Professional Documents

Culture Documents

Cycloconverters Topologies

Uploaded by

juan_fimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cycloconverters Topologies

Uploaded by

juan_fimCopyright:

Available Formats

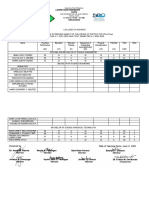

2786 IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 55, NO.

7, JULY 2008

Current-Source Converter and Cycloconverter

Topologies for Industrial Medium-Voltage Drives

Bin Wu, Fellow, IEEE, Jorge Pontt, Senior Member, IEEE, Jos Rodrguez, Senior Member, IEEE,

Steffen Bernet, Member, IEEE, and Samir Kouro, Member, IEEE

AbstractThis paper, along with an earlier published paper as

Part 1, provides a comprehensive review of the state of the art

of high-power converters (above 1 MW) for adjustable-speed ac

drives. In this highly active area, different converter topologies

have been developed for various drive applications in the industry.

Due to its extensive coverage, the subject is divided into two parts:

multilevel voltage source and current source converter topologies.

This paper is focused on the second part and covers the current

source converter technologies, including pulsewidth-modulated

current-source inverters (CSIs) and load-commutated inverters.

In addition, this paper also addresses the present status of the

direct converter, which is also known as cycloconverter (CCV).

This paper focuses on the latest CSI and CCV technologies and

an overview of the commonly used modulation schemes. It also

provides the latest technological advances and future trends in

CSI- and CCV-fed large drives. This paper serves as a useful

reference for academic researchers and practicing engineers in the

eld of power converters and adjustable-speed drives.

Index TermsCurrent-source inverter (CSI), cycloconverter

(CCV), high-power drives, load-commutated inverter (LCI).

I. INTRODUCTION

P

OWER converters for adjustable-speed drives can be clas-

sied into direct and indirect converter topologies [1],

[2]. In addition, indirect topologies can be grouped into two

main categories: current- and voltage-source converters. The

latter type of converters, particularly multilevel voltage-source

converters, was previously addressed in the rst part of this

paper [3]. This paper will present the rest of the power con-

verter topologies used in medium-voltage ac drives applications

(2.313.8 kV), which appear in the darkened boxes of the

classication shown in Fig. 1.

For the direct converters, the cycloconverter (CCV) is the

most used topology in high-power applications, which uses

an array of power semiconductor switches to directly connect

Manuscript received November 18, 2007; revised April 9, 2008. This work

was supported in part by the Universidad Tcnica Federico Santa Mara, in

part by the Chilean National Fund of Scientic and Technological Development

(FONDECYT) under Grant 1070725, and in part by the Industrial Electronics

and Mechatronics Millenium Science Nucleus P04-048-F (Mideplan, ICM).

B. Wu is with the Department of Electrical and Computer Engineering,

Ryerson University, Toronto, ON M5B 2K3, Canada (e-mail: bwu@ee.

ryerson.ca).

J. Pontt, J. Rodrguez, and S. Kouro are with the Department of Electronics

Engineering, Universidad Tcnica Federico Santa Mara, Valparaso 110-V,

Chile (e-mail: jpo@elo.utfsm.cl; jrp@elo.utfsm.cl; samir.kouro@ieee.org).

S. Bernet is with the Power Electronics Group, Department of Electrical

Engineering and Information Technology, Dresden University of Technology,

01069 Dresden, Germany (e-mail: steffen.bernet@tu-berlin.de).

Color versions of one or more of the gures in this paper are available online

at http://ieeexplore.ieee.org.

Digital Object Identier 10.1109/TIE.2008.924175

the power supply to the machine, converting a three-phase ac

voltage with a xed magnitude and frequency to a three-phase

ac voltage with variable magnitude and variable frequency [4].

It allows power ow in both directions in an efcient way. CCV

drives are a mature technology with technical advantages in

low-speed range and high-torque applications, such as grinding

mills. Another example is a 400-MW hydropumped storage

drive with a 20-pole generator/motor fed by a 72-MVA three-

phase 12-pulse CCV [5]. Matrix converters also belong to this

category but are not addressed in this paper since the power

rating of these converters is only up to 150 kVA [6] until now,

unable to reach the megawatt level for large drives due to the

limitation of the bidirectional switching devices required by the

converters.

The indirect converters can be divided into voltage source

and current source topologies, depending on the dc-link energy

storage components. The voltage source converters normally

use dc capacitors in the dc-link circuits, whereas the current

source converters employ dc inductors (chokes) in the dc

circuit.

Current-source inverter (CSI) technology is well suited for

high-power drives [7], [8]. The CSI can generally be divided

into pulsewidth-modulation (PWM) CSI and load-commutated

inverters (LCIs). The former uses symmetrical gate turn-off

(GTO) or integrated gate-commutated thyristor (IGCT) as a

switching device, whereas the latter inverter employs silicon-

controlled rectier (SCR) devices. Generally speaking, the

current-source converters feature a simple converter struc-

ture, low switch count, low switching dv/dt, and reliable

overcurrent/short-circuit protection, as summarized in Table I.

The main drawback lies in its limited dynamic performance

due to the use of large dc choke. High-power CSI drives

in the megawatt range are widely used in the industry. It is

estimated that a minimum of 700 units of large CSI-fed drives

has annually been produced worldwide in recent years.

LCIs are one of the earliest inverters developed for variable-

speed drives [9], [10]. Synchronous motors (SMs) are normally

used in the LCI drives since the SCR switches in the inverter

do not have self-turn-off capability and their commutation is

assisted by the SM operating at a leading power factor. The

LCI is suitable for very large drives with a power rating of tens

of megawatts. This is mainly due to the use of SCR devices

that lead to low manufacturing cost and high energy efciency

in comparison to the insulated-gate bipolar transistor or IGCT

devices used in other types of drives. A typical example of the

LCI drives is a 100-MW SM drive installed in NASAs wind

tunnel test facility [11].

0278-0046/$25.00 2008 IEEE

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

WU et al.: CURRENT-SOURCE CONVERTER AND CCV TOPOLOGIES FOR INDUSTRIAL MEDIUM-VOLTAGE DRIVES 2787

Fig. 1. Classication of converters for high-power drives (> 1 MW).

TABLE I

COMPARISON OF VOLTAGE- AND CURRENT-SOURCE CONVERTER TECHNOLOGIES

The succeeding sections present the different converter

topologies, drive congurations, and corresponding modulation

schemes. The latest technological advancements and the future

trends of the large drives are also addressed.

II. PWM CSIS

This section is mainly focused on CSI technology, including

PWM CSIs for induction motor drives and LCIs for SM drives.

The PWM CSI can also be employed for SM drives. Since the

CSI drive conguration for the SMs remains the same as that

for the induction motors, the CSI-based synchronous drives are

not discussed here.

A. PWM-CSI-Fed AC Drives With SCRs

The PWM CSI was proposed in the early 1970s [12] and

gained more attention during the 1980s [13]. The inverter uses

switching devices with self-extinguishable capability. Prior to

the advent of GCTs in the late 1990s, GTOs were predomi-

nantly employed in high-power CSI drives [14], [15]. Fig. 2

shows a typical 6600-V PWM CSI drive with an 18-pulse SCR.

The PWM CSI requires a three-phase capacitor C

f

at its

output to assist the commutation of the switching devices. The

capacitor provides a current path for the energy trapped in

the leakage inductances of the motor at the moment when a

GTO or GCT in the inverter is turned off. Otherwise, a high-

voltage spike would be induced, causing damage to the switch-

ing devices. The capacitor also serves as a harmonic lter,

Fig. 2. Typical 6600-V PWM CSI drive with an 18-pulse SCR.

improving the motor current and voltage waveforms. The value

of capacitor is normally in the range of 0.30.5 per unit (p.u.)

for CSI drives with a switching frequency of about 400 Hz.

Multipulse SCRs can be used as a front end for the CSI

drive. Among various rectier topologies, the 18-pulse SCR is

a preferred choice due to its high performance-to-price ratio.

For a given voltage and power rating, the 12-pulse rectier has

a cost advantage over the 18-pulse rectier, but its line current

total harmonic dispersion (THD) may not meet the harmonic

guidelines set by most standards. The 24-pulse rectier has a

better line current THD than the 18-pulse rectier, but it costs

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

2788 IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 55, NO. 7, JULY 2008

more due to the increased number of SCR devices and complex

phase-shifting transformer [16].

Six-pulse SCR bridges, which are used as current source

rectiers (CSRs) [17], can be connected in series to form the

multipulse rectier, as shown in Fig. 2, with three units for

an 18-pulse conguration. The inverter side uses three series-

connected GCT devices per branch. With a voltage rating of

6500 V for SCRs and GCTs, the drive is capable of operating

at a utility voltage of 6600 V (line to line). The CSI drive with

an 18-pulse rectier can meet the harmonic requirements set

by IEEE Standard 519-1992. Current source topologies may

also be used for active power lters to compensate harmonic

currents in electrical power systems [18], [19].

