Professional Documents

Culture Documents

Scanner Install Manual

Uploaded by

Eduardo ParrudoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scanner Install Manual

Uploaded by

Eduardo ParrudoCopyright:

Available Formats

V

V

E

E

S

S

D

D

A

A

LaserSCANNER

INSTALLATION MANUAL

VLS Models VLS-200

VLS-204

VLS-214

VLS-300

VLS-304

VLS-314

VLS-600

VLS-700

October 2003

Version 1.2

Publication history

Release 1.2 October, 2003

Copyright Information

This document may not be reproduced, in whole or in part, by any means without the prior express

written permission of the copyright owner. Copyright 2003 Vision Fire & Security Pty Ltd

A.C.N. 008 009 514

Disclaimer

The manufacturer reserves the right to change designs or specifications without obligation and without

further notice. VESDA, LaserTEKNIC, LaserPLUS, LaserSCANNER, LaserCOMPACT, VESDAnet,

VESDAlink, ASPIRE, AutoLearn, VSM, VConfig, InfoWORKS, PROACTIV and PRECISION are

trademarks used under licence by the distributor.

Codes and Standards Information

Vision Products strongly recommends that this guide is read in conjunction with the appropriate local

codes and standards for smoke detection systems and electrical connections. This guide contains

generic information and some sections may not comply fully with all local codes and standards. In

these cases, the local codes and standards must take precedence.

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, the user is encouraged to try to correct the interference by one or more of the

following measures:

Reorientate or relocate the receiving antenna

Increase the separation between the equipment and receiver

Connect the equipment to a power outlet which is on a different power circuit from which the

receiver is connected

Consult the dealer or an experienced radio/television technician for help

FM 3611 Hazardous Approval Warning

Exposure of some chemicals may degrade the sealing of relays used on the detector. Relays used on

the detector are marked "TX2-5V" or "G6S-2-5V" or "EC2-5NU".

Approvals and Standards

The product complies with the following standards.

AS 1603.8 FCC Class B

AS/NZS 3548 AS2211

EN50081-1 21 CFR 1010.2

EN50130-4 21 CFR 1010.3

EN 60950

Safety Label

The LaserSCANNER incorporates a Laser device and is classified as a Class 1 Laser product that

complies with FDA Regulations 21 CFR 1040.10 and 1040.11. The laser is housed in a sealed

Detector chamber and contains no serviceable parts. This laser emits invisible light and can be

hazardous if viewed with the naked eye. Under no circumstances should the Detector Chamber

be opened. There is a safety label on the Detector Chamber as shown below.

Figure 1 The Laser Warning Label

Contents

1. Introduction.................................................................................................................... 2

2. Cabling Requirements .................................................................................................. 3

2.1Power Cables........................................................................................................................ 3

2.2Power Consumption ............................................................................................................. 3

2.3Data Cables .......................................................................................................................... 3

3. LaserSCANNER Specifications.................................................................................... 4

4. LaserSCANNER Dimensions........................................................................................ 5

5. Battery Backup Calculations........................................................................................ 7

6. Installation...................................................................................................................... 8

6.1Check Procedure Before Installation .................................................................................... 8

6.2Removal of Front Cover........................................................................................................ 9

Component Location inside Detector Enclosure ..................................................................... 10

6.4Display and Programmer Module Orientation .................................................................... 10

6.5Removal of Metal Knockout Holes for Cable Entry ............................................................ 11

6.6Exhaust Port Options.......................................................................................................... 11

6.7Securing the Mounting Bracket........................................................................................... 12

6.8Attaching the Detector onto the Bracket ............................................................................. 12

6.9Connecting the Air Sampling Pipe...................................................................................... 13

6.10 Cabling Using Glands and Conduits ............................................................................. 13

6.10.1 Using Glands ......................................................................................................... 13

6.10.2 Using Conduits ...................................................................................................... 13

6.11 Termination Card Details............................................................................................... 14

6.12 Procedure to Terminate Wires to the Termination Card ............................................... 14

6.13 Terminating the Power Wires to the Termination Card................................................. 15

6.14 Connecting the VESDAnet Wires to the Termination Card (If required) ....................... 15

6.15 Terminating the Relay Wires to the Termination Card.................................................. 16

6.16 Closing Up the LaserSCANNER ................................................................................... 18

6.17 Pipe Bonding Check...................................................................................................... 18

7. Power Up...................................................................................................................... 19

7.1Power Up the System......................................................................................................... 19

8. Preliminary System Checks ....................................................................................... 20

8.1Logging On to the System.................................................................................................. 20

8.2VESDAnet Communication Check ..................................................................................... 20

8.3Normalise the Air Flow and Clearing Air Flow Faults ......................................................... 21

8.4Basic Pass/Fail Smoke Test ............................................................................................... 22

9. Installation Checklist................................................................................................... 23

10. VESDA Product Warranty Conditions....................................................................... 24

LaserSCANNER Installation Manual VESDA

2 Version 1.2

1. Introduction

Scope of this Manual

This manual is intended for installation technicians to be able to install, perform basic power and

preliminary device checks for the LaserSCANNER detector. It does not cover information for

commissioning. All VESDA equipment is to be commissioned by personnel who have attended

a VESDA accreditation course.

Use the checklist in Section 9 to verify that the installation has been correctly completed. Fill out

the details in the checklist sheet for the site and submit it to the appropriate personnel.

CAUTION

The Detector must only be installed by VESDA accredited personnel.

The performance of the system depends on the pipe network designed for the site.

Any alteration to the pipe network may alter the performance of the system. The

ASPIRE design tool is to be used to verify the suitability of any pipe network design

and subsequent alterations. ASPIRE is available from your distributor or local

Vision office.

The IP rating for the LaserSCANNER is IP 30. This rating indicates the device is not to

be installed where there is the possibility of any water or liquid falling onto the

device.

WARNING

It is strongly recommended that the mounting bracket be used during installation.

The chassis assembly and Central Processor Card should NOT TO BE REMOVED or

disassembled during installation.

Follow the installation procedure outlined in this manual.

VESDA

LaserSCANNER Installation Manual

Version 1.2 3

2. Cabling Requirements

The terminals on the termination card in the LaserSCANNER will accept wire sizes up to 2.5sq

mm (12 AWG).

2.1 Power Cables

Use the power ratings for the detector and the modules to determine the required wire sizes.

Refer to the table below for power ratings.

