Professional Documents

Culture Documents

Operating Instruction PDF

Uploaded by

namduong368Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operating Instruction PDF

Uploaded by

namduong368Copyright:

Available Formats

Subject to alterations in design

Copyright by ZF

These operating instructions are protected by copyright. Any

reproduction and dissemination in whatever form also in

adapted, paraphrased or extracted form in particular as a

reprint, photomechanical or electronic reproduction or as a

storage in data-processing equipment or data networks without

approval by the holder of the copyright is prohibited and will be

prosecuted under civil and criminal law.

Printed in Germany

Automatic transmission

HP 500, HP 590, HP 600

for trucks and special vehicles

Status: June 1995

Technical modifications reserved.

4139 758 130a

Transmission version i = 3.43 (short)

Connection for

emergency steering pump

Secondary

pump

004 718

Transmission version i = 5.60 (long)

PTO

Emergency

steering pump

004 719

Secondary

pump

3

PREFACE

Before starting the vehicle, please:

read the operating instructions carefully, paying particular

attention to the safety notes.

follow the maintenance notes to guarantee transmission

operating safety.

ZF Customer Service experts are available to assist you with

maintenance work on transmission and with any problems

that may occur. The addresses are listed on the attached foldout.

NOTE

All data in this booklet refer to the basic version of the Ecomat transmission. Due to the large number of installation

options, no precise data for any specific vehicle can be given.

If there are any differences between the operating instructions given in this booklet and those given in the vehicles

own operating manual, please follow the instructions in

the vehicle operating manual.

We wish you pleasant driving with the ZF Ecomat.

ZF Friedrichshafen AG

Commercial Vehicle Transmissions Division

D-88038 Friedrichshafen

Telephone: (0 75 41) 77-0 Telefax: (0 75 41) 77-8000

SAFETY NOTES

The following safety notes are used in these operating

instructions:

NOTE

Refers to special processes, techniques, data, use of auxiliary

equipment etc.

CAUTION

This is used when incorrect, unprofessional working practices

could damage the product.

! DANGER

This is used when lack of care could lead to personal injury

or death.

CONTENTS

1. TECHNICAL DATA

2. DESCRIPTION

3. OPERATION

4. MAINTENANCE

5. TROUBLESHOOTING NOTES

TABLE OF CONTENTS

1.

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.

2.1

2.2

2.3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ecomat system solution . . . . . . . . . . . . . . . . . . . .

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A 800/3D transfer case . . . . . . . . . . . . . . . . . . . . .

10

10

14

16

3.

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.2

3.3

3.4

3.5

3.6

3.7

3.7.1

3.7.2

3.8

3.8.1

3.8.2

3.8.3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driving instructions . . . . . . . . . . . . . . . . . . . . . . .

Speed range selector . . . . . . . . . . . . . . . . . . . . . . .

Starting the engine . . . . . . . . . . . . . . . . . . . . . . . .

Gear selection . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulling away . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Kickdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accelerator interlock . . . . . . . . . . . . . . . . . . . . . .

Retarder operation . . . . . . . . . . . . . . . . . . . . . . . .

Stopping, parking . . . . . . . . . . . . . . . . . . . . . . . . .

Tow-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tow-starting without secondary pump . . . . . . . . .

Tow-starting with secondary pump . . . . . . . . . . .

Towing away . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Towing away without secondary pump . . . . . . . .

Towing away with secondary pump . . . . . . . . . . .

Emergency steering pump . . . . . . . . . . . . . . . . . .

18

18

18

18

19

20

20

21

22

22

23

24

24

24

25

25

26

26

3.9

3.10

3.11

3.12

3.13

Temperature monitoring . . . . . . . . . . . . . . . . . . . .

Status monitoring . . . . . . . . . . . . . . . . . . . . . . . . .

PTOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Twin cabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HST 18 auxiliary control unit . . . . . . . . . . . . . . .

27

28

28

28

29

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil grades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ecomat oil quantities . . . . . . . . . . . . . . . . . . . . . .

Ecomat oil level check . . . . . . . . . . . . . . . . . . . . .

Oil level check at operating temperature . . . . . . .

Reference measurements . . . . . . . . . . . . . . . . . . .

Check procedure if heat exchanger is separately

installed above transmission centre . . . . . . . . . . .

4.4

Transmission oil heating methods . . . . . . . . . . . .

4.5

Oil change intervals . . . . . . . . . . . . . . . . . . . . . . .

4.6

Ecomat oil drain, oil fill . . . . . . . . . . . . . . . . . . . .

4.7

Oil fill for A 800/3D transfer case . . . . . . . . . . . .

4.7.1 Initial fill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.2 Oil level check . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8

Checking load sensor adjustment . . . . . . . . . . . . .

4.9

Electronic accelerator equipment and EDC units

30

30

30

30

31

32

Troubleshooting notes . . . . . . . . . . . . . . . . . . . .

41

4.

4.1

4.2

4.3

4.3.1

4.3.2

4.3.3

5.

33

33

34

35

36

36

37

38

40

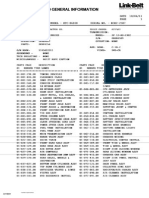

TECHNICAL DATA

Max. perm.

Max. weight (t)

input

at engine torque DIN 70020/ISO 1585

Series No. of

speed

Fire service Refuse Construction

gears

(rpm)

vehicles

vehicles machinery 1stgear 2nd

4

HP 500

HP 590

1)

2)

3)

4)

3rd

4th

5th

6th .

R.