To improve the performance of the CSRs, advanced control

schemes, such as state feedback controls, can also be em-

ployed [20].

B. Modulation Techniques

The switching pattern design for the CSI should generally

satisfy two conditions: 1) DC current i

d

should be continuous,

and 2) the inverter PWM current i

w

should be dened. The

two conditions can be translated into a switching constraint: At

any instant of time (excluding commutation intervals), there are

only two sets of series-connected switches conducting, i.e., one

set in the top half of the bridge such as S

1

in Fig. 2 and the other

in the bottom half of the bridge such as S

2

. Various modulation

techniques have been developed for the PWM CSI, including

selective harmonic elimination (SHE), trapezoidal pulsewidth

modulation (TPWM), and space vector modulation (SVM).

The SHE is an ofine modulation scheme that can eliminate

a number of unwanted low-order harmonics in the inverter

PWM current i

w

[21]. Because high-power applications require

low losses, low switching frequency is needed. This is why

three, ve, or seven switching angles per quarter of a cycle

are preferred. In the case shown in Fig. 3(a), ve pulses are

employed. The switching angles are precalculated and then

imported into a digital controller for implementation. Fig. 3(a)

shows a typical SHE waveform that satises the CSI switching

constraint. There are ve pulses per half cycle with ve switch-

ing angles in the rst /2 period. However, only two out of the

ve angles, i.e.,

1

and

2

, are independent. Given these two

angles, all other switching angles can be derived.

The two switching angles provide two degrees of freedom,

which can be used either to eliminate two harmonics in i

w

without modulation index control or to eliminate one harmonic

and provide an adjustable modulation index. The rst option is

preferred since the adjustment of inverter output current i

w

is

normally accomplished by varying i

d

through rectier control,

instead of inverter modulation index control. The switching

angles for the elimination of various current harmonics are

given in [16].

Fig. 3(b) shows the principle of trapezoidal modulation,

where v

m

is a trapezoidal modulating wave and v

cr

is a triangu-

lar carrier wave. Similar to the carrier-based PWM schemes for

voltage-source inverters (VSIs), the gate signal is generated by

comparing v

m

with v

cr

. However, the trapezoidal modulation

does not generate any gate signals in the center /3 interval of

Fig. 3. Modulation schemes for CSIs: (a) SHE, (b) trapezoidal PWM, and

(c) SVM.

the positive half cycle or in the negative half cycle of the inverter

fundamental frequency. Such an arrangement can satisfy the

switching constraint mentioned earlier.

In addition to the TPWM and SHE schemes, the CSI can also

be controlled by SVM [22]. A typical space vector diagram for

the CSI is shown in Fig. 3(c), where

I

1

I

6

are active vectors

and

I

0

is zero vector. The active vectors form a regular hexagon

with six equal sectors, whereas the zero vector

I

0

lies at the

center of the hexagon.

For a given length and position,

I

ref

can be synthesized

by three nearby stationary vectors, based on which switching

states of the inverter can be selected and gate signals for the

switches can be generated. When

I

ref

passes through sectors

one by one, different sets of switches are turned on or off. The

inverter output frequency corresponds to the rotating speed of

I

ref

, whereas the magnitude of its output current can be adjusted

by the length of

I

ref

.

The SVM scheme has not yet found practical applications

mainly due to the following three facts: 1) The magnitude of

the inverter output current is normally adjusted through the

rectier, instead of the inverter modulation index; 2) the by-

pass (shoot-through) operation of the SVM scheme will cause

additional switching losses; and 3) the harmonic performance

of the SVM is not as good as that of the SHE scheme. However,

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

WU et al.: CURRENT-SOURCE CONVERTER AND CCV TOPOLOGIES FOR INDUSTRIAL MEDIUM-VOLTAGE DRIVES 2789

Fig. 4. Switching frequency f

sw

versus inverter output frequency f

1

.

Fig. 5. CSI-fed drive with PWM rectier and inverter.

the SVM scheme features easy digital implementation and su-

perior dynamic performance. It can be used in future CSI drives

with time-critical control algorithms such as active damping

control for LC resonance suppression [23].

A typical switching pattern arrangement for industrial CSI

drives is illustrated in Fig. 4, where f

sw

is the GCT switching

frequency, f

1

is the inverter fundamental output frequency,

and N

p

is the number of pulses per half cycle of the inverter

PWM current i

w

. The SHE scheme is used at high inverter

output frequencies, whereas the TPWM scheme is utilized

when the motor operates at low speeds. The SHE scheme

has much better harmonic performance than TPWM, but it is

difcult, if not impossible, to simultaneously eliminate more

than six harmonics. The harmonic performance of the TPWM

has minimal effects on the CSI drives since the drives normally

operate at a frequency of above 30 Hz with the SHE scheme. To

minimize switching losses, the maximum switching frequency

of the inverter is normally below 500 Hz in industrial CSI drives

[16]. The efciency of the overall drive varies, depending on the

input rectier conguration and the modulation method; it has

been reported that the CSI achieves efciencies close to their

VSI counterparts [24].

C. PWM CSI-Fed AC Drives With PWM Rectiers

Fig. 5 shows a typical conguration of the CSI drives with

a single-bridge PWM CSR as a front end. The rectier and in-

verter have identical topologies using symmetrical GCTs. With

the GCT voltage rating of 6500 V and two GCTs connected in

series in each of the converter branches, the drive is capable of

operating at the utility voltage of 4160 V (line-to-line).

The PWM rectier can use either the SVM or SHE schemes.

The SHE scheme is preferred due to its superior harmonic

performance. With a switching frequency of 420 Hz and the

utility frequency of 60 Hz, a maximum of three low-order

current harmonics (the 5th, 7th, and 11th) can be eliminated.

The other harmonics can be attenuated by the lter capacitor,

leading to a low line current THD.

DC current i

d

can be adjusted by the rectier delay angle or

modulation index control. The delay angle control produces a

lagging power factor that can compensate the leading current

produced by the lter capacitor, resulting in an improved power

factor. Furthermore, when the CSI drive is used in fan or pump

applications, its input power factor can be made to be near

unity over a wide speed range [25]. This can be realized by

using the SHE scheme with a delay angle control and properly

selecting the line- and motor-side lter capacitors. This control

scheme features a simple design procedure, easy digital imple-

mentation, and reduced switching loss, and is implemented in

commercial CSI drives.

Similar to the VSI drives, the rectication and inversion

process in the CSI drive generates common-mode (CM) volt-

ages [26], [27]. If not mitigated, the CM voltages would appear

on the motor, causing premature failure of its winding insula-

tion. The problem can effectively be solved by introducing an

isolation transformer and grounding the neutral of the inverter

lter capacitor, as shown in Fig. 5. In doing so, the CM voltages

will be transferred to the transformer winding, and the motor is

no longer subject to any CM voltages.

D. Transformerless CSI Drives

As discussed earlier, one of the major problems in CSI- and

VSI-based medium voltage drives is the CM voltage, which

would cause premature failure of motor winding insulation if

not mitigated.

Generally speaking, there are four possible solutions to

the CM voltages in the current-source-fed drives. 1) Add an

isolation transformer to block the CM voltages. This solution

has a couple of added benets: The leakage inductance of the

transformer can serve as a lter for harmonic reduction; and the

transformer may be arranged as a phase-shifting transformer for

multipulse rectiers for harmonic cancellation. 2) Add to the

dc link an integrated dc choke that provides both differential

and CM inductances. The main advantage of this approach is

the low cost due to the elimination of the isolation transformer.

3) Add a CM choke to the dc link for CM voltage suppression in

addition to the differential choke that is inherently required by

current-source-fed drives. 4) Add a three-phase ac CM reactor

either on the supply side or on the motor side to block the

CM voltages. The rst brings a few drawbacks such as high

cost, increased drive size and weight, and high operating cost

due to transformer power losses. The latter two solutions are

considered not practical due to the high cost of additional

components and the loss of the benets that the isolation/

phase-shifting transformer can provide. In summary, the inte-

grated dc choke technology is a viable and practical solution for

the time being to the elimination of the isolation transformer in

a current-source-fed drive.

Fig. 6 shows the schematic of a transformerless CSI drive,

where an integrated dc choke with a single magnetic core and

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

2790 IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 55, NO. 7, JULY 2008

Fig. 6. Transformerless CSI drive with an integrated dc choke.

four coils (two differential coils and two CM coils) is used

[28]. The choke can provide two inductances: a differential

inductance L

d

that is inherently required by the CSI drive and

a CM inductance L

cm

that can block the CM voltage. The

use of the integrated dc choke leads to the elimination of the

isolation transformer, resulting in a signicant reduction in

manufacturing and operating costs. To ensure that the stator

winding of the motor is not subject to any CM voltages, the

neutral points of the line- and motor-side lter capacitors are

directly connected together or through a small RL network.

