Professional Documents

Culture Documents

Aalco Metric Tru-Bore

Uploaded by

disasterdazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aalco Metric Tru-Bore

Uploaded by

disasterdazCopyright:

Available Formats

0229 Metric Brochure cover

5/5/04

1:53 pm

Page 3

Technical Publication

No. 001

ISSUE 1. 05.01.04

Metric Tru-Bore* Stainless Steel Tube & Fittings

0229 Metric Brochure cover

12/5/04

4:07 pm

Page 4

Metric Tru-Bore* Stainless Steel Tube & Fittings

*Tru-Bore is a registered trade mark of Outokumpu Stainless Tubular Products. Information supplied by, and reproduced with the permission of Outokumpu Stainless Tubular Products.

Advantages

Range

This ID based system brings many advantages including the following:

light weight

Recyclability

Systems flexibility including

Simple fabrication and erection

ease of alteration

Good mechanical properties

Fast welding times

Good ductility

Low consumables usage

Low maintenance

Attractive appearance

Long service life

Clean/hygienic/high-tec image

Smooth surface with no

Low environmental impact

coatings or linings

Quality

Manufactured by Outokumpu Stainless Tubular Products, one of the

worlds largest manufacturers of all stainless steel products, Metric

Tru-Bore tube and fittings come with the assurance of high quality

plus numerous approvals, including DEFRA.

Size

The size range runs from 8mm to 900mm, with wall thicknesses from

A complete range of fittings including

elbows, tees, reducers, end caps, collars,

backing flanges and clamps is available.

Grades available are:

EN 1.4432 (316L High Molybdenum)

EN 1.4307 (304L)

EN 1.4571 (316 Titanium/316Ti)

Aalco, the UKs largest independent

multi-metals stockholder, offers a

complete range of semi-finished

products in stainless steel, aluminium,

copper, brass, bronze and nickel alloys.

For a copy

of the full Aalco

catalogue please

contact your local

branch as shown

on the back of

this brochure.

The 10,000 item standard stock range is

supported by extensive processing

facilities as well as bespoke items for

Visit our website at:

www.aalco.co.uk

particular industries and individual

1.0mm to 5.0mm. Larger/heavier sizes available on fast-track production. customers.

The information contained herein is based on our present knowledge and experience and is given in good faith. However, no liability will be accepted by the Company in respect of any action taken by any third party in reliance thereon.

As the products detailed herein may be used for a wide variety of purposes and as the Company has no control over their use, the Company specifically excludes all conditions or warranties expressed or implied by statute or otherwise as

to dimensions, properties and/or their fitness for any particular purpose. Any advice given by the Company to any third party is given for that partys assistance only and without any liability on the part of the Company.

Any contract between the Company and a customer will be subject to the Companys Conditions of Sale.

The extent of the Companys liabilities to any customer is clearly set out in those Conditions; a copy of which is available on request.

WEIGHTS

All weights shown in this publication are for guidance only. They are calculated using nominal dimensions and scientifically recognised densities. Please note that in practice, the actual weight can vary significantly from the

theoretical weight due to variations in manufacturing tolerances and compositions.

0229 Metric Brochure text

14/5/04

5:24 pm

Page 1

Stock of Welded Stainless Steel Metric Tube

DN

15

15

20

20

25

25

25

32

32

32

40

40

50

50

50

65

65

65

75

80

80

100

100

125

125

150

150

200

200

250

300

OD

18

20

23

25

28

30

32

35

38

40

43

44.5

51

53

54

68

69

70

78

83

84

103

104

128

129

153

154

203

204

254

304

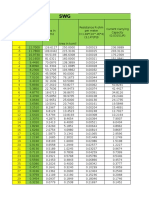

Weight per metre (kg) for given Wall Thickness in mm

1.5mm

2.0mm

0.620

0.695

0.901

0.808

0.883

0.995

1.070

1.402

1.146

1.258

1.371

1.803

1.903

1.559

2.128

1.859

2.454

1.934

2.604

2.498

3.355

3.405

2.870

3.061

4.107

3.812

5.108

4.751

6.360

5.690

7.612

7.568

10.116

12.620

15.214

DN

100

100

150

150

200

200

200

250

250

300

300

300

350

350

400

400

450

500

500

600

600

700

800

900

OD

106

108

156

158

205

206

208

255

256

305

306

308

355

356

406

408

456

506

508

606

608

708

808

910

Weight per metre (kg) for given Wall Thickness in mm

2.5mm

3.0mm

4.0mm

5.0mm

7.737

10.417

11.493

15.425

12.677

15.249

20.433

15.807

19.005

18.937

22.761

30.449

22.067

26.517

30.273

40.465

34.029

37.785

50.481

45.297

60.497

70.508

80.524

113.00

Dimensional Tolerances to SS/EN/ISO 1127

Outside Diameter (Designation D3): + or 0.75% / minimum + or 0.3mm

Outside Diameter for tubes 203mm O/D & above (Designation T2): + or 1.0% / minimum + or 0.5mm

Wall Thickness (Designation T3): + or 10% / minimum + or 0.15mm

Lengths

6 meter random lengths with plain ends

Finish

Grades:

12mm to 18mm: Bright Annealed or Annealed & Pickled (Supplier Option)

20mm to 70mm: Annealed & Pickled

78mm and over: Not Heat Treated, Pickled

EN 1.4432 (316L High Molybdenum) EN 1.4307 (304L) EN 1.4571 (316 Titanium/316Ti)

Note

Tube above DN600 may be supplied with two or more longitudinal welds

0229 Metric Brochure text

14/5/04

5:24 pm

Page 2

Stock of Welded Stainless Steel Metric Elbows in grades 1.4432/1.4307/1.4571

45/90 Elbows Radius D+100

45/90 Elbows Radius 1.5D

Data refers to 90 Bends only.