Weight 3) Install.

length

[mm]

(kg)

L

3.43

2.01

1.43

1.00

4.84

300

693

28 t

28 t

1)

3.43

2.01

1.43

1.00

0.83

4.84

310

693

1150 Nm

1050 Nm

1050 Nm

5.60

3.43

2.01

1.43

1.00

4.84

344

795

5.60

3.43

2.01

1.43

1.00

0.83

4.84

356

795

3.43

2.01

1.43

1.00

4.84

305

693

5

5

2 800

28 t

28 t

1)

3.43

2.01

1.43

1.00

0.83

4.84

315

693

1250 Nm

1250 Nm

1)

5.60

3.43

2.01

1.43

1.00

4.84

354

795

5.60

3.43

2.01

1.43

1.00

0.83

4.84

366

795

3.43

2.01

1.43

1.00

4.84

320

693

3.43

2.01

1.43

1.00

0.83

4.84

330

693

5.60

3.43

2.01

1.43

1.00

4.84

364

795

3.43

2.01

1.43

1.00

0.83

0.59

4.84

330

693

5.60

3.43

2.01

1.43

1.00

0.83

4.84

376

795

5

5

5

HP 600

Ratios

2 800

2 650

5

6

2650 2)

2650

28 t

28 t

1600 4)

1400

Only after consultation with ZF

At i = 0.59; nmax = 1600 rpm _ only after consultation with ZF

Transmission with retarder and oil cooler (without oil)

For fire service vehicles above 1600 Nm, only after consultation

with ZF

Oil fill quantity for initial fill: approx. 30 l

DESCRIPTION

Description

2.1

Ecomat system solution

NOTE

The components shown in the following system diagram can

be found in the text under the same numbers.

10

Fig. 1

004 887

DESCRIPTION

Key to drawing

1

Interface for vehicle electrical system

15

Temperature sensor

Status monitoring lamp

16

Pressure reduction valve (1.2 bar)

Temperature gauge

17

Retarder reduction solenoid valve

Console selector

18

Accelerator interlock (Antigas) solenoid valve

Identification plate

19

Mechanical switch for retarder actuation

EST 18 electronic control unit

20

Brake pedal

Connector plug for MOBiDIG 200

21

Antigas cylinder

Wiring

22

Kickdown switch

Engine speed-dependent PTO

23

Accelerator pedal

10

From auxiliary air supply,

internal diameter of pressure lines = 6 to 8 mm

24

Linkage to injection pump

25

Load sensor for detection of engine load condition

11

Cooling water connections

26

Pressure reduction valve (3.0 bar)

12

Solenoid valve accumulator

27

Retarder control OFF switch

13

ZF-Ecomat

28

PTO switch (ON/OFF)

14

Retarder solenoid valve

10

11

DESCRIPTION

Ecomat system solution

u The desired speed range can be preselected using the

speed range selector (4).

The Ecomat system diagram illustrates one of the possible

Ecomat system set-ups using all necessary components.

All electrical connections required between the Ecomat system and the vehicle electronic system are located in the interface to the vehicle electrical system (1).

The EST 18 electronic control unit (6) controls the transmission and monitors all functions. The automatic control

unit gathers data from the vehicle and transmission (speed

range, engine load condition, etc.) and processes these to produce signals used for controlling the transmission hydraulic

system.

For special applications, the EST 21 is available instead of the

EST 18.

The driver may intervene in the Ecomat control system using

the following equipment:

12

speed range selector (console switch) (4)

kickdown switch (22)

acelerator pedal (23)

mechanical switch for retarder actuation (19)

u The lamp (2) is used for status monitoring. The lamp does

not light under normal operating conditions.

! DANGER

If this lamp flashes (frequency 0.2 sec), transmission

damage is imminent and danger of accidents!

Restricted system monitoring!

If this occurs, immediately drive to the nearest service

station. Drive slowly to reduce transmission loading.

u The kickdown switch (22) is used to move the shift points

towards higher engine speeds, so the transmission remains

in each gear longer when accelerating and shifts out of

each gear sooner when decelerating.

u The air pressure in the air supply to auxiliary consumers

(10) line is reduced to 3 bar by means of the pressure

reduction valve (26). This corresponds to the maximum

retarder torque.

DESCRIPTION

u The mechanical switch for retarder actuation is operated

by pressing down the brake pedal and outputs a signal

(+24 V) to the EST 18 (6) provided that switch (27) is

closed.

u The temperature sensor (15) is installed on the cooler

connection piece to monitor oil temperature. The information from the temperature sensor is sent to the temperature gauge (3) from where the oil temperature may be

read.

u The oil temperature may be read on temperature gauge (3).

In addition, a switch point for "excess temperature"

(145C) is built in. This contact switch is used to activate

the retarder torque reduction process.

u Load sensor (25) monitors the engine load condition at the

pump filling control lever of the injection pump and sends

this information to the EST 18 (6).

Pressures for operating the clutch elements are modulated

according to the engine load condition using a proportional solenoid valve in the electrical/hydraulic control

unit.

u The accelerator interlock cylinder (21) or pneumatic

cylinder interrupts acceleration for 1 second when the

transmission is shifted from neutral into another speed

range. This protects the clutches as they should only be

loaded with full engine torque after approx. 1 second.

The accelerator interlock cylinder (21) is activated via the

accelerator interlock solenoid valve (18).

During the retarder torque reduction process, the retarder

reduction solenoid valve (17) is energized. Compressed air

flows through the pressure reduction valve (16) and

solenoid valve (17) to the retarder solenoid valve (14).