The concept of the integrated choke is veried on a low-

power laboratory CSI drive. The laboratory drive has the same

conguration as that in Fig. 6, except that a six-pulse SCR was

used, instead of the PWM rectier. The inverter operates at

a fundamental frequency of 57.7 Hz with the lter capacitor

of C

f

= 0.31 p.u. The switching frequency of the inverter is

180 Hz. The motor operates under no-load conditions, at which

the CM voltage reaches its highest level.

Fig. 7 shows the measured waveforms of the drive with the

integrated dc choke installed, where v

A

is the stator line-to-

ground voltage, v

o

is the stator neutral-to-ground voltage, and

i

cm

is the common current [16]. Fig. 7(a) shows the waveforms

of the drive with L

d

= 1.0 p.u. and L

cm

= 0 (the CM coils

are not used). The neutral point of lter capacitor C

f

is left

open. The stator neutral-to-ground voltage v

o

, which should

be zero when the motor is powered by a three-phase utility

supply, is essentially the total CM voltage v

cm

generated by the

rectier and inverter. It contains triplen harmonics, which are of

zero-sequence components, with the third and sixth harmonics

being dominant. Line-to-ground voltage v

A

is composed of two

components: the motor phase (line-to-neutral) voltage v

Ao

and

its neutral-to-ground voltage v

o

. Obviously, the CM voltage

superimposed on phase voltage v

A

is severely distorted with

high peaks, causing damages to the motor insulation system.

With the CM coils connected in the drive (L

cm

= 4.8 p.u.)

and the capacitor neutral grounded, the measured waveforms

are as shown in Fig. 7(b). Comparing with Fig. 7(a), we can

make two observations.

1) The waveform for v

A

is close to sinusoidal and free of

CM voltages. The CM voltage is fully blocked by the in-

tegrated dc choke. This observation can be veried by the

waveform for v

o

(v

o

= v

cm

), which is essentially zero.

2) A small amount of CM current i

cm

ows to ground

through the lter capacitor. For the CSI drive with a

PWM rectier shown in Fig. 6, the CM current i

cm

Fig. 7. Waveforms measured from a laboratory CSI drive with an integrated

dc choke: (a) L

cm

= 0 and (b) L

cm

= 4.8 p.u.

ows between the rectier and inverter through the two

capacitor neutrals and therefore will not cause any neutral

current in the utility supply.

Finally, it should be noted that the design of the integrated dc

choke is not unique. A cost-effective design with only two coils

on a magnetic core is currently employed in the transformerless

CSI drive, but the details of this choke cannot be released

here. This technology has been used in commercial CSI drives

since 2002 by one major manufacturer, Rockwell Automation

Canada. Another valid design is given in [29].

E. Parallel CSIs

To increase the power rating of a CSI-fed drive, two or more

CSIs can operate in a parallel manner [30]. Fig. 8 illustrates

such a conguration where two inverters are connected in par-

allel. Each inverter has its own dc choke, but the two inverters

share a common lter capacitor C

f

at their output.

The parallel operation of the two inverters may cause un-

balanced dc currents. The main reasons for the unbalanced

operation include the following: 1) unequal ON-state voltages of

the semiconductor devices, which affect steady-state dc current

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

WU et al.: CURRENT-SOURCE CONVERTER AND CCV TOPOLOGIES FOR INDUSTRIAL MEDIUM-VOLTAGE DRIVES 2791

Fig. 8. Parallel CSIs for large CSI drives.

balance; 2) variations in the time delay of the gating signals of

the two inverters, which affects both transient and steady-state

current balance; and 3) manufacturing tolerance in dc choke

parameters. The dc current can be balanced by making use of

redundant switching states of the parallel inverters [16].

Fig. 9 shows a set of waveforms measured from a laboratory

parallel CSI drive operating at 1500 r/min. The dc currents i

1

and i

3

in Fig. 9(a) are kept balanced by the drive controller,

except for the middle portion of the current waveforms, where

the current balance control algorithm is temporarily disabled.

The steady-state motor voltage and current waveforms are

shown in Fig. 9(b), which are close to sinusoidal. The parallel

CSI technology can nd applications in the CSI drives with a

power rating of higher than 10 MW. However, while there are

functional and cost advantages to a single dc link, having two

or more dc current supplies has advantages in terms of reliabil-

ity, redundancy, and ac mains capability for canceling current

harmonics, which are issues that also need to be considered.

III. LCI-FED SM DRIVES

A. Topology Description

LCI is one of the earliest inverters developed for variable-

speed drives [9], [10]. Fig. 10 shows a basic conguration of the

LCI-fed SM drive. It is mainly composed of a phase-controlled

rectier and an SCR inverter. The rectier provides an ad-

justable dc current i

d

, which is smoothed by a dc inductor L

d

and then feeds the inverter. Since the SCR device does not have

self-extinguishing capability, it can naturally be commutated by

load voltage with a leading power factor. The ideal load for

the LCI is, therefore, SMs operating at a leading power factor,

which can easily be achieved by adjusting rotor eld current i

f

.

The LCI is unable to use any PWM scheme. Inverter output

current i

A

is of a quasi-square wave. However, the motor

voltage waveform v

AB

is close to sinusoidal superimposed

with voltage spikes caused by SCR commutations. The motor

current contains low-order harmonics, such as the 5th, 7th, 11th,

and 13th. These harmonic currents cause torque pulsations, as

well as additional power losses in the motor [31].

The LCI-fed drive features low manufacturing cost and high

efciency due to the use of inexpensive SCR devices and lack

of PWM operation. The LCI is suitable for very large drives

with a power rating of tens of megawatts, where the initial

Fig. 9. Measured inverter dc- and ac-side waveforms of the parallel

converters: (a) dc current transient response and (b) steady-state ac waveforms.

Fig. 10. Basic conguration of LCI-fed SM drive.

investment and operating efciency are of great importance.

However, the input power factor of the drive changes with

its operating conditions. In addition, the rectier input current

is highly distorted. In practical applications, the LCI drive is

equipped with harmonic lters to reduce line current THD, as

shown in Fig. 10. The lters can also serve as a power factor

compensator.

B. Latest Technology for Large LCI-Fed Drives

Fig. 11 shows a block diagram of a 100-MW variable-speed

LCI-fed SM fan drive [32]. The power converter section of

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

2792 IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 55, NO. 7, JULY 2008

Fig. 11. Block diagram of 100-MW LCI-fed drive system.

the drive consists of two independent channels, resulting in a

total of four identical six-pulse SCR bridges. To reduce the

line current THD, the line-side bridges are congured as a

12-pulse rectier, where the 5th, 7th, 17th, and 19th harmonic

currents produced by the six-pulse bridges are canceled by a

phase-shifting transformer with 30

phase shift between its two

secondary windings.

The line current distortion can further be reduced by har-

monic lters connected to the tertiary winding of the trans-

former or active lters [33]. These series-resonant LC lters

are normally tuned to the 3rd, 5th, 11th, and 13th harmonic

frequencies to attenuate possible 3rd and 5th harmonic currents

produced by the voltage distortion/unbalance of the utility grid

and also to mitigate the 11th and 13th harmonic currents that are

not eliminated by the 12-pulse rectier. Power factor correction

can be achieved by the proper design of the LC lters [32].

These lters can produce a leading current that can compensate

the lagging current produced by 12-pulsed rectier.

Both the line-side and motor-side bridges can operate in rec-

tifying or inverting mode, allowing the synchronous machine

to operate as a motor or generator. For fast dynamic braking,

the load mechanical energy can automatically be converted to

electrical energy by the LCI and then sent back to the utility

supply.

The SM has two sets of stator windings with 30

electrical

phase shift between the two windings. It is essentially a six-

phase motor for the reduction of torque pulsations caused by

quasi-square current waveforms in each of the stator windings.

As a result, the torque pulsations and mechanical stress on the

shaft train are greatly reduced.

The efciency of the LCI drive is usually very high. When

the drive operates under the rated conditions, the converter

efciency can be higher than 99%. This is very important

in large drives, where a small reduction in energy efciency

translates into high operation costs.

Megawatt-range drives require high reliability due to down-

time production losses. LCI-based drives have been a cost-

effective solution for very large power applications for

adjustable-speed drives; even its reliability comes close to

that of CCV drives [34]. Production losses due to converter

unavailability in a typical grinding mill application can rise up

to USD 17 000 per hour. Hence, fast and accurate detection and

diagnose of a fault can reduce emergency maintenance or trou-

bleshooting times. Some fault conditions due to asymmetrical

operation of a 12-pulse LCI drive and remedial strategies have

been presented [35], [36]. A review of important failure sources

involved in grinding mill applications is presented in [37]. In

[38], the switching failure of CSIs is analyzed, and a detection

and protection method is presented, to avoid overcurrents and

system damage.