45 Bends in sizes below DN200

are cut from 90s

DN (D)

25

40

50

65

80

100

100

125

125

150

200

250

300

350

400

450

500

600

700

800

900

OD

30

44.5

54

69

84

104

106

129

131

154

156

204

205

206

254

255

256

304

305

306

355

356

406

456

506

508

606

608

708

710

808

810

910

wall (T)

2

2

2

2

2

2

3

2

3

2

3

2

2.5

3

2

2.5

3

2

2.5

3

2.5

3

3

3

3

4

3

4

4

5

4

5

5

H/R

125

140

150

165

180

200

200

225

225

250

250

300

300

300

350

350

350

400

400

400

450

450

500

550

600

600

700

700

800

800

900

900

1000

Weight kg

0.27

0.46

0.61

0.90

1.16

1.61

2.43

2.25

3.40

2.99

4.51

4.77

5.97

7.19

6.94

8.69

10.45

9.52

11.90

14.30

15.62

18.74

23.78

29.40

35.61

47.57

49.90

66.52

88.60

101.91

113.84

142.47

179.00

90 Elbows Radius 3D

Data refers to 90 Bends only.

45 Bends in sizes below DN200

are cut from 90s

DN (D)

15

20

25

32

40

50

65

80

100

125

150

200

250

300

350

400

450

500

600

OD

18

23

28

35

44.5

54

69

84

86

104

106

129

154

156

204

205

206

254

256

304

306

356

406

408

456

506

508

510

606

608

wall (T)

1.5

1.5

1.5

1.5

2

2

2

2

3

2

3

2

2

3

2

2.5

3

2

3

2

3

3

3

4

3

3

4

5

3

4

H/R

30

35

32.5

45

60

73

95

123

123

150

150

188

225

225

300

300

300

375

375

450

450

525

600

600

675

750

750

750

900

900

Weight kg

0.030

0.050

0.060

0.100

0.220

0.320

0.450

0.770

1.180

1.200

1.820

1.880

2.690

4.060

4.770

5.970

7.190

7.430

11.190

10.710

16.090

22.500

29.040

38.620

36.760

45.400

60.420

75.370

65.420

87.080

DN (D)

80

100

125

150

200

250

300

OD

85

104

105

130

155

205

206

256

306

wall (T)

2.5

2

2.5

2.5

2.5

2.5

3

3

3

H/R

240

300

300

375

450

600

600

750

900

Weight kg

2.00

2.40

3.10

4.80

6.80

12.10

14.50

22.50

32.50

For further information on any

of these products please call

your local branch details on

the back page.

0229 Metric Brochure text

14/5/04

5:24 pm

Page 3

Stock of Welded Stainless Steel Metric Tees in grades 1.4432/1.4307/1.4571

Pressed Equal Tees

Pulled Equal Tees

Pulled Reducing Tees

L=Hx2

DN

15

20

25

32

40

50

65

75

80

100

125

150

200

250

300

350

400

450

500

600

OD (D)

20

25

30

38

44.5

54

69

79

84

104

105

106

129

130

154

155

156

205

206

256

306

356

406

456

508

608

wall (T)

2

2

2

2.5

2

2

2

2

2

2

2.5

3

2

2.5

2

2.5

3

2.5

3

3

3

3

3

3

4

4

H

23

33

38

50

60

73

80

80

80

90

90

90

115

115

135

135

135

175

175

216

254

279

305

343

381

432

R

10.5

15.5

18

24

28

30

27.5

32

30

25

25

25

40

40

40

40

40

57

57

75

80

72

90

100

105

110

Weight kg

0.06

0.11

0.14

0.30

0.35

0.51

0.70

0.75

0.80

1.30

1.80

2.20

2.10

2.80

3.10

4.00

5.00

6.10

8.20

10.00

13.00

18.00

26.00

32.00

44.00

58.00

DN

40

50

65

80

100

125

150

200

250

300

350

400

OD

44

54

69

84

104

129

154

204

254

306

356

406

wall (T)

2

2

2

2

2

2

2

2

2

3

3

3

L*

47.5

57

63.5

85.5

105

124

143

178

216

300

350

400

H*

24

29

38.5

45

55

69

84

110

140

168

195

223

Weight kg

0.20

0.30

0.50

0.60

1.20

1.50

2.10

4.30

5.80

13.40

18.18

22.54

* Approximate

DN1 x DN2

50

25

40

65

40

50

80

40

50

65

100

50

65

80

125

80

100

150

80

100

125

200

100

125

150

250

150

200

300

200

OD1

54

54

69

69

84

84

84

104

104

104

129

129

154

154

154

204

204

204

254

254

306

x OD2

x 28

x 44

x 44

x 54

x 44

x 54

x 69

x 54

x 69

x 84

x 84

x 84

x 84

x 104

x 129

x 104

x 129

x 154

x 154

x 204

x 206

wall (T)

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

L*

57

57

63.5

63.5

85.5

85.5

85.5

105

105

105

124

124

143

143

143

178

178

178

216

216

300

H*

29

29

38

38

45

45

45

55

55

55

69

69

84

84

84

110

110

110

140

140

165

Weight kg

0.30

0.30

0.50

0.50

0.60

0.60

0.60

1.20

1.20

1.20

1.50

1.50

2.10

2.10

2.10

4.30

4.30

4.30

5.80

5.80

13.50

* Approximate

Tru-Bore is a registered trade mark of Outokumpu Stainless

Tubular Products. Information supplied by, and reproduced with the

permission of Outokumpu Stainless Tubular Products.

