Professional Documents

Culture Documents

UPVC Versus Aluminium - Construction Insights

Uploaded by

Mahesh Mahtolia0 ratings0% found this document useful (0 votes)

28 views7 pagesUPVC Versus Aluminium - Construction Insights

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUPVC Versus Aluminium - Construction Insights

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views7 pagesUPVC Versus Aluminium - Construction Insights

Uploaded by

Mahesh MahtoliaUPVC Versus Aluminium - Construction Insights

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

Article Courtsey: NBMCW J uly 2013

Fenestrations: uPVC vs Aluminium

Ar. Apurva Bose Dutta

The Indian Fenestration Industry

The term 'fenestration' is derived from the word 'fenestra' in Latin terminology and is used to

refer to facades and openings (typically doors and windows) in buildings and wall envelopes.

Although faced with numerous challenges, the Indian fenestration industry has been accepted

as an emerging industry looking at the advancement in its size, technology and potential.

Today's well travelled customers have started comprehending the actual value of fenestrations

rather than treating them as just 'aesthetic elements which act as barriers between the

outside and the interior worlds'. Today, there has been no dearth of discussions of energy

efficiency in the backdrop of the alarmingly increasing global warming. India, as the highest

recipient of solar radiation in the world needs to maximise on the benefits of this renewable

power and mitigate the ill-effects in the form of abundant heat gained at places where it is not

required. Here, comes the actual value of fenestrations which if designed on ideal principles

can aid us in combating such challenges.

The fenestration industry witnessed a leap in the 90s with an incredible growth in the demand

of doors and windows with the rising demand of the housing sector. Aluminium windows

started in the early 90s while uPVC (unplasticised polyvinyl chloride) windows entered in the

late 90s. All thanks to the surge in the construction industry and rapid industrialisation and the

modernisation of airports in India, a number of global players especially dealing with

aluminium products have stepped into the Indian fenestration industry.

The energy efficiency factor in fenestrations has caught up in an unprecedented manner and it

has been accepted globally that windows are the 'single most important area in the envelope

or shell of the building for preventing energy loss'. Quality products like double glazed and

laminated glass are being considered as serious options by users when it comes to sound

efficiency, thermal comfort etc.

Newer technological advancements have not only enhanced the design of fenestrations but

have also stepped into the management part of their logistics. The days of excel sheets, faulty

quotations which would lead to trouble for the fabricator (leading to problems like raw material

wastage, errors in profile calculations etc) are over. The market today has versatile softwares

for the fabricators like a Window Maker (founded in UK with regional headquarters in

Vadodara) that takes care of all these concerns by providing up-to-date information for

analysis and decision making.

Materials for Fenestrations

The materials for fenestrations include aluminium, wood, steel and uPVC. Reports suggest that

the traditional materials of aluminium, wood and steel dominate the market with a market

share of 45%, 25% and 25% respectively; while the newer material of uPVC (which presently

has a low market share of 5%) is the fastest growing material. Steel windows haven't been

observed to give much performance and have been bogged down by lack of standardisation

while the wooden windows market (with limited availability of wood due to environmental

concern) is totally fragmented (with individual or group of carpenters working on site) and

only a couple of state-of-the-art industrial manufacturers. The introduction of uPVC has been a

steadfast initiative to develop fenestrations best suited to the Indian climate.

There have been ongoing deliberations on the comparisons between uPVC and aluminium in

terms of strength, performance, costeffectiveness and eco-friendliness . While aluminium

scores with its numerous advantages of high strength to weight ratio (making feasible light

structures with innate stability), design flexibility (its extrusion enabling numerous range of

forms) and its durability, alloys of aluminium make it very efficient for light management and

are corrosion-resistant and immune to the harmful effects of UV rays. It has an easy

maintenance (a mere routine cleaning is required) that leads to lots of cost savings over the

product's lifetime. Other advantages with the material are its environmentfriendly nature,

various colour as well as finishes availability.

Mumbai headquartered Hindalco Industries Limited, the market leader in aluminium offers

aluminium extruded profiles used for a wide range of architectural applications like Windows,

Doors, Hardwares, Curtain Wallings/Structural Glazing etc. Mr A Jayagopal, Vice President &

SBU Head - Extrusions while dwelling on the advantages of aluminium over uPVC says,

"Aluminium scores over uPVC in almost all attributes like strength, aesthetics, temperature

stability, fire resistance, sound proofing, maintenance and in being endlessly recyclable."

Hindalco has introduced quality aluminium windows under their brand 'Eternia'. This brand

contains three sliding and three casement systems from Italy with different typologies (such

as external / internal opening, pivot, top hung, tilt and turn etc for casement systems and 2

Track / 3 Track, with fixed frame for sliding systems and mosquito mesh system). Fine quality

hardware and accessories (sourced from renowned European companies) ensure effective

functioning of the windows.

