Professional Documents

Culture Documents

Production Process

Uploaded by

Leo Milosev0 ratings0% found this document useful (0 votes)

68 views4 pagesThere are three basic types of plastic pipes: solid wall pipes made from a single layer of thermoplastic material, structured wall pipes with an optimized design for material usage and performance, and barrier pipes that incorporate a flexible metallic layer between three bonded layers to provide additional protection for pipe contents. Pipes are normally produced via extrusion, injection molding, blow molding, or rotational molding depending on the part. Pipes can be joined through push fit joints, solvent cementing, or welding systems to form reliable connections.

Original Description:

PVC pipe production process

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThere are three basic types of plastic pipes: solid wall pipes made from a single layer of thermoplastic material, structured wall pipes with an optimized design for material usage and performance, and barrier pipes that incorporate a flexible metallic layer between three bonded layers to provide additional protection for pipe contents. Pipes are normally produced via extrusion, injection molding, blow molding, or rotational molding depending on the part. Pipes can be joined through push fit joints, solvent cementing, or welding systems to form reliable connections.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

68 views4 pagesProduction Process

Uploaded by

Leo MilosevThere are three basic types of plastic pipes: solid wall pipes made from a single layer of thermoplastic material, structured wall pipes with an optimized design for material usage and performance, and barrier pipes that incorporate a flexible metallic layer between three bonded layers to provide additional protection for pipe contents. Pipes are normally produced via extrusion, injection molding, blow molding, or rotational molding depending on the part. Pipes can be joined through push fit joints, solvent cementing, or welding systems to form reliable connections.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

Production processes

Basic Types of Pipe

There are three basic types of plastic pipes:

Solid wall pipe

Extruded pipes consisting of one layer of

a homogeneous matrix of thermoplastic

material which is ready for use in a

pipeline.

Structured wall

pipe

Structured-wall pipes and fittings are

products which have an optimized

design with regard to material usage to

achieve the physical, mechanical and

performance requirements.

Structured Wall Pipes are tailor made

solutions of piping systems, for a

variety of applications and in most

cases developed in cooperation with

users.

Barrier pipe

Pipe incorporating a flexible

metallic layer as the middle of

three bonded layers. Barrier

pipe is used, for example, to

provide additional protection

for the contents passing

through the pipe (particularly

drinking water) from

aggressive chemicals or other

pollution when laid in ground

contaminated by previous

use.

Most plastic pipe systems are made from thermoplastic materials. The production method involves melting the material, shaping and then cooling.

Pipes are normally produced by extrusion.

Pipe Extrusion

Pipes made from PVC, PE and

PP and other thermoplastics are

usually manufactured by

extrusion.

This process starts by feeding

plastic material (pellets, granules,

flakes or powders) from a hopper

into the barrel of the extruder.

The material is gradually melted

by the mechanical energy

generated by turning screws and

by heaters arranged along the

barrel.

The molten polymer is then

forced into a die, which shapes

the polymer into a pipe that

hardens during cooling.

A great advantage of extrusion is

that pipes can be made to any

length. Due to its flexibility,

pipes can be made at long lengths

even coiling on a reel. Another

advantage is the extrusion of

pipes with integrated coupler

including rubber seal.

Jointing

Pipes can be connected in a

variety of ways to form reliable

and leak-free pipe systems. They

can be connected by either a push

fit joint with rubber seal or by a

solvent cement system or by

welding.

Straight pipes are mostly

connected by pushing the plain

end of one pipe into the socketed

end of another. This technology

is mainly used by PVC and PP

piping systems. A variety of

fittings are available to make

branches or bends or to connect

the pipe to other materials.

PE pipes for water pressure and

gas distribution can also be

connected by welding systems.

Two pocesses are mostly used:

Butt welding to connect pipe to

pipe ends, and electro welding of

fittings containing a heating wire

to allow melting of materials

together. A variety of fittings are

available. Welding systems have

proven to be very reliable.