0229 Metric Brochure text

14/5/04

5:24 pm

Page 4

Stock of Welded Stainless Steel Metric Reducers in grades 1.4432/1.4307/1.4571

Concentric Reducers

DN1

25

30

40

x

x

x

x

50 x

x

65 x

x

80 x

x

x

100 x

x

x

125 x

x

x

150 x

x

x

200 x

x

x

250 x

x

x

300 x

x

x

DN2

20

25

25

25

25

40

40

50

40

50

65

50

65

80

50

80

100

80

100

100

125

100

125

150

125

150

200

200

200

150

150

200

200

250

250

OD1 x OD2

28 x 23

33 x 28

43 x 28

44 x 29

54 x 29

54 x 44

69 x 44

69 x 54

84 x 44

84 x 54

84 x 69

104 x 54

104 x 69

104 x 84

129 x 54

129 x 84

129 x 104

154 x 84

154 x 104

156 x 106

154 x 129

204 x 104

204 x 129

204 x 154

254 x 129

254 x 154

254 x 204

255 x 205

256 x 206

304 x 154

306 x 156

304 x 204

306 x 206

304 x 254

306 x 256

Eccentric Reducers

wall (T)

1.5

1.5

1.5

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

2

2

2

2

2

2

2

2.5

3

2

3

2

3

2

3

Length

15

15

45

45

75

30

75

45

120

90

45

150

105

60

225

135

75

210

150

150

75

300

225

150

375

300

150

150

150

450

450

300

300

150

150

Weight kg

0.01

0.02

0.08

0.07

0.16

0.08

0.16

0.09

0.40

0.30

0.17

0.57

0.44

0.28

1.03

0.75

0.43

1.22

0.98

1.49

0.52

2.28

1.85

1.33

3.55

3.04

1.71

2.14

2.57

5.13

7.70

3.80

5.70

2.09

3.14

DN1 x DN2

350 x 200

x 250

x 300

400 x 200

x 250

x 300

x 350

450 x 300

x 350

x 400

500 x 300

x 350

x 400

x 450

600 x 400

x 450

x 500

OD1 x OD2

356 x 206

356 x 256

356 x 306

406 x 206

406 x 256

406 x 306

406 x 356

456 x 306

456 x 356

456 x 406

506 x 306

506 x 356

506 x 406

506 x 456

606 x 406

606 x 456

606 x 506

wall (T)

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

Length

450

300

150

600

450

300

150

450

300

150

600

450

300

150

600

450

300

Weight kg

9.41

6.84

3.71

13.84

11.10

7.98

4.28

13.02

9.25

4.91

18.80

14.60

10.70

5.50

23.07

18.18

12.67

For the complete range of

Aalco products please contact

your local branch and request

a catalogue details on the

reverse of this brochure.

DN1 x DN2

40

25

50 x 25

x 40

65 x 40

x 50

80 x 40

x 50

x 65

100 x 50

x 65

x 80

125 x 80

x 100

150 x 80

x 100

x 125

200 x 100

x 125

x 150

250 x 150

x 200

300 x 200

200

x 250

250

350 x 250

x 300

400 x 250

x 300

x 350

450 x 400

500 x 400

x 450

600 x 400

x 450

x 500

OD1 x OD2

44 x 29

54 x 29

54 x 44

69 x 44

69 x 54

84 x 44

84 x 54

84 x 69

104 x 54

104 x 69

104 x 84

129 x 84

129 x 104

154 x 84

154 x 104

154 x 129

204 x 104

204 x 129

204 x 154

254 x 154

254 x 204

304 x 204

306 x 206

304 x 254

306 x 256

356 x 256

356 x 306

406 x 256

406 x 306

406 x 356

456 x 406

506 x 406

506 x 456

606 x 406

606 x 456

606 x 506

wall (T)

