Professional Documents

Culture Documents

Kilfrost Winter Best Practice Guide - Edition 3

Uploaded by

DimitriosMonogios100%(1)100% found this document useful (1 vote)

797 views44 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

797 views44 pagesKilfrost Winter Best Practice Guide - Edition 3

Uploaded by

DimitriosMonogiosCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 44

Kilfrost Winter Division

Best Practice Guide

Winter Season Edition 3

2

Kilfrost Group Plc

4th Floor, Time Central

32 Gallowgate Newcastle Upon Tyne

NE1 4SN

UK

Telephone: +44 (0) 1434 323 184

Fax: 0191 230 0426

Email: info@kilfrost.com

www.kilfrost.com

Kilfrost Ltd

Albion Works Haltwhistle

Northumberland

NE49 0HJ

UK

Telephone: +44 (0) 1434 320 332

Kilfrost Inc

6250 Coral Ridge Drive

Suite 130

Coral Springs

Florida 33076, USA

Telephone: +1 954-282-5050

Fax: 1-800-483-2578

Email: usa.sales@kilfrost.com

www.kilfrost.com

Kilfrost (Beijing) Trading Co. Ltd

2709, China World Office 1

No. 1 JianGuo Men Wai Avenue

Beijing

100004

China

Telephone: +8610 6535 4020

Fax: +8610 6535 4090

Email: china.sales@kilfrost.com

www.kilfrost.cn

3

Abbreviations 4 4.7 Interaction with Runway De-Icing Fluids 23

References 5 4.8 Fluid Limitations 23

1.0 Introduction 6 4.8.1 Two-Step De/Anti-Icing 23

1.1 De/Anti-Icing 7 4.8.2 Type I Fluid 23

1.1.1 De-Icing 7 4.8.3 Type II / IV Fluid 23

1.1.2 Anti-Icing 7 5.0 Fluid Quality Testing 24

1.1.3 Kilfrost Fluid Types 8 5.1 Sampling Regime 24

2.0 Kilfrost Fluids 10 5.1.1 Fluid Acceptance at Delivery 24

2.1 Type I Fluids 10 5.1.2 Heated Storage 24

2.1.1 Kilfrost DF Plus 10 5.1.3 Vehicle Checks 24

2.1.2 Kilfrost DF

Sustain

10 5.1.4 Laboratory Checks 24

2.1.3 Kilfrost DF Plus (88) 10 5.2 Sampling Procedures 25

2.1.4 Kilfrost DF Plus (80) 10 5.2.1 Safety Considerations 25

2.1.5 Physical and Performance Properties 11 5.2.2 Equipment Required 25

2.1.6 Toxicity 12 5.2.3 Sampling from a Delivery Truck 26

2.1.7 Environmental 12 5.2.4 Sampling from an IBC 26

2.2 Type II Fluids 13 5.2.5 Sampling from a Storage Tank 26

2.2.1 Kilfrost ABC-3 13 5.2.6 Sampling from a Nozzle 26

2.2.2 Kilfrost ABC-K Plus 13 5.3 Field Tests 27

2.2.3 Physical and Performance Properties 14 5.3.1 Visual Inspection 27

2.2.4 Toxicity 15 5.3.2 Refractive Index/ Brix 27

2.2.5 Environmental 15 5.3.3 Viscosity 28

2.3 Type IV Fluid 16 5.3.4 pH Value 29

2.3.1 Kilfrost ABC-S Plus 16 5.4 Laboratory Tests 30

2.3.2 Physical and Performance Properties 16 5.5 Downgrading Fluids 30

2.3.3 Toxicity 17 6.0 Fluid Performance Measures 31

2.3.4 Environmental 17 6.1 Lowest Operational Use Temperature 31

3.0 Handling and Storage 18 6.2 Freezing Point 31

3.1 Plant and Equipment 18 6.3 Aerodynamic Acceptance 31

3.1.1 Storage Tanks 18 6.4 Holdover 32

3.1.2 Pumps and Transfer Lines 18 6.5 Water Spray Endurance Test (WSET) 33

3.1.3 Heating 19 6.6 High-Humidity Endurance Test (HHET) 33

3.1.4 Fluid Transitions 20 6.7 Material Compatibility 33

4.0 Fluid Application 21 6.8 Hard Water Compatibility 34

4.1 Making Dilutions 21 6.9 Surface Tension 34

4.2 De-Icing 21 6.10 Viscosity 34

4.2.1 Removal of Frost 21 6.11 pH Value 35

4.2.2 Removal of Ice 21 6.12 Refractive Index (R.I.) / Brix 35

4.2.3 Removal of Snow 21 6.13 Flash Point 35

4.3 Anti-Icing 22 6.14 Biodegradability 35

4.4 One-Step De/Anti-Icing 22 6.15 Aquatic Toxicity 36

4.5 Two-Step De/Anti-Icing 22 6.16 Fluid Disposal 36

4.6 Fluid Residue 23 7.0 Appendix 37

Contents

Refractive Indices, Brix and Freezing

Point Charts

4

Abbreviations

ADF Aircraft De-icing Fluid

AEA Association of European Airlines

AMS Aerospace Material Specification

BLDT Boundary Layer Displacement Thickness

BOD Biochemical Oxygen Demand

CAAC Civil Aviation Administration of China

COD Chemical Oxygen Demand

EASA European Aviation Safety Agency

FAA Federal Aviation Authority

GRP Glass-reinforced Plastic

HHET High Humidity Endurance Test

ISO International Organisation for Standardisation

LC50 Lethal Concentration (Median)

LD50 Lethal Dose (Median)

LOUT Lowest Operational Use Temperature

OECD Organisation for Economic Co-operation and Development

PE Polyethylene

PP Polypropylene

PVC Polyvinylchloride

RDF Runway De-Icing Fluid

RI Refractive Index

SAE Society of Automotive Engineers

TC Transport Canada

TD50 Toxic Dose (Median)

WSET Water Spray Endurance Test

5

References

SAE Documents

Copies of SAE publications are available from: Society of Automotive

Engineers, 400 Commonwealth Drive, Warrendale, PA 15096-001, USA.

www.sae.org

ISO Documents

Copies of ISO documents are available from: International Organisation for

Standardisation, Case Postale 56, CH-1211, Genve 20, Switzerland.

www.iso.ch

AEA Documents

Copies of AEA documents are available from: Association of European

Airlines, Avenue Louise 350, B-1050 Brussels, Belgium.

www.aea.be

See also:

Airline winter procedure manuals

Airframe manufacturers recommendations

All information in this guide is for informational purposes only.

Users should refer to their own local guidelines, airframe

manufacturers guidance, statutory regulation and other information

before commencing operations. Kilfrost shall not be held responsible

for any damages resulting from any error, inaccuracy or omission

contained in this publication.

6

1.0 Introduction

Contamination with frost, ice or snow can disrupt the airflow over critical

surfaces of an aircraft and therefore seriously affect its aerodynamic

performance and controllability. In order to operate aircraft safely in winter

conditions it is necessary to remove this frozen contamination, and if

appropriate, protect against further contamination during taxiing and other

waiting times.

Kilfrost de/anti-icing fluids are freezing point suppressants based on aqueous

1, 2- and 1, 3- propylene glycol mixtures containing additives such as thickening

agents, surfactants, defoamers, corrosion inhibitors and dyes. These products

are formulated for application in the removal of frozen deposits, having

freezing points below that of pure water.

Type I Fluids are designed to de-ice aircraft surfaces and are unthickened

products. The thickening agents in Type II / IV products hold these low freezing

point fluids on the aircraft surface to produce coatings that provide protection

against the subsequent formation of frozen contamination. These thickening

agents have pseudo plastic / shear-thinning properties, allowing the fluids to

reduce in viscosity under the shear stresses experienced during take-off and

therefore not to affect aerodynamic performance.

7

1.1 De/Anti-Icing

The primary goal of de/anti-icing operations is to provide a clean-wing for

take-off so that a pilot has maximum control of their aircraft. A clean wing is

one that is free from frozen contamination. However, small amounts of fluid

may remain on the wing for a brief period after take-off in the form of a very

thin film.

While de/anti-icing fluids provide protection against frozen precipitation, it is

also necessary that they do not interfere with the aerodynamics of the aircraft

during take-off.

In order to achieve a clean-wing it is necessary for de/anti-icing fluids to lose

viscosity as a result of the increase in air pressure experienced during take-off.

This reduction in viscosity allows the fluid to flow freely from the wing, leaving

a clean surface.

