Professional Documents

Culture Documents

Technologies For Valorization of Bio-Wastes - Pptn.

Uploaded by

Padmini RajuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technologies For Valorization of Bio-Wastes - Pptn.

Uploaded by

Padmini RajuCopyright:

Available Formats

Technologies for valorization of

Bio-wastes

Sami SAYADI

Laboratory of Bioprocesses

Regional Excellency Pole AUF

Centre of Biotechnology at Sfax, Tunisia

e-mail: sami.sayadi@cbs.rnrt.tn

Feedstocks

Feedstocks

/

/

solid

solid

agro

agro

-

-

wastes

wastes

A feedstockis the general name given to materials that can be

transformed. Feedstocks can vary tremendously, but are normally

derived fromliving organisms and are often termed as organic

materials.

The most common and abundant formof feedstock is lignocellulosic

wastes, (more often described as green wasteor yard waste). Other

feedstocks include household kitchen waste, commercial waste from

supermarkets, restaurants, kitchens and food processors,

There are also industrial feedstocks such as paper pulp, some

biodegradable plastics and sewage sludge.

For est er

For est er

domai n

domai n

Sahar i en

Sahar i en

domai n

domai n

Cul t ur es

Cul t ur es

domai n

domai n

Bi o Bi o- -f uel f uel ? ?

Bi o Bi o- -f er t i l i zer f er t i l i zer ? ?

Bi o Bi o- -based based c hemi c al s c hemi c al s? ?

- -Smal l l and ar ea Smal l l and ar ea w i t h w i t h Ener gy Ener gy, ,

f er t i l i zer f er t i l i zer def i c i enc i es def i c i enc i es

- -Bi o Bi o- -w ast es w ast es non non val or i zed val or i zed

Available bio

Available bio

-

-

waste materials as possible

waste materials as possible

renewable resources and bio

renewable resources and bio

-

-

based

based

coumpounds

coumpounds

Agro-industrial wastessuchas

Agricultural and foresterie solid wastes (pruning )

Fishconditonningwastes

Slaughterhouseswastes

Dairywastesandwhey

Olive mill wastes (Olive wastewaters, leaves, husks)

Dates wastes and Grapes husks

ssame wastescommonlyusedin makingsweets

Sugar Beets

Grual waste(wheat) as a source of glucose syrup

Sewagesludge(more than90 WWTP in Tunisia)

Solidwastes(9 landfillsare under construction plus that of J . Chakir whichis

operatingsince1999)

Muni c i pal Muni c i pal Sol i d Sol i d Wast es Wast es

Mar k et s Mar k et s w ast es w ast es

Agr i c ul t ur al Agr i c ul t ur al Wast es Wast es (Gr een (Gr een w ast es w ast es) )

Tr i mmi ng Tr i mmi ng, , pr uni ng pr uni ng of of pal m pal m and and ol i ve ol i ve

t r ees t r ees , , f or est f or est .. ..

Agr o Agr o f ood f ood w ast es w ast es (ol i ve (ol i ve w ast es w ast es

gr ape gr ape mar c mar c

WWTP WWTP sl udge sl udge

Far mer Far mer w ast es w ast es ( (manur e manur e,..) ,..)

Ref Ref. PR . PR Krauss Krauss Tunis, 6 Tunis, 6- -7 7 december december 2006 2006

Bi o

Bi o

-

-

Wast es

Wast es

,

,

Feedst oc k s

Feedst oc k s

i n

i n

Tuni si a

Tuni si a

2 000 000 t /an 2 000 000 t /an

100 000 t /an 100 000 t /an

5 000 000 t /an 5 000 000 t /an

300 000 t /an 300 000 t /an

5 400 000 t /an

1 250 000 t /an 1 250 000 t /an

Technologies for

Technologies for

bio

bio

-

-

waste

waste

treatment

treatment

and

and

Valorisation (

Valorisation (

most

most

adapted

adapted

to

to

the

the

Tunisian

Tunisian

context

context

)

)

A broad variety of technologies for conversion of biomass

and/or waste to valuable compounds, The treatment and

utilisation of these residues and waste for energy, recycling

and added value compounds can contribute significantly to

greenhouse gas emission reduction.

