Professional Documents

Culture Documents

Bkf4143-Process Engineering Economics 11213 PDF

Uploaded by

JeevanNairOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bkf4143-Process Engineering Economics 11213 PDF

Uploaded by

JeevanNairCopyright:

Available Formats

Univer siti

Al

Malaysia

PA HA NG

Engineer ing Cr eativIty

FACULTY OF CHEMICAL & NATURAL RESOURCES ENGINEERING

FINAL EXAMINATION

COURSE

:

PROCESS ENGINEERING ECONOMICS

COURSE CODE: BKF4143

LECTURER: MOH]) NOOR BIN NAWI

ANWARUDDIN HISYAM

DATE: 10 JANUARY 2013

DURATION: 3 HOURS

SESSION/SEMESTER : SESSION 2012/2013 SEMESTER I

PROGRAMME CODE : BKB/BKCIBKG

INSTRUCTIONS TO CANDIDATE:

1. This question paper consists of FIVE (5) questions. Answer ALL questions.

2.

All answers to a new question should start on new page.

3.

All the calculations and assumptions must be clearly stated.

4.

Candidates are not allowed to bring any material other than those allowed by

the invigilator into the examination room.

EXAMINATION REOUTREMENTS:

PEE Student's Handbook

DO NOT TURN THIS PAGE UNTIL YOU ARE TOLD TO DO SO

This examination paper consists of ELEVEN (11) printed pages including front page.

CONFIDENTIAL

BKB/BKC/BKG/12131/BKF4143

QUESTION 1

Formalin is a 37 wt% solution of formaldehyde in water. Formaldehyde and urea are

used to make urea-formaldehyde resins that subsequently are used as adhesives and

binders for particle board and plywood.

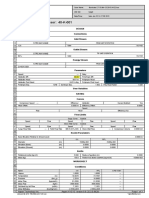

The Process Flow Diagram, PFD for Unit 800 Formalin production of

58,647 metric

tonnes per annumis shown in Figure B.7.1.

All the major pieces of equipment are

illustrated in Figure B.7.1.

The reactor used is the type of jacketed non-agitated

reactor. Table B.7.1, B.7.2 & B.7.3 provides the information for the Stream, Utility

and Major Equipment Summaries as shown in Figure B.7.1.

The following Table 1 shows bare module costs for all major equipment:

Table 1: List of equipment and its bare module cost, CBM.

Equipment

Bare Module Cost,

CBM

Methanol Preheater, E-801 $210,456

Air Preheater, E-802 $257,890

Reactor Effluent Cooler, E-803 W

Tower Reboiler, E-804 $315,485

Tower Condenser, E-805 $310,782

Product Cooler, E-806 $302,896

Feed Air Compressor, C-801 $205,780

Methanol Feed Pump, P-801(A/B) $60,196 X 2

Tower Reflux Pump, P-802(A/B) $45,560X2

Product Pump, P-803(A/13) X

Formaldehyde Absorber, T-801 $1,850,650

FormaldehydeTower, T-802 Y

Formaldehyde Reactor, R-801 Z

Tower Reflux Drum, V-801 $350,950

a) Estimate the bare module cost,

CBM

for the equipment as per Table 1?

i) Reactor Effluent Cooler, E-803; W

(5 Marks)

ii) Product Pump, P-803(A!B); X

(4 Marks)

iii) Formaldehyde Tower, T-802;Y

(7 Marks)

2

CONFIDENTIAL

BKB/BKC/BKG/121311BKF4143

iv)Formaldehyde Reactor, R-801; Z

(5 Marks)

Given other information as follows:

a. Reactor Effluent Cooler, E-803:-

Floating-head, shell and tube heat exchanger

Area = 28.16 m2

Material of construction = Carbon Steel.

b. Product Pump, P-803(A!B)

Stainless Steel, Centrifugal! Electric Drive

Power0 .5kW

75% efficiency

c. Formaldehyde Tower, 1-802

Material of construction (tower) = Stainless steel

Diameter tower = 2.5m

Height/Length = 19 in

31 SS sieve trays, 70% efficient trays

Max Pressure rating of 200 kPa

d. Formaldehyde Reactor, R-801

Carbon Steel, Floating head Counter flow Exchanger

A=140.44 m2; Q=8,928 MJ/hr; Max Pres. Rating = 350 kPa

b) Estimate the total bare module costs, (CTM) and grass roots costs, (CGR) for the

facility.