1.1.1 De-Icing

De-icing is the process of removing frozen deposits such as frost, ice and snow

from the external surfaces of an aircraft. De-icing fluids do not offer any significant

extended protection against the subsequent build-up of frozen contamination..

This is the primary purpose of Type I fluids.

1.1.2 Anti-Icing

Anti-icing is the process of protecting a surface against future build up of frozen

deposits. Anti-icing treatments are effective for an extended period of time, known

as holdover. This is the primary function of Type II and Type IV fluids.

Holdover times are dependent on the type and dilution of the anti-icing fluid used

as well as the prevailing weather conditions (intensity of precipitation, humidity,

air temperature and aircraft skin temperature).

8

1.1.3 Kilfrost Fluid Types

1.1.3.1 Type I Fluids

Kilfrost Type I fluids are manufactured and qualified to SAE AMS 1424 / ISO 11075

specifications.

1

Type I fluids are primarily used for de-icing and do not offer any significant anti-icing

holdover protection. Because of this, Type I fluids are commonly used as part of a

two-step de/anti-icing procedure when the final application of a Type II or Type IV

fluid provides the required extra holdover protection.

Kilfrost offers four Type I fluid options:

Kilfrost DF Plus, a triazole-free de-icing fluid.

Kilfrost DF

Sustain

, a triazole-free de-icing fluid based on a bio-derived glycol.

Kilfrost DF Plus (88), a triazole-free de-icing fluid developed exclusively for

the North American market.

Kilfrost DF Plus (80), a triazole-free de-icing fluid developed exclusively for

the Scandinavian market.

1.1.3.2 Type II Fluids

Kilfrost Type II fluids are manufactured and qualified to SAE AMS 1428 / ISO 11078

specifications.

1

Type II fluids can be used for de-icing purposes but (unlike Type I fluids) also offer

extended anti-icing holdover protection and can be used in a variety of ways:

Unheated and undiluted for anti-icing.

Unheated and diluted for anti-icing.

Heated and undiluted for de/anti-icing as a one step process.

Heated and diluted for de/anti-icing as a one step process .

Heated and diluted as the de-icing stage in a two step process,

when used with the unheated and undiluted fluid as a step-two.

Kilfrost offers two different Type II fluid options:

Kilfrost ABC-3, Kilfrosts original de/anti-icing fluid.

Kilfrost ABC-K PLUS, a triazole-free de/anti-icing fluid offering extended

holdover times.

1

The most recent versions of SAE Standards are available from the Society of Automotive

Engineers, Inc., 400 Commonwealth Drive, Warrendale, PA 15096-0001, www.sae.org

9

1.1.3.3 Type IV Fluids

Kilfrost Type IV de/anti-icing fluid is manufactured and qualified to SAE AMS

1428 / ISO 11078 specifications.

1

Type IV fluids offer maximum anti-icing holdover protection, but can also be used

for de-icing purposes. Similar to Type II fluids, Type IV fluids can be used in a variety

of ways:

Unheated and undiluted for anti-icing.

Unheated and diluted for anti-icing.

Heated and undiluted for de/anti-icing as a one step process.

Heated and diluted for de/anti-icing as a one step process.

Heated and diluted as the de-icing stage in a two step process,

when used with the unheated and undiluted fluid as step two.

ABC-S Plus is Kilfrosts triazole-free Type IV de/anti-icing fluid, offering maximum

protection against freezing precipitation.

10

2.0 Kilfrost Fluids

2.1 Type I Fluids

2.1.1 Kilfrost DF Plus

Kilfrost DF Plus is a triazole-free Type I de-icing fluid, qualified to SAE AMS 1424

and ISO 11075 (latest revisions). Type I fluids are used primarily for de-icing

purposes and offer limited anti-icing holdover protection.

2.1.2 Kilfrost DF

Sustain

Kilfrost DF

Sustain

is a triazole-free Type I de/anti-icing fluid, qualified to SAE AMS

1424 and ISO 11075 (latest revisions), but is manufactured from a bio-glycol which

is derived from a sustainable source.

2.1.3 Kilfrost DF Plus (88)

Kilfrost DF Plus (88) is a triazole-free Type I de-icing fluid, qualified to SAE AMS

1424 and ISO 11075 (latest revisions) and manufactured exclusively for the North

American market.

2.1.4 Kilfrost DF Plus (80)

Kilfrost DF Plus (80) is a triazole-free Type I de-icing fluid, qualified to SAE AMS

1424 and ISO 11075 (latest revisions) and developed specially to meet stringent

Scandinavian environmental requirements. Kilfrost DF Plus (80) is available

exclusively in the Scandinavian region.

Type I

11

2.1.5 Physical and Performance Properties

SAE AMS 1424

(a) Requirement: pH change 1.0, no separation, no deposits

(b) Requirement: pH change 0.5, no separation, no deposits

(c) WSET performed with a precipitation rate of 5 g dm

-2

h, at 5 C (41F)

(d) HHET performed with an average frost accumulation rate of 0.3 g dm

-2

h after 4 hours at an

air temperature of 0C (32F) and frosticator temperature at -5 C (23F)

12

2.1.6 Toxicity

(a) OECD 401, est

2.1.7 Environmental

13

2.2 Type II Fluids

2.2.1 Kilfrost ABC-3

Kilfrost ABC-3 is Kilfrosts original Type II anti-icing fluid, qualified to SAE AMS

1428 and ISO 11078 (latest editions), and was the first commercially available

Type II fluid. Users should refer to the generic holdover times published by the

FAA, TC and the AEA for this product.

3

2.2.2 Kilfrost ABC-K Plus

Kilfrost ABC-K Plus is a triazole-free Type II anti-icing fluid, offering extended

holdover compared to ABC-3. This product is also qualified to SAE AMS 1428 and

ISO 11078 (latest editions).

3

a) www.faa.gov b) www.tc.gc.ca c) www.aea.

Type II

14

2.2.3 Physical and Performance Properties

SAE AMS 1428

(a) Requirement: +10 to -20 % viscosity change, pH change 1.0, no separation, no deposits

(b) Requirement: pH change 0.5, no separation, no deposits

(c) Brookfield Mixer: 3500 rpm, 5 min, 20C (68F)

(d) WSET performed with a precipitation rate of 5 g dm

-2

h, at 5C (41F)

(e) HHET performed with an average frost accumulation rate of 0.3 g dm

-2

h after 4 hours

at an air temperature of 0C (32F) and frosticator temperature at -5C (23F)

15

2.2.4 Toxicity

(a) OECD 401 (est)

2.2.5 Environmental

16

2.3 Type IV Fluid

2.3.1 Kilfrost ABC-S Plus

Kilfrost ABC-S Plus is a triazole-free Type IV fluid qualified to SAE AMS 1428

and ISO 11078 (latest editions) and offers maximum anti-icing holdover

protection against freezing precipitation, especially snow, and can be used cold

to prevent the build-up of frost, ice and snow.

2.3.2 Physical and Performance Properties

SAE AMS 1428

(a) Requirement: +10 to -20 % viscosity change, pH change 1.0, no separation, no deposits

(b) Requirement: pH change 0.5, no separation, no deposits

(c) Brookfield Mixer: 3500 rpm, 5 min, 20C (68F)

(d) WSET performed with a precipitation rate of 5 g dm

-2

h, at 5C (41F)

(e) HHET performed with an average frost accumulation rate of 0.3 g dm

-2

h after 4 hours at an

air temperature of 0C (32F) and frosticator temperature at -5C (23F)

Type

IV

17

2.3.3 Toxicity

(a) OECD 401 (est)

2.3.4 Environmental

18

3.0 Handling and Storage

Correct fluid handling is of paramount importance in order to ensure satisfactory

performance of de/anti-icing fluids. Incorrect storage and application of fluid can

result in adverse effects on performance.

3.1 Plant and Equipment

3.1.1 Storage Tanks

Kilfrost fluids should be stored in dedicated opaque storage tanks. Fluid should not

be exposed to direct sunlight as this can cause degradation. Tanks should

be designed to prevent contamination of the fluid with rainwater or frozen

precipitation. The temperature range of the stored product should remain between

-20 and +30C (-4 and 86F). A stock rotation policy should be adopted to

ensure that fluid is not held beyond its shelf life.

Suitable materials for the construction of storage tanks include:

Stainless steel

Mild steel only with a suitable internal lining

Galvanised steel for temporary storage of cold fluid only

Aluminium alloy for cold fluid only

Glass reinforced plastic (GRP) consult manufacturer

for temperature limitations

Moulded plastic consult manufacturer for temperature limitations

Tanks should be inspected annually for signs of corrosion

and / or contamination on the inside of the tank.

