Professional Documents

Culture Documents

1 s2.0 S016816990000171X Main

Uploaded by

Piyo BudiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S016816990000171X Main

Uploaded by

Piyo BudiCopyright:

Available Formats

Computers and Electronics in Agriculture

31 (2001) 1729

Measuring image analysis attributes and

modelling fuzzy consumer aspects for tomato

quality grading

Gerhard Jahns

a,

*, Henrik Mller Nielsen

b

, Wolfgang Paul

a

a

Institute of Biosystems Engineering, Bundesallee 50, D-38116 Braunschweig, Germany

b

Department of Agricultural Sciences, Agro6ej 10, DK-2630 Taastrup, Denmark

Abstract

Quality grading is done by the consumer in a fuzzy way according to his senses sight,

touch and smell. Visual appearance is the main source of information and can be broken

down by image analysis to attributes like size, colour, shape, defects and abnormalities.

Moreover, these attributes are often correlated with nutritional or other sensual quality

parameters. Starting with such basic quality attributes, with the example of tomatoes a

reasoning is proposed, mapping various fuzzy consumer aspects to overall quality classes.

The objective is to achieve an automatic rating of fruit quality, modelling consumer aspects

and producer needs. Such a mapping of fuzzy image analysis attributes to an overall visual

quality reduces destroying tests. The reasoning can easily be rearranged and optimised

according to varying consumers expectations. 2001 Elsevier Science B.V. All rights

reserved.

Keywords: Image processing; Fuzzy reasoning; Tomato quality

www.elsevier.com/locate/compag

1. Introduction

Ofcial quality denitions for fruit or vegetables are hardly more than a rough

rating on size and colour. Where the USDA grade standard for tomatoes (USDA,

1991) species six maturity stages based on the dominating colour of the tomato,

the EU standard as described by (AID, 1992) effectively has two stages: green and

* Corresponding author. Tel.: +49-531-596466; fax: +49-531-596369.

E-mail address: gerhard.jahns@fal.de (G. Jahns).

0168-1699/01/$ - see front matter 2001 Elsevier Science B.V. All rights reserved.

PII: S0168- 1699( 00) 00171- X

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 18

Table 1

Quality items as seen by the consumer

Size, colour, defects, maturity Sight

Firmness, grip, maturity Touch

Juiciness, sweetness, sourness, aroma Smell/taste

Hope for vitamins, nutrients, valuable elements Nutrients

Fear of plant protection agents, nitrate, natural toxins Toxins

red (a Dutch auction colour scale covers 12 colour classes). No objective measures

of shape are given, whereas size grading is done by measuring the largest diameter:

3035, 3540, 4047, 4757, 5767, 6782, 82102 and 102 mm and more. The

size tolerance for each interval is 2 mm. Tomatoes are divided into three classes

(class Extra, class I, and class II) based upon the overall state of the tomato

(rmness, number and extend of defects or blemishes), but most of these state

variables are not specied in an objective manner. With respect to uniformity:

tomatoes from the classes Extra and I should have the same colour and maturity.

So far with ofcial quality denitions. Clearly, the consumer is looking for more.

The produce should be appealing by sensual check (sight, touch, organoleptic, etc.),

nutritional values should be satised and security factors (residues of fertiliser or

plant protection agents as well as natural toxins) must be met. Thus Table 1 would

be the ideal denition from the consumers point of view. One has to admit, that

Table 1 contains several fuzzy denitions, items set up irrespective whether the

quality characteristics are measurable or not. So the ideal consumer quality has to

be translated into practice. The quality items in Table 1 have to be translated into

easily measurable factors.

Table 2 is a breakdown of Table 1 relating physical quality parameters to what

interests the consumer or the grower. Measurements according to Table 2 would be

a full scale quality assessment, denitely not manageable in practical production.

But with these measurements, correlation between the above parameters can be

achieved. Table 3 is a possible reduction of Table 2, relating some of these quality

parameters to image analysis. It is shown later on, that attributes of appearance

correlate also with quality parameters like rmness, sugar/acid ratio or vitamin C.

