Professional Documents

Culture Documents

Inspect

Uploaded by

HaleemUrRashidBangashCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspect

Uploaded by

HaleemUrRashidBangashCopyright:

Available Formats

A Health and Safety Guideline for Your Workplace

How to Conduct

Workplace Inspections

What is a Workplace Inspection?

A workplace inspection is a planned walkthrough of a workplace or selected areas or

locations of a workplace. Inspections are needed

to critically examine all factors (equipment,

processes, materials, buildings, procedures) that

have the potential to cause injury or illness, and

to identify where action is necessary to control

hazards. A schedule of planned inspections is an

essential element of a health and safety program

in which standards are established and

compliance monitored.

Who should Conduct

Inspections?

Ontarios Occupational Health and Safety Act

places responsibility on a worker health and safety

representative to conduct an inspection of physical

conditions. However, the employer still has the

prime responsibility for providing a healthy and

safe workplace. The implementation of effective

and regular inspections is one way in which an

employers general legal duties may be met.

However, a joint inspection, consisting of both

management and worker representatives, would

be in keeping with the participative approach of

the Act.

How often should Inspections

be Conducted?

The worker health and safety representative

must inspect the workplace at least once a month.

However, if this is not practical, he or she shall

inspect the physical condition of the workplace

at least once a year, inspecting at least a part of it

every month. The inspection must be conducted

according to a schedule set by the joint health

and safety committee or, in smaller workplaces

of 6 to 19 employees, by the employer and health

and safety representative. In drawing up the

schedule, consider:

the number of different processes or

operations;

hazardous equipment that must be inspected at

set intervals and, in some cases, as determined

by legislation (for example, cranes and slings);

processes with high hazard potential that may

require separate and more frequent inspections;

the number of shifts inspections should not

be confined only to one particular shift because

the nature of the activity may vary from one

shift to another;

special inspections whenever a new process

or piece of machinery is introduced into

the workplace.

Industrial Accident Prevention Association 2007. All rights reserved.

Preparing for the Inspection

Recording Observation

The success of workplace inspections depends on

having the necessary information. There should

also be an overall system of management controls

which is flexible enough to allow for changes to be

made, for example in equipment or work practices,

when needed.

It is necessary to review all the information

collected and rank each issue in terms of its

importance. All identified hazards should be

classified A, B, or C, as follows:

Class A Hazard

A condition or practice likely to cause

permanent disability, loss of life or body part,

and/or extensive loss of structure, equipment or

material. For example, an unguarded saw.

Class B Hazard

A condition or practice likely to cause serious

injury or illness, resulting in temporary

disability or property damage that is disruptive

but not extensive. For example, spilled oil on

the main aisle.

Class C Hazard

A condition or practice likely to cause minor,

non-disabling injury or illness, or nondisruptive property damage. For example,

handling solvents without using proper

protective gloves.

To properly identify hazards, the person or

persons conduction the inspection should have the

necessary training, which should include:

the plant layout a floor plan is helpful

in preparing for the inspection, and

recording findings;

the potential hazards associated with the

various machinery, equipment, materials,

and processes;

existing controls, applicable standards

and regulations;

how to use the information from:

Ministry of Labour inspection

reports/orders;

results of previous inspections;

accident data;

maintenance reports.

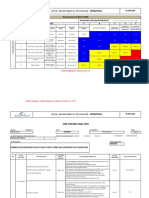

Conducting the Inspection

To ensure that all items are covered during the

inspection, it is useful to develop checklists

which contain reference, in point form, to all

potential hazards. These checklists should never

be considered as permanent lists. They should be

reviewed and added to or revised as necessary

for example, when machinery or processes are

changed or when accident experience reveals

previously unsuspected hazards. Figure 1 is a

sample checklist for hazardous materials. In

addition to Hazardous Materials, the checklist

should include references to the hazards of

Equipment and Machinery (tools, machinery and

guarding, materials handling equipment) and

Physical Factors (floors, exits, lighting, work

station layout, task design, noise).