13

DESCRIPTION

2.2

Design

Transmissions in the Ecomat series consist of a hydrodynamic

torque converter based on the Fttinger principle, with a lockup clutch, a hydrodynamic retarder and a rear-mounted

multiple-speed planetary transmission.

The hydrodynamic retarder is located between the torque

converter and planetary transmission. This means that braking

force is dependent on the gear engaged. Therefore, full

braking power is available even at low speeds. Braking torque

can either be infinitely variable or divided into individual

retardation steps.

2

The torque converter provides smooth starting without

mechanical wear and compensates automatically for various

load conditions by providing the necessary input torque.

The various gears in the planetary transmission are engaged

automatically with no interruption in traction. Gearshifts are

performed in response to signals from the EST 18 electronic

control unit. In response to various variables in the vehicle

and transmission, the EST 18 sends signals to the hydraulic

solenoid valves which actuate the corresponding clutches and

brakes.

A lock-up clutch in the torque converter provides a direct

mechanical link between engine and planetary transmission

after the vehicle start-up phase, thus eliminating the power

losses seen in conventional automatic transmissions where the

torque converter remains in operation all the time.

14

Braking on downhill slopes or in city traffic can be carried

out wear-free using the retarder, as this is not a friction brake.

ZF also supplies high-performance PTOs for all truck and

special vehicle operating systems. These are engine speeddependent and are engageable or permanently engaged,

depending on version. When the PTO is engaged, the

converter lock-up clutch is disengaged and an upshift

interlock comes into operation.

DESCRIPTION

The ZF Ecomat transmission can be supplied as a short

version (for ratios up to 3.43) and a long version (for ratios up

to 5.60).

The long version contains an additional planetary gear train

for ratios i = 5.60 with the length L = 102 mm.

2

Fig. 2: Transmission design for i = 3.43 0.83

3.43 0.59

Fig. 3: Transmission design for i = 5.60 0.83

(shown with PTO)

L = 102 mm

004

114

004 114

004 113

004 113

15

DESCRIPTION

2.3

A 800/3D transfer case

Key to drawing

a

Ecomat connection

Output flange to front axle (DIN 165)

Output flange to rear axle (DIN 165)

Transmission mounting M16 x 1,5; 19 deep,

Tightening torque 200 Nm

Speedo connection E2 DIN 75 532; i = 1.545

u Transfer case ratio i = 1.02

Compressed air connection M12 x 1.5 for differential

interlock

u The output direction of rotation is identical to the input

Costal plug M27 x 1,5 for differential interlock

Oil drain plug SW17

Oil fill and oil overflow check SW17

Connection for ventilation M10 x 1

The A 800/3D transfer case is available for all-wheel drive vehicles and has a pneumatically engaged lockable transfer differential. The transfer case can be flange-mounted on the Ecomat or separately installed.

2

u Torque distribution between front/rear axles optionally

1 : 1.83 or 1 : 3.35

direction. Lubrication is separate from the Ecomat

transmission.

u Maximum input torque = 16 000 Nm.

u Maximum permissible input speed on transfer case

(without heat exchanger ) is 2 650 rpm.

u For special applications, the maximum permissible input

speed on the transfer case (with heat exchanger) is

3000 rpm.

16

Oil quantity approx. 6.5 l, oil as per List of Lubricants

TE-ML 02

DESCRIPTION

e

d

f/g

c

004 945

Fig. 4

17

OPERATION

Operation

3.1

Driving instructions

3.1.1 Speed range selector (4)

Selector lever position:

R

N

D

1, 2, 3

= Reverse

= Neutral

= Automatic forward drive (Drive)

= Restricted automatic forward speed ranges

CAUTION

If the specified clutch slip times are exceeded during gear

change, the lamp (2) on the dashboard (status monitoring)

begins to flash.

Risk of transmission damage!

004 715

Fig. 5

3.1.2 Starting the engine

Restricted system monitoring!

It is only permissible to start the engine when:

In this case, the vehicle must be driven to the nearest

workshop under part-load only.

vehicle is stationary (brake on)

selector lever is in neutral position

NOTE

Starter interlock If the selector lever is not in neutral

position, the engine cannot be started.

18

OPERATION

CAUTION

Jump starting only permitted on battery, never on starter

motor!

CAUTION

Never move the selector lever whilst accelerator pedal is

depressed!

Never switch ingition ON/OFF while vehicle is moving

Accelerator interlock (Antigas)

The accelerator interlock device prevents acceleration for 1

second when shifting from neutral to another speed range.

3.1.3 Gear selection

Errors possible during gear selection

Conditions:

Selector lever in neutral position

Accelerator pedal depressed or nEng > 900 rpm

Vehicle stationary (brake on)

Brake pedal not depressed - transmission with gear select

interlock

Accelerator pedal in idling position nEng < 900 rpm

Selecting reverse R when road speed > approx. 3 km/h

Then, select the desired speed range and direction of travel

using the selector lever.

Transmission with additional External gear interlock

function

(To be installed additionally by the vehicle manufacturer - as

recommended by ZF)

Select the desired speed range . The system only engages

the corresponding gear if the brakes are on.

No further gear engages once the desired speed range has

been selected.

In this case:

Selector lever in neutral position

Select desired speed range again, ensuring conditions

described above are met.

19

OPERATION

3.1.4 Pulling away

After selecting desired speed range, wait approx. 1 to 2

seconds before releasing brake and depressing accelerator.

-15

CAUTION

Do not pull away at temperatures below -15 C.

