Professional Documents

Culture Documents

Loctite 406 OLD en

Uploaded by

Joseph BernardOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Loctite 406 OLD en

Uploaded by

Joseph BernardCopyright:

Available Formats

Technical Data Sheet

LOCTITE 406 (OLD)

November-2010

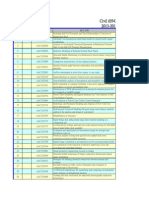

TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity @ 25 C

Viscosity, Cone & Plate, mPas (cP):

Temperature: 25 C, Shear Rate: 3,000 s-1

Viscosity, Brookfield - LVF, 25 C, mPas (cP):

Spindle 1, speed 30 rpm

Flash Point - See MSDS

1.05

12 to 22LMS

100

%

60

75

50

20%

RH

25

0

10

20

30

40

Cure Time, seconds

50

60

15 to 25

TYPICAL CURING PERFORMANCE

Under normal conditions, the atmospheric moisture initiates the

curing process. Although full functional strength is developed

in a relatively short time, curing continues for at least 24 hours

before full chemical/solvent resistance is developed.

Cure Speed vs. Substrate

The rate of cure will depend on the substrate used. The table

below shows the fixture time achieved on different materials

at 22 C / 50 % relative humidity. This is defined as the time to

develop a shear strength of 0.1 N/mm.

Fixture Time, seconds:

Steel (degreased)

Aluminum (etched)

Zinc dichromate

Neoprene

Rubber, nitrile

Cure Speed vs. Humidity

The rate of cure will depend on the ambient relative humidity.

The following graph shows the tensile strength developed with

time on Buna N rubber at different levels of humidity.

RH

Commercial Item Description A-A-3097:

LOCTITE 406 (OLD) has been qualified to Commercial

Item Description A-A-3097. Note: This is a regional approval.

Please contact your local Technical Service Center for more

information and clarification.

Cure Speed vs. Bond Gap

The rate of cure will depend on the bondline gap. Thin bond

lines result in high cure speeds, increasing the bond gap will

decrease the rate of cure.

LOCTITE 406 (OLD) is designed for bonding of plastics and

elastomeric materials where very fast fixturing is required.

2 to 10

2 to 10

15 to 50

5 to 15

40

This Technical Data Sheet is valid for LOCTITE 406

(OLD) manufactured prior to the dates outlined in the

"Manufacturing Date Reference" section.

ABS

PVC

Polycarbonate

Phenolic

% Full Cured Strength @ 22 C

PRODUCT DESCRIPTION

LOCTITE 406 (OLD) provides the following product

characteristics:

Technology

Cyanoacrylate

Chemical Type

Ethyl cyanoacrylate

Appearance (uncured) Transparent, colorless to straw

colored liquidLMS

Components

One part - requires no mixing

Viscosity

Low

Cure

Humidity

Application

Bonding

Key Substrates

Plastics and Rubbers

10 to 20

2 to 10

30 to 90

<5

<5

Cure Speed vs. Activator

Where cure speed is unacceptably long due to large gaps,

applying activator to the surface will improve cure speed.

However, this can reduce ultimate strength of the bond and

therefore testing is recommended to confirm effect.

TDS LOCTITE 406 (OLD), November-2010

TYPICAL PROPERTIES OF CURED MATERIAL

Hot Strength

Tested at temperature

100

0.1

120

Electrical Properties:

Dielectric Constant / Dissipation Factor, IEC 60250:

0.1-kHz

2.65 / <0.02

1-kHz

2.75 / <0.02

10-kHz

2.75 / <0.02

Volume Resistivity, IEC 60093, cm

101015

Surface Resistivity, IEC 60093,

101015

Dielectric Breakdown Strength,

25

IEC 60243-1, kV/mm

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

After 24 hours @ 22 C

Lap Shear Strength, ISO 4587:

Steel (grit blasted)

Aluminum (etched)

Zinc dichromate

ABS

PVC

Polycarbonate

Phenolic

Neoprene

Nitrile

Tensile Strength, ISO 6922:

Steel (grit blasted)

Buna-N

After 10 seconds @ 22 C

Tensile Strength, ISO 6922:

Buna-N

N/mm

(psi)

N/mm

(psi)

N/mm

(psi)

N/mm

(psi)

N/mm

(psi)

N/mm

(psi)

N/mm

(psi)

N/mm

(psi)

N/mm

(psi)

N/mm

(psi)

N/mm

(psi)