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

2

3

3

3

3

3

3

3

3

3

3

3

3

Length

45

75

30

75

45

120

90

45

150

105

60

135

75

210

150

75

300

225

150

300

150

300

300

150

150

300

150

450

300

150

150

300

150

600

450

300

Weight kg

0.07

0.16

0.08

0.16

0.09

0.40

0.30

0.17

0.57

0.44

0.28

0.75

0.43

1.22

0.98

0.52

2.28

1.85

1.33

3.04

1.71

3.80

5.70

2.09

3.14

6.84

3.71

11.10

7.98

4.28

4.91

10.70

5.50

23.07

18.18

12.67

0229 Metric Brochure text

14/5/04

5:24 pm

Page 5

Stock of Metric Collars

200

Pressed Collars DWSR (diagonal Weld and Stiffening Rib) in grades

D1

Weight kg

0.04

0.06

0.08

0.11

0.14

0.18

0.25

0.32

0.32

0.33

0.52

0.44

0.69

0.51

0.80

0.56

0.83

D

45

58

68

78

88

102

122

138

138

158

158

188

188

212

212

268

268

150

T1

3

3

3

3

3

3

3

3

3

2.5

4

2.5

4

3

4

2

3

DN

200

250

300

350

400

450

500

600

125

D1 x T x H

20 x 2 x 9

25 x 2 x 10

30 x 2 x 12

38 x 2 x 14

44.5 x 2 x 17

54 x 2 x 18

69 x 2 x 20

79 x 2 x 23

84 x 2 x 24

104 x 2 x 27

106 x 3 x 27

129 x 2 x 27

131 x 3 x 27

154 x 2 x 27

156 x 3 x 27

204 x 2 x 26

206 x 3 x 26

DN

15

20

25

32

40

50

65

75

80

100

Pressed Collars NPR (Not Pressure Rated) in grades 304L & 316L

Pressed Collars grades 1.4432/1.4307/1.4571

D1

206

256

306

356

406

456

506

608

T

3

3

3

3

3

3

3

4

D

260

320

370

430

480

530

580

680

H

25

26

26

26

30

30

30

40

Weight kg

0.80

1.05

1.30

1.61

1.96

2.15

2.46

4.71

Angle Collars in grades 1.4432/1.4307/1.4571

1.4432/1.4307/1.4571

DN

250

300

350

400

450

500

600

D1 x

256 x

306 x

356 x

406 x

456 x

506 x

608 x

T

3

3

3

3

3

3

4

xH

x 31

x 35

x 43

x 43

x 45

x 45

x 45

T1

3

3

3

3

3

3

4

D

320

370

430

482

532

585

685

DR

285

338

387

440

490

542

640

Weight kg

1.2

1.5

2.1

2.4

2.8

3.1

5.0

DN

200

250

300

350

400

450

500

600

700

800

900

D1

208

258

308

358

408

458

508

510

608

610

708

710

808

810

910

D

260

310

360

428

478

530

580

598

682

700

783

800

885

900

1000

Bar size

30 x 30 x 4

30 x 30 x 4

30 x 30 x 4

30 x 30 x 4

40 x 40 x 4

40 x 40 x 4

40 x 40 x 4

50 x 50 x 5

40 x 40 x 4

50 x 50 x 5

40 x 40 x 4

50 x 50 x 5

40 x 40 x 4

50 x 50 x 5

50 x 50 x 5

Weight kg

0.9

1.1

1.4

2.8

3.2

3.5

4.0

6.3

4.8

7.5

5.5

8.6

6.3

9.8

12.0

0229 Metric Brochure text

14/5/04

5:24 pm

Page 6

Stock of Metric Flanges

Mild Steel Backing Flanges (Loose Spinning Type)

Mild steel Zinc Plated and Passivated

with drilling dimensions to BS10 Table D

Reduced Thickness

Mild Steel PPA 571 Coated (Grey) with drilling

dimensions to BS4504 PN16 Reduced Thickness

DN

DN

25

32

40

50

65

80

100

125

150

200

250

300

350

400

450

500

600

Flange OD

D

115

140

150

165

185

200

220

250

285

340

405

460

520

580

640

715

840

Bolt Hole

PCD D1

85

100

110

125

145

160

180

210

240

295

355

410

470

525

585

650

770

No of

Bolt Holes

4

4

4

4

4

8

8

8

8

12

12

12

16

16

20

20

20

Bolt Hole

Dia d

14

18

18

18

18

18

18

18

22

22

26

26

26

30

30

33

36

Flange ID

d1

35

42

50

60

75

90

110

136

161

213

262

313

364

418

470

520

630

Flange

thk H

10

10

10

10

10

10

10

12

12

12

16

19

22

22

25

25

25

Flange Wt

kgs/pc

0.6

1.0

1.2

1.4

1.7

1.7

1.9

3.1

3.8

4.8

8.6

12.3

17.2

19.9

26.3

33.7

43.5

Bolt Hole

Dia d

36

39

39

Flange ID

d1

725

825

925

Flange

thk H

35

42

48

Flange Wt

kgs/pc

59

92

116

Mild steel PPA 571 Coated (Grey) with drilling

dimensions to BS4504 PN16 Reduced Thickness

to Table D

DN

700

800

900

Flange OD

D

900

1025

1125

Bolt Hole

PCD D1

840

950

1050

No of

Bolt Holes

24

24

28

25

32

40

50

65

80

100

125

150

200

Flange OD

D

114.30

120.60

133.30

152.40

165.10

184.10

215.90

254.00

279.40

336.60

Bolt Hole

PCD D1

82.60

87.30

98.40

114.30

127.00

146.00

177.80

209.50

234.90

292.10

No of

Bolt Holes

4

4

4

4

4

4

4

8

8

8

Bolt Hole

Dia d

14

14

14

18

18

18

18

18

18

18

Flange ID

d1

35

42

50

60

75

90

110

136

161

213

Flange

thk H

4.8

6.4

6.4

8

8

10

10

13

13

13

Flange Wt

kgs/pc

0.3

0.5

0.6

0.9

1.0

1.4

1.9

3.4

3.9

5.1

Bolt Hole

Dia d

14

18

18

18

18

18

18

18

22

22

22

22

22

26

26

26

29

Flange ID

d1

35

42

50

60

75

90

110

136

161

213

262

313

364

418

470

520

630

Flange

thk H

10

10

10

10

10

10

10

12

12

12

16

19

22

22

25

28

31

Flange Wt

kgs/pc

0.6

1.0

1.2

1.4

1.7

1.8

1.9

3.1

3.8

4.9

8.0

11.0

15.5

18.1

22.1

25.4

30.0

Mild steel Zinc Plated and Passivated with

drilling dimensions to BS4504 PN10 Reduced

Thickness (Unipipe)