Warm up the engine for approx. 5 mins. with

selector lever in neutral position.

3

3.2

Speed ranges

Precise details of the speed range selector and the ratios

available in the various speed ranges can be found in the

vehicle operating manual / instructions.

Each speed range is allocated certain range of gears. Gears

are only shifted at the shift points defined by the EST 18.

Manual override of the automatic shift cycles (by shifting

through the speed ranges) is of no advantage.

20

! DANGER!

If the transmission is shifted into N whilst the vehicle is

moving, the connection between engine and transmission is

broken. This means engine and retarder braking power

is lost.

Risk of accident! Actuate brake!

For safety reasons, the transmission is automatically shifted

into N if a fault occurs in the EST 18 or if current in the

transmission is lost.

Driving downhill

When descending steep hills, select speed range 1, 2 or 3 as

required to limit upshifts.

! DANGER!

In extreme cases, the upshift interlock cuts out to protect

the engine.

In this case, the transmission can shift up into the

highest gear whatever speed range is selected. Risk of

accidents!

OPERATION

Changing direction of travel

Before shifting from forwards to reverse or vice versa, ensure:

Vehicle is stationary

Engine is at idling speed

Selector lever is in neutral position

Then, select gear as described in Section 3.1.3.

3.3

Kickdown

To make use of max. engine power, select higher gearshift

points using the kickdown switch (to accelerate or on uphill

gradients).

Depress the accelerator pedal past the full-load pressure

point - kickdown position

Kickdown

Accelerator

Full-load

(Pressure point

Kickdown

Kickdown switch

004 886

Fig. 6

Installation example:

Pneumaticallyactuated accelerator

interlock device

21

OPERATION

3.4

Accelerator interlock (Antigas)

The accelerator interlock device prevents acceleration for 1

second when the transmission is shifted from neutral into

another speed range.

Retarder actuation

The retarder can be activated using a hand-operated lever or a

foot pedal. It is actuated via electronic switch contacts or

pressure switches in the braking circuit (refer to vehicle

operating manual / instructions).

This procedure protects the clutches as they should only be

loaded with full engine torque after approx.1 second.

NOTE

All special vehicles such as refuse collection trucks, dumpers,

mobile cranes, fire service vehicles etc. are equipped with an

accelerator interlock.

Conditions for retarder operation

(Retarder engaged/actuated)

Accelerator in idling position

Road speed > approx. 3 km/h

In this case, the system prevents upshifts

(upshift interlock).

3.5

Retarder operation

The retarder is a wear-free hydrodynamic brake. The braking

power depends on which gear is engaged. The retarder should

be applied whenever braking is required. This saves wear on

the service brakes, as they do not become hot even when

driving downhill for long periods.

22

CAUTION

If the accelerator pedal is depressed, the retarder disengages.

The upshift interlock cuts out.

OPERATION

The retarder must be disengaged:

on icy roads

if oil temperature is too high (> 145 C)

During retarder operation, the oil temperature must not

exceed 145 C. The oil temperature is monitored by a gauge

or a warning device (see Section 3.9, Temperature

monitoring).

The (foot) pedal control can be switched off using the

toggle switch on the dashboard

Return the hand-operated lever to zero position after each

braking operation

! DANGER!

If the permissible oil temperature of 145 C is exceeded,

the retarder is automatically reset.

Risk of accident due to reduced braking power!

3.6

Stopping, parking

Stopping

The vehicle can be stopped at any time, regardless of the

selector lever position. The EST 18 selects the appropriate

starting gear.

During short stops:

The selector lever can be left in gear

Apply brakes

During longer stops:

Selector lever in neutral position

Parking

Always apply the parking brake if leaving the vehicle.

! DANGER!

When the engine is stopped, there is no direct mechanical

link between the engine and the axle. Vehicle may roll

away.

23

OPERATION

3.7

Tow-starting

3.7.1 Tow-starting without secondary pump

CAUTION

It is neither possible nor permissible to start the engine by

towing the vehicle if there is no secondary pump - risk of

transmission damage!

NOTES

The necessary tow-starting speed depends on

Transmission ratio

Programmed starting gear

Axle ratio

Tyre size

Temperature

Therefore, fixed values cannot be given. Please refer to your

Vehicle Operating Instructions for the correct tow-starting

speed for your vehicle.

3.7.2 Tow-starting with secondary pump

CAUTION

Check whether your Ecomat transmission is equipped with a

secondary pump * which provides the transmission clutches

with the necessary oil pressure if tow-starting is required.

Always use a tow bar

Move the speed range selector to position D

Keep accelerator pedal in full-load position

Switch off retarder, if installed

Accelerate the vehicle quickly to prescribed tow-starting

speed

* Refer to pages 2 and 3

24

CAUTION

Tow-starting at temperatures below -15 C is not permissible

risk of transmission damage.

3.8

Towing away

Axle ratio

OPERATION

12

CAUTION

If you suspect the transmission may be damaged, disconnect

the propshafts between the Ecomat and drive axles before

towing.

Exception: In dangerous situations, it is permissible to tow

away before disconnecting the drive line (e.g. on cross-roads

or in tunnels etc.).