Injection Moulding

Fittings such as joints, elbows or T-pieces are usually produced by injection-moulding.

In injection-moulding, the plastic

material is fed from a hopper into

the melting section of the

injection-moulding machine.

After melting, the material is

transported forward by the screw

and homogenised before being

injected into the mould to form

the shape of the desired product.

In the cooling step, the plastic

solidifies. Then the mould is

opened and the product is ejected.

Blow Moulding

In the blow moulding process, the plastic is melted and extruded into a hollow tube that is then captured by closing it into a cooled metal mould.

Air is then blown into the tube inflating it into the desired shape. After the plastic has cooled sufficiently, the mould is then opened and the part

is ejected.

Inspection chambers, manholes, septic and storage tanks are some of the products manufactured by this technique. Typically, these products are

much lighter and easier to handle than non plastic materials.

Rotational Moulding

The rotational moulding process is a high temperature, low pressure plastic forming method that uses biaxial rotation to produce hollow, one piece

parts. In the plastic pipe industry, it is typically used to make large inspection chambers, water and septic tanks from polyethylene (PE) or

polypropylene (PP).

You might also like

- TC Debbie ReportDocument125 pagesTC Debbie ReportphucNo ratings yet

- Retaining Walls 0113Document16 pagesRetaining Walls 0113sossaifjmNo ratings yet

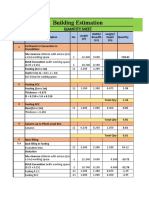

- Building Estimation Excel Sheet 1Document31 pagesBuilding Estimation Excel Sheet 1sqqpqq1No ratings yet

- Geoplast Slabs Solution English BrochureDocument52 pagesGeoplast Slabs Solution English BrochureMohamedNo ratings yet

- Bison Hollow Core FloorsDocument16 pagesBison Hollow Core FloorsJohn WoodsNo ratings yet

- Glass Reinforced PlasticsFrom EverandGlass Reinforced PlasticsBrian ParkynRating: 5 out of 5 stars5/5 (1)

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Notes On Design of RCC ElementsDocument3 pagesNotes On Design of RCC ElementsrangarajanNo ratings yet

- NIKM Business Proposal OK Rev2Document9 pagesNIKM Business Proposal OK Rev2Gunawan Tabrani100% (1)

- PVC BrochureDocument16 pagesPVC Brochurerbsith258No ratings yet

- Cast Stone Association Technical Manual PDFDocument52 pagesCast Stone Association Technical Manual PDFneilattardNo ratings yet

- 9785 en v1 FlatrigmaDocument4 pages9785 en v1 FlatrigmahugodanielsousaNo ratings yet

- Purlins & GirtsDocument105 pagesPurlins & Girtsrajkumar_chinniahNo ratings yet

- Knowledge Sharing On Aac1Document16 pagesKnowledge Sharing On Aac1parthNo ratings yet

- DX BrochureDocument44 pagesDX BrochureAbhinav RastogiNo ratings yet

- Amount BHD SL No Description Qty Unit Rate BHDDocument3 pagesAmount BHD SL No Description Qty Unit Rate BHDmunnumma50% (2)

- Biotox Gold 2.0-2021 Relaunch ReviewDocument6 pagesBiotox Gold 2.0-2021 Relaunch ReviewChinthaka AbeygunawardanaNo ratings yet

- Industrial ConstDocument34 pagesIndustrial Constkirti0% (1)

- HZS 180 Concrete Batching PlantDocument2 pagesHZS 180 Concrete Batching PlantHenan NF Mechanical Installation Co., Ltd.No ratings yet

- Tech Report 1Document24 pagesTech Report 1Juan Carlos Quispe CharaNo ratings yet

- 02.prestressed Concrete PresentationDocument15 pages02.prestressed Concrete PresentationAR1941MUBBASHIRA LAKDAWALANo ratings yet

- Steel Rebar Industry ProfileDocument34 pagesSteel Rebar Industry ProfileOvidiu TomaNo ratings yet