3.1.2 Pumps and Transfer Lines

Excessive mechanical shear can cause a decrease in the viscosity of anti-icing

fluids, which will have an adverse effect on the actual holdover times versus

recommended values. Certain pump-types are therefore recommended

for transfer and use of anti-icing fluid:

Progressing cavity multi-pass circulation

Diaphragm multi-pass circulation / discharge

Centrifugal (single pass only)

Dedicated transfer lines should be clearly labelled and manufactured from glycol-

resistant materials, such PP, PE or PVC. Transfer lines should be clean and free

from contaminants before use.

19

3.1.3 Heating

Excessive exposure to heat can lead to the thermal degradation of de/anti-icing

fluids. Heat can also cause loss of moisture due to evaporation, leading to a

change in the glycol content and affecting both the freezing point and viscosity

of the fluid. A reduction in pH, an increase in glycol content and discolouration are

all signs of excessive thermal exposure.

Kilfrost de/anti-icing fluids can be heated satisfactorily using heat exchangers

powered by hot water, steam or oil. Direct exposure to high surface-temperature

heating devices such as electric elements and flame heaters can seriously

degrade de/anti-icing fluids and should be avoided.

The temperature of heat exchange surfaces should not exceed a maximum of

120C (248F), with the temperature of the fluid reaching no higher than 95C

(203F) for Type I fluids. For thickened Type II / IV fluids the temperature of the

fluid should not exceed 70C (158F) and piping with 90 turns and T-stops should

be avoided to minimise shear.

In order to assist heat transfer and avoid localised overheating it is important

to circulate fluids when heating. The temperature of the heat-exchange surface

should be considered when determining the rate of fluid circulation.

3.1.3.1 Standby Heated Storage

In order to avoid thermal degradation of de/anti-icing fluids it is preferable

to store fluids cold. During active de/anti-icing events however, it may be

advantageous to store heated standby fluid. In such instances, fluids should be

maintained at temperatures not exceeding 60C (140F) and for a period not

exceeding 3 months.

3.1.3.2 Heating for Application

Kilfrost-icing fluids are suitable for use in de-icing operations at maximum

temperatures of 80 to 95C (176 to 203F). Fluids should not be maintained

at these temperatures for periods exceeding 7 days for Type I fluids or periods

exceeding 3 days for Type II / IV fluids.

20

3.1.4 Fluid Transitions

The cross-contamination of aircraft de/anti-icing fluids can seriously affect

performance, and for this reason fluids should never be mixed together.

It is therefore necessary to ensure that all units and equipment are completely

cleaned during a fluid changeover. It is recommended that the following steps

be followed during fluid changeovers:

1. Drain fluid from the entire system

2. Flush all tanks, pipelines, taps and heaters with water

3. Check for signs of contamination and / or corrosion of the equipment

Kilfrost FL Solvent can be used to remove any solid or gelatinous residues

(see Section 3.1.4.1 for further instruction)

4. Fill with new fluid

5. Collect fluid samples from all positions in the system (see Section 5.2)

6. Perform fluid checks (see Section 5.3).

3.1.4.1 Kilfrost FL Solvent

Kilfrost FL Solvent is an alkaline-based cleaning fluid used to remove residues,

such as hardness salts and thickener deposits that may have built up over a

winter period in storage tanks and the tanks of de/anti-icing vehicles. These

residues may be broken down and flushed out of the fluid tanks using a diluted

solution of Kilfrost FL Solvent as described below:

1. Drain the system and flush with cold water to remove any loose deposits

2. Fill the system with clean water and add the necessary quantity of FL Solvent

to provide a 5% solution (e.g. 5 litres of FL Solvent in 95 litres of water)

3. Circulate the solution for 30 to 60 minutes Allow to stand for 24 hours

4. Re-circulate for 5 to 10 minutes and drain the fluid

5. Wash through twice with cold water, using 1000 litres each time

6. Dispose of used fluid according to local regulations.

21

4.0 Fluid Application

4.1 Making Dilutions

Clean mains water should be used for all dilutions (see Section 6.8). It is

recommended that water is heated, typically to around 95C (203F), before

adding to the cold de/anti-icing fluid. It is then necessary to mix the water / fluid

mixture, which can be achieved by circulating the fluid through a suitable pump or

by using a mechanical stirrer located within the mixing tank. Consistent refractive

index readings for samples taken from the top, middle and bottom of the mixing

tank can be used as an indication of sufficient mixing.

Water loss from fluids during heated storage may require a fluids dilution to be

adjusted and should be monitored by the operator.

4.2 De-Icing

This is largely achieved through a combination of thermal energy and mechanical

force, which act to melt, dislodge and remove frozen accumulations from an

aircrafts surface. Consult airframe manufacturers for guidelines on maximum

pressure use in order to avoid structural damage to the aircraft.

Fluid should be diluted to a predetermined ratio according to fluid type,

air temperature and aircraft skin temperature

The diluted fluid should be heated to between 80 and 95C (176 to 203F)

(see Section 3.1.3)

Fluid should be applied at close range in order to minimize heat loss.

4.2.1 Removal of Frost

Set nozzle to give a fan-spray, covering a large area of the aircraft surface.

Use a medium flow rate

Traverse spray over frozen surfaces, keeping close to the aircraft skin.

4.2.2 Removal of Ice

Direct a jet of hot fluid at close range onto a single area until the bare surface

is exposed

Heat will be transmitted in all directions by the aircraft surface, raising

its temperature above the freezing point

Frozen deposits can then be flushed away with low or high flow as required.

4.2.3 Removal of Snow

For light deposits, use a medium flow rate, set nozzle to give a solid (coarse)

spray in order to give a large droplet pattern and traverse spray over frozen

surfaces, keeping close to the aircraft skin

For wet snow, a high flow rate is more effective. Heat combined with hydraulic

force should be used to melt and remove frozen deposits.

22

4.3 Anti-Icing

Anti-icing should only be performed in accordance with the airframe

manufacturers instructions.

Select a fluid type and concentration to suit prevailing weather conditions

and required holdover time.

- Maximum holdover is achieved using unheated concentrate fluid

Apply an even and continuous coating of fluid to the surface of the aircraft

wings and vertical stabilisers.

- Cold anti-icing fluid should only be applied to surfaces free from frozen

contamination

- Reduce pump speed and adjust nozzle to give a wide fine spray. High

fluid flow rates and pressures associated with de-icing procedures are

not necessary

- Sufficient fluid has been applied to the wing when the fluid begins to drip

from the leading and trailing edges.

Aircraft should not receive further coatings of anti-icing fluid on top of

existing films. If re-protection is required, the aircraft must first be treated

with hot de-icing fluid prior to a further application of an anti-icing coating.

4.4 One-Step De/Anti-Icing

A one-step de/anti-icing procedure is generally used where an aircraft is

contaminated with frozen deposits, but where there is no simultaneous precipitation.

One-step procedures can be performed with Type I fluids or using Type II / IV

fluids in order to provide extended holdover.

4.5 Two-Step De/Anti-Icing

A two-step de/anti-icing procedure involves the removal of frozen contamination

from the aircraft surface followed by the application of a protective coating in a

subsequent step:

Step 1. Removal of frozen contamination from the aircraft surface. Performed

using heated (80 to 95C / 176 to 203F) de-icing fluid (diluted Type I or diluted

Type II / IV) and is followed within 3 minutes by:

Step 2. Protection of the aircraft surface against subsequent frozen

contamination using unheated anti-icing fluid (Type II / IV).

23

4.6 Fluid Residue

The repeated use of a one-step de-icing procedure with a thickened Type II or

Type IV fluid can lead to a build-up of thickener residue in critical areas of the

wings and stabiliser. These residues can re-hydrate and expand to form gel-like

materials that can re-freeze during flight, restricting flight control systems.

4

A regularly scheduled inspection and cleaning process should be in place when

a one-step procedure is used with thickened fluids.

4.7 Interaction with Runway De-Icing Fluids

Application of anti-icing fluids to aircraft surfaces contaminated with even

small amounts of runway de-icing fluid (RDF) can have a dramatic effect on

the performance of the fluid.

5

This can occur under two main circumstances:

1. Aircraft de/anti-icing fluid flows from the wing during take-off, contacting a runway surface

that has been previously treated with runway de-icing fluid.