10

rdyn m

6

3.8.1 Towing away without secondary pump

Towing away at temperatures down to -15 C

Selector lever in neutral position

Max. towing time 2 hours

10

20

0,4

0,5

30

40

0,6

50

Max. towing speed, see graph

Abschleppgeschwindigkeit

v km/h

Towing speed

v [km/h]

Towing away at temperatures below -15 C

Selector lever in neutral position

Max. towing time 2 hours

Max. towing speed 5 km/h

000 855

Fig. 9: Towing speed graph

Example:

Axle ratio:

Dynam. tyre radius:

Towing speed. max.:

iA = 7.6

rdyn = 0.490

18 km/h

25

OPERATION

3.8.2 Towing away with secondary pump

CAUTION

Check whether your Ecomat transmission is equipped with a

secondary pump* which guarantees the lubrication oil supply

to the transmission when towing away.

Towing away at temperatures down to -15 C

Towing away at temperatures below -15 C

Move the speed range selector to position N

Max. towing speed 5 km/h

CAUTION

If you suspect the transmission may be damaged, disconnect

the propshaft between the transmission and the driving axles

before towing.

Move the speed range selector to position "N".

Always observe legal speed limits when towing a vehicle. ZF

does not impose specific maximum towing speeds.

CAUTION

If you suspect the transmission may be damaged, disconnect

the propshaft between the transmission and the driving axles

before towing.

3.8.3 Emergency steering pump

The emergency steering pump* attached to the output cover is

connected to the output shaft and therefore operated continuously when the vehicle is being driven. The emergency

pump speed corresponds to the propshaft speed. Should the

auxiliary steering pump fail, or if the vehicle is on tow, the

emergency steering pump keeps the power steering operational.

! DANGER!

If the propshafts are disconnected, the assistance provided

by the emergency steering pump is no longer available.

* Refer to pages 2 and 3

26

* Refer to pages 2 and 3

OPERATION

3.9

Temperature monitoring

The temperature is monitored by a gauge or warning device.

Permissible oil temperatures:

Operating temperature:

Normal driving:

Retarder operation:

Converter operation:

approx. 85 C

max. 100 C

max. 145 C

max. 110 C

What to do if the permissible oil temperatures are

exceeded:

Drive at part-load in low speed range

Disengage the retarder (also refer to Section 3.5)

If this does not cause the oil temperature to drop:

Stop the vehicle

Move selector lever into neutral position

Run engine at higher revs

! DANGER!

If oil temperature exceeds 145 C, the retarder is

automatically reset.

Risk of accidents due to reduced braking power!

If the temperature does not fall to within the permissible

range within a few seconds, possible causes include:

oil level too low

defective coolant circuit

Temperature gauge

transmission damage

Please inform the nearest ZF Service Point!

004 717

Fig. 10

Green range

Green/red range

Red range

for all normal operating conditions

only for braking operation with retarder

oil temperature too high

27

OPERATION

3.10

Status monitoring

The transmission is monitored every time the vehicle circuit

voltage is switched on or during operation by the diagnosis

system in the EST 18 electronic control unit.

3.11

PTOs

Engagement conditions:

Accelerator pedal in idling position

Engine speed < 900 rpm

! DANGER!

If the status monitoring lamp (2) is flashing, there is grave

danger of transmission damage and system monitoring is

only restricted.

Risk of accidents!

3

In this case, the vehicle must be driven under part-load to the

nearest workshop so that the fault can be corrected!

Selector lever in N

(see vehicle operating manual / instructions)

NOTE

If these conditions are not fulfilled, PTO engagement is

blocked. When the PTO is engaged, the converter lock-up

clutch remains disengaged and an upshift interlock comes into

operation.

3.12

Twin cabs

Some applications have twin cabs. In these cases, when the

selector lever is being used by one cab, the other cab is

blocked by means of a detent solenoid.

28

OPERATION

3.13

HST 18 auxiliary control unit

The HST 18 auxiliary control unit was developed in order to

move the vehicle during assembly and to provide an emergency control function should the EST 18 electronic control

unit malfunction.

The HST 18 auxiliary control unit is fitted to the 55-pin plug

instead of the EST 18 electronic control unit and allows 1 forward and the reverse gear to be engaged. Gear shifts whilst

driving are no longer possible.

Operation instructions for the HST 18

Apply parking brake to prevent vehicle from rolling away

unintentionally.

Move speed range selector to position N .

Switch off engine and ignition.

Remove plug from EST 18 control unit.

Connect plug to HST 18 auxiliary control unit and secure.

Start engine.

Select gear using selector lever:

Position N

= Neutral

Position D

= Forwards (gear is engaged, neither

upshift nor downshift occurs.)

Position R

= Reverse

DANGER!

All safety functions are de-activated when using the HST 18

auxiliary control unit.

Danger of accidents!

Therefore, the following points must be observed without

exception:

Shifts from N to D or from N to R ;

must only be carried out at idling speed and when the

vehicle is stationary.

The transmission can also be shifted at higher speed.

However, this leads to transmission damage.

When switching between forwards and reverse operation

or vice versa, ensure that the vehicle is stationary.

After shifting to D or R, always wait for approx. 2

seconds so that the transmission is engaged before

accelerating.

29

MAINTENANCE

Maintenance

Good maintenance means safe transmission operation. It is

therefore especially important to carry out any necessary

maintenance work in the correct manner.

4.1

Oil grades

Only oils as per the applicable ZF List of Lubricants

TE-ML 14 can be used for filling the Ecomat transmission.

CAUTION

Ecomat transmissions with flange-mounted A800/3D

transfer case have a separate oil circuit!

Only oils as per the applicable ZF List of Lubricants can be

used for filling the transmission / transfer case:

Ecomat transmission:

TE-ML 14

A 800/3D transfer case:

TE-ML 02

The latest Lists of Lubricants can be requested from all ZF

After-Sales Centres.