- Workshop 3Document4 pagesWorkshop 3Ajiri IvoviNo ratings yet

- Pre Cast WallDocument18 pagesPre Cast WallRyan Jhes TolentinoNo ratings yet

- Promains PVC Pipe and Fittings Product Guide Jan 2012 2Document16 pagesPromains PVC Pipe and Fittings Product Guide Jan 2012 2NaeemSiddiquiNo ratings yet

- Pre-Cast Concrete - Full Case Study1Document14 pagesPre-Cast Concrete - Full Case Study1anant_350872837No ratings yet

- Prestressed Concrete Structures: Under The Guidance Of: Prof. & Head Department of Civil EngineeringDocument42 pagesPrestressed Concrete Structures: Under The Guidance Of: Prof. & Head Department of Civil EngineeringPtp AbyNo ratings yet

- Product Data: Beam Lintels LengthsDocument2 pagesProduct Data: Beam Lintels LengthsRakesh ParaliyaNo ratings yet

- Building EstimationDocument22 pagesBuilding EstimationMelkamu AmusheNo ratings yet

- Designing of Multi-Cavity Extrusion Die To Increase Productivity: A Survey and PerspectiveDocument6 pagesDesigning of Multi-Cavity Extrusion Die To Increase Productivity: A Survey and PerspectiveIJRASETPublicationsNo ratings yet

- Pad Foundation Design ExerciseDocument1 pagePad Foundation Design ExerciseRobbie DoyleNo ratings yet

- REPORTDocument49 pagesREPORTSalin ShresthaNo ratings yet

- Development Feasibility TemplateDocument12 pagesDevelopment Feasibility Templatezakiur15No ratings yet

- PVC Crust Foam Board Manufacture Process ControDocument1 pagePVC Crust Foam Board Manufacture Process ControFrank ZhangNo ratings yet

- Project Profile On Fly Ash Bricks Srs EnterprisesDocument17 pagesProject Profile On Fly Ash Bricks Srs EnterprisesRAHUL SHARMANo ratings yet

- C231-Subsoil and Foundation DrainsDocument11 pagesC231-Subsoil and Foundation DrainsTsoekem SessouNo ratings yet

- PellX 20 35 KW Pellet Burner Installation Manual US V1Document51 pagesPellX 20 35 KW Pellet Burner Installation Manual US V1António CruzNo ratings yet

- Pool Overflow Stones Collection-2013Document96 pagesPool Overflow Stones Collection-2013Keri MasonNo ratings yet

- 1.1 Concept of Prefabrication StructureDocument20 pages1.1 Concept of Prefabrication StructureAkriti VashishthaNo ratings yet

- Sustainable FoundationsDocument4 pagesSustainable Foundationsk1l2d3No ratings yet

- ACT Group Assignment 1 - Industrial BuildingDocument30 pagesACT Group Assignment 1 - Industrial BuildingManogna Sai PadiNo ratings yet

- Hollow Slab / Concrete Beams MachineryDocument26 pagesHollow Slab / Concrete Beams Machineryprensoland100% (1)

- Custom Precast Concrete 2015 0Document21 pagesCustom Precast Concrete 2015 0Anggit PraNo ratings yet

- Architecture of HolesDocument12 pagesArchitecture of HolesAbhijeet SurveNo ratings yet

- Oman Ophiolite Precast - Corporate BrochureDocument24 pagesOman Ophiolite Precast - Corporate BrochurePSPNo ratings yet

- Rotomoulding Machine FINAL0000000000Document42 pagesRotomoulding Machine FINAL0000000000Nikhil PanchalNo ratings yet

- CLC Blocks ProposolDocument5 pagesCLC Blocks ProposolGyi TawNo ratings yet

- C11 Gypsum and SystemDocument5 pagesC11 Gypsum and SystemphilipyapNo ratings yet

