Professional Documents

Culture Documents

Boiler Efficiency Calculation

Uploaded by

Suparna BhoseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boiler Efficiency Calculation

Uploaded by

Suparna BhoseCopyright:

Available Formats

RELIANCE JAMNAGAR

RPCTEFH - SHEET-1 of 5

PROCEDURE FOR CALCULATION OF THERMAL EFFICIENCY OF FIRED HEATERS

THERMAL EFFICIENCY OF FIRED HEATER ENUMERATED BELOW IS BASED ON API 560

Definitions:

Thermal efficiency is defined as total heat absorbed divided by the total heat input.

Total heat absorbed is equal to the total heat input minus the total heat losses.

Total heat input is equal to the sum of the net heat of combustion of the fuel ( LHV ) and the sum of sensible heat

of the air, fuel and atomising medium to the system. In case of steam Air Preaheating, it also includes heat

input in steam for such purpose.

Total heat losses are equal to the sum of radiation heat loss and stack heat loss.

Radiation heat loss is a defined percentage of the net heat of combustion of the fuel

Stack heat loss is the total sensible heat of the flue gas components at the temperature of flue gas when it leaves

the last heat exchange surface.

Sensible heat correction is the sensible heat differential at test temperature when compared with a datum

temperature of 60deg. F ( 16deg C ) for air, fuel, and the atomising medium. { for steam as an atomising medium,

the datum enthalpy is 1087.7 Btu / l

EFFICIENCY = (TOTAL HEAT INPUT - TOTAL HEAT LOSSES ) / ( TOTAL HEAT INPUT ) * 100

Further details on the same are given in the API, a copy of which is being sent along with this communication.

Confidential - Property of Reliance

The following steps to be followed while using the worksheet.

1. Go to Tools ---> Options ----> Calculation; Select iteration. Input Maximum iterations 100 and Maximum Change 0.001.

Select Manual calculation

2. Fuel Oil and Fule Gas composition to be entered in "FUEL_DETAILS" sheet. Also enter LHV of Fuel Oil in the same sheet.

3. If O2 composition of stack is available on wet basis pl. use "EFF_CALCULATION_WET_BASIS" sheet, if it is available on

dry basis then use "EFF_CALCULATION_DRY_BASIS" sheet.

4. Input data in column "C" only in sheets "EFF_CALCULATION_WET_BASIS" or "EFF_CALCULATION_WET_BASIS"

5. After entering all the input data, Press F9 OR SAVE the file to refresh calculations.

PROCEDURE TO USE THE WORKSHEET

RELIANCE : RPCTEFH - SHEET- 2 of 5

Confidential - Property of Reliance

Fuel Oil

Fuel Composition wt%

C = 87.00%

H = 13.00%

LHV (Kcal/kg) 10000

Fuel Gas

Component Composition MW O

2

req. (Kgmol/hr) CO

2

gen (Kgmol/hr) H

2

O gen (Kgmol/hr) LHV

(Kcal/kgmol)

Nitrogen 6.10% 28 0 0.0000 0.0000 0

H2O 0.00% 18 0 0.0000 0.0000 0

H2S 0.00% 34 0 0.0000 0.0000 123810

NH3 0.00% 17 0 0.0000 0.0000 67744

CO2 0.60% 44 0 0.0060 0.0000 0

Hydrogen 23.80% 2 0.119 0.0000 0.2380 57796

methane 36.60% 16 0.732 0.3660 0.7320 191760

ethylene 10.20% 28 0.306 0.2040 0.2040 316190

ethane 18.10% 30 0.6335 0.3620 0.5430 341260

propane 1.80% 44 0.09 0.0540 0.0720 488520

propylene 0.00% 42 0 0.0000 0.0000 460430

iC4 0.00% 58 0 0.0000 0.0000 633040

iC4= 0.00% 56 0 0.0000 0.0000 603350

nC4= 0.00% 56 0 0.0000 0.0000 607370

nC4 0.90% 58 0.0585 0.0360 0.0450 635040

cis-2-C4= 0.00% 56 0 0.0000 0.0000 605730

trans-2-C4= 0.00% 56 0 0.0000 0.0000 604730

iC5 0.00% 72 0 0.0000 0.0000 780130

nC5 0.00% 72 0 0.0000 0.0000 782050

CP 0.00% 68 0 0.0000 0.0000 468290

C6+ 0.00% 78 0 0.0000 0.0000 928950

98.10% 17.90 1.94 1.03 1.83 10750 Kcal/kg

Note: Please input your data in "B" Column only

Rest all data is calculated by Excel.