4.2

Ecomat oil quantities

For initial filling of dry transmission

(without oil cooler)

approx. 30 ltr

After installing new/exchange

transmission

approx. 20 ltr

At oil changes

approx. 15 ltr

The above quantities are for guidance only, the precise

quantity must always be determined by measuring with the

dipstick.

Oil quantities for A800/3D see Section 4.7.

4.3

Ecomat oil level check

It is essential for the Ecomat transmission to be operated with

the correct oil level.

Too little oil leads to mal-functions and damage.

Too much oil results in transmission overheating.

30

MAINTENANCE

CAUTION

The oil level must be checked regularly at operating

temperature. This is the only way of ensuring that the

level is correct.

Check oil level once weekly see Section 4.3.1.

Under certain circumstances, the oil level must first be

checked when the transmission oil is cold see Section

4.3.2. Always recheck afterwards at operating

temperature.

If the heat exchanger is located higher than the centre line

of transmission (separate installation), the oil level should

be checked as described in Section 4.3.3.

After waiting approx. 2 minutes, the oil level must be within

the warm range.

CAUTION

The idling speed should be set between 500 and 700 rpm.

On no account may it fall below 450 rpm.

Hot range 80 - 90 C

4.3.1 Oil level check at operating temperature

S 0024

For correct results, the oil level must be checked when the

transmission oil is hot (80 - 90C).

We recommend that this check is performed once weekly,

preferably after finishing a journey.

Fig. 12

Conditions:

Park vehicle on level ground

Switch speed range selector to neutral

Run engine at idling speed

31

MAINTENANCE

4.3.2

Reference measurements

This approximate oil level check, which is performed with the

transmission oil cold, is used in the following exceptional

cases:

Oil level check before starting engine

The oil level must be within or above the stationary range

nEng = 0.

If the oil level is higher, do not drain off any oil!

When using a transmission for the first time

After long periods out of use or before first operating a

vehicle received from elsewhere

After in-vehicle repairs to the transmission: e.g. removal of

oil sump, hydraulic control module, oil cooler etc.

Stationary range (nEng = 0)

After oil change or filter replacement

The oil level check should be carried out in two stages:

S 0025

Fig. 13

Level check before starting engine

Level check after starting engine

Oil level check after starting engine

Run the engine at idling speed for approx. 3 to 5 minutes

(speed range selector in neutral) and then check the oil level.

The oil level should be within the cold range (30C).

If the oil level is higher, do not drain off any oil!

32

MAINTENANCE

CAUTION

After cold-starting at sub-zero temperatures, the dipstick must

dip at least 10 mm into the oil before it is permissible to run

the transmission up to temperature.

An accurate oil level check at operating temperature must

then be made as soon as possible (see Section 4.3.1).

4.3.3 Oil level check with separate heat exchanger

installed higher than centre line of transmission

The oil level check must be carried out under the following

conditions:

Run transmission in neutral position for 15 to 20 seconds

and engine speed 1200 to 1500 rpm.

Allow the engine to return to idling speed. Within

3 minutes, perform the oil level check after starting

engine and then the oil level check at operating

temperature.

Cold range 30 C

4.4

Methods of heating up transmission oil

S 0026

Fig. 14

If the transmission oil cannot be heated up during normal

operation, it must be heated up as follows:

Engage parking brake

Select D speed range

Apply service brakes

33

MAINTENANCE

If required, repeatedly run engine for between 15 to 20

seconds under part-load at 1200 to 1500 rpm.

CAUTION

Max. permissible oil temperature 110 C.

After each heating-up phase, allow engine to run for

15 to 30 seconds at 1 500 to 2000 rpm with transmission in

neutral position.

Once operating temperature has been reached:

Move transmission into neutral position

Run engine at idling speed for 2 to 3 minutes

Then, carry out oil level check as per Section 4.3.1.

4

4.5

Oil change intervals

CAUTION

The filter must be renewed after every oil change.

Mineral ATF (Automatic Transmission Fluids)

For normal operation (max. 110 C)

every 30 000 km

For heavy (high temperature) applications

(110 150 C)

every 20 000 km

In construction machinery or special vehicles

(mobile cranes, refuse vehicles etc.)

every 1 000 hrs. of

operation

However, at least once every year

Synthetic ATF oils

For normal operation (max. 110 C)

every 90 000 km

For heavy (high temperature) applications

(110 150 C)

every 60 000 km

In construction machinery or special vehicles

(mobile cranes, refuse vehicles etc.)

every 3 000 hrs. of

operation

However, at least once every two years

If mineral ATF is replaced by synthetic ATF, the next oil

change interval is 45 000 km.

All subsequent intervals are 90 000 km.

Oil change intervals for A800/3D see Section 4.7.

34

MAINTENANCE

4.6

Ecomat oil drain, oil fill

Drain oil only at operating temperature!

Engine stationary

Replace filter cover (tighten bolts to 25 Nm)

Unscrew oil drain plug (1) and drain oil.

Screw in oil drain plug (1) (tightening torque 50 Nm)

Remove filter cover (2).

Remove dipstick (3)

Renew filter cartridge, Cu rings and O-rings.

Add oil (oil quantity, see Section 4.2)

Check oil level as per Section 4.3

S 0020

S 0022

Fig. 15

Fig. 16

35

MAINTENANCE

4.7

Oil drain, oil fill for A 800/3D transfer case

CAUTION

Separate oil circuit!

The lubrication for the A800/3D transfer case is independent

of that for the Ecomat basic transmission.

NOTE

The vehicle must be level before oil fill can take place.