- Wa Builders GuideDocument40 pagesWa Builders Guidessss2345No ratings yet

- Structural SteelDocument6 pagesStructural SteelKevin VargheseNo ratings yet

- ABS - Application of Ergonomics To Marine SystemsDocument222 pagesABS - Application of Ergonomics To Marine SystemsJDPNetoNo ratings yet

- ALC The Intelligent Building SystemDocument7 pagesALC The Intelligent Building SystemkucingmioewNo ratings yet

- The Green Way To BuildDocument4 pagesThe Green Way To BuildnfahmiNo ratings yet

- Info Waterproofing Basement WallsDocument1 pageInfo Waterproofing Basement Wallsbeck.26No ratings yet

- Supreme Beam and Block FloorDocument8 pagesSupreme Beam and Block FloorDoralba V NolanNo ratings yet

- Industrial Building: by Tausif Kauswala Adit College V.V. Nagar, Anand, Gujarat, IndiaDocument59 pagesIndustrial Building: by Tausif Kauswala Adit College V.V. Nagar, Anand, Gujarat, IndiaPhuong ThaoNo ratings yet

- Table of ContentsDocument4 pagesTable of Contentsvrb126No ratings yet

- Every Little Thing You Need To Learn About Plastic ExtrusionqyeyzDocument2 pagesEvery Little Thing You Need To Learn About Plastic Extrusionqyeyzbankspot1No ratings yet

- Injection Permanent Molding and Extrution Machine: Case StudyDocument7 pagesInjection Permanent Molding and Extrution Machine: Case StudyBrown MeshNo ratings yet

- 3D Printing BasicsDocument14 pages3D Printing BasicsLeo MilosevNo ratings yet

- CNC KodoviDocument2 pagesCNC KodoviLeo MilosevNo ratings yet

- Standardni Programm Aktuatora 2014 - 01Document75 pagesStandardni Programm Aktuatora 2014 - 01Leo Milosev100% (1)

- Generalni CNC KodoviDocument2 pagesGeneralni CNC KodoviLeo MilosevNo ratings yet

- Autocad ShortcutDocument2 pagesAutocad ShortcutSon Roy AlmerolNo ratings yet

- SolidCAM InstructionsDocument4 pagesSolidCAM InstructionsGotaya Loka Poojitha0% (1)

- ATtiny Examples For ProgramingDocument10 pagesATtiny Examples For ProgramingLeo MilosevNo ratings yet

- Keypad TutorialDocument3 pagesKeypad TutorialLeo MilosevNo ratings yet

- Knock ArudinoDocument6 pagesKnock ArudinoLeo MilosevNo ratings yet

- The Blender 2.5 Cheat Sheet - Useful Keyboard ShortcutsDocument6 pagesThe Blender 2.5 Cheat Sheet - Useful Keyboard Shortcutsmixer5056100% (4)

- The Blender 2.5 Cheat Sheet - Useful Keyboard ShortcutsDocument6 pagesThe Blender 2.5 Cheat Sheet - Useful Keyboard Shortcutsmixer5056100% (4)

- BB5006 Coastboat BentDocument24 pagesBB5006 Coastboat BentMunteanuCNo ratings yet

- Formech Vacuum GuideDocument64 pagesFormech Vacuum GuideDanilo Carneiro ArrudaNo ratings yet

- Sorting Algorithms in Fortran: Dr. Ugur GUVENDocument10 pagesSorting Algorithms in Fortran: Dr. Ugur GUVENDHWANIT MISENo ratings yet

- 2019q123.ev3-Descon Engro Level Gauges-QDocument7 pages2019q123.ev3-Descon Engro Level Gauges-Qengr_umer_01No ratings yet

- FL Switch 2000Document124 pagesFL Switch 2000marcosNo ratings yet

- CV Old NicDocument4 pagesCV Old NicTensonNo ratings yet

- Mech VibrationDocument14 pagesMech VibrationSquakx BescilNo ratings yet

- Helical Coil FlowDocument4 pagesHelical Coil FlowAshish VermaNo ratings yet

- Auburn Bsci ThesisDocument5 pagesAuburn Bsci Thesisafksaplhfowdff100% (1)

