauss and

H, Of 4000 - 5000 Oe.

U. Bonded Nea Magnets

The primary issue with bonded ne0 is achieving full

densification and good higb temperature performance. The

use of a plastic binder material causes a reduction in the

achievable density and a limitation of the maximum operating

temperature. Addi ti ~~l l y, bonded ne0 magnets fall between

sintered femtes and sintered neo. The effort then has been to

address both ends of the spectrum - reduce cost to compete

with ferrite magnets and increase the operating temperature

rating as well as magnetic properties to compete with the

sintered neo magnets.

Magneqnench, the cbief producer of the bonded ne0

powder has been working in both these regards.

Improvements in processing the powder as well as other

strategic decisions have helped address cost issues and

improvements in processing and advancements in coating

technologies have helped address performance issues.

Magnequench in conjunction with Daido Steel Co. recently

announced the development of new anisotropic powders

using the Magnequench rapid quenching process along with a

special plastic deformation process that resulted in magnets

with BH,, of 22MGOe with maximum operating

temperature of 100C and BH, of 17MGOe with maximum

operating temperature of 125T [l], [9].

Another candidate for making bonded neo magnets is

the so-called HDDR process initially developed by

Mitsubishi Materials Co. NdFeB powder is subjected to

hydrogen under pressure (hydrogenation), which causes the

powder to become very brittle (disproportionation) and thus

allows milling to fmer particles. The hydrogen is then

desorbed and the NdFeB recombined to produce anisotropic

bonded ne0 magnets with energy product of around

ISMGOe. Recently Aichi Steel Corp. reported a modified

HDDR process called the d-HDDR where they controlled the

pressure at which the hydrogenation takes place. This

allowed themto achieve greater anisotropy and makebonded

ne0 magnets with a BH, of - 25MGOe [l].

Group ho l d uses a different approach in their bonded

magnets offering where a femte-neo blend is used. In these

ferrite-neo hybrids, NdFeB powder is blended with the

strontium (or barium) ferrite. This results in isotropic

magnets in which the ferrite and NdFeB compensate each

others temperature characteristics and provide a more

temperature stable magnet. The cbaracteristics are affected by

the relative percentages of the blends. This is shown in Fig.

2b. These magnets address both the increased flux

requirement and increased temperature resistance

requirement but are weaker than the bonded ne0 magnets

described above [4].

III. Sintered Ne0 Magnets

Developments in sintered ne0 mapets have focused on

improving strength and high temperature capability. With the

increasing use of high powerhigh performance automotive

applications like eleceic power steering, integrated starter

alternator, mction motors for EV/HEV, the demand for high

temperahue performance has increased. With a Curie

temperature of - 320C, this has been a challenge. Recently

Sumitomo reported magnets capable of operation up to 2ZOT

with 250C capable magnets also being developed [I], [8].

From a strength point of view, the theoretical m

energy product for a single NdlFel.BI crystal is 64MGOe.

This gives a B, of about 1.6T. Recently Kaueko (Sumitomo)

and Rodewald (Vacumschmelze) reported magnet properties

in the neighborhood of 15.19kG ( B3, 9.8kOe&) and

56MGOe (BH-) [l], [2], [3], [SI. They achieved this by

optimizing the alloy composition, improved domain

alignment by the use of alternating pulsed orienting field and

optimizing the sintering conditions to optimize the

microstructure of the magnets. These values are close to the

practical limit for sintered NdFeB magnets.

A major thrust in research has been in processing to

improve domain alignment and powder purity to achieve the

high performance magnets. Another area of focus has been

510

Authorized licensed use limited to: INDIAN INSTITUTE OF TECHNOLOGY DELHI. Downloaded on October 10, 2008 at 08:48 from IEEE Xplore. Restrictions apply.

, - _. _..-

Fig. 2b - "Farite-NCO" mapel material from Group h o l d 141.