RELIANCE : RPCTEFH - SHEET- 3 of 5

FUEL COMPOSITION INPUT SHEET

Confidential - Property of Reliance

AIR

INPUT OUTPUT

1 FO Firing rate (Kg/hr) 3496 Fired Duty (MMKcal/hr) 35.0

Sencible Heat Input ex FO (MMKcal/hr) 0.15

2 FG Firing rate (Kg/hr) 0 Heat Input ex Atomising Steam (MMKcal/hr) 0.11 Cp, av., (Air) (Kca/0K,Kgmole) 6.96 STACK Mol% Kgmol/hr

Heat Input ex Steam Air Preheating (MMKcal/hr) 0.01 Cp, av., (H2O) (Kca/0K,Kgmole) 7.94 CO2 = 11.02% 253.5

3 Mol. % O2 in Flue Gas (Wet Basis) 2.60 Heat Input ex Pilot Gas (MMKcal/hr) 0.00 RADIATION LOSS O2 = 2.60% 59.8

4 Stack Temp. (

o

C) 200.0 Total Heat Input (MMKcal/hr) 35.2 Qr (MMKcal/hr) = 0.52 M (Kgmol/hr) (Dry) 2032.7 N2 = 69.84% 1605.8

5 Ambient Temp. (

o

C) 30 H2O (V) (Kgmol/hr) 52.8 31.0 H2O 16.53% 380.1

6 Relative Humidity of Air 60.0% Total Loss Enthalpy of air (MMKcal/hr) 0.01 100.00% 2299.1

7 Moles Water Vap./ Moles Dry Air 0.026 1. Through Flue Gas (MMKcal/hr) 2.93 200.0 Stack

8 Radiation loss (percent of heat released) 1.50% 2. Through Radiation Loss (MMKcal/hr) 0.52

9 Air inlet temp. after steam heater 31.0 Total 3.5

PROCESS FLUID IN Heat Loss through Stack

10 Atomizing Steam flow (TPH) 1.8 1. Through Dry Flue Gas (kcal/hr) 2400145

11 Pilot Gas flow (kg/hr) 0.0 Total Heat Absorbed (MMKcal/hr) 31.79 2. Through Water Vap. (kca/hr) 527734

12 Fuel Oil Inlet Temp. (

o

C) 120 Total (MMKcal/hr) 2.93

13 Fuel Oil Sp. Heat. (Kcal/kg/0K) 0.48 Thermal Efficiency ( h ) = 90.20%

14 Enthalpy of Atomising Steam (Kcal/kg) 673 Excess Air Used = 16.3%

Cp, av., (CO2) (Kca/0K,Kgmole) 9.75

Flue Gas Composition Mole % Cp, av., (O2) (Kca/0K,Kgmole) 7.19

CO2 = 11.02% Cp, av., (N2) (Kca/0K,Kgmole) 6.99

O2 = 2.60% Cp, av., (H2O) (Kca/0K,Kgmole) 8.17

N2 = 69.84%

H2O = 16.53% PROCESS FLUID OUT

Fuel Gas

Heat Supplied ex Fuel Gas (MMKcal/hr) 0.00

FUEL OIL

wt% Kg/hr

C = 87.00% 3041.5

H = 13.00% 454.5 AIR

M (kg/hr) = 3496.00

Cal. Value (Kcal/kg) 10000

Heat Supplied ex Fuel Oil (MMKcal/hr) 34.96

Note: 1. Please input your data in "C" Column only

2. Ambient Temp. use as datumtemp. for simplification of calculation

RELIANCE : RPCTEFH - SHEET- 4 of 5

CALCULATED DATA WITH DIAGRAM

HEATER

FIRED

WORKSHEET FOR EFFICIENCY CALCULATION OF FIRED HEATER

(BASIS: O2 ANALYSIS IN FLUE GAS ON WET BASIS)