Anaerobic digestion: biomethanisation

Composting

Biogaz from landfills

Solid state fermentation

New molecular processes and technologies for conversion of biomass and bio-

waste into added value chemicals should emerge

UNDER EXPLORATION

Fermentation of lignocellulosic material and production of ethanol (Norh part)

Fermentation of dates residues in ethnol (South part)

Olea

Olea

europaea

europaea

L.: olive oil tree

L.: olive oil tree

Economic, cultural, historical Economic, cultural, historical .importance in Tunisia .importance in Tunisia

Olea europaea L., which

belongs to the Oleaceae is

considered a drought-resistant

species because it thrives in

areas where water stress is

frequent such as arid and semi-

arid regions.

It has been postulated that the

mean water requirement for

olive is 2000 m

3

/ha year (Ryan

and Robards, 1998).

In desert climates, olives are

frequently used as yard trees.

Olea

Olea

europaea

europaea

L.

L.

Schematic Diagram of Olive Oil Production Processes

Selection & Weighing

Selection & Weighing

Air Suction Unit

Air Suction Unit

Leaves & Dust

Leaves & Dust

Water

Water

Washing

Washing

Washing Wastewater

Washing Wastewater

Crushing

Crushing Water

Water

Temperature adjustment

Temperature adjustment

Horizontal Centrifugation

Horizontal Centrifugation

Vertical Centrifugation

Vertical Centrifugation

Solid residue

Solid residue

Wastewater

Wastewater

Oil

Oil

Storage Tank

Storage Tank

Micro-Filtration

Micro-Filtration

Bottling

Bottling

I

I

-

-

Co

Co

-

-

c ompost i ng of t he ol i ve pr oc essi ng

c ompost i ng of t he ol i ve pr oc essi ng

sol i d w ast e (Husk s): agr onomi c t est s

sol i d w ast e (Husk s): agr onomi c t est s

(

(

pot at oe

pot at oe

)

)

Industrial test of co-compostingolive husks(C) withchickenmanure(N) Agronomictests using

potatoswererealizedContact: ridha.hachicha@enis.rnu.tn.

Abi d N. and Sayadi S (2006). Det r i ment al Ef f ec t s of Ol i ve Mi l l Wast ew at er on t he Compost i ng Pr oc ess

-of Agr i c ul t ur al Wast es. Wast e Management , 26: 1099-1107.

Olive mill effluents and leaves should be considered as

Olive mill effluents and leaves should be considered as

wastes to be valorized rather than pollutants

wastes to be valorized rather than pollutants

Minutes

0 5 10 15 20 25 30 35

V

o

l

t

s

0,00

0,02

0,04

0,06

0,08

V

o

l

t

s

0,00

0,02

0,04

0,06

0,08

F3

F2

F1

SEC-HPLC of polyphenols in OMWW

OH

OH

HO O

OH

HO

O

O

OH

OH

O

O

O

OH

O

O OH

O O

O

Cl ean Tec hnol ogy Pr oc esses w er e used t o pr oduc e hi gh added val ue

c hemi c al s suc h as hydr ox yt yr osol , ol eur opei n, pol yhydr ox ybut yr at e,

and phenol i c pol ymer s (di mmer s, t r i mer s, ol i gomer s) of phenol i c

3 t o 5 Kg of ant i ox i dant s c oul d be r ec over ed /t on of OMW mak i ng val ue

addi t i on t o OMW an at t r ac t i ve ent er pr i se (Food addi t i ves)

II

II

-

-

Production of High added value

Production of High added value

compounds from olive mill by

compounds from olive mill by

-

-

products

products

Development of recovery processes: liquid-liquid extrcation,

membrane filtration, hydrolysis,

0

100

200

300

400

500

600

700

0 40 80 120

Temps (min)

I

n

d

i

c

e

p

e

r

o

x

i

d

e

(

m

q

/

k

g

)