511

Authorized licensed use limited to: INDIAN INSTITUTE OF TECHNOLOGY DELHI. Downloaded on October 10, 2008 at 08:48 from IEEE Xplore. Restrictions apply.

to improve the temperature capability. The use of

dysprosium is cmmon to increase H, but this is an

expensive element. Materials processing to use other

elements in place of Dy are being studied to address this issue

as well. Fig. 3 shows the range of properties for sintered neo

magnets fromShinEtsu Magnetics [7]. The line is the l i t

on properties that can be reasonably achieved in the opinion

of the author.

Corrosion has been a major issue for NdFeB magnets.

Various coatings have been studied and developed and has

largely ameliorated t hi s concern. In recent times, the use of

hydrogen fuel cells bas created a new concern for corrosion

protection. Hydrogen is extremely corrosive to NdFeB, a fact

that is exploited in the HDDR process. Outside of that, the

effect is detrimental. ShhEtsu Magnetics bas repoIted

development of a new coating that has shown promise in

protecting against hydrogen [7]. More details on this new

coating are forthcoming. Typical coatings used are epoxy

coating, nickel plating, a l u " chromate ion vapor

deposition. The relative merits are based on the application.

In the opinion of the author, the aluminum ion vapor

deposition with chromate coating works very well for

automotive application offering good corrosion resistance,

good adhesion properties and good dimensional control.

Most voice coil motor magnets tend to use nickel coating and

the epoxy coating tends to be acceptable for general industrial

applications.

W. Other Materinls

Other developments have been to get away fkomNdFeB

base to counter supply issues as well as extend the l i ts that

are inherent. In this regard, work is being done using

Sm2Fe17N3 (Samarium Iron Nitride (SmFeN)). Its properties

can theoretically surpass those of NdFeB but the processing

is much morecomplex and not yet suitable for commercial

production. Sumitomo Metal Miniig CO has produced

injection molded isotropic SmFeN magnets with an energy

product of - 15MGOe by a reduction & diffusion process.

Work is on going in the study of magnets made with a

combination of SmFeN/FeN and it bas been reported that

properties of SmFeNFeN combmation can theoretically

reachanenergyproductof I5OMGOeandaB.of2.IT [SI.

Nanocomposites (combmation of had and soft

magnetic materials) are another development where the

potential for very high-energy product exists. Soft magnetic

material is added to the hard phase to reduce dependence on

the rare-earth elements. The high saturation magnetization of

the soft phase and the high anisotropy of the hard phase

combine to offer the potential for BH, approaching

-90MGOe. Prof. Sam Liu of the University of Dayton

reported making powder level samples with a BH,, of

93MGOe [I], [Z]. Recently (February 2003), Prof. Liu

reported making nanocomposite magnets with a BH- of

35MGOe 161. The research seems to hold the promise of

living up to its potential but more development is needed

Samarium Cobalt magnets are briefly mentioned for

their inherent ability to operate at high temperatures.

Currently the strongest SmCo magnet is -28MGOe and can

operate up to -3OOOC. SmCo magnets capable of operating up

to 500C have been reported by Electron Energy Magnets

having hear 2" quadrant B-H characteristics up to the

operating temphue limit. On going research is focussed

on increasing the maximumenergy product over 30MGOe

and developing temperature compensated SmCo magnet

grades for operation up to 50OoC [l], [Z]. Fig. 4 shows the

historical progress of rare earth magnets.

Years

Fig.4DNClopmntsinrarc-earthma%nctsovertheycars(CaunesyOfPmf:

S. Lis. University of Dq"

B. Sop Magnetic Materialr

As mentioned earlier, there bas been no fundamental

change in soft magnetic material other than processing. Most

of the development in this area has been to improve

production process to increase consistency, develop better

coatings, and reduce costs. The limits on the steel arethe

same -peak saturation flux densities for the CRML grades of

- 2T and peak permeability of 2000-3000 at 1.ST. The core

loss is a fimction of composition, thickness, processing and is

typically 5Wkg. As mentioned earlier, Co-Fe steels and the

like are not considered here due to their relatively specialized

use.

The one new development has been in soft magnetic

composites where iron particles of -150pm in size coated

with a thin inorganic surface insulation along with various

organic additives are pressed in a die and then annealed and

cured to formthe desired pari (e.g. stator of the motor). This

material has inherently lower permeability (- 500) and

saturation flux density (1.8T) than lamination steel and

slightly bigber core loss (- 10WKg). It also has a lower

mechanical strength compared to lamination steel [lo], [I ll.