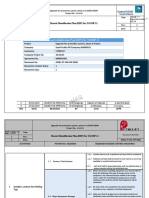

Although the law does not specify an official

reporting form, a good form is valuable in ensuring

that management, and others responsible for follow

up, are made aware of problems. Such a form

can also serve as a valuable reference for spot

inspections and periodic checks by the supervisor,

as well as for review by the joint health and safety

committee. The sample Workplace Inspection

Recording Form in Figure 2 is available on our

website: www.iapa.ca. It allows for recording

observations made during the inspection, as well

as for noting recommendations and subsequent

corrective actions.

How to Conduct Workplace Inspections

Industrial Accident Prevention Association 2007. All rights reserved.

Review/Follow Up

Resource Materials

After each inspection, it is important that the

information obtained is given careful consideration

and, where indicated, corrective action taken. The

results of inspections are indicators of the success

or failure of management policies and practices

and should be examined for possible changes.

Although all identified hazards should ultimately

be eliminated or minimized, the responsible

supervisor or manager must be informed of hazards

posing an immediate danger so that corrective

action can be taken quickly.

Occupational Health and Safety Act and

Regulations for Industrial Establishments

LPMA0010201

Joint Health & Safety Committee Kit

LPKA0090309

Inspecting Physical Conditions: Guidelines for

Setting Standards LPBA0140410

Joint Health & Safety Committees (one day

training program)

The information obtained from regular inspections

should also be reviewed carefully to identify

trends and to help monitor the effectiveness of

a companys health and safety program. Over a

period of time, this review will help:

highlight the need for training in certain areas;

provide insight as to why accidents are

occurring in certain areas;

establish priorities for corrective action;

establish or improve safe work practices;

indicate areas, equipment, etc., which may

require more in-depth hazard analysis.

To order IAPA products please call Customer Care

at 1-800-406-IAPA (4272)

How to Conduct Workplace Inspections

Industrial Accident Prevention Association 2007. All rights reserved.

Figure 1

Sample Checklist for Hazardous Materials

Observations/Comments

Identification

Containers labelled to meet legal requirements?

_____________________________

Labels easy to read?

_____________________________

Material safety data sheets (MSDSs) available,

Current and complete?

_____________________________

Preventive Measures Ventilation

Ventilation adequate?

(Evidence of dust, fumes, etc., may be caused by

inadequate or malfunctioning ventilation.)

_____________________________

Handling Procedures and Equipment

Handling procedures adequate and followed?

_____________________________

Industrial hygiene facilities provided? (for

example, locker rooms, showers, laundry

facilities, etc.)

_____________________________

Eating/drinking on job prohibited where

swallowing the material may be a problem?

_____________________________

No Smoking signs posted near flammables/

combustibles?

_____________________________

Leaks and Spills

Evidence of leaks or spills?

_____________________________

Cleaning procedures adequate and followed?

_____________________________

Waste Disposal

Waste disposal procedures adequate and

followed?

_____________________________

Storage

Storage conditions adequate?

_____________________________

Safety containers for flammable liquids?

_____________________________

PPE

Personal protective equipment (PPE) adequate

and used?

Gloves

Respirators

Eye Protection

Footwear

Other

_____________________________

_____________________________

_____________________________

_____________________________

_____________________________

How to Conduct Workplace Inspections

Industrial Accident Prevention Association 2007. All rights reserved.

How to Conduct Workplace Inspections

Industrial Accident Prevention Association 2007. All rights reserved.

HAZARDS

OBSERVED

HAZARD

CLASS

REPEAT ITEM

YES

NO

RECOMMENDED

ACTION

(FOR INFORMATION): ___________________________________

COPIES TO: (FOR ACTION): ______________________________

ITEM (and location of item):

ACTION TAKEN

COMPLETED

AUTHORIZED

SIGNATURE

_____________________

INSPECTED BY: _____________________

BY

WHOM WHEN

DATE OF INSPECTION: ___________________

DEPARTMENTS/AREAS COVERED: ________________________

FOR FOLLOW-UP

TIME OF INSPECTION: ___________________

INSPECTION LOCATION(S): _______________________________

Workplace Inspection Recording Form

Figure 2

INDUSTRIAL ACCIDENT PREVENTION

ASSOCIATION, 2001, 2005, 2006, 2007.

