Professional Documents

Culture Documents

A New Model For Laminar, Transitional, and Turbulent Flow of Drilling Muds

Uploaded by

Leidy Laura Álvarez BerríoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A New Model For Laminar, Transitional, and Turbulent Flow of Drilling Muds

Uploaded by

Leidy Laura Álvarez BerríoCopyright:

Available Formats

Society of Petroleum Engineers

SPE 25456

A New Model for Laminar, Transitional, and Turbulent Flow

of Drilling Muds

T.O. Reed, Conoco Inc., and AA Pilehvari, U. of Tulsa

SPE Members

Copyright 1993, Society of Pf1.\roleum Engineers, Inc.

This peper was prepared for presentation at the Production Operations Symposium held In Oklahoma City, OK, U.S.A., March 21-23, 1993.

This paper was selected for presentation by an SPE Program Commillee following review of information contained In an abstract submitted by the author(s). Contents of the paper,

as presented, have not been reviewed by the Society of Petroleum Engineers and are SUbject to correction by the author(s). The material, as presented, does not necessarily reflect

any of the Society of Petroleum Engineers, Its officers, or members. Papers presented at SPE meetings are subject to publication review by Editorial Committees of the Society

of Petroleum Engineers. Permission to copy Is restricted to an abstract of not more than 300 words. illustrations may not be copied. The ebstrect should contain conspicuous acknowledgment

of and by whom the paper is presented. Write Librarian, SPE, P.O. Box 833836, Richardson, TX 75083-3838, U.S.A. Telex, 163245 SPEUT.

ABSTRACT

The concept of an "Effective" diameter is introduced for the flow of

drilling muds through annuli. This new diameter accounts for both

annular geometry and the effects of a non-Newtonian fluid. It

provides the link between Newtonian pipe flow and non-Newtonian

flow through concentric annuli. The method is valid in any flow

regime and can be used to determine whether a DOn-Newtonian flow

is laminar, transitional, or turbulent. An analytical procedure is

developed for computing frictional pressure gradients in all three flow

regimes. The analysis also quantifies bow flow transition is delayed

by increasing the yield stress of a fluid. In addition, it is shown that

transition in an annulus is delayed to higher pump rates as the ratio

of inner to outer diameter increases. Furthermore, the method

accounts for wall roughness and its affects on transition81 and

turbulent pressure gradients for non-Newtonian flow through pipes

and concentric annuli. Finally, the method runs on a 386 PC in only

a few seconds.

INTRODUCTION

The standard API methods for drilling hydraulics assume either a

Power Law or a Bingham Plastic rbeology modeL In reality, most

drilling muds correspond mucb more closely to the Modified Power

Law or Herschel-Bulkley rbeological model. This distinction is

particularly important for the annular geometries typical of normal

drilling conditions where shear rates are usually low and the Power

Law underestimates and Bingham Plastic model overestimates

frictional pressure drops. This paper also shows that these two

classical models, respectively, underestimate and overestimate pump

rates required for transition from laminat to turbulent flow.

Although there have been a number of papers pUblished on the

laminar flow of yield-pseudoplastics through annuli/-J none claim to

be uniformly valid for laminar, transitional, and turbulent flow. This

can be accomplished by introducing tbe concept of an "Effective"

diameter which accounts.for both annular geometry and the effects

of a non-Newtonian fluid. This diameter also enables the inclusion

of the effects of wall roughness on frictional pressure gradients and

the process of flow transition. Furthermore, the resulting model can

be used to determine whether flow of a non-Newtonian fluid through

References and illustrations at end of paper.

a pipe or concentric annulus is laminar, transitional, or fully turbu-

lent.

A derivation of the model is presented in the Appendix. Some

additional background and results from the model are given in the

fonowing discussions.

NEWTONIAN FLOW

RelatioDShip Between Pipe and Annular Flows. A considerable

number of "equivalent" diameters have been proposed over the years

for flow through conduits other than circular pipes.1O-1z The purpose

of defining such a diameter is to introduce definitions of friction

factor and Reynolds number that will enable application of the wen-

known relations for pipe flow to other geometries. In particular, the

objective is to be able to calculate what the frictional pressure drop

will be for a given fluid at a particular flow rate.

h shown in the Appendix, the friction factor for a concentric

annulus should be based on the Hydraulic Diameter, Dhy> which is

simply the difference between the inner and outer diameters. The

Reynolds number should be based on an Diameter equal

to the square of Lamb's Diameter, D

L

, divided by Dhyt see

Appendix Eqs. A.12, 13 and 14. When the friction factor and

. Reynolds number are defined in this manner, the classical relations

for Newtonian pipe flow, e.g., the Moody Diagram, can be applied

directly to concentric annuli. In fact, Jones and Leung

13

have proven

that these definitions also apply to fully-turbulent flow through an

annulus. This was demonstrated by showing that a variety of

experimental data for concentric annuli agree with the Colebrook

Equation for turbulent pipe flow, which is equivalent to the fully

turbulent and hydraulica1ly rough portions of the Moody Diagram.

Flow Transition in Annuli. In addition to being applicable in the

laminar and turbulent regimes, these same definitions can also be

used to predict the "critical" Reynolds number at which laminar flow

ends and transition to turbulence begins. Prof. Hanks and his

students have published experimental data on flow transition in

concentric annuli.

I

4-15 Some of their data is shown in Fi&- 1. The

dashed curve is the results of predictions from a transition theory

469

2

A NEW MODEL FOR LAMINAR, TRANSmONAL, AND

ruRBULENT FLOW OF DRILLINGMUDS SPE2S456

developed by Hanks in the early 1960s.7,1"17 The solid curve comes

from simply setting the Reynolds number, based on the Equivalent

Diameter of Jones and Leung, equal to 2100. A Reynolds number

based only on Lamb's Diameter is used for the ordinate in order to

display how the critical values vary with diameter ratio. It is readily

seen that the much simpler transition criterion provides better

agreement with Hanks' experimental data. The new criterion shows

that transition from laminar flow is delayed to progressively higher

velocities or pump rates as diameter ratio increases.

NON-NEWTONIAN FLOW

Pipe Flow. Prof. Metzner and his students reported some ~ i o n r i n

work in the 19508 on non-Newtonian flow through pipes.!l-Z1 Their

experiments with Power-Law fluids in pipes provided the first clear

definitions of how the friction factor varies with Reynolds number in

the laminar, transitional, and turbulent regimes. They found that a

decreasing power-law exponent delays transition to higher Reynolds

numbers and shifts the turbulent friction factors downward. This is

a direct result of increasing degrees of the phenomenon called wshear

thinning."

In addition to the test data, Metzner and his students also developed

a novel analysis that provided a way to generalize their results for

Power-Law fluids to all time-independent, non-Newtonian fluids.

They simply defined:

Wall Shear Stress = K' x (Newtonian Shear Rate)N (1a)

or using standard symbols:

, N

T

w

= K x (8 v / D) ..........uo (1b)

From this equation, it follows that the definition of the exponent WNW

is:

N =d(ln Twl / d(ln (8 v / D)] (1e)

They showed how the two parameters "K'w and WNW can be applied to

Power-Law (PL) fluids and Bingham Plastics (BP). The Appendix

provides the details on how this approach can also be applied to a

Herschel-Bulkley (BB) fluid, which is essentially a combination of the

PL and BP rheological models.

The Metzner group also developed the following relation for wall

shear rate in a pipe for a general fluid with time-independent

properties.

Generalized Pipe Shear Rate:

'Yw = (3N + 1) 8 v / (4N D) uo (2)

This expression led us to the following conclusion. An "Effective

w

diameter can be defined so that the generalized shear rate can be put

into the same form as the shear rate for Newtonian pipe flow, viz.,

(8 v/D). Using this logic, the Effective Diameter for generalized non-

Newtonian pipe flow is:

WElTective

w

Pipe Diameter =D

eff

=4N D/(3N + 1) .... (3)

The wEffective

w

diameter for non-Newtonian pipe flow is the

diameter of a circular pipe that would have the identical pres-

sure drop for flow ofa Newtonian fluid with viscosity equal to

the "apparent" viscosity and the same average velocity as the

non-Newtonian flow. Note that this diameter is less than the

physical diameter for pseudoplastics (N < 1) and is greater than the

physical diameter for di1atant fluids (N > 1). As will be shown, the

Effective Diameter makes it easier to relate non-Newtonian and

Newtonian flows. The advantage of such a connection is that the

well-established friction factor relations for Newtonian flows can then

be applied to non-Newtonian flows. This greatly simplifies the task

of computing frictional pressure drops for such flows.