Oil quantity:

approx. 6.5 l

Oil grade:

see ZF List of Lubricants TE-ML 02

Oil change interval: see Section 4.5 Ecomat

This list can be requested from all ZF Service points.

Drain oil only at operating temperature!

Engine stationary

Unscrew oil drain plug (1) and drain oil.

Screw in oil drain plug (1) (tightening torque 50 Nm)

36

4.7.1 Initial fill

Engine stationary

Unscrew oil fill plug (2).

Fill in 5.5 litres of oil.

NOTE

Fill in oil slowly to avoid backflow and overflow at the

opening.

Screw in oil fill plug.

Start engine and carry out a short test run (200 - 300 metres).

Park vehicle on level ground.

After 5 to 10 minutes:

Remove oil fill plug (2) and fill in oil until it flows over at

the opening.

NOTE

Fill in oil slowly to avoid backflow.

Screw in oil fill plug.

(Tightening torque 50 Nm)

MAINTENANCE

4.7.2 Oil level check

Start engine and carry out a short test run (200 - 300 metres).

Park vehicle on level ground.

After 5 to 10 minutes:

Remove oil fill plug (2) and fill in oil until it flows over at

the opening.

NOTE

Fill in oil slowly to avoid backflow.

Screw in oil fill plug.

(Tightening torque 50 Nm)

004 720

Fig. 17

2

1

37

MAINTENANCE

4.8

Checking load sensor adjustment

The load sensor adjustment must be checked:

following maintenance work to the transmission or engine

following hard shifts

at least every 3 months

CAUTION

Do not use stops on load sensor housing for setting.

Do not loosen bolts on load sensor housing or nut on shaft.

Check ball heads for wear (too much backlash) and grease

filling.

Check procedure

(The engine must be at the correct setting before the check is

begun).

The check can be carried out using marks on the front (Fig. 18)

or the top of the housing (Fig. 19).

Stops

Switch off engine

Engage parking brake

Slowly depress accelerator pedal until pressure point is

reached (injection pump full-load stop) do not depress

pedal beyond this point

Retain accelerator pedal position load sensor lever mark

must correspond to full-load mark (high) on housing.

Release accelerator pedal until idling position is reached

Load sensor lever mark must correspond to idling mark

(low) on housing.

38

000 822

Fig. 18

low

high

MAINTENANCE

low

000 824

Fig. 19

high

Key to drawing (Fig. 20)

1

2

3

4

5

6

7

Accelerator pedal

Kickdown overtravel plunger

Kickdown switch

Antigas cylinder

Load sensor

Injection pump on engine

Injection pump full-load stop

A

B

C

D

Idling position

Full-load position

Stop position

Air supply

S 0093

Fig. 20

39

MAINTENANCE

4.9

Electronic accelerator equipment and EDC units

The engine load signal is not recorded by the load sensor but

electronically.

For electronic accelerator

equipment units:

For EDC units:

from the electronic system of

the electronic accelerator

equipment to the EST 18

directly from the engine electronic system to the EST 18

If problems occur

please contact the nearest vehicle manufacturer service

point.

40

TROUBLESHOOTING NOTES

Fault

Possible cause

Remedy

Engine will not start

Selector lever not in Neutral

Select neutral.

Plug of electronic control unit loose

Connect plug.

Starter interlock relay fault

Exchange relay.

Load sensor not in idling position

Check and/or readjust the load sensor/

injection pump.

Engine idling speed > 900 rpm

Adjust the engine idling speed.

Only for transmissions with External

gear interlock function:

Service brakes not applied

Apply service brakes.

Electronic control unit in failure mode

Switch ignition off/on.

Oil level too low

Check/correct oil level.

Transmission fault

Request ZF service.

Oil level too high

Check/correct oil level.

Retarder engaged

Disengage the retarder using hand lever.

Internal fault

Request ZF service.

Oil level too low

Check/correct oil level.

Retarder solenoid valve not functioning

Check solenoid valve/electrical connections.

If necessary, request ZF service.

No gear engages in transmission

Vehicle does not move

Oil temperature too high

Retarder does not work

41

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- ZF - 3HP12 For BMW Workshop ManualDocument36 pagesZF - 3HP12 For BMW Workshop Manualnamduong368100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- AutoCAD 2014 Tutorial 3DDocument26 pagesAutoCAD 2014 Tutorial 3DseleneletoNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- TEREX AC1000 - Load Chart PDFDocument116 pagesTEREX AC1000 - Load Chart PDFduongpnNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Energies 10 00666 PDFDocument46 pagesEnergies 10 00666 PDFnamduong368No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- CBD&CBG 25manual PDFDocument120 pagesCBD&CBG 25manual PDFnamduong368No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Link Belt HTC86100 Parts Manual PDFDocument423 pagesLink Belt HTC86100 Parts Manual PDFnamduong368No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- SM-751 - 67 To 88 PDFDocument22 pagesSM-751 - 67 To 88 PDFnamduong368100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 3 - Electrical System PDFDocument39 pages3 - Electrical System PDFnamduong3680% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Manitowoc 11000-1 Parts Manual PDFDocument1,040 pagesManitowoc 11000-1 Parts Manual PDFnamduong368100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Manitowoc 8500-1 Parts Manual PDFDocument1,046 pagesManitowoc 8500-1 Parts Manual PDFnamduong368100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Link Belt RTC80130 Parts Manual PDFDocument453 pagesLink Belt RTC80130 Parts Manual PDFnamduong368100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Manitowoc 4600 S4 Lubrication Guide PDFDocument40 pagesManitowoc 4600 S4 Lubrication Guide PDFnamduong368100% (1)