Temoi n 200 ppm 500 ppm

Use of recovered compounds for fats

stabilization

Olive leaves and branches are the byproducts of

farming of the olive grove and can be found in

high amounts in the olive oil industries (10% of

the total weight of the olives) and during pruning

of olive trees

Extract and

pur compounds

IC

50

[g/ml]

BHT 0 .87

Hydroxytyrosol 0.58

Enzymatic

hydrolysis extract

0.65

Oleuropein 1.19

Ethyl acetate

extract

1.25

CH

3

OH/H

2

O

extract

1.57

III

III

-

-

Highly added value products from olive leaves

Highly added value products from olive leaves

and branches

and branches

Bouaziz M, Fki I, J emai H. Ayadi M. Sayadi S. Food Chem. (2007), in press

Bouaziz M., Bouallagui Z., Sayadi S. J. Arid Land Studies, 2006, 54, p 435-438

3,4-dihydroxyphenyl ethanol production through

enzymatic hydrolysis of olive leaf extract

Destabilisation of the molecule by the cleavage of the osidic bound

(Feuilles doli vi er)

OMW by-product

4-hydroxyphnyl thanol,

3,4-dihydroxyphnyl thanol,

Acide para-coumarique

Acide syringique,

Acide frulique,

4-Acide phnyl actique,

Acide vanillique,

oleuropeine,

etc

Bacteria, fungi, enzymes

High added

value product

Antioxydants

Aroma

Preservation C

Examples

3,4DHPE

Enzyme

ORAC

4-hydroxyphnyl thanol

oleuropeine,

IV

IV

-

-

Clean technologies for the bioconversion of

Clean technologies for the bioconversion of

available aromatics in highly added value products

available aromatics in highly added value products

ORAC

Heterogenous catalysis

Heterogenous catalysis

Ar. Hydroxylase

CH

2

CH

2

OH

OH

CH

2

CH

2

OH

OH

OH

3,4-di-hydroxyphnyl thanol

Yield 85 %

ORAC

ORAC

4-hydroxyphnyl thanol

Ex 1

Ex 1

-

-

hydroxylation of

hydroxylation of

tyrosol

tyrosol

by resting cells

by resting cells

0

20

40

60

80

100

120

0 2 4 6 8 10 12 14 16 18

Time (h)

Y

i

e

l

d

(

%

)

0,8

0,9

1

1,1

1,2

1,3

1,4

1,5

O

D

(

6

0

0

n

m

)

Bouallagui, Z. and Sayadi, S. J . Agric. Food Chem. (2006)

L L

OH

N. Allouche, M. Damak, R. Ellouz, and S. Sayadi : App. Environ. Microbiol., 2004, p. 21052109

natural labelled products

avoid purification steps of intracellular enzymes

reuse of the cellular catalyst;

stabilized enzyme activities and protection against toxicity

Reaction implicating a cascade of enzyme

Cofactors (NADH, NADPH,); later on regenerated

during the metabolism

OH

OH OH

OH

OH

OH

OH

OH

p - h y d r o x y p h en y l ac e t i c

ac i d

Ty r o s o l Hy d r o x y t y r o s o l 3,4- d i h y d r o x y p h e n y l -

ac et i c ac i d

OH

Ri n g c l eav ag e

O

O

OH

EX.2 Hydroxylation of OMW phenolic precursors by immobilized cells

NADH,H

+

+ O

2

NAD

+

+H

2

O

m-t yr osol (3-hydr ox yphenyl et hanol )

and o-t yr osol (2-hydr ox yphenyl et hanol )

w er e c ompl et el y t r ansf or med i nt o 3-

hydr ox yphenyl ac et i c ac i d and 2-

hydr ox yphenyl ac et i c ac i d r espec t i vel y

vi a t he ox i dat i on of t he si de c hai n

c ar bon of t he t r eat ed subst r at es

4-hydr ox yphenyet hanol (p-t yr osol ) and

4-hydr ox yphenyl ac et i c ac i d w er e

r espec t i vel y bi o-c onver t ed i nt o 3,4

di hydr ox yphnyl t hanol and 3,4-

di hydr ox yphnyl ac et i c ac i d,

r espec t i vel y .