(7 Marks)

c) Using Chemical Engineering Plant Cost Index (CEPCI), what would be the CGR

value in year 2011?

(2 Marks)

3

a i m

to Stora ge

Ta nk

P-803A/B

Figure B.7.1 Unit 800: Formalin Process Flow Diagi:im

OTI

C rQ

-t

1

-t

C L

0

0

0

-t

2

C

0

C -80 1P-60 1A/BE-80 1E-80 2 R-80 1T-80 1T-80 2 E-80 3 E-80 4E-80 5V -aol P-80 2 A/B P-50 3 A/BE-80 6

Feed Ai rMetha nolMetha nolAi r Form a ldehyde Form a ldehyde Form a ldehyde Rea ctor TowerTowerTower Tower ProductProduct

C om pressor Feed Pum pPrehea ter Prehea ler Rea ctorAbsorberTowerEffluent Reboi ler C ondenser Rellux Rellux Pum pC ooler

C ooler Drum Pum p

>

I

CONFIDENTIAL

BKB/BKC/BKG/121311BKF4143

Appendix B Information for the Preliminary Design of Eleven Chemical Processes 9 8 5

Table B.7.1 Stream Tables for Unit 8 00

Stream Number 1 2 3 4 5 6

Temp ("C) 25.00 30.00 40.66 40.78 183.01 150.00

Fres kPa 101.325 120.00 101.325 300.00 300.00 265.00

Vappr fraction 1.0 0.0 0.0 0.00 1.0 1.0

Total kg/h 4210.54 2464.75 3120.31 3120.31 145.94 99.92

Total kmol/h 1.45.94 76.92 99.92 99.92 4210.54 3120.31

C omp onent k mol/ h

Methanol 0.0 76.92 94.11 94.11 0.0 94.12

Ox y gen

30.66 0.0 0.0 0.0 30.66 0.0

Formaldehyde 0.0 0.0 0.0 0.0 0.0 0.0

Water 0.0 0.0 5.81 5.81 0.0 0.0

Hydrogen 0.0 0.0 0.0 0.0 0.0 0.0

Nitrogen 115.28 0.0 0.0 0.0 115.28 0.0

Stream Number 7 8 9 10 1 1 12

Temp ("C) 200.00 171.94 200.00 100.00 30.00 84.57

Pres kPa 265.00 255.00 185.00 150.00 150.00 140.00

Vapor fraction 1.0 1.0 1.0 1.0 0.0 1.0

Total kmol/h 145.94 245.86 7330.82 7330.82 2576.15 5354.21

Total kg/h 4210.54 7330.85 278.03 278.03 143.00 224.16

C omp onent k niot/ h

Methanol 0.0 94.12 31.45 31.45 0.0 13.35

Oxygen 30.66 30.66 0.15 0.15 0.0 0.15

Formaldehyde 0.0 0.0 62.67 62.67 0.0 0.04

Water 0.0 5.81 66.82 66.82 1.43.00 93.68

Hydrogen 0.0 0.0 1.66 1.66 0.0 1.66

Nitrogen 115.28 115.28 115.28 115.28 0.0 11.5.28

(continued)

Table B.7.1: Stream Components

CONFIDENTIAL

BKB/BKC/BKG/1 21 31/BKF4J 43

A p p e n d i c e s

9 8 6

Table B.7.1 Stre am Table s for Un i t 8 00

( C o n t i n u e d )