C. Applications

Because of its simplicity and reliability, the LCI congura-

tion is applied in large drives where high dynamical perfor-

mance is not required, such as high-power fan drives, grinding

mills, and high-power motor and generator starters. The start-

ing function is very important for the black starting of large

generators with island operation, especially for recovering after

a power blackout.

In a conventional LCI-fed drive, the drive can slowly be

started by pulsing the dc-link current produced by the rectier.

This process continues until the SM generates sufcient in-

duced voltage to naturally commutate the inverter. This method

features no extra components but suffers a long starting time.

To solve the problem, an LCI-fed commutatorless series motor

drive has been proposed [39]. The drive is composed of a three-

phase diode rectier, an LCI, and an SM with its eld winding

connected in series with the dc link. This unique design enables

the drive to operate over the entire speed range, including

startup, with better dynamic performance.

Another interesting application of LCIs has been pro-

posed for a container ship [40], where a 24-pulse SCR

rectierinverter system serves as a frequency converter. This

converter converts a voltage of 14 Hz to 25.7 Hz generated by a

shaft generator to a bus voltage of 6.6 kV with a xed frequency

of 60 Hz for the ships main distribution system. In addition,

LCI-based medium-voltage ship electric propulsion is available

in the industry

1

with 24- or 48-pulse conguration, from 0 to

150 r/min and up to 2 21 MW.

IV. CCVS

A. Topology Description

Phase-controlled CCVs are direct acac converters based on

the antiparallel connection of thyristor converters without a dc

link employing a well-known and mature control technology of

natural commutation, as described in [41] and [42].

The basic operating principle is to use a switch arrange-

ment, as shown in Fig. 12(a) (six-pulse CCV), to synthesize

a variable-amplitude and low-frequency ac voltage by succes-

sively connecting the load to the different phases of the ac

supply Fig. 12(b).

The main advantages are the low switching losses and,

therefore, high efciency; the inherent bidirectional power ow

capability through the complete speed range; very high power

ratings with lowspace requirement; simple and robust structure;

low maintenance; and high reliability. The drawbacks are the

limited frequency range ( source frequency), low power

1

[Online]. Available: www.industry.siemens.com.

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

WU et al.: CURRENT-SOURCE CONVERTER AND CCV TOPOLOGIES FOR INDUSTRIAL MEDIUM-VOLTAGE DRIVES 2793

Fig. 12. Six-pulse CCV: (a) power circuit (one phase) and (b) waveform

synthesis.

factor at low modulation indexes of about 0.8, and generation of

harmonic currents, which cause harmonic voltages in the power

supply network. Installation of lter circuits is often necessary.

This has enabled the use of CCVs for the development of high-

power drive systems for control in low-speed range and high-

torque applications, such as cement mills, ore grinding mills,

ship propulsion, and mine winders [34], [43].

This section highlights the applications in ore grinding mills,

where near 60% of the electrical energy consumed in mining

plants is employed by grinding mill drives in concentrator

facilities. Economy of scale pushes the trend for larger mill

sizes in the range of 1121 MW, as presented in [37], with

applications for semiautogenous and Ball grinding mills. The

mechanical limitations of girth gears have motivated the use

of wraparound SMs for gearless motor drives (GMDs) fed by

high-power CCVs operating with variable speed [37], [44],

[45]. Fig. 13(a) presents the power circuit of a CCV-fed mill

drive with an SM with a single three-phase winding, where

two sets of six-pulse CCVs fed by transformers with star-

delta secondaries built a 12-pulse CCV, using 72 thyristors for

reducing the harmonic interaction at the network and at the

machine side. Double stator winding motors are also employed.

The voltage and current output waveforms of a 12-pulse

CCV under steady-state operation are illustrated in Fig. 13(b)

and (c), respectively. The controlled three-phase voltages and

currents of the machine follow the references given by the

control system, to meet the position, speed, and torque required

by the grinding process.

B. Latest Advances

In order to improve the performance and reliability of

CCV-fed drives, two current issues are being faced: network

Fig. 13. Twelve-pulse CCV feeding a synchronous machine with single stator

winding: (a) power circuit, (b) output voltages, and (c) controlled phase current

with zero-crossing time of 2 ms.

harmonic interaction and commutation failures [46][49].

Harmonic interaction and reactive power compensation are

mitigated with proper modeling and lter design, including the

behavior of weak network and interharmonics, as described in

[50][52]. The network harmonic interaction is mainly char-

acterized by the injection of interharmonics and subharmonics

components by the CCV operation, which affects the power

quality of the supply. This important subject has been addressed

in many contributions, including its analysis, modeling, simu-

lation and experimental studies, harmonic reduction methods,

and their impact on the power quality [52][58].

Loss of control of natural commutations under abnormal

operating conditions at the power network is a very important

weakness to be mitigated. A commutation failure can produce

a short circuit at the machine terminals through the CCV, as

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

2794 IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 55, NO. 7, JULY 2008

Fig. 14. Application of CCV-fed gearless drives for mineral grinding mills.

described in [59]. At short-circuit condition, important forces

can be generated within the machine against the soil plates in

fundaments, resulting in system shutdown and even damages.

This demands proper coordination of electrical protection and

sizing of machine fundaments for avoiding stator frame dis-

placement and friction between stator and rotor poles of the

machine, as presented in [46]. In addition, harmonic torque

components may excite mechanical resonances [48]. Methods

for mitigating these effects are under development.

In order to improve reliability and performance, current R&D

work is dedicated to reduce the probability of such failures with

improved structural dynamics modeling with nite-element

analysis for the following: 1) improved monitoring of the net-

work and drive operating conditions; 2) improved electrical and

mechanical robustness of the motor; 3) improved foundation

system; and 4) improved control for eliminating the chance of

a two-phase short circuit at the machine terminals. In addition,

improved process control of grinding within the mill is a current

target in order to smooth the load uctuations and to gain

better availability and reliability of the system, avoiding stresses

and overloads. New instrumentation such as Impactmeter and

SAGanalizer has been described in [48] and [50].

C. Applications

As mentioned earlier, CCVs are used for high-power low-

speed applications, due to their high efciency and speed-

frequency limitations. They have found a special market:

gearless cement mills, steel rolling mills, ore grinding mills,

pumps and compressors, mine winders, and ship drives [60].

Fig. 14 shows a simplied diagram of the semiautogenous

grinding mill process for copper production, in which four

CCV-fed gearless SM drives are controlled using space vector

control [61].

Table II presents the typical parameters of an SM for a GMD

mill drive of 12.7 MW, highlighting the estimation of the short-

circuit torque as six times the rated torque.

As mentioned before, the CCVis also used in ship propulsion

[62], [63]. Industrial available drives can be found in 6- and

12-pulse congurations, with maximum power of 2 11 MW

and speeds ranging from 0 to 190 r/min.

1

The CCV can also be

found in hydropumped storage [5] applications.

TABLE II

TYPICAL PARAMETERS OF A SYNCHRONOUS MACHINE FOR A SAG MILL

V. FUTURE TREND

The current source converter technology has been used

in high-power adjustable-speed drives over the past two

decades. The drive technology has evolved with three major

technological developments. In the late 1980s, the current

source drive was composed of a 12- or 18-pulse SCR and

a GTO PWM inverter operating at a switching frequency of

about 200 Hz. This drive conguration was used until late

1990s when the GCT device became commercially available,

with which the GTO devices in the inverter were replaced. In

the meantime, the switching frequency of the GCT inverter was

increased to about 420 Hz. To overcome the drawbacks of the

SCRs, the latest generation current source drive employs a GCT

PWM rectier with a GCT inverter. This drive conguration

has been on the market since 2003.

The use of the GCT rectier incorporated with the integrated

dc choke technology presented in the previous sections has

led to the elimination of the phase-shifting (or isolation) trans-

former in the drive, resulting in signicant cost reduction for

the drive manufacturer and end user as well. Considering the

unique features of the current source drive, such as simple con-

verter structure, reliable short-circuit protection, transformer-

less design, and inherent four quadrant operation, it is expected

that this drive technology will increasingly be used in various

industrial applications in the future.

In todays current source drives, the SHE technique is a dom-

inant modulation scheme. When the drive operates at low motor

speeds, where it is very difcult to eliminate a large number of

low-order harmonics, the trapezoidal PWM can be employed.

Although the SHE scheme provides a superior harmonic

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

WU et al.: CURRENT-SOURCE CONVERTER AND CCV TOPOLOGIES FOR INDUSTRIAL MEDIUM-VOLTAGE DRIVES 2795

performance in comparison to other modulation schemes, this

is an ofine scheme with less exibility and limited dynamic

performance.

With the improvements of GCT switching characteristics, it

is expected that the SVM scheme with a switching frequency

of 500 Hz or higher will play a role in the future drives. The

increased switching frequency will improve the harmonic and

dynamic performance of the drive, whereas the exibility of

the SVM scheme will facilitate the implementation of advanced

drive control schemes. As a result, the current source drives can

be extended to other industrial applications that require high

system dynamic performance.