DN

25

32

40

50

65

80

100

125

150

200

250

300

350

400

450

500

600

Flange OD

D

115

140

150

165

185

200

220

250

285

340

395

445

505

565

615

670

780

Bolt Hole

PCD D1

85

100

110

125

145

160

180

210

240

295

350

400

460

515

565

620

725

No of

Bolt Holes

4

4

4

4

4

8

8

8

8

8

12

12

16

16

20

20

20

0229 Metric Brochure text

14/5/04

5:24 pm

Page 7

Stock of Metric Flanges

Epoxy Coated Aluminium Backing Flanges with drilling dimensions

Pressed Stainless Steel

to BS4504 PN16 and thickness to DIN 2642 NP10

Backing Flanges Grade 316

to DIN 2642, PN10/200C

DN

50

65

80

100

125

150

200

250

300

350

400

450

500

600

Flange OD

D

165

185

200

220

250

285

340

405

460

520

580

640

715

840

Bolt Hole

PCD D1

125

145

160

180

210

240

295

355

410

470

525

585

650

770

No of

Bolt Holes

4

4

8

8

8

8

12

12

12

16

16

20

20

20

Bolt Hole

Dia d

18

18

18

18

18

22

22

26

26

26

30

30

33

36

Flange ID

d1

58

73

90

110

135

160

212

262

312

362

413

466

517

620

Flange

thk H

16

16

18

18

18

18

20

22

22

22

25

25

28

30

Flange Wt

kgs/pc

0.73

0.90

1.08

1.23

1.52

1.90

2.71

3.66

4.25

5.23

7.17

7.50

9.62

12.65

DN

15

20

25

32

40

50

65

80

100

125

150

200

250

300

D1

20

25

30

38

44.5

56

69

86

106

131

156

206

256

306

D

95

105

115

140

150

165

185

200

220

250

285

340

395

445

d1

38

48

53

68

77

91

108

123

141

168

192

245

295

345

d2

24

30

34

40

48

58

73

90

110

135

160

212

262

312

D1

65

75

85

100

110

125

145

160

180

210

240

295

350

400

H

11.5

14

16

16.5

17.5

19.5

21

22

23

25

27

31

34

38

T

3

3

3

3

4

4

4

5

6

6

7

8

8

8

No holes

4

4

4

4

4

4

4

8

8

8

8

8

12

12

d

13.5

13.5

13.5

17.5

17.5

17.5

17.5

17.5

17.5

17.5

21.5

21.5

21.5

21.5

kg

0.20

0.26

0.33

0.46

0.66

0.81

0.98

1.36

1.74

2.19

3.28

4.63

6.18

7.45

Pressed Stainless Steel

Blind Flanges Grade 316 to

DIN 2642, PN10/200C

Tru-Bore is a registered trade mark of Outokumpu Stainless

Tubular Products. Information supplied by, and reproduced with the

permission of Outokumpu Stainless Tubular Products.

DN

15

20

25

32

40

50

65

80

100

125

150

200

D

95

105

115

140

150

165

185

200

220

250

285

340

d1

38

48

53

68

77

91

108

123

141

168

192

245

D1

65

75

85

100

110

125

145

160

180

210

240

295

d2

22

28

35

45

54

68

84

98

117

141

169

220

R

25

30

40

50

60

75

80

95

115

170

200

250

H

11.5

14

16

16.5

17.5

19.5

21

22

23

25

27

31

T

3

3

3

3

4

4

4

5

6

6

7

8

No holes

4

4

4

4

4

4

4

8

8

8

8

8

d

13.5

13.5

13.5

17.5

17.5

17.5

17.5

17.5

17.5

17.5

21.5

21.5

kg

0.21

0.27

0.34

0.48

0.70

0.87

1.08

1.55

2.14

2.79

4.25

6.66

0229 Metric Brochure text

14/5/04

5:24 pm

Page 8

Metric Grade EN1.4462/316L Stainless Steel Tube Clamps

DN

15

20

20 -25

25

32

40

50

65

80

100

125

150

200

250

300

350

400

450

500

600

For Tube OD mm

18 - 22

23 - 24

25 - 28

30 - 33

35 - 38

43 - 44.5

53 - 54

68 - 70

82 - 84

102 - 106

127 - 131

152 - 156

202 - 206

252 - 256

302 - 306

353 - 356

404 - 406

454 - 458

504 - 508

606 - 608

B

25

25

25

25

25

30

40

40

40

40

40

40

40

40

50

50

50

50

50

50

C

44

46

52

57

63

69

87

100

131

148

177

198

244

298

369

413

464

515

567

669

T

2

3

3

3

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

Metric Zinc Plated Mild Steel Tube Clips

Bolt Size

M6 x 20

M6 x 20

M6 x 20

M6 x 20

M6 x 20

M6 x 20

M8 x 25

M8 x 25

M8 x 25

M10 x 25

M10 x 25

M10 x 25

M12 x 35

M12 x 50

M16 x 50

M16 x 50

M16 x 50

M16 x 60

M16 x 60

M16 x 65

DN

15

20

25

32

40

50

65

75

80

100

125

150

200

250

300

350

400

450

500

600

Clip dia

18

23

28

35

43

54

68

78

84

104

128

155

204

255

306

358

406

458

508

608

Matl dims

30 x 5

30 x 5

30 x 5

30 x 5

30 x 5

30 x 5

30 x 5

30 x 5

40 x 6

40 x 6

40 x 6

40 x 6

50 x 6

50 x 6

65 x 8

65 x 10

65 x 10

65 x 10

65 x 10

65 x 10

Hole Centre

59

67

68

77

86

97

111

112

124

143

193

212

264

316

382

428

485

550

610

718

O/length

94

98

100

105

116

129

143

158

180

201

235

262

329

390

467

514

570

655

703

806

Bolt dia

35 x 10

35 x 10

35 x 10

35 x 10

35 x 10

35 x 10

35 x 10

35 x 10

40 x 12

40 x 12

40 x 12

40 x 12

50 x 16

50 x 16

65 x 20

70 x 20

70 x 20

70 x 20

70 x 20

70 x 20

Weight kg/pair

0.23

0.26

0.30

0.32

0.36

0.42

0.45

0.50

0.88

0.95

1.15

1.30

2.10

2.50

5.50

7.00

7.80

8.80

9.80

11.40

Stock of Welded Stainless Steel Metric Pressed End Caps in grades 1.4432/1.4307/1.4571

DN

50

80

100

125

150

200

10

OD (D)

54

84

104

129

154

206

Wall (T)

2

2

2

2

2

3

Weight kg

0.1

0.2

0.3

0.4

0.5

1.3

DN

250

300

350

400

450

500

600

OD (D)

256

306

356

406

458

508

608

Wall (T)