2. Runway de-icing fluid is sprayed onto the aircraft surfaces when the engine thrust reversers are

applied during the landing roll. This contamination contacts the aircraft de/anti-icing fluid during

subsequent de/anti-icing procedures.

4.8 Fluid Limitations

4.8.1 Two-Step De/Anti-Icing

When performing a two-step de/anti-icing procedure, the freezing point of

the fluid used in the first step must not be greater than 3C (5F) above

ambient temperature.

4.8.2 Type I Fluid

The freezing point of a Type I fluid used either during a one-step de-icing process or in the

second step of a two-step process must be at least 10C (18F) below the outside air

temperature. Fluid should never be used below the lowest operational use temperature

(LOUT, see Section 6.1).

In order to determine the freezing point of a dilute Type I fluid refer to Section 7.0 Appendix.

Type I fluid is supplied as a concentrate and should not be used undiluted. Kilfrost do not

recommend the use of Type I de-icing fluids at concentrations higher than 69%.

4.8.3 Type II / IV Fluid

The freezing point of a Type II / IV fluid used in de/anti-icing operations must be at

least 7C (13F) below the outside air temperature. Fluid should never be used

below the lowest operational use temperature (LOUT).

4

EASA Safety information Bulletin, 2008-29

5

EASA Safety information Bulletin, SIB No. 2010-26R1

24

5.0 Fluid Quality Testing

The various conditions under which de/anti-icing fluids are transferred, stored,

heated and applied can all have an impact on the performance of the fluids.

Regular quality checks should be performed in order to ensure that fluids are

in a satisfactory condition for use throughout the season.

The following sections are intended to provide a best-practice guide on which fluid

operators should base their internal fluid inspection procedures.

5.1 Sampling Regime

5.1.1 Fluid Acceptance at Delivery

Check that the fluid corresponds to the fluid ordered

Check that the delivery documents correspond to the fluid delivered

Check that the delivered fluids correspond to the vehicle tanks / storage tank

Prior to the transfer of a delivered fluid to a storage tank or vehicle tank,

a sample should be obtained and the following checks performed:

Check visual appearance of fluid

Check refractive index / Brix value of fluid

Check pH value of fluid

Perform a field viscosity check (for Type II and Type IV fluids only).

5.1.2 Heated Storage

Where fluid is stored at elevated temperature for prolonged periods,

the following checks should be performed at intervals not exceeding two weeks:

Visual inspection

Refractive index / Brix

pH value

Field viscosity check (for Type II and Type IV fluids only).

5.1.3 Vehicle Checks

Refractive index checks should be performed on fluid samples obtained from

the nozzles of de/anti-icing trucks on a daily basis.

5.1.4 Laboratory Checks

Laboratory checks should be performed at the start, middle and end of the

de-icing season. Samples should be taken from all storage tanks and

de/anti-icing vehicle tanks and nozzles.

Samples should be checked for:

Visual condition

Refractive index / BRIX

pH value

Field viscosity check (for Type II and Type IV fluids only).

25

5.2 Sampling Procedures

It is important to ensure that fluid samples are obtained in the correct manner

such that the samples represent the bulk of the fluid and simulates aeroplane

application.

To ensure that the necessary safety margins are maintained between the start

of the de-icing/anti-icing operation and takeoff, the fluid used to both de-ice

and anti-ice aeroplane surfaces must be in an ex-fluid manufacturers

condition and at the correct concentration.

Due to the possible effect of vehicle/equipment heating

and/or delivery system components on fluid condition, it is necessary

for the sampling method to simulate typical aeroplane application.

Kilfrost recommends that operators take samples from all static and vehicle

fluid storage tanks and from the nozzles of all de/anti-icing vehicles at the start,

middle and end of the de/anti-icing season.

5.2.1 Safety Considerations

Prior to sampling the operator should consult the MSDS for the fluid being

sampled and be aware of any hazards associated with the product.

It is advised that operators use the following protective equipment when obtaining

fluid samples:

Safety glasses or face shield

Anti-slip boots

Protective gloves (insulated when collecting hot fluid samples)

Operators must also be aware of the hazards associated with working in an airport

environment, such as truck and aircraft movement, jet blast and boom movement.

5.2.2 Sampling Requirements

All samples sent to the Kilfrost laboratory must be clearly labelled and a complete

list must accompany the samples. Samples which do not comply with these simple

requirements will not be tested and re-samples will be requested.

Kilfrost Ltd. recommends the use of clean and dry sample containers of 500ml to

1000ml with an opening diameter of at least 50mm. High-density polyethylene

bottles are acceptable and preferred.

Other types of bottles, for example fizzy drink, glass and contaminated bottles are

not acceptable and testing may be refused if samples arrive in such bottles.

The labels for all samples, which should be securely attached to the sample container,

must also contain the following information:

Airport Name and 3-Lettercode

Fluid Brand Name (e.g. Kilfrost ABC-3, etc)

Fluid Type and Concentration (e.g. SAE Type II 100%)

Sample Origin (e.g. Vehicle Tank, Main Nozzle, etc)

Sample Date

Refractive Index

pH Value

Contact Details (Airline name, company name, email and telephone address)

26

5.2.3 Sampling from a Delivery Truck

Open the truck valve and drain fluid of a sufficient quantity to ensure

that the lines are completely flushed.

Collect an additional 500-1000 ml of fluids to be used as the

representative sample

Record all necessary details of the sample and label fully.

5.2.4 Sampling from an IBC

Break the seal and open the IBC lid at the top

Lower the sample thief into the centre of the IBC

Open the sample thief and allow the container to fill

Remove the sample thief when full

Fill a clean, dry sample container from the sample thief

Dry the sample container and label appropriately

Tighten the IBC screw lid and apply a label detailing the sampling

date and name of sampler to the sample container.

5.2.5 Sampling from a Storage Tank

Access the storage tank via a top opening

Lower the sample thief into the centre of the storage tank

Open the sample thief and allow the container to fill

Remove the sample thief when full

Fill a clean, dry sample container from the sample thief

Dry the sample container and label appropriately

Close the storage tank and apply a label detailing the sampling

date and name of sampler to the sample container.

5.2.6 Sampling from a Nozzle

The preferred method is to spray the fluid onto a purpose built stand,

consisting of a suitable plate (from fluid application) and an associated

fluid collection system. In the absence of such a stand, the application

can be made onto a clean polythene sheet (approx 2mx2m) laid directly

on the ground. Depending on wind speed/direction at the time of

sampling the polythene sheet may require to be weighted down at the edges,

to prevent movement. The distance between the spray nozzle and the surface

shall be approximately 3 m, and the fluid shall be sprayed perpendicular to the

surface. Where different spray patterns and flow rates are used during routine

de-icing/anti-icing operations, samples shall be taken at typical nozzle

settings (e.g. fine, medium or coarse) and flow rates for anti-icing.

Select the required spray pattern and flow rate for the fluid to be sampled

Spray a sufficient quantity of fluid in order to purge the lines

Check the refractive index / Brix value in order to confirm that the fluid is at the

correct concentration

Spray the fluid into the fluid collector from a distance of 3 meters and perpendicular

to the collector surface

Collect sufficient fluid in order to retain a sample of approximately 1 litre

Record all necessary details of the sample and label fully

Note: It is preferable to keep the nozzle open between purging the line and

collecting the fluid sample in order to avoid excessive shearing of the fluid.

27

5.3 Field Tests

Field tests are designed to provide a fast and simple analysis of de/anti-icing

fluids. If there is any doubt about the quality of a fluid, a sample should be

provided for analysis by the Kilfrost laboratory, which will confirm the suitability

of the fluids for use.

5.3.1 Visual Inspection

Using a transparent container check the fluid sample for signs of discolouration

or contamination. All Kilfrost fluids should be homogenous, clear and free from

particulates.

5.3.2 Refractive Index / Brix

Refractive index (RI) / Brix measurements permit a simple determination of the

glycol level in any fluid mix. The glycol level is directly related to the mixture ratio

and the freezing point of the fluid (see Kilfrost conversion charts in the Appendix).

RI / Brix measurements can be made using simple hand held field

refractometers as described below. Alternatively, digital refractometers

can be used according to manufacturers guidelines.

Equipment required:

Field refractometer

Plastic pipettes

Tissue paper

Check the instrument calibration:

1. Lift the cover flap and place a small amount of distilled water onto the prism

2. Close the flap and hold the instrument up to the light and look through

the eyepiece

3. Rotate the eyepiece to focus the scale

4. Check that the RI reads 1.333 ( 0.002) or that the Brix value reads exactly zero

A correct reading RI of 1.333 or zero Brix reading indicates that the instrument is

accurate over the entire scale.

