Professional Documents

Culture Documents

Installation, Operation & Maintenance Manual for DA Pump

Uploaded by

Edgar CanelasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation, Operation & Maintenance Manual for DA Pump

Uploaded by

Edgar CanelasCopyright:

Available Formats

INSTALLATION

OPERATION &

MAINTENANCE

DA PUMP I/B

BALL/BALL CONFIGURATION

D

A

B

/

B

READ THIS BEFORE PROCEEDING

It should be understood that the information contained in this manual does not relieve operating and maintenance

personnel from the responsibility of exercising normal good judgement in the installation, operation, and mainte-

nance of the pump and its components.

Only qualified personnel should work on this equipment, and only after reading this manual and becoming familiar

with all of the safety notices and procedures contained herein. Safe and successful operation of this equipment is

dependent upon its proper handling, installation, operation, and maintenance as described in this manual.

It should be understood that the contents of this manual do not add to or modify any prior or existing warranty,

agreement, commitment, and/or relationship between Flowserve and the purchaser. The sales contract between

the parties contains the sole warranty for this equipment.

During initial start-up of this equipment, it is recommended that the service of a Flowserve service supervisor be

obtained to assure trouble-free operation. In some cases, the presence of a Flowserve service supervisor may be

a contractual requirement for continuation of warranty. Check your contract.

To schedule a service supervisor, contact Flowserve Corporation, Customer Service Department (1-800-547-

8671 or 908-859-7372), or contact the nearest Flowserve sales office.

D

A

B

/

B

Table Of Contents

Section 1

Introduction

Pump Data Sheet 1-1

Approximate Weights 1-1

Introduction 1-2

Safety 1-2

Description 1-2

CASING 1-2

IMPELLERS 1-3

CASING RINGS 1-3

CHANNEL RINGS 1-3

CENTER SLEEVE 1-3

CENTER BUSHING 1-3

THROTTLING SLEEVE 1-3

THROTTLING BUSHING 1-3

SHAFT 1-3

SHAFT SLEEVES 1-3

BEARINGS 1-3

STUFFING BOXES 1-4

RECEIPT INSPECTION 1-4

UNPACKING 1-4

Care During Storage 1-4

Painting/Rust Preventive 1-4

Lifting Equipment 1-5

TO LIFT UNIT 1-5

TO LIFT DRIVER 1-5

TO LIFT PUMP 1-5

TO LIFT UPPER HALF CASING 1-5

TO LIFT PUMP ROTOR 1-5

D

A

B

/

B

Table Of Contents

Extended Storage Requirements 1-5

GENERAL 1-5

INSPECTION UPON ARRIVAL 1-6

STORAGE AREA 1-6

STORAGE PREFERRED (DRY) 1-6

GENERAL 1-6

ROTOR STORAGE 1-6

INSPECTION AND MAINTENANCE 1-6

STORAGE NON-PREFERRED (WET) 1-8

Painting And Preservation 1-8

Start-Up 1-8

Drivers 1-8

Section 2

Installation

Location 2-2

Foundation 2-2

Installation Check List 2-2

Level The Bedplate 2-3

PRELIMINARY ALIGNMENT 2-3

Grouting 2-4

Shaft/Coupling Alignment 2-4

TYPES OF MISALIGNMENT 2-5

ALIGNMENT 2-5

HORIZONTAL MOVE 2-7

VERTICAL MOVE 2-8

CHECK COUPLING ALIGNMENT 2-8

ASSEMBLE AND LUBRICATE COUPLING 2-8

DOWEL PUMP AND DRIVER 2-8

HOT ALIGNMENT CHECK 2-9

ALIGNMENT DATA SHEET SHEET 1 OF 2 2-10

ALIGNMENT DATA SHEET SHEET 2 OF 2 2-11

ALIGNMENT DATA EXAMPLE 2-12

D

A

B

/

B

Table Of Contents

Piping 2-13

SUCTION AND DISCHARGE PIPING 2-13

BY-PASS LINE 2-13

SUCTION STRAINER 2-14

Coupling Alignment Check 2-15

Gib Block Installation 2-15

Inspection Of Oil Rings Before Start-Up 2-16

Commissioning Of Equipment 2-16

Section 3

Operation

Technical Data 3-1

SPECIFIC GRAVITY 3-1

VISCOSITY 3-1

CHANGING PUMP SPEED 3-1

NET POSITIVE SUCTION HEAD (NPSH) 3-1

Operating Precautions 3-1

Pre-Operational Checks 3-2

PUMP INSTRUMENTATION SET POINTS 3-2

Initial Start-Up Procedure 3-3

Operating Checks 3-3

Normal Start-Up 3-4

Securing The Pump 3-4

Section 4

Troubleshooting

Troubleshooting 4-1

Flowserve Corporation Pump Service Centers 4-4

D

A

B

/

B

Table Of Contents

Section 5

Lubrication

Lubricating Oil 5-1

Oil Specifications 5-1

Oil Temperature 5-2

Cleaning The Lubrication System Prior To Operation 5-2

Trico Oiler Setting 5-2

Section 6

Shaft Sealing

Mechanical Seal 6-1

MECHANICAL SEAL REMOVAL 6-1

Section 7

Maintenance

General 7-1

Preventive Maintenance Schedule 7-2

Torque Values 7-3

Coupling Removal 7-3

Dismantling Procedure 7-3

THRUST BEARING REMOVAL 7-3

PLAIN BEARING REMOVAL 7-4

REMOVAL OF STUFFING BOX PARTS 7-4

ROTOR REMOVAL 7-4

DISMANTLING THE ROTOR 7-5

HEATING IMPELLERS FOR REMOVAL 7-5

Inspection And Renewal Of Parts 7-6

Parting Flange Gasket 7-7

Parting Flange Torque Procedure 7-8

D

A

B

/

B

D

A

B

/

B

Table Of Contents

Bearing Handling Information 7-8

BEARING HANDLING 7-8

BEARING INSTALLATION 7-9

BEARING REMOVAL 7-9

BEARING CLEANING 7-9

Reassembly Of Pump 7-10

REBUILDING ROTOR 7-10

INDICATE AND DYNAMIC-BALANCE ROTOR 7-11

INSTALLING ROTOR IN CASING 7-11

ASSEMBLE STUFFING BOX EXTENSION 7-12

CHECK ROTOR VERTICAL LIFT 7-12

CHECK ROTOR AXIAL FLOAT 7-12

HORIZONTAL AND VERTICAL SHAFT ALIGNMENT 7-13

CENTRALIZE ROTOR AXIALLY 7-14

SET THRUST BEARING END PLAY 7-14

INITIAL THRUST BEARING ASSEMBLY 7-15

FINAL THRUST BEARING ASSEMBLY 7-15

FINAL ASSEMBLY 7-16

Section 8

Parts Information

Service Instructions 8-1

Ordering Instructions 8-1

Recommended Spare Parts 8-2

Exploded View No. 1 Typical Rotor Assembly 8-3

Exploded View No. 2 Lower Half Bushings, Rotor & Casing Assembly 8-4

Exploded View No. 3 Upper Half Bushings & Casing Assembly 8-5

Exploded View No. 4 Shaft Sealing 8-6

Exploded View No. 5 Plain Bearing End 8-7

Exploded View No. 6 Thrust Bearing End 8-8

D

A

B

/

B

Table Of Contents

Flowserve Corporation Pump Service Centers 8-9

Flowserve Corporation Domestic Sales Facilities 8-10

Flowserve Corporation International Sales Facilities 8-12

D

A

B

/

B

Introduction

1-2

INTRODUCTION

This manual contains instructions for installation,

operation and maintenance of your Flowserve Cen-

trifugal pump. It has been designed to provide safe

and reliable service. However, it is both a pressure

vessel and a piece of rotating machinery. Therefore

the operator(s) must exercise good judgement and

proper safety practices to avoid damage to the

equipment and surroundings and prevent personal

injury.

The instructions in this manual are intended for the

guidance of personnel with a general training in op-

eration and maintenance of Centrifugal Pumps. It is

our hope that you will become acquainted with its

content as an aid to better pump performance. This

manual should be read in its entirety before installing

and/or operating the equipment. The Assembly

Drawings (included in Appendix) and General Ar-

rangement Drawing (included in Appendix) should

be consulted for accurate details and determination

of specific optional features that are furnished with

your pump. All numbers in parentheses ( ) following

part names correspond with Exploded View Noun

Codes. EXAMPLE. (1-003A) Exploded View #1,

Noun Code #003A Impeller Assembly. Exploded

Views are included in Section 8.

NOTE

The installation/commissioning of this equipment

must be conducted in accordance with API Recom-

mended Practices 686/PIP REIE 686 First Edition.