3

3

3

3

4

4

4

Weight kg

2.0

3.5

5.6

8.7

14.0

19.0

30.0

T = Wall

0229 Metric Brochure cover

12/5/04

4:06 pm

ABERDEEN

41 Castle Terrace

Aberdeen AB11 5EA

Tel: 01224 596611

Fax: 01224 596622

e-mail: aberdeen@aalco.co.uk

BELFAST

The Belfast Metal Centre

McKinney Industrial Estate

54 Mallusk Road

Newtownabbey BT36 4PX

Tel: 02890 838 838

Fax: 02890 837 837

e-mail: belfast@aalco.co.uk

BIRMINGHAM

Shelah Road

Halesowen

West Midlands B63 3PH

Tel: 0121 585 3600

Fax: 0121 585 6864

e-mail: birmingham@aalco.co.uk

CHEPSTOW

Avenue West

Newhouse Park Estate

Chepstow

Monmouthshire NP16 6UD

Tel: 01291 638 638

Fax: 01291 638 600

e-mail: chepstow@aalco.co.uk

May 2004

DYFED

Units 3-4

Capel Hendre Industrial Estate

Ammanford

Carmarthenshire SA18 3SJ

Tel: 01269 842044

Fax: 01269 845276

e-mail: dyfed@aalco.co.uk

Page 2

GLASGOW

117 Clydesmill Place

Cambuslang Investment Park

Glasgow G32 8RF

Tel: 0141 646 3200

Fax: 0141 646 3260

e-mail: glasgow@aalco.co.uk

NEWCASTLE

First Avenue

Team Valley Trading Estate

Gateshead

Tyne & Wear NE11 0NU

Tel: 0191 491 1133

Fax: 0191 491 1177

e-mail: newcastle@aalco.co.uk

STOKE

Unit F, Forge Way

Brown Lees Industrial Estate

Biddulph

Stoke-on-Trent ST8 7DN

Tel: 01782 375700

Fax: 01782 375701

e-mail: stoke@aalco.co.uk

HULL

Saxon Way

Priory Park West

Hessle

Hull HU13 9PB

Tel: 01482 626262

Fax: 01482 626263

e-mail: hull@aalco.co.uk

NORWICH

Roundtree Way

Mousehold Lane

Norwich NR7 8SR

Tel: 01603 787878

Fax: 01603 789999

e-mail: norwich@aalco.co.uk

LEEDS

Unit 1, Revie Road

off Elland Road

Leeds LS11 8JG

Tel: 0113 276 3300

Fax: 0113 276 0382

e-mail: leeds@aalco.co.uk

NOTTINGHAM

Harrimans Lane

Dunkirk

Nottingham NG7 2SD

Tel: 0115 988 2600

Fax: 0115 988 2636

e-mail: nottingham@aalco.co.uk

SWANLEY

Units 6 & 7

Pedham Place Industrial Estate

Wested Lane

Swanley

Kent BR8 8TE

Tel: 01322 610900

Fax: 01322 610910

e-mail: swanley@aalco.co.uk

LIVERPOOL

207 Great Howard Street

Liverpool L5 9ZH

Tel: 0151 207 3551

Fax: 0151 207 2657

e-mail: liverpool@aalco.co.uk

SLOUGH

Unit 2, 552 Fairlie Road

Slough Trading Estate

Slough

Berkshire SL1 4PY

Tel: 01753 619900

Fax: 01753 512227

e-mail: slough@aalco.co.uk

MANCHESTER

Express Trading Estate

Stone Hill Road

Farnworth

Bolton BL4 9NN

Tel: 01204 863456

Fax: 01204 863430

e-mail: manchester@aalco.co.uk

SOUTHAMPTON

Test Lane

Nursling

Southampton SO16 9TA

Tel: 02380 875200

Fax: 02380 875275

e-mail: southampton@aalco.co.uk

www.aalco.co.uk

You might also like

- Huck BOM: The Highest Strength Blind Fasteners in The WorldDocument5 pagesHuck BOM: The Highest Strength Blind Fasteners in The WorldEldori1988No ratings yet

- Monolithic Insulating JointsDocument5 pagesMonolithic Insulating JointsTran Thanh TungNo ratings yet

- TYCO Keystone F14.Lined - Butterfly.valve enDocument4 pagesTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuNo ratings yet

- BB BARS AND ACCESSORIES SYSTEMDocument7 pagesBB BARS AND ACCESSORIES SYSTEMKS LeeNo ratings yet

- Outokumpu Stainless Mesh Fabric DatasheetDocument2 pagesOutokumpu Stainless Mesh Fabric DatasheetAriel NemcoNo ratings yet

- 2019 Peerless Industrial Catalog LGIDocument150 pages2019 Peerless Industrial Catalog LGIalan camposNo ratings yet

- PE PipeDocument54 pagesPE PipeMuhammad SalmanNo ratings yet

- Deltabeam EngDocument20 pagesDeltabeam EngAmir OmeraševićNo ratings yet

- IS 2062 Rev 2011Document10 pagesIS 2062 Rev 2011Ganesh LohakareNo ratings yet

- Specification: Ms 136 & Bs 6004 Voltage Rating: 450/750V Conductor: Plain Annealed Copper Wire Insulation: General Purpose PVC CompoundDocument40 pagesSpecification: Ms 136 & Bs 6004 Voltage Rating: 450/750V Conductor: Plain Annealed Copper Wire Insulation: General Purpose PVC CompoundsofyanshahNo ratings yet

- Grid Coupling PDFDocument6 pagesGrid Coupling PDFsgupta_615796100% (1)

- c70 Data Sheet AIREXDocument2 pagesc70 Data Sheet AIREXestecoboatNo ratings yet

- Jubilee Product BrochureDocument36 pagesJubilee Product BrochureAnonymous Wyb8Y1No ratings yet

- Tuberias Schedule 40 Fittings, Unions & SaddlesDocument74 pagesTuberias Schedule 40 Fittings, Unions & SaddlesFelix SanchezNo ratings yet

- Ficha Tecnica TermoencogibleDocument33 pagesFicha Tecnica TermoencogibleNACION001No ratings yet

- Equipo Hot Tap de 42 inDocument5 pagesEquipo Hot Tap de 42 inSerch Villa100% (1)

- Datasheet 10715d24db3da273 0Document1 pageDatasheet 10715d24db3da273 0lucratoruNo ratings yet

- All-Purpose Chain & Fittings Guarante Ed To Make The Right ConnectionDocument8 pagesAll-Purpose Chain & Fittings Guarante Ed To Make The Right ConnectionHong Chee FongNo ratings yet

- Hadley Group Ultrazed and Ultrabeam 63mm System ManualDocument68 pagesHadley Group Ultrazed and Ultrabeam 63mm System ManualTarek-Aziz BihiNo ratings yet