Fig. 5 compares typical B-H curves for lamination steel and

SMC material.

The lower initial permeability and the lower saturation is

easily seen fromFig. 5. Despite the seeming drawbacks of

this material it offers some interesting features and

possibilities for making motors. Due to its manufacturing

512

Authorized licensed use limited to: INDIAN INSTITUTE OF TECHNOLOGY DELHI. Downloaded on October 10, 2008 at 08:48 from IEEE Xplore. Restrictions apply.

process, it is easy to make complex shapes while maintaining

good dimensional tolerances. The 3-D nature offers the

possibility of sue and weight savings by allowing shapes that

are optimized for the application.

Lamination stee 6 SMC material B n cum* Comparison

2.5 7

m

material

Fig. 5 Camparison of typical B-H CY" for l a " steel a d SMC

Prof. Alan Jack of the University of Newcastle upon

Tyne is heavily involved in research using this material and

had published several papers showcasing the capabilities of

the soft magnetic composite material [IO], [ll], [12]. Recent

reports by other authors have discussed the use of SMC in

various applications in automotive, home appliances,

industrial applications. Use of SMC in different motor types

has also been reported [12].

There are certain applications where the material use

offers some benefits not obtained from conventional

lamination material. While this material holds promise, it is

by no means a replacement for the conventional lamination

steel. A lot of research is ongoing to exploit the properties of

this material.

It was mentioned earlier in the paper that no major

developments have occurred in conventional lamination

steels. By this it is meant that nothing has happened that has

allowed low carbon, low silicon steel to have saturation flux

density of 2.5T or have an an-hysteretic B-H loop. This is at

least not in the knowledge of the author.

Most of the work has been to improve processes to

increase consistency in steel properties, reduce core loss by

improved purity, development of new and improved surface

coatings and in general to improve the usability of the steel.

A lot of development has taken place in these areas.

European Electrical Steels has reported activities in the above

areas in developing low loss steels that they market under the

Polycor brand [13].

Following the foregoing discussion, Fig. 6 shows the new

map showing the ranges of the various permanent magnet

materials.

60

50

10

0

Distribution of Magnet grades and their relative properties

I - I

0 5 10 15 20 25 30

Hci (kOe)

Fig. 6: Ranges of various magnetp d e s

the size of the motor for a given power size or provide more

power for the same motor size. An example is given for a

111. IMPACT ON MOTOR DESIGNS

surface PM motor. The baseline numbers are for a motor with

35Mme sintered N G ~ ~ magnets p, =1,23~, H, =21koe,

BH, =35MGOe). The best sintered NdFeB magnet

The basic impact of magnet properties on motor design is

well known - a stronger magnet offers the potential to reduce

513

Authorized licensed use limited to: INDIAN INSTITUTE OF TECHNOLOGY DELHI. Downloaded on October 10, 2008 at 08:48 from IEEE Xplore. Restrictions apply.

reported to date (Rodewald, B. =1.519T, H, =9.8kOe,

BH,. =56.7MGOe) is used and the impact on motor size

and performance compared in per unit numbers.

It is seen from Table I that the 23% increase in B, offers

a - 20% increase in output or a -20% reduction in size

(length). In the above study the diameters and winding were

unchanged. The data is at m m temperature (25C). The flux

densities are obviously higher and so will be the saturation

effects. This is reflected in the higher torque ripple numbers.

TABLE I

COMPARISON ofMOTOR PARAhETER5

With the advent of the new materials there are lot of

choices for the motor designer. At the same time, it is

important that the material characteristics be properly

understood so as to optimize the design. In addition to

material, new processing techniques have been developed

that offer additional possibilities.

With the new materials, new process can bedeveloped to

take full advantage of their capabilities and perhaps simplify

and economize the production process. Conventional bonded

magnets have been used as rings made by exhusion, injection

or compression molding. Matsushita Electric Industrial Co.,

has reported the use of rolled flexible bonded magnets for

small motors, molding magnet material directly on to the

rotor back iron or even molding the magnet material into

pockets in a rotor core for IPM motors [l], 121. In doing so

they report new techniques for manufacturing motors with the

new types of magnets that offer advantages in size, process

and perhaps cost over the conventional techniques of motor

manufacturing.

