Professional Documents

Culture Documents

Materials - Chemical Composition (Requirements) For Carbon Alloy Steels Used in Piping Applications

Uploaded by

Vamsikrishna LakamsaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materials - Chemical Composition (Requirements) For Carbon Alloy Steels Used in Piping Applications

Uploaded by

Vamsikrishna LakamsaniCopyright:

Available Formats

6/22/2014

Materials - Chemical Composition (Requirements) for Carbon Alloy Steels used in Piping applications home

sitemap

about

jobs

abbreviations

EXPLORE the WORLD

fun

of

question

conversion

links

copyright

misc

search

contact

contact

PIPING

DOCS MATL SOCIETIES PIPES FLANGES FITTINGS VALVES BOLTS GASKETS EQPT SPECIALS STEEL DIN STEAM OTHERS

home

sitemap

about

jobs

abbreviations

EXPLORE the WORLD

fun

of

question

conversion

links

copyright

misc

search

PIPING

DOCS MATL SOCIETIES PIPES FLANGES FITTINGS VALVES BOLTS GASKETS EQPT SPECIALS STEEL DIN STEAM OTHERS

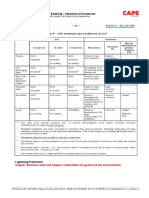

Chemical Requirements Carbon Alloy Steels used in Piping applications

ASTM A53

Specification for Seamless and Welded Black and Hot-Dipped Galvanized Steel Pipe

Unbelievable: Mother makes Rs 300.000/m from home! (ConsumerTips)

Composition, max, %

Element

Mn

Cu (1)

Ni (1)

Cr (1)

Mo (1)

V (1)

Type S (seamless pipe)

Grade A

0.25

0.95

0.05

0.045

0.40

0.40

0.40

0.15

0.08

Grade B

0.30

1.20

0.05

0.045

0.40

0.40

0.40

0.15

0.08

Type E (electric-resistance-welded)

Grade A

0.25

0.95

0.05

0.045

0.40

0.40

0.40

0.15

0.08

Grade B

0.30

1.20

0.05

0.045

0.40

0.40

0.40

0.15

0.08

0.05

0.045

0.40

0.40

0.40

0.15

0.08

Mn

Cu (1)

Ni (1)

Cr (1)

Mo (1)

V (1)

Type F (furnace-welded pipe)

Grade A

0.30

1.20

Composition, max, %

Element

Type S (seamless pipe)

Grade A

0.25

0.95

0.05

0.045

0.40

0.40

0.40

0.15

0.08

Grade B

0.30

1.20

0.05

0.045

0.40

0.40

0.40

0.15

0.08

Type E (electric-resistance-welded)

Grade A

0.25

0.95

0.05

0.045

0.40

0.40

0.40

0.15

0.08

Grade B

0.30

1.20

0.05

0.045

0.40

0.40

0.40

0.15

0.08

Type F (furnace-welded pipe)

file:///C:/Users/suresh/Desktop/PIPES/Materials%20-%20Chemical%20Composition%20(Requirements)%20for%20Carbon%20Alloy%20Steels%20used%20i

1/6

6/22/2014

Materials - Chemical Composition (Requirements) for Carbon Alloy Steels used in Piping applications -

Grade A

0.30

1.20

0.05

0.045

0.40

0.40

0.40

0.15

0.08

Note:

1. The total composition for these five elements shall not exceed 1.00%.

ASTM A105

Specification for C arbon Steel Forgings for Piping Applications

Composition, %

Element

Mn

P Special Offers.