Refer to API 610 Eighth Edition Appendix `L for

baseplate grouting requirements.

Copies of API Recommended `Practices 686/PIP

REIE 686 First Edition may be obtained from

America Petroleum Institute, 1220 L Street, N.W.,

Washington, DC 20005. Telephone (202) 682-

8000.

SAFETY

It is assumed that your safety department has estab-

lished a safety program based upon a thorough

analysis of industrial hazards. Before installing and

operating or performing maintenance on the pump

and associated components described in this man-

ual, the safety program must be reviewed to ensure

that it covers the hazards arising from high- speed

rotating machinery.

It is important that due consideration be given to

those hazards which arise from the presence of

electrical power, hot oil, high-pressure and high-tem-

perature liquids, toxic liquids and gases and flamma-

ble liquids and gases. Proper installation and care

of protective guards, shutdown devices and over-

pressure protection equipment should also be con-

sidered a mandatory part of any safety program.

Also essential are special precautionary measures to

prevent the possibility of applying power to the

equipment at any time when maintenance work is in

progress. The prevention of rotation due to reverse

flow should not be overlooked.

In general, all personnel should be guided by all the

basic rules of safety associated with the equipment

and the process.

DESCRIPTION

The DA pump is a multistage, single suction op-

posed impeller, horizontally split volute pump.

The suction and discharge nozzles are cast integral

with the lower half casing.

Rotating parts are accessible by removing the up-

per-half casing which can be removed without

breaking suction and discharge piping.

CASING

The casing provides for immediate containment of

the liquid being pumped, while directing the flow of

liquid from the suction nozzle to the impellers and

subsequently through the volute to the discharge

nozzle.

D

A

B

/

B

Introduction

1-3

The casing halves are sealed by the use of a gasket

and are joined together by studs, which are installed

in the lower half casing and fastened with washers

and cap nuts.

IMPELLERS

The impellers are single suction, enclosed type, one-

piece construction and are dynamically balanced.

They are fitted with renewable impeller rings (front

and back) which are held in place by headless set-

screws.

The impellers are keyed, have a shrink fit to the

pump shaft and are held in axial position by a split

ring.

CASING RINGS

Casing rings are positioned over the impeller front

rings. These rings are tubular and renewable.

CHANNEL RINGS

Renewable channel rings are positioned over the

impeller back rings. They divide the casing into

stages. These rings are horizontally split and are

held together by shoulder screws.

CENTER SLEEVE

A renewable type center sleeve is used under the

center bushing. The center sleeve is tubular and

keyed to the shaft (via the impeller key).

CENTER BUSHING

The renewable center bushing is horizontally split,

the two halves are held together by socket-head

capscrews and taper dowel pins. It is held in posi-

tion by the raised annular ring of the bushing en-

gaging the annular groove in the casing.

The center bushing, in conjunction with center

sleeve, divides the casing at the center (back-to-

back) impellers.

THROTTLING SLEEVE

Renewable type throttling sleeve is used under the

throttling bushing. The throttling sleeve is tubular,

keyed, has a shrink fit to the shaft, and is held in po-

sition by a split ring.

THROTTLING BUSHING

Renewable type throttling bushing is used. It is held

in position by the annular ring of the bushing en-

gaging the annular groove in the casing.

The throttling bushing, in conjunction with the throt-

tling sleeve, allows pressure to be bled off thru the

balance lines, so that pressure on the stuffing boxes

is balanced. The throttling bushing also balances

the axial thrust of the pump rotor.

SHAFT

The high-strength shaft is ground over its entire

length to close tolerances. The shaft is designed to

transmit the required power without vibration and is

stepped at each impeller fit for ease of assembly and

disassembly.

SHAFT SLEEVES

Renewable shaft sleeves are provided with pumps

equipped with packed stuffing boxes to protect the

shaft at the stuffing box areas. The sleeves are tu-

bular type, keyed to the shaft, and held in position by

the retaining rings.

BEARINGS

The plain and thrust ball bearings are lubricated by

means of oil rings, which run on journal sleeves and

in the oil reservoir of the bearing housings.

The plain ball bearing is a single-row deep-groove

type, free to adjust axially in the bearing housing.

The thrust ball bearing is of the double-row

(mounted back-to-back) angular-contact type, and is

of ample size to carry the thrust loads encountered

in service. The pump bearings are renewable.

D

A

B

/

B

Introduction

1-4

STUFFING BOXES

The stuffing boxes are cast integral with the casing.

The suction and discharge end stuffing boxes can be

equipped with a cartridge type mechanical seal or

stuffing box packing.

RECEIPT INSPECTION

NOTE

The following information regarding receiving is only

offered as a general guideline to the customer.

Flowserve Corp. requires that all receiving be con-

ducted in accordance with specifications set forth in

Chapter 3 -`Jobsite Receiving and Protection from

API Recommended Practices 686/PIP REIE 686,

First Edition.

The pump and its associated equipment were care-

fully inspected at the factory prior to shipment to en-

sure compliance with the purchase requirements

and job specification. It is suggested that the pump

be inspected upon arrival and that any irregularities

or damage be reported to the carrier immediately.

The condition of the skid and covering is indicative of

the way the shipment was handled. Broken skids,

torn coverings, bent hold-down bolts, broken straps,

etc. indicate rough handling.

The protective covers on the pump nozzles should

be in place and undamaged. The shipping papers

should be checked to determine satisfactory arrival

of any special tools, loose parts, and/or spare parts,

etc., which are usually preserved and packed in a

separate box attached to the skid.

If any damage is discovered and/or parts are miss-

ing, notify the carrier or nearest Flowserve office

immediately.

UNPACKING

The pump should arrive already mounted on the

bedplate and it is therefore suggested that the un-

packing of the equipment should proceed per in-

struction as outlined in this manual.

In general, care is to be taken when removing crat-

ing, coverings, and strapping in order not to damage

any auxiliary equipment and/or the paint finish.

CARE DURING STORAGE

(see Extended Storage Requirements)

If it is necessary to store the unit any length of time

before installation, find a vibration-free location that

is protected from unfavorable weather.

The nozzle covers provided with the unit should be

left in place during storage.

Electric motors (pump driver) should not be stored in

damp places without special protection (refer to

motor manufacturers instructions).

PAINTING/RUST PREVENTIVE

Internal parts of the pump and bearing housings are

protected prior to shipment with a thin-film polar-type

rust preventive [pump internals (Ferrocote 5684),

bearing housings (MIL-C-16173 Grade 3)]. This can

be removed by flushing with petroleum solvents.

External machined surfaces are protected with dura-

ble drying-type rust preventive (MIL-C-16173 Grade

1). This can be removed with kerosene or safety

solvent (Tower No. 392).

External non-machined surfaces are painted with

one coat of gray enamel followed by a coat of multi-

color speckle lacquer.

Exception: External non-machined surfaces of the

pump [if operating at a temperature above 200

o

F.

(94

o

C)] are painted with a high-temperature alumi-

num base paint.

Parts ordered separately are protected with a thin-

film polar-type rust preventive. This can be removed

with petroleum solvents.

D

A

B

/

B

Introduction

1-5

D

A

B

/

B

LIFTING EQUIPMENT

NOTE

The following information regarding lifting is only of-

fered as a general guideline to the customer. Flows-

erve Corp. requires that all lifting and rigging be

performed in accordance with specifications set forth

in Chapter 2 - `Lifting and Rigging from API Rec-

ommended Practices 686/PIP REIE 686, First Edi-

tion.

WARNING

MAKE SURE THAT ANY EQUIPMENT USED TO

LIFT THE PUMP OR ANY OF ITS COMPONENTS

IS CAPABLE OF SUPPORTING THE TOTAL

WEIGHT ENCOUNTERED. MAKE SURE THAT

ALL PARTS ARE PROPERLY RIGGED BEFORE

ATTEMPTING TO LIFT.

TO LIFT UNIT

Pump, driver and bedplate can NOT be lifted as a

unit. Driver must be removed from bedplate before

lifting.

To lift pump and bedplate or just bedplate, sling bed-

plate from all lifting eyes. Failure to do this may re-

sult in permanent deformation of bedplate.

TO LIFT DRIVER

Refer to driver manufacturers instructions.

TO LIFT PUMP

Install sling from overhead hoist and under bearing

housing mounting brackets (cast portion of casing

where bearing housings attach).

WARNING

DO NOT LIFT ENTIRE PUMP FROM CAST LIFT-

ING LUGS ON UPPER HALF CASING. THESE

LUGS ARE FOR LIFTING UPPER HALF CASING

ONLY.

TO LIFT UPPER HALF CASING

Rig to overhead hoist from cast lifting lugs provided.