From a design aspect, the temperature and the B-H

characteristics of the new magnets have to be considered but

also the manufacturing process. Manufacturing a motorhotor

where the magnet material is directly bonded on to the rotor

iron for example, results in end magnet propelties beiig

different from magnet powder properties. This needs to be

taken into consideration during the motor design process to

ensure proper motor design.

The use of SMC materials is a very good example of the

above comments. Due to its inherent isotropic, "3-D" nature,

conventional design methodologies will not provide the best

design for a motor using SMC materials.

The higher strength magnets (flux output and high

temperame capability) are key elements in providing

reasonable motor designs to facilitate the automotive

applications needs. These magnets enable high power

density, compact motor designs for electric power steering,

traction motor for EV/HEV as well as other applications

where the tight confies of the automotive under-the-hood

dictate the package size. The new bonded neo magnets will

help provide means to address applications that need similar

compact motors for applications that arenot as high power.

In the end, it all boils down to cost. For automotive

applications, the cost for the neo magnets would have to

continue to decrease. Bonded ne0 magnets need to approach

the cost of femte magnets and sintered neo magnets need to

approach the current cost of bonded ne0 magnets. There is a

txend along these lines but the costs have to drop more to

ensure wide acceptance and use.

N. CONCLUSIONS

This digest has attempted to provide an insight into

the new materials available for PM motor designers. Some

discussion and thoughts on the impact of these materials has

been provided. Some thoughts on magnets costs have also

been made. The new materials can be helpful in facilitating

motorized applications for a wide range of automotive needs.

ACKNOWLEDGMENTS

The author gratefully acknowledges James Krajczynski

of Globe Motors for his help and discussions.

REFERENCES

[I ] G.C. Hadjipanayis, M.J. Bonder, Eds. h o c . Of I Th

Intemational workrhop on Rare Earth Magnets and their

Applications, Delaware USA Aug. 2002,

[2] H. Kaneko, M. Homma, M. Okada, Eds. Proc. Of Is"

Intemational workrhop on Rare Earth Magnets andtheir

Applications, Aug. ZOM), Sendai, J apan

[3] Gorham Advanced Materials, Permanent Magnet $stem

& Power Electronics for Motion Control, September

2002, Cincinnati, on USA

[4] P. Campbell, Magnetics Tutoriol, magnetweb.com

[ 5] Magnet Catalogs, Websites of Sumitomo & Ugimag

OlnD://www.sumitomosma.co~,

(hitu://www.carbonelorraine.com/urrimag), 2002.

2002

[a] S.Liu, Private Communications, University of Dayton,

[7] T. Minowa, Private Communications, Shin Etsu, 2002

[ 8] Y. Matsuura, Y.Kaneko, Private Communications,

Sumitomo, 2002

191 G. Riley, A. Albers, Private Communications,

Magnequench, 2002

[IO] P. Jansson, A. Jack, Magnetic Assessment of SMC

Materials, Proc. Of the 21'" Annual Conf. On Properties

and Applications of Magnetic Materials, IIT Chicago,

May 2002

[I I] A.G. Jack, "Experience with the use of soft magnetic

composites in electrical machines," Proceedings of

ICEM-98, Istanbul, pp. 1441-1448.1998.

514

Authorized licensed use limited to: INDIAN INSTITUTE OF TECHNOLOGY DELHI. Downloaded on October 10, 2008 at 08:48 from IEEE Xplore. Restrictions apply.

[12] A. Jack, B. Mecrow, P. Dickinson, C. Madison, D.

Stephenson, T. Evans, J. Burdess, Soft Magnetic

Composites - An Examination of Potential, courtesy

Hoganas.

1131 A. Coombs, Improved l ow loss high permeability

gades, processing and properties, J. Phys. W, France 8,

pp. 475-482

515

Authorized licensed use limited to: INDIAN INSTITUTE OF TECHNOLOGY DELHI. Downloaded on October 10, 2008 at 08:48 from IEEE Xplore. Restrictions apply.