S

Si

Cu

Ni

Cr

Mo

0.35

max

0.601.05

0.035

max

0.040

max

0.100.35

0.40

max (1)

0.40

max (1)

0.30

max (1-2)

0.12

max (1-2)

0.08

max

Mn

Si

Cu

Ni

Cr

Mo

0.35

max

0.601.05

0.035

max

0.040

max

0.100.35

0.40

max (1)

0.40

max (1)

0.30

max (1-2)

0.12

max (1-2)

0.08

max

Composition, %

Element

Notes:

1. The sum of C opper, Nickel, Niobium, Molybdenum and Vanadium shall not exceed 1.00%.

2. The sum of Niobium and Molybdenum shall not exceed 0.32%.

Note: For each reduction of 0.01% below the specified carbon maximum (0.35%), an increase of 0.06% Manganese above the specified

maximum (1.05%) will be permitted up to a maximum of 1.35%.

ASTM A106

Specification for Seamless C arbon Steel Pipe for High-Temperature Service

Composition, %

Element

Mn

max

Grade A

0.25 (1)

0.27-

Si

Cr

Cu

Mo

Ni

max

max

min

max (3)

max (3)

max (3)

max (3)

max (3)

0.035

0.035

0.10

0.40

0.40

0.15

0.40

0.08

0.93

Grade B

0.30 (2)

0.291.06

0.035

0.035

0.10

0.40

0.40

0.15

0.40

0.08

Grade C

0.35 (2)

0.291.06

0.035

0.035

0.10

0.40

0.40

0.15

0.40

0.08

Mn

Si

Cr

Cu

Mo

Ni

max

max

min

max (3)

max (3)

max (3)

max (3)

max (3)

Composition, %

Element

C

max

Grade A

0.25 (1)

0.270.93

0.035

0.035

0.10

0.40

0.40

0.15

0.40

0.08

Grade B

0.30 (2)

0.291.06

0.035

0.035

0.10

0.40

0.40

0.15

0.40

0.08

Grade C

0.35 (2)

0.291.06

0.035

0.035

0.10

0.40

0.40

0.15

0.40

0.08

Notes:

file:///C:/Users/suresh/Desktop/PIPES/Materials%20-%20Chemical%20Composition%20(Requirements)%20for%20Carbon%20Alloy%20Steels%20used%20i

2/6

6/22/2014

Materials - Chemical Composition (Requirements) for Carbon Alloy Steels used in Piping applications -

1. For each reduction of 0.01% below the specified C arbon maximum, an increase of 0.06% Manganese above the specified maximum will be

permitted up to a maximum of 1.35%.

2. Unless otherwise specified by the purchaser, for each reduction of 0.01% below the specified C arbon maximum, an increase of 0.06%

Manganese above the specified maximum will be permitted up to a maximum of 1.65%.

3. These five elements combined shall not exceed 1%.

ASTM A216

Specification for Steel C astings, C arbon, Suitable for Fusion Welding, for High-Temperature Service

Composition, % max

Grade

Mn

Si

Cu

Ni

Cr

Mo

WCA

UNS J02502

0.25(1)

0.70(1)

0.04

0.045

0.60

0.30

0.50

0.50

0.20

1.00

WCB

0.30(2)

1.00(2)

0.04

0.045

0.60

0.30

0.50

0.50

0.20

1.00

0.25(3)

1.20(3)

0.04

0.045

0.60

0.30

0.50

0.50

0.20

1.00

UNS J03002

WCC

UNS J02503

Composition, % max

Grade

Mn

Si

Cu

Ni

Cr

Mo

WCA

0.25(1)

0.70(1)

0.04

0.045

0.60

0.30

0.50

0.50

0.20

1.00

0.30(2)

1.00(2)

0.04

0.045

0.60

0.30

0.50

0.50

0.20

1.00

0.25(3)

1.20(3)

0.04

0.045

0.60

0.30

0.50

0.50

0.20

1.00

UNS J02502

WCB

UNS J03002

WCC

UNS J02503

Notes:

1. For each reduction of 0.01% below the specified maximum C arbon content, an increase of 0.04% manganese above the specified maximum

will be permitted up to a maximum of 1.10%.

2. For each reduction of 0.01% below the specified maximum C arbon content, an increase of 0.04% Mn above the specified maximum will be

permitted up to a maximum of 1.28%.