Refractive Index / Brix Measurement:

1. Lift the cover flap and place a small amount of sample onto the prism

2. Close the flap and hold the instrument up to the light and look through the eyepiece

3. Rotate the eyepiece to focus the scale

4. Read the scale at the borderline position between the light and dark areas.

5. Refer to the Kilfrost R.I. / Brix conversion charts in order to determine the

concentration/freezing point of the fluid

6. Thoroughly clean the prism after use with water and dry using a clean tissue.

Note: The refractometer uses a fixed, non-adjustable scale that is set to read correctly at

20C (68F). The refractive index / Brix of the sample will vary with the temperature of the refractometer.

It is therefore important that measurements are made with the refractometer at 20C (68F).

All Kilfrost RI / Brix / freezing point charts correlate to measurements made at 20C (68F).

28

5.3.3 Viscosity

The viscosity of Type II / IV anti-icing fluid is critical to the performance of the fluid.

Kilfrost have introduced the use of Flow Cup Viscometers as a simple viscosity

field test to ensure that thickened anti-icing fluids are within the correct viscosity

range for use. The viscosity of the fluid is expressed in seconds (s) flow time when

the fluid is flowing through an orifice at a specified temperature.

Equipment Required:

1. Kilfrost flow cup (specific to fluid type / dilution)

2. Sample container (with an opening diameter of over 50 mm / 2 inches)

3. Thermometer

4. Stopwatch

5. Kilfrost flow cup viscosity chart (fluid specific).

Viscosity Measurement

1. Ensure that the viscometer is clean and dry prior to use

2. Pour a minimum of 400 ml / 13.5 ounces of fluid into a container with an opening diameter not less

than 50 mm / 2 inches (Image 1)

3. Immerse the cup in the container and leave for around one minute in order to reach thermal

equilibrium (Image 2)

4. Determine the temperature of the fluid using a thermometer

5. Raise the cup vertically out of the fluid in a quick and steady motion. As the top edge of the cup

breaks the surface of the fluid, start the stopwatch (Image 3)

6. During the time of flow, hold the cup vertically no more than 15 cm (6 inches) from the surface of

the fluid

7. Stop timing when a continuous flow of fluid breaks from the cup orifice (Image 4)

8. Check the flow time against the limits provided by Kilfrost for the specific fluid type and dilution at

the temperature of measurement.

29

Caution

Check that the flow cup has fully drained at the end of each measurement. If

fluid remains in the cup the measurement should be disregarded and the flow

cup cleaned and dried thoroughly prior to making subsequent measurements.

Heavily aerated fluids may give artificially high flow times.

Use water or mild soap and water to clean the viscometer.

Dry the viscometer thoroughly after use.

Never use metal tools in contact with the flow cups. Any damage caused to

the flow cup orifice can seriously affect the accuracy of results.

When a Kilfrost fluid sample of disputed viscosity is identified using a Flow Cup

Viscometer, the final decision on its acceptability should always be based on a

Brookfield viscometer reading according to the test method described in SAE

AMS1428 or according to FAA, TC or AEA recommendations for de/anti-icing of

aircraft (latest editions).

5.3.4 pH Value

The pH value of Kilfrost de/anti-icing fluids is used as an indication of fluid

degradation. Portable digital pH meters can be used to provide accurate pH

readings, however pH indicator paper can also be used as follows:

1. Take a piece of pH indicator paper and put it in the fluid so that it becomes wetted

with the fluid

2. Remove the pH indicator paper from the fluid and compare its colour with

the colour of the table provided with the pH indicator paper and read the corresponding pH value

3. Compare the pH-value with the limits provided by Kilfrost for that

product /dilution (see Section 2.0)

Note: The pH of a fluid changes with temperature. pH measurements should therefore

be performed at 20C (68F).

30

5.4 Laboratory Tests

Laboratory checks should be performed at the start and in the middle of the season,

and as appropriate at end of the season if required. Samples should be taken from

all storage tanks and de/anti-icing vehicle tanks and nozzles.

Kilfrost offers a free sample analysis service for all of its de/anti-icing customers.

Laboratory analysis is performed by qualified chemists using accurate scientific

instruments in a controlled environment.

All samples sent to the Kilfrost laboratory should be clearly labelled

with the following information:

Airport Name and 3-Lettercode

Fluid Brand Name (e.g. Kilfrost ABC-3, etc.)

Fluid Type and Concentration (e.g. SAE Type II 100%,)

Sample Origin (e.g. Vehicle Tank, Main Nozzle, etc.)

Sample Date

Refractive Index

pH Value

Contact Details (Airline name, company name, email and telephone address)

Contact details should also be provided with every set of fluid samples

and samples should be sent to the relevant laboratory using the addresses below:

Technical Support Team

Kilfrost Ltd.

Albion Works

Haltwhistle

Northumberland

NE49 0HJ

UK

Telephone: +44 (0) 1434 320 332

Email: info@kilfrost.com

(NB Please check the refractive index prior to sending samples to ensure the glycol

content meets the required dilution.)

5.5 Downgrading Fluids

In instances where the viscosity of a Type II or Type IV fluid is below the required

limit for use as an anti-icing fluid, it is possible to downgrade the fluid for use as

a Type I de-icer.

The downgrading of Type II and Type IV fluids should only be done when all

other properties of that fluid (pH, RI and appearance) remain within specification.

Downgraded fluids should only be used below the normal concentrations usually

used for anti-icing.

If there is any doubt regarding the suitability of a fluid for use, please contact the

Kilfrost Technical Support Team for specific information on downgrading fluids.

Technical Support Team

Kilfrost Inc.

195 University Park Drive

Suite 109

Edwardsville

IL 62025

US

Telephone: 954-282-5033

Email: requests@kilfrost.com

31

6.0 Fluid Performance Measures

This section provides definitions and descriptions of many of the fluid performance

facets associated with aircraft de/anti-icing operations.

6.1 Lowest Operational Use Temperature (LOUT)

The lowest operational use temperature of a fluid is the minimum outside air temperature

(OAT) or aircraft skin temperature at which a fluid can be used.

The LOUT is generally the higher of:

The freezing point of the fluid, plus 10C (18F) for a Type I and plus 7C

(13F) for a Type II / IV fluid.

The lowest temperature at which the fluid meets the acceptable aerodynamic

performance for a particular aircraft type (see Section 6.3).

The LOUTs for Kilfrost de/anti-icing fluids are dependent on the fluid type and level of dilution.

See section 2.0 for product-specific LOUT values.

6.2 Freezing Point

The freezing point of Kilfrost de/anti-icing fluids can be determined by measuring

the refractive index (RI) or Brix value of the fluid. These values can be related to

the concentration of glycol and can therefore be used to determine the freezing

point of that fluid (see Appendix). Details of how to measure the refractive index

of a fluid can be found in Section 5.3.2.

6.3 Aerodynamic Acceptance

The aerodynamic acceptance of a fluid is based on the ability of that fluid to

flow from the surface of an aircraft during take-off to leave an acceptable thickness

of wet film, known as the Boundary Layer Displacement Thickness (BLDT).

As the temperature of a fluid is reduced, its viscosity generally increases. An

increase in viscosity will have a negative effect on the ability of the fluid to be

sheared from an aircrafts surface during take-off, therefore limiting the lowest

operational temperature of the fluid.

High-speed aerodynamic acceptance tests are performed in the laboratory using

a wind tunnel to assess the flow-off properties of fluids under conditions equivalent to

the take-off speeds of large transport jet aircraft that exceed 100 -110 knots over an

acceleration time of around 23 seconds. Analogous low-speed aerodynamic acceptance

tests can also be performed to mimic the take-off speeds of slower aircraft that typically

exceed around 60 knots with acceleration times of around 16 seconds. These tests

characterise the LOUT at which a fluid has acceptable wing flow-off characteristics

during simulated take-off conditions.

The lowest operational use temperatures published by Kilfrost take into account

the aerodynamic performance of each specific product at a particular dilution.

32

6.4 Holdover

Holdover is the estimated time for which de/anti-icing fluids will prevent the

formation of frost, ice and snow on the protected surfaces of an aircraft. In practical

terms, it denotes the period of time that a pilot has been between the application of

de/anti-icing fluid and take-off. If this time is exceeded, the aircraft must return to the

start of the de/anti-icing operation.