Table 2

Physical parameters related to the needs of consumers and producers

Quality aspects Properties Sensorics

Area, spectral analysis, texture, Weight, maturity, shape, position, Image analysis

curvature greenback, surface defects

Penetrometer Elasticity, hardness skin, maturity E-Modulus, rupture

Taste intensity, aroma Human team Taste limit

Sugars, vitamin C, BRIX, TOC, Photometrics, Nutritionals, sugar/acid ratio specic ions

test strips NO

3

, K

+

, Ca

2+

pH-value, conductivity Electronics Acidity, total salts

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 19

Table 3

Quality parameters related to image analysis

Image analysis attributes Consumer aspects

Weight, Area

Spectral analysis Maturity, elasticity, sugar/acid ratio, greenback

Texture Surface defects

Curvature Shape

Finally, a fuzzy rating is recommended as a basis to process such a basic

quality parameter set. Here a reduction to image analysis attributes is proposed,

but other automatically measurable parameters are easily included. The main

objective is to reduce quality assessment to few characteristics, which can be

measured by non contact and non destroying tests, preferably by image process-

ing. Only a few and random destroying extra checks are necessary then for

counter checking.

2. Image analysis and quality attributes

A standard colour camera, frame grabber and PC is used for image analysis

to measure visible quality parameters. Illumination is done in a half sphere in

order to avoid shadows. Further descriptions may be found in Nielsen and Paul

(1995). Here only the results of practical quality assessments are summarised.

2.1. Size and size distribution

Size is taken here as (1) the largest diameter the major axis and (2) the

area of a tomato viewed from above. The minor axis and perimeter measure are

needed later for computing the shape indices in the following section. The area

is computed from the 2D image of a tomato and so an estimate of the tomatos

weight/volume is achieved (Fig. 1).

The highest degree of correlation was found between area measured by image

analysis and weight measured using a scale:

W=0.0021A

1.3614

, (R

2

=0.9955) (1)

where A is the area (mm

2

) and W is the weight (g) (Eq. (1)). Using the above

relationship, the mean absolute error of weighing a tomato by determining the

area using image analysis would be 2.06% (approximately 1.8 g for 90 g

tomato). Thus, size and size distribution or weight and weight distribution can

be recorded automatically with a high degree of accuracy by image analysis.

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 20

2.2. Colour and colour uniformity

The colour of a tomato is an accepted measure for its maturity stage (Sarkar and

Wolfe, 1985a,b; Choi et al., 1995). The procedure for estimating the maturity stage

of a tomato by measuring its colour using image analysis is done by placing the

tomato on a small plate having approximately the same luminance as the

tomatoes in the illumination chamber and an RGB image is acquired. Using

colour calibration data, the RGB image, I

RGB

(i, j ), is converted to a standardised

CIE/XYZ image (Nielsen and Paul, 1995, 1996).

The result of computing is either a normalised red/green index or better the

dominating wavelength as maturity index. For some 60 Pannovy tomatoes the

result of the colour discrimination is compared to human grading, as shown in Fig.

2. Overlapping is found at maturity stages 68, thus the human grouping of the

tomatoes is not perfect.

2.3. Shape and cur6ature

The global shape measures compactness and eccentricity is estimated from the

measured parameters area, perimeter, major and minor axis as shown in Fig. 3.

This provides a simple method of judging the overall shape of tomatoes.

In order to locate and determine the extent of local shape errors, an analysis of

the tomato boundary curvature is an efcient solution. The boundary curvature is

computed from the smoothed version of the contour data (Figs. 4 and 5).

This method clearly detects and locates concavities and convexities, also a not

sellable curvature.

Fig. 1. Relationship between area measured by image analysis (blossom end view) and weight measured

using a scale for tomatoes of different size and maturity.

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 21

Fig. 2. Dominating wavelength as maturity index.