- AC AMMETER / Moving Iron: Model AECDocument33 pagesAC AMMETER / Moving Iron: Model AECRoonar Aponte NoaNo ratings yet

- Sample Engagement LetterDocument5 pagesSample Engagement Letterprincess_camarilloNo ratings yet

- Subsea Pipeline Job DescriptionDocument2 pagesSubsea Pipeline Job DescriptionVijay_DamamNo ratings yet

- VDRL - Press. GaugesDocument9 pagesVDRL - Press. GaugesSourav RayNo ratings yet

- Classical School of Thought: Ms. Salma ShaheenDocument62 pagesClassical School of Thought: Ms. Salma ShaheenQasim Ali100% (1)

- Selux Installation Manual PDFDocument75 pagesSelux Installation Manual PDFIgorr75% (8)

- Lecture 5: Triangulation Adjustment Triangulation: in This Lecture We Focus On The Second MethodDocument5 pagesLecture 5: Triangulation Adjustment Triangulation: in This Lecture We Focus On The Second MethodXogr BargarayNo ratings yet

- Molecules of Life PDFDocument113 pagesMolecules of Life PDFArpit Pradhan100% (1)

- Perfect Picture SummaryDocument3 pagesPerfect Picture SummaryReiaNo ratings yet

- Autodesk Design Review: About DWF and DWFXDocument7 pagesAutodesk Design Review: About DWF and DWFXNesreNo ratings yet

- Epidemiological Triad of HIV/AIDS: AgentDocument8 pagesEpidemiological Triad of HIV/AIDS: AgentRakib HossainNo ratings yet

- DTS Nozzles R3Document2 pagesDTS Nozzles R3meilia teknikNo ratings yet

- Electric Valve Actuator Type Car: For 2 & 3-Way Valves Type G/L/M/S 2Fm-T & G/L/M/S 3Fm-T Page 1 of 4 0-4.11.08-HDocument4 pagesElectric Valve Actuator Type Car: For 2 & 3-Way Valves Type G/L/M/S 2Fm-T & G/L/M/S 3Fm-T Page 1 of 4 0-4.11.08-HMuhd Khir RazaniNo ratings yet

- Department of Labor: BC Retaining Wall CodeDocument2 pagesDepartment of Labor: BC Retaining Wall CodeUSA_DepartmentOfLaborNo ratings yet

- Exam C - HANATEC142: SAP Certified Technology Associate - SAP HANA (Edition 2014)Document10 pagesExam C - HANATEC142: SAP Certified Technology Associate - SAP HANA (Edition 2014)SadishNo ratings yet

- (Essential Skills For Nurses Series) Philippa Sully - Joan Dallas-Essential Communication Skills For Nursing and Midwifery-Mosby - Elsevier (2010) PDFDocument250 pages(Essential Skills For Nurses Series) Philippa Sully - Joan Dallas-Essential Communication Skills For Nursing and Midwifery-Mosby - Elsevier (2010) PDFRetno SumaraNo ratings yet

- January 11, 2019 Grade 1Document3 pagesJanuary 11, 2019 Grade 1Eda Concepcion PalenNo ratings yet

- Theben Timer SUL 181DDocument2 pagesTheben Timer SUL 181DFerdiNo ratings yet

- Braun MR30 Hand BlenderDocument2 pagesBraun MR30 Hand BlenderHana Bernard100% (1)

- Calculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementDocument52 pagesCalculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementNavice Kie100% (1)

- 1.6 FSI Inlet Manifold Removal Guide - Audi A2 Owners' ClubDocument3 pages1.6 FSI Inlet Manifold Removal Guide - Audi A2 Owners' Clubdusan jovanovicNo ratings yet

- What On Earth Is A MainframeDocument132 pagesWhat On Earth Is A MainframeCarlos DantasNo ratings yet