Example Example 3: BIOCONVERSION OF 2 PRECURSORS P 3: BIOCONVERSION OF 2 PRECURSORS P- -TYROSOL TYROSOL

AND P AND P- -HYDROXYPHENYL ACETIC ACID HYDROXYPHENYL ACETIC ACID

- - STEREOSPECIFICITY OF ACTION STEREOSPECIFICITY OF ACTION

Minutes

0 10 20 30 40 50

V

o

lt

s

0,0

0,5

1,0

1,5

V

o

lt

s

0,0

0,5

1,0

1,5

Channel A

EX T0

EX T0

Minutes

0 10 20 30 40 50

V

o

lt

s

0,0

0,2

0,4

0,6

V

o

lt

s

0,0

0,2

0,4

0,6

Channel A

EX Tf

EX Tf

Aromatic Enrichment conditions Isolated strains

Tyrosol

50 g/l NaCl

37 C

150 r.p.m

5 mM tyrosol

12 strains

YAS1,2,3

FE1,2,3

IM1,2,3

SL1,2,3

p-coumaric acid

100 g/l NaCl

37 C

150 r.p.m

5 mM p-coumaric

4 strains

IMPA, IMPB

IMPC, IMPD

Ferulic acid

100 g/l NaCl

37 C

150 r.p.m

5 mM ferulic

2 strains

MAR

MBR

Ex ampl e 4: Bi oc onver si on of ar omat i c st r uc t ur es i n ex t r eme

c ondi t i onsBy-pr oduc t s of ol i ve f er ment at i on/br i ne

Abdel k af i S, Sayadi S, Ben Al i Gam Z, Casal ot L, Labat M (2006) FEMS Mi c r obi ol .

Let t .,

Abdel k af i S, M. Labat , M. Chamk ha, Casal ot L, Sayadi S (2005) FEMS Mi c r obi ol .

Let t .

Degradation pathway of

Degradation pathway of

ferulic

ferulic

acid by

acid by

Halomonas

Halomonas

elongata

elongata

strain MAR

strain MAR

Metabolis of ferulic acid

Oxidation C

3

-aliphatic chain

0

20

40

60

80

100

1 2 3 4 5

Repeated time of biotransformation

Y

i

e

l

d

o

f

v

a

n

i

l

l

i

c

a

c

i

d

(

%

)

Accumulation of vanillic acid by resting cells

Ex 5: Degradation of tyrosol by the use of catalyst (Al-

Fe)PILC in the presence of UV and Hydrogen

peroxide

0

20

40

60

80

100

0 5 10 15 20 25

Temps (h)

C

o

n

v

e

r

s

i

o

n

d

u

t

y

r

o

s

o

l

(

%

UV/H

2

O

2

/(Al-Fe)PILC

UV/H

2

O

2

H

2

O

2

/(Al-Fe)PILC

Conditions [tyrosol] = 500 ppm

[H

2

O

2

] = 2.10

-2

M

[Catalyst] = 500 ppm

= 254 nm

Najjar W., AzabouS., Sayadi S. and Ghorbel A. Appl. Cat: B Env. (2007), 74:11-18

AzabouS., Najjar W., Gargoubi A., Ghorbel A. and Sayadi S. App. Cat. B Env(2007), 77:166-174

CH

2

OH

HO

Tyrosol

CH

2

OH

HO

HO

Hydroxytyrosol

0

0,1

0,2

0,3

0,4

0,5

0,6

0 5 10 15 20 25 30

Ti me(h)

tyrosol

Hydroxytyrosol

3,4-DHPA

t =0 h

t =4 h

Ex 5

Ex 5

-

-

hydroxylation of

hydroxylation of

tyrosol

tyrosol

by (Al

by (Al

-

-

Fe)PILC

Fe)PILC

Azabou S., Najjar W., Ghorbel A. and Sayadi S. J .Agric. Food. Chem(2007), 55:4877-4882.