Combustion APH

SteamAPH

Confidential - Property of Reliance

AIR

INPUT OUTPUT

1 FO Firing rate (Kg/hr) 4000 Fired Duty (MMKcal/hr) 104.5

Sencible Heat Input ex FO (MMKcal/hr) 0.08

2 FG Firing rate (Kg/hr) 6000 Heat Input ex Atomising Steam (MMKcal/hr) 0.16 Cp, av., (Air) (Kca/0K,Kgmole) 7.01 STACK Mol% Kgmol/hr

Heat Input ex Steam Air Preheating (MMKcal/hr) 3.47 Cp, av., (H2O) (Kca/0K,Kgmole) 8.05 CO2 = 11.23% 634.5

3 Mol. % O2 in Flue Gas (Wet Basis) 3.68 Heat Input ex Pilot Gas (MMKcal/hr) 0.23 RADIATION LOSS O2 = 3.68% 207.9

4 Stack Temp. (

o

C) 184.0 Total Heat Input (MMKcal/hr) 108.4 Qr (MMKcal/hr) = 2.61 M (Kgmol/hr) (Dry) 6084.2 N2 = 85.09% 4806.5

5 Ambient Temp. (

o

C) 30 H2O (V) (Kgmol/hr) 158.2 109.0 100.00% 5648.9

6 Relative Humidity of Air 60.0% Total Loss Enthalpy of air (MMKcal/hr) 3.47 H2O 1155.0

7 Moles Water Vap./ Moles Dry Air 0.026 1. Through Flue Gas (MMKcal/hr) 7.79 184.0 Stack

8 Radiation loss (percent of heat released) 2.50% 2. Through Radiation Loss (MMKcal/hr) 2.61

9 Air inlet temp. after steam heater 109.0 Total 10.4

PROCESS FLUID IN Heat Loss through Stack

10 Atomizing Steam flow (TPH) 2.2 1. Through Dry Flue Gas (kcal/hr) 6339413

11 Pilot Gas flow (kg/hr) 21.1 Total Heat Absorbed (MMKcal/hr) 98.0 2. Through Water Vap. (kca/hr) 1448942

12 Fuel Oil Inlet Temp. (

o

C) 70 Total (MMKcal/hr) 7.79

13 Fuel Oil Sp. Heat. (Kcal/kg/0K) 0.48 Thermal Efficiency ( h ) = 90.4%

14 Enthalpy of Atomising Steam (Kcal/kg) 683 Excess Air Used = 19.4%

Cp, av., (CO2) (Kca/0K,Kgmole) 9.69

Flue Gas Composition Mole % Cp, av., (O2) (Kca/0K,Kgmole) 7.17

CO2 = 11.23% Cp, av., (N2) (Kca/0K,Kgmole) 6.97

O2 = 3.68% Cp, av., (H2O) (Kca/0K,Kgmole) 8.15

N2 = 85.09%

H2O = 0.00% PROCESS FLUID OUT

Fuel Gas

Heat Supplied ex Fuel Gas (MMKcal/hr) 64.50

FUEL OIL

wt% Kg/hr

C = 87.00% 3480.0

H = 13.00% 520.0 AIR

M (kg/hr) = 4000.00

Cal. Value (Kcal/kg) 10000

Heat Supplied ex Fuel Oil (MMKcal/hr) 40.00

Note: 1. Please input your data in "C" Column only

2. Ambient Temp. use as datumtemp. for simplification of calculation

RELIANCE : RPCTEFH - SHEET- 5 of 5

CALCULATED DATA WITH DIAGRAM

HEATER

FIRED

WORKSHEET FOR EFFICIENCY CALCULATION OF FIRED HEATER

(BASIS: O2 ANALYSIS IN FLUE GAS ON DRY BASIS)

Combustion APH

SteamAPH

Confidential - Property of Reliance

You might also like

- ENERGY PERFORMANCE ASSESSMENT OF BOILERSDocument22 pagesENERGY PERFORMANCE ASSESSMENT OF BOILERSBrijesh SrivastavNo ratings yet

- Calculation of Boiler EfficiencyDocument14 pagesCalculation of Boiler EfficiencyBharat Choksi100% (1)

- 4.10.4 Performance Evaluation of BoilersDocument7 pages4.10.4 Performance Evaluation of BoilersGanti AsegarNo ratings yet

- Boiler Efficiency MeasurementDocument7 pagesBoiler Efficiency MeasurementManoj MishraNo ratings yet

- Determining Boiler EfficiencyDocument7 pagesDetermining Boiler EfficiencySuprio KamalNo ratings yet