18 to 26

(2,610 to 3,770)

11 to 19

(1,595 to 2,755)

6 to 14

(870 to 2,030)

4 to 6

(580 to 870)

4 to 6

(580 to 870)

3.5 to 4.5

(510 to 650)

5 to 15

(725 to 2,175)

5 to 15

(725 to 2,175)

5 to 15

(725 to 2,175)

12 to 25

(1,740 to 3,625)

5 to 15

(725 to 2,175)

N/mm 6.9LMS

(psi)

(1,000)

TYPICAL ENVIRONMENTAL RESISTANCE

Cured for 1 week @ 22 C

Lap Shear Strength, ISO 4587:

Mild Steel (grit blasted)

Henkel Americas

+860.571.5100

% Strength @ 22 C

8010-6

75

50

25

0

50

100

150

Temperature, C

Heat Aging

Aged at temperature indicated and tested @ 22 C

% Initial Strength @ 22 C

After 24 hours @ 22 C

Physical Properties:

Coefficient of Thermal Expansion,

ISO 11359-2, K-1

Coefficient of Thermal Conductivity, ISO 8302,

W/(mK)

Glass Transition Temperature, ASTM E 228, C

125

60C

100

80 C

75

50

100 C

25

0

1000

2000

3000

Exposure Time, hours

4000

5000

Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 22 C.

% of initial strength

Environment

100 h

500 h

Motor oil (MIL-L-46152)

40

100

100

1000 h

95

Gasoline

22

100

100

100

Water/glycol 50/50

22

100

100

100

Ethanol

22

100

100

100

Isopropanol

22

100

100

100

Freon TA

22

100

100

100

Heat/humidity 95% RH

40

80

75

65

Heat/humidity 95% RH

on polycarbonate

40

100

100

100

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials.

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Directions for use:

1. For best performance bond surfaces should be clean and

free from grease.

2. This product performs best in thin bond gaps (0.05 mm).

3. Excess adhesive can be dissolved with Loctite cleanup

solvents, nitromethane or acetone.

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE 406 (OLD), November-2010

Loctite Material SpecificationLMS

LMS dated May-16, 2003. Test reports for each batch are

available for the indicated properties. LMS test reports include

selected QC test parameters considered appropriate to

specifications for customer use. Additionally, comprehensive

controls are in place to assure product quality and

consistency. Special customer specification requirements may

be coordinated through Henkel Quality.

Storage

Store product in the unopened container in a dry location.

Storage information may be indicated on the product container

labeling.

Optimal Storage: 2 C to 8 C. Storage below 2 C or

greater than 8 C can adversely affect product properties.

Material removed from containers may be contaminated during

use. Do not return product to the original container. Henkel

Corporation cannot assume responsibility for product which

has been contaminated or stored under conditions other than

those previously indicated. If additional information is required,

please contact your local Technical Service Center or

Customer Service Representative.

Conversions

(C x 1.8) + 32 = F

kV/mm x 25.4 = V/mil

mm / 25.4 = inches

m / 25.4 = mil

N x 0.225 = lb

N/mm x 5.71 = lb/in

N/mm x 145 = psi

MPa x 145 = psi

Nm x 8.851 = lbin

Nm x 0.738 = lbft

Nmm x 0.142 = ozin

mPas = cP

Note

The data contained herein are furnished for information only

and are believed to be reliable. We cannot assume

responsibility for the results obtained by others over whose

methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production

methods mentioned herein and to adopt such precautions as

may be advisable for the protection of property and of persons

against any hazards that may be involved in the handling and

use thereof. In light of the foregoing, Henkel Corporation

specifically disclaims all warranties expressed or implied,

including warranties of merchantability or fitness for a

particular purpose, arising from sale or use of Henkel

Corporations products. Henkel Corporation specifically

disclaims any liability for consequential or incidental

damages of any kind, including lost profits. The discussion

herein of various processes or compositions is not to be

interpreted as representation that they are free from

domination of patents owned by others or as a license under

any Henkel Corporation patents that may cover such

processes or compositions. We recommend that each

prospective user test his proposed application before repetitive

use, using this data as a guide. This product may be covered

by one or more United States or foreign patents or patent

applications.

Trademark usage

Except as otherwise noted, all trademarks in this document

are trademarks of Henkel Corporation in the U.S. and

elsewhere. denotes a trademark registered in the U.S.

Patent and Trademark Office.