On the other hand, CCVs are a mature and well-established

technology. It seems that CCVs will still dominate high-power

low-frequency operation applications for some years to come,

due to their efciency, reliability, and very high power ratings

with low space requirement. Despite the maturity of the tech-

nology, power quality and interharmonic performance remain

a topic of interest and study of many researchers [52][58].

System monitoring, fault detection, and diagnosis are also some

trends under development for this technology [48], [59].

VI. CONCLUSION

With the recent technological advancements, high-power

adjustable-speed drives are increasingly used in industry. To-

gether with the rst part [3], this paper provides a com-

prehensive overview of the state-of-the-art high-power drive

technologies. This part focuses on current source converter

and CCV technologies for high-power drives. Current-source-

converter-fed drives are todays converter family with the high-

est power rating in industrial drive applications. CSI-PWM

converter drives offer new interesting performance, overcoming

some drawbacks of natural commutated LCI- and CCV-fed

drives. However, LCI and CCV drives have a strong presence

in the industry with a niche in very high power applications

(>10 MW).

This paper covers various converter topologies and drive

congurations. In addition, different PWM techniques were

reviewed, latest drive technologies were discussed, and future

trends were analyzed. This paper serves as a useful reference

for academic researchers and practicing engineers working in

the eld of high-power converters and adjustable-speed drives.

REFERENCES

[1] K. H. J. Chong and R. D. Klug, High power medium voltage drives, in

Proc. PowerCon, Nov. 2124, 2004, vol. 1, pp. 658664.

[2] R. D. Klug and N. Klaassen, High power medium voltage drives

Innovations, portfolio, trends, in Proc. Eur. Conf. Power Electron. Appl.,

Sep. 1114, 2005, 10 pp.

[3] J. Rodrguez, S. Bernet, B. Wu, J. Pontt, and S. Kouro, Multilevel

voltage-source-converter topologies for industrial medium-voltage

drives, IEEE Trans. Ind. Electron., vol. 54, no. 6, pp. 29302945,

Dec. 2007.

[4] M. H. Rashid, Power Electronics Handbook, 2nd ed. New York:

Academic, 2006.

[5] H. Akagi, The state-of-the-art of power electronics in Japan, IEEE

Trans. Power Electron., vol. 13, no. 2, pp. 345356, Mar. 1998.

[6] T. Podlesak, D. Katsis, P. Wheeler, J. Clare, L. Empringham, and

M. Bland, A 150-kVA vector-controlled matrix converter induction

motor drive, IEEE Trans. Ind. Appl., vol. 41, no. 3, pp. 841847,

May/Jun. 2005.

[7] M. Salo and H. Tuusa, Avector-controlled PWMcurrent-source-inverter-

fed induction motor drive with a new stator current control method, IEEE

Trans. Ind. Electron., vol. 52, no. 2, pp. 523531, Apr. 2005.

[8] P. Cancelliere, V. D. Colli, R. Di Stefano, and F. Marignetti, Model-

ing and control of a zero-current-switching DC/AC current-source in-

verter, IEEE Trans. Ind. Electron., vol. 54, no. 4, pp. 21062119,

Aug. 2007.

[9] S. D. Sudhoff, E. L. Zivi, and T. D. Collins, Start up performance of

load-commutated inverter fed synchronous machine drives, IEEE Trans.

Energy Convers., vol. 10, no. 2, pp. 268274, Jun. 1995.

[10] N. Mohan, T. M. Undeland, and W. P. Robbins, Power

ElectronicsConverters, Applications and Design, 2nd ed. Hoboken,

NJ: Wiley, 1995.

[11] R. Bhatia, H. U. Krattiger, A. Bonanini et al., Adjustable speed drive

with a single 100-MW synchronous motor, ABB Rev., no. 6, pp. 1420,

1998.

[12] K. P. Phillips, Current-source converter for AC motor drives, IEEE

Trans. Ind. Appl., vol. IA-8, no. 6, pp. 679683, Nov./Dec. 1972.

[13] M. Hombu, S. Ueda, and A. Ueda, A current source GTO inverter with

sinusoidal inputs and outputs, IEEE Trans. Ind. Appl., vol. IA-23, no. 2,

pp. 247255, Mar. 1987.

[14] P. Espelage, J. M. Nowak, and L. H. Walker, Symmetrical GTO current

source inverter for wide speed range control of 2300 to 4160 Volts, 350 to

7000 HP induction motors, in Conf. Rec. IEEE IAS Annu. Meeting, 1988,

pp. 302307.

[15] N. R. Zargari, S. C. Rizzo et al., A new current-source converter using a

symmetric gate-commutated thyristor (SGCT), IEEE Trans. Ind. Appl.,

vol. 37, no. 3, pp. 896903, May/Jun. 2001.

[16] B. Wu, High-Power Converters and AC Drives. Piscataway, NJ: IEEE

Press, 2006.

[17] S. Rees, New cascaded control system for current-source rectiers,

IEEE Trans. Ind. Electron., vol. 52, no. 3, pp. 774784, Jun. 2005.

[18] B. M. Han and S. I. Moon, Static reactive-power compensator using soft-

switching current-source inverter, IEEE Trans. Ind. Electron., vol. 48,

no. 6, pp. 11581165, Dec. 2001.

[19] M. Salo and H. Tuusa, A new control system with a control delay

compensation for a current-source active power lter, IEEE Trans. Ind.

Electron., vol. 52, no. 6, pp. 16161624, Dec. 2005.

[20] A. Klnne and F. W. Fuchs, Optimal state feedback control of a vec-

tor controlled current source rectier, in Proc. 9th EPE, Graz, Austria,

Aug. 2729, 2001.

[21] J. R. Espinoza, G. Joos, J. I. Guzman, L. A. Moran, and R. P. Burgos,

Selective harmonic elimination and current/voltage control in current/

voltage-source topologies: A unied approach, IEEE Trans. Ind.

Electron., vol. 48, no. 1, pp. 7181, Feb. 2001.

[22] J. Ma, B. Wu, and S. Rizzo, A space vector modulated CSI-based AC

drive for multimotor applications, IEEE Trans. Power Electron., vol. 16,

no. 4, pp. 535544, Jul. 2001.

[23] J. Wiseman, B. Wu, and G. S. P. Castle, A PWM current source rectier

with active damping for high power medium voltage applications, in

Proc. IEEE PESC, 2002, pp. 19301934.

[24] Y. Suh, J. K. Steinke, and P. K. Steimer, Efciency comparison of

voltage-source and current-source drive systems for medium-voltage ap-

plications, IEEE Trans. Ind. Electron., vol. 54, no. 5, pp. 25212531,

Oct. 2007.

[25] Y. Xiao, B. Wu, and N. Zargari, Design of line/motor side capacitors

for PWM CSR-CSI drives to achieve optimal power factor in high power

fan/pump applications, in Proc. IEEE Appl. Power Electron. Conf., 1997,

pp. 333337.

[26] J. Rodrguez, L. Moran, J. Pontt, R. Osorio, and S. Kouro, Modeling and

analysis of common-mode voltages generated in medium voltage PWM-

CSI drives, IEEE Trans. Power Electron., vol. 18, no. 3, pp. 873879,

May 2003.

[27] S. Wei, N. Zargari, B. Wu et al., Comparison and mitigation of common

mode voltages in power converter topologies, in Conf. Rec. IEEE IAS

Annu. Meeting, 2004, pp. 18521857.

[28] B. Wu, S. Rizzo, N. Zargari, and Y. Xiao, An integrated DC link choke

for elimination of motor common-mode voltage in medium voltage

drives, in Conf. Rec. IEEE IAS Annu. Meeting, Chicago, IL, 2001, vol. 3,

pp. 20222027.

[29] P. Hammond, Apparatus and method to reduce common mode voltage

from current source drive, U.S. Patent 5 905 642, May 18, 1999.

[30] D. Xu, N. Zargari, B. Wu et al., A medium voltage AC drive with

parallel current source inverters for high power applications, in Proc.

IEEE PESC, 2005, pp. 22772283.

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

2796 IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 55, NO. 7, JULY 2008

[31] R. Emery and J. Eugene, Harmonic losses in LCI-fed synchronous mo-

tors, IEEE Trans. Ind. Appl., vol. 38, no. 4, pp. 948954, Jul./Aug. 2002.

[32] R. Bhatia, H. Krattiger, A. Bonanini, D. Schafer, J. T. Inge, and

G. H. Sydnor, Adjustable speed drive using a single 135 000 HP synchro-

nous motor, IEEE Trans. Energy Convers., vol. 14, no. 3, pp. 571576,

Sep. 1999.

[33] S. Kwak and H. A. Toliyat, Current-source-rectier topologies for sinu-

soidal supply current: Theoretical studies and analyses, IEEE Trans. Ind.