Type I fluids provide limited holdover, especially in conditions of frozen

precipitation, whereas Type II / IV fluids, which contain pseudo plastic thickening

agents, providing thicker coatings on the external surfaces of the aeroplane. The

increased viscosity of anti-icing fluids ensures that they hold the freezing point

suppressant on the wing, providing extended holdover.

The duration of the holdover period is dependent on the fluid type, concentration

and the moisture content of the prevailing weather conditions. Holdover times can

be evaluated in the laboratory using the Water Spray Endurance Test (WSET) and

High Humidity Endurance Test (HHET) see Sections 6.5 and 6.6 respectively.

Both of these test methods were originally developed by Kilfrost but have since

been adopted as industry standards.

Minimum anti-icing performance

For a one-step procedure (Section 4.4), the holdover time commences at the

start of the de-icing operation. For two-step procedures, the holdover time

commences at the start of the anti-icing step.

Holdover charts are published independently by the FAA, TC, AEA and CAAC.

2

2

a) www.faa.gov b) www.tc.gc.ca c) www.aea.be d) www.caac.cn

33

6.5 Water Spray Endurance Test (WSET)

The water spray endurance test was developed to provide a laboratory-based

technique for evaluating the holdover performance of anti-icing fluids under

conditions of freezing precipitation.

The test is performed in a climatic chamber with the temperature controlled at -5C

(23F). De/anti-icing fluid, at a temperature of 20C 5 (68F), is poured onto an

aluminium plate that is tilted at an angle of 10 and a temperature of -5C (23F).

A fine water mist is sprayed onto the plate at a rate of 5 g dm

-2

h. This is equivalent

to a precipitation rate of 0.5 mm per hour. Gravitational forces cause the fluid to run

down the inclined plate, causing the fluid thickness at the top of the plate to be

lower than at the lower end of the plate. Ice formation therefore initiates at the top

of the plate and spreads downwards. The WSET time correlates to the time taken

for the progressing ice front to reach a distance of 2.5 cm from the top of the plate.

6.6 High-Humidity Endurance Test (HHET)

The high-humidity endurance test was developed to provide a laboratory-based

technique for evaluating the holdover performance of anti-icing fluids under

specific frosting conditions.

The test is performed in a climatic chamber with the temperature controlled at 0C

(32F) and with a relative humidity of 96 %. Under these conditions, the frost

formation rate is equivalent to 0.3 g dm

-2

h. De/anti-icing fluid, at a temperature

of 20 C 5 (68F), is poured onto an aluminium plate that is tilted at an angle of 10

and set at a temperature of -5C (23F). Gravitational forces cause the fluid to run

down the inclined plate, causing the fluid thickness at the top of the plate to be

lower than at the lower end of the plate. Ice formation therefore initiates at the top

of the plate and spreads downwards. The HHET time correlates to the time taken

for the progressing ice front to reach a distance of 2.5 cm from the top of the plate.

6.7 Material Compatibility

Kilfrost de/anti-icing fluids are specially formulated in order to provide compatibility

with the materials used in the construction of aircraft. As a result, under normal

conditions of use, Kilfrost fluids will not cause metallic corrosion, painted surfaces

to discolour, acrylic or polycarbonate surfaces to mar or craze, or elastomeric

hoses and gaskets to soften.

Kilfrost fluids meet all of the material compatibility tests outlined in the relevant

SAE AMS 1424 / 1428 specifications.

34

6.8 Hard Water Compatibility

Hard water is known to have a negative effect on the performance of

de/anti-icing fluids.

As a guide, Kilfrost recommend that the water used for the dilution of

de/anti-icing fluids be within the following specification, equating to

moderately hard conditions, to be used as a practical maximum limit

of water hardness.

Total hardness: <180ppm CaCO3

Conductivity: <400 S cm-1

pH: 6.00 8.00

If there is any doubt regarding the suitability of the water being used for

the dilution of de/anti-icing fluids, a sample should be provided for analysis

to the Kilfrost laboratory.

6.9 Surface Tension

The surface tension of a fluid defines its ability to wet a particular surface.

Kilfrost de/anti-icing fluids are specially formulated with wetting agents

in order to facilitate their wetting onto aircraft surfaces to provide effective and

uniform coverage.

6.10 Viscosity

The viscosity of a fluid defines its resistance to flow. Kilfrost de/anti-icing fluids

are designed to reduce viscosity under the application of shear stresses of

the magnitudes experienced during take-off. This property enables the fluids to

provide uniform coatings on the surface of a stationary wing, having a thickness

that is optimised in order to provide extended holdover properties while

maintaining the ability to flow from the aircraft surface under the shear stresses

generated during take-off.

When a thickened fluid is subject to excessive shear e.g. through use of incorrect

pumping equipment (see Section 3.1.2), the viscosity of the fluid can be

permanently altered, having a negative effect on fluid performance and holdover

time. The viscosity of Type II / IV fluids should therefore be checked on a regular

basis in order to ensure satisfactory performance (see Section 5.3.3).

35

6.11 pH Value

The pH of an aqueous mixture is a measure of its acidity or basicity. Neutral

substances (i.e. those that are neither acidic nor basic) have a pH of 7.0 at

20C (68F). It is important to ensure that the pH value of a Kilfrost fluid is

within the specified limits in order to ensure that the fluid performs satisfactorily.

The pH of a fluid can be determined using either pH indicator paper or a pH meter

(see Section 5.3.4).

6.12 Refractive Index (R.I.) Brix

The refractive index / Brix value of a fluid can be used to determine its glycol

concentration, and therefore characterise the freezing point of that fluid.

Kilfrost publish charts for the conversion of refractive index and Brix values

into glycol concentrations and freezing points (see Appendix). Section 5.3.2

provides guidelines for the determination of refractive index and BRIX values.

6.13 Flash Point

Kilfrost de/anti-icing fluids are non-flammable under normal conditions of storage

and application and have no flash point.

6.14 Biodegradability

The biodegradation of a substance is determined by comparing the rate at

which aerobic bacteria are able to oxidise the organic matter present in a

substance (a process that consumes oxygen) with the maximum theoretical

oxygen consumption required for complete oxidation of the organic substances

present. The latter of these values is estimated using a chemical oxidation process,

giving what is known as the Chemical Oxygen Demand (COD).

The bacterial oxidation of a substance is determined by measuring the quantity of

oxygen consumed during the action of biomass on the substance over a period of

time and is reported as the biochemical oxygen demand (BOD).

The biodegradability of a substance is defined as: BOD / COD.

Kilfrost de/anti-icing fluids have been determined to be readily biodegradable,

however the rapid biodegradation of large quantities of fluid in surface and

wastewater streams may lead to temporary oxygen depletion, potentially having

an adverse affect on aquatic life. It is therefore preferable for run-off from

de/anti-icing operations to be contained and directed to wastewater treatment

plants (where the organic matter can be biodegraded prior to release) or

glycol reclamation facilities rather than being released immediately into waterways.

36

6.15 Aquatic Toxicity

There are two general mechanisms through which aircraft de/anti-icing fluids

that are allowed to enter surface water can have adverse affects:

1. Oxygen depletion due to biological degradation (see previous section)

2. Components of the fluid may be toxic to aquatic life

The toxicity of a fluid is defined as the amount of fluid that an organism can be

exposed to before it becomes toxic to that organism.

Kilfrost ADFs comply with the aquatic testing requirements set out in the SAE

AMS 1424 and SAE AMS 1428 documents.

1

It is recommended however, that

run-off from de-icing operations is contained and diverted to either waste water

treatment plants or glycol reclamation systems.

6.16 Fluid Disposal

It is the responsibility of the user to ensure that the disposal of de/anti-icing fluids

is done in accordance with the laws and regulations of local governing bodies.

1

The most recent versions of SAE Standards are available from the Society of Automotive

Engineers, Inc., 400 Commonwealth Drive, Warrendale, PA 15096-0001, www.sae.org

37

7.0 Appendix

Kilfrost DF Plus and DF Plus (80)

Refractive Index, Brix and Freezing Point Chart

38

(a) LOUT: -32C (-26F) at 69% vol. dilution

39

Kilfrost DF

Sustain

Refractive Index, Brix and Freezing Point Chart

(a) LOUT: -41C (-42F) for 68.32 determined using Boundary Layer Displacement Thickness (BLDT) values per

AMS 1424 and 5900

40

Kilfrost DF Plus (88) (c)

Refractive Index, Brix and Freezing Point Chart

(a) Acceptance range for product as delivered

(b) (b) LOUT for 63/37 is -32C (-25F) as determined by using Boundary Layer Displacement Thickness

(BLTD) values per AMS 1424 and AS5900

(c) Must be diluted prior to use

41

Kilfrost ABC-3, ABC-K Plus and ABC-S Plus

Refractive Index, Brix and Freezing Point Chart

42

LOUT:

Kilfrost ABC-3: -27C (-16.5F)at 100%, -14C (7F) at 75% and -3C (27F) at 50% dilution.