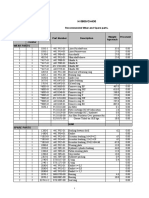

2.2 Power Consumption

The power requirements for the detector to operate are as follows:-

Operating voltage: 18VDC to 30VDC

Power Consumption (W)

@ 24VDC

Current Consumption (mA)

@ 24VDC

Quiescent With Alarm Quiescent With Alarm

LaserSCANNER with

Blank Plates @ 3000rpm

5.8 7.4 240 310

LaserSCANNER with

Blank Plates @ 3500rpm

6.7 8.4 280 350

LaserSCANNER with

Blank Plates @ 4000rpm

8.4 10.1 350 420

LaserSCANNER with

Blank Plates @ 4200rpm

9.6 11.3 400 470

Programmer Module

0.6

(Backlight Off)

2.2

(Backlight On)

20

(Backlight Off)

80

(Backlight On)

Display Module Only 1.6 2.2 60 80

Table 1 Power and Current Consumption for LaserSCANNER Detector and Modules

2.3 Data Cables

The recommended RS 485 data cable for interconnecting to other detector units on the

VESDAnet loop is Belden 9841 (or equivalent). The cable characteristics are as follows:-

24 AWG, Twisted pair, Shielded, 120 ohms impedance

The maximum specified length for the RS485 cable between any two devices on VESDAnet is

1300m (4000ft).

LaserSCANNER Installation Manual VESDA

4 Version 1.2

3. LaserSCANNER Specifications

Supply Voltage

18 to 30VDC

Power Consumption

See table 1, page 2

Dimensions (WHD)

350mm x 225mm x 125mm (13.8in x 8.9in x 4.9in)

Weight

4.0kg (9lbs) including Display and Programmer module

Operating Temperature

Detector Ambient: 0

to 39

C (32

F to 103

F)

Sampled Air: -20

to 60

C (-4

to 140

F)

Humidity: 10-95% RH, non-condensing

Sampling Pipe Network

Aggregate pipe length: 200m (650ft)

Pipe Modelling Design Tool: ASPIRE

Pipe Size

Internal Diameter: 15-21mm (9/16 7/8in)

External Diameter: 25mm (1in)

(25mm to 1inch adaptor supplied for USA market)

Relays

7 or 12 Relays option. Contacts rated 2A @ 30VDC.

Programmable to energised or de-energised states.

Scan Sector Delay

Min 8 seconds, max 15 seconds

Scan Threshold Delay

Min 0 seconds, max 10 seconds

Relays Default

Configuration

7 Relays:

12 Relays:

Alert, Action, Fire 1, Fire 2, Maintenance, Urgent

Fault and Isolate. (7 x NO/NC contacts)

Alert, Action, Fire 1, Fire 2, Maintenance, Urgent

Fault and Isolate, First Alarm Sector 1 to 4 and

Scan. (10 x NO, 2 x NO/NC contacts)

IP Rating

IP30

Cable Access

8 x 25mm (1in) knockouts in various positions.

Cable Termination

Screw terminal blocks (0.2-2.5sq mm, 30-12 AWG)

Sensitivity Range

0.005 to 20.00% obs/m

(0.0015 to 6.25% obs/ft)

Threshold Setting Range

Alert: 0.005 1.990% obs/m

(0.0015 - 0.6218% obs/ft)

Action: 0.010 1.995% obs/m

(0.0031 - 0.6234% obs/ft)

Fire 1: 0.015 2.00% obs/m

(0.0046 0.625% obs/ft)

Fire 2: 0.020 20% obs/m

(0.0062 6.25% obs/ft)**

** Limited to 12% obs/m (4% obs/ft) in UL mode

Key Software Features

Event log: Up to 18,000 events stored on FIFO basis.

AutoLearn: Minimum 15 minutes.

Maximum 15 days, 23hrs, 59 minutes.

Recommended minimum period 14 days.

During AutoLearn thresholds are NOT changed from

pre-set values.

Referencing: Compensation for external ambient conditions.

Four Alarm Levels per Sector: Alert, Action, Fire 1 and Fire 2.

Two Fault Warning Levels: Maintenance and Urgent fault.

Maintenance Aids: Filter and flow monitoring.

Event reporting via VESDAnet or event log.

Auto Scan and Thresholds Setting: Detector selects the

appropriate scan threshold automatically.

VESDA

LaserSCANNER Installation Manual

Version 1.2 5

4. LaserSCANNER Dimensions

CE = Cable Entry Ports (25.4mm, 1.0in )

EP = Exhaust Air Port

Figure 1 Dimensions in mm (in) of LaserSCANNER with Mounting Bracket

(Rear View, Normal Orientation)

Note: Remove the centre pages of this manual for installation template. We strongly

recommend the use of this mounting bracket.

51.0

(2.0)

35.0

(1.37)

21.0

(0.83)

CE

350 (13.8)

209 (8.24)

EP

77.5

(3.05)

12.0

(0.47)

207 (8.15)

28.5

(1.12)

Mounting

Bracket

Bridge and

Lance

225

(8.9)

200

(7.87)

319

(12.56)

LaserSCANNER Installation Manual VESDA

6 Version 1.2

CE = Cable Entry Port (25.4mm, 1.0in )

CP = Exhaust Pipe Outlet Option or Cable Entry Port

Figure 2 Dimensions in mm (in) for the LaserSCANNER

26.0(1.02)

34

(1.33)

26.0

(1.02)

350(13.8)

35

(1.37)

45.0

(1.77)

34

(1.33)

34

(1.33)

34.0

(1.33)

Inlet Air Ports

CE

TOP VIEW

RIGHT HAND

SIDE VIEW

LEFT HAND

SIDE VIEW

FRONT VIEW

28.5

(1.12)

CP

CE

225

(8.9)

26.0

(1.02)

2

5

.

4

(

1

.

0

)

125 (4.9)

BOTTOM VIEW

141.4 (5.58)

26.0

(1.02)

CE

Exhaust Air

Port

35

(1.37)

45.0

(1.77) 20.2

(0.88)

VESDA

LaserSCANNER Installation Manual

Version 1.2 7

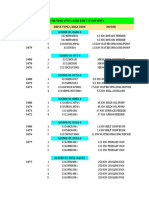

5. Battery Backup Calculations

The nominal supply voltage is 24 VDC. Use Table 2 to calculate and to determine the battery

backup requirements for your VESDA system. Refer to Table 1, page 3 for power consumption

details.