All rights reserved. As part of IAPAs mission to inform and

educate, IAPA permits users to reproduce this material for their

own internal training and educational purposes only. For any

other purpose, including use in conjunction with fee for service

or other commercial activities, no part of this material may be

used, reproduced, stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical, photocopy,

recorded, or otherwise, without the express prior written

permission of the Industrial Accident Prevention Association.

The information contained in this material is provided

voluntarily as a public service. No warranty, guarantee

or representation is made by IAPA as to the correctness,

suitability, fitness, or sufficiency of any information contained

in this material. Use of this material means that the user agrees

that IAPA and its employees will not have and are released

from any liability whatsoever, however caused or arising, in

connection therewith. Users also acknowledge that it cannot

be assumed that all acceptable safety measures are contained

in this material or that additional measures may not be required

in the conditions or circumstances that are applicable to the

user or his/her organization, and that the user will personally

make his/her own assessment of the information contained in

this material.

While IAPA does not undertake to provide a revision service

or guarantee accuracy, we shall be pleased to respond to your

individual requests for information.

Revised: May 2007

Industrial Accident Prevention Association

Toll-free: 1-800-406-IAPA (4272)

Website: www.iapa.ca

How to Conduct Workplace Inspections

You might also like

- Audit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19From EverandAudit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19No ratings yet

- 00 - Petrobel IMS Overview FinalDocument52 pages00 - Petrobel IMS Overview FinalAhmed El AmraniNo ratings yet

- Health and Safety Procedure - Hazard Identification Risk Assessment and ControlDocument6 pagesHealth and Safety Procedure - Hazard Identification Risk Assessment and ControlMohamad Zakwan Zach ZakariaNo ratings yet

- Health and Safety Management Manual With Procedures ExampleDocument13 pagesHealth and Safety Management Manual With Procedures ExampleVepxvia NadiradzeNo ratings yet

- CPWD Maintenance Manual 2019Document81 pagesCPWD Maintenance Manual 2019pawan2scribdNo ratings yet

- HS329Document10 pagesHS329chahiNo ratings yet

- Regulatory Risk AnalysisDocument2 pagesRegulatory Risk AnalysisArmand LiviuNo ratings yet

- EMS APG Risks and OpportunitiesDocument3 pagesEMS APG Risks and Opportunitiesdio39saiNo ratings yet

- Lead Exposure Control PlanDocument3 pagesLead Exposure Control PlanShahzeb HassanNo ratings yet

- Centre of Maritime Excellence SDN BHD: (Company No. 402703-T)Document1 pageCentre of Maritime Excellence SDN BHD: (Company No. 402703-T)Syafiq SudinNo ratings yet

- Al Majal QMS - 2018Document19 pagesAl Majal QMS - 2018Adam DeviatteyNo ratings yet

- BP Code of Conduct EnglishDocument28 pagesBP Code of Conduct EnglishAhmed El batalNo ratings yet

- Explosion in Paint Spraying BoothDocument4 pagesExplosion in Paint Spraying BoothAyman HassanNo ratings yet

- Safety Audit PDFDocument11 pagesSafety Audit PDFaqibNo ratings yet

- Ppe ChecklistDocument1 pagePpe ChecklistIvan BaraćNo ratings yet

- Waste-Management Program Audit ChecklistDocument1 pageWaste-Management Program Audit Checklistbionana0% (1)

- Environmental Conservation Rules, 1997 (ECR'97)Document2 pagesEnvironmental Conservation Rules, 1997 (ECR'97)নরকেররাজপুত্রNo ratings yet

- ISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFDocument5 pagesISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFpurva02No ratings yet

- Incident / Injury Occurrence Report Part BDocument2 pagesIncident / Injury Occurrence Report Part BHamzaNoumanNo ratings yet

- Demobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaDocument10 pagesDemobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaNasrullahNo ratings yet

- Siemens' Motor HandbookDocument20 pagesSiemens' Motor HandbookJerome BaesNo ratings yet

- RISK Mba 17Document22 pagesRISK Mba 17Cecily Sandra100% (1)

- Management Review SystemDocument4 pagesManagement Review SystemDwitikrushna Rout100% (1)

- Safety ProgramDocument21 pagesSafety ProgramSits RdddNo ratings yet

- Draft Report For Public Comment - Chevron Richmond Refinery FireDocument68 pagesDraft Report For Public Comment - Chevron Richmond Refinery Firekanakarao1100% (1)

- Food Poisoning Investigation Form Version 3 - 0 - 0Document10 pagesFood Poisoning Investigation Form Version 3 - 0 - 0shahanaa AR100% (1)

- Equipment Inspection ChecklistDocument4 pagesEquipment Inspection ChecklistBharathi SilambarasanNo ratings yet

- Final COP-Section 1Document86 pagesFinal COP-Section 1Arbaz KhanNo ratings yet

- Frequently Asked Questions About The Life-Saving RulesDocument6 pagesFrequently Asked Questions About The Life-Saving RulesTFattahNo ratings yet

- Iso 14001 English PDFDocument5 pagesIso 14001 English PDFkemalNo ratings yet

- Premobilisation Wheel Loader InspectionDocument1 pagePremobilisation Wheel Loader InspectionArjun Satheesan100% (1)

- Black Spot Contamination in PelletDocument13 pagesBlack Spot Contamination in PelletkhuelvNo ratings yet

- Electronic Open Assessment FAQsDocument2 pagesElectronic Open Assessment FAQsshiyas M.MNo ratings yet

- Controller CVDocument4 pagesController CVtdr184No ratings yet

- Work Health and Safety Regulations 2012 (SA) : A Guide To Chapter 10 - MinesDocument24 pagesWork Health and Safety Regulations 2012 (SA) : A Guide To Chapter 10 - MinestalabiraNo ratings yet

- Guidance On Conducting Environment Audit PDFDocument71 pagesGuidance On Conducting Environment Audit PDFShane RodriguezNo ratings yet

- Round Rock Independent School District: ConstructionDocument6 pagesRound Rock Independent School District: ConstructionLloyd Tongoona BwakuraNo ratings yet

- S-MatrixDocument8 pagesS-MatrixkhktvnNo ratings yet

- HSE - Cirks Construction IncDocument87 pagesHSE - Cirks Construction IncCharlie OriasNo ratings yet

- Health Safety and Environment Policy Corporate About AGLDocument2 pagesHealth Safety and Environment Policy Corporate About AGLShashi Shekhar100% (1)

- TQM Unit 5 - IsO 14000 SystemDocument62 pagesTQM Unit 5 - IsO 14000 SystemBabin DhasNo ratings yet

- LSR Confined Space Toolbox TalkDocument14 pagesLSR Confined Space Toolbox TalkThura Aung100% (1)

- CH 2Document18 pagesCH 2suresh84123No ratings yet

- Welcome To Formulation: Zaher@ntu - Edu.sgDocument29 pagesWelcome To Formulation: Zaher@ntu - Edu.sgWeimingTanNo ratings yet

- ISO 14001 Certification ChecklistDocument4 pagesISO 14001 Certification ChecklistEyob SNo ratings yet

- HSE-P-11 Planned General Inspection Issue 2.1Document5 pagesHSE-P-11 Planned General Inspection Issue 2.1eng20072007No ratings yet

- Environmental Objectives & Targets Ver1407Document8 pagesEnvironmental Objectives & Targets Ver1407Veera RagavanNo ratings yet

- Environmental Management System Caterpillar of Australia Pty LTDDocument33 pagesEnvironmental Management System Caterpillar of Australia Pty LTDaaditya naresh panwarNo ratings yet