TO LIFT PUMP ROTOR

Using slings that will not damage shaft, rig around

shaft close to the impellers and to overhead hoist.

Carefully lift rotor from lower half casing.

EXTENDED STORAGE REQUIREMENTS

NOTE

The following information regarding receiving is only

offered as a general guideline to the customer.

Flowserve Corp. requires that all receiving be con-

ducted in accordance with specifications set forth in

Chapter 3 `Jobsite Receiving and Protection from

API recommended Practices 686/PIP REIE 686,

First Edition.

GENERAL

During extended periods of storage prior to installa-

tion and from the time of installation until commercial

operation, precautions must be taken to protect the

pump from deterioration. The various parts of the

pump are protected prior to shipment by applying

varying grades of preservatives and paint. However,

during shipment and handling, the preservatives are

subjected to conditions that can cause their removal.

Also, during extended periods of time, the pre-

servative may deteriorate. The following procedures

should be followed to prevent deterioration of the

pump during the extended storage period. These

procedures may also be supplemented by the expe-

rience of the person(s) performing the tasks.

It should be noted, that unless otherwise agreed to,

full responsibility and costs associated with the stor-

age and inspection of this equipment rests with the

customer.

Introduction

1-6

CAUTION

IF PUMP IS EQUIPPED WITH A MECHANICAL

SEAL AND IS STORED OR HAS NOT BEEN RUN

FOR 1 YEAR OR MORE, THE MECHANICAL

SEAL MUST BE REMOVED BEFORE START-UP

AND FACES RE-LAPPED TO GUARD AGAINST

THE POSSIBILITY OF SEAL LEAKAGE. WHEN

RE-INSTALLING THE SEAL, NEW "O RINGS

AND GASKETS MUST BE USED.

INSPECTION UPON ARRIVAL

When the pump is received, it should be inspected

for damage or other signs of rough handling. Any

damage found should be reported to the carrier im-

mediately.

Inspect the preservative coating on the various

parts. If necessary, renew the preservative in areas

where it has been rubbed off or scraped.

Inspect all painted surfaces. If necessary, touch up

the areas where paint has been chipped or scraped.

Inspect all covers over pump openings and piping

connections. If covers or seals for the covers are

damaged or loose, they are to be removed, and a

visual inspection made of the accessible interior ar-

eas for accumulation of foreign materials or water. If

necessary, clean and recoat the interior parts with

preservative to restore the parts to the as shipped

condition. Install or replace covers and fasten se-

curely.

STORAGE AREA

When selecting a storage area, the following should

be taken into consideration:

1. The deterioration of the equipment will be propor-

tionate to the class/type of storage provided.

2. The expenses involved in restoring the equip-

ment at time of operation will be proportionate to the

class/type of storage provided.

STORAGE PREFERRED (DRY)

GENERAL

If at all possible, the pump and its components

should be stored indoors where they will be pro-

tected from the elements. If it is not possible to store

the pump and its components indoors, precautions

must be taken to protect them from the elements.

Regardless of whether storage is inside or outside,

the storage area should be vibration-free. All boxes

that are marked for inside storage must be stored

indoors. The pump and its components, when

stored outdoors, should be protected from dirt, dust,

rain, snow or other unfavorable conditions by cover-

ings of heavy-gauge plastic sheets, canvas, water-

proof burlap or other suitable coverings.

All equipment must be placed upon skids or blocks

to prevent contact with the ground and surface con-

taminants. Equipment must be adequately sup-

ported to prevent distortion and bending.

ROTOR STORAGE

It is recommended that pump rotor be stored in the

pump. Multistage diffusor-type pump rotors that

cannot be stored in the pump must be supported at

the channel rings so that rotor weight is evenly distri-

buted. Single-stage and volute-type pump rotors not

stored in pump must be supported close to im- pel-

ler(s) to eliminate sag that may cause rotor to take a

permanent set.

INSPECTION AND MAINTENANCE

1. Customer Inspection And Maintenance

The stored equipment is to be placed on a periodic

inspection schedule by the customer.

D

A

B

/

B

Introduction

1-7

NOTE

The responsibility for setting up an inspection and

maintenance schedule rests with the customer and

will be dependent upon the class/type of storage

provided. It would be expected that initially in- spec-

tion would occur weekly, then depending upon the

inspection reports being favorable or unfavorable,

inspection would continue weekly, monthly, or quar-

terly, as may be determined. Inspection reports

must be kept on file.

Each inspection should consist of a general surface

inspection.

(a) Pump supports are firmly in place.

(b) Pump covers over openings are firmly in place.

(c) Pump covering, plastic or tarps, is firmly in place.

Any holes or tears must be repaired to prevent en-

trance of dirt or water.

(d) Pump rotors stored in pump should be rotated 1-

1/4 revolutions at least once a week to prevent rotor

from taking a permanent set.

CAUTION

IF PUMP IS EQUIPPED WITH SLEEVE BEAR-

INGS THE OIL RING INSPECTION PLUG ON TOP

OF THE BEARING HOUSING IS TO BE REMOVED

AND A SMALL AMOUNT OF OIL POURED OVER

THE JOURNALS BEFORE TURNING.

Single-stage and volute-type pump rotors stored

separately should be rotated 1-1/4 revolutions

weekly.

(e) Pump covers are periodically removed from

openings and interior accessible areas inspected. If

surface rusting has occurred, clean and repaint or

recoat with preservative.

(f) If rusting occurs on exterior surfaces, clean and

repaint or recoat with preservative.

(g) Loosen casing drain plugs to allow seepage of

any accumulated moisture.

(h) Periodically remove bearing covers and inspect

for accumulation of moisture, rust and foreign mate-

rial. As required, clean bearings and bearing hous-

ing and represerve. Install bearing cover and secure

to assure maximum protection. Bearings removed

for storage should be coated with pre- servative,

wrapped in oil/wax paper, and stored in a warm dry

area.

(i) Check individually wrapped parts for signs of de-

terioration. If necessary, renew preservative and

wrapping.

2. Six Months Prior To Installation

Six months prior to the scheduled installation date, a

Flowserve Corporation representative is to be em-

ployed to conduct an inspection. All costs involved

during inspection, dismantling, restoration, replace-

ment of parts, and reassembly will be the responsi-

bility of the customer. All necessary labor, tools, and

cranes will be supplied by the customer. This in-

spection will include (not necessarily in its entirety)

but not be limited to, the following:

(a) An inspection of all periodic inspection records

as kept on file by the customer, and all inspection

reports that have been compiled during the storage

period.

(b) An inspection of the storage area to determine

the as stored condition of the equipment prior to

any protection covers being removed.

(c) An inspection of the equipment with protection

covers and flange covers removed.

(d) Depending upon the length of time the equip-

ment was stored, the class/type of storage provided,

(i.e.: indoor, heated, unheated, ground floor, con-

crete floor, out-of-doors, under roof, no roof, water-

proof covering, on concrete, on ground) and as a

result of the inspection of a, b and c above, the

Flowserve representative may require a partial or

complete dismantling of the equipment.

(e) Dismantling may necessitate restoration of

painted or preserved surfaces, and/or replacement

of gaskets, O rings, packing, and/or mechanical

seal and bearings. Use only Flowserve recom-

mended replacement materials.

D

A

B

/

B

Introduction

1-8

Upon completion of the inspection, the Flowserve

Corporation representative shall submit a report to

the customer, and to the Manager of Customer

Service, stating in detail the results of the inspection.

3. One Month Prior To Installation

One month prior to installation of the equipment, a

Flowserve Corporation representative is to be em-

ployed to conduct a final inspection. This final in-

spection will be made to assure that the require-

ments of the six-month inspection report were satis-

factorily completed and that the equipment is ready

for installation.

Upon completion of this inspection, the Flowserve

Corporation representative shall submit a final report

to the customer, and to the Manager of Customer

Service, advising the results of the final inspection.

STORAGE NON-PREFERRED (WET)

It is not recommended that the rotor be subjected to

extended periods of submergence or wetting prior to

start-up. However, it is recognized that in some

cases, a long period of time may lapse from instal-

lation until commercial operation.

If the pump must be stored after being installed and

wetted, the following inspection and maintenance

procedures should be performed.

1. Isolate pump with valving tag (seal) all valves.

2. Preserve the pump internals.

(a) Corrosive Pumpage.

Fill pump with a 1% solution of Immunol 1809 and

water, (or owner-approved preservative). Immunol

is a water-phase corrosion inhibitor for ferrous and

mixed-metal couples and is composed of 5% sodium

nitrate with polyglycols, copper corrosion inhibitor,

and other organic materials. The pump should be

filled to highest level possible, affording the greatest

protection possible to all internal parts of the pump.