NORMAL LOAD @ 24 V DC FULL ALARM LOAD @ 24 VDC

EQUIPMENT LOAD

(mA)

QTY TOTAL

(ma)

LOAD

(mA)

QTY TOTAL

(ma)

LaserSCANNER

(No display &

programmer)

Display Module

Programmer Module

Remote Display

Other 24V loads

TOTAL (mA)

TOTAL (mA)

X

X

STANDBY HOURS

ALARM HOURS

=

X 1.06

STANDBY CAPACITY

(mAHr)

ALARM CAPACITY

(mAHr)

TOTAL CAPACITY =

STANDBY + ALARM

(mAHr)

DIVIDE BY 1000

MULTIPLY BY BATTERY

FACTOR 1.25

AHr

Table 2 Calculations to Determine the Battery Backup Requirements

LaserSCANNER Installation Manual VESDA

8 Version 1.2

6. Installation

6.1 Check Procedure Before Installation

(a) Do not install your LaserSCANNER if there are any signs of shipping damage to the

product. Inform your distributor if there is any damage.

(b) Check the model of the LaserSCANNER is correct as per the design specifications for the

site. Refer to the model number located on the product and approvals label attached at the

bottom of the detector.

(c) Identify the location where the detector is to be mounted. The LaserSCANNER can be

mounted on a wall or a suitable secure surface. There are two allowable mounting positions

for the LaserSCANNER as shown in Figure 3.

Normal Orientation: Mounting the detector with the inlet air ports on the top right

hand side of the box and the exhaust air port at the bottom.

Inverted Orientation: Mounting the detector with the inlet air ports at the bottom

left hand side of the box and the exhaust air port on the top.

(d) Verify that the selected mounting location is suitable to fit the detector by test fitting the

LaserSCANNER onto the actual mounting position or use the drilling template supplied with

this manual. Ensure there is 150mm of clear space around the air inlet, exhaust and cable

entry ports to allow for pipe and cable entry.

(e) Verify that the cable entry points and the sampling air pipes are at its correct locations.

(f) Determine the type of fasteners required for attaching the mounting bracket onto the

mounting surface. The size of the mounting holes on the mounting bracket is 6mm

(15/64in).

Note: For LaserSCANNER detectors mounted in the Inverted Orientation position, the

display and/or programmer modules have to be rotated 180 . Refer to Section 6.4

for procedure to rotate the modules. The position of the Programmer and Display

modules can be interchanged.

Figure 3 LaserSCANNER Orientation, Normal (left), Inverted (right)

Inlet Air Ports

Cable Entry

Ports

Cable

Entry

Ports

Aspirator

B

D

P

B

P

D

Exhaust Air

Ports

Cable Entry

Ports

Cable Entry

Ports

B=Blank Plate

P=Programmer Module**

D=Display Module**

**The location of the Programmer and Display

modules depends on the model of your VLS

Detector.

VESDA

LaserSCANNER Installation Manual

Version 1.2 9

6.2 Removal of Front Cover

(a) Insert a 4mm x 1mm flat blade screwdriver (A) into notch. Refer to Figure 4.

(b) Gently open the blank plate (B) with the screwdriver.

(c) Lift out the two screw covers (C) with a flat blade screwdriver.

(d) Use a Philips head screwdriver and remove the four retaining screws (D). Screws are

captive and are retained within the front cover. Refer to Figure 4.

(e) When the front cover is opened, there are two plastic straps joining the cover to the

enclosure.

(f) If the front cover is to be separated from the enclosure do the following:-

i) On the rear of the front cover or on the enclosure side, twist the plastic strap 90 and

slip strap out through slot.

ii) Locate the cable loom that connects the central processor card to the back of a display

or programmer module that is located on the front cover. On the back of the

programmer or display module, disconnect this cable connector from its socket

(labelled Term) if present.

Note: Mark this connector and socket before removing if you are unsure of the

wiring.

Figure 4 Removing the Blank Plate, Screw Covers, Retaining Screws, Programmer and Display

Modules.

Termination Card

Screws (D)

Screws (D)

Display, Programmer or

Blank Plate Location

(A)

Blank Plate (B)

(C)

(E)

LaserSCANNER Installation Manual VESDA

10 Version 1.2

6.3 Component Location inside Detector Enclosure

Figure 5 Components inside Detector Enclosure

6.4 Display and Programmer Module Orientation

The detector is shipped from the factory with the display, programmer and/or blank plates

positioned in the normal orientation. Refer to Figure 3. If the detector is to be mounted in the

inverted orientation, perform the following steps to rotate the modules.

(a) Remove the front cover as per Section 6.2.

(b) Locate the cable loom that connects the Central Processor Card to the display or

programmer module located on the font cover. Remove this cable connector from its socket

(labelled Term).

(c) Insert a 4mm wide x 1mm flat blade screwdriver into gap between module and front cover

(E). Refer to Figure 4.

(d) Gently lever screwdriver to lift out modules.

(e) Rotate modules 180 and gently re-insert into the same compartment until modules are

flush with the front cover. Refer to Figure 3 for orientation. Ensure the metal fingers are

located on the exterior of the Display/Programmer.

(f) Re-connect the cable loom to the socket (labelled Term) on the display or programmer

module. Refer to Figure 6 below for cable termination diagram.

Figure 6 Cable Terminations between Modules and Central Processor Card

X1 X2

TERM

EXP

11

X1

TERM

X2

EXP

Programmer

Module

Display

Module

EXPANSION

11

Central Processor Card

To Next

Module

Aspirator

Laser Detector

Chamber

Air Filter Cartridge

VESDAnet

socket

Termination Card

(7 Relays)

or optional

12 Relays Card

Wire Terminal Strips

CPU Card

(Under Backing Sheet)

VESDAnet

Number

FOK LED

Connector

VESDA

LaserSCANNER Installation Manual

Version 1.2 11

6.5 Removal of Metal Knockout Holes for Cable Entry

(a) Determine the cable entry holes to be used. Refer to Figure 7.

(b) Using the ball end of a small hammer, gently tap onto the required knockout holes to break

away the metal pieces.

OR

Punch out the knockout holes with the blade of a screwdriver or a punch tool.

6.6 Exhaust Port Options

There are three exhaust air outlet positions (Bottom, Rear and Left Side) located on the exhaust

air manifold. Refer to Figure 7. Any of these outlets may be used to vent the air into the

atmosphere or back to the fire zone. Select an appropriate exhaust outlet to suit the site

condition and remove the appropriate plug with a screwdriver.

If the side exhaust is to be used perform the following:-

(a) Punch out the knockout hole located on the left side of the enclosure with the ball end of a

small hammer or a screwdriver (A).