- Steam and Gas Tables with Computer EquationsFrom EverandSteam and Gas Tables with Computer EquationsRating: 3 out of 5 stars3/5 (2)

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantFrom EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNo ratings yet

- Boiler Performance CalculationDocument1 pageBoiler Performance Calculationagusnnn50% (2)

- Boiler EfficiencyDocument10 pagesBoiler Efficiencyromi_hamdani100% (4)

- Design and Analysis of Air PreheaterDocument14 pagesDesign and Analysis of Air PreheaterTJPRC Publications100% (1)

- Boiler Efficiency Calculations SheetDocument5 pagesBoiler Efficiency Calculations Sheetkalyanm20351578% (9)

- PTC 4.1 Boiler Test EficiencyDocument11 pagesPTC 4.1 Boiler Test EficiencyPra Tiwi100% (2)

- Boiler Efficiency-An AnalysisDocument18 pagesBoiler Efficiency-An AnalysisDebasish ChowdhuryNo ratings yet

- Indirect Boiler Efficiency Method Heat BalanceDocument8 pagesIndirect Boiler Efficiency Method Heat BalanceMohsin MajeedNo ratings yet

- Waste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobDocument30 pagesWaste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobMoriyasuNguyen100% (1)

- Biomass Combustion ManojDocument16 pagesBiomass Combustion Manojsugandaraj522No ratings yet

- Boiler Efficiency FactorsDocument17 pagesBoiler Efficiency FactorsSolai100% (4)

- Calculating Multiplication Factors for Converting Oleum to Sulphuric AcidDocument12 pagesCalculating Multiplication Factors for Converting Oleum to Sulphuric AcidYalamati Satyanarayana100% (1)

- Combustion CalculationsDocument6 pagesCombustion CalculationsMauro FerrareseNo ratings yet

- Coal CombustionDocument3 pagesCoal CombustionRahul ChandrawarNo ratings yet

- Evaporator (D-1) Design ExcelDocument7 pagesEvaporator (D-1) Design ExceldiRkdARyLNo ratings yet

- Combustion Calculation: 165472 Power Plant EngineeringDocument43 pagesCombustion Calculation: 165472 Power Plant Engineeringluiz0carlos0martinel100% (2)

- Turbine Heat Rate CalculationDocument2 pagesTurbine Heat Rate Calculationkaruna34650% (2)

- Steam Turbine EfficiencyDocument71 pagesSteam Turbine EfficiencyAnonymous LjE1R12CasNo ratings yet

- Air Heater Performance Test - 200 MW Manual Input SheetDocument5 pagesAir Heater Performance Test - 200 MW Manual Input SheetSHIVAJI CHOUDHURYNo ratings yet

- Condenser CalculationDocument6 pagesCondenser Calculationgreenenergykolkata100% (2)

- Gacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDocument6 pagesGacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDurga PrasadNo ratings yet

- NATURAL GAS BOILER CALCULATIONS INSTRUCTIONSDocument20 pagesNATURAL GAS BOILER CALCULATIONS INSTRUCTIONS@sss100% (1)

- Boiler CalculationDocument2 pagesBoiler CalculationShamsur Rahman RussellNo ratings yet

- Indirect MethodDocument6 pagesIndirect MethodFarurrodin Syah AlfahrobiNo ratings yet

- Boiler NG CalculationDocument9 pagesBoiler NG CalculationChirag DarjiNo ratings yet

- Shell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsDocument6 pagesShell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsrajachemNo ratings yet

- CFBC Boiler Training ManualDocument4 pagesCFBC Boiler Training ManualGusti Prasetyo Rendy AnggaraNo ratings yet

- Coal-Fired Power Plant Financing DataDocument241 pagesCoal-Fired Power Plant Financing DatanardoNo ratings yet

- Boiler EfficiencyDocument32 pagesBoiler Efficiencyइंजी. महेन्द्र प्रताप सिंह100% (2)

- Combustion CalcsDocument8 pagesCombustion CalcsZhaqir HusseinNo ratings yet

- Steam Calculation 2008 0326Document53 pagesSteam Calculation 2008 0326Myungkwan HaNo ratings yet

- BoilerDocument29 pagesBoilerhonchoabhiNo ratings yet

- Combustion Basics ExplainedDocument48 pagesCombustion Basics ExplainedJeevanandam ShanmugasundaramNo ratings yet