You might also like

- ACM2 TAU Datasheet enDocument5 pagesACM2 TAU Datasheet envishiwizardNo ratings yet

- Part Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisDocument6 pagesPart Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisIjabiNo ratings yet

- ReadmeDocument4 pagesReadmevishiwizardNo ratings yet

- TRL Definitions PDFDocument1 pageTRL Definitions PDFBHARadwajNo ratings yet

- 50 SCS Automotive Coatings - Rev0913Document4 pages50 SCS Automotive Coatings - Rev0913vishiwizardNo ratings yet

- Jeas 1012 787Document5 pagesJeas 1012 787vishiwizardNo ratings yet

- LJLVJK LVJJV LKJVDocument5 pagesLJLVJK LVJJV LKJVvishiwizardNo ratings yet

- Hardware Inloop Simulation IEEE LabVIEWDocument1 pageHardware Inloop Simulation IEEE LabVIEWvishiwizardNo ratings yet

- Electric Vehicle Motor Design NotesDocument131 pagesElectric Vehicle Motor Design NotesvishiwizardNo ratings yet

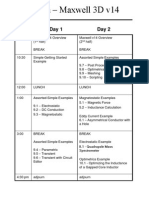

- Maxwell 3D v14 Training AgendaDocument1 pageMaxwell 3D v14 Training AgendavishiwizardNo ratings yet

- Engineered PlasticsDocument61 pagesEngineered Plastics고병석No ratings yet

- 5 SmanualDocument16 pages5 SmanualMark ThomasNo ratings yet

- Op - XT546 246 346 - Op288 V03Document2 pagesOp - XT546 246 346 - Op288 V03vishiwizardNo ratings yet

- Nit 3600 1Document5 pagesNit 3600 1vishiwizardNo ratings yet

- Big Energy Series 11.5.2012 Qing-Chang ZhongDocument1 pageBig Energy Series 11.5.2012 Qing-Chang ZhongvishiwizardNo ratings yet

- FAB Resistivity White PaperDocument8 pagesFAB Resistivity White PapervishiwizardNo ratings yet

- Presentation 1Document1 pagePresentation 1vishiwizardNo ratings yet

- Maxwell 2dDocument7 pagesMaxwell 2dvishiwizardNo ratings yet

- Brushless Motor FundamentalsDocument13 pagesBrushless Motor FundamentalsvishiwizardNo ratings yet

- Electrical Resin BenefitsDocument2 pagesElectrical Resin BenefitsvishiwizardNo ratings yet

- FTF Aut f0234Document38 pagesFTF Aut f0234vishiwizardNo ratings yet

- Wittich2011 SonkusaleVanderveldeDocument1 pageWittich2011 SonkusaleVanderveldevishiwizardNo ratings yet

- Cam DesignDocument13 pagesCam DesignvishiwizardNo ratings yet

- Lit Survey RamamurthyDocument9 pagesLit Survey RamamurthyvishiwizardNo ratings yet

- How to Check a MOSFETDocument2 pagesHow to Check a MOSFETvishiwizardNo ratings yet

- Sona SPEED CatalogueDocument13 pagesSona SPEED CataloguevishiwizardNo ratings yet

- Sensors Used in HEVDocument4 pagesSensors Used in HEVvishiwizard100% (1)

- Motor Primer1Document2 pagesMotor Primer1vishiwizardNo ratings yet

- A Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesDocument1 pageA Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesvishiwizardNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Vol88 PDFDocument32 pagesVol88 PDFArnold Thamrin van LutteranNo ratings yet

- Permanent Magnet Motor Drives With Switched Stator WindingsDocument315 pagesPermanent Magnet Motor Drives With Switched Stator Windingsrasim_m1146No ratings yet

- Properties of Magnets Magnets: - RoundDocument1 pageProperties of Magnets Magnets: - Roundtushar7000No ratings yet

- Samarium Cobalt Magnets DatasheetDocument6 pagesSamarium Cobalt Magnets DatasheetOneil ZárateNo ratings yet

- 2011 Hard Magnetic Materials A PerspectiveDocument11 pages2011 Hard Magnetic Materials A PerspectivemelchequeNo ratings yet