- Hypac C766C, C778B - Om PDFDocument122 pagesHypac C766C, C778B - Om PDFnamduong368100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LTM 1130-5.1 - PN - Technical Specification PDFDocument18 pagesLTM 1130-5.1 - PN - Technical Specification PDFnamduong368No ratings yet

- Breaker KOM PDFDocument50 pagesBreaker KOM PDFnamduong368100% (5)

- 14 - Schematics FORKLIFT PDFDocument6 pages14 - Schematics FORKLIFT PDFnamduong3680% (1)

- CLT-755 Allison Transmission SpecificationsDocument8 pagesCLT-755 Allison Transmission Specificationscascade192% (12)

- ZF Ecosplit 1341 758 101 Operating Instructions PDFDocument27 pagesZF Ecosplit 1341 758 101 Operating Instructions PDFnamduong368100% (2)

- ZF 16S-151 DD 1315.051.324 - 2004 Spare Parts CatalogDocument49 pagesZF 16S-151 DD 1315.051.324 - 2004 Spare Parts CatalogLuis Fabricio Guayllas100% (3)

- European - JE Pistons AudiDocument2 pagesEuropean - JE Pistons AudivepsmotorsportNo ratings yet

- HUFFY Bicycle Multispeed - ManualDocument44 pagesHUFFY Bicycle Multispeed - ManualottuserNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Yanmar PDFDocument13 pagesYanmar PDFmarcosluna68100% (1)

- Caterpillar 3126Document0 pagesCaterpillar 3126manuel12515100% (22)

- Verificare Bujii IncandescenteDocument1 pageVerificare Bujii IncandescentemihaimartonNo ratings yet

- Price Forvolvo 940 Spare PartDocument15 pagesPrice Forvolvo 940 Spare Partaswad97No ratings yet

- Cat C32 ACERT™ DITTA-SCAC Marine Propulsion EngineDocument3 pagesCat C32 ACERT™ DITTA-SCAC Marine Propulsion EngineSu truong vanNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- PAAE229540 Manual en PDFDocument522 pagesPAAE229540 Manual en PDFSalman Kapoor100% (1)

- Meritor WABCO Hydraulic Anti-Lock Braking Systems (HABS) For Medium-Duty Trucks, Buses, and Motor Home ChassisDocument8 pagesMeritor WABCO Hydraulic Anti-Lock Braking Systems (HABS) For Medium-Duty Trucks, Buses, and Motor Home ChassisDieselkNo ratings yet

- Catalogue PAI - 2017 Water PumpsDocument531 pagesCatalogue PAI - 2017 Water PumpsEver Rivera100% (4)

- Principles of Helicopter FlightDocument3 pagesPrinciples of Helicopter Flightapi-26338869100% (2)

- SuperScan Special Function ListDocument24 pagesSuperScan Special Function ListArda Akberk100% (1)

- Rosa Bus BE64DDocument4 pagesRosa Bus BE64DAnonymous 2VaeSa0dVgNo ratings yet

- 2016 Nissan Rogue Service Repair Workshop Manual PDFDocument25 pages2016 Nissan Rogue Service Repair Workshop Manual PDFpecno1100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ford Error CodesDocument23 pagesFord Error CodesAltin Skenduli100% (1)

- BMW X5xDrive25d - NewOrderDocument6 pagesBMW X5xDrive25d - NewOrdertuhin.ahmedNo ratings yet

- Bme001 - Advanced Internal Combustion EnginesDocument2 pagesBme001 - Advanced Internal Combustion Engineskannurunani2004No ratings yet

- Brake Booster Seminar ReportDocument17 pagesBrake Booster Seminar ReportArshad Karanath MH100% (3)

- Ae 1 Module PDFDocument113 pagesAe 1 Module PDFUnni HaridasNo ratings yet

- UntitledDocument488 pagesUntitledivan alves100% (1)

- PWR 301a Mod 1Document3 pagesPWR 301a Mod 1angerico rafilNo ratings yet

- Technical Documentation Engine Spare Parts Catalogue: MAN Diesel & TurboDocument450 pagesTechnical Documentation Engine Spare Parts Catalogue: MAN Diesel & TurboMrberkNo ratings yet

- Chapter Three: Engine CyclesDocument45 pagesChapter Three: Engine Cyclesapeff97No ratings yet

- Triumph Bonneville 750 T140V Parts Manual 1973Document81 pagesTriumph Bonneville 750 T140V Parts Manual 1973cosky00% (1)

- SU InstructionsDocument8 pagesSU InstructionsSiddeNo ratings yet

- M272 Engine Part 2Document42 pagesM272 Engine Part 2aivanov22100% (2)

- Remove & Install Cylinder Head AssemblyDocument2 pagesRemove & Install Cylinder Head AssemblyJuan LopezNo ratings yet

- Cube 2007 MTB HardtailsDocument35 pagesCube 2007 MTB HardtailsZagoni-Szabo Jozsef-CsabaNo ratings yet

- D96 Service Kits and Parts List: CAP177 - D96 SEPT 2017 - Rev BDocument32 pagesD96 Service Kits and Parts List: CAP177 - D96 SEPT 2017 - Rev BrobertNo ratings yet

- Flowchart SCR Test Routine - MS - 2008-09-05Document4 pagesFlowchart SCR Test Routine - MS - 2008-09-05gilbertoNo ratings yet

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceFrom EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)