Stre am Numbe r

13

14

15

Temp ('Q

89.85

75.46

10664

Pres kPa

150.00

130.00

150.00

Vapor mole fraction

0.0

0.0

0.0

Total kg/h

4552.75

655.56

3897.06

Total kmol/h

196.87

23.00

173.86

Comp on e n t kmot/h

Methanol

18.10

17.19

0.90

Oxygen

0.00

0.00

0.00

Formaldehyde

62.63

0.00

62.63

Water

116.14

5.81

110.33

Hydrogen

0.00

0.00

0.00

Nitrogen

0.00

0.00

0.00

16

17

--

18

106.71

35.00

73.36

350.00

315.00

120.00

0.0

0.0

0.0

3897.06

3897.06

655.56

173.86

173.86

23.00

0.90

0.90

17.19

0.00

0.00

0.00

62.63

62.63

0.00

110.33

110.33

5.81

0.00

0.00

0.00

0.00

0.00

0.00

Table 8 .7.2

Uti li ty Stre am Flow Summary for Un i t 8 00

E -8 01

E -8 02

E -8 03

E -8 04

mps

hps

cw

mps

2063 kg/h

45.43 kg

23,500 kg/h

18,949 kg/h

E -8 05

E -8 06

R -8 01

cw

cw

bfw - mps

775,717 kg/h

27,957 kg/h

3723 kg/h

Table B.7.3 Major E qui p me n t

Summary for Un i t 8 00

Compressor

D-801 A/B (not shown on PFD)

C-801

Electric/exploSIonProof

kW (shaft)

Carbon steel

W 195kW

Centrifugal

Power = 18 3

95% efficient

(continued)

70% efficient

Table B.7.1: Stream Components (Continued), Table B.7.2: UtililyStream and Table

B.7.3: Major Equipment

6

CONFIDENTIAL

BKB/J3KC/BKG/12131/BKF4143

Appendix B Information for the Preliminary Design of Eleven Chemical Processes 9 8 7

Table B.7 .3 Major Equipment Summary for Unit 8 00 (Continued)

Heat Exchangers

E- 8 0 1

A = 405 in'

1-2 exchanger, floating head, carbon steel

Process stream in shell

Q=4111MJ/h

Maximum pressure rating of 350 kPa

E-802

A = 4.62 m2

1-2 exchanger, floating head, carbon steel

Process stream in tubes

Q = 76.75 MJ/h

Maximum pressure rating of 350 kPa

E-803

A = 28.16 m2

1-2 exchanger, floating head, carbon steel

Process stream in shell

Q =

983.23 MJ/h

Maximum pressure rating of 350 kl'a

Reactors

R- 8 0 1, Heat- Exchanger Portion

A = 140.44 m2

Counterfiow exchanger, floating head, carbon

steel

Process stream in tubes

Q =

8,928 MJ/h

Maximum pressure rating of 350 kPa

Pumps

P8 O1 A/B

Centrifugal /electric drive

Carbon steel

Power = 0.3 kW

80% efficient

P- 8 0 2 AJB

Centrifugal/electric drive

Carbon steel

Power = 1.7 kW

80% efficient

E-804

A = 37.3 m2

1-2 exchanger, kettle reboiler, stainless steel

Process stream in shell

Q = 37,755 Mi/h

Maximum pressure rating of 250 kPa

E-805

A = 269 m2

1-2 exchanger, floating head, stainless steel

Process stream in shell

Q

= 32,456 Mj/h

Maximum pressure rating of 250 kPa

E-806

A = 41 m

1-2 exchanger, floating head, stainless steel

Process stream in tubes

Q

= 1169.7 MJ/h

Maximum pressure rating of 400kPa

R-801, Reactor Portion

Thin layers of silver wire gauze suspended

above heat exchanger tube bank

P-803 A/B

Centrifugal /electric drive

Stainless steel

Power = 0.5 kW

75% efficient

(continued)

Table B.7.3 Major Equipment (Continued)

7

CONFIDENTIAL

BKB/BKC/BKC/121311BKF4143

988

Table B.7.3 Major Equipment Summary for Unit 800

( Cont inued)

Towers

T- 801

Carbon steel

10 m of packing

2-in ceramic Bed Saddles

20 theoretical stages

1.00 kPa/m pressure drop

Diameter = 0.86 m

Packing factor = 45

Maximum pressure rating of 300 kPa

Vessel

V-801

Horizontal

Stainless steel

LID = 4.0

Volume = 4.2 m3

T-802

Stainless steel

31 SS sieve trays plus reboiler and partial

condenser

70% efficient trays

Feed on tray 18

Reflux ratio = 37.34

0.6096 m tray spacing, 0.091 in weirs

Column height 19 m

Diameter = 2.5 in

Maximum pressure rating of 200 kl'a

Whim simulating an entire process, we recommend first using the Shortcut:

distillation column within the process for the methanol-Water/formaldehyde dis-

tillation. A rigorous column solver should then be used as a separate item to

simulate the column based on the results obtained from the shortcut column.