2.4. Spots and scars

The colour distribution of a tomato is easily evaluated using, e.g. the dominating

wavelength. The histogram of the dominating wavelength of the pixels of a

discoloured tomato (Figs. 6 and 7) shows a clear threshold value between the

yellow spots and the red colours, thus providing a way of detecting colour

abnormalities. The histogram method is also easily capable of detecting greenback

tomatoes or tomatoes with bottom-end rot. Either the total spread of the distribu-

Fig. 3. Example of shape sorting based on the calculated compactness and eccentricity values: a

misshapen (C=0.9725, E=0.8683) and a perfectly shaped (C=0.99807, E=0.9929) tomato.

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 22

Fig. 4. Tomato with several local shape errors located by analysing the boundary curvature (Fig. 3).

tion or the attribute more than one peak can be taken as a measure for colour

abnormalities. Furthermore, scars or injuries can be detected with texture analysis

(differences in reection within neighbouring pixels) or black/white discrimination,

see Fig. 8. Surface injuries have as a result a discontinuity in reection.

2.5. Correlation between optical quality attributes and inner 6alues

Within different stages of maturity or different groups of constituents, values of

quality parameters sometimes develop in parallel. It is interesting to look at

correlation between these measurements. The aim is to reduce tedious measure-

ments, because when the fruits of one variety are coming from the same greenhouse

Fig. 5. The boundary curvature calculated for the tomato shown in Fig. 4.

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 23

Fig. 6. Unevenly coloured tomato (yellowish spots). The overlay shows the areas found by analysing the

histogram of dominating wavelengths.

with more or less the same nutrition and climate, quality assessment should be

reduced to non contact, non destructive tests.

The clearest correlation is between colour and rmness. Both measures have to

do with maturity. No doubt, maturity can easily and with good result be measured

with colour assessment (Fig. 9). Only a weak correlation exists between Brix and

maturity (Fig. 10). The same can be stated about maturity and vitamin C (Fig. 11).

Although there is a tendency, the correlation is not very good.

Fig. 7. Histogram (number of pixels) of the unevenly coloured tomato depicted in Fig. 6 over the

dominating wavelength of each pixel.

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 24

Fig. 8. Reection discontinuities in the red band of an over mature tomato with a scar.

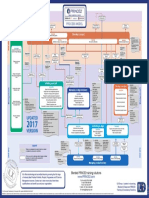

3. Fuzzy fusion: quality attributes

For the overall objective of fuzzy mapping, a model for processing the visual

fuzzy parameters into some classes of an output parameter total visual quality is

proposed.

3.1. Basic quality attributes

Consumers as well as producers need some basic quality standard, which is

generally accepted and is measurable by devices reasonable in price. Producers can

assess the results of their management decisions, consumers are looking for better

quality. As a result from the above discussions attributes and classes listed in Fig.

12 and Table 4, for quality assessment are proposed. According to mans impres-

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 25

Fig. 9. Correlation between maturity and rmness.

sion, the proposed parameters are not crisp numbers, but distributions around a

given value. Here fuzzy triangular distributions are chosen with peak values of one.

The membership functions decrease to zero at the peak memberships of the

forgoing or following classes, as can be seen in the attached windows of Fig. 10 or

Fig. 11. Because the following fuzzy reasoning was done with a professional

software system, FUZZY CONTROL MANAGER (FCM) www.transfertech.de, varia-

tions like other membership functions (i.e. Gauss, etc.) could easily be applied.

3.2. Fuzzy rating of consumer aspects

Parameters for contour and shape as well as colour and colour uniformity are the

basic parameters to be processed. These four parameters belong to fuzzy classes

according to consumers judgements (Fig. 13). Contour and shape are processed by

fuzzy reasoning to an output called geometry, colour and colour distribution to an

Fig. 10. Correlation between maturity and BRIX value

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 26

Fig. 11. Correlation between maturity and vitamin C.

output impression. Both give the overall appearance, which had to be checked for

cracks and faults. The attribute cracks is more or less a knockout criterion. When

no discontinuities in colour or reection can be detected, a further grading to size

gives an overall visual quality as result.

The processing is done with classical fuzzy AND operators: IF (X1 AND X2)

THEN Y1. Also operators like GAMMA (compensatory AND) may be applied.