- Boiler efficiency and flue gas analysis calculationsDocument50 pagesBoiler efficiency and flue gas analysis calculationsDilip MishraNo ratings yet

- Upl HBDSDocument32 pagesUpl HBDSSuparna BhoseNo ratings yet

- Calculation For Requirement of Theoretical Amount of AirDocument13 pagesCalculation For Requirement of Theoretical Amount of AirDivya Bharathi RavuriNo ratings yet

- Properties of Saturated Steam - Pressure in BarDocument3 pagesProperties of Saturated Steam - Pressure in BarahijaNo ratings yet

- Circulating Fluidized Bed BoilersDocument86 pagesCirculating Fluidized Bed BoilersNguyen Quyet ThangNo ratings yet

- Plant Heat Rate at Ibpl 63mw On 1.7.13Document5 pagesPlant Heat Rate at Ibpl 63mw On 1.7.13Karthi KeyanNo ratings yet

- Achieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015Document25 pagesAchieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015ansarNo ratings yet

- Hindalco Boiler EfficiencyDocument32 pagesHindalco Boiler EfficiencySourav MahapatraNo ratings yet

- Excess Air: Gas Savings CalculationDocument7 pagesExcess Air: Gas Savings CalculationsudheerpaiNo ratings yet

- Basic Heat Exchanger DesignDocument10 pagesBasic Heat Exchanger DesignKvspavan KumarNo ratings yet

- Mass ConverterDocument18 pagesMass ConverterDinesh CR7No ratings yet

- FGD Mass BalanceDocument45 pagesFGD Mass Balancevikash_jawahar1379100% (2)

- 1.5 NPS RecuperatorDocument7 pages1.5 NPS RecuperatorAnonymous pVoSWn8yh0No ratings yet

- Verification of Capacity of Secondary Air Fan For Bagasse Fired BoilerDocument2 pagesVerification of Capacity of Secondary Air Fan For Bagasse Fired BoilerAu TagolimotNo ratings yet

- Auxiliary Power Consumption Sample for Power PlantsDocument2 pagesAuxiliary Power Consumption Sample for Power Plantsabhiknit0% (1)

- HMBD 15 MWDocument3 pagesHMBD 15 MWDebkumar958No ratings yet

- Energy and Process Optimization for the Process IndustriesFrom EverandEnergy and Process Optimization for the Process IndustriesNo ratings yet

- Fuel Property Estimation and Combustion Process Characterization: Conventional Fuels, Biomass, Biocarbon, Waste Fuels, Refuse Derived Fuel, and Other Alternative FuelsFrom EverandFuel Property Estimation and Combustion Process Characterization: Conventional Fuels, Biomass, Biocarbon, Waste Fuels, Refuse Derived Fuel, and Other Alternative FuelsNo ratings yet

- Fluidized Bed Boilers: Design and ApplicationFrom EverandFluidized Bed Boilers: Design and ApplicationRating: 4.5 out of 5 stars4.5/5 (4)

- Circulating Fluidized Bed Boilers: Design and OperationsFrom EverandCirculating Fluidized Bed Boilers: Design and OperationsRating: 4.5 out of 5 stars4.5/5 (6)

- Combustion and Mass Transfer: A Textbook with Multiple-Choice Exercises for Engineering StudentsFrom EverandCombustion and Mass Transfer: A Textbook with Multiple-Choice Exercises for Engineering StudentsRating: 3 out of 5 stars3/5 (1)

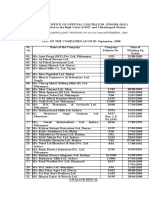

- Following Are The Guidelines For Gaseous DischargeDocument1 pageFollowing Are The Guidelines For Gaseous DischargeSuparna BhoseNo ratings yet

- Waste Composition (Singlie Solution)Document2 pagesWaste Composition (Singlie Solution)Suparna BhoseNo ratings yet

- Boiler Efficiency CalculationDocument5 pagesBoiler Efficiency CalculationSuparna Bhose100% (3)

- Upl HBDSDocument32 pagesUpl HBDSSuparna BhoseNo ratings yet

- Cost Estimation Co Generation Mode For Power: Annexure - 2Document3 pagesCost Estimation Co Generation Mode For Power: Annexure - 2Suparna BhoseNo ratings yet