However, due to the non-ideality of the thermodynamics, the actual column sim-

TabLe 8.7.4 K-values for Formaldehyde/Water/Methanol System [2]

P(psia) =14.696

T (C)

Chemical Component

Formaldehyde. Water Methanol

0 .1 0.123 1.000 0.273

67.1 0.266 0.491 1.094

72.1 0.336 0.394 1.435

748 0.374 0.453 1.598

84.6 0.546 0.607 2359

97.6 0.693 1.105 2.589

99.9 0.730 1.198 2.595

150.1 1.220 2.460 3.004

Table B.7.3 Major Equipment (Continued)

8

CONFIDENTIAL

BKB/BKCIBKG/12131/BKF4143

QUESTION 2

A RM 200,000 process equipment loan at 10% interest, compounded monthly, is

to be repaid in 48 monthly payments.

a) What is the monthly payment and the total amount repaid?

(5 Marks)

b) What monthly deposit would have to be make-up at the end of each month for

48 months in order to accumulate a fund of RM 200,000 on the last deposit

date with which to purchase this equipment?

(5 Marks)

Now, assume an interest rate of 6% compounded monthly is being paid on all

deposits. What is the total of the 48 deposits? Compare your results with those from

Part (a).

(6 Marks)

QUESTION 3

In Hazwani, liMP graduate chemical engineer working in Palm Oil Refinery

Plant is evaluating several alternatives to supply electricity to the plant. Normally,

she will pay RM 5,000,000.00 for electricity purchased from Tenaga Nasional

Berhad (TNB) for the first year and expect an increase of RM 500,000.00

annually.

Alternatively, she plans to build a 5000 kW Power Plant. His operating cost for

the power plant are estimated to be RM 180,000.00 per year. So, she is

considering two alternative fuels:

Alternative I - WOOD

Installation Cost

Fuel Consumption

Fuel Cost

Incremental Cost Rate

No Salvage value

RM1500/ kW

30,000 metric tonnes per year

RM50 per ton

RM5 per ton per year after year one

9

CONFIDENTIAL

BKB/BKC/BKG/12131/BKF4143

Alternative II - OIL

Installation Cost

Fuel Consumption

Fuel Cost

Incremental Cost Rate

No Salvage value

RM1200/kW

56,000 barrels per year

RM55 per barrel

RM3 per barrel per year after year one

If interest rate is 12%, and the analysis period is 10 years, perform equivalent

uniform annual worth (EUAW) analysis on each alternative as the following:

i)Do Nothing (Use TNB supply)

(5 Marks)

ii)Using Wood or

(5 Marks)

iii)Using Oil?

(5 Marks)

Which alternative should be the best choice for Jr. Hazwani?

(3 Marks)

QUESTION 4

a) The Fermenter for Bioprocess Equipment costs RM 355,000.00 and has an

estimated salvage value of RM 35,000.00 at the end of 5 years useful life.

Compute the depreciation schedule for the equipment by;

i) Straight Line Method (SL)

(2 Marks)

ii) Double Declining Balance Method (DDB)

(4 Marks)

iii)Sum of Years Digit Method (SOYD)

(4 Marks)

10

CONFIDENTIAL

BKB/BKC/BKG/121311BKF4143

b) The Company believes the above equipment can give annual receipts of RM

200,000.00 and annual disbursement of RM 120,000.00. Using the same figures as

part (a) with Straight Line Depreciation Method and Corporate Tax Rate of 25%;

i)

What is the prospective internal rate of return (IRR) before income tax?

(5 Marks)

ii)

What is the prospective internal rate of return (IRR) after the taxes?

(5 Marks)

QUESTION 5

The cost of capital is the company's cost of using funds provided by creditors and

shareholders. A company's cost of capital is the cost of its long -term sources of funds:

debt, preferred equity, and common equity!

a) What is the difference between IRR and WACC?