Kilfrost ABC-K Plus: -29C (-20F)at 100%, -14C (7F) at 75% and -3C (27F) at 50% dilution.

Kilfrost ABC-S Plus: -28C (-18F)at 100%, -14C (7F) at 75% and -3C (27F) at 50% dilution.

(a) Refractive indices in the range 1.3900 to 1.3930 are acceptable for neat Type II and Type Iv fluids.

43

44

Global leaders in de/anti-icing

Kilfrost Limited 4th Floor Time Central 32 Gallowgate, Newcastle

upon Tyne NE1 4SN UK T +44 (0)1434 320 332

Kilfrost, Inc. 6250 Coral Ridge Drive, Suite 130, Coral Springs,

Florida 33076 USA T +1 954-282-5050

www.kilfrost.com

Kilfrost (Beijing) Trading Co., Ltd

2709, China World Office 1, No. 1 Jian Guo Men Wai Avenue,

Beijing,100004, China. T +86 10 6535 4020

www.kilfrost.cn

Kilfrost Ltd

Date of issue: September 2013

Edition No 03

Please check www.kilfrost.com for further updates

You might also like

- ANSYS Tutorial CFX Re-Meshing - EDRDocument12 pagesANSYS Tutorial CFX Re-Meshing - EDRnes1b0No ratings yet

- Membrane Gas-Solvent Contactor Trials of CO2 Absorption From SyngasDocument10 pagesMembrane Gas-Solvent Contactor Trials of CO2 Absorption From SyngascurlychemNo ratings yet

- Lec 1Document27 pagesLec 1Ihab OmarNo ratings yet

- 06 Sparger PDFDocument17 pages06 Sparger PDFHafidho Ilham MNo ratings yet

- Co 2Document23 pagesCo 2sri pragnaNo ratings yet

- Pondash Vs Dry FlyashDocument8 pagesPondash Vs Dry FlyashMere HamsafarNo ratings yet

- Models of Imperfectly Mixed ReactorsDocument7 pagesModels of Imperfectly Mixed ReactorsBlessy Gabayno100% (1)

- Inputs For Performance Mode: Maximum Throughput Case (9m Tower)Document18 pagesInputs For Performance Mode: Maximum Throughput Case (9m Tower)Theodoros AtheridisNo ratings yet

- Turbulence: MIE1207 September, 2012Document128 pagesTurbulence: MIE1207 September, 2012Sepehr SaNo ratings yet

- Boundary LayerDocument16 pagesBoundary LayerSayak GhoshNo ratings yet

- Novel Method Gas Separation-PresentationDocument43 pagesNovel Method Gas Separation-PresentationelelefanterozadoNo ratings yet

- Introduction To ANSYS CFD Professional: Best Practice GuidelinesDocument11 pagesIntroduction To ANSYS CFD Professional: Best Practice GuidelinesMahir SoyerNo ratings yet

- Distillation Columns Containing Structured Packings. A Comprehensive Model For Their Performance. 1. Hydraulic ModelsDocument11 pagesDistillation Columns Containing Structured Packings. A Comprehensive Model For Their Performance. 1. Hydraulic ModelsJohan Sebastian Moreno LaraNo ratings yet

- Agitated Vessel Heat TransferDocument7 pagesAgitated Vessel Heat TransferalokbdasNo ratings yet

- 12 PDO Heat TransferDocument55 pages12 PDO Heat Transferaxel2100No ratings yet

- Basket FilterDocument8 pagesBasket Filterarachman297988No ratings yet

- FGDDDDocument40 pagesFGDDDMary Grace VelitarioNo ratings yet

- MCcabe Thiele by NRTLDocument24 pagesMCcabe Thiele by NRTLgggggg82No ratings yet

- 20-53-00 Tablas PDFDocument24 pages20-53-00 Tablas PDFAndres GuerreroNo ratings yet

- Perry TabsDocument2 pagesPerry TabsJILLIAN DALUPONo ratings yet

- Openfoam Open Source CFD On Anselm: Supercomputing For Industry - Sc4IndustryDocument65 pagesOpenfoam Open Source CFD On Anselm: Supercomputing For Industry - Sc4IndustrytensianNo ratings yet

- Batch Processing Systems Engineering - Fundamentals and Applications For Chemical EngineeringDocument885 pagesBatch Processing Systems Engineering - Fundamentals and Applications For Chemical EngineeringitzelselNo ratings yet

- Final ExamDocument6 pagesFinal ExamTej ChoksiNo ratings yet

- Transformer On Line MonitoringDocument6 pagesTransformer On Line MonitoringSiva KumarNo ratings yet

- Structure PackingDocument8 pagesStructure PackingKalpesh MoreNo ratings yet

- UntitledDocument12 pagesUntitledapi-256504985No ratings yet

- LNG The Next Big ThingDocument23 pagesLNG The Next Big Thingyasuni1000No ratings yet

- How To Minimise Scaleup DifficultiesDocument6 pagesHow To Minimise Scaleup Difficultieskishore.charuNo ratings yet

- Pressure DropDocument36 pagesPressure DropdesignselvaNo ratings yet

- Chemical Process Safety: Kathmandu UniversityDocument16 pagesChemical Process Safety: Kathmandu UniversityRojan PradhanNo ratings yet

- 05 Degree of Freedom AnalysisDocument6 pages05 Degree of Freedom AnalysisLucas Wang100% (1)

- Flooding Capacity in Packed Towers: Database, Correlations, and AnalysisDocument12 pagesFlooding Capacity in Packed Towers: Database, Correlations, and Analysisaslam_bechemNo ratings yet

- CALDENTEY, C., J. A Mechanistic Model For Liquid Hydrocyclones (LHC)Document109 pagesCALDENTEY, C., J. A Mechanistic Model For Liquid Hydrocyclones (LHC)euderfilhoNo ratings yet

- CFD Multiphase Modeling of Fluidized Bed Using Fluent SoftwareDocument44 pagesCFD Multiphase Modeling of Fluidized Bed Using Fluent SoftwareAnonymous P8Bt46mk5INo ratings yet

- Bubble Wake Dynamics in Liquids and Liquid-Solid SuspensionsFrom EverandBubble Wake Dynamics in Liquids and Liquid-Solid SuspensionsNo ratings yet

- $RQ2A4QGDocument377 pages$RQ2A4QGKHANNo ratings yet

- Fixed-Bed Reactor PDFDocument6 pagesFixed-Bed Reactor PDFAlan ZagoNo ratings yet

- DCD 6 - Plate Design PDFDocument53 pagesDCD 6 - Plate Design PDFChristopher RileyNo ratings yet

- Falling FilmDocument21 pagesFalling FilmGhaya Bani RushaidNo ratings yet

- StichlmanirBravoFair General Model DP Packed ColumnDocument10 pagesStichlmanirBravoFair General Model DP Packed Columnmcusseglio3931No ratings yet

- Tutorial ACM 10.1Document52 pagesTutorial ACM 10.1Muhammad SalmanNo ratings yet

- CFD ReportDocument26 pagesCFD Reportkirankumar kymar100% (1)

- The Size of CombustorDocument3 pagesThe Size of Combustorzia_ghiasiNo ratings yet

- Difference Between Continuous and Batch ProcessDocument4 pagesDifference Between Continuous and Batch ProcessPresupuesto 2020No ratings yet

- Modeling Mineral Size Reduction in The Closed-Circuit Ball Mill at The Pine Point Mines Concentrator (1981)Document18 pagesModeling Mineral Size Reduction in The Closed-Circuit Ball Mill at The Pine Point Mines Concentrator (1981)Ryan Cunningham100% (1)

- PMMA Test MethodDocument8 pagesPMMA Test MethodFirman MuttaqinNo ratings yet

- Argon Recovery From Silicon Crystal FurnaceDocument7 pagesArgon Recovery From Silicon Crystal FurnaceasdfqwerNo ratings yet

- Energy From Waste Plants With Carbon Capture FinalDocument34 pagesEnergy From Waste Plants With Carbon Capture FinalJonson CaoNo ratings yet