This solution, when drained, will result in a thin resi-

dual oil film (less than .0005 in.(.0127 mm) on all

internals after the water has evaporated. This resi-

due provides added corrosion protection until pump

is again filled with liquid or put into service.

(b) Non-Corrosive Pumpage.

Fill pump with pumpage to the highest level possible.

Periodically open drain connection to drain off any

moisture that may have accumulated. Refill to high-

est level possible. Drain and inspect pump prior to

start-up.

3. Rotate pump rotor 1-1/4 revolutions at least once

a week. Make sure bearings have adequate lubrica-

tion before turning rotor.

4. Periodically remove bearing covers and inspect

for accumulation of moisture, rust and foreign mate-

rial. As required, clean bearings and bearing hous-

ing and represerve. Install bearing cover and secure

to assure maximum protection.

PAINTING AND PRESERVATION

Paints and preservatives used are either Flowserve

Corporation standard or special as required by the

contract specification. Refer to RUST PREVEN-

TIVE for the description of paints and preservatives

used on this order or contact the branch office

through which the order was placed.

START-UP

Prior to and during start-up, any requirement for the

services of a Flowserve Corporation representative

will revert to the original contract agreement for the

equipment purchased.

DRIVERS

Generally storage must be indoors and dry. See the

specific manufacturers storage requirements.

D

A

B

/

B

Installation

2-1

NOTE

The installation/commissioning of this equipment must be conducted in accordance with API Recommended

Practices 686/PIP REIE 686 - First Edition. Refer to API 610 - Eighth Edition - Appendix `L` for baseplate grout-

ing requirements.

Copies of API Recommended Practices 686/PIP REIE 686 - First Edition may be obtained from - America Pe-

troleum Institute, 1220 L Street, N.W., Washington, D.C. 20005. Telephone: (202) 682-8000.

The following ASTM Specifications are furnished as references for test methods used in conjunction with installa-

tion of grouting materials and should be used to obtain proper results.

ASTM C 78-84 Test Method for Flexural Strength for Concrete.

ASTM C 109-90 Test Method for Compressive Strength of Hydraulic Cement Mortars - Modified.

ASTM C 469-87a Test Method for Static Modulus of Elasticity and Poissons Ratio of Concrete in Compres-

sion.

ASTM C 496-90 Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens.

ASTM C 531-85 Test Method for Linear Shrinkage and Coefficient of Thermal Expansion of Chemical Re-

sistant Grouts and Monolithic Surfacings - (Modified).

ASTM C 666-90 Test Method for Resistance of Concrete to Rapid Freezing and Thawing.

ASTM C 939-87 Test Method for Flow of Grout for Preplaced Aggregate Concrete (Flow Cone Method).

ASTM C 942-86 Test Method for Compressive Strength of Grouts for Preplaced Aggregate Concrete in

the Laboratory.

ASTM C 1090-88 Test Method for Measuring Changes in Height of Cylindrical Specimens from

Hydraulic Cement Grout.

ASTM C 1107-91 Standard Specification for Packaged Hydraulic-Cement Grout (Non-Shrink).

(CRD-C 621-92)

ACI 351 Grouting for Support of Equipment and Machinery.

24 Hour Test MBT Test Method for Grout Performance.

MINIMUM REQUIREMENTS FOR EPOXY GROUT

[TYPICAL PROPERTIES AT 73

o

F.(23

o

C.)]

ASTM D-635 Fire Resistant

ASTM C-579B Minimum Compressive Strength 12000 psi

ASTM C-827 Height Change @ 90

o

F.(38

o

C.) Positive Effective Bearing Area 95%

ASTM C-1181 Maximum Creep in 1 Year 1.6X10

-3

in/in at 140

o

F., 400 psi

ASTM C-307 Minimum Tensile Strength 1800 psi (12.4 MPa)

ASTM C-580 Minimum Flexural Strength 3800 psi (26.2 MPa)

ASTM C-580 Minimum Flexural Secant Modulus 1.8X10

6

psi (1.2X10

4

MPa)

ASTM C-531 Maximum Coefficient of Expansion 17X10

-6

in/in/

o

F.

Maximum Peak Exotherm 1000 gm insulated 95

o

F.(35

o

C.)

Full Aggregate Must Be Used.

D

A

B

/

B

Installation

2-2

LOCATION

Install the unit close to the source of the liquid to be

pumped.

When selecting the location, be sure to allow ade-

quate space for operation as well as for mainte-

ance operations involving dismantling and inspection

of parts.

Head room is an important consideration, as an

overhead lift of some type is required.

FOUNDATION

NOTE

The following information regarding foundation is

only offered as a general guideline to the customer.

Flowserve Corp. requires that all foundations be de-

signed/installed in accordance with specifications set

forth in Chapter 4 - `Foundations from API Recom-

mended Practices 686/PIP REIE 686, First Edition.

The design of foundations, is not the responsibility of

Flowserve Corp. It is therefore recommended that

the customer consult a competent specialist skilled

in the field of foundations, to insure proper design/

installation of the foundation.

The foundation should be sufficiently rigid and sub-

stantial to prevent any pump vibration and to perma-

nently support the bedplate at all points.

The most satisfactory foundations are made of rein-

forced concrete. These should be poured well in

advance of the installation to allow proper time for

drying and curing.

The General Arrangement Drawing will furnish an-

chor bolt locations, size of bolts, etc.

Template For Hanging Foundation Bolts

The sketch illustrates a recommended foundation

bolt arrangement. Notice the large washer with lugs

at the bottom. It should be welded to the bolt and

pipe sleeve to prevent turning.

Allow a little more than the specified threaded bolt

length above the rail of the baseplate. The excess

can always be cut off it not needed.

A rough finish top surface is best when applying

grout.

INSTALLATION CHECK LIST

1. Level Bedplate

2. Preliminary Alignment

3. Grout Bedplate

D

A

B

/

B

Installation

2-3

4. Align Shaft/Coupling

5. Piping

6. Check Coupling Alignment

LEVEL THE BEDPLATE

NOTE

The following information regarding leveling of

equipment is only offered as a general guideline to

the customer. Flowserve Corp. requires that all lev-

eling of equipment be performed in ac- cordance

with specifications set forth in Chapter 5 - `Mounting

Plate Grouting from API Recommended Practices

686/PIP REIE 686, First Edition.

Before putting the unit on the foundation, thoroughly

clean the top of the foundation. Break off any loose

pieces of cement and roughen the top with a chisel

to afford a good hold for grout.

NOTE

Coupling bolting and spacer piece (when used) must

be removed from between pump/driver half couplings

before lifting baseplate with pump element.

NOTE

When lifting bedplate with pumping element, sling

bedplate from all lifting eyes provided. Failure to do

this may result in permanent deformation of bed-

plate.

Prepare enough iron wedges or shims to be placed

on each side of each foundation bolt. These wedges

should be about 4 in.(102 mm) to 6 in.(152 mm) long

by 2 in.(51 mm) to 3 in.(76 mm) wide and thick

enough to allow for 1-1/4 in.(32 mm) of grout under

the edge of the bedplate. Place wedges as shown in

sketch.

Level the bedplate by using a machinists level on

the machined surfaces of the pump and driver pads.

When the bedplate is leveled, pull down the founda-

tion bolts so they are snug. The bedplate may have

been disturbed by tightening the foundation bolts;

therefore, recheck with level and make necessary

adjustments by wedges or shimming.

As a final bedplate alignment check on spacer type

couplings, install a mounting bracket for dial indi-

cator on driver hub. Fasten or clamp indicator on

mounting bracket, so that dial indicator button is con-

tacting the face of the pump half coupling, and zero

the dial indicator. (Non-spacer type coupling should

be check with tapered wedge or feeler gages.)

Rotate the driver half coupling (in direction of pump

rotation) 90

o

. Record this reading.

Repeat this procedure until readings have been

taken at four 90

o

positions.

PRELIMINARY ALIGNMENT

Using the previous procedure, shim and/or wedge

bedplate until pump and driver are within .003 in.

(.076 mm).

D

A

B

/

B

Installation

2-4

GROUTING

NOTE

The following information regarding grouting is only

offered as a general guideline to the customer.

Flowserve Corp. requires that all grouting be in-

stalled in accordance with specifications set forth in

Chapter 5 - `Mounting Plate Grouting from API Rec-

ommended Practices 686/PIP REIE 686, First Edi-

tion.

It is recommended that the customer consult a com-

petent specialist skilled in the field of grouting, to

insure the proper installation of all grouting.

Build a dam around the foundation. It is a matter of

personal preference whether the leveling wedges un-

der the bedplate should be removed after grouting. If

you do want to remove the wedges, carefully mark

their locations before pouring grout.