While uPVC has enjoyed a global popularity over many years, it has recently started getting

adequate attention in India. Though with a higher cost as compared to other materials like

aluminium and wood, it has some inherent features that are indispensable. It has a heat

insulation that has been found to be 2.2 times better than aluminium windows, thus leading to

saving of more energy; it gives an excellent sound proofing, is completely selfextinguishing

and there is no discolouration when subjected to intense heat and UV exposure. It also

prevents condensation. Its multipoint tilt and turn hardware can make the transformation from

a sash window to a vertical tilting window easily. As also in the case of aluminium, it doesn't

need any special maintenance, is corrosion resistant, has an attractive appearance, is

environmentfriendly, recyclable and has a high durability. Though achievable at a higher

cost, yet uPVC in terms of solar heat gain coefficient and thermal transmittance U values is

much superior to aluminium. It is said that the life cycle savings come out to be more incase

of uPVC. Its initial challenge of its low aesthetics have also been overcome now, with

availability of diverse options in colour and texture; however aesthetically it still can't match

the sheer brilliance of aluminium and its joints and corners and the slimmer profiles. It is also

suited the best for all weather conditions prevailing throughout India. Its earlier sensitivity to

UV rays has also been dealt with technological advancements and by addition of anti-oxidants

and stabilisers. The water tightness and sound proofing are also reported to be better in uPVC

units due to the difference in the joinery details of both the materials. Incase of aluminium the

joints can emerge as areas of weakness as the frame sections can move due to climate

expansion and contraction.

New Delhi based Profine India Window Technology Pvt Ltd is a 100% subsidiary of Profine

GmbH - the world-wide leading manufacturer of uPVC Window and Door profiles. Under their

successful brand Koemmerling, the extrusion of window profiles and PVC sheets was started in

1967. The product range includes casement window and door system (inward / outward

open), tilt and turn window system, sliding windows and doors, sliding folding doors, tilt and

slide door etc. Komalit Z - a high performance compound used and developed exclusively by

Koemmerling is a uPVC blend of the highest impact grade, especially suited for tropical

climates. The use of calcium-zinc instead of lead in the uPVC profiles renders them more

resistant to the aggressive weather conditions. Mr Farid Khan,CEO of Profine India Window

Technology Pvt Ltd dwelling on the advantages of uPVC over aluminium states, "uPVC is dust

proof, has a versatile colour range, security, easy care and longevity and is a product for

extreme conditions. It scores over aluminium in terms of sound Insulation, Heat reduction and

fire resistance. uPVC windows and doors have a greater energy saving potential than any

other window material and rank at the top of the league in eco-efficiency analyses. They have

the highest thermal insulation property compared to other framing materials like Aluminium,

wood etc. Their extrusion process is also relatively energy efficient compared with aluminium.

They can be fully recycled and reused for production."

Pune based Eureka India is a well known manufacturer and supplier of a varied range of PVC

and wooden doors. Incase of PVC doors, they have Solid PVC Flush Door, Solid PVC Panel

Doors and Solid PVC Laminate Doors. Mr Uttam Khatode, Deputy Manager - production and

key accounts of the firm drawing differences between uPVC and aluminium elaborates, "uPVC

is a petrochemical product and hence is more ecofriendly than aluminium. Cost wise it is

comparable to aluminium since it comes in various grades. The A grade is more costly than

the aluminium section but if the grade drops, the cost also drops. Talking about strength, if we

speak about doors, uPVC has 100 times more strength than aluminium keeping in mind the

utilisation and operation system required in doors which need to be operated atleast 5-6 times

in a day. Incase of fixing, since aluminium sections are fixed with a screw, after a certain while

they start making noise when the door/windows are opened. In case of uPVC and PVC, the

joint is more durable since it is made of using a solvent hence it never becomes loose. PVC

panels are put in doors with cement solvents while aluminium sections are fixed with rubber

gaskets; hence when the rubber gasket comes out, the middle panel also automatically comes

out. While uPVC and PVC doors are made in the factory, aluminium sections are labour and

handmade. We can paint PVC doors with regular oil-based paints while aluminium doors can't

be painted - they have to be powder coated."

One thus concludes that it is difficult to pinpoint on which of the two materials of aluminium or

uPVC is superior. Though aluminium is still preferred by a majority in India, but both

aluminium as well as uPVC windows and doors have their own markets which they cater to.