(5 Marks)

b) Briefly outline the Cost of Capital Processing Steps?

(5 Marks)

c) The Plant Design Company will raise capital in the following proportions:

Debt: 40 percent; Preferred stock: 1 Opercent; Common stock: 50 percent.

Calculate the weighted average cost of capital, WACC if its cost of debt is

3.6percent, its cost of preferred stock is 8 percent, and its cost of common

stock is 12 percent?

(6 Marks)

END OF QUESTION PAPER

11

You might also like

- Mandate Letter FormDocument2 pagesMandate Letter FormDesikan100% (1)

- Lab 5 Full ReportDocument9 pagesLab 5 Full Reporttirahanafi100% (1)

- Design of An Plant For Manufacturing of AcetaldehydeDocument4 pagesDesign of An Plant For Manufacturing of AcetaldehydeClaudio Martinez BernalNo ratings yet

- Team 4 Final PresentationDocument25 pagesTeam 4 Final Presentationlux0008No ratings yet

- Allyl CDocument15 pagesAllyl CTengku Mohd Imran0% (1)

- Rakon 2007 Annual ReportDocument64 pagesRakon 2007 Annual Reportjjmaloney100% (3)

- Problem 1:: Problems & SolutionsDocument12 pagesProblem 1:: Problems & SolutionsFrancisco MarvinNo ratings yet

- Dossier Marketfinal-2Document30 pagesDossier Marketfinal-2Tiri WuNo ratings yet

- Turton AppBDocument114 pagesTurton AppBamms9988No ratings yet

- DME ProcessDocument5 pagesDME ProcessAndres FragosoNo ratings yet

- Simulation Using PFR (Aspen Plus)Document10 pagesSimulation Using PFR (Aspen Plus)Cik Tiem NgagimanNo ratings yet

- UAEU Phthalic Anhydride ProjectDocument78 pagesUAEU Phthalic Anhydride ProjectminumcincauNo ratings yet

- Preliminary Design of Dimethyl Ether Production ProcessDocument114 pagesPreliminary Design of Dimethyl Ether Production ProcessAdesuwa O'sae0% (1)

- Tutorial - Steam Generation 18-5-2020Document2 pagesTutorial - Steam Generation 18-5-2020Shazni AhamedNo ratings yet

- Appendix B - Design ProjectsDocument114 pagesAppendix B - Design Projectsh297No ratings yet

- Che 455 Fall 2009 Major 1 Phthalic Anhydride Production: BackgroundDocument20 pagesChe 455 Fall 2009 Major 1 Phthalic Anhydride Production: Backgroundاحمد الدلالNo ratings yet

- MCG 2131 Exam 08Document6 pagesMCG 2131 Exam 08子豪王No ratings yet

- Hysys - CWs and Quiz Questions - ChE 17Document42 pagesHysys - CWs and Quiz Questions - ChE 17Nahidul Islam ChonjuryNo ratings yet

- THERMO HOMEWORKDocument8 pagesTHERMO HOMEWORKcalebgriffin31No ratings yet

- Heater and HRSG CO2 emissionsDocument23 pagesHeater and HRSG CO2 emissionsAbdul QodirNo ratings yet

- Anggi Bagus FixDocument23 pagesAnggi Bagus FixAbdul QodirNo ratings yet

- KelomplkDocument23 pagesKelomplkAbdul QodirNo ratings yet

- Exergía Acido NitricoDocument35 pagesExergía Acido NitricoAnita BuelvasNo ratings yet

- (2018) Final Exam +solutions PDFDocument23 pages(2018) Final Exam +solutions PDFTman LetswaloNo ratings yet

- Perf#1 - 10715 - 4 Mill - HPH567is - Beban 400Document5 pagesPerf#1 - 10715 - 4 Mill - HPH567is - Beban 400Khoirotul LatifahNo ratings yet

- CAD FileDocument75 pagesCAD FilepurtikaNo ratings yet

- Model No 11:: Problem StatementDocument6 pagesModel No 11:: Problem StatementSohail ZafarNo ratings yet