Ex: 6 Enzymatic synthesis of lipophilic

compound from p-hydroxyphenyl ethanol

The hydrophilic character of some polyphenols limits their application

Synthesis of lipophilic derived products

Lipase;

acylant;40C

Aissa I., Bouaziz M., Ghamgui H., Kamoun A.,Miled N.,Sayadi S.,Gargouri Y.

J. Agric. Food Chem. 2007, 55,p 1029810305

monoacetylated compound (+95%)

Peroxide values of refined husk oils stored at 50C and supplemented

with: (x) BHT at 200 ppm, () OMW extract at 200 ppm, () OMW

extract at 500 ppm, () hydroxytyrosol at 200 ppm, () control.

I. FKI, N. ALLOUCHE AND S. SAYADI, Food Chem., 2005, 93:197-204.

Some activities of the obtained antioxidants

Refined husk oil stabilization

Peroxide values of refined

olive oils stored at 50C and

supplemented with: (x) BHT

at 200 ppm, () OMW extract

at 200 ppm, () OMW

extract at 500 ppm, ()

hydroxytyrosol at 200 ppm,

() control.

The oxidation of refined husk and olive oils stored at 50 after the addition of

OMWW extract was measured by peroxide values (PV) and conjugated diene

formation CD (data not shown).

Both parameters CD and PV measure the primary product of lipid oxidation.

Oils treated with purified hydroxytyrosol and BHT exhibited the lowest

peroxide values as compared with the control sample.

0

1,5

3

1 2 3 4 5 6

Treatment

A

I

Effect of HCD and OMW phenolic extracts on

serum lipids levels in rats

HCD diet increase of AI compared with the rats fed normal

diet.

HCD diet + MeOH extracts, purified compounds and OMW

decrease of AI.

I. FKI, M. BOUAZIZ, Z. SAHNOUN AND S. SAYADI, 2005, Bioorganic and Medicinal Chem., 13: 5362 5370.

ABTS

Poly R-478

RBBR

Negative strain Positive strain

Precoce (24h)

Amongst 400 fungal strains isolated

on solide medium, 67 strains are

able to oxidyze ABTS and

decolorize the chromogenes

Screening fromlocal biotopes of fungal strains producing

laccases and peroxidases on solid medium + chromogene

N CBS LiP MnP Lac

Collection Strain (U/l) (U/l) (U/l)

CTM 10125 Phlebia Sp - 182 (8) 19 (7)

CTM 10133 Oxyporus latemarginatus 4 (7) 108 (8) -

CTM 10136 Oxyporus latemarginatus 6,5 (2) 202 (11) -

CTM 10154 Trametes trogii 25 (5) 67,2 (6) 8990 (10)

CTM 10155 Polyporus Sp 35 (4) 96,7 (2) 7393 (10)

CTM 10156 Trametes trogii 5,5 (1) 56,5 (7) 9956 (7)

CTM 10313 Stereum annosum - - 97 (9)

CTM 10476 Trichoderma atroviride - - 9005 (6)

Phylogenic characterization of novel strains able to produce Lac, MnP

and/or LiP

0

10

20

30

40

50

60

0 1 2 3 4 5 6 7 8 9 10

0

5000

10000

15000

20000

25000

30000

Residual BOD5

Residual COD

Biomass

Laccase activity

Time (days)

B

i

o

m

a

s

s

;

R

e

s

i

d

u

a

l

B

O

D

5

;

R

e

s

i

d

u

a

l

C

O

D

(

g

l

-

1

)

L

a

c

c

a

s

e

a

c

t

i

v

i

t

y

(

U

l

-

1

)

Ti me c our se of gr ow t h and l ac c ases pr oduc t i on by Tr amet es t r ogi i DSM 17786

c ul t ur ed i n 7-l i t r es bi or eac t or on OMW:w at er (80:20)-based medi a suppl ement ed w i t h ur ea

(2 g L

-1

) and Resi dual BOD

5

and COD c onc ent r at i ons.