- Example Risk Assessment For A Bricklaying Company: Setting The SceneDocument9 pagesExample Risk Assessment For A Bricklaying Company: Setting The SceneSorin TecNo ratings yet

- Plant and Vicinity Checklists PDFDocument2 pagesPlant and Vicinity Checklists PDFmj santosNo ratings yet

- UAE Law No. - 21 - of 2005 Concerning Waste Management in Abu Dhabi Emirate EngDocument9 pagesUAE Law No. - 21 - of 2005 Concerning Waste Management in Abu Dhabi Emirate EngwholenumberNo ratings yet

- Hse Manager Interview Questions and AnswersDocument3 pagesHse Manager Interview Questions and AnswerssureshNo ratings yet

- Resume of Judy HuntDocument3 pagesResume of Judy Huntapi-12295621No ratings yet

- Iso 9001 - 2015 ALISONDocument5 pagesIso 9001 - 2015 ALISONAymane LAKHALNo ratings yet

- OHS BrochureDocument2 pagesOHS Brochureprassna_kamat1573No ratings yet

- Safety Data Sheet: Delo Gold Ultra SAE 15W-40Document6 pagesSafety Data Sheet: Delo Gold Ultra SAE 15W-40Nasta Ina RobayasaNo ratings yet

- 001 Alignment MatrixDocument17 pages001 Alignment MatrixBea Mok100% (1)

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Document1 pageBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashNo ratings yet

- BI 10-02133, March 2020, Safety Statistics ReoportDocument3 pagesBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- BI 10-02133, March 2020, Safety Statistics ReoportDocument3 pagesBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Document1 pageBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashNo ratings yet

- BI 10-02133, March 2020, Safety Statistics ReoportDocument3 pagesBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- BI 10-02133, WEEK 06, Safety Statistics Reoport NDocument1 pageBI 10-02133, WEEK 06, Safety Statistics Reoport NHaleemUrRashidBangash100% (1)

- BI 10-02133, March 23 2020, SAFETY STATISTICSDocument2 pagesBI 10-02133, March 23 2020, SAFETY STATISTICSHaleemUrRashidBangashNo ratings yet

- 01 Safety Statistics by Haleem Ur Rashid, BI 10-02185Document3 pages01 Safety Statistics by Haleem Ur Rashid, BI 10-02185HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 pagesHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 pagesHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNo ratings yet

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Document36 pages5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 pagesHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNo ratings yet

- 20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020Document27 pages20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020HaleemUrRashidBangash100% (2)

- 13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020Document31 pages13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020HaleemUrRashidBangashNo ratings yet

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pages9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDocument31 pagesHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashNo ratings yet

- 13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020Document31 pages13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 pagesHazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNo ratings yet

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Document36 pages5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashNo ratings yet

- 14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020Document31 pages14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020HaleemUrRashidBangash100% (1)

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pages9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pages9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- 11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020Document36 pages11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pages9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Document36 pages5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashNo ratings yet

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Document36 pages4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashNo ratings yet

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Document36 pages4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashNo ratings yet

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Document36 pages4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashNo ratings yet

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pages9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDocument31 pagesHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashNo ratings yet

- PG Medium Voltage Cat2015april LOWRES1Document140 pagesPG Medium Voltage Cat2015april LOWRES1esoares1990No ratings yet

- Problems of Management in The 21st Century, Vol. 6, 2013Document81 pagesProblems of Management in The 21st Century, Vol. 6, 2013Scientia Socialis, Ltd.No ratings yet

- 2 Toni BielicDocument6 pages2 Toni BielicSadullah AvdiuNo ratings yet

- The University of Zambia: Mansa College of EducationDocument6 pagesThe University of Zambia: Mansa College of EducationKapela AjayNo ratings yet

- Tropical Bosiet Tropical Huet and Tropical Foet Revision 3 Amendment 9 Available 1st November 2018Document67 pagesTropical Bosiet Tropical Huet and Tropical Foet Revision 3 Amendment 9 Available 1st November 2018AhmadHambaliNo ratings yet