(b) To remove the plug (B), insert a screwdriver into the slot on the plug and turn.

(c) Run a 25mm (1in) pipe through the side hole and insert the pipe into the exhaust port

ensuring there is a firm fit.

(d) Do not glue this pipe to the exhaust port.

Caution: Do not remove the plug located at outlet (B) if there is no pipe attached to this

outlet.

Figure 7 Exhaust Port Options and location of Cable Entry Ports

Cable Entry Ports

(Two on Rear)

Cable Entry Ports

(May be used for

Exhaust Air Pipe)

Side Exhaust

Air Outlet (B)

(Plug not shown)

(A)

Bottom Exhaust

Air Outlet

(One Outlet on Rear)

Air Inlet Port 1

Air Inlet Port 4

Air Inlet Port 2 Air Inlet Port 3

LaserSCANNER Installation Manual VESDA

12 Version 1.2

6.7 Securing the Mounting Bracket

Warning: Make sure that there are no electrical wires or plumbing behind the mounting

position before drilling. Ensure the mounting position is flat.

a) Remove the drilling template from the centre page of this manual.

b) Determine the orientation for the detector (Normal or Inverted Orientation). Place the drilling

template onto its mounting location in the correct orientation and drill out the appropriate

holes. Refer to the drilling template for orientation.

c) Use the appropriate fasteners to suit the mounting surface. Secure the bracket to the

surface.

6.8 Attaching the Detector onto the Bracket

(a) Determine the required orientation for the LaserSCANNER. Refer to Figure 3 for orientation.

(b) Place the three bridges located on the rear of the detector onto the three lances located on

the mounting bracket. Refer to Figure 8.

(c) Push the detector downwards until it locks onto the lances and engages the fitting dimples.

(d) Check the unit does not slip off its bracket.

(e) To remove, push the detector upwards and pull away from wall.

(f) To prevent unwanted removal of the detector, insert screw into the keyhole slot at location

shown on template and tighten screw. Drill out these holes before mounting the detector

onto its mounting bracket by using the supplied template to locate the screw hole position.

Insert at least one screw into one key hole slot located around the Termination Card area.

Figure 8 Mounting the Detector onto the Mounting Bracket

Mounting Bracket

Rear of Detector

Bridge

Lance

Fitting Dimples

VESDA

LaserSCANNER Installation Manual

Version 1.2 13

6.9 Connecting the Air Sampling Pipe

The air inlet ports are designed to fit a standard pipe of 25mm (1in) OD. A tapering of the air

inlet ports prevent the pipes from being inserted beyond 15mm (5/8in).

Any of the four inlet ports may be used. Ensure that the correct pipes in use are selected when

programming the detector.

Note: There must be a length of 500mm (19.6in) of straight pipes before terminating the

pipes at the air inlet ports of the detector.

Note: When using a inch pipe which has a 1 1/16 inch OD, use the adaptor supplied

with the LaserSCANNER to connect the pipes to the inlet manifold.

a) De-burr and square off the end of the sampling air pipes. Ensure the pipes are free from

swarf.

b) Remove the plugs from the inlet and exhaust ports. Do not remove the plugs from the

inlet ports if the ports are not used.

c) Insert the pipes into the inlet and/or exhaust ports ensuring a firm fit. DO NOT glue these

pipe connections.

d) Pipe the exhaust air where necessary.

Caution: DO NOT GLUE THE AIR INLET AND EXHAUST PIPE CONNECTIONS.

Glued connections make disconnecting the sampling air pipes from the

LaserSCANNER extremely difficult during maintenance and will result in

damage to the equipment.

6.10 Cabling Using Glands and Conduits

6.10.1 Using Glands

(a) If using cable glands, use the correct gland size to fit into the 25mm (1in) cable entry port.

(b) Run the wires through the glands and into the LaserSCANNER enclosure. Use your local

codes and electrical standards for cabling.

6.10.2 Using Conduits

(a) Terminate the conduits at the cable entry ports on the sides of the box using the appropriate

conduit connectors.

(b) Run the wires through the conduits and into the LaserSCANNER enclosure. Use your local

codes and electrical standards for cabling.

LaserSCANNER Installation Manual VESDA

14 Version 1.2

6.11 Termination Card Details

Figure 9 Termination Card Details for 7 Relays

Figure 10 Termination Card Details for 12 Relays

6.12 Procedure to Terminate Wires to the Termination Card

Use the appropriate local wiring standards or use the following suggested procedure listed

below. Check Sections 6.13, 6.14 and 6.15 for specific information on terminal connections.

(a) Strip off 5 to 7mm (0.2 to 0.3in) of outer insulation from each wire.

(b) For multi-stranded wire only - Twist wire strands together.

Terminal A Terminal B Terminal C

Pin 1

Pin 11

Pin 1 Pin 1

Pin 10

Pin 12

VESDAnet

Socket

Terminal A Terminal B Terminal C

1 VESDAnet A+ 1 Isolate (NO) 1 Fire 2 (NC)

2 VESDAnet A- 2 Isolate (C) 2 Fire 2 (C)

3 Shield 3 Isolate (NC) 3 Fire 2 (NO)

4 VESDAnet B+ 4 Minor Fault (NO) 4 Fire 1 (NC)

5 VESDAnet B- 5 Minor Fault (C) 5 Fire 1 (C)

6 Shield 6 Minor Fault (NC) 6 Fire 1 (NO)

7 Power (+) 7 Urgent Fault (NO) 7 Action (NC)

8 Power (-) 8 Urgent Fault (C) 8 Action (C)

9 Power (+) 9 Urgent Fault (NC) 9 Action (NO)

10 Power (-) 10 Alert (NO) 10 GPI -

11 Alert (C) 11 GPI +

12 Alert (NC)

GPI = General Purpose Input

FOK LED

Connector

Terminal A Terminal B Terminal C

1 VESDAnet A+ 1 Urgent Fault (NO) 1 Fire 1 (NO)

2 VESDAnet A- 2 Urgent Fault (C) 2 Fire 1 (C)

3 Shield 3 Urgent Fault (NC) 3 Fire 1 (NC)

4 VESDAnet B+ 4 Relay 1 (NO) 4 Relay 12 (NO)

5 VESDAnet B- 5 Relay 1 (C) 5 Relay 12 (C)

6 Shield 6 Relay 2 (NO) 6 Relay 11 (NO)

7 Power (+) 7 Relay 2 (C) 7 Relay 11 (C)

8 Power (-) 8 Relay 4 (NO) 8 Relay 10 (NO)

9 Power (+) 9 Relay 4 (C) 9 Relay 10 (C)

10 Power (-) 10 Relay 5 (NO) 10 Relay 9 (NO)

11 Relay 5 (C) 11 Relay 9 (C)

12 Relay 7 (NO) 12 Relay 8 (NO)

13 Relay 7 (C) 13 Relay 8 (C)

14 GPI -

15 GPI +

Terminal A Terminal B Terminal C

Pin 1 Pin 1 Pin 1

Pin 10

Pin 13

Pin 15

VESDAnet

Socket

GPI = General Purpose Input

FOK LED

Connector

VESDA

LaserSCANNER Installation Manual

Version 1.2 15

(c) On the termination card, remove the plugs from its terminal sockets.