Reference 1.3

Manufacturing Date Reference

This Technical Data Sheet is valid for LOCTITE 406 (OLD)

manufactured prior to the dates below:

Made in:

EU

China

India

U.S.A.

Last manufacturing date:

October 2011

Pending

Pending

Pending

Henkel Americas

+860.571.5100

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Plywood Shear Wall DesignDocument7 pagesPlywood Shear Wall DesignmlamourNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Solidworks Simulation WeldsDocument38 pagesSolidworks Simulation Weldsfiuto_rights_1404802100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- A.W.Skempton - (1951) - The Bearing Capacity of ClaysDocument13 pagesA.W.Skempton - (1951) - The Bearing Capacity of ClaysAnonymous PibYPgh100% (3)

- Norma ASTM E606Document16 pagesNorma ASTM E606Karina Gnzalz100% (1)

- Comparing Bond Strength of Steel Reinforcing Bars To Concrete Using Beam-End SpecimensDocument4 pagesComparing Bond Strength of Steel Reinforcing Bars To Concrete Using Beam-End SpecimensSofía Córdoba Sáenz100% (1)

- DFI-ADSC Micropile Guide SpecDocument39 pagesDFI-ADSC Micropile Guide Specpk100% (2)

- Flat Slab Formwork Falsework1Document80 pagesFlat Slab Formwork Falsework1Amin ZuraiqiNo ratings yet

- Atc 24 PDFDocument58 pagesAtc 24 PDFNavid100% (4)

- Bs 7910 SummaryDocument11 pagesBs 7910 Summaryluchogilmour100% (1)

- 2n2222 DatasheetDocument9 pages2n2222 DatasheetHoàng Quốc HuyNo ratings yet

- Bill of Materials for Low-Cost Accelerometer Evaluation BoardDocument1 pageBill of Materials for Low-Cost Accelerometer Evaluation BoardJoseph BernardNo ratings yet

- DSDocument4 pagesDSsamirbergonziNo ratings yet

- Riva-128 Datasheet PDFDocument77 pagesRiva-128 Datasheet PDFAdrian EGNo ratings yet

- Bill of Materials For LM4849-MH Demo Board: Assembly NotesDocument1 pageBill of Materials For LM4849-MH Demo Board: Assembly NotesJoseph BernardNo ratings yet

- 5-Terminal, Multi-Function, Full-Mold, Low Dropout Voltage Dropper TypeDocument6 pages5-Terminal, Multi-Function, Full-Mold, Low Dropout Voltage Dropper TypeJoseph BernardNo ratings yet

- Tps 54340Document44 pagesTps 54340Joseph Bernard100% (1)

- Bill of Materials For LM4849-MH Demo Board: Assembly NotesDocument1 pageBill of Materials For LM4849-MH Demo Board: Assembly NotesJoseph BernardNo ratings yet

- Bill of Materials for Low-Cost Accelerometer Evaluation BoardDocument1 pageBill of Materials for Low-Cost Accelerometer Evaluation BoardJoseph BernardNo ratings yet

- Semiconductor 2N3904U: Technical DataDocument5 pagesSemiconductor 2N3904U: Technical DataJoseph BernardNo ratings yet

- 3Document25 pages3Joseph BernardNo ratings yet

- 4Document20 pages4Joseph BernardNo ratings yet

- Application Note: Interfacing The X24C44/45 Novrams To The Motorola 6803 MicrocontrollerDocument6 pagesApplication Note: Interfacing The X24C44/45 Novrams To The Motorola 6803 Microcontrollerconti51No ratings yet

- Silicon Zener Diodes: V: 43 - 200 Volts P: 0.5 WattDocument2 pagesSilicon Zener Diodes: V: 43 - 200 Volts P: 0.5 WattJoseph BernardNo ratings yet

- 1 5ke10aDocument7 pages1 5ke10aJoseph BernardNo ratings yet

- 85508Document4 pages85508Joseph BernardNo ratings yet

- Silicon Tuning Diodes: V I T TDocument4 pagesSilicon Tuning Diodes: V I T TJoseph BernardNo ratings yet

- BZX100ADocument11 pagesBZX100AJoseph BernardNo ratings yet

- IR25XB..H 25.0 Amps Single Phase Full Wave Bridge RectifierDocument5 pagesIR25XB..H 25.0 Amps Single Phase Full Wave Bridge RectifierJoseph BernardNo ratings yet