But these operators need a careful design. To ease plausibility control according to

human reasoning the whole system has been broken down to rule bases with two

inputs only. With such an approach the rule base is easily surveyed.

Fig. 14 gives an example of mapping the contour variables and shape variables

to appearance. The best appearance is with even contour and round shape. The

Fig. 12. Elements for automatic assessment of visual quality.

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 27

Table 4

Fuzzy variables and classes for quality assessment

Classes (triangular membership) Variable

Contour Deep incuts, light incuts, even, light swelling, severe deformation

Mishappen, lengthened, attened, round Shape

Green, breaker, turning, pink, mature red Colour

Even, light irregular, severe irregular, spots Colour uniformity

Cracks, no cracks Cracks

Excellent, good, medium, bad, very bad Appearance

Very small, small, medium, large, very large Size

Visual quality Not sellable, poor, medium, good, excellent

two-dimensional inuence mapping can easily be checked and tested due to

consumer intentions. The output membership distribution for constant shape and

parameters is also shown, defuzzication is straightforward.

Because of this stepwise tuning of parts of the model also the total visual quality

seems reasonable (Fig. 15). The shape and colour are mapped here to the fuzzy

quality output. The mountain of good quality gives an excellent feeling for

parameter inuences. The program also allows an optimisation of input parameters

for membership functions by back-propagation, if enough consumer interviews on

total quality are available.

4. Conclusion

Sorting and quality rating is normally done by experts. In consequence it is

subjective and the results show inter and intra individual variations. To achieve

objective and reproducible results, a quality assessment based on measured optical

characteristics and on a fuzzy model of consumer quality rating is proposed.

Optical measurements show a good correlation in respect to maturity parameters.

Fig. 13. Fuzzy tomato quality grading.

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 28

Fig. 14. Mapping of geometry on appearance.

Fig. 15. Mapping of colour and shape on quality.

G. Jahns et al. / Computers and Electronics in Agriculture 31 (2001) 1729 29

So contact or destructive measurements can be reduced to a minimum. The fuzzy

impression of consumers modelled by fuzzy logic can be ne tuned if enough data

are available. The proposed principle of modelling consumer quality can be adapted

and applied to other products, too.

Acknowledgements

This work was funded by the EU MACQU project contract No. AIR3-CT93-

1603. The funding is gratefully acknowledged.

References

AID, 1992. Quality standard for vegetables. Auswertungs- und Informationsdienst fu r Ernahrung,

Landwirtschaft und Forsten (AID) e.V. 53179 Bonn, Germany.

Choi, K., Lee, G., Han, Y.J., Bunn, J.M., 1995. Tomato maturity evaluation using colour image

analysis. Trans. Am. Soc. Agric. Eng. 38 (1), 171176.

Nielsen, H.M., Paul, W., 1995. Quality measurements of tomatoes by image analysis. Acta Hort. 421, 2.

Nielsen, H.M., Paul, W., 1996. Tomato quality: correlations between image analysis and destructive

tests. Paper AGENG 96, Madrid, 2326, September.

Sarkar, N., Wolfe, R.R., 1985a. Feature extraction techniques for sorting tomatoes by computer vision.

Trans. Am. Soc. Agric. Eng. 28 (3), 970979.

Sarkar, N., Wolfe, R.R., 1985b. Computer vision based system for quality separation of fresh market

tomatoes. Trans. Am. Soc. Agric. Eng. 28 (5), 17141718.

USDA, 1991. United States standards for grades of fresh tomatoes. USDA Agricultural Marketing

Service, Washington, DC.