Electron., vol. 53, no. 3, pp. 984987, Jun. 2006.

[34] H. Stemmler, High-power industrial drives, Proc. IEEE, vol. 82, no. 8,

pp. 12661286, Aug. 1994.

[35] A. N. Alcaso and A. J. M. Cardoso, Asymmetrical operation of a twelve-

pulse LCI drive system with power converter faults, in Proc. 35th Annu.

IEEE PESC, Jun. 2025, 2004, vol. 6, pp. 43784382.

[36] A. N. Alcaso and A. J. M. Cardoso, Remedial operating strategies for a

twelve-pulse LCI drive system, in Proc. IEEE Int. Conf. Ind. Technol.,

Dec. 1012, 2003, vol. 1, pp. 619624.

[37] J. Rodrguez, J. Pontt, P. Newman, R. Musalem, L. Morn, and

G. Alzamora, Technical evaluation and practical experience of high

power grinding mill drives in mining applications, IEEE Trans. Ind.

Appl., vol. 41, no. 3, pp. 866874, May/Jun. 2005.

[38] J. Pontt, J. Rodrguez, J. Rebolledo, J. San Martn, E. Cid, and

G. Figueroa, High-power LCI grinding mill drive under faulty condi-

tions, in Conf. Rec. IEEE IAS Annu. Meeting, Oct. 26, 2005, vol. 1,

pp. 670673.

[39] S. SenGupta, K. Mukherjee, T. Kumar Bhattacharya, and A. K.

Chattopadhyay, Performance of an SCR-inverter-based commutatorless

series motor with load commutation and unaided startup capability, IEEE

Trans. Ind. Appl., vol. 36, no. 4, pp. 11511157, Jul./Aug. 2000.

[40] B. Clegg, H. R. Grifths, D. J. Hall, and P. J. Tavner, The application of

drives and generator technology to a moderncontainer ship, in Proc. 9th

Int. Conf. Elect. Mach. Drives, 1999, pp. 312316.

[41] B. R. Pelly, Thyristor Phase-Controlled Converters and Cycloconverters.

Hoboken, NJ: Wiley, 1971.

[42] L. Gyugi and B. R. Pelly, Static Power Frequency Changers. Hoboken,

NJ: Wiley, 1976.

[43] H. Akagi, Large static converters for industry and utility applications,

Proc. IEEE, vol. 89, no. 6, pp. 976983, Jun. 2001.

[44] S. A. Greer, Selection criteria for SAG mill drive systems, IEEE Trans.

Ind. Appl., vol. 26, no. 5, pp. 901908, Sep./Oct. 1990.

[45] J. Regitz, Evaluation of mill drive options, IEEE Trans. Ind. Appl.,

vol. 32, no. 3, pp. 653662, May/Jun. 1996.

[46] C. Meimaris, B. Lai, and L. Cox, Remedial design of the worlds

largest SAG mill gearless drive, in Proc. Int. Conf. SAG, Vancouver, BC,

Canada, 2001, pp. 7483.

[47] J. Pontt, J. Rodrguez, W. Valderrama, G. Seplveda, P. Chavez,

B. Cuitino, P. Gonzalez, and G. Alzamora, Current issues on high-power

cycloconverter-fed gearless motor drives for grinding mills, in Proc.

IEEE ISIE, Jun. 911, 2003, vol. 1, pp. 369374.

[48] J. Pontt, F. Rojas, J. Rodrguez, J. Rebolledo, J. San Martn, I. Illanes,

E. Cceres, R. Aguilera, P. Newman, and W. Valderrama, Issues on

reliability of cycloconverter-fed high-power gearless mill drives, in Proc.

Comminution, Perth, Australia, Mar. 1418, 2006.

[49] L. Nieto and M. Ahrens, Gearless mill drive protection improvements

and its behaviour at minera escondida ltda., in Conf. Rec. IEEE IAS Annu.

Meeting, Sep. 2327, 2007, pp. 17661772.

[50] J. Pontt, J. Rodrguez, W. Valderrama, and G. Seplveda, Resonance

effects, power quality and reliability issues of high-power converters-fed

drives employed in modern SAG circuits, Miner. Eng., vol. 17, no. 11/12,

pp. 11251134, Nov./Dec. 2004.

[51] R. Errath, P. Burmeister, and A. Sapin, SAG mill operation with weak

network conditions, in Proc. Int. Conf. SAG, Vancouver, BC, Canada,

2001. CD-ROM.

[52] J. Pontt, J. Rodrguez, J. San Martn, R. Aguilera, J. Rebolledo,

E. Caceres, I. Illanes, and P. Newman, Interharmonic currents assessment

in high-power cycloconverter-fed drives, in Proc. IEEE PESC, Jeju,

Korea, Jun. 2006, pp. 16.

[53] P. Syam, P. K. Nandi, and A. K. Chattopadhyay, Improvement in

power quality and a simple method of subharmonic suppression for

a cycloconverter-fed synchronous motor drive, Proc. Inst. Electr.

Eng.Electr. Power Appl., vol. 149, no. 4, pp. 292303, Jul. 2002.

[54] P. Syam, G. Bandyopadhyay, P. K. Nandi, and A. K. Chattopadhyay,

Simulation and experimental study of interharmonic performance of

a cycloconverter-fed synchronous motor drive, IEEE Trans. Energy.

Convers., vol. 19, no. 2, pp. 325332, Jun. 2004.

[55] P. Syam, P. K. Nandi, and A. K. Chattopadhyay, Effect of output cur-

rent ripple on the input supply current and the power quality for a

cycloconverter-fed drive, Proc. Inst. Electr. Eng.Electr. Power Appl.,

vol. 151, no. 4, pp. 425433, Jul. 2004.

[56] Y. Liu, G. T. Heydt, and R. F. Chu, The power quality impact of cy-

cloconverter control strategies, IEEE Trans. Power Del., vol. 20, no. 2,

pp. 17111718, Apr. 2005.

[57] Z. Wang and Y. Liu, Modeling and simulation of a cycloconverter drive

system for harmonic studies, IEEE Trans. Ind. Electron., vol. 47, no. 3,

pp. 533541, Jun. 2000.

[58] P. Syam and A. K. Chattopadhyay, Discussion of The power quality

impact of a cycloconverter control strategies, IEEE Trans. Power Del.,

vol. 21, no. 3, p. 1758, Jul. 2006.

[59] J. Pontt, J. Rodrguez, J. Rebolledo, K. Tischler, and N. Becker, Op-

eration of high power cycloconverter-fed gearless drives under abnor-

mal conditions, IEEE Trans. Ind. Appl., vol. 43, no. 3, pp. 814820,

May/Jun. 2007.

[60] A. K. Chattopadhyay, Cycloconverters and cycloconverterfed drives: A

review, J. Ind. Hist. Sci., vol. 77, no. 5, pp. 397419, 1997.

[61] W. Leonard, Control of Electrical Drives. New York: Springer-Verlag,

1997.

[62] P. English, The evolution of marine and drilling drives in todays

market, in Proc. Dynamic Positioning Conf., Sep. 1819, 2001.

CD-ROM.

[63] D. Gritter, S. Kalsi, and N. Henderson, Variable speed drive options

for electric ships, in Proc. IEEE Elect. Ship Technol. Symp., 2005,

pp. 354357.

Bin Wu (S89M92SM99F08) received the

Ph.D. degree in electrical and computer engineer-

ing from the University of Toronto, Toronto, ON,

Canada, in 1993.

From 1992 to 1993, he was with Rockwell Au-

tomation as a Senior Engineer. He joined Ryerson

University, Toronto, where he is currently a Professor

with the Department of Electrical and Computer

Engineering and the Natural Sciences and Engineer-

ing Research Council of Canada (NSERC) and the

Rockwell Industrial Research Chair in Power Elec-

tronics and Electric Drives. He is also the Founder of the Laboratory for

Electric Drive Applications and Research (LEDAR), Ryerson University. He

has published more than 140 technical papers and a Wiley-IEEE Press book.

He is the holder of 16 patent disclosures in the area of power electronics, energy

systems, advanced controls, and adjustable-speed drives.

Dr. Wu is a Fellow of the Engineering Institute of Canada. He is an

Associate Editor for the IEEE TRANSACTIONS ON POWER ELECTRONICS

and the IEEE Canadian Review. He is a Registered Professional Engineer in

the Province of Ontario, Canada. He was the recipient of the Gold Medal of

the Governor General of Canada, the Premiers Research Excellence Award,

Ryerson Distinguished Scholar Award, Ryerson Research Chair Award, and

the NSERC Synergy Award for Innovation.

Jorge Pontt (M00SM04) received the Engi-

neer and M.S. degrees in electrical engineering

from the Universidad Tcnica Federico Santa Mara

(UTFSM), Valparaso, Chile, in 1977.

Since 1977, he has been a Professor with the

Department of Electrical Engineering and the De-

partment of Electronics Engineering, UTFSM, under

the R&D and graduate program of power electronics.