(d) Insert the correct wires into the terminal plugs.

(e) Tighten terminal plug screw.

(f) Repeat steps (c) to (e) as required.

(g) Insert plugs into the correct sockets on the termination card.

(h) Check the wires are attached to its terminals.

(i) Ensure no bare wires are exposed at the terminals. The wire insulation must touch the

terminal plugs at the pin connection opening.

(j) Check the terminations are correct by referring to the appropriate circuit diagrams in

Sections 6.13, 6.14 and 6.15.

6.13 Terminating the Power Wires to the Termination Card

a) Refer to Figure 9 or 10 for the location of the power terminals on the termination card.

b) Connect the power wires to the Power terminals as shown in Figure 11.

Figure 11 Wire Connection Details for Power

6.14 Connecting the VESDAnet Wires to the Termination Card (If required)

a) Refer to Figure 9 or 10 for the VESDAnet terminal location on the termination card.

b) Connect the VESDAnet wires as shown in Figure 12. This diagram is only an example for

five detectors. This wiring method is similar for two or more detectors.

c) Maintain the wiring polarity throughout the network. Do not leave any VESDAnet

terminals unconnected.

NOTE: The detector is shipped from the factory with the VESDAnet terminals linked as shown

in Figure 13. If the detector is not to be used in a VESDAnet loop and is to be used as a

stand-alone detector the VESDAnet terminals must be wired as per Figure 13.

NOTE: It is strongly recommended that the Closed Loop configuration shown in Figure 12 is

installed, to achieve a redundant fault tolerant loop. An Open Loop configuration is

possible by not linking the VESDAnet wires between detector 1 and detector 5. Detector

1 and detector 5 must be programmed to the Opened Loop Configuration.

Terminal A

Power (-)

Power (-)

Power (+)

Power (+)

GND

8

9

10

7

+24V

GND

From 24V

Power

Supply

+24V

24V Power to

Next Device

LaserSCANNER Installation Manual VESDA

16 Version 1.2

Figure 12 Wire Connection Details for VESDAnet (Closed Loop)

Figure 13 Wire Connection Details for VESDAnet Loop (Stand Alone Set Up)

6.15 Terminating the Relay Wires to the Termination Card

a) Refer to Figure 9 or 10 for the relay terminals location on the termination card.

b) Connect the relay wires to the terminals as per Figure 14 and your site requirements.

Detector 3

Terminal A

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

Shield

A-

A+

Shield

B-

B+

Detector 1

Terminal A

Detector 2

Terminal A

Detector 4

Terminal A

Shield

B+

B-

Shield

A-

A+

Shield

A-

A+

B-

Shield Shield

B-

B+

Shield

Shield

A-

A+

B-

B+

Detector 5

Terminal A

B+

Shield

A-

A+

B+

6

5

4

2

3

1

Shield

A-

A+

Shield

B-

Terminal A

VESDA

LaserSCANNER Installation Manual

Version 1.2 17

Figure 14 Wire Termination Details for 7 and 12 Relays

NO

GPI

11

10

GPI+

C

GPI-

9

8

Terminal C

7

6

5

4

3

NO

NC

NC

NO

C

2

1

C

NC

Fire 2

(Relay 7)

Fire 1

(Relay 6)

Action

(Relay 5)

}

}

}

}

Terminal Pins location for 7 Relays (Default Relay Assignments)

Isolate

(Relay 1)

Terminal B

Alert

(Relay 4)

12

11

10

NC

C

C

NO

9

8

7

6

5

4

3

NC

NO

NO

NC

C

2

1

C

NO

Minor Fault

(Relay 2)

Urgent Fault

(Relay 3)

}

}

}

}

NC

Terminal Pins location for 12 Relays (Default Relay Assignments)

Minor Fault

(Relay 2)

Terminal B

C

Alert

(Relay 4)

11

10

C

NO

NO

9

8

7

6

5

4

3

NO

NO

C

NC

C

2

1

C

NO

Urgent Fault

(Relay 3)

Isolate

(Relay 1)

}

}

12

NO

}

}

}

}

Action

(Relay 5)

Fire 2

(Relay 7)

13

C

Terminal C

First Alarm Sector 4

(Relay 11)

Scan

(Relay 12)

7

6

5

4

3

NO

NO

C

NC

C

2

1

C

NO

Fire 1

(Relay 6)

}

}

C

First Alarm Sector 2

(Relay 9)

11

10

C

NO

NO

9

8

}

}

C

GPI

15

14

GPI+

NO

GPI-

13

12

}

}

First Alarm Sector 3

(Relay 10)

First Alarm Sector 1

(Relay 8)

}

LaserSCANNER Installation Manual VESDA

18 Version 1.2

6.16 Closing Up the LaserSCANNER

a) Tie all wires together into neat looms using cable ties.

b) If the front cover was removed do the following:-

i) Reattach the plastic straps to the front cover.

ii) Re-connect the removed cable loom to the Term socket located on the rear of the

display or programmer module.

c) Perform the power up as per section 7 and preliminary checks as per section 8.

d) Close up the LaserSCANNER and secure the cover with the four screws.

e) Re-attach the blank plate and screw covers to its location.

6.17 Pipe Bonding Check

(a) Check all the pipe joints are fully sealed and bonded to eliminate unwanted air leaks.

(b) Check the pipe joints at the air inlet ports of the LaserSCANNER ARE NOT bonded and the

pipe fits firmly into the air inlet socket.

(c) Check all pipes are securely attached to a mounting surface with the proper fasteners.

(d) Check the number and sizes of the sampling air holes on the pipes are correct.

(e) Check the routing of the pipes is correct with reference to the site plan.

VESDA

LaserSCANNER Installation Manual

Version 1.2 19

7. Power Up

Caution Powering up the system must be done by VESDA accredited personnel.