The remaining variable that is needed to define the Generalize

Reynolds Number is the "apparent" Newtonian viscosity. This

parameter is defined by:

App. Viscosity =Shear Stress/Shear Rate @ Wall (4a)

1J.w,app =K' (8 v / D)N/ 'Yw ..................................uo.... (4b)

With these definitions, the Generalized REynolds number (GRE) is

defined as:

NRe,O =p v Deffl 1J.w,app uo (5)

This expresses the Reynolds number for non-Newtonian pipe flow in

the same algebraic form as for a Newtonian fluid Metzner &Reed!g

showed that the GRE is related to laminar friction factor by the

same classical equation for Newtonian flow, viz,

F

c

=16/ NRe,o , Laminar Non-Newtonian Flow...... (6)

These authors showed that experimental pipe flow data for a variety

of non-Newtonian fluids followed this relationship. Later experi.

ments with Power-Law fluids in turbulent pipe flow led Dodge &

Metzner3l to modify the classical Colebrook equation for turbulent

friction factors in Newtonian pipe flow, see Eq. A-45. This was

necessary in order to correlate the data because the shear-rate exp0-

nent was found to be a significant parameter. In particular, friction

factors decrease with decreasing values of the Power-Law exponent.

Figure Z shows the correlations Dodge & Metzner developed for

laminar and turbulent flow. The transition zones were not correlated

by these authors, but their experimental data follows the indicated

curves between the end of laminar flow and the beginning of fully-

turbulent low. As described in the Appendix, a new correlation for

the transition zones bas been developed based on the experimental

data of Dodge & Metzner. The curves in the transition zones are

from this new correlation.

The generalized shear-rate exponent "Nil can be used to extend the

data of Dodge & Metzner for Power-Law fluids to other non

Newtonian fluids. In partiCUlar, Dodge & Metzner derived the

appropriate equations for the GRE, shear rate, and apparent

viscosity for flow of a BP through pipes. Their work is extended to

Herschel-Bulkley fluids and concentric annuli. in the Appendix.

However, before discussing annular flow, it is appropriate to first

discuss some results from the new transition criterion for fluids with

a yield stress.

Hanks and Pratt

J

proposed a model for flow of Bingham Plastics

through pipes. Their paper also includes a transition criterion. They

chose to base their criterion on the so-called Bingham Plastic

Reynolds number and the Hedstrom number. These two dimension-

less parameters are defined in the Appendix, see Eqs. A-50 and

A-51. Unfortunately, the BP Reynolds number is not a legitimate

measure of Reynolds number effects simply because the Plastic Vis

cosity (PV) is a constant and does not vary with shear rate as the

apparent viscosity does. Furthermore, the Hanks and Pratt criterion

does not agree with experimental data at higher values of the

Hedstrom number.

J

This disagreement is shown in Fig. 3. Other

investigators have also noted this disagreement.Z1-22 In contrast, the

solid curve in Fig. 3 is based on the new transition criterion which

requires the critical condition for any fluid to occur when the product

470

SPE 25456 T. REED AND A. PILEHVARI 3

of the Fanning friction factor and the GRE equals 16.1. (As may be

seen from Eq. 6, this product is 16 in Jaminar flow, and it exceeds this

value wben transiqon begins.) This generalized transition criterion is

designed to reduce to a critical Reynolds number of 2100 for

Newtonian pipe flow, see last section of Appendix.

The underprediction of the data by the Hanks and Pratt criterion is

even more apparent when critical values of the GRE are plotted as

a function. of Hedstrom number, Fig. 4. Here it becomes clear that

tbe Hanks and Pratt criterion predicts decreasing flow rates for

transition as the Yield Point (YP) increases. This certainly violates

tbe expected trend. The new generalized criterion show the expected

trend, i.e., higher pump rates, are required to achieve transition as

tbe yP of a BP increases.

It is instructive to plot the friction factors for BP pipe flow through

all three flow regimes with Hedstrom number as a parameter. This

is sbownin Fig. 5. This figure shows bow an increasing yP delays

transition to higher pump rates and also extends tbe transition zone

over a progressively wider range of pump rates. For example, wben

tbe Hedstrom number is 500,000, the flaw is not fully turbulent until

a Reynolds number of 100,OOO! This compares with a common value

of about 3,000 for Newtonian pipe flow.

It is particularly important to observe that all of the curves for

eventually merge into tbe turbulent curve for Newtonian

flow. This occurs because the yP becomes progressively less

significant as sbear rate increases. Hence, the curves have the

expected asymptotes. . There is one other point to notice from

comparing Figs. 5 and 3. A BP bas a sbear-rate exponent of 1;

wbereas, a PL fluid generally bas a nonunity exponent. This is the

basic reason wby the friction factor curves for different values of the

sbear-rate exponent do not merge and remain distinct for all

Reynolds numbers. In tum, this implies that a Herschel.Bulkley fluid

will exhibit somewbat different behavior since it combines tbe BP and

tbe PL rbeological models. In particular, one can infer that a yield

stress will delay and extend the transition zone, and tbe transitional

values of friction factor will eventually merge with the fully-turbulent

curve for a PL fluid with an exponent equal to whatever appears in

tbe Herscbel-Bulkley model, see Eq. 7 below.

At tbis point, it is appropriate to introduce some viscometer data for

a representative drilling mud. Some typical rotating-cup data are

shown in Fig. 6. Dial readings for six: rotary speeds are given. The

two parameters in the BP model (YP and PV) and the PL model (K

and "n") are determined according to standard API procedures by

fitting these two rheological models to the 300 and 600 rpm data. In

contrast, the three parameters of the HB model allow a good fit to

all six data points. Since annular flow shear rates are normally below

the 100 rpm (170 sec-I) viscometer data, it is important to have a

model which is valid at low shear rates. On the other hand, the HB

model can also be used to estimate frictional pressure drops and flow

regimes for flow through drill pipes where shear rates are high. The

HB parameters for the particular data of Fig. 6 are:

T = Yield Stress + K (Shear Rate)-

::: 14 +0.281 (,y)o.m Ibf/l00 ft2 [0.4788 Pal (7)

These parameters will be used for illustration purposes in Figs. 7 tbru

11. A weight of 12 ppg [1,438 kglmJ] will also be assumed for this

example mud.

Figure 7 presents friction factors through the transition zone for the

example mud flowing through pipes. The PL model leads to transi-

tion at lower pump rates. Initiation of transition is delayed to higher

pump rates based on the HB model, but fully-turbulent flow occurs

at about the same GRE as for tbe PL case. The HB curve for fully-

turbulent flow does not merge witb the PL curve at higher Reynolds

numbers because the sbear rate exponent for the PL model is only

0566. The results for the BP model is as expected, i.e., transition is

delayed tbe most by using this model. Furthermore, the extent of.

the transition zone is expanded significantly, and the GRE is an

order-of-magnitude larger before fully-turbulent flow is achieved.

In order to relate these results to a typical field application, consider

flow through a standard weight 5-incb drill pipe with an ID of

4.276 incbes. Fu1Iy-turbuient flow is achieved at a GRE of 3800 and

a pump rate Of 270 gpm [17.0 lis] using the PL model. The corre-

sponding results for the HB model occurs at a GRE of 4100 and a

pump rate of 310 gpm [19.6 lis]. In contrast, tbe BP model leads

to a prediction of fully-turbulent flow at a GRE of 22,300 and a

pump rate of 670 gpm [42.3 Urn]. (Note: The analysis does not

account for the effects of restrictions at tool joints whicb could cause

flow transition to begin at lower pump rates.)

It is also of interest to compare the frictional pressure gradients for

a realistic pump rate of 600 gpm [37.85 lis]. The results for the PI..,

HB, and BP models, respectively, are 0.085, 0.099, and 0.104 psilft

[22.62 kPa/m]. The relative close values for the HB and BP fluids

are a result of the HB being fully turbulent and the BP being in

transition at this pump rate. Again, if tool joints caused transition to

occur at lower pump rates and the BP were in fully-turbulent flow at

600 gpm [37.85 lis], then the difference between pressure drops for

the HB and BP would be larger.

Annular Flow. The flow model can be extended to concentric annuli

by altering tbe definition of the "Effective" diameter to include the

effects of the different geometry. The "Effective" diameter for a

concentric annuli is equal to DJIy IG. The "Effective" diluneter for

non-Newtonian flow through a concentric annulus is the dia-

meter of a circular pipe that would have the identical pressure

drop for flow ofa Newtonian fluid with a viscosity equal to the

"effective" viscosity, which is based on the average wall shear

rate in the annulus, and has a velocity equal to the non-

Newtonian annular flow velocity.

The "an function is based on a correlation of the analytical solution

by Fredrickson and Bird! for flow of a Power-Law fluid through a

concentric annulus. This function is dependent on both tbe ratio of

inner to outer diameters and the shear-rate exponent. The function

is defined in the Appendix by Eq. A-34. This correlation can be

applied to other fluids by using the generalized exponent "N", Eq. 1c,

in place of the usual PL exponent "n." The details are given in the

Appendix under tbe beading "Non-Newtonian Annular Flow."

The following discussion will focus on some results for a typical field-

size annulus. A 12-1/4" x 5" [31.12 emx 12.7 em] annulus is selected

for illustrative purposes. The same mud rbeology, Eq. 7, and a

weight of 12 ppg [1,438 kg! m

J

] will again be used for computing

frictional pressure gradients through the annulus. It is pertinent to

note that the weight of the mud does not affect laminar frictional

gradients, but weight does influence transitional and turbulent

gradients.