3. For each reduction of 0.01% below the specified maximum C arbon content, an increase of 0.04% manganese above the specified maximum

will be permitted to a maximum of 1.40%.

ASTM A234

Specification for Piping Fittings of Wrought C arbon Steel and Alloy Steel for Moderate and High Temperature Service

Composition, %

Grade

Mn

max

max

0.050

0.058

WPB

0.30

0.29-

(1,2,3,4,5)

max

1.06

WPC

(2,3,4,5)

0.35

max

0.291.06

0.050

WP1

0.28

max

0.300.90

0.045

0.058

0.045

Si

Cr

Mo

Ni

Cu

Others

0.10

0.40

0.15

0.40

0.40

V 0.08

min

max

max

max

max

max

0.10

min

0.40

max

0.15

max

0.40

max

0.40

max

V 0.08

0.100.50

max

0.440.65

file:///C:/Users/suresh/Desktop/PIPES/Materials%20-%20Chemical%20Composition%20(Requirements)%20for%20Carbon%20Alloy%20Steels%20used%20i

3/6

6/22/2014

Materials - Chemical Composition (Requirements) for Carbon Alloy Steels used in Piping applications -

WP12 CL1

0.050.20

0.300.80

0.045

0.045

0.60

max

0.801.25

0.440.65

WP12 CL2

0.050.20

0.300.80

0.045

0.045

0.60

max

0.801.25

0.440.65

WP11 CL1

0.05-

0.30-

0.030

0.030

0.50-

1.00-

0.44-

0.15

0.60

1.00

1.50

0.65

WP11 CL2

0.050.20

0.300.80

0.040

0.040

0.501.00

1.001.50

0.440.65

WP11 CL3

0.05-

0.30-

0.040

0.040

0.50-

1.00-

0.44-

0.20

0.80

1.00

1.50

0.65

WP22 CL1

0.050.15

0.300.60

0.040

0.040

0.50

max

1.902.60

0.871.13

WP22 CL3

0.05-

0.30-

0.040

0.040

0.50

1.90-

0.87-

0.15

0.60

max

2.60

1.13

WP5 CL1

0.15

max

0.300.60

0.040

0.030

0.50

max

4.06.0

0.440.65

WP5 CL3

0.15

0.30-

0.040

0.030

0.50

4.0-

0.44-

max

0.60

max

6.0

0.65

WP9 CL1

0.15

max

0.300.60

0.030

0.030

1.00

max

8.010.0

0.901.10

WP9 CL3

0.15

0.30-

0.030

0.030

1.00

8.0-

0.90-

max

0.60

max

10.0

1.10

WPR

0.20

max

0.401.06

0.045

0.050

WP91

0.08-

0.30-

0.020

0.010

0.12

0.60

1.602.24

0.751.25

0.20-

8.0-

0.85-

0.40

V 0.18-

0.50

9.5

1.05

max

0.25

Nb 0.060.10

N 0.030.07

Al 0.02 max(6)

Ti 0.01 max(6)

Zr 0.01 max(6)

WP911

0.090.13

0.300.60

0.020

0.010

0.100.50

8.09.5

0.901.10

0.40

max

V 0.180.25

Nb 0.0600.10

N 0.040.09

Al 0.02 max(6)

B 0.00030.006

W 0.901.10

Ti 0.01 max(6)

Zr 0.01 max(6)

file:///C:/Users/suresh/Desktop/PIPES/Materials%20-%20Chemical%20Composition%20(Requirements)%20for%20Carbon%20Alloy%20Steels%20used%20i

4/6

6/22/2014

Materials - Chemical Composition (Requirements) for Carbon Alloy Steels used in Piping applications -

Composition, %

Grade

Mn

max

max

0.058

Si

Cr

Mo

Ni

Cu

Others

0.10

min

0.40

max

0.15

max

0.40

max

0.40

max

V 0.08

0.10

0.40

0.15

0.40

0.40

V 0.08

min

max

max

max

max

max

1.602.24

0.751.25

WPB

(1,2,3,4,5)