- Temperature Effects On Permanent MagnetsDocument3 pagesTemperature Effects On Permanent MagnetsMona Mohamed SafwatNo ratings yet

- Metal Recovery From Spent Samarium Cobalt Magnets UsingDocument7 pagesMetal Recovery From Spent Samarium Cobalt Magnets UsingsonficyusNo ratings yet

- Recoma 35E: Recoma Sintered Samarium Cobalt MagnetsDocument1 pageRecoma 35E: Recoma Sintered Samarium Cobalt MagnetsNareshNo ratings yet

- Is BN 9789526040011Document116 pagesIs BN 9789526040011Sanjay JadhavNo ratings yet

- LiquifloCatalog 2009 EngineeringDocument67 pagesLiquifloCatalog 2009 Engineeringleo cejaNo ratings yet

- Seminar Report On Magnetic Materials and Application in AutomotiveDocument41 pagesSeminar Report On Magnetic Materials and Application in AutomotiveSarath Nair0% (1)

- Benchmarking of Electric and Hybrid Vehicle Electric Machines, Power Electronics, and BatteriesDocument8 pagesBenchmarking of Electric and Hybrid Vehicle Electric Machines, Power Electronics, and BatteriesMehdi Raza KhorasaniNo ratings yet

- Accessories For Acoustic Emission Systems: SpecificationDocument26 pagesAccessories For Acoustic Emission Systems: SpecificationMaria Cristina DijmarescuNo ratings yet

- Magnets Catalog 2001Document20 pagesMagnets Catalog 2001geckx100% (2)

- General Description: Magnet Selection Guide Application NoteDocument15 pagesGeneral Description: Magnet Selection Guide Application NotesekoNo ratings yet

- A Review of Magnetic Repulsion EngineDocument4 pagesA Review of Magnetic Repulsion Enginejoy 11No ratings yet

- User Manual: Dantam K. Rao Technical Director Magweb UsaDocument29 pagesUser Manual: Dantam K. Rao Technical Director Magweb Usaalok bhatnagarNo ratings yet

- Modular Chemical Pump System ISOchemDocument22 pagesModular Chemical Pump System ISOchem백종수No ratings yet

- Herbst - R2Fe14B Materials Intrinsic Properies and Technological AspectsDocument85 pagesHerbst - R2Fe14B Materials Intrinsic Properies and Technological AspectsPatrícia CanazartNo ratings yet

- Gear PumpDocument58 pagesGear Pumpsgupta_615796100% (5)

- Permanent Magnet CatalogDocument40 pagesPermanent Magnet CatalogAjit KalelNo ratings yet

- Permanent Magnet Technology in Wind Power GeneratorsDocument6 pagesPermanent Magnet Technology in Wind Power GeneratorsPaulius BruneikaNo ratings yet

- MLX90380 - Triaxis® Resolver: 1. Features and Benefits 2. Application ExamplesDocument29 pagesMLX90380 - Triaxis® Resolver: 1. Features and Benefits 2. Application Examplesdany weinfeldNo ratings yet

- Magnets for Industry: Powerful Solutions for All ApplicationsDocument50 pagesMagnets for Industry: Powerful Solutions for All Applicationssalty.mothNo ratings yet

- Magnets in Maxillofacial Prosthodontics ManuscriptDocument14 pagesMagnets in Maxillofacial Prosthodontics ManuscriptShankar arumugamNo ratings yet

- Magnetic Repulsion EngineDocument18 pagesMagnetic Repulsion EngineDarshan bsNo ratings yet

- The Magic of Magnetic Drive Pumps - July03!13!15Document3 pagesThe Magic of Magnetic Drive Pumps - July03!13!15ho-faNo ratings yet

- Dtic Ada108550Document141 pagesDtic Ada108550rasoolNo ratings yet

- Mag Drive PumpsDocument5 pagesMag Drive PumpsakkineniNo ratings yet

- Magnet Selection Homogenous Field Application Note MelexisDocument8 pagesMagnet Selection Homogenous Field Application Note MelexisCelis CedeñoNo ratings yet