Figure 8 sbows bow the ratio of tbe generalized exponent "N" over

the shear-rate exponent Om" varies with shear rate for the example

HB fluid. As may be seen from Eq. 7, "m" bas the numerical value

of 0.792. Figure 8 shows bow "N" approacbes "m" as wall sbear rate

increases. This is the expected trend because the influence of the

Yield Stress (YS) on T

w

becomes progressively less with increasing

sbear rate, compare Eqs. 1b and 7. In the limit of infinite sbear rate,

N=m.

Figure 8 also identifies tbe initiation of transition at 1910 gpm

[1205 lis], and fully-turbUlent flow begins at 2010 gpm [126.8 lis].

This simply tells us that the flow is laminar over the range of pump

rates that are normally used in the field. Unfortunately, the

does not tell us bow drill string dynamics may influence flow

471

4

A NEW MODEL FOR LAMINAR, lRANsmONAL, AND

TURBULENT FLOW OF DRTI..LING MUDS SPE2S456

transition. It is reasonable to expect the energy added to the flow by

the agitation may cause transition at lower pump rates.

Another parameter in the model is the ratio of Effective diameter

over the Equivalent diameter. This ratio partia1Iy removes geometric

effects and highlights the non-Newtonian effects. Fipre' shows this

ratio approaches unity as "N" goes to one. This is the expected

limiting condition for Newtonian flow. Since Fig. 8 shows that "N"

increases with pump rate, the Effective diameter also increases with

pump rate. This has the net effect of reducing the magnitude of the

increase in frictional pressure gradient as pump rate is increased, i.e.,

the fluid is "shear thinning."

This leads to the question, what happens to the "apparent" viscosity

as pump rate increases? An "Effective" viscosity is defined in a man-

ner analogous to pipe flow. The primary difference for an annulus

is: the "Effective" viscosity is defined by the average wall shear stress

acting on the inner and outer walls and divided by the average wall

shear rate, see Eq. A-43. This viscosity is presented in Fig. 10 as a

function of pump rate. It continuously decreases with pump rate and

. has a noticeable drop at transition from laminar to turbulent flow.

This is caused by the rapidly increasing shear rate as transition occurs.

Figure 11 presents friction factors as a function of the GRB for the

example annulus and mud properties. For smooth walls, the increase

in friction factor through the transition zone is small. As indicated in

Fig. 8, the transition zone occurs between pump rates of 1910 and

2010 gpm [120.5-126.8 I.Js].

An example of the effects of rough walls is also included in Fig. 11.

It may be noticed that the initiation of transition occurs at the same

GRB' This is consistent with the experimental data of Nikuradse for

Newtonian pipe flow, see Schlichting.

24

As indicated in the figure,

transition to turbulent flow takes place over a smaller range of pump

rates, 1910 to 1970 gpm [120.5 to 124.3 I.Js], and the fully turbulent

pressure drops are approximately 70 percent larger than the corre-

sponding turbulent friction factors for smooth walls.

The "relative roughness" for this illustration is approximately 0.01.

This is based on dividing the absolute roughness height by the

"Equivalent" diameter, Eq. A-14. However, the correct definition of

relative roughness for non-Newtonian flows is the ratio of absolute

roughness over the "Effective" diameter. Hence, relative roughness

varies with the fluid and the shear rate.

Table 1 present a list of some of the relevant parameters through the

transition zone for the rough-wall case. It can be seen that the

relative roughness decreases as pump rate increases. The authors

believe these are the first computations for the effects of wall

roughness on non-Newtonian pressure gradients in the transitional

and turbulent regimes. (Note: pressure gradients are given in units

of inches of water per foot; these units are equal to 0.0361 psiIft or

0.8164kPa/m.)

Finally, Fig. 12 compares the model with test data for a Mixed Metal

Hydroxides (MMH) mud system flowing through a 5.023" x 2.375"

[12.76 cmx 6.03 em] annulus. The tests were conducted in Amoco's

Drilling Hydraulics Test Facility by personnel from the Petroleum

Engineering Department, Tulsa University. Pressure drops were

measured over a length of 50 ft [15.24 m]. Pump ratj:s were varied

from 50 to 500 gpm [3.16 to 31.55 I.Js]. Experimental data for a high

and a low rheology MMH fluid are included in Fig. 12 The

corresponding rotating-cup viscometer readings at the six standard

speeds are: 327,57.3,61.5,63.0,66.5 and 25,13.5,18.3,220,28.0.

These values are the average of readings for four different samples

taken during the time of a tesL

As indicated in Fig. 12, the high-rheology fluid appears to have been

in the laminar-flow regime for the entire range of pump rates. The

model predicts transition at higher pump rates and friction factors

that continuously decrease through the transition zone. According

to the model, the flow is not fully turbulent until a GRB of 18,000

and a pump rate of 77JJ gpm [45.42 I.Js]. The predicted values of

turbulent friction factors are nearly constant for a wall roughness of

0.00018 in. [0.0046 mm].

The above value of wall roughness gave good agreement between

predicted turbulent friction factors and experimental data for thelow-

rheology fluid. Unfortunately, water tests to determine wall

roughness for the annulus were not performed. However, Fig. 12

shows encouraging agreement between predictions for the low-

rheology fluid and the corresponding data through au three flow

regimes.

Additional tests wereconductedwith bentonitemuds flowing through

rough pipes. In these cases, wall roughness was determinedvia water

tests, and predictions from the model, using the experimental values

of wall roughness, agree very closely with the test data for au three

flow regimes. This data covers a GRB range of 500 to 270,000 and

includes relative roughness values up to 0.002. Because of space

limitations, these non-Newtonian pipe-flow data are not presented

here.

CONCLUSIONS

1. A new analysis has been developed for non-Newtonian flow

through pipes and concentric annuli. The method is based oil

relating non-Newtonian flows to Newtonian flows. The advan-

tage is that well-established results for Newtonian flows can be

applied to non-Newtonian flows.

2 The "Effective" diameter is a key concept of the method. It

accounts for both geometric and non-Newtonian fluid effects

on frictional pressure gradients in pipes and annuli.

3. Results agree with finite-difference computations for laminar

flow of a Herscbel-Bullcley fluid through concentric annuli.

4. The analysis is valid for the laminar, transitional, and fully-

turbulent flow regimes. The method incorporates a new transi-

tion criteria that accounts for a delay in flow transition with

increasing ratio of the inner-to-outer diameters in concentric

annuli. This agrees with experimental data reported in the

literature.

5. Model predictions of critical Reynolds numbers agree with

published data for BP pipe flows.

6. The Herschel-Bulkley rheolOgical model is used which includes

Newtonian, Power-Law, and BinghamPlastics as special cases.

This IDOre accurate rheological model is equally valid for

predictions of pressure gradients in drill pipes and the large

annuli typical of full-scaJe

7. When using the same viscometer data, results from the

analyses show transition from laminar to turbulent flow occurs

at higher pump rates than for a Power-Law fluid, but signifi-

cantly lower than the corresponding Bingham Plastic fluid

8. The Colebrook equation for turbulent friction factors has been

extended so that it applies to non-Newtonian flows through

pipes and concentric annuli with smooth or rough walls.

9. The method accounts for the effects of wall roughness on

frictional. pressure gradients in transitional flow.

10. Model predictions of pressure gradients in au three flow

regimes have beenverified by experimental data for MMHand

bentonite flowing through pipes and annuli with varying

degrees of wall roughness.

472

SPE 25456 T. REED AND A PILEHVARI 5

7

w

= shear stress at walls of a pipe or annulus

11. The method runs on a 386 PC in only a.few seconds. This is

made possible by avoiding either or finite-

element numerical solutions. Furthermore, the capabilities of

these numerical techniques ha\ie not yet been developed to

model transitional nor turbulent flow of a Herschel-Bulkley

fluid.

NOMENCLATURE

JLw.eff

p

7

= "effective" Newtonian viscosity at walls of an annulus,

Eq. A-43

= fluid density, Ibm/gal

= shear stress, Ibf/l00 tt2

A = parameter used to define "N" for a Herschel-Bulkley

fluid, Eq. A-31

D = internal diameter of a circular pipe, in.

D

eff

= Effective diameter of either a pipe or annulus, Eq. A-37,

in.

Dhy = hydraulic diameter, Do - D

j

, in.

D

j = inner diameter of annulus = drill pipe OD, in.

D

L

= Lamb's diameter for a concentric annulus, Eq. A-l2, in.