7.1 Power Up the System

(a) Disconnect the power terminals from the Termination card before turning ON the power.

(b) Turn ON the power to the detector.

(c) Check the voltage at the Power terminals is 24VDC+/-6V. If the voltage is out of

specification, turn OFF the power and troubleshoot.

(d) If the measured voltages are within specification, then reconnect the terminal plugs and

turn on the power.

(e) Repeat measurements for other detectors connected onto the same power supply routing.

(f) The system takes approximately 15 seconds to power up.

(g) If the system fails to power up:-

Check all power wires are secured to its terminals.

Check the polarities of the power wires are correctly terminated.

h) On power up.

The aspirator starts up and air is felt flowing out of the exhaust port.

If a Programmer module is fitted, the VESDA name will appear on the LCD screen.

If a Display module is fitted, the following indicators are lit:-

Fire Alarm Threshold indicators

Smoke Threshold Levels on Bar Graph

2 digit indicator

Various fault indicators if there are any faults

System OK indicator if there are no faults

If any of the above does not happen, contact your commissioning engineer or distributor to

troubleshoot.

Note: The detector may show faults immediately after power up and this is normal. Reset the

detector by pressing the RESET switch on the front cover of the detector to unlatch the

relays and fault lights. The fault lights on the front cover will light up and this is normal.

Proceed to section 8.

LaserSCANNER Installation Manual VESDA

20 Version 1.2

8. Preliminary System Checks

Perform the following preliminary system Setup and checks before commissioning.

(a) Logging onto the system with a PC or a LCD Programmer. See Section 8.1.

(b) VESDAnet communication checks. See section 8.2

(c) Normalise the airflow. See section 8.3

(d) Basic pass/fail smoke test. See section 8.4

8.1 Logging On to the System

Check with your distributor for the default User Levels and PIN numbers to log on to the system.

Fault code 25 or 26 is generated when a LCD Programmer or a PC-Link HLI device is

connected to the VESDAnet socket. This fault clears when the programming device is

disconnected from the detector.

Procedure

LCD Programmer

Module

Hand Held LCD

Programmer

PC Programmer

Connecting the

programming

device to a

Detector or to a

VESDAnet

socket.

No physical connection

required

Plug the LCD

Programmer cable into

the VESDAnet socket on

the Termination card or

to a remote terminal.

Refer to Figure 5 for

location of the VESDAnet

socket on the

Termination Card.

Connect the PC via a

PC-Link HLI device to

the VESDAnet socket on

the Termination Card or

to a remote terminal.

Refer to Figure 5 for

location of the VESDAnet

socket on the

Termination Card.

Logging onto

the system.

Press any programmer

key to display the Logon

screen.

Press any programmer

key to display the Logon

screen.

Run VConfig Basic or

VConfig Pro program

from the PC.

Enter your

Access Level

and PIN

Number.

Use the Programmer

keys to enter your

access level and PIN

number. Press when

completed.

Use the Programmer

keys to enter your

access level and PIN

number. Press when

completed.

Enter your Access Level

and PIN Number when

the Logon screen

appears.

8.2 VESDAnet Communication Check

Note: This test verifies the VESDAnet system is functioning correctly and all devices

connected on VESDAnet are communicating. Write down the VESDAnet number for

each detector, programmer and display module. The location of the VESDAnet number

for the detector is shown in Figure 5. The programmer and display modules have this

number located at the bottom left hand side of the front face.

If any of the listed VESDAnet numbers and devices are incorrect, check the

VESDAnet wiring to all devices.

Procedure LCD Programmer PC Programmer

Display the

VESDAnet numbers.

Select Show Wiring Order .

Read the displayed devices and

VESDAnet numbers.

Check the details with your list.

Select the Device Tree command

from the View menu.

From the Device Tree window,

click on all the + signs to expand

the tree.

Check all the listed devices and

VESDAnet numbers against your

list.

VESDA

LaserSCANNER Installation Manual

Version 1.2 21

8.3 Normalise the Air Flow and Clearing Air Flow Faults

Note: This procedure normalises the airflow for all pipes in use and takes approximately 11 minutes.

It is important to correctly select the pipes in use before Normalising. Check the airflow is

approximately 100% when completed.

Procedure LCD Programmer PC Programmer

Set the Air Pipes in

use for sampling.

Select Setup by Zone Zone

Number Detector Air Flow

Flow Control

Set the pipes in use for sampling.

! = Selected.

Select Device Tree from View

menu

From the Device tree window, click

on all the + sign to expand the

tree.

Double click on detector to open a

window with multiple tabs.

Click on the Airflow tab when

window appears.

Select the pipes in use.

! = Selected.

Click on the Apply button.

Set the Aspirator

Speed.

Select Setup by Zone Zone

Number Detector Air Flow

Flow Control

Set the Aspirator RPM value by

using the arrow keys. Set the

value as per the ASPIRE

calculation for that site.

In the same window that displays

the Airflow tab, click on the

Aspirator tab.

Change the Aspirator RPM to the

value as per the ASPIRE

calculations.

Click on the Apply button.

Normalise the

Airflow. Wait for 11

minutes to

complete

Normalising.

Select Setup by Zone Zone

Number Detector Air Flow

Normalise Normalise Start

Select the Normalise Airflow

command from the Device menu.

Check the Active Events List

displays the alarm.

Check in the Device tree window,

the word Normalising appears next

to the Detector being Normalised.

Check the Airflow

after Normalising is

approximately

100%.

Select Setup by Zone Zone

Number Detector Air Flow

Normalise Current % Flow

OR

Select Setup by Zone Zone

Number Detector Status

Double click on the Detector being

Normalised.

Click on the Current Flow tab in

the window with multiple tabs.

Reset the Detector. Select Setup by Zone Zone

Number Detector Zone

Control Reset Start

Click on the Reset icon or select

Reset from the Zone menu.

Note: Detectors with software version 3.x.x and above will have a Normalising fault (77) reported

during the Normalising process.

LaserSCANNER Installation Manual VESDA

22 Version 1.2

8.4 Basic Pass/Fail Smoke Test

Note: This test verifies the detector will sense smoke. It does not replace any appropriate

commissioning test. Use the table below to perform this test by using one of the

following devices.

Procedure Display Module LCD Programmer PC Programmer

Isolate the

Detector.

Press the Isolate

button located on

the Display.

Check the Isolated

indicator lights up.

Select Setup by Zone

Zone Number Detector

Zone Control Isolate

Start

Select Setup by Zone

Zone Number Detector

Status and check

the detector is Isolated.