- THE PEOPLE OF FARSCAPEDocument29 pagesTHE PEOPLE OF FARSCAPEedemaitreNo ratings yet

- Spsi RDocument2 pagesSpsi RBrandy ANo ratings yet

- AE-Electrical LMRC PDFDocument26 pagesAE-Electrical LMRC PDFDeepak GautamNo ratings yet

- Cianura Pentru Un Suras de Rodica OjogDocument1 pageCianura Pentru Un Suras de Rodica OjogMaier MariaNo ratings yet

- Standard Deviation IntroductionDocument3 pagesStandard Deviation IntroductionShyam ShresthaNo ratings yet

- English Week3 PDFDocument4 pagesEnglish Week3 PDFLucky GeminaNo ratings yet

- Huawei WCDMA Primary Scrambling Code PlanningDocument22 pagesHuawei WCDMA Primary Scrambling Code PlanningZeljko Vrankovic90% (31)

- Factsheet B2B PunchOut en 140623Document2 pagesFactsheet B2B PunchOut en 140623Curtis GibsonNo ratings yet

- Clean Agent ComparisonDocument9 pagesClean Agent ComparisonJohn ANo ratings yet

- Overview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsDocument11 pagesOverview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsVenkatesh RadhakrishnanNo ratings yet

- 2016 Mustang WiringDocument9 pages2016 Mustang WiringRuben TeixeiraNo ratings yet

- TLE8 Q4 Week 8 As Food ProcessingDocument4 pagesTLE8 Q4 Week 8 As Food ProcessingROSELLE CASELANo ratings yet

- Amul ReportDocument48 pagesAmul ReportUjwal JaiswalNo ratings yet

- Injection Timing (5L) : InspectionDocument2 pagesInjection Timing (5L) : InspectionaliNo ratings yet

- The Effect of Dodd-Frank On Divorcing Citizens 1Document5 pagesThe Effect of Dodd-Frank On Divorcing Citizens 1Noel CookmanNo ratings yet

- Amar Sonar BanglaDocument4 pagesAmar Sonar BanglaAliNo ratings yet

- Vehicle Registration Renewal Form DetailsDocument1 pageVehicle Registration Renewal Form Detailsabe lincolnNo ratings yet

- Statement of Compulsory Winding Up As On 30 SEPTEMBER, 2008Document4 pagesStatement of Compulsory Winding Up As On 30 SEPTEMBER, 2008abchavhan20No ratings yet

- Cold Forging Process TutorialDocument28 pagesCold Forging Process TutorialpanyamnrNo ratings yet

- 'K Is Mentally Ill' The Anatomy of A Factual AccountDocument32 pages'K Is Mentally Ill' The Anatomy of A Factual AccountDiego TorresNo ratings yet

- Newcomers Guide To The Canadian Job MarketDocument47 pagesNewcomers Guide To The Canadian Job MarketSS NairNo ratings yet

- SEO Design ExamplesDocument10 pagesSEO Design ExamplesAnonymous YDwBCtsNo ratings yet

- WhatsoldDocument141 pagesWhatsoldLuciana KarajalloNo ratings yet

- Socially Responsible CompaniesDocument2 pagesSocially Responsible CompaniesItzman SánchezNo ratings yet

- Unit 1 Writing. Exercise 1Document316 pagesUnit 1 Writing. Exercise 1Hoài Thương NguyễnNo ratings yet

- The Changing Face of War - Into The Fourth GenerationDocument5 pagesThe Changing Face of War - Into The Fourth GenerationLuis Enrique Toledo MuñozNo ratings yet

- Environmental Assessment of Sewer ConstructionDocument32 pagesEnvironmental Assessment of Sewer ConstructionKaleab TadesseNo ratings yet

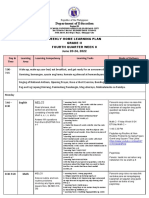

- Department of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Document8 pagesDepartment of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Evelyn DEL ROSARIONo ratings yet

- Single-Phase Induction Generators PDFDocument11 pagesSingle-Phase Induction Generators PDFalokinxx100% (1)

- SD-SCD-QF75 - Factory Audit Checklist - Rev.1 - 16 Sept.2019Document6 pagesSD-SCD-QF75 - Factory Audit Checklist - Rev.1 - 16 Sept.2019Lawrence PeNo ratings yet