Do = outer diameter of annulus = borehole diameter

F

c

= Fanning friction factor, 7..... /(1/2 p v2)

Flam = Fanning friction factor in laminar flow

Fir = Fanning friction factor in transition reginie

F

lUrb

= Fanning friction factor in turbulent flow

G = an ExIog correlation factor, Eq. A-34

He = Hedstrom number, Eq. A-51

K = consistency indexused for either a Power-Law, Eq. A-19,

or a Herschel-Bulkley fluid, Eq. A-29, Ibf-sec"'/l00 ft2

K'

= generalized index of Metzner and Reed,

Eq. Ib, Ibf-sec"/l00 ft '

L = length of pipe or annulus over which pressure drop is

measured

m = flow behavior index for Herschel-Bulkley fluids, Eqs. 7

andA-29

N = generalized flow behavior index of Metzner and Reed,

Eqs. Ib and lc

NRe,G

= Generalized REynolds number, Eq. A-44

n = flow behavior index for PL fluids, Eq. A-19

PV = plastic viscosity for a Bingham Plastic fluid

RCoL

=

Reynolds number based on D

L

v

= velocity of flow = flow rate/cross-sectional area

X = ratio of yP 1wall shear stress, Eq. A-54b

Y = an ExIog correlation factor, Eq. A-32

yP

=

yield point for a Bingham Plastic, Ibf/l00 tt2

YS

=

yield stress for a Herschel-Bulkley fluid, Eqs. 7 and A-29,

Ibf/l00 ft2 .

Z

=

an ExIog correlation factor, Eq. A-33

Greek Letters

e = absolute height of wall roughness, in.

.

'Yw,avg = average shear rate at walls, Eq. A-41, 1/see

JLw,app = "apparent" Newtonian viscosity, Eq. A-23, Ibf-sec/l00 ft2

ACKNOWLEDGEMENTS

We thank the management of Conoco, Inc. for permission to publish

this paper. We also thank Amoco, Inc. for allowing tests in their

research facilities by R Subramanian, a Tulsa University graduate

student

REFERENCES

1. Fredrickson, A G., and Bird, R B., "Non-Newtonian Flow in

Annuli," IntI. Engr. Chem. (March 1958) SO, No.3, 347-52.

2. Hanks, R W., "The Laminar-Turbulent Transition for Fluids

with a Yield Stress," AlChE1. (May 1963) 9, No.3, 306-09.

3. Hanks, R W. and Pratt, D. R, "On the Flow of Bingham

Plastic Slurries in Pipes and Between Parallel Plates," SPFJ

(Dec. 1967) 342-46.

4. Hanks, R W. and Ricks, B. L, "Laminar-Turbulent Transition

in Flow of Pseudoplastic Fluids with Yield Stresses," AlAA.

Jour. ofHydronaulics (Oct. 1974) 8, No.4, 163-66.

5. Hanks, R W., "The Axial Laminar FlowofYield-Pseudoplastic

Fluids in a Concentric Annulus,"IntI. Engr. CMm. Process Des.

Dev. (1979) 18, No.3, 488-93.

6. Haciislamoglu, M., and Langlinais, J., "Non-Newtonian Flowin

Eccentric Annuli," ASME J. Energy Resources Tech., (Sept

1990) lU, No.3, 163-169.

7. Oltafor, M. N. and Evers, J. F., "Experimental Comparison of

Rheology Models for Drilling Fluids," paper SPE 24086

presented at the 1992 Western Regional Meeting, BakerSfield,

CA, Mar. 3O-Apr. 1.

S. Gucuyencr, H. Land Mehmetoglu, T., "Flowof Yield-Pseudo-

plastic Fluids through a Concentric Annulus," AlChE 1.

(July 1992) 38, No.7, 1139-43.

9. Chin, W. c., Borehole Flow Modeling, Gulf Publishing Co.,

Houston (1992).

10. Miller, c., "Predicting Non-Newtonian FlowBehavior in Duets

of Unusual Cross Section," IntI. Eng. Chem. Pundom. (1972)

11, No.4, 524-28.

11. Hanks, R W., "On the Prediction of Non-Newtonian Flow

Behavior in Duets of Noncircular Cross Section," IntI. Eng.

Fundam.. (1974), No.1, 62-6.

12. Jensen, T. B. and Sharma, M. P. "Study of Friction Factor

Equivalent Diameter Correlations for Annular Flow of Non-

Newtonian Drilling Fluids," ASME 1. Energy Resources Tech.

(Dec. 1987) 109, 200-05.

13. Jones, O. C. Jr., and Leung, J. C. M., "An Improvement in the

Calculation of Turbulent Friction in Smooth Concentric

Annuli," ASME Jour. Fluids Engineering (Dec. 1981) 103,

615-23.

14. Hanks, R W., "Critical Reynolds Numbers, for Newtonian

Flow in Concentric Annuli," AlChEJ. (Jan. 1980) Z', No.1,

152-4.

473

6

A NEW MODEL FOR LAMINAR, TRANSmONAL, AND

TIJRBULENT FLOW OF DRILIJNG MUDS SPE 25456

15. Hanks, R. W., and Peterson, J. M., "Complex Transitional

Flows in Concentric Annuli," AlChE1. (Sept. 1982) 28, No.5,

SOO-06.

16. Hanks, R. W., "Tbe Laminar-Turbulent Transition in Noniso-

thermal Flow of Pseudoplastic Fluids in Tubes," AlChE 1.

(Sept. 1962) 8, No.4, 467-71.

17. Hanks, R. W., "Tbe Laminar-Turbulent Transition for Flow in

Pipes, Concentric Annuli, and Parallel Plates," AlChE lour.

(Jan. 1963) 9, No.1, 45-8.

18. Hanks, R. W., "ATheory of Laminar Flow Stability,"AlChE1.

(Jan. 1969) 15, No. I, 25-8.

19. Metzner, A. B., and Reed, J. C., "Flow of Non-Newtonian

Fluids - Correlation of the Laminar, Transition and Turbulent

flow Regions," AlChE 1. (Dec. 1955) I, No.4, 434-40.

20. Metzner, A. B., "Non-Newtonian Fluid Flow," [nil. Eng. Chem.

(Sept. 1957) 49, No.9, 1429-32.

21. Dodge, D. W., and Metzner, A. B., "Turbulent Flow of Non-

Newtonian Systems," AlChEl. (June 1959) 5, No. 2, 189-204.

22. Mishra, P., and Tripathi, G., "Transition from Laminar to

Turbulent Flow of Purely VISCOUS Non-Newtonian Fluids in

Tubes," Chem. Engt'. Sci. (1971) ZCi, 915-21.

23. Franco, V., and Verduzco, M. B., "Transition Critical Velocity

in Pipes Transporting Slurries with Non-Newtonian Behavior,"

Proc. 14th Miami Univ., Coral Gables, Multipbase Transport

&. Particulate Phenomena Int'l Symp., Vol. 4, 289-99, Miami

Beach, FL, 1988.

24. Schlichting, H., BoundtllY Layer Theory, 7th eel, McGraw-Hill

.Book Co. New York (1979), 616-20.

25. Bourgoyne, A. T. Jr., Chenevert, M. R, Millheim, K. K., and

Young, F. S. Jr., Applied Drilling Engineering, Society of

Pe.troleum Engineers, Richardson, 'IX, p. 140, 1986.

26. Govier, G. W., and Aziz, K., The Flow ofComplex MIXtures in

Pipes, Van Nostrand Reinhold Co., New York (1972) 201-2.

27. Hanks, R. W., "Low Reynolds Number Turbulent Pipeline

Flow of Pseudohomogeneous Slurries," Proc., Hydrotransport

5, Fifth Int'l Cont on the Hydraulic Transport of Solids in

Pipes, . British Hydromechanics Research Association

(May 1978) paper C2.

28. Theory and Application of Drilling Fluid Hydraulics, A.

Whittaker and EXLOG Staff (ed.), International Human

Resources Dev. Corp., Boston (1985), 102.

29. Hanks, R. W., "Tbe Not so "Generalized" ReynOlds Number,"

Proc. 4th Int'l Tech. Conf. on Slurry Transport, Slurry Trans-

port Association, Washington, D.C. (1979) 91-98.

30. Churchill, S. WOJ "Friction Factor Equation Spans All F1uid-

Flow Regimes," Chemical Engineering, (1977) Nov. 7, 91-2.

31. Wilson, N. W., and Azad, R. S., "A Continuous Prediction

Method for FullyDeveloped Laminar, Transitional, and Turbu-

lent F1ows.in Pipcs,"ASMElour. ofAppliedMec1uJnics (1975)

March, 51-4.

APPENDIX-DERIVATION OF MODEL

The analysis begins with the question: Is there any way to relate

Newtonian pipe flow to non-Newtonian annular flow? If this is

possible, then all of the well-established knowledge about Newtonian

pipe flow can then be applied to the more difficult non-Newtonian

problem. This can be accomplished by first introducing an"Equiva-

lent" diameter to relate a concentric annular geometry to a Circular

pipe. Next, this concept can be extended by introducing an "Effec-

tive" diameter which properly accounts for non-Newtonian effects.