Select Device Tree from

the View menu.

Select the detector to be

Isolated from the Device

Tree window.

Click on the Isolate icon

or Isolate Zone

command from the

Zone menu.

View Active Events list

for response to

Isolation.

Inject Smoke

into any one

of the

sampling air

pipes and

observe the

following

events.

Scan starts

Sounding device on

Detector beeps.

Red LEDs on front

panel lights up.

Smoke bar graph

indicator lights up

showing smoke

level.

2 digit indicator

shows smoke

intensity level when

Smoke Level is

selected.

Select Setup by Zone

Zone Number Detector

Status and check

the smoke level value.

Alarms reported in

Status menu.

Sounding device on the

Detector beeps.

Smoke alarm displays

on the Active Events

List window.

After the

smoke has

cleared,

Reset the

Detector to

clear the

alarms.

Press the Reset

button once to clear

the alarms and

various fault

indicators.

Select Setup by Zone

Zone Number Detector

Zone Control Reset

Reset

Click on the Reset icon

or select the Reset

command from the

Zone menu.

De-Isolate the

detector.

Press the Isolate

button once.

The Isolated

indicator goes off.

Select Setup by Zone

Zone Number Detector

Zone Control Isolate

Stop

Select Setup by Zone

Zone Number Detector

Status and check

the Isolated alarm is

cleared.

Select the Device Tree

command from the View

menu.

Click on the detector to

be De-Isolated from the

Device Tree window.

Click on the De-Isolate

icon or select the De-

Isolate Zone command

from the Zone menu.

View Active Events list

for the Isolated alarm to

clear from the list.

VESDA

LaserSCANNER Installation Manual

Version 1.2 23

9. Installation Checklist

Site Name:

Zone: ..

Detector Serial Number/s:

Perform the following checks listed below to ensure that all the necessary items are

completed before handing over to a commissioning engineer.

INSTALLATION CHECKS

Yes No

1. Was the LaserSCANNER detector intact in the box?

" "

2. Is the LaserSCANNER securely locked onto its mounting

bracket?

" "

3. Are the sampling air pipes firmly connected to the air inlet ports?

Note- The pipes must not be glued.

" "

4. Have the power wires been connected to the correct terminals

on the termination card?

" "

5. Have the alarm signalling wires been terminated to the correct

terminals on the termination card?

" "

6. Have the VESDAnet wires been connected to the correct

terminals on the termination card?

" "

7. Has the plug at the exhaust port been removed and the exhaust

pipe (if fitted) not glued?

" "

8. Has the front cover been replaced correctly?

" "

9. Have the Preliminary System Checks been performed?

" "

10. Is the air sampling pipework installed and checked as per the

site plans?

" "

Installation of your LaserSCANNER is now complete.

Name of Installer: .

Signature: .................................................................................

Date:

LaserSCANNER Installation Manual VESDA

24 Version 1.2

10. VESDA Product Warranty Conditions

1. Vision Systems warrants that new VESDA products (excluding consumable items) will

conform to its published specifications and remain in good working order during the warranty

period of 24 (twenty four) months from date of shipment from Vision Systems.

2. Vision Systems also warrants that product serviced or repaired by its service department will

remain in good working order for a warranty period of 12 (twelve) months from the date of

service. This service or repair warranty is only available on product less than 7 (seven) years

old and only covers those component parts of the product serviced, repaired or replaced.

3. Should product under warranty not be in good working order, Vision Systems will, at its

option, either repair or replace the product or its component parts at no additional charge.

4. Spare parts and replacement product, covered under this warranty, will be furnished on an

exchange basis and will, at the option of Vision Systems either be new, equivalent to new or

reconditioned. Returned parts and products to Vision Systems becomes the property of

Vision Systems.

5. This warranty does not cover the repair or damage to the product resulting from negligence

or misuse, improper storage or handling of the product; from accident or disaster; from use

of non- Manufacturer modifications to the product other than in accordance with Vision

Systems instructions; attachment of features not approved by Vision Systems in writing; or

services by persons not authorised by Vision Systems in writing to service the product.

Warranty service may be obtained by:

1. Notifying Vision Systems and giving full description of fault.

2. Vision Systems will first attempt to rectify fault by supplying replacement component parts.

3. If rectification is not achieved by component part replacement then distributor is to return

faulty product to Vision Systems at Vision Systems cost once Vision Systems has given

approval to do so.

Australia and Asia

The Americas

Europe and the Middle East www.vesda.com

Vision Fire & Security

Private Bag 215

495 Blackburn Road

Mount Waverley, VIC, 3149

Australia

Ph +61 3 9211 7200

Fax +61 3 9211 7201

Free Call 1 800 700 203

Vision Fire & Security

700 Longwater Drive

Norwell, MA 02061, USA

Ph +781 740 2223

Toll Free 800 229 4434

Fax +781 740 4433

Vision Fire & Security

Vision House, Focus 31 Mark Road

Hemel Hempstead

Herts, HP2 7BW UK

Ph +44 1442 242 330

Fax +441442 249 327

Part Number: 19148 Revision: 05

You might also like

- The Warlock of Firetop MountainDocument189 pagesThe Warlock of Firetop Mountainvallaksus100% (4)

- IMGshadow PDFDocument132 pagesIMGshadow PDFEduardo Parrudo0% (1)

- Cooling Water Pump.e3s - R00 - CONDocument8 pagesCooling Water Pump.e3s - R00 - CONEduardo ParrudoNo ratings yet

- 07 VESDA Pipe Network Design Guide A4 IE LoresDocument54 pages07 VESDA Pipe Network Design Guide A4 IE LoresEduardo ParrudoNo ratings yet

- En Fc101 ManualDocument124 pagesEn Fc101 ManualEduardo ParrudoNo ratings yet

- 21 VLF-250 Product Manual LoresDocument58 pages21 VLF-250 Product Manual LoresEduardo ParrudoNo ratings yet

- 06 Xtralis VESDA SDM Communications Guide A4 LoresDocument18 pages06 Xtralis VESDA SDM Communications Guide A4 LoresEduardo ParrudoNo ratings yet

- 10 Kuzzin Jimbos KielbasaDocument1 page10 Kuzzin Jimbos KielbasaEduardo ParrudoNo ratings yet

- 14 Updated VESDA Answer SheetDocument1 page14 Updated VESDA Answer SheetEduardo ParrudoNo ratings yet