0.30

max

0.291.06

0.050

WPC

0.35

0.29-

0.050

(2,3,4,5)

max

1.06

WP1

0.28

0.30-

max

0.90

WP12 CL1

0.050.20

0.300.80

0.045

0.045

0.60

max

0.801.25

0.440.65

WP12 CL2

0.050.20

0.300.80

0.045

0.045

0.60

max

0.801.25

0.440.65

WP11 CL1

0.050.15

0.300.60

0.030

0.030

0.501.00

1.001.50

0.440.65

WP11 CL2

0.050.20

0.300.80

0.040

0.040

0.501.00

1.001.50

0.440.65

WP11 CL3

0.05-

0.30-

0.040

0.040

0.50-

1.00-

0.44-

0.20

0.80

1.00

1.50

0.65

WP22 CL1

0.050.15

0.300.60

0.040

0.040

0.50

max

1.902.60

0.871.13

WP22 CL3

0.05-

0.30-

0.040

0.040

0.50

1.90-

0.87-

0.15

0.60

max

2.60

1.13

WP5 CL1

0.15

max

0.300.60

0.040

0.030

0.50

max

4.06.0

0.440.65

WP5 CL3

0.15

0.30-

0.040

0.030

0.50

4.0-

0.44-

max

0.60

max

6.0

0.65

WP9 CL1

0.15

max

0.300.60

0.030

0.030

1.00

max

8.010.0

0.901.10

WP9 CL3

0.15

0.30-

0.030

0.030

1.00

8.0-

0.90-

max

0.60

max

10.0

1.10

WPR

0.20

max

0.401.06

0.045

0.050

WP91

0.080.12

0.300.60

0.020

0.010

0.045

0.058

0.045

0.10-

0.44-

0.50

0.65

0.200.50

8.09.5

0.851.05

0.40

max

max

V 0.180.25

Nb 0.060.10

N 0.030.07

Al 0.02 max(6)

Ti 0.01 max(6)

Zr 0.01 max(6)

WP911

0.09-

0.30-

0.020

0.010

0.10-

8.0-

0.90-

0.40

V 0.18-

file:///C:/Users/suresh/Desktop/PIPES/Materials%20-%20Chemical%20Composition%20(Requirements)%20for%20Carbon%20Alloy%20Steels%20used%20i

5/6

6/22/2014

Materials - Chemical Composition (Requirements) for Carbon Alloy Steels used in Piping applications -

0.13

0.60

0.50

9.5

1.10

max

0.25

Nb 0.0600.10

N 0.040.09

Al 0.02 max(6)

B 0.00030.006

W 0.901.10

Ti 0.01 max(6)

Zr 0.01 max(6)

Notes:

1. Fittings made from bar or plate may have 0.35 max carbon.

2. Fittings made from forgings may have 0.35 max C arbon and 0.35 max Silicon with no minimum.

3. For each reduction of 0.01% below the specified C arbon maximum, an increase of 0.06% Manganese above the specified maximum will be

permitted, up to a maximum of 1.35%.

4. The sum of C opper, Nickel, Niobium, and Molybdenum shall not exceed 1.00%.

5. The sum of Niobium and Molybdenum shall not exceed 0.32%.

6. Applies both to heat and product analyses.

top of page

top of page

Werner Slken 2008 - 2014. All rights reserved.

Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. Albert Einstein

Werner Slken 2008 - 2014. All rights reserved.

Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. Albert Einstein

file:///C:/Users/suresh/Desktop/PIPES/Materials%20-%20Chemical%20Composition%20(Requirements)%20for%20Carbon%20Alloy%20Steels%20used%20i

6/6

You might also like

- Product Range:: SpecificationsDocument2 pagesProduct Range:: SpecificationsVamsikrishna LakamsaniNo ratings yet

- Sample Page: 3. The Master Sheet Unit ObjectivesDocument7 pagesSample Page: 3. The Master Sheet Unit ObjectivesDeepak Pai BNo ratings yet

- Chemical Composition of Carbon Steel, Carbon Steel Pipe, Carbon Steel Tubes, Alloy Steel Pipe, Alloy Steel Tubes, Mumbai, IndiaDocument2 pagesChemical Composition of Carbon Steel, Carbon Steel Pipe, Carbon Steel Tubes, Alloy Steel Pipe, Alloy Steel Tubes, Mumbai, IndiaVamsikrishna LakamsaniNo ratings yet

- Rail StandardsDocument1 pageRail StandardsVamsikrishna LakamsaniNo ratings yet

- Technical Drawing SpecificationsDocument21 pagesTechnical Drawing SpecificationsmialitaNo ratings yet

- Steam Turbine Oil ChallengesDocument10 pagesSteam Turbine Oil Challengessevero97No ratings yet

- Turbine Governing SystemDocument32 pagesTurbine Governing SystemVamsikrishna Lakamsani100% (2)

- Engineering DrawingsDocument30 pagesEngineering DrawingsvamsiklNo ratings yet

- Structural 2Document9 pagesStructural 2Samik MukherjeeNo ratings yet

- Ijmerr 515fad7b15b9fDocument13 pagesIjmerr 515fad7b15b9fVamsikrishna LakamsaniNo ratings yet

- Process-Piping-Pipeline Engg PDP - Ray R10copiesDocument40 pagesProcess-Piping-Pipeline Engg PDP - Ray R10copiesVamsikrishna LakamsaniNo ratings yet

- Piping PDFDocument46 pagesPiping PDFGORO43100% (1)

- CANDU - 234-7 Turbine Gioverning SystemDocument32 pagesCANDU - 234-7 Turbine Gioverning SystemGuruxyzNo ratings yet

- Governing and Protection SystemDocument15 pagesGoverning and Protection SystemVamsikrishna Lakamsani100% (1)

- 02-3 Prime MoversDocument32 pages02-3 Prime MoversVamsikrishna LakamsaniNo ratings yet

- Utility TurbinesDocument67 pagesUtility TurbinesBapu612345No ratings yet

- 57MW STEAM TURBINE PRESENTATIONDocument27 pages57MW STEAM TURBINE PRESENTATIONSagar BahirjeNo ratings yet

- Turbo Generator & Its AuxiliariesDocument89 pagesTurbo Generator & Its Auxiliariestrung2iNo ratings yet

- Governing SystemDocument8 pagesGoverning SystemVamsikrishna LakamsaniNo ratings yet

- Turbine Oil System Care and MaintenanceDocument2 pagesTurbine Oil System Care and MaintenanceJaeman ParkNo ratings yet

- 55 TurbineDocument47 pages55 TurbineChandan M M DvgNo ratings yet

- SIPAT 660 MW Turbo - Governing & Protection SystemDocument49 pagesSIPAT 660 MW Turbo - Governing & Protection SystemVamsikrishna LakamsaniNo ratings yet

- Condition Monitoring For Steam Turbines IDocument38 pagesCondition Monitoring For Steam Turbines IjavedNo ratings yet

- 55 TurbineDocument47 pages55 TurbineChandan M M DvgNo ratings yet

- Governing SystemDocument8 pagesGoverning SystemVamsikrishna LakamsaniNo ratings yet

- Governing SystemDocument8 pagesGoverning SystemVamsikrishna LakamsaniNo ratings yet

- Energy and Power ConversionsDocument2 pagesEnergy and Power Conversionsarvin_erNo ratings yet

- GoverningDocument19 pagesGoverningBalkishan DyavanapellyNo ratings yet

- SCI Stainless Pipe and Tubing 0709Document7 pagesSCI Stainless Pipe and Tubing 0709Nguyen Dinh AnhNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Periodic TableDocument1 pagePeriodic TableAisyah AlkatiriNo ratings yet