- 1mbi400nb 120Document9 pages1mbi400nb 120Joseph BernardNo ratings yet

- General Purpose Single Operational Amplifier: DescriptionDocument10 pagesGeneral Purpose Single Operational Amplifier: DescriptionJoseph BernardNo ratings yet

- Data SheetDocument59 pagesData SheetJoseph BernardNo ratings yet

- DSDocument4 pagesDSsamirbergonziNo ratings yet

- High-Energy Triggered Spark Gaps Triggergaps: Description DescriptionDocument4 pagesHigh-Energy Triggered Spark Gaps Triggergaps: Description DescriptionJoseph BernardNo ratings yet

- 2Document2 pages2Joseph BernardNo ratings yet

- 1N100 To 1N276Document79 pages1N100 To 1N276Luis de la CruzNo ratings yet

- DSDocument4 pagesDSsamirbergonziNo ratings yet

- Tas 5721Document72 pagesTas 5721Joseph BernardNo ratings yet

- Z043B - Z0200B: Silicon Zener DiodesDocument2 pagesZ043B - Z0200B: Silicon Zener DiodesJoseph BernardNo ratings yet

- Check Fatigue Failure of Material with 1034 MPa UTSDocument7 pagesCheck Fatigue Failure of Material with 1034 MPa UTSprakush01975225403No ratings yet

- Which Drill Pipe Is The Less Resistant To Buckling Steel, Aluminum or Titanium Drill PipeDocument11 pagesWhich Drill Pipe Is The Less Resistant To Buckling Steel, Aluminum or Titanium Drill PipeMejbahul SarkerNo ratings yet

- Thermoplastics at Work: Comprehensive Review of Municipal PVC Pipe ProductsDocument6 pagesThermoplastics at Work: Comprehensive Review of Municipal PVC Pipe Productsvmi_dudeNo ratings yet

- JOPE Maciej Witek PublishedDocument11 pagesJOPE Maciej Witek PublishedVinh Do ThanhNo ratings yet

- Engineering-Civil (0543)Document48 pagesEngineering-Civil (0543)myusuf_engineerNo ratings yet

- Self-Balancing Two-Wheeler Using GyroscopeDocument33 pagesSelf-Balancing Two-Wheeler Using Gyroscopemilan mottaNo ratings yet

- Ce133p 2 WSD NSCP 2015Document2 pagesCe133p 2 WSD NSCP 2015RapNo ratings yet

- CHAPTER SEVEN - HIGHWAY PAVEMENT DESIGN-Part I PDFDocument93 pagesCHAPTER SEVEN - HIGHWAY PAVEMENT DESIGN-Part I PDFAbdullahi omarrNo ratings yet

- Deformacao AxialDocument31 pagesDeformacao AxialANTONIONo ratings yet

- Welded ConnectionsDocument34 pagesWelded ConnectionsMoonzeNo ratings yet

- Aslan GFRP Product Data SheetDocument12 pagesAslan GFRP Product Data SheetYanny JimNo ratings yet

- 6 PDFDocument8 pages6 PDFmegaNo ratings yet

- B 103 - B 103M - 98 - Qjewmy9cmtaztqDocument6 pagesB 103 - B 103M - 98 - Qjewmy9cmtaztqPRASANTH PRASANTHNo ratings yet

- Derivation of Flexure FormulaDocument26 pagesDerivation of Flexure FormulaKashif TaRarNo ratings yet

- ME Mech. Design Engineering 2017Document46 pagesME Mech. Design Engineering 2017Sagar SawantNo ratings yet

- Relationship Among Seam Strength, Weft-Way Fabric Strength and Stitch Density of B. Twill Jute BagDocument5 pagesRelationship Among Seam Strength, Weft-Way Fabric Strength and Stitch Density of B. Twill Jute Bagbook1999No ratings yet

- Dislocations and Strengthening Mechanisms: 7 - 1 I N T R o D U C T I o NDocument16 pagesDislocations and Strengthening Mechanisms: 7 - 1 I N T R o D U C T I o NstevangracianoNo ratings yet

- Engineering Structures: Edmond K.C. Tang, Hong HaoDocument13 pagesEngineering Structures: Edmond K.C. Tang, Hong HaoFouad KehilaNo ratings yet

- HDPE Double Side TextureDocument1 pageHDPE Double Side TextureArun Chandra BabuNo ratings yet

- Design Principles: Crane Sheave BasicDocument6 pagesDesign Principles: Crane Sheave BasicUsman GhaniNo ratings yet