.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Victorian AOD Intake Tool Turning Point AuditDocument8 pagesVictorian AOD Intake Tool Turning Point AuditHarjotBrarNo ratings yet

- Autoregressive-Moving Average (ARMA) ModelsDocument34 pagesAutoregressive-Moving Average (ARMA) Modelsflaviorochaavila100% (1)

- VoorbeeldDocument99 pagesVoorbeeldRobin VosNo ratings yet

- Spotify Strategig Possining and Product Life Cycle Four Basic Stages.Document5 pagesSpotify Strategig Possining and Product Life Cycle Four Basic Stages.Jorge YeshayahuNo ratings yet

- I. Inversion: Grammar: Expressing EmphasisDocument7 pagesI. Inversion: Grammar: Expressing EmphasisSarah BenraghayNo ratings yet

- Elitmus PapersDocument21 pagesElitmus Papersanon_879320987No ratings yet

- Constitutional Law Sem 5Document5 pagesConstitutional Law Sem 5Ichchhit SrivastavaNo ratings yet

- Case KohortDocument37 pagesCase KohortNasir AhmadNo ratings yet

- MacbethDocument2 pagesMacbethjtwyfordNo ratings yet

- Reading Activity - A Lost DogDocument3 pagesReading Activity - A Lost DogGigsFloripaNo ratings yet

- Midterm Examination: General MathematicsDocument5 pagesMidterm Examination: General MathematicsJenalyn CardanoNo ratings yet

- Rights As Bribes ResaltadoDocument89 pagesRights As Bribes ResaltadoAndresAmarillaNo ratings yet

- Docshare - Tips Upstream Advanced c1 Test BookletDocument3 pagesDocshare - Tips Upstream Advanced c1 Test BookletCosmin OaieNo ratings yet

- p2 Process Model 2017Document1 pagep2 Process Model 2017Miguel Fernandes0% (1)

- RFP Nms 070708Document183 pagesRFP Nms 070708Md RajaulNo ratings yet

- Adeyinka Wulemat Olarinmoye - The Images of Women in Yoruban Folktales PDFDocument12 pagesAdeyinka Wulemat Olarinmoye - The Images of Women in Yoruban Folktales PDFAngel SánchezNo ratings yet

- General Mathematics - Module #3Document7 pagesGeneral Mathematics - Module #3Archie Artemis NoblezaNo ratings yet

- Macguffin: History and UseDocument5 pagesMacguffin: History and UseGeraldo CostaNo ratings yet

- Curriculum Vitae: Lungnila Elizabeth School of Social Work, Senapati, Manipur August 2016-June 2018Document4 pagesCurriculum Vitae: Lungnila Elizabeth School of Social Work, Senapati, Manipur August 2016-June 2018Deuel khualNo ratings yet

- Why Do We Hate Hypocrites - Evidence For A Theory of False SignalingDocument13 pagesWhy Do We Hate Hypocrites - Evidence For A Theory of False SignalingMusic For youNo ratings yet

- Liquid Holdup in Large-Diameter Horizontal Multiphase PipelinesDocument8 pagesLiquid Holdup in Large-Diameter Horizontal Multiphase PipelinessaifoaNo ratings yet

- DaybreaksDocument14 pagesDaybreaksKYLE FRANCIS EVANo ratings yet

- LTRC FInal Report 558 Development of Performance-Based Specifications For Louisiana Asphalt MixturesDocument149 pagesLTRC FInal Report 558 Development of Performance-Based Specifications For Louisiana Asphalt MixtureswalaywanNo ratings yet

- Slides - Simple Linear RegressionDocument35 pagesSlides - Simple Linear RegressionJarir AhmedNo ratings yet

- Notification On Deemed Examination Result NoticeDocument2 pagesNotification On Deemed Examination Result Noticesteelage11No ratings yet

- MATH3161 MATH5165 T1 2023 OutlineDocument10 pagesMATH3161 MATH5165 T1 2023 OutlineDouglusNo ratings yet

- PracticeProbs (5 - 27 - 07) - CMOS Analog ICs PDFDocument70 pagesPracticeProbs (5 - 27 - 07) - CMOS Analog ICs PDFmyluvahanNo ratings yet

- The University of Southern Mindanao VisionDocument9 pagesThe University of Southern Mindanao VisionNorhainie GuimbalananNo ratings yet

- Sample Letter of Request To Validate The QuestionnaireDocument2 pagesSample Letter of Request To Validate The QuestionnaireSamantha AceraNo ratings yet

- A0 Unit1 Lesson3A PP GB AmbDocument9 pagesA0 Unit1 Lesson3A PP GB AmbMasterkolo KamisNo ratings yet