Build Dam Around Foundation Before Pouring Grout

Use a quality, high strength, non-shrink epoxy grout

- mix and install per manufacturers instructions.

Holes are provided in the bedplate to permit pouring the

grout and stirring. They also act as air vents. Fill under

the bedplate completely, stirring to assure proper distri-

bution of the grout. Check to see that the grout flows

under the edges of the bedplate evenly.

NOTE

Do not vibrate bedplate when grouting; make sure bed-

plate is vented properly and all areas indicated on Gen-

eral Arrangement drawing are thoroughly puddled to

prevent any resonant problems.

When the grout is thoroughly hardened, remove the

dam and wedges, if desired, filling in the holes they

leave with grout.

SHAFT/COUPLING ALIGNMENT

NOTE

The following information regarding shaft alignment

is only offered as a general guideline to the custom-

er. Flowserve Corp. requires that all shaft alignment

be performed in accordance with specifications set

forth in Chapter 7 - `Shaft Alignment from API Rec-

ommended Practices 686/PIP REIE 686, First Edi-

tion.

CAUTION

SHAFT ALIGNMENT MUST BE CORRECT FOR

SUCCESSFUL OPERATION. RAPID WEAR, NOISE,

VIBRATION AND ACTUAL DAMAGE TO THE

EQUIPMENT MAY BE CAUSED BY SHAFT MIS-

ALIGNMENT. THE SHAFTS MUST BE ALIGNED

WITHIN THE LIMITS GIVEN WITHIN THIS SECTION.

NOTE

Adjustments to correct the alignment in one direction

may alter the alignment in another direction. Always

check in all directions after making any adjustments.

D

A

B

/

B

Installation

2-5

Coupled equipment must be aligned to minimize un-

necessary stresses in shafts, bearings and coupling.

Flexible couplings will not compensate for appreci-

able misalignment. Foundation settling, thermal ex-

pansion or nozzle loads resulting in baseplate/foun-

dation deflection and vibration during operation may

require the full coupling misalignment capability.

TYPES OF MISALIGNMENT

There are two types of shaft misalignment: Angular

and offset. Therefore, two sets of measurements

and corrections are required. Both types of mis-

alignment can occur in horizontal and vertical planes

and are present in most applications.

A. Angular Misalignment

In angular misalignment, the centerline of the shafts

intersect, but are not on the same axis.

B. Offset Misalignment

In offset misalignment, the shaft centerline are par-

allel but do not intersect.

Offset Misalignment

Combination Offset

And

Angular Misalignment

ALIGNMENT

A. Measure Gap

The first step in shaft/coupling alignment is to bring

the pump and driver shafts into their proper axial

position. The shaft gap, or distance between cou-

pling hubs, must be in accordance with the certified

General Arrangement Drawing and must be mea-

sured with pump and driver shafts in the center of

their axial end float. Motor with sleeve bearings is to

be aligned with rotor at magnetic center.

Move driver to insure proper gap distance.

NOTE

It is recommended that the pump hold-down bolting be

torqued and the pump be dowelled before taking any

alignment measurements. This makes the pump the

fixed machine and the driver the movable machine. In

certain cases, however, it may be impractical to move

the driver; therefore, the pump may have to be moved.

When this case exists, the pump should not be dow-

elled until after final alignment.

B. Measure Angular Misalignment

Refer to ALIGNMENT DATA SHEET and exam-

ples.

D

A

B

/

B

Installation

2-6

CAUTION

PUMP SHAFT SHOULD NOT BE ROTATED MORE

THAN NECESSARY WHEN ALIGNING SHAFTS.

DAMAGE COULD OCCUR TO INTERNAL WEARING

PARTS WHICH ARE LUBRICATED BY THE PUMP

LIQUID.

The angular misalignment can best be determined

by the use of a hand-held inside micrometer, marked

B on sketch. All measurements should be taken at

the same radial distance from the shaft centerline,

as close as possible to the hub outside diameter.

The location of these measurements is defined as

the D dimension on the ALIGNMENT DATA

SHEET. Do not move the shafts axially while ro-

tating the shafts and taking measurements. Both

hubs must be rotated together to cancel possible

hub face runout. The relative measurement (top

minus bottom, right minus left) is the important num-

ber.

1. Mark both coupling hubs at 3,6,9 and 12 oclock

positions so they can be rotated together and at 90

o

intervals.

2. Starting with the 12 oclock markings of both hubs

in the top center position, measure the gap at top,

bottom, right and left side. Record these dimensions

on ALIGNMENT DATA SHEET Sheet 1, Part 1 in

the 0

o

Column.

NOTE

Right side and left side are determined when viewing

the driver coupling from the pump.

3. Rotate both shafts 90

o

in the direction of pump

rotation. Measure gap dimensions at the four loca-

tions as in Step 2. Record on ALIGNMENT DATA

SHEET-Sheet 1, Part 1 in the 90

o

Column.

4. Repeat Step 3 until measurements have been

taken at the four positions (0

o

,90

o

,180

o

,270

o

).

5. Rotate both shafts to the starting position (12

oclock markings at top center) and recheck dimen-

sion recorded in Step 2.

6. For 0

o

,90

o

,180

o

,270

o

Columns, subtract the bot-

tom from the top and left from right. Record in their

respective blocks on Data Sheet. Watch sign nota-

tions.

7. Total the different numbers (reading across), di-

vide by 4 and record the average_____. Record in

Open At _____ the shaft relative angular position.

NOTE

The inside faces of the driver and pump half hubs

must be parallel within .001 in.(.0254 mm).

C. Measure Offset Misalignment

Offset misalignment is measured using a dial indi-

cator on the outside diameter of the coupling hubs

and rotating the hubs together to cancel rim surface

inaccuracies.

1. Starting with the 12 oclock markings of both hubs

on top center, fasten or clamp an indicator on driver

hub, marked A on sketch, with dial indicator button

contacting alignment surface on the pump hub.

2. Zero the dial indicator.

3. Rotate both coupling hubs (in the direction of

pump rotation) 90o and take a reading. Record on

ALIGNMENT DATA SHEET-Sheet 1, Part 2 in the

proper right side or left side blank (right or left sides

are determined when viewing the driver half coupling

from the pump).

4. Repeat Step 3 until readings have been taken at

the four 90

o

positions (top center, right, bottom and

left).

5. Rotate both shafts to the starting position (12

oclock markings at top center) and verify indicator

returns to zero.

D

A

B

/

B

Installation

2-7

NOTE

The sum of the top and bottom readings should al-

ways equal the sum of the left and right readings. If

the sums are not equal, check for indicator bracket

deflection, hub surface irregularity or loose radial

bearings.

6. Using the formula on ALIGNMENT DATA

SHEET-Sheet 1, Part 2, subtract the top from the

bottom indicator reading, divide by 2. This will yield

the vertical misalignment.

7. Using the formula on ALIGNMENT DATA

SHEET-Sheet 1, Part 2, subtract the left from the

right indicator reading, divide by 2. This is the hori-

zontal misalignment.

8. Circle the proper high or low and left or right posi-

tion of the driver hub, using the rules given on the

Data Sheet.

NOTE

The outside diameters of pump and driver coupling

hubs must be aligned within .003 in.(.0762 mm) TIR.

D. Movement Calculations (ALIGNMENT DATA

SHEET-Sheet 2).

1. Sketch the relative driver shaft position in the side

and top views. These sketches will assist visualizing

the required equipment move.

2. Alignment depends upon the relationship be-

tween D, L

I

and L

o

.

Use the formula G X L to determine the required

move. D

NOTE

D = Diameter of the circle at which angular

misalignment readings were taken (not

coupling diameter).

G

y

= Gap difference (top minus bottom) taken

from sheet 1, Part 1.

G

H

= Gap difference (right minus left) taken from

Sheet 1, Part 1.

L

I

= Distance from driver coupling hub to cen-

terline of driver inboard hold-down bolt.

L

O

= Distance from driver coupling hub to cen-

terline of driver outboard hold-down bolt.

3. Record vertical offset from Sheet 1, Part 2 and

vertical move obtained from calculations in the IN-

BOARD, and OUTBOARD DRIVER PEDESTAL

SHIFT columns. Also record the required direction

of shift (raise or lower).

4. Record horizontal offset from Sheet 1, Part 2 and

horizontal move obtained from calculations in the

INBOARD, and OUTBOARD DRIVER PEDESTAL

SHIFT columns. Also record the required direction

of shft (right or left).

5. Total the move requirements (watch move direc-

tion). This will yield the required horizontal move

(right or left) and the vertical move (raise or lower)

required at each mounting foot.