Though aluminium being a metal is always costlier than uPVC which is actually a plastic

(aluminium of good grade and with thermal break system proves to be costlier than uPVC

doors and windows); the aesthetics of aluminium remain more because of it being a hand

assembled crafted product whereas uPVC products are mass productions. Aluminium products

last longer and are easier to recycle, uPVC scores due to its environmental advantages.

Standards for a Quality Product

Mr Khan while stating that uPVC is a multi-level project which requires extrusion, fabrication

and installation, admits that there has been no standardisation such as BIS so far, which

hampers the marketing of these products in India. Currently, the uPVC doors and windows are

still being made as per international standards however reports suggest that the uPVC

Windows & Doors Manufacturers Association (UWDMA) is in the process of submitting an India

centric draft standard to BIS.

In the absence of any industry standards, the aluminium windows market has its share of

problems too. "It is a heavily fragmented segment, and in the absence of any regulatory body

and industry standards, there is much left to be desired in the quality of aluminium windows.

The concept of branded aluminium windows is not as strong in India like in the US, UK and

Europe where there are several established brands. However now branded aluminium windows

have started entering the Indian market and when branded products are available, one is

certain that some science has gone into designing and developing these window systems and

that there is consistency in quality. On the other hand uPVC windows have emerged quickly to

capture 3-4% of the windows market, aided by heavy advertising," explains Mr Jayagopal.

Challenges for Marketing

As much as is the growing popularity of these products, there exist significant challenges that

the suppliers are facing while marketing these products in India. Lack of awareness of the

quality and the benefits of uPVC, and the lack of awareness of energy conservation are the

challenges for marketing of uPVC in India. "The unorganised manner in which the industry

runs, the high cost of uPVC as compared to conventional products, and workmanship are some

of the other challenges. We still find well entrenched low priced traditional materials being

used like aluminium in urban areas, wood in semi-urban and rural areas, MS in government

buildings. We notice that there is a competition on price and not on quality," adds Mr Khan.

However, Mr Khatode feels that since uPVC doors are already a hit with people and builders

(for whom aluminium extrusion doors are outdated), their marketing is not a problem at all.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- BiodieselDocument59 pagesBiodieselhugoNo ratings yet

- Smaw AssessmentDocument3 pagesSmaw Assessmenteunice achina79% (24)

- EON One With Diluter by Vital DiagnosticsDocument2 pagesEON One With Diluter by Vital DiagnosticsMahesh MahtoliaNo ratings yet

- Eyecare IndDocument10 pagesEyecare Indtanushree26No ratings yet

- Enerpac PATG1102NDocument72 pagesEnerpac PATG1102NAnonymous G6ceYCzwtNo ratings yet

- Indian Healthcare Business ModelsDocument27 pagesIndian Healthcare Business ModelsMahesh MahtoliaNo ratings yet

- Leak Test Procedure of BoilerDocument3 pagesLeak Test Procedure of BoilerDavid Hoffman100% (3)

- Afghanistan Exporters & Importers DirectoryDocument20 pagesAfghanistan Exporters & Importers Directoryvamsi krishnaNo ratings yet

- Hydrogen Hubs at Ports: Opportunities to Advance Clean Energy TransitionDocument11 pagesHydrogen Hubs at Ports: Opportunities to Advance Clean Energy TransitionHariharan SNo ratings yet

- NREL - IEC 61400-12 - WTG Power Performance MeasurementDocument23 pagesNREL - IEC 61400-12 - WTG Power Performance Measurementjomoran100% (3)

- 3D Company ProfileDocument12 pages3D Company ProfileMahesh MahtoliaNo ratings yet

- India Home Health Care ServicesDocument3 pagesIndia Home Health Care ServicesMahesh MahtoliaNo ratings yet

- Samvedna Senior CareDocument2 pagesSamvedna Senior CareMahesh MahtoliaNo ratings yet

- Indian Healthcare Industry PresentationDocument28 pagesIndian Healthcare Industry PresentationMahesh MahtoliaNo ratings yet

- Healthcare Expenditures IndiaDocument9 pagesHealthcare Expenditures IndiaMahesh MahtoliaNo ratings yet

- Epoch Elder Care Provides High Quality Assisted Living HomesDocument17 pagesEpoch Elder Care Provides High Quality Assisted Living HomesMahesh MahtoliaNo ratings yet

- Nursing Homes - Clinics IndiaDocument5 pagesNursing Homes - Clinics IndiaMahesh MahtoliaNo ratings yet

- Hospital Equipment Survey InsightsDocument5 pagesHospital Equipment Survey InsightsMahesh MahtoliaNo ratings yet

- 3D Market Research Company ProfileDocument12 pages3D Market Research Company ProfileMahesh MahtoliaNo ratings yet

- Dental Industry in India HfbjbveinivekDocument24 pagesDental Industry in India HfbjbveinivekAtishPatelNo ratings yet