- Pocket Formula GuideDocument68 pagesPocket Formula GuideMike StevensonNo ratings yet

- Benzene Process PFD AnalysisDocument63 pagesBenzene Process PFD AnalysisRodelas Janine100% (2)

- M Liszka Pinch ExamplesDocument40 pagesM Liszka Pinch Examplesstharik3722No ratings yet

- Cogeneration Unit Technical DataDocument7 pagesCogeneration Unit Technical DataElias RizkNo ratings yet

- Separation of Ammonia and WaterDocument9 pagesSeparation of Ammonia and WaterAnonymous NyvKBWNo ratings yet

- CR4-Results and DiscussionDocument8 pagesCR4-Results and DiscussionAbdulbari UshNo ratings yet

- Engineering Declaration Unit # 2 JindalDocument16 pagesEngineering Declaration Unit # 2 JindalVIBHAV100% (1)

- Appendix A: - .Sizing of Distillation ColumnsDocument14 pagesAppendix A: - .Sizing of Distillation ColumnsBlack WidowNo ratings yet

- Model No 10:: Problem StatementDocument6 pagesModel No 10:: Problem StatementSohail ZafarNo ratings yet

- 427-Landfill Gas Collection and RecoveryDocument37 pages427-Landfill Gas Collection and RecoveryJocelyn MasonNo ratings yet

- Acetone Project StatementDocument7 pagesAcetone Project StatementAmr TarekNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/APR 2007/KJM451Document10 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/APR 2007/KJM451Diraf AlipNo ratings yet

- Compressor: 40-K-001: Stream Name 131Document3 pagesCompressor: 40-K-001: Stream Name 131Ioana PopescuNo ratings yet

- Produce Acetic Anhydride Using Aspen PlusDocument9 pagesProduce Acetic Anhydride Using Aspen PlusHoneydaa Fitra100% (2)

- Analysis of Waste Heat Recovery Boiler Efficiency Evaluation of Boiler - Direct Method - Indirect MethodDocument7 pagesAnalysis of Waste Heat Recovery Boiler Efficiency Evaluation of Boiler - Direct Method - Indirect MethodHasan Ahmed100% (1)

- Cyclohexane Production Unit: Presented by Brian CliftonDocument28 pagesCyclohexane Production Unit: Presented by Brian Cliftonalpha2013No ratings yet

- Energy Production from biomass gasification by molten carbonate fuel cells: process simulation and optimizationDocument6 pagesEnergy Production from biomass gasification by molten carbonate fuel cells: process simulation and optimizationNaason VelascoNo ratings yet

- Mass Transfer Design Question PaperDocument11 pagesMass Transfer Design Question PaperAbdul Majid IaNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Hydrogen Production TechnologiesFrom EverandHydrogen Production TechnologiesMehmet SankirNo ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Sustainable Retail RefrigerationFrom EverandSustainable Retail RefrigerationJudith A. EvansRating: 5 out of 5 stars5/5 (1)

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Hydroprocessing for Clean Energy: Design, Operation, and OptimizationFrom EverandHydroprocessing for Clean Energy: Design, Operation, and OptimizationNo ratings yet

- Training Needs Analysis - A LayoutDocument1 pageTraining Needs Analysis - A LayoutJeevanNairNo ratings yet

- Audit Plan - ScheduleDocument2 pagesAudit Plan - ScheduleJeevanNairNo ratings yet

- Layout and FlowDocument38 pagesLayout and FlowJeevanNair100% (1)

- QM001 Difference Between Quality Assurance and Quality ControlDocument2 pagesQM001 Difference Between Quality Assurance and Quality ControlSandeep KumarNo ratings yet

- Audit Plan - ScheduleDocument2 pagesAudit Plan - ScheduleJeevanNairNo ratings yet

- Industry Code of Practice On Chemicals Classification & Hazard CommunicationDocument374 pagesIndustry Code of Practice On Chemicals Classification & Hazard Communicationcoo_areNo ratings yet

- Material Requirement Planning and Master Prod ScheduleDocument68 pagesMaterial Requirement Planning and Master Prod ScheduleJeevanNairNo ratings yet