ChakrounH., Sayadi S., Machichi T and DhouibH. J ournal of chemical technology

and biotechnology (2009), in press

.

Laccases production on OMW in 7litres fermenter by Trametes trogii

for further polymerization/oxidation reactions

-

-

Laccase

Laccase

mediated

mediated

polymers

polymers

synthesis

synthesis

laccases catalyze the oxidative coupling of phenolic

compounds.

Formation of polymerized products ranging from dimers to

pentamers (NMR), during the oxidation of several olive

phenolics by T. togii laccases.

These proposed procedures are alternative approaches to

obtain valuable chemicals such polymers of catechol and

tyrosol in an environmentally friendly way which could

encourage their use in medical and food industries .

Minutes

0 5 10 15 20 25 30 35 40 45 50

V

o

lts

0,0

0,5

1,0

Detector A (280nm)

10 0,5h

10 0,5h

Minutes

0 5 10 15 20 25 30 35 40 45 50

V

o

lts

0,0

0,2

0,4

0,6

Detector A (280nm)

15 18h

15 18h

0

20

40

60

80

100

0 2 4 6 8

I

n

h

i

b

i

t

i

o

n

o

f

b

i

o

l

u

m

i

n

e

s

c

e

n

c

e

o

f

V

i

b

r

i

o

f

i

s

h

e

r

i

I

B

(

%

)

Time

(h)

Fraction S+ Laccase Fraction S+ Laccase of of Trametes Trametes

versdicolor versdicolor

After After 30 min 30 min

2,5 g/l of phenolic monomers polymerized

Formation of insoluble matter

Minutes

0 10 20 30 40 50

V

o

l

t

s

0.0

0.2

0.4

0.6

0.8

V

o

l

t

s

0.0

0.2

0.4

0.6

0.8

Channel A

Laccase 28h119

Laccase 20028h123

HPLC after enzymaticreaction

Polymres

Laccases for the synthesis of polymers from

olive phenolic wastes

Minutes

0 10 20 30 40 50

V

o

lt

s

0.0

0.5

1.0

1.5

V

o

lt

s

0.0

0.5

1.0

1.5

Channel A

Laccase To' 119

Laccase To' 119

1

7 9

2 3 4 5

6

8

10

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Finite Pointset Method For Simulation of The Liquid Liquid Flow Field in An ExtractorDocument12 pagesFinite Pointset Method For Simulation of The Liquid Liquid Flow Field in An ExtractorPadmini RajuNo ratings yet

- Analysis of Soybean Protein Derived Peptides and The Effects of Various Factors On Lunasin Concentration in Soybean and Soy ProductsDocument11 pagesAnalysis of Soybean Protein Derived Peptides and The Effects of Various Factors On Lunasin Concentration in Soybean and Soy ProductsPadmini RajuNo ratings yet

- Enzymatic Hydrolysis of Wheat Gluten by Proteases and Properties of The Resulting HydrolysatesDocument5 pagesEnzymatic Hydrolysis of Wheat Gluten by Proteases and Properties of The Resulting HydrolysatesPadmini RajuNo ratings yet

- Measuring Trypsin Inhibitor in Soy Meal - Suggested Improvements in Std. Method PDFDocument7 pagesMeasuring Trypsin Inhibitor in Soy Meal - Suggested Improvements in Std. Method PDFPadmini RajuNo ratings yet

- ADM Novasoy Isoflavone Product SheetDocument6 pagesADM Novasoy Isoflavone Product SheetPadmini RajuNo ratings yet

- Australian Patent PublicationDocument37 pagesAustralian Patent PublicationPadmini RajuNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Overview of Design Features and Performance CharacteristicsDocument13 pagesOverview of Design Features and Performance Characteristicstata_77No ratings yet

- Pawai Dam Progress, Blance Work StatusDocument4 pagesPawai Dam Progress, Blance Work StatusWater Supply Project PannaNo ratings yet