HORIZONTAL MOVE

The dial indicators shown below are required to ac-

curately measure the move in the horizontal direc-

tion. Move the driver by bumping with soft ham-

mer/mallet or using the jackscrews (if provided).

The amount of horizontal relocation required is the

total of the horizontal move calculation (bottom of

Sheet 2).

D

A

B

/

B

Installation

2-8

VERTICAL MOVE

Before moving the equipment vertically, it is im-

portant that the vertical thermal expansion be taken

into consideration. The preceding vertical move cal-

culations are based on pump and driver shafts being

set on the same plane. Refer to General Arrange-

ment Notes and/ or driver instructions for recom-

mended cold vertical setting (if thermal expansion is

a factor).

The shims between the equipment feet and mount-

ing surface should be clean and dry. This is espe-

cially critical for pumps that have been in service for

some time and need to be realigned. Water, dirt and

rust may change the height of the shim pack over a

period of time. Shims should be made large enough

to support the weight of the equipment on its

mounting foot. Do not use many thin shims, as this

may result in a spongy mounting.

Recommended Shim Design

Move the equipment vertically by adding or removing

the calculated thickness of shims. Torque equip-

ment hold-down bolting to required values.

NOTE

It is recommended, the completed ALIGNMENT

DATA SHEET be retained as part of your perma-

nent maintenance file.

CHECK COUPLING ALIGNMENT

The angular and offset coupling alignment must be

rechecked.

1. Coupling faces are to be parallel within .001

in.(.0254 mm) TIR.

2. Coupling outside diameters are to be aligned

within .003 in.(.0762 mm) TIR.

3A. Motor-Driven: Bump the motor and check

motor rotation (see Troubleshooting).

3B. Turbine-Driven: Check turbine rotation. (If

wrong, consult turbine manufacturer.)

ASSEMBLE AND LUBRICATE COUPLING

1. Assemble and lubricate coupling per the manu-

factur- ers instructions included in Appendix of this

manual.

2. Install coupling guard.

DOWEL PUMP AND DRIVER

A. Cold Pumps [temperature below 200

o

F.(94

o

C.)]

Pump hold-down bolts are to be torqued to the

proper value and dowel pins put in two diagonally

opposite feet.

B. Hot Pumps

Pumps handling liquids at temperatures of 200

o

F.

(94

o

C.) and over are designed to permit the casing

to expand with temperature away from coupling end

of pump. The units that come under this classifica-

tion must have the pump supports or feet dowelled

to the baseplate at the coupling end. This maintains

the coupling gap at the desired amount.

The pump feet at the opposite end are held from

moving vertically by the use of a self locking nut.

The clearance between the base of the nut and the

top of the pump foot should be .002 in.(.051 mm).

D

A

B

/

B

Installation

2-9

The horizontal movement is controlled by a Gib

block running parallel to the length of the pump at

each of the outboard feet. The Gib Blocks are

bolted and dowelled to the baseplate at the time of

mounting at the factory. A .010 in.(.254 mm) gap is

maintained between the Gib Block and pump foot.

IMPORTANT

The self locking nuts which hold the pump from

moving in a vertical motion are clamped tight to the

pump foot at time of shipment. The .002 in.(.051

mm) clearance must be established at time of in-

stallation.

C. Pump Driver

Refer to driver outline drawing and/or driver

instructions for dowelling information.

HOT ALIGNMENT CHECK

A hot check can only be made after the unit has

been in operation a sufficient length of time to

assume its NORMAL operating temperature and

conditions. If the unit has been properly cold set, the

offset misalignment will be within .003 in.(.076 mm)

TIR and the angular misalignment will be within .001

in.(.0254 mm) TIR when in operation. If not, make

adjustments.

WARNING

DO NOT ATTEMPT ANY MAINTENANCE, IN-

SPECTION, REPAIR OR CLEANING IN THE

VICINITY OF ROTATING ELEMENT. SUCH

ACTION COULD RESULT IN INJURY TO

OPERATING PERSONNEL.

D

A

B

/

B

2-10

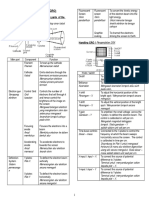

HORIZONTAL PUMPS SHEET 1 OF 2

NAME DATE TIME

ALIGNMENT DATA FOR SERIAL NUMBER

PUMP TEMPERATURE

PART 1 ANGULAR ALIGNMENT CHECK

POSITION 0

o

90

o

180

o

270

o

TOTALS

TOP Open At

BOTTOM Average

DIFF. (T-B)

*RIGHT SIDE Open At

*LEFT SIDE Average

DIFF. (R-L)

* Right and Left side are determined when viewing the driver hub from the pump.

PART 2 OFFSET ALIGNMENT CHECK

TOTAL INDICATOR READINGS RULES TO APPLY TO THE RESULTS BELOW:

INDICATE When Indicator Mounted On The Driver Reads

BY ARROW .000 TOP

DIRECTION Negative = Driver Coupling Is High & Left

OF ROTATION

Positive = Driver Coupling Is Low & Right

OFFSET

ALIGNMENT

CHECK

LEFT RIGHT

SIDE SIDE

BOTTOM

Driver Coupling Is (Circle Correct One):

High Or Low And Right Or Left

VIEW OF DRIVER HALF COUPLING

HUB VIEWED FROM PUMP

Vertical Offset Bottom - Top

= = = =

Misalignment 2

Horizontal Offset Right - Left

= = = =

Misalignment 2

D

A

B

/

B

2-11

ALIGNMENT DATA SHEET

HORIZONTAL PUMPS SHEET 2 OF 2

TOP

PUMP

AXIS LEFT RIGHT

(FIXED) PUMP

BOTTOM AXIS

(FIXED)

SIDE VIEW (VERTICAL MOVE) TOP VIEW (HORIZONTAL MOVE)

VERTICAL ANGULAR MOVE CALCULATION MOVE DRIVER TO CORRECT ALIGNMENT

G X L

Driver Inboard Pedestal Shift = V I = =

D

G X L

Driver Outboard Pedestal Shift = V O = =

D

INBOARD DRIVER PEDESTAL SHIFT OUTBOARD DRIVER PEDESTAL SHIFT

MILS DIRECTION MILS DIRECTION

OFFSET MOVE

ANGULAR MOVE

TOTAL

HORIZONTAL ANGULAR MOVE CALCULATION MOVE DRIVER TO CORRECT ALIGNMENT

G X L

Driver Inboard Pedestal Shift = H I = =

D

G X L

Driver Outboard Pedestal Shift = H O = =

D

INBOARD DRIVER PEDESTAL SHIFT OUTBOARD DRIVER PEDESTAL SHIFT

MILS DIRECTION MILS DIRECTION

OFFSET MOVE

ANGULAR MOVE

TOTAL

D

A

B

/

B

2-12

D

A

B

/

B

Installation

2-13

D

A

B

/

B

WARNING

BEFORE ATTEMPTING ANY INSPECTION OR

REPAIR ON THE PUMP, THE DRIVER CONTROLS

MUST BE IN THE OFF POSITION, LOCKED

AND TAGGED TO PREVENT INJURY TO PER-

SONNEL PERFORMING SERVICE ON THE PUMP.

PIPING

NOTE

The following information regarding piping is only

offered as a general guideline to the customer.

Flowserve Corp. requires that all piping and related

systems be designed/installed in accordance with

specifications set forth in Chapter 6 -`Piping from

API recommended practices 686/PIP REIE 686,

First Edition.

The design of piping, and related systems, is not the

responsibility of Flowserve Corp. It is therefore rec-

ommended that the customer consult a competent

specialist skilled in the field of piping, to insure

proper design/installation of all piping.

SUCTION AND DISCHARGE PIPING

These units are furnished for a particular service

condition. Changes in the hydraulic system may

affect performance adversely. This is especially true

if the changes reduce the pressure at the suction

flange. In case of doubt, contact the nearest Flows-

erve Office.

Suction and discharge piping should be of ample

size, be installed in direct runs, and have a minimum

of bends.

NOTE

Provision must be made to support piping external to

the pump to prevent excessive nozzle loads and

maintain pump-driver alignment.

Install a check valve and a gate valve in the dis-

charge pipe on the pump. When the pump is

stopped, the check valve will protect the pump

against excessive pressure and will prevent the

pump from running backward. The check valve

should be installed between the gate valve and the

pump nozzle in order to permit its inspection. The

gate valve is also useful in priming and starting the

pump.

Keep the suction pipe short and direct. Use a suc-

tion pipe at least one size larger than the pump suc-

tion nozzle. Keep the suction pipe free of all air

pockets.

IMPORTANT

A spool piece should be installed in suction line so

that the suction screen may be installed and re-

moved.