He leads the Laboratory for Reliability and Power

Quality, UTFSM (LACSE) and is currently the Di-

rector of the Millennium Nucleus on Industrial Elec-

tronics and Mechatronics (NEIM), UTFSM. He is a coauthor of the software

Harmonix, which is used in harmonic studies in electrical systems. He is also

a Consultant in the mining industry, particularly in the design and application

of power electronics, drives, instrumentation systems, and power quality issues,

with management of more than 80 consulting and R&D projects. He has had

scientic stays at the Technische Hochschule Darmstadt, Darmstadt, Germany

(19791980); the University of Wuppertal, Wuppertal, Germany (1990); and

the University of Karlsruhe, Karlsruhe, Germany (20002001). He is a

Cofounder of the spin-off company ETT Ltda. (Chile) related to instrumen-

tation for large grinding mills. He has published more than 100 refereed journal

and conference proceeding papers.

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

WU et al.: CURRENT-SOURCE CONVERTER AND CCV TOPOLOGIES FOR INDUSTRIAL MEDIUM-VOLTAGE DRIVES 2797

Jos Rodrguez (M81SM94) received the Engi-

neer degree from the Universidad Tcnica Federico

Santa Mara, Valparaso, Chile, in 1977, and the

Dr.-Ing. degree from the University of Erlangen,

Erlangen, Germany, in 1985, both in electrical

engineering.

Since 1977, he has been with the Depart-

ment of Electronics Engineering, University Tcnica

Federico Santa Mara, where he is currently a

Professor. From 2001 to 2004, he was the Director

of the Department of Electronics Engineering. From

2004 to 2005, he served as Vice Rector of academic affairs, and since 2005, he

has been the Rector of the university. During his sabbatical leave in 1996, he

was responsible for the Mining Division, Siemens Corporation, Santiago, Chile.

He has extensive consulting experience in the mining industry, particularly in

the application of large drives such as cycloconverter-fed synchronous motors

for SAG mills, high-power conveyors, and controlled ac drives for shovels and

power quality issues. He has directed more than 40 R&D projects in the eld of

industrial electronics. He has coauthored more than 250 journal and conference

proceeding papers and contributed one book chapter. His research group has

been recognized as one of the two centers of excellence in engineering in Chile

from2005 to 2008. His main research interests include multilevel inverters, new

converter topologies, and adjustable-speed drives.

Prof. Rodrguez has been an active Associate Editor for the IEEE Power

Electronics and IEEE Industrial Electronics Societies since 2002. He has served

as Guest Editor for the IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS

in four instances [Special Sections on Matrix Converters (2002), Multilevel

Inverters (2002), Modern Rectiers (2005), and High Power Drives (2007)].

Steffen Bernet (M97) received the Diploma de-

gree from Dresden University of Technology,

Dresden, Germany, in 1990, and the Ph.D. degree

from Ilmenau University of Technology, Ilmenau,

Germany, in 1995, both in electrical engineering.

In 1995 and 1996, he was a Postdoctoral Re-

searcher with the Department of Electrical and

Computer Engineering, University of Wisconsin,

Madison. In 1996, he joined ABB Corporate Re-

search, Heidelberg, Germany, where he led the Elec-

trical Drive Systems Group. From 1999 to 2000, he

was responsible for the ABB research worldwide in the areas power electronics

systems, drives, and electric machines. From 2001 to 2007, he was a Professor

of power electronics with Berlin University of Technology, Berlin, Germany.

Since June 2007, he has been a Professor with the Power Electronics Group,

Department of Electrical Engineering and Information Technology, Dresden

University of Technology. During the past 17 years, he has conducted com-

prehensive research on power semiconductors, static power converters, and

ac motor drives. He has published more than 70 papers in the eld of power

electronics.

Dr. Bernet was the recipient of the 2005 Second Prize Paper Award at IEEE

PESC and Committee Second Prize Paper Awards from the Industrial Power

Converter Committee and the Power Electronic Devices and Components

Committee of the IEEE Industry Applications Society.

Samir Kouro (S04M08) was born in Valdivia,

Chile, in 1978. He received the M.Sc. and Ph.D.

degrees in electronics engineering from the Uni-

versidad Tcnica Federico Santa Mara (UTFSM),

Valparaso, Chile, in 2004 and 2008, respectively.

In 2004, he joined the Department of Electronics

Engineering, UTFSM, as a Research Assistant, and

is currently an Associate Researcher. His research

interests include power converters and adjustable-

speed drives.

Dr. Kouro was distinguished as the youngest

researcher in Chile being granted a government-funded research project

(FONDECYT) as Principal Researcher in 2004.

Authorized licensed use limited to: Universidad Tecnica Federico Santa Maria. Downloaded on December 18, 2008 at 14:36 from IEEE Xplore. Restrictions apply.

You might also like

- High Voltage Direct Current Transmission: Converters, Systems and DC GridsFrom EverandHigh Voltage Direct Current Transmission: Converters, Systems and DC GridsNo ratings yet

- Traction Motor DesignDocument11 pagesTraction Motor DesignS.m. FerdousNo ratings yet

- Average Synchronous Torque of Synchronous Machines, With Particular Reference To Reluctance MachinesDocument3 pagesAverage Synchronous Torque of Synchronous Machines, With Particular Reference To Reluctance MachinesAbhishek AgarwalNo ratings yet

- CYCLOCONVERTERSDocument46 pagesCYCLOCONVERTERSHari Haran100% (1)

- High Performance Cooling of Traction BrushlessDocument96 pagesHigh Performance Cooling of Traction BrushlessdftghsNo ratings yet

- Axial PErmanent MAgnetDocument6 pagesAxial PErmanent MAgnetSatyam Swarup100% (1)

- Cycloconverter ManualDocument6 pagesCycloconverter ManualShankar ArunmozhiNo ratings yet

- Ata 24Document9 pagesAta 24Prince AbbasNo ratings yet

- Tip Speed RatioDocument4 pagesTip Speed Ratiomaantom3No ratings yet

- Design of Synchronous MachinesDocument17 pagesDesign of Synchronous MachinesNiteshNarukaNo ratings yet

- EEE8155 Design and Analysis of Electrical Machines and DrivesDocument13 pagesEEE8155 Design and Analysis of Electrical Machines and DrivesstephenNo ratings yet

- Generalized PDFDocument14 pagesGeneralized PDFgurunathan1414% (7)

- 8MS Three-Phase Synchronous MotorsDocument163 pages8MS Three-Phase Synchronous MotorsrrrNo ratings yet

- BLDC and PMS Motor ComparisonDocument26 pagesBLDC and PMS Motor ComparisonAnimesh MukherjeeNo ratings yet

- PMSM Control Strategy ComparisonDocument4 pagesPMSM Control Strategy Comparisonpersian67No ratings yet

- Induction Motor Design PDFDocument46 pagesInduction Motor Design PDFdiptiNo ratings yet

- Design and Dynamic Study of A 6 KW External Rotor Permanent Magnet Brushless DC Motor For Electric DrivetrainDocument7 pagesDesign and Dynamic Study of A 6 KW External Rotor Permanent Magnet Brushless DC Motor For Electric DrivetrainMC ANo ratings yet

- Lipo PDFDocument11 pagesLipo PDFjalilemadiNo ratings yet

- Lecture Notes On Permanent Magnet Brushless DC Motor Drive For Light Electric Vehicle ApplicationDocument24 pagesLecture Notes On Permanent Magnet Brushless DC Motor Drive For Light Electric Vehicle ApplicationAshish KumarNo ratings yet

- 4E Roadmap for Energy Efficient Electric Motors and Motor SystemsDocument30 pages4E Roadmap for Energy Efficient Electric Motors and Motor SystemsCarlos LopezNo ratings yet

- Induction Motor Drive Control MethodsDocument8 pagesInduction Motor Drive Control MethodsRudra Kumar MishraNo ratings yet

- 2.review of Literature and Statement of ProblemDocument6 pages2.review of Literature and Statement of ProblemsheriabhiNo ratings yet

- Modelling of The Three-Phase Induction Motor Using SIMULINKDocument3 pagesModelling of The Three-Phase Induction Motor Using SIMULINKsajs20175% (4)

- Internal Combustion Engine History and DesignDocument43 pagesInternal Combustion Engine History and Designwlkngs87No ratings yet

- Treating Harmonics in Electrical Distribution Systems PDFDocument18 pagesTreating Harmonics in Electrical Distribution Systems PDFkgskgm100% (1)

- Modeling and Analysis of 6 Phase Synchronous MotorDocument14 pagesModeling and Analysis of 6 Phase Synchronous MotorArif IqbalNo ratings yet

- A Review of Structural and Thermal Analysis of Traction MotorsDocument11 pagesA Review of Structural and Thermal Analysis of Traction MotorsGari PastranaNo ratings yet