- Method 4500Document14 pagesMethod 4500Daisuke NuñezNo ratings yet

- Review On Automotive Body Coating ProcessDocument4 pagesReview On Automotive Body Coating ProcessIJEMR JournalNo ratings yet

- Description of Different Water Intakes For SWRO PlantsDocument19 pagesDescription of Different Water Intakes For SWRO PlantsAnonymous eCD5ZRNo ratings yet

- S 02301r DrainDocument3 pagesS 02301r DrainIrwan JoeNo ratings yet

- Membrane Comparison ChartDocument3 pagesMembrane Comparison ChartHeri Gunawan100% (1)

- Bio1 3Document11 pagesBio1 3HarmonyChuiNo ratings yet

- Corrosion MonitoringDocument80 pagesCorrosion Monitoring이선엽86% (7)

- Water Quality (4th Edition) - Principles and Practices of Water Supply Operations SeriesDocument226 pagesWater Quality (4th Edition) - Principles and Practices of Water Supply Operations SeriesLenin PatiñoNo ratings yet

- Indonesia - Jakarta Urgent Flood Mitigation ProjectDocument107 pagesIndonesia - Jakarta Urgent Flood Mitigation ProjectMeita Tristida ArethusaNo ratings yet

- A264 MsdsDocument11 pagesA264 Msdsjangri1098No ratings yet

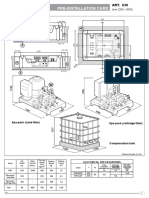

- Pre-Installation Card: Spa-Pack (Sand Filter) Spa-Pack (Cartridge Filter)Document4 pagesPre-Installation Card: Spa-Pack (Sand Filter) Spa-Pack (Cartridge Filter)ahoirebaNo ratings yet

- Pricelist Januari 2022Document8 pagesPricelist Januari 2022Penghuni BumiNo ratings yet

- TOC Application Handbook2 14FDocument128 pagesTOC Application Handbook2 14FHelton N. AndradeNo ratings yet

- Cad Floor Plan-P1Document1 pageCad Floor Plan-P1raymond erasmoNo ratings yet

- Groundwater TharDocument14 pagesGroundwater TharSmehrunnisaNo ratings yet

- Ud Form 3Document5 pagesUd Form 3Khuzaimah IbrahimNo ratings yet

- MSDS Turalik XT 46Document4 pagesMSDS Turalik XT 46satriaNo ratings yet

- GB 50108-2008-EnDocument70 pagesGB 50108-2008-En柳德米拉No ratings yet

- Corrosion in The Oil and Gas Industry-An Increasing Challenge For MaterialsDocument10 pagesCorrosion in The Oil and Gas Industry-An Increasing Challenge For Materialswidjai10No ratings yet

- Mind Map Upsr Complete 1Document88 pagesMind Map Upsr Complete 1Noorain MohammadNo ratings yet

- Influence of Inclination of Thin Core On Stability of Upstream Slope of Earth and Rockfill DamsDocument15 pagesInfluence of Inclination of Thin Core On Stability of Upstream Slope of Earth and Rockfill DamsShaheerKhaleequzzamanNo ratings yet

- 3rd Term English Test Back To NatureDocument2 pages3rd Term English Test Back To NatureMaria MeriemNo ratings yet

- Air Fillter - Ly Thuyet Loc Cho CleanroomDocument101 pagesAir Fillter - Ly Thuyet Loc Cho CleanroomMai Phuong Phan TranNo ratings yet

- Design Basis Manual Pipeline - OnshoreDocument9 pagesDesign Basis Manual Pipeline - OnshoreDenstar Ricardo SilalahiNo ratings yet

- RollitupDocument3 pagesRollitupweedinthereNo ratings yet

- Solar Thermal SystemsDocument16 pagesSolar Thermal SystemsSujit Kumar0% (1)

- Report Jf303 Tunstern Inert Gas (Tig)Document12 pagesReport Jf303 Tunstern Inert Gas (Tig)aizatulasmira60% (5)

- STD1494 FRDocument20 pagesSTD1494 FREric FernandoNo ratings yet