BY-PASS LINE

CAUTION

OPERATION AT LOW FLOWS RESULTS IN

PUMP HORSEPOWER HEATING THE LIQUID. A

BYPASS MAY BE REQUIRED TO PREVENT VA-

PORIZATION AND SUBSEQUENT PUMP DAM-

AGE. MECHANICAL DAMAGE MAY RESULT

FROM CONTINUOUS OPERATION AT FLOWS

LESS THAN 25% OF DESIGN OPERATING POINT

(see General Arrangement drawing & name-

plate).

WARNING

WHEN PUMP IS EQUIPPED WITH MANIFOLDED

VENT AND DRAIN LINES, EACH LINE MUST BE

EQUIPPED WITH AN INDIVIDUAL VALVE TO

PREVENT ANY LIQUID FROM A HIGH PRES-

SURE LINE FLOWING INTO A LOW PRESSURE

LINE. THESE VALVES MUST BE KEPT IN THE

CLOSED POSITION DURING PUMP OPERATION.

Installation

2-14

D

A

B

/

B

SUCTION STRAINER

In a new installation, great care should be taken to

prevent dirt, scale and welding beads from entering

the pump. Even when piping has been previously

flushed, it is difficult to break loose the oxides and

mill scale which will become free when the pipe

heats and cools several times. Numerous close

running clearances are vulnerable to abrasive matter

present in new piping. Foreign material may be

large enough, or of sufficient volume, to jam a pump,

with probable damage to both pump and drive

equipment. Smaller size material passing through

the pump can cause rapid pump wear and prema-

ture pump failure.

This pump is provided with the exception that it will

be pumping clean liquids (unless otherwise stated in

the order and addressed in the proposal). Flows-

erve pumps are provided with running clearances

ranging typically from 0.005 inch(0.12 mm) to 0.030

inch(0.80 mm), depending on the service. It is im-

practical to install a suction strainer to remove par-

ticulate of this size. Such particles will normally pass

through the pump without causing damage, provi d-

ing the concentrations are minor.

The possibility exists that, on shutdown of the pump,

such particles can become trapped in the close run-

ning clearances during coastdown, causing binding.

Flowserve cannot recommend a procedure that will

totally prevent such binding; however, we strongly

suggest that systems be cleaned and thoroughly

flushed prior to connecting the pump to the piping to

minimize particles entering the pump. Starting and

stopping of the pump should be MINI-MIZED as

pumps are most susceptible to dirt during starts and

stops.

In the event that binding on coastdown occurs, it is

unlikely that the binding can be remedied by hand

rolling the rotor, and partial disassembly may be re-

quired to clean the affected parts. It should be noted

that increased particle concentrations increase the

probability of coastdown binding and seizures, as

well as erosion damage.

CAUTION

EXCESSIVE FORCE USED TO TRY TO FREE A

BOUND ROTOR MAY CAUSE DAMAGE BEYOND

MINOR CLEAN-UP AND REPAIR OF ROTOR

PARTS.

Generally, a pump should not be installed without

start-up strainer protection. The suction piping

should be thoroughly flushed before installing the

suction strainer and connecting the suction piping to

the pump. The strainer should be installed in the

inlet piping near the pump, making certain that it is

located where it may be readily serviced (cleaned).

Be sure, however, that the installed strainer will not

distort the flow to the pump suction nozzle.

Do not install the strainer directly on the pump suc-

tion nozzle. For a cone-type strainer, the down-

stream end of the cone should be no closer than four

(4) pipe diameters from the pump suction nozzle.

Basket-type strainers typically introduce greater flow

disturbances and should be installed at least six (6)

pipe diameters from the pump suction nozzle.

The Flowserve standard for suction strainers con-

sists of conical-shaped steel plate with 1/8 perfora-

tions. The open area of the strainer should be a

minimum of three times the area of the pump suc-

tion.

Installation

2-15

D

A

B

/

B

At all times when using suction strainers, it is critical

that the pressure drop across the strainer be con-

stantly monitored to ensure that the pump suction

pressure does not fall below that required to prevent

pump cavitation. Pressure (or vacuum) gauges

should be installed on both sides of the strainer so

that the pressure drop across the strainer can be

monitored. During start-up of the system, the

gauges should be monitored continuously. Consult

the plant engineer or system designer for the allow-

able pressure differential across the strainer prior to

operating the pump. Pressure differential across the

strainer and/or screen is typically no more than 2 3

psig. An increase in the differential pressure be-

tween the two gauges indicates that the strainer or

screen is becoming clogged with dirt and scale.

Before the pressure drop becomes so severe that

cavitation occurs, the pump should be shut down

and the strainer cleaned. Alarm settings to protect

the pump from damaging cavitation and loss of suc-

tion need to be supplied by the plant engineer or

system designer prior to operating the pump. Typi-

cal alarm settings to protect the pump from damag-

ing cavitation and loss of suction would be 5 psig

differential pressure across the strainer (screen).

The suction piping should be arranged such that the

ultimate strainer configuration (location) allows ready

access for cleaning.

The strainer may be fitted with a finer screen to filter

the inlet flow. When this is done, 40 mesh screen is

typically used for start-up operation, at reduced flow

rates. For final operation in a closed system, the

suction strainers are normally removed after the

system is cleaned. For critical pump applications,

where continuous screening of suction flow is desir-

able, and in open systems, 20 mesh screening is

typically used for permanent strainers. At all times,

when using screens and suction strainers, it is criti-

cal that pressure drop across the screen and/or

strainer be constantly monitored to ensure that the

pump suction pressure does not fall below that re-

quired to prevent cavitation.

When dirt and scale have been removed from the

system, as indicated by no further change in pres-

sure drop across the strainer with time, the start-up

strainer may be removed or the screen may be re-

placed with one having larger openings. If a perma-

nent strainer will be used during normal operation,

the pressure differential needs to be monitored on a

continuous basis.

If a permanent strainer is not used, the start-up

strainer needs to be temporarily reinstalled when-

ever the system is opened up for repair or routine

maintenance. As long as a suction strainer or

screen remains in place, the differential pressure

should be monitored on a regular basis.

CAUTION

THE PRESSURE DROP ACROSS THE STRAINER

IS A DIRECT REDUCTION IN THE NPSH AVAILA-

BLE TO THE PUMP. NPSH AVAILABLE MUST

ALWAYS EXCEED THE NPSH REQUIRED BY THE

PUMP. THIS REQUIREMENT MAY LIMIT THE

PUMP FLOW RATE, PARTICULARLY DURING

START-UP OPERATION. ALARMS OR AUTO-

MATIC PUMP SHUT-DOWN DEVICES SHOULD

BE INSTALLED TO MINIMIZE THE POSSIBILITY

OF PUMP DAMAGE. IT IS THE RESPONSBILITY

OF THE PUMP OPERATOR TO OBTAIN THE AL-

LOWABLE PRESSURE DROP ACROSS THE

STRAINER FOR SAFE PUMP OPERATION FROM

THE PLANT ENGINEER OR SYSTEM DESIGNER

PRIOR TO OPERATION OF THE PUMP.

COUPLING ALIGNMENT CHECK

Refer to the section entitled SHAFT/COUPLING

ALIGNMENT and perform a coupling alignment

check as outlined. This check is recommended to

insure the alignment has not been disturbed during

the grouting of the bedplate or while installing suc-

tion and discharge piping.

GIB BLOCK INSTALLATION

Gib blocks are installed to control the direction of

thermal growth while maintaining pump-motor cou-

pling alignment. They are installed after baseplate

has been leveled and grouted, suction and dis-

charge piping connected, and final shaft coupling

alignment is completed.

Gib blocks are shipped loose and field installed at

the site. The following procedure must be followed

for correct installation of gib blocks.

Step 1

Fully torque the hold-down bolts in the drive-end of

pump feet to torque values listed in the instruction

manual (refer to Pump Sectional Assembly Drawing

in Appendix).

Installation

2-16

D

A

B

/

B

Step 2

Install the dowel pins in the pump drive-end feet by

reaming the foot and baseplate for the tapered

dowel provided.

Step 3

Position the gib blocks to obtain a 0.010 inch(.25

mm) clearance between the gib block and the side of

the non-drive end pump foot as noted on the at-

tached figure. Drill and tap the capscrew holes for

the gib blocks.

Gib Block Installation Sketch

Step 4

Tighten the hold-down bolts for the gib blocks.

Step 5

Install the dowel pin in the gib blocks by reaming the

block and baseplate for the tapered dowel provided.

Step 6

Tighten the hold-down locknuts on the non-drive end

pump feed to establish a 0.002 inch(.05 mm) gap

between the locknut and the pump foot.