- 4.4 Mounting VESDA Pipe Network Installation Guide.Document40 pages4.4 Mounting VESDA Pipe Network Installation Guide.Eduardo Parrudo100% (1)

- 4.4.1 On-Ceiling Sampling VESDA Pipe Network Design GuideDocument1 page4.4.1 On-Ceiling Sampling VESDA Pipe Network Design GuideEduardo ParrudoNo ratings yet

- 5 Order of Operations For VESDA StartupDocument1 page5 Order of Operations For VESDA StartupEduardo ParrudoNo ratings yet

- 09 Xtralis VESDA LCD Programmer TDS A4 IE LoresDocument2 pages09 Xtralis VESDA LCD Programmer TDS A4 IE LoresEduardo ParrudoNo ratings yet

- 11 Vesda Eco Detector Tds A4 LoresDocument2 pages11 Vesda Eco Detector Tds A4 LoresEduardo ParrudoNo ratings yet

- Xtralis VESDA VLP - VLS Quick Install Sheet - Multi LingualDocument2 pagesXtralis VESDA VLP - VLS Quick Install Sheet - Multi LingualEduardo ParrudoNo ratings yet

- 2 ASD MatrixDocument1 page2 ASD MatrixEduardo ParrudoNo ratings yet

- 01 Xtralis XAS Product Overview Us LoresDocument22 pages01 Xtralis XAS Product Overview Us LoresEduardo ParrudoNo ratings yet

- 03 Xtralis Inline Filter TDS A4 IE LoresDocument2 pages03 Xtralis Inline Filter TDS A4 IE LoresEduardo ParrudoNo ratings yet

- 03 VESDA HLI Sliding Windows TDS A4 IE LoresDocument2 pages03 VESDA HLI Sliding Windows TDS A4 IE LoresEduardo ParrudoNo ratings yet

- 08 VESDA Display Modules TDS A4 LoresDocument2 pages08 VESDA Display Modules TDS A4 LoresEduardo ParrudoNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CMT Saw Blade 230.524.08M PDFDocument2 pagesCMT Saw Blade 230.524.08M PDFkikuNo ratings yet

- GE6162 EPL Lan Manual - ElectricalDocument42 pagesGE6162 EPL Lan Manual - ElectricalDhamu DharanNo ratings yet

- Crompton Price ListDocument92 pagesCrompton Price Listramancs67% (9)

- Esquema Eletrico - 177926-1Document481 pagesEsquema Eletrico - 177926-1Sam Päron100% (1)

- Hydraulic Block Pilot Oil D3 Atw 5KDocument8 pagesHydraulic Block Pilot Oil D3 Atw 5KSteven Y.MNo ratings yet

- APK 20091019 Electrocardiography+CablesDocument18 pagesAPK 20091019 Electrocardiography+Cablesأحمد العريقيNo ratings yet

- Lsa Code: International Life-Saving Appliance CodeDocument55 pagesLsa Code: International Life-Saving Appliance CodeПрохор ВахрушевNo ratings yet

- SodiumDocument4 pagesSodiumGopal VenkayyaNo ratings yet

- AJ-1800 AJ-2000: Colour Inkjet PrinterDocument48 pagesAJ-1800 AJ-2000: Colour Inkjet PrinterGeorge Cristian CatunaNo ratings yet

- Recommended Wear and Spare Parts. Qty. Installed in Each Crusher Weight Kgs/each Price/unitDocument4 pagesRecommended Wear and Spare Parts. Qty. Installed in Each Crusher Weight Kgs/each Price/unitAndrey StrukovNo ratings yet

- XB4BG21Document4 pagesXB4BG21Mikel IglesiasNo ratings yet

- With ASME ' U ' StampDocument4 pagesWith ASME ' U ' StampOSWALINFRA HEDNo ratings yet

- Link Belt RTC8060Document12 pagesLink Belt RTC8060Jerome YangNo ratings yet

- LEVALIGN Expert - 2 Page Flyer - DOC 06.300 - 17 03 11 - enDocument2 pagesLEVALIGN Expert - 2 Page Flyer - DOC 06.300 - 17 03 11 - enplueluvNo ratings yet

- Ver Información Más Reciente de Juego: Grupo EnteroDocument2 pagesVer Información Más Reciente de Juego: Grupo EnteroJose Rafael Ramos ChiquilloNo ratings yet

- MX2010 1704e6ryqDocument455 pagesMX2010 1704e6ryqRicardo GarciaNo ratings yet

- Steps To Assemble A PCDocument4 pagesSteps To Assemble A PCTiana HaynesNo ratings yet

- Smartsync Operation Audible/Visible Notification With Horn and Synchronized Flash, Non-AddressableDocument6 pagesSmartsync Operation Audible/Visible Notification With Horn and Synchronized Flash, Non-Addressableramzi jaberNo ratings yet

- Cam and FollowerDocument6 pagesCam and FollowerMUHAMMAD UMAR KAMRANNo ratings yet

- CATALOG EVERWELL CABLES March 2019Document46 pagesCATALOG EVERWELL CABLES March 2019umar farooqNo ratings yet

- 2 Communication SignalDocument27 pages2 Communication SignalAlen YbanezNo ratings yet

- OCS Material Price FormDocument1 pageOCS Material Price FormAji Dezi DestiajiNo ratings yet

- Detector de Gas - TGas-1031Document6 pagesDetector de Gas - TGas-1031Fernando BonillaNo ratings yet

- VANTAGE 2000: Performance DataDocument18 pagesVANTAGE 2000: Performance DataPaul MartinNo ratings yet

- (ZU-ing)Document37 pages(ZU-ing)Vladimir KrivenokNo ratings yet

- Same Rating VFD'S and Soft Starter'SDocument6 pagesSame Rating VFD'S and Soft Starter'SShafique AbdiNo ratings yet

- The Silk Ax1445 Flange Facing MachineDocument2 pagesThe Silk Ax1445 Flange Facing MachineSamsam SamNo ratings yet

- IFU - IntelliSave AX700 Anesthesia Machine - EnglishDocument148 pagesIFU - IntelliSave AX700 Anesthesia Machine - EnglishDani RafartNo ratings yet

- Lecture 01-1 Fundamental of Tubes and Other DevicesDocument43 pagesLecture 01-1 Fundamental of Tubes and Other DevicesIvandelist X100% (1)

- Paradise Datacom Fiber Optic Interface For Compact Outdoor SSPAs 205489 RevNDocument6 pagesParadise Datacom Fiber Optic Interface For Compact Outdoor SSPAs 205489 RevNarzeszutNo ratings yet