The development of the procedure begins with an analysiS of Iaminar

flow in pipes and annuli. Next, fully-turbulent flow is analyzed and

wall roughness is introduced. FJnally, a procedure is developed for

predicting when transition from laminar to turbulent flow begins and

when it ends.

LAMINAR NEWrONIAN FLOWS

Pipe Flow. The purpose of the following discussion is to introduce

the terminology that will be used. The solution forisothermaI fully-

developed viscous flow of a Newtonian fluid through a circUlar pipe

was derived by Hagen and Poiseuille in the 1800s. Their equation

for frictional pressure gradient is:

dP / elL =32,.,. v/0

2

(A-I)

Next, we note that a Newtonian fluid is defined to be one for which

shear stress is linearly proportional to shear rate, i.e., Shear Stress =

viscosity xShear rate.

T = ,.,. 'Y (A-2)

Equations A-I and A-2 can be related via a simple force balance

between the pressure gradient that drives flow through the pipe and

the viscous forces at the wall that oppose the motion. This provides

the following equation.

Tw =dP / elL X 0 /4 (A-3)

The subscript OW" refers to the shear stress and shear rate at the

inside wall of a pipe. An expression for shear rate at the waU can be

obtained by combining Eqs. A1, A-2, and A-3, viz.,

'Yw =8 v/ 0 (A.4)

The next step is to introduce the Fanning friction factor, which is

defined byEq. A-5.

F

f

= T

w

/ (Ia p v2) =dP / elL X 0 / (2 P v2) (A-S)

Since the friction factor is traditionally expressed as a function of

Reynolds number, this parameter is introduced next.

N

Re

=Pv D /,.,. (A-6)

Both the friction factor and the Reynolds number are dimensiOnless,

and the two can be related by combining Eqs. A-I, A-5 and A-6 to

obtain the classical relation for laminar pipe flow.

F

f

=16/ N

Re

(A-7)

Note that the friction factor and the Reynolds number both include

fluid density in their definitions. As may be seen from Eq. A.l, the

frictional pressure gradient in a laminar flow is independent of fluid

density. However, pressure drops in transitional and turbulent flows

are a function of the fluid density. Hence, these two dimensionless

parameters are useful in aU three flow regimes. This completes the

elementary definitions that are used sUbsequently in the analysis of

non-Newtonian annular flows.

Concentric Annular Flow. Lamtr' derived a solution for Newtonian

flow through a concentric annulus that is very similar to the Hagen.

Poiseuille solution for pipe flow. His equation for the frictional

prcasure gradient is:

474

SPE 25456 T. REED AND A PILEHVARI 7

As before, a force balance between the pressure gradient and the

opposing viscous shear stresses at the inner and outer boundaries of

an annulus can be constructed to obtain a relation between them.

The results are:

Tw,avg =(To Do + Tj Dj ) I (Do + Dj )

=dP I dL X (Do - D

j

) 14 (A-9)

This expression for average wall shear stress can now be used to

define the Fanning friction factor for annular flow.

F

c

=Tw,avg I (1/2 Py) =dP I dL x Dhy I (2 PY) (A-IO)

Next, we require this be the same function of Reynolds number as

for laminar pipe flow, Eq. A-7. This leads to the following equation

for Reynolds number.

N

Re

= P v D

L

2

1(p. Dhy) = Pv Deq I p. (A-U)

The various diameters are defined as:

Lamb's diameter:

D

L

= [00

2

+ Dl- (D

0

2

- Dl) Iln(D

o

I D

j

)]112,

see Eqs. A-I and A-S ..... (A-12)

Hydraulic diameter:

Dhy =Do - D

j

=Outer diameter-Inner diameter (A-l3)

Equivalent diameter:

Deq =D

L

2

1Dhy' Concentric Annulus (A-14)

An average wall shear rate can be defined that is consistent with Eq.

A-9 fOr the averagewall shear stress. For isothermal Newtonian flow,

the relation is:

Tw,avg = p. 'Yw,avg =p. (S v I Deq) (A-IS)

The term in parentheses for wall shear rate in an annulus is analo-

gous to Eq. A-4 for pipe flow.

The "Equivalent" diameter is the diameter of a circular pipe

that will have the identical frictional pressure drop as the

concentric annulus when the fluid is Newtonian and has the

same viscosity and the same average velocity (= flow ratel

cross-sectional area). The Equivalent diameter provides the

similarity link between pipe flow and annular flow. This concept is

applicable to transitional and turbulent flows if it is also stipulated

that the Newtonian fluid bas the same density. However, the next

step is to demonstrate how this diameter can be used when analyzing

non-Newtonian laminar flow in an annulus.

LAMINAR NON-NEWI'ONIAN FLOWS

Pipe Flow. Metzner and ReedIt and Dodge and Metznefl reported

some pioneering work in the 19S0s on non-Newtonian pipe flow.

Here we will briefly review their work and then extend their work to

the case of annular flows. Metzner and Reed developed the

following generalized expression for shear rate at the wall of a pipe

when the flow is laminar and the fluid has time-independent proper-

ties.

'Yw =[(3 N + I) 14 N] x (S v I D) (A-16)

Where "N" is defined as:

N = d[ln T

w

] I d[ln(Sv I D)]

= d[ln(dP I dL x D14)] Id[ln (Sv I D (A-17)

nNn is the slope of a log-log plot of the two variables (dP/dL D/4)

and (BvID). This slope varies with flow rate and rheological

properties. For a general time-independent non-Newtonian fluid,

Metzner & Reed used N to express wall shear stress as a function of

the Newtonian shear rate at the wall of a pipe, Eq. A-4.

T

w

=dP/dLxD/4=K'(Sv/D)N (A-IS)

In general, both K' and N are functions of Two In cases where the

slope of the log-log plot is not constant, N is the slope of a line that

is tangent at a particular point on the curve for In(dP/dL x D/4)

versus In(BvID). When N is a constant and equal to 1, K' reduces

to the Newtonian coefficient ofviscosity, and Eq. A-18 reduces to the

form of Eq. A-2 When N is greater than 1, the fluid is a dilatant,

and when N is less than 1, the fluid is a pseudoplastic. Hence, as

noted by Metzner & Reed, N is a measure of a fluid's non-Newtoni

an behavior. K' is a measure of the fluid's consistency and increases

as the fluid becomes more viscous.

In the case of a Power-Law fluid, Eq. A-18 becomes:

T

w

= dP I dLx D 14 = K' (Sv I Dt = K ('YW)B (A-19)

For this type of fluid, N =n =constant, and Metzner & Reed's

generalized consistency index becomes:

K' =K [(3n + I) 14n]B (A-20)

Here the AK" without a superscript is simply called the consistency

index. Note that Eqs. A-19 and A-20 are consistent with Eq. A16

for shear rate at the pipe wall. The expression for the generaIized

consistency index is more complex for a Bingham Plastic. The

derivation of K' for this type of fluid is presented in a clear and

straight-forward manner in a paper by Metzner.

Metzner & Reed defined a Generalized REynolds number (GRE)

by retaining the standard definition for friction factor and then

requiring it be related to Reynolds number by the classical relation,

Eq. A-7. They obtained the following equation for their GRE.

NRe,G =p ~ IK' SN-1 (A-21)

In the case of a Power-Law fluid, this equation becomes:

NRe,PL =Pv2- DB I {K [(3D + I) 14n]- S_1} .. (A-ZZ).

This equation can be put into a simpler form by introducing an

"apparent" Newtonian viscosity based on shear rate at the wall. The

apparent viscosity is defined by dividing wall shear-stress by wall

shear-rate. For a Power-Law fluid, the apparent viscosity bas the .

following form.

JLw,app =T

w

l'Yw =K [(3n + I) 14n x (S vI D)]"";1 (A-23)

. I"')'

When this expression for apparent viscosity is introduced uliO

Eq. A-22, the GRE for a Power-Law fluid reduces to:

475

8

A NEW MODEL FOR LAMINAR, TRANSmONAL, AND

TURBULENT FLOW OF DRILLING MUDS SPE25456

NRe,PL =P D V I #.&w" (3n + 1) 14n] (A-24)

Now, this equation for Reynolds number can be simplified even

further and put into the cIassical form for Newtonian flow by defining

an "Effective" pipe diameter which includes the remaining effects of

a Power-Law fluid. Hence, the obvious definition of an "Effective"

diameter for flow of a Power-Law fluid through a circular pipe with

diameter D is:

0eff =4n D I (3n + I), Power-Law pipe flow.. (A-25)

With this definition of the "Effective" diameter, the GRE for flow of

a Power-Law fluid through a pipe becomes:

NRe,PL = P V D

eff

IIJ.w,app (A-26)

By comparing Eqs. A-16 and A-25, it may be seen that the definition

for an "Effective" pipe diameter can be generalized to tbe case of any

time-independent fluid by simply replacing On" with N in Eq. A-25.

Hence, the generalized "Effective" pipe diameter is defined as follows.