INSPECTION OF OIL RINGS BEFORE

START-UP

CAUTION

A PROBLEM CAN ARISE WHEN PUMPS ARE

TRANSPORTED BY VEHICLE OR WHEN BEING

LIFTED BY A CRANE. JARRING OR UNEVEN

LIFTING OF PUMPS CAN CAUSE THE OIL RINGS

TO MOVE OUT OF POSITION. IF THE OIL RINGS

ARE OUT OF POSITION AT START UP, THE

BEARINGS WILL NOT GET LUBRICATION AND

EVENTUALLY WILL FAIL.

BEFORE START UP TAKES PLACE, REMOVE

THE 1/2 INCH NPT PLUGS ON THE TOP OF THE

HOUSING AND CONFIRM THAT THE OIL RINGS

ARE IN THEIR PROPER POSITION (SEE FIG-

URE).

COMMISSIONING OF EQUIPMENT

Commissioning of all equipment must be performed

in accordance with specifications set forth in Chapter

9 -`Commissioning from API Recommended Prac-

tices 686/PIP REIE 686, First Edition.

Operation

3- 1

D

A

B

/

B

TECHNICAL DATA

These pumps are furnished for a particular service

condition. Changes in the hydraulic system may

affect the pumps performance adversely. This is

especially true if the changes reduce the pressure at

the suction flange or if the liquid temperature is in-

creased. In case of doubt, contact the nearest

Flowserve Office.

SPECIFIC GRAVITY

The capacity and total head of liquid developed by a

centrifugal pump are fixed for every point on the

curve and are always the same for the same speed.

Neither capacity nor total head will be affected by a

change in the specific gravity of the liquid pumped.

However, since the developed pressure and the

brake horsepower to drive the pump are a function

of the specific gravity of the liquid, both will be af-

fected in direct proportion by any change in specific

gravity. Therefore, a change in specific gravity will

affect the discharge gage pressure. Any changes

should be noted, in that they may overload the

pumps driver.

VISCOSITY

The pump is designed to deliver rated capacity at

rated head for a liquid with a particular viscosity.

When contemplating operation at some viscosity

other than that for which the pump was originally

designed, the changed conditions should be referred

to Flowserve Corp. for our recommendations.

CHANGING PUMP SPEED

Changing the speed of a centrifugal pump changes

the capacity, total head and brake horsepower. The

capacity will vary in a direct ratio with the speed,

whereas the total head will vary as the ratio of the

speed squared. The brake horsepower will vary as

the ratio of the speed cubed, except in cases where

the speed change also reduces the efficiency of the

pump.

NET POSITIVE SUCTION HEAD (NPSH)

Any liquid, hot or cold, must be pushed into the im-

peller of the pump by some absolute pressure, such

as the atmosphere or the pressure of the vessel

from which the pump takes its suction.

The head of liquid necessary to push the required

flow into the pump is called the Net Positive Suction

Head. This value, more commonly called NPSH, is

measured above the vapor pressure of the liquid at

the pumping temperature.

There are two kinds of NPSH. The NPSH required

by the pump, as shown on the pump curve, is the

head needed to cover the losses in the pump suc-

tion. The second NPSH is that available in the sys-

tem, taking into account friction loss in suction pip-

ing, valves, fittings, etc. In all cases, the NPSH

Available (measured above vapor pressure) must

exceed the NPSH Required in order to push the liq-

uid into the pump.

OPERATING PRECAUTIONS

WARNING

DO NOT WIPE DOWN IN THE VICINITY OF RO-

TATING PARTS. IF UNUSUAL NOISE OR VI-

BRATIONS OCCUR, SECURE THE PUMP AS

SOON AS POSSIBLE.

WARNING

THE UNIT MUST NOT BE OPERATED UNLESS

COUPLING GUARD IS BOLTED IN PLACE.

FAILURE TO OBSERVE THIS COULD RESULT IN

INJURY TO OPERATING PERSONNEL.

WARNING

WHEN PUMP IS EQUIPPED WITH MANIFOLDED

VENT AND DRAIN LINES, EACH LINE MUST BE

EQUIPPED WITH AN INDIVIDUAL VALVE TO

PREVENT ANY LIQUID FROM A HIGH PRES-

SURE LINE FLOWING INTO A LOW PRESSURE

LINE. THESE VALVES MUST BE KEPT IN THE

CLOSED POSITION DURING PUMP OPERATION.

Operation

3- 2

D

A

B

/

B

WARNING

OBSERVE EXTREME CAUTION WHEN VENTING

AND/OR DRAINING HAZARDOUS LIQUIDS.

WEAR PROTECTIVE CLOTHING IN THE PRES-

ENCE OF CAUSTIC, CORROSIVE, VOLATILE,

FLAMMABLE, OR HOT LIQUIDS. DO NOT

BREATHE TOXIC VAPORS. DO NOT ALLOW

SPARKING, FLAMES, OR HOT SURFACES IN VI-

CINITY OF THE EQUIPMENT.

CAUTION

TO MAINTAIN CLOSE RUNNING CLEARANCES

AND BEARING LUBRICATION, THE PUMP

SHOULD NOT BE OPERATED BELOW THE

SPEED OF 1800 RPMS.

1. Never operate the pump with suction valve

closed.

2. Never operate pump unless it is filled with liquid

and vented.

3. Never operate the pump unless a liquid source is

available.

PRE-OPERATIONAL CHECKS

At initial start-up and after the equipment has been

overhauled.

1. Ensure pump and piping are clean. Before put-

ting the pump into operation, it should be thoroughly

flushed to remove the rust preventive as well as any

foreign matter which may have accumulated during

installation.

Take all possible care not to contaminate your sys-

tem.

2. Clean and flush bearing housings. Fill reservoir

with oil to the proper level (see LUBRICATION).

CAUTION

CHECK THAT OIL RINGS ARE PROPERLY POSI-

TIONED AND NOT HUNG-UP.

3. Ensure rotor is aligned within casing (see MAIN-

TENANCE).

4. Turn rotor by hand or with strap to make sure it

turns freely.

5. Check stuffing box.

A. If pump is equipped with a mechanical seal, en-

sure it is properly assembled and tightened (refer to

SHAFT SEALING section).

CAUTION

MOST CARTRIDGE SEALS ARE EQUIPPED WITH

A SPACER BETWEEN THE GLAND PLATE AND

DRIVE COLLAR. THIS SPACER MUST BE RE-

MOVED BEFORE STARTING UNIT.

B. If pump is equipped with a packed box, insure

box is properly packed (refer to SHAFT SEALING

section).

6. Ensure coupling is properly aligned and lubri-

cated, and pump and driver are properly dowelled

(refer to SHAFT/COUPLING ALIGNMENT proce-

dure).

7. Ensure coupling guard is in place.

8. Check torque of all bolting and plugs for tight-

ness.

PUMP INSTRUMENTATION SET POINTS

The following set points apply to these DA Pumps

which use a ball/ball bearing arrangement.

Bearing metal temperature

Normal 140

o

to 180

o

F.(60

o

to 82

o

C.)

Alarm 190

o

F.(88

o

C.)

Shutdown 200

o

F.(93

o

C.)

Bearing housing vibration

Normal .1 to .3in/sec(2.5 to 7.6 mm/sec)

Alarm .4 in/sec(10.2 mm/sec)

Shutdown .5 in/sec(12.7 mm/sec)

INITIAL START-UP PROCEDURE

1. Close discharge valve if valve is not already

closed.

Operation

3- 3

D

A

B

/

B

2. Prepare the driver for start-up in accordance with

the manufacturers instructions.

3. Warm-Up Pump.

Avoid severe thermal shocks to the pump as a result

of sudden liquid temperature changes. The pump

must be preheated prior to start-up. Unless other-

wise specified, the external temperature of the cas-

ing must be within 100

o

F.(55.6

o

C.) of the tempera-

ture of the liquid to be pumped at time of start-up.

Due to the heavy metal sections, the casing will lag

the liquid temperature during such changes, and

severe temperature stresses and subsequent mis-

alignment of machined fits may result. Pre-heating

is accomplished by circulating a small amount of hot

fluid through the casing by utilizing vents, drains or

bypass from discharge. Preheat pump slowly at a

rate not to exceed 100

o

F.(55.6

o

C.) per hour.

4. Prime pump and ensure pump suction valve is

open.

CAUTION

BEFORE STARTING OR WHILE OPERATING THE

PUMP, THE CASING AND SUCTION LINE MUST

BE COMPLETELY FILLED WITH THE LIQUID

BEING PUMPED. THE ROTATING PARTS DE-

PEND ON THIS LIQUID FOR LUBRICATION, AND

THE PUMP MAY SEIZE IF OPERATED WITHOUT

LIQUID.