- QM001 Difference Between Quality Assurance and Quality ControlDocument2 pagesQM001 Difference Between Quality Assurance and Quality ControlSandeep KumarNo ratings yet

- Jis A 5908 e 2003Document28 pagesJis A 5908 e 2003JeevanNair100% (1)

- Elvax and WaxDocument5 pagesElvax and WaxJeevanNairNo ratings yet

- MatlabDocument14 pagesMatlabJeevanNairNo ratings yet

- Chemical Reaction EngineeringDocument4 pagesChemical Reaction EngineeringJeevanNairNo ratings yet

- Statement of Changes in EquityDocument24 pagesStatement of Changes in EquityChristine SalvadorNo ratings yet

- New Format Exam Q Maf620 - Oct 2009Document5 pagesNew Format Exam Q Maf620 - Oct 2009kkNo ratings yet

- D B R R C S R: George G. Kaufman and Kenneth E. ScottDocument29 pagesD B R R C S R: George G. Kaufman and Kenneth E. Scottedo_recobaNo ratings yet

- RERADocument16 pagesRERAanugyamishra327No ratings yet

- Investment:: Process of Estimating Return and Risk of A Security Is Known As Security AnalysisDocument76 pagesInvestment:: Process of Estimating Return and Risk of A Security Is Known As Security AnalysisDowlathAhmedNo ratings yet

- 70 07 Key Metrics Ratios AfterDocument16 pages70 07 Key Metrics Ratios Aftermerag76668No ratings yet

- Tenants in Common 1031 ExchangeDocument2 pagesTenants in Common 1031 ExchangeRayNo ratings yet

- E Book SeewbanDocument102 pagesE Book SeewbanGeorge Diamandis1No ratings yet

- Top 50 Indonesian billionaires' net worth in 2017Document4 pagesTop 50 Indonesian billionaires' net worth in 2017Irfan PohanNo ratings yet

- JWCh07 PDFDocument29 pagesJWCh07 PDF007featherNo ratings yet

- Earnings Presentation FY24 Q3Document35 pagesEarnings Presentation FY24 Q3Zerohedge JanitorNo ratings yet

- Azizi Completes 479-Unit Aura in Downtown Jebel Ali - Projects and Tende...Document20 pagesAzizi Completes 479-Unit Aura in Downtown Jebel Ali - Projects and Tende...Sanabel EliasNo ratings yet

- Private Placement & Venture CapitalDocument18 pagesPrivate Placement & Venture Capitalshraddha mehtaNo ratings yet

- Relationship Between GDP, Inflation and MonopolyDocument3 pagesRelationship Between GDP, Inflation and MonopolyDeepti VermaNo ratings yet

- Lorenzo Ona V CIRDocument1 pageLorenzo Ona V CIREryl YuNo ratings yet

- BP Investment AppraisalDocument71 pagesBP Investment Appraisalprashanth AtleeNo ratings yet

- Model Trust Deed for Public CharityDocument12 pagesModel Trust Deed for Public CharityYugandhar venkatram100% (1)

- Tertiary sector servicesDocument2 pagesTertiary sector servicesDaniel RandolphNo ratings yet

- MIF Group 1 AnswersDocument3 pagesMIF Group 1 AnswersEryn GabrielleNo ratings yet

- Impact of FDI in Indian EconomyDocument7 pagesImpact of FDI in Indian EconomyDEVARAJ KGNo ratings yet

- GSCL Annual Report 2008-10Document46 pagesGSCL Annual Report 2008-10Sasmita Mishra SahuNo ratings yet

- A Comparative Study of Marketing Strategies of HDFC With Icici BankDocument10 pagesA Comparative Study of Marketing Strategies of HDFC With Icici BankXtremeInfosoftAlwarNo ratings yet

- IaaifDocument96 pagesIaaifsmitpatel652No ratings yet

- Accounting TerminologyDocument26 pagesAccounting TerminologyCynard Gonzales EspiloyNo ratings yet

- Mudit PatniDocument2 pagesMudit PatniMudit PatniNo ratings yet

- Selfridges - Company CapsuleDocument14 pagesSelfridges - Company Capsulekidszalor1412No ratings yet