- 1 DAY OSH MANDATORY REG. FORM (January 22, 2020) PDFDocument2 pages1 DAY OSH MANDATORY REG. FORM (January 22, 2020) PDFpeme baguioNo ratings yet

- Introduction in To Occupational Health and Safety: Jamal HassanDocument37 pagesIntroduction in To Occupational Health and Safety: Jamal HassanFarxiya AbdiNo ratings yet

- ElectricalDocument9 pagesElectricalSamson MbuguaNo ratings yet

- CH - Incentive PlansDocument36 pagesCH - Incentive PlansAashish MittalNo ratings yet

- NEC Document For Recloser ServicesDocument40 pagesNEC Document For Recloser ServiceshbaocrNo ratings yet

- Oisd GDN 192 PDFDocument205 pagesOisd GDN 192 PDFShweta WalawalkarNo ratings yet

- Tle9 q1 Mod4 Required Personal Protective Equipment in Horticultural WorkDocument19 pagesTle9 q1 Mod4 Required Personal Protective Equipment in Horticultural WorkAngelaNo ratings yet

- Learner Assessor BSBWHS521Document58 pagesLearner Assessor BSBWHS521Anzel Anzel0% (1)

- Strategic Management BOAST COMPANYDocument55 pagesStrategic Management BOAST COMPANYPamela Ledesma SusonNo ratings yet

- Internship Diary 2019-2020Document28 pagesInternship Diary 2019-2020Nilotpal RaiNo ratings yet

- MSDS ChemTreat CL4126 PDFDocument9 pagesMSDS ChemTreat CL4126 PDFjawaidchemicalsNo ratings yet

- Presidential Decree No 626Document19 pagesPresidential Decree No 626Adrianne BenignoNo ratings yet

- Emanuel McCray Coronavirus Covid19 Compensation ComplaintDocument102 pagesEmanuel McCray Coronavirus Covid19 Compensation ComplaintEmanuel McCrayNo ratings yet

- Qpeo2 001Document7 pagesQpeo2 001Daniel Cowie0% (1)

- SDS - Pearl Glaze Part BDocument8 pagesSDS - Pearl Glaze Part BIsabelo AbaoNo ratings yet

- Peracetic Acid Fact SheetDocument2 pagesPeracetic Acid Fact SheetJainil PanchalNo ratings yet

- Responses To OSH Issues and Concerns: Learning Module 03Document24 pagesResponses To OSH Issues and Concerns: Learning Module 03Jimwell Arnie Dela CruzNo ratings yet

- Fiji Policy in Ohs in Schools PDFDocument40 pagesFiji Policy in Ohs in Schools PDFDoreenNo ratings yet

- QCF HSC 027 Contribute To Health and Safety in Health and Social CareDocument4 pagesQCF HSC 027 Contribute To Health and Safety in Health and Social CareCONSTANTINE WESSELSNo ratings yet

- Universiti Kuala Lumpur: Malaysian Institute of Chemical & Bioengineering TechnologyDocument4 pagesUniversiti Kuala Lumpur: Malaysian Institute of Chemical & Bioengineering TechnologyAbdul QayyumNo ratings yet

- Safety Data Sheet Blend of Polyalkylene Glycol and AdditivesDocument6 pagesSafety Data Sheet Blend of Polyalkylene Glycol and AdditivesmelvinkuriNo ratings yet

- Engineering Excellence: Technology at It's BestDocument50 pagesEngineering Excellence: Technology at It's BestAhmed Salah KhalifaNo ratings yet

- TR Attractions and Theme Parks NCIIDocument115 pagesTR Attractions and Theme Parks NCIIAljon BalanagNo ratings yet

- Anglais TechniqueDocument3 pagesAnglais TechniqueSã MìNo ratings yet

- Associate Handbook FinalDocument57 pagesAssociate Handbook FinalBrenda KingNo ratings yet

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsFrom EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsRating: 5 out of 5 stars5/5 (1)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneFrom EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneRating: 4.5 out of 5 stars4.5/5 (5)

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)