- Bollard GuideDocument8 pagesBollard GuideCtr YlNo ratings yet

- Stepped CouplingDocument10 pagesStepped Couplingdleonar2207No ratings yet

- Sae J51-2004Document11 pagesSae J51-2004khhoseNo ratings yet

- GRP Pipe Catalog PDFDocument9 pagesGRP Pipe Catalog PDFSugumar SNo ratings yet

- Catalogo Huck C50L PDFDocument8 pagesCatalogo Huck C50L PDFVladimir SepulvedaNo ratings yet

- John Crane 502Document6 pagesJohn Crane 502Eh OngNo ratings yet

- Pipes Standars and DimsDocument68 pagesPipes Standars and Dimsmatteo_1234No ratings yet

- Kit Cerramiento de Camisa en DiqueDocument4 pagesKit Cerramiento de Camisa en Diqueheldermanuel100No ratings yet

- SWG & MM ConversionDocument70 pagesSWG & MM Conversionshalu2980% (10)

- HDP-Victaulic Estilo 995Document4 pagesHDP-Victaulic Estilo 995hugorubenzNo ratings yet

- Standard Sieves and Mesh SizesDocument4 pagesStandard Sieves and Mesh SizesAbdul HamidNo ratings yet

- WIT-PE 500 Design Manual RBDocument24 pagesWIT-PE 500 Design Manual RBMadusha TisseraNo ratings yet

- Tooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool CompanyDocument4 pagesTooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool Companyjavier_mor69No ratings yet

- Z PurlinsDocument27 pagesZ Purlinsmassive85No ratings yet

- AutomotiveDocument32 pagesAutomotiveMos CraciunNo ratings yet

- AV Industrial Products LTD Catalogue Anti Vibration MountsDocument52 pagesAV Industrial Products LTD Catalogue Anti Vibration MountsAV Industrial Products LtdNo ratings yet

- Con BFM Connecting SleevesDocument2 pagesCon BFM Connecting SleevesRhiieeNo ratings yet

- Europa Valve Non Slam Check ValvesDocument16 pagesEuropa Valve Non Slam Check ValvesBryan KellyNo ratings yet

- SKF BRG ClearenceDocument6 pagesSKF BRG ClearenceNath Boyapati100% (2)

- 8 t2 SC SeriesDocument16 pages8 t2 SC SeriesAntony VeNo ratings yet

- CF500 Leighs PaintsDocument8 pagesCF500 Leighs PaintsAlekxNo ratings yet

- Excalibur 8018 C3 MRDocument2 pagesExcalibur 8018 C3 MRaxcess450No ratings yet

- Industrial Enclosures Catalogue Oct 10 Complete - 2Document88 pagesIndustrial Enclosures Catalogue Oct 10 Complete - 2Harsha Jayanath GajanayakaNo ratings yet

- Softline Technical Specification BrochureDocument6 pagesSoftline Technical Specification BrochureChristopherJonesNo ratings yet

- Torque Systems MDM-5000 Product GuideDocument4 pagesTorque Systems MDM-5000 Product GuideElectromateNo ratings yet

- 2010walkway Expanded MetalDocument2 pages2010walkway Expanded MetalthorenNo ratings yet

- Aalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97Document3 pagesAalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97sgupta_192494No ratings yet

- CIR CatalogDocument12 pagesCIR Catalogchaupha1No ratings yet

- Outershield® MC710-H - ENDocument2 pagesOutershield® MC710-H - ENdeepak2803No ratings yet

- Deltabeam Brochure EngDocument20 pagesDeltabeam Brochure EngymitevNo ratings yet

- Jaw Crusher Eng 20141031 PDFDocument12 pagesJaw Crusher Eng 20141031 PDFBkiri AbderrahimNo ratings yet

- Stainless Steel Amari - StocklistDocument64 pagesStainless Steel Amari - Stocklistskenny1No ratings yet

- Hdpe PipeDocument7 pagesHdpe PipeAattakaariNo ratings yet

- C & Zed Purlins Design Manual and Catalogue BC783d01Document31 pagesC & Zed Purlins Design Manual and Catalogue BC783d01GnabBangNo ratings yet

- Pig Sig VDocument8 pagesPig Sig VAsemota OghoghoNo ratings yet

- Trelleborg Bollard GuideDocument9 pagesTrelleborg Bollard Guidenmh43No ratings yet

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 pagesElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkNo ratings yet

- ERIKS - Simrit Merkel Omegat Stangafdichtingen (OMS-SPR)Document6 pagesERIKS - Simrit Merkel Omegat Stangafdichtingen (OMS-SPR)Sérgio GomesNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Design Criteria For Fired HeatersDocument50 pagesDesign Criteria For Fired Heatersdisasterdaz100% (2)

- Specific Gravity of Sulphur at TemperatureDocument1 pageSpecific Gravity of Sulphur at TemperaturedisasterdazNo ratings yet

- Piping Guides From VesselsDocument12 pagesPiping Guides From VesselsdisasterdazNo ratings yet

- Skypod: Eye-Catching, Affordable and Easy To Install Pitched PVC-U Lantern RoofsDocument16 pagesSkypod: Eye-Catching, Affordable and Easy To Install Pitched PVC-U Lantern RoofsdisasterdazNo ratings yet

- Stress Calculation For A Double Pipe Support LugDocument6 pagesStress Calculation For A Double Pipe Support LugdisasterdazNo ratings yet

- Clip Design For Use With Vessel BracketsDocument46 pagesClip Design For Use With Vessel BracketsdisasterdazNo ratings yet

- ABB - BundsDocument1 pageABB - BundsdisasterdazNo ratings yet

- Sky Pod InstallDocument12 pagesSky Pod InstalldisasterdazNo ratings yet

- Aalco Catalogue PDFDocument72 pagesAalco Catalogue PDFdisasterdazNo ratings yet