- Automation in Electrical Power Systems - A Barzan - First Edition - 1977 - MIRDocument419 pagesAutomation in Electrical Power Systems - A Barzan - First Edition - 1977 - MIRAriyasinghe AmunumullegamaNo ratings yet

- EE2403 Special Electrical MachinesDocument19 pagesEE2403 Special Electrical MachinesvasanthavananNo ratings yet

- Lec9 - Basics of Electric Drives - IMDocument10 pagesLec9 - Basics of Electric Drives - IMTeofilo DedietroNo ratings yet

- G2 Consulting - Motor Design and Power Electronics Course OverviewDocument188 pagesG2 Consulting - Motor Design and Power Electronics Course OverviewFehan Arif MalikNo ratings yet

- SEMIKRON Application Manual Power SemiconductorsDocument466 pagesSEMIKRON Application Manual Power SemiconductorsthietdaucongNo ratings yet

- Unbalanced Magnetic Pull and Air-Gap Monitoring For Large HydrogeneratorsDocument2 pagesUnbalanced Magnetic Pull and Air-Gap Monitoring For Large HydrogeneratorsbasilecoqNo ratings yet

- How To Design Multi-Kw Converters For Electric Vehicles Part 4 - Power Factor Correction PDFDocument9 pagesHow To Design Multi-Kw Converters For Electric Vehicles Part 4 - Power Factor Correction PDFoszemNo ratings yet

- C2000 Microcontroller WorkshopDocument342 pagesC2000 Microcontroller WorkshopShanon RustoffNo ratings yet

- WPM 0119 Digimag PDFDocument40 pagesWPM 0119 Digimag PDFJoeNo ratings yet

- KLS Gogte Institute Course Report on Ultracapacitors in EVsDocument7 pagesKLS Gogte Institute Course Report on Ultracapacitors in EVsShardulNo ratings yet

- Wound-Field Synchronous Machine DrivesDocument62 pagesWound-Field Synchronous Machine DrivesKorlpate BhaskarNo ratings yet

- Sigmadrive Range Manual Provisional ReleaseDocument47 pagesSigmadrive Range Manual Provisional ReleaseJanson Rojas HernándezNo ratings yet

- Speed Control of Separately Excited DC Motor Using Fuzzy Logic ControllerDocument6 pagesSpeed Control of Separately Excited DC Motor Using Fuzzy Logic ControllerseventhsensegroupNo ratings yet

- High-efficiency water-cooled axial-flux PM machine for electric vehicle wheel driveDocument7 pagesHigh-efficiency water-cooled axial-flux PM machine for electric vehicle wheel driveSteven SullivanNo ratings yet

- WKU ECED Regular CurriculumDocument308 pagesWKU ECED Regular Curriculumnegasa oliNo ratings yet

- Unified Theory of Machine Paper PDFDocument1 pageUnified Theory of Machine Paper PDFOladeji Ifedayo RNo ratings yet

- AmplidyneDocument2 pagesAmplidynetetrix50% (2)

- Fundamentals of Electrical Drives - G. K. Dubey PDFDocument121 pagesFundamentals of Electrical Drives - G. K. Dubey PDFAnonymous l7YZBdNo ratings yet

- Poly Phase Induction Motors in Power PlantsDocument58 pagesPoly Phase Induction Motors in Power PlantsDipikaNo ratings yet

- PMBLDC Motor DriveDocument55 pagesPMBLDC Motor DriveSushant SinghNo ratings yet

- A High Efficiency Flyback Micro-Inverter With A New Adaptive Snubber For Photovoltaic ApplicationsDocument29 pagesA High Efficiency Flyback Micro-Inverter With A New Adaptive Snubber For Photovoltaic ApplicationsChristian EmenikeNo ratings yet

- Cogging TorqueDocument12 pagesCogging Torqueanil_nitkianNo ratings yet

- Modeling and Simulation of Reluctance Motor Using Digital ComputerDocument5 pagesModeling and Simulation of Reluctance Motor Using Digital ComputerroyourboatNo ratings yet

- Analysis of Permanent Magnet Synchronous MotorDocument15 pagesAnalysis of Permanent Magnet Synchronous Motormalini72No ratings yet

- DC-DC ConverterDocument24 pagesDC-DC ConverterkandularanjithNo ratings yet

- Asynchronous MachinesDocument34 pagesAsynchronous MachinesAndi FalihNo ratings yet

- Modeling and analysis of multiphase electric machines for high-power applicationsDocument272 pagesModeling and analysis of multiphase electric machines for high-power applicationsQasim AlazzeNo ratings yet

- Electrical Overstress (EOS): Devices, Circuits and SystemsFrom EverandElectrical Overstress (EOS): Devices, Circuits and SystemsNo ratings yet

- Electric Motor Signature AnalysisDocument119 pagesElectric Motor Signature AnalysisMarco Bertoldi100% (2)

- Manual Cargador de BateríasDocument66 pagesManual Cargador de Bateríasjuan_fimNo ratings yet

- Universal Motor Controller UMC100: Motor Management System and AccessoriesDocument32 pagesUniversal Motor Controller UMC100: Motor Management System and Accessoriesjuan_fimNo ratings yet

- Universal Motor Controller UMC100: Motor Management System and AccessoriesDocument32 pagesUniversal Motor Controller UMC100: Motor Management System and Accessoriesjuan_fimNo ratings yet

- Repuestos PowellDocument4 pagesRepuestos Powelljuan_fimNo ratings yet

- Editor de Aplicaciones PDFDocument74 pagesEditor de Aplicaciones PDFAlejandro Cereceda CamposNo ratings yet

- Umc DTM ManualDocument60 pagesUmc DTM Manualjuan_fimNo ratings yet

- Electrical Machinery - Dr. P S BimbhraDocument338 pagesElectrical Machinery - Dr. P S BimbhraSumeet Mukherjee50% (2)

- Diode Rectifier Circuits and Filters ExplainedDocument23 pagesDiode Rectifier Circuits and Filters Explainedkaliman2010No ratings yet

- Umc DTM ManualDocument60 pagesUmc DTM Manualjuan_fimNo ratings yet

- PCM600 Getting Started Guide 757866 ENaDocument60 pagesPCM600 Getting Started Guide 757866 ENaLeslie LarsenNo ratings yet

- Motor Protective SettingsDocument28 pagesMotor Protective Settingsjuan_fimNo ratings yet

- New Charge Frozen Protection For MillDocument14 pagesNew Charge Frozen Protection For Milljuan_fimNo ratings yet

- ManualembutirDocument3 pagesManualembutirjuan_fimNo ratings yet

- Accesorios ABBDocument34 pagesAccesorios ABBjuan_fimNo ratings yet

- Eaton - Type VCP - Vacuum BKR - 01Document70 pagesEaton - Type VCP - Vacuum BKR - 01Dean BartlettNo ratings yet

- ATP ManualDocument270 pagesATP ManualJose Jorge Fontalvo100% (1)

- RP 02204001 eDocument20 pagesRP 02204001 ejuan_fimNo ratings yet

- PonJun03A ConfDocument6 pagesPonJun03A Confjuan_fimNo ratings yet

- Goldshc00004 E16 E15Document2 pagesGoldshc00004 E16 E15juan_fimNo ratings yet

- Thesis Ideas (List of Titles)Document13 pagesThesis Ideas (List of Titles)kimberl0o0% (2)

- BA 301 Syllabus (Summer 2018) Chuck Nobles Portland State University Research & Analysis of Business ProblemsDocument11 pagesBA 301 Syllabus (Summer 2018) Chuck Nobles Portland State University Research & Analysis of Business ProblemsHardlyNo ratings yet

- Amisha's First Year ReviewDocument4 pagesAmisha's First Year Reviewbam100% (1)

- Global Network - Torishima-EnglishDocument10 pagesGlobal Network - Torishima-Englishmayakanon4198No ratings yet

- Sanjeev Resume UpdatedDocument2 pagesSanjeev Resume UpdatedSanjeevSonuNo ratings yet

- 1994Document200 pages1994Dallas County R-I SchoolsNo ratings yet

- 1 PilotStudyDocument4 pages1 PilotStudyPriyanka SheoranNo ratings yet

- Monstrous Acts Problematizing Violence in Young Adult LiteratureDocument11 pagesMonstrous Acts Problematizing Violence in Young Adult LiteratureKimMerciecaNo ratings yet

- Tel: O771629278 Email: Shanmuganathan Sathiyaruban.: B.SC (Eng), Ceng, MieslDocument4 pagesTel: O771629278 Email: Shanmuganathan Sathiyaruban.: B.SC (Eng), Ceng, MieslsathiyanNo ratings yet

- 50 Habits of Highly Successful PeopleDocument1 page50 Habits of Highly Successful Peoplell_pabilonaNo ratings yet

- 2nd Sem Result MbaDocument2 pages2nd Sem Result MbaPrem KumarnNo ratings yet