- 3D Market Research Company ProfileDocument12 pages3D Market Research Company ProfileMahesh MahtoliaNo ratings yet

- 3D Market Research Company ProfileDocument12 pages3D Market Research Company ProfileMahesh MahtoliaNo ratings yet

- Profile NEXGEN EnterpriseDocument8 pagesProfile NEXGEN EnterpriseMahesh MahtoliaNo ratings yet

- Profile NEXGEN EnterpriseDocument8 pagesProfile NEXGEN EnterpriseMahesh MahtoliaNo ratings yet

- NexGen Healthcare ProjectsDocument12 pagesNexGen Healthcare ProjectsMahesh MahtoliaNo ratings yet

- NexGen Company Profile NDocument10 pagesNexGen Company Profile NMahesh MahtoliaNo ratings yet

- NexGen Company Profile NDocument10 pagesNexGen Company Profile NMahesh MahtoliaNo ratings yet

- NexGen Company ProfileDocument15 pagesNexGen Company ProfileMahesh Mahtolia100% (1)

- Polygeneration As A Future Sustainable Energy Solution  " A Comprehensive ReviewDocument24 pagesPolygeneration As A Future Sustainable Energy Solution  " A Comprehensive ReviewSagar KumarNo ratings yet

- Types of LightsDocument6 pagesTypes of LightsAlfred Harvey ElacionNo ratings yet

- Studies of Solvent Effect of Aquo Methanol Solvent System On Kinetics and Activation Parameters of Base Catalised Hydrolysis of Ethyl CinnamateDocument3 pagesStudies of Solvent Effect of Aquo Methanol Solvent System On Kinetics and Activation Parameters of Base Catalised Hydrolysis of Ethyl CinnamateIJEACS UKNo ratings yet

- S55E3Document8 pagesS55E3Rozalina AzianNo ratings yet

- Project Report by Manish YadavDocument53 pagesProject Report by Manish Yadavmanish yaduvanshiNo ratings yet

- Masdar 2020 Annual Sustainability ReportDocument35 pagesMasdar 2020 Annual Sustainability ReportAbdallah BasbousNo ratings yet

- The Bioethanol-To-ethylene (B.E.T.E.) ProcessDocument13 pagesThe Bioethanol-To-ethylene (B.E.T.E.) ProcessolieNo ratings yet

- Power SystemsDocument60 pagesPower SystemsKoustav DasguptaNo ratings yet

- ADVANCED 12 FINAL TEST ResueltoDocument8 pagesADVANCED 12 FINAL TEST ResueltoLos locos de suyoNo ratings yet

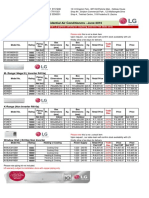

- LG Trade Price List June 2016Document2 pagesLG Trade Price List June 2016musturNo ratings yet

- What is Solar EnergyDocument13 pagesWhat is Solar EnergyhiyaNo ratings yet

- Designing of HV Power Substation and Layout - EEPDocument13 pagesDesigning of HV Power Substation and Layout - EEPSuresh Umadi100% (1)

- Recent Trends in Power Electronics Technology - Vijaya BhaskarDocument67 pagesRecent Trends in Power Electronics Technology - Vijaya BhaskarMukundMikkilineniChowdaryNo ratings yet

- Analysis of Power ConvertersDocument10 pagesAnalysis of Power ConvertersNmg KumarNo ratings yet

- 100ah - 12V - 6FM100 VISIONDocument2 pages100ah - 12V - 6FM100 VISIONBashar SalahNo ratings yet

- Research Paper Chapter 1-3Document22 pagesResearch Paper Chapter 1-3johnis19dcNo ratings yet

- Ecp57vol12 035Document8 pagesEcp57vol12 035sumitrochakrabortiNo ratings yet

- DC GeneratorsDocument3 pagesDC GeneratorsUswa ZainabNo ratings yet

- Etl 1110-2-311Document12 pagesEtl 1110-2-311Juan Carlos Villagrán FanteNo ratings yet

- Cussons Boiler Instructon ManualDocument32 pagesCussons Boiler Instructon Manualjakakolenk100% (1)

- TI 801-02 Volume 2 - Statement of WorkDocument81 pagesTI 801-02 Volume 2 - Statement of WorkMohamed FathiNo ratings yet

- SCORE Provides Energy for Sarawak DevelopmentDocument162 pagesSCORE Provides Energy for Sarawak DevelopmentMani JackNo ratings yet

- 0530-DWG-BSC-40-005 Conduit Size Layout Rev02Document1 page0530-DWG-BSC-40-005 Conduit Size Layout Rev02Luis Marín DíazNo ratings yet