0eff =4N D I (3N + I), Generalized Effective

pipediameter . (A-27)

Neither Metzner, his students, nor subsequent workers foresaw any

value in introducing the "Effective" diameter that is defined here. As

we shall see, it is indeed very helpful in extending their work on non-

Newtonian pipe flow to non-Newtonian annular flow.

Before continuing on to annular flow, an expression is needed for N

that is applicable to Herschel-BuIkIey (HB) fluids. Since N is defined

by Eq. A-17, a relation between wall shear stress and flow rate for an

HB fluid is necessary in order to evaluate N. The required relation-

Ship can be found in the book by Govier and Aziz.:IlI The resulting

equation for N is given below.

lIN = -3 + 'T

w

{(I + m)/[m ('T

w

- YS)] + 2('T

w

- YS)

[A(3m + 1)] + 2 YS/[A(2m + I)]} (A-28)

Where:

'T

w

=K' (8 v/D)N =YS +K <'Yw )IIl, HB fluid .. (A-29)

YS =Yield Stress

m =Exponent on shear rate is different from a -

Power-Lawfor clarity; Hanks%7... (A-30)

A = ('T

w

- YS)2/(3m + 1) + 2 YS ('T

w

- YS)/(2m + 1)

+ YS

2

/(m + 1) .. (A-31)

Concentric Annular Flow. Based on a cursory examination of the

foregoing discussions, it might appear that the work of Metzner &

Reed

l

' on non-Newtonian pipe flow could be applied to concentric

annuli by combining the "Equivalent" and the "Effective" diameters

and using the average wall shear rates and shear stresses in place of

the corresponding parameters at the wall of a pipe. However, a

solution for non-Newtonian annular flow is more involved. Fortu-

nately, a simple solution has been previously developed for laminar

flow of a Power-Law fluid through concentric annuli. The needed

solution appears in a book by ExIog's staff.

21

Their solution consists

of the following equations.

Y =0.37 (A-32)

Z = 1- [1- (Oil D

o

)Y]l/

Y

(A-33)

G =(1 + Z/2) [(3 - Z) n + 1] 1[(4 - Z) n] .. (A-34)

dP I dL =(4 KI DIIy) [8 v G I DIIy]Il (A-3S)

The authors state that this correlation is based on the analytical

solution originally obtained by Fredrickson and Bird.t This equation

can be related to Power-Law pipe flow by rearranging Eq. A-35 into

the form of Eq. A-19, viz.:

'T

w

=dP I dL x Oily 14 =K (8 V G I OIly)1l

=K (8 vI Oeff)1l (A-36)

Hence, the "Effective" diameter for laminar Power-Lawflow through

a concentric annulus is more complicated than simply inserting Deq

into Eq. A-25. It is defined by Eq. A-36 to be equal to:

=Oily I G =Effective Diameter for non-

Newtoman flow through Concentric Annuli ... (A-37)

We have designated Eq. A-37 as being valid for a general non-

Newtonian fluid because G can be generalized by simple replacing

On" with nNw in Eq. A-34. This Effective Dianleter is a function of

both the annular geometry and the rheology of the fluid. and it

provides the link between non-Newtonian annular flow and Newtoni-

an pipe flow.

The ExIog correlation can also be applied to flow of an HB fluid by

noting:

T. - YS =[dP/dL]HB X DIIy 14 - YS == K (8 v/Deff)8l (A-38)

or

[dP I dL]HB x DIIy 14 =YS + K (8 v I D

eff

)1Il ..... (A-39)

Hence, the utility of the ExIog correlation can be extended by simply

adding the Yield Stress to the average wall shear stress created by

movement of the fluid and (1) replacing On" with "N" in the definition

of G, Eqs. A-32 and A-34, and (2) replacing On" with Om" in

Eq. A-35.

A summary of the most relevant equations are given below for non-

Newtonian laminar flow of an HB fluid through an annulus.

N =d[In I d[In (Sv I Deq)]

= d[dP I dL x DIIy 14)] Id[In (Sv I Oeq)] (A-40)

'YWVI =(8 vI Dar> (A-41)

'TW,aYI = dP I dLx Oily I 4 = YS + K <'YW,aYl)1II .. (A-42)

1J.w.eff == 'Tw,aYl/-Yw,aYI (A-43)

NRe,G =P v Oeff/1J.w,eff (A-44)

The friction factor for annular flow is not affected and remains the

same, Eq. A-10. In addition, the relation between friction f8ctor and

the GeneralizedReynolds number, Eq. A-7, also remains unchanged.

In order to verif)' these results, an example calculation was done

using this model, and the predicted frictional pressure gradient was

compared with the corresponding result from the recent finite-

476

SPE 25456 T. REED AND A Pll..EHVARI 9

difference solution by Haciialamoglu and Langlinais.' They baYe

computed the frictional pressure gradient generated byflowofan lIB

fluid through a concentric annulus for the following conditions: Do

= 10 in. [25.4 em], D

i

= 7 in. [17.8 em], K = 250 eq. cP, "m" =

0.70, YS = 51bf/100 fi2, and a pump rate of 200 gpm [12.6 IJs].

For these conditions, the authors report a calculated pressure

gradient of 0.00870 psiIft. Using the method outlined herein, a

prcssure gradicnt of 0.0086 psiIft is obtained. This conclusively

disproves the claim by Hanks that thc Generalized Reynolds

Number cannot be applied to annular flows.

TURBULENT NEWTONIAN FLOW

Jones and Leuni' proved thatthc equivalent diameter, as defined by

Eq. A-14, could also be used in turbulent flow to relate concentric

annuli to circular pipes. They assembled a range of test data and

showed frictional pressure gradients in a smooth annulus could be

correlated by using thc "Equivalent" diameter in thc classical

Colcbrook for smooth pipes. This leads to the next

question: Can this be extended to non-Newtonian flows? In order

to answer this question, we next tum our attention to the work by

Dodge and Metzner on nOD-Newtonian pipe flows.

TURBULENT NON-NEWTONIAN FLOW

Pipe Flow. Dodgc and Metznefl were able to correlate turb\llent

pipe-flow data for a varicty of nOD-Newtonian fluids.

accomplished by using the GREof Metzner and Reed and modiJYing

the Colebrook Equation. They proposed the following form of

Colebrook's Equation for all time-independent fluids flowing through

smooth circular pipes.

1 / F

r

1l2

=(4 / Nl7S) log FP - Nfl)] - 0.40 / N1.2(A-4S)

In order to apply this equation correctly, the apparent viscosity must

be computed in a particular way. Dodge & Metzn,:r emphasized !b&t

the shear rate in Eq. A-23 must be based on an unagmary laminar

flow velocity that will generate the same wall shear stress as the

turbulent flow. Hence, an iteration is required in order to obtain the

correct apparcnt viscosity.

Concentric Annular Flow. This equation can also be applied to flow

through concentric aDDuli by simply using Deff, Eq. A-37, in the

GRE, Eq. A-44, and again defining the friction factor to be based on

the avcrage wall shear stress or frictional pressure gradient in an

annulus, Eq. A-10. Similarly, values of N are calculated by using thc

average wall shear stress in Eq. A-28. In. addition, the average wall

shear rate must be based on a laminar flowvelocity that will generate

the same wall shear stress as the turbulent flow. This imaginary

velocity can be computed by setting 1"w in Eq. A-38 equal to the

turbulent strcss and iterating. This vclocity is then used to calculate

the corresponding laminar shear rate, Eq. A-41, and an cffective

viscosity, Eq. A-43, which is used in the dcnominator of the General-

ized Reynolds Number. With these changes in definitions of

Reynolds number, friction factor and N, Eq. A-45 can be used to

compute turbulent pressure gradients for flow of a lIB fluid through

concentric annuli.

Effects of Wall Ro......ess. Colcbrook's original equation for

Newtonian turbulent flow also includes a term to account for the

effects of wall roughness.

2S

Colebrook's equation is equivalent to thc

turbulent portions of the well-mown Moody Diagram and can be

written in thc following form.

1 / F

r

1l2 =- 4 log [(0.27 E / D) + 1.26 / (N

Re

Fr)](A-46)

477

The relative wall roughness is specified by the ratio "E I D".

The corresponding equation ofDodge &Metzner for turbulent nOD-

Newtonian flow, Eq. A-45, can be rearranged into this same form.

This results in a ncw equation for turbulent friction factors which

combines nOD-Newtonian and wall-roughness effects.

l.2

1/ F

r

1l2 =- 4 log [(0.27 E / D

eff

) + 1.26

r

/

FP - Nf2) ] ... (A-47)

This extended form of the Colebrook equation can be applied to

non-Newtonian flow through pipes and concentric annuli by simply

using the correct forms for the frictiOD factor, the Effective Diame-

ter, and the Generalized Reynolds number.