- Aalco Hygienic Tube PDFDocument18 pagesAalco Hygienic Tube PDFdisasterdazNo ratings yet

- Teddington Catalogue 2013Document76 pagesTeddington Catalogue 2013Joanna NewtonNo ratings yet

- Aalco Stainless Steel PDFDocument21 pagesAalco Stainless Steel PDFdisasterdazNo ratings yet

- Aalco Metric Tru-Bore PDFDocument11 pagesAalco Metric Tru-Bore PDFdisasterdazNo ratings yet

- Teddington Layman S GuideDocument7 pagesTeddington Layman S GuideAdnan Ahmed KidwaiNo ratings yet

- Aalco Square and Rect Tube PDFDocument2 pagesAalco Square and Rect Tube PDFdisasterdazNo ratings yet

- System1200 27 TPS1200 Setup Methods enDocument4 pagesSystem1200 27 TPS1200 Setup Methods endisasterdazNo ratings yet

- Aalco CatalogueDocument72 pagesAalco CataloguedisasterdazNo ratings yet

- Aalco Hygienic TubeDocument18 pagesAalco Hygienic TubedisasterdazNo ratings yet

- Aalco Stainless SteelDocument21 pagesAalco Stainless SteeldisasterdazNo ratings yet

- Aalco Square and Rect TubeDocument2 pagesAalco Square and Rect TubedisasterdazNo ratings yet

- CEMS A 10 Part II APPXDocument3 pagesCEMS A 10 Part II APPXaldairlopesNo ratings yet

- Raw material size and foundation details for vibrating screenDocument1 pageRaw material size and foundation details for vibrating screenpatelchiragisNo ratings yet

- Topic 2 Wood JointsDocument54 pagesTopic 2 Wood JointsMachalyn Chua100% (2)

- Swage HeightDocument3 pagesSwage HeightAnkit JainNo ratings yet

- Schedule of Doors and WindowsDocument1 pageSchedule of Doors and WindowsGeorge DimakilingNo ratings yet

- Binding WireDocument7 pagesBinding WireMehta & Associates PMC NRDANo ratings yet

- Effect of Preheating and Stress Relief on ASTM A516 Gr. 70 SteelDocument3 pagesEffect of Preheating and Stress Relief on ASTM A516 Gr. 70 SteelLalit ModiNo ratings yet

- TB019P Concrete Intersections - A Guide For Design and ConstructionDocument28 pagesTB019P Concrete Intersections - A Guide For Design and ConstructionGonzalo PradoNo ratings yet

- Katalog PT Gunung Garuda Steel WF ProfileDocument4 pagesKatalog PT Gunung Garuda Steel WF ProfileibnugantengNo ratings yet

- List of Items and Corresponding Test For QCPDocument4 pagesList of Items and Corresponding Test For QCPSheila Marie Menes OmegaNo ratings yet

- DSI ALWAG Systems - Mechanical Anchors and Rebar Rock Bolts PDFDocument16 pagesDSI ALWAG Systems - Mechanical Anchors and Rebar Rock Bolts PDFxenNo ratings yet

- PDF N1301281618440Document2 pagesPDF N1301281618440Agustin CesanNo ratings yet

- Two Storey Interior LayoutDocument32 pagesTwo Storey Interior LayoutEricka Jane CeballosNo ratings yet

- BBR CMI Tendon Brochure - Optimize PDFDocument32 pagesBBR CMI Tendon Brochure - Optimize PDFWenix008 OniNo ratings yet

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDocument4 pagesPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServicemarykongNo ratings yet

- TDS - Glenium 51 PDFDocument3 pagesTDS - Glenium 51 PDFAlexi ALfred H. TagoNo ratings yet

- AASHTO 2002-LFD Flexural CapacityDocument1 pageAASHTO 2002-LFD Flexural Capacitycaner_kurtoglu-1No ratings yet

- Build retaining walls and prevent erosionDocument2 pagesBuild retaining walls and prevent erosionEdsun CaraleNo ratings yet

- Astm C 617Document6 pagesAstm C 617ArunselvanNo ratings yet

- Ari Armaturen 1Document26 pagesAri Armaturen 1Ardi 4791No ratings yet

- Table 6 1 AWS D1 1 D1 1M 2010 PDFDocument1 pageTable 6 1 AWS D1 1 D1 1M 2010 PDFFu AdNo ratings yet

- SPARE PARTS MANUAL of AM7 SHC2 RH VERSION, Edition - Dec '16 TMDocument74 pagesSPARE PARTS MANUAL of AM7 SHC2 RH VERSION, Edition - Dec '16 TMMECHANICAL KOLLAMNo ratings yet

- Control of Chilling Tendency in Grey Cast Iron ReuDocument6 pagesControl of Chilling Tendency in Grey Cast Iron ReuMURSELIM ALINo ratings yet

- Hyd-Stc-Phe - Boq - 13.10.2023Document2 pagesHyd-Stc-Phe - Boq - 13.10.2023AMOLNo ratings yet

- Uncoated High-Strength Steel Bar For Prestressing ConcreteDocument3 pagesUncoated High-Strength Steel Bar For Prestressing ConcreteFRANZ RICHARD SARDINAS MALLCONo ratings yet

- PRICE LIST (Decorative Division) : SR #: Packing Price Incl. GST Carton Packing Product NameDocument1 pagePRICE LIST (Decorative Division) : SR #: Packing Price Incl. GST Carton Packing Product Namemudassar nazarNo ratings yet

- Single bolt capacity and fillet weld strengthDocument17 pagesSingle bolt capacity and fillet weld strengthabhijitNo ratings yet

- Final BMC Glass FlooringDocument20 pagesFinal BMC Glass FlooringARAV PRAJAPATINo ratings yet

- New Kalzen Construction System for Indian HousingDocument2 pagesNew Kalzen Construction System for Indian Housingrakkesh01No ratings yet

- Design of RC StructuresDocument1 pageDesign of RC Structureskamalnitrr0% (3)