- Investigation Into The Effect of Tool-Chip Contact Length OnDocument5 pagesInvestigation Into The Effect of Tool-Chip Contact Length OnAbid HussainNo ratings yet

- KS4 Metallic BondingDocument17 pagesKS4 Metallic BondingGian CarloNo ratings yet

- Module 1 16 - IIWDocument1,119 pagesModule 1 16 - IIWsree100% (1)

- Valley Plating Works Spec SheetDocument1 pageValley Plating Works Spec Sheetrheins2000No ratings yet

- Section IiDocument1,365 pagesSection Iiprabhu100% (3)

- JP Morgan Global Metals & Mining OctoberDocument40 pagesJP Morgan Global Metals & Mining OctoberjkzhouNo ratings yet

- Ferrous Alloys: SeptemberDocument12 pagesFerrous Alloys: SeptembersunsirNo ratings yet

- 3.40 Sketch Within A Cubic Unit Cell The Following PlanesDocument6 pages3.40 Sketch Within A Cubic Unit Cell The Following PlanesHarshil TejaniNo ratings yet

- Comparison Table For Pipes and Fittings PDFDocument1 pageComparison Table For Pipes and Fittings PDFrcpretoriusNo ratings yet

- Flujograma BaseDocument6 pagesFlujograma BaseJose AriasNo ratings yet

- Basic Knowledge of Silver & GoldDocument4 pagesBasic Knowledge of Silver & GoldShashi Bisht80% (5)

- ASME B 31.3 preheat temparature tableDocument2 pagesASME B 31.3 preheat temparature tableabdulNo ratings yet

- CD4mcu Data SheetDocument1 pageCD4mcu Data SheetAde Bagus SetiawanNo ratings yet

- Silicon Carbide: 1. Exposure DataDocument71 pagesSilicon Carbide: 1. Exposure DataDwi IraNo ratings yet

- Dislocation MotionDocument40 pagesDislocation Motionart180No ratings yet

- 2014-T6 Aluminum HF 15 BarDocument1 page2014-T6 Aluminum HF 15 BarPallavi DeshmukhNo ratings yet

- Material EquivalentDocument2 pagesMaterial EquivalentdilipNo ratings yet

- TGN-PE-02 Temper Bead WeldingDocument9 pagesTGN-PE-02 Temper Bead WeldingNatrajiNo ratings yet

- Astm A276Document7 pagesAstm A276Joffre ValladaresNo ratings yet

- AJM Process Explained in 40 CharactersDocument12 pagesAJM Process Explained in 40 CharactersAnonymous N73Nk4RwsNo ratings yet

- Use of Geometallurgy To Predict Tailing Leach Acid Consumption at Olimpic DamDocument10 pagesUse of Geometallurgy To Predict Tailing Leach Acid Consumption at Olimpic DamWiku PadmonoboNo ratings yet

- 4 MCQ UNIT 4 (Part 1)Document19 pages4 MCQ UNIT 4 (Part 1)Hrishikesh RahinjNo ratings yet

- Cementing Materials: Semi-Finished ProductDocument7 pagesCementing Materials: Semi-Finished ProductMD.MOSHIUR RAHMANNo ratings yet

- AxiWeld Exothermic Welding System PDFDocument24 pagesAxiWeld Exothermic Welding System PDFNimish TaterhNo ratings yet

- Selection of Conductors For Structural ProtectionDocument6 pagesSelection of Conductors For Structural ProtectionSandeep SinghNo ratings yet

- Updated Mohs Scale PDFDocument2 pagesUpdated Mohs Scale PDFHarshNo ratings yet

- AlloysDocument4 pagesAlloysM.zuhair asifNo ratings yet

- Application Datasheet: Standard Designation For Wrought Copper AlloysDocument72 pagesApplication Datasheet: Standard Designation For Wrought Copper AlloysdeveshNo ratings yet

- Failure Analysis of Refractory Anchors of A PowerDocument8 pagesFailure Analysis of Refractory Anchors of A PowerVinh Do ThanhNo ratings yet