There is a legitimate question about whether the coefficient for thc

roughness term (0.27) should be a function of N or not. Note that

the Effective Diameter is a function of N, and in the case of

pseudoplastics (N < I), a given wall roughness, Eo will cause a greater

percent increase in the frictional pressure gradient than occurs in

Newtonian flow. It is uncertain whether this is sufficient to properly

account for the influence of non-Newtonian fluids on wall roughness

cffects. Additional tests with bentonitc muds in rough pipes (E =

0.0047 in. [0.119 mm] from water tests) show good agreement with

Eq. A-47 up to Reynolds numbers of 270,000. However, additional

tests with systematic variations of mud properties and relative rough-

ness are needed before Eq. A-47 can be verified conclusively. In the

meantime, this equation is proposed for calculation of frictional

pressure gradients in turbulent non-Newtonian flow through pipes

and concentric annuli with either smooth or rough walls.

TRANSmONAL FLOW

Geometric Effect&. Hanks

1

and Hanks and Pctcrson

lS

havc rcported

experimental measurements of transitional flow through concentric

annuli for Newtonian fluids. Reference 15 presents experimental

data for concentric annuli with four different ratios of iDDer-to-outer

diameter (aspect ratio). The reported values of Reynolds number at

transition are plotted in Fig. 1. Hanks also included the results from

a transition theory that he first began developing back in the early

1960s."'6,17 His predictions for the complete range of aspect ratios is

shown in Fig. 1 as a dashed line. Hanks' theory shows a maximum

in transition Reynolds number at an aspect ratio of about 0.15.

However, thc experimental data docs NOT corroborate the trend of

Hanks' theoretical predictions.

The solid curve in Fig. 1 is based on the "Equivalent" diameter of

Jones & Leung

13

, Eq. A-14. If the critical Reynolds number is based

on this diameter and set equal to 2100, the following equation is

obtained.

(NRe,Eq)c:rit =DEq P V / ,.,. =2100 (A-48)

This equation can be rearranged into a Reynolds number based on

Lamb's diameter, Eq. A-l2.

(N&e,0c:rit =D

L

P v / ,.,. =2100 x Dhy / D

L

......... (A-49)

This provides a transition ReynOlds number that varies with aspect

ratio and reduces to the correct relation for Simple pipe flow. This

equation is plotted as the solid curve in Fig. 1. It should be noticed

that the Reynolds number based on Deq, Eq. 54, does exactly what

it is supposed to do in that it successfully combines the critical

Reynolds number for all concentric annuli into an equation that has

the same form as the classical relation for pipe flow. Hcnce, the

10

A NEW MODEL FOR LAMINAR, TRANSmONAL, AND

TIJRBULENT FLOW OF DRllJ.JNG MUDS SPE2S456

similarity analysis properly accounts for geometric effects. As before,

this idea can be extended to include non-Newtonian effects by using

the "Effective" diameter, Eq. A-37.

Non-Newtonian Etl'eet&. In Hanks' 1963 -paper, he used the same

theory as he used for Newtonian flow through concentric annuli to

predict transition Reynolds numbers for Bingham Plastics in pipes.

He plotted his results in terms of a critical Bingham Plastic Reynolds

number. The BinghamPlastic Reynolds number for a pipe is defined

as:

NRe,BP = D Pv / (Plastic Viscosity) (A-50)

Note that this is not a correct measure of Reynolds number effects

because the Plastic VISCOSity (PV) is coiJstant for a given fluid, and,

in reality, the apparent viscosity will vary with shear rate, Eq. A-43.

Hanks' critical values for the Bingham Plastic Reynolds number are

shown in Fig. 3 as a function of Hedstrom number. The "critical"

Reynolds number is a measure of the flow rate at which laminar flow

ends and transition begins. The Hedstrom number is a measure of

the influence of a fluid's yield stress on the flow. For the case of a

Bingham Plastic flowing through a pipe, it is defined as:

-He = Hedstrom No. = p yp l)2 / (pV)2 ...... (A-51)

Hanks' theoretical values ofcritical BinghamPlastic Reynolds number

appear to agree with measured data up to a Hedstrom number of

about 5,000 as plotted in his original 1963 paper.

z

At higher values,

his theory diverges from the data, see Fig. 3. In contrast, the solid

curve in this figure passes through the experimental data. This curve

was generated by utilizing the Generalized Effective diameter for a

pipe, Eq. A-27, and the correct "apparent" viscosity to define a

Generalized Reynolds number, Eq. A-26.

Next, the new transition criterion requires the critical condition for

any fluid to occur when the product of the Fanning friction factor and

the GREequals 16.1. This generalized transition criterion is designed

to reduce to a critical Reynolds number of 2100 for Newtonian pipe

flow. The GRE for pipe flow is related to the BP Reynolds number

via the equation below.

Where the apparent viscosity for BinghamPlastic pipe flow is defined

by:

J.I.w,app =(YP +PVx'Yw) / 'Yw (A-53)

The wall shear rate is defined by Eq. A-16 for pipe flow, and N, given

by Eq. A-28, reduces to the following expression for a Bingham

Plastic.

N

BP

= (3 - 4X + X

4

) /3(1 - X

4

), (A-54a)

with: X = yP / T

w

(A-54b)

This agrees with the results of Metzner' for BP fluids and, again,

demonstrates the consistency of the similarity analysis.

Friction Factors through the Transition Regime. In a 1977 paper,

Churchill

30

developed a simple method for calculating friction factors

through the transition zone in Newtonian pipe flow. Churchill

devised the following procedure for combining laminar and turbulent

friction factors in order to calculate friction factors through the

transition zone. He first defined an intermediate term based on the

transitional and fully-turbulent friction factors; this termis designated

F

1

and is defined by:

(F

1

)-8 =(F1r)-8 + (F

tudl

)-8 (A-55)

F

1

is then used in a similar equation involving the laminar friction

factor to compute friction factor through the transition zone.

(Ff)12 = (F

1

)12 + (F

Iam

)12 (A-56)

This equation can then be solved for friction factor at !!!!! Reynolds

number or flow regime.

Churchill selected the following functional form for friction factor in

the transition zone.

Fir =Const. x N

Re

2

(A-57)

Based on the numerical computations of Wilson and Azad

31

Churchill chose a value of 1.42x for the constant when the fluid

is Newtonian. We have extended Churchill's analysis to non-

Newtonian fluids by replacing the constant coefficient with a function

of "N". An analysis of the friction factor curves of Dodge and

MetzneeZ1 for "n" =I, 0.8, 0.6 and 0.4, Fig. 2, and using the generally

accepted criterion of 2100 for transition in Newtonian pipe flows led

to the following equation for this coefficient.

C(N) = 9.4 x 10-

9

/ [4.767 - 2.167 N] 2 (A-58)

This equation should be used in place of the constant coefficient in

Eq. A-57. In addition, the Reynolds number can be replaced with

the GRE. This leads to the following equation for transitional

friction factors in pipe and concentric annuli.

Fir = C(N) x (NRe,G) 2 (A-59)

This is a new relationship for transitional friction factors in circular

pipes and concentric annuli. Note from Table 1 that "N" varies

through the transition zone. Furthermore, by incorporating "N" in

Eq. A-58, the equation applies equally well to Newtonian, Power-

Law, Bingham Plastics, and Herschel-Bulkley fluids.

When this definition of friction factor for the transition zone is used

in Churchill's procedure, Eqs. A-55 and A-56, the product of friction

factor and GRE is equal to 16.1 when the GRE = 2100 for

Newtonian pipe flow. This requirement produces increasingly higher

pump rates for the initiation of transition as yield stress of a fluid

increases. Transition is assumed to be complete when the friction

factor from Eq. A-56 is within 1 percent of the turbulent friction

factor from the extended Colebrook equation, Eq. A47.

478

I Fig. 3 Transition in Bingham Plastic plpeflows. I

Thousands

I

en

!""l

i>

.....

.....

10

8

1.0

0.8

0.8

....... 0.4

.......:.... :... ; ..:..:.:.:.:.

' ' ..'. ,'. , .'. '.

. . . . . . . .

; : :..:. .:.:.

. . .

..:..1..

10

4

10

6

HEDSTROM NUMBER

..1.

....... ; ...

1:21 ... "-\.

Fig. 4 - Critical Generalized Reynolds Number for

Btngham Plastic pipeflows

l-

f-'

..--

I--

I

1,.-1-'

V

I---

FFORE .. 18.1

l/

I

i-o'f:

----

I

..

..

..

..

..

I

..

..

HANKS (1883) I

..

..

..

I

1800

1500

1200 3

10

2400

2100

2700

3000

I Fig. 2 - Fiction factor. for Power-Law plpeflows. I

0.1 c: :.. ,.; :..:.: .:.. 1 :. L: :.1 : J

a:

t

if

z

o

! ...

!

z

z

if

' ' -. 0' _._.

.. ....

0.001' I I I I 1 I III I I I I I I II' I I I I I! II!