- Impact of Thermal Power Plant Fly Ash and Its Its Mitigation MesureDocument11 pagesImpact of Thermal Power Plant Fly Ash and Its Its Mitigation MesureShamshad Ahmad100% (1)

- Production of 80,000 Mtpa of Benzene, Toluene and Xylene (BTX) From PygasDocument19 pagesProduction of 80,000 Mtpa of Benzene, Toluene and Xylene (BTX) From PygasCalvin Lin Jia RongNo ratings yet

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDocument8 pagesVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasNo ratings yet

- Maintenence Economic AnalysisDocument26 pagesMaintenence Economic AnalysisSameer SawantNo ratings yet

- Rev MTC For PackedDocument15 pagesRev MTC For PackedAldren RebaLdeNo ratings yet

- Dow Corning RTV InfoDocument20 pagesDow Corning RTV InfoLevent ÖnderNo ratings yet

- Life Cycle Evaluation of Hydrogen and Other Potential Fuels For AircraftsDocument17 pagesLife Cycle Evaluation of Hydrogen and Other Potential Fuels For Aircraftsyounseok choiNo ratings yet

- 2016 Honeywell Annual Investor Conference Presentation PDFDocument202 pages2016 Honeywell Annual Investor Conference Presentation PDFDharmeshNo ratings yet

- Detailed Analysis of Backward Facing Step With Different Turbulence Models and Laminar Flow - Reattachment and Recirculation PointDocument9 pagesDetailed Analysis of Backward Facing Step With Different Turbulence Models and Laminar Flow - Reattachment and Recirculation PointInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- SGS Analysis of South African CoalDocument2 pagesSGS Analysis of South African CoalAamirMalik71% (7)

- Rdsospntc45 2006 Rev 1Document20 pagesRdsospntc45 2006 Rev 1Sushil GambhirNo ratings yet

- Bulletin 141 Afqrjos Checklist Issue 33 04 - 2022 V2Document10 pagesBulletin 141 Afqrjos Checklist Issue 33 04 - 2022 V2ElieNo ratings yet

- Rapid Improvement Workshop ProcessDocument4 pagesRapid Improvement Workshop ProcessDimitriosMonogiosNo ratings yet

- TAEASS403B Participate in Assessment Validation: Release: 1Document7 pagesTAEASS403B Participate in Assessment Validation: Release: 1DimitriosMonogiosNo ratings yet

- How To Drive Continuous Learning Outside The Formal Training EnvironmentDocument47 pagesHow To Drive Continuous Learning Outside The Formal Training EnvironmentDimitriosMonogiosNo ratings yet

- Key Outcome Questions:: See Addendum For Tips On Using This Toolkit RemotelyDocument9 pagesKey Outcome Questions:: See Addendum For Tips On Using This Toolkit RemotelyDimitriosMonogiosNo ratings yet

- Leadership Training and Development A Comprehensive Guide To Building A Leadership PipelineDocument26 pagesLeadership Training and Development A Comprehensive Guide To Building A Leadership PipelineDimitriosMonogios100% (1)

- How To Plan and Strategize Successful Remote Employee Training Programs in 2021Document56 pagesHow To Plan and Strategize Successful Remote Employee Training Programs in 2021DimitriosMonogiosNo ratings yet

- The Shift To Virtual Learning Scalable Training For Modern WorkforcesDocument21 pagesThe Shift To Virtual Learning Scalable Training For Modern WorkforcesDimitriosMonogiosNo ratings yet

- Safety Culture Survey 2010Document102 pagesSafety Culture Survey 2010DimitriosMonogiosNo ratings yet

- AIHR HR Competency FrameworkDocument25 pagesAIHR HR Competency FrameworkDimitriosMonogiosNo ratings yet

- An Introduction To HumanfactorsDocument43 pagesAn Introduction To HumanfactorsDimitriosMonogiosNo ratings yet

- Human Factors in Accident Investigation: David BirkbeckDocument30 pagesHuman Factors in Accident Investigation: David Birkbecksafety86No ratings yet

- Building World-Class Business Leaders Through Experiential LearningDocument21 pagesBuilding World-Class Business Leaders Through Experiential LearningDimitriosMonogiosNo ratings yet

- Icing Lecture 2013 AccessibleDocument52 pagesIcing Lecture 2013 AccessibleDimitriosMonogiosNo ratings yet

- KLM f70 CaseDocument4 pagesKLM f70 CaseDimitriosMonogiosNo ratings yet

- Airside SafetyDocument4 pagesAirside SafetyDimitriosMonogiosNo ratings yet

- Human Behavior ModelDocument230 pagesHuman Behavior ModelDimitriosMonogiosNo ratings yet

- Filcar vs. EspinasDocument2 pagesFilcar vs. EspinasBrian ThunderNo ratings yet

- CH7Document34 pagesCH7Abdul AzizNo ratings yet

- Chapter 1Document2 pagesChapter 1Reymond Homigop GalarpeNo ratings yet

- Cultural Safety Jesus SantiniDocument2 pagesCultural Safety Jesus Santinisq4mc4vqckNo ratings yet

- Shell Omala s2 GX 320 TdsDocument2 pagesShell Omala s2 GX 320 TdsOnie Hammamz OylNo ratings yet

- Sampling PowerpointDocument21 pagesSampling PowerpointMuhammad Furqan Aslam AwanNo ratings yet

- Aml Questionnaire For Smes: CheduleDocument5 pagesAml Questionnaire For Smes: CheduleHannah CokerNo ratings yet

- Data Loss PreventionDocument20 pagesData Loss Preventiondeepak4315No ratings yet

- Rectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadDocument3 pagesRectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadbashaNo ratings yet

- Introduction To Content AnalysisDocument10 pagesIntroduction To Content AnalysisfelixNo ratings yet

- Sec 11Document3 pagesSec 11Vivek JhaNo ratings yet

- Multicomponent Distillation Shortcut MethodDocument5 pagesMulticomponent Distillation Shortcut MethodDiegoAndréVegaDávalosNo ratings yet

- Ara FormDocument2 pagesAra Formjerish estemNo ratings yet

- Google-Analytics 01Document28 pagesGoogle-Analytics 01Smm Store24No ratings yet

- Final Exam - Comprehensive - 10.24.16Document5 pagesFinal Exam - Comprehensive - 10.24.16YamateNo ratings yet

- Lucero Flores Resume 2Document2 pagesLucero Flores Resume 2api-260292914No ratings yet

- Routing Fundamentals: How A Juniper Device Makes Forwarding DecisionsDocument8 pagesRouting Fundamentals: How A Juniper Device Makes Forwarding DecisionsLarsec LarsecNo ratings yet

- ADAMDocument12 pagesADAMreyNo ratings yet

- Goat Farm ProjectDocument44 pagesGoat Farm ProjectVipin Kushwaha83% (6)

- Universal Marine: Welcome To Our One Stop Marine ServicesDocument8 pagesUniversal Marine: Welcome To Our One Stop Marine Serviceshoangtruongson1111No ratings yet

- Eletrical InstallationDocument14 pagesEletrical InstallationRenato C. LorillaNo ratings yet

- Research On Surface Roughness by Laser CDocument5 pagesResearch On Surface Roughness by Laser CfatmirhusejniNo ratings yet

- Ababio v. R (1972) 1 GLR 347Document4 pagesAbabio v. R (1972) 1 GLR 347Esinam Adukpo100% (2)

- AutoCAD Civil 3D Performance Optimization 2Document5 pagesAutoCAD Civil 3D Performance Optimization 2Renukadevi RptNo ratings yet

- Mysuru Royal Institute of Technology. Mandya: Question Bank-1Document2 pagesMysuru Royal Institute of Technology. Mandya: Question Bank-1chaitragowda213_4732No ratings yet

- Invidis Yearbook 2019Document51 pagesInvidis Yearbook 2019Luis SanchezNo ratings yet

- Evaporator EfficiencyDocument15 pagesEvaporator EfficiencySanjaySinghAdhikariNo ratings yet

- Java ProgramsDocument36 pagesJava ProgramsPrashanth MohanNo ratings yet

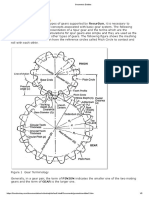

- Geometric Entities: Basic Gear TerminologyDocument5 pagesGeometric Entities: Basic Gear TerminologyMatija RepincNo ratings yet

- Profile Romblon IslandDocument10 pagesProfile Romblon Islandderella starsNo ratings yet