10

2

10

3

10

4

10&

GENERALIZED REYNOLDS NUMBER

.......:.... ;... ; ..:..:.:.:.:.

o

z

>=

W

II:

o

W

N

::::i

<

II:

W

Z

W

CJ

oJ

t=

it

o

2285

2672

10

8

<> HANKSl19801

o HANKSPETERSONI19821

10

4

10

6

HEDSTROM NUMBER

............................... 1 I

j

TEST DATA RANGE ... .-

HANKS (1963)

.....--

I . I I I

1600 I i I I J I I I I

o M U U U

INNER DIAMETER I OUTER DIAMETER

1800

22

20

o 18

z

16

...

o 14

z

ti 12

a:

g; 10

... 8

:J

i= 6

5 4

2

o

10

3

Fig. 1 - Transition in Newtonian Annular flow.

""

a

.=

g 2700 ; : : : : :- .

rn 0:<>

Q :

I ...,.:.: :.,.- --; --" ,.. "C, '.'.':'.'.' ,.,., ,.:.:.

z 2100' _.. '. .. HANKSf1980t :

2 : : : ; .

to-

iii

I

to-

.j:l.

......

tv

;I>

t::Dt;;

.... - .

....................................

12-1/4" x 5" Annulus

Example Mud Properties

300 < Pumprate < 2100 gpm

............ : : : .

- - -

. . . .

...................................................

I I

..........................................................

. . .. - . .. . .. .

'-:._..

...... ---1 n-ensltlon. 1910 -_.:-- ..

100 200 300 400 500 800

ROTATIONAL SPEED OF VISCOMETER RPM

Fig. 6 - Comparison of Viscometer data for typical

water-benntonlte mud with three rheological models.

0.6( I I I I I I

f!!

Z 0.5

2

0.4

II..

o

20.3

.' 0.2

E

-

Z0.1

80

'"

70

...

-

0

80

0

,..

.....

HED

-

10

3

:e &0

10

4

C!)

10&

Z

a

5x10& c(

W

a:

-I

c(

a

10&

................ \ ............

. . .

.- - - .

... ; .....

...

::1i ansition : - - - - - :.

_.

. . .

.......... : .

........ :. :-:.:.

". ," t : .' - .: .... r ",.,"

..:.... :... ..:. -: . : -:.:-

10

3

10

4

GENERALIZED REYNOLDS NUMBER

................ ... '., . . .. . .. '.' ." .........

Fig. 6 - Effects of Hedstrom Number on

transition of Bingham Plastics In plpeflovv.

... -..... ..... -

0.01

cr:

0

l-

e,)

Z

0

j::

e,)

iii:

II..

"

Z

Z

z

0.1

a:

z

0

0.01

it

IL

CJ

Z

Z

0.001

10

2

o

0.001 3

10 10

4

10

5

GENERALIZED REYNOLDS NUMBER

Fig. 7 - Effects of three rheological models

on flow transition In pipes .

0

'

I I I I I I

o 50 100 150 200 260 300

AVERAGE ANNULAR WALL SHEAR RATE (1Isec)

IFIG. 8 EFFECTS OF SHEAR RATE ON EXPONENT "N"I

0\

1.2, , 260. i iii ii' i

en

til

0\

121/4" x 6" Annulus

Example Mud Properties

.................. .................

........ 1

.............

fI)

0

160

(J

!!

>

ti

tb 601- .. ,

............................

. . .

121/4" x 5" Annulus

Example Mud Properties

.....: : ; : : ; : : : .

1

0.2

0.8

I

-0.6

0.4

Fig. 9 - EFFECTS'OF SHEAR ItATE EXPONENT

ON EFFECTIVE DIAMETER OF ANNULUS

i>

'"d

....

21

...

19

t'

6" 23/8" Annulus

MMH Mud System

, to

7 9 11 13 16 17

PUMPRATE 1 100 IGPM)

5

0 "

..................... , , , .

. . . . . .

......;. .. -;":- .:. ; .. -: :- .:. :- .. .. ;..; -:.; .:-:.,

0' , I I I , , , I ,

3

Fig. 10 - EFFECTS OF PUMPRATE ON

EFFECTIVE VISCOSITV IN ANNULUS

0.1\ : : : :'S;:: ::i: :; :;:;: i :;:;:;: :::::; :::;: ::;: :;: >:;;; ::::::;: ::;: :;:; :;: :::;1

c:J

z

i

z

a:

e

IL

Z

o

ti 0.01

iii!

Yo

1

.; :- .;. -:-:.:-;. :- .. -:.. : -:. : .:-:.,

12-1/4" x 6" Annulus

Example Mud Properties

t

..... .:. .:-:-: ;. ',:::: ::: ':--:'

0.11'" .?S.;., '. " '..' "'l

:::::-,: . : :::::::: :::::::: :::::: ::::: :::: ::: :::: ::::::::::: ::::::::::: : ::

0' , I J I II I I I I

o 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

"N" GENERALIZED SHEAR RATE EXPONENT

a:

z

0

ti 0.01

iii!

Yo

c:J

z

i

z

it

.....

I I I ) 5

0.001 2 3 104 10

10 10

I I , 6

0.001 ' 2 3 104 10

10 10

GENERALIZED REYNOLDS NUMBER GENERALIZED REYNOLDS NUMBER

FIG. 11 - FRICTION FACTORS FOR ANNULI

WITH SMOOTH AND ROUGH WALLS

FIG. 12 - COMPARISON OF MODEL WITH TEST

DATA FOR MMH IN A ROUGH ANNULUS

......

!.

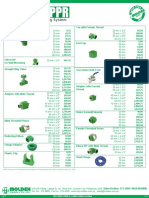

TABLE 1

PARAMETERS FOR TRANSITION ZONE IN ROUGH 12-Yl X 5" ANNULUS

------- --- - - - - -- ----

MUD FANNING

VELOCITY FRICTION GENERAL.

RELATIVE FPGRAD

(GPM (FfIMIN)- "N" FACI'OR REY. NO. W"GRE FLOW TYPE (l/SEe ROUGHNESS (In.H,llIFt)

1860. 364.5 .3609 .6151E-02 26042E+03 16.02 LAMINAR 186.2 .015627 .4034

1870. 366.5 .3617 .6098E-02 26284E+03 16.03 LAMINAR 187.1 .015607 .4043

1880. 368.4 .3625 .6046E-02 26S29E+03 16.04 LAMINAR 188.0 .015588 .4051

1890. 370.4 .3634 .5996E-02 26781E+03 16.06 LAMINAR 188.9 .015567 .4060

1900. 3724 .3643 .5947E-02 27042E+03 16.08 LAMINAR 189.9 .015545 .4070

1910. 374.3 .3653 .5901E-02 27314E+03 16.12 lRANSIT 191.1 .015522 .4081

1920. 376.3 .3664 .5857E-02 27603E+03 16.17 lRANSIT 1924 .015497 .4093

1930. 378.2 .3679 .5819E-02 27947E+03 16.26 lRANSIT 194.1 .015462 .4110

1940. 380.2 .3699 .5790E-02 28359E+03 16.42 lRANSIT 196.4 .015417 .4131

1950. 3822 .3741 .5797E-02 29083E+03 16.86 lRANSIT 201.4 .015321 .4179

1960. 384.1 .5574 .1061E-Ol 6.0752E+03 64.46 lRANSIT 634.7 .012561 .7728

1970. 386.1 .5595 .1060E-Ol 6.1540E+03 65.25 TIJRBULENT 644.6 .012539 .7802

1980. 388.0 .5617 .1060E-Ol 6.2329E+03 66.05 lURBULENT 654.7 .012517 .7876

1990. 390.0 .5637 .1059E-Ol 6.3121E+03 66.84 lURBULENT 664.8 .012496 .7950

2000. 3920 .5658 .1058E-Ol 6.3915E+03 67.63 lURBULENT 674.9 .012476 .8024

2010. 393.9 .5678 .1057E-Ol 6.4711E+03 68.43 lURBULENT 685.2 .012456 .8099

2020. 395.9 .5699 .1057E-Ol 6.5509E+03 69.23 lURBULENT 695.5 .012436 .8175

2030. 397.8 .5718 .1056E-Ol 6.6310E+03 70.03 lURBULENT 706.0 .012417 .8251

2040. 399.8 .5738 .1055E-Ol 6.7112E+03 70.83 1URBULENT 716.5 .012398 .8327

2050. 401.8 .5757 .1055E-Ol 6.7917E+03 71.63 TIJRBULENT 727.1 .012379 .8403

2060. 403.7 .5776 .1054E-Ol 6.8724E+03 7244 lURBULENT 737.7 .012361 .8480

2070. 405.7 .5795 .1053E-Ol 6.9533E+03 73.25 lURBULENT 748.5 .012343 .8557

2080. 407.6 .5814 .1053E-Ol 7.0344E+03 74.06 lURBULENT 759.4 .012326 .8635

2090. 409.6 .5832 .1052E-Ol 7.1157E+03 74.87 lURBULENT 770.3 .012309 .8713

2100. 411.6 .5850 .1052E-Ol 7.1972E+03 75.68 lURBULENT 781.3 .012292 .8791

......

>-

tl:i

Cr.1

hjt'"'

tJ-

n

OS

en

til

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)