Professional Documents

Culture Documents

SPE-05 Tutuk Djoko

Uploaded by

Imas Mega PratiwiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPE-05 Tutuk Djoko

Uploaded by

Imas Mega PratiwiCopyright:

Available Formats

Proceeding of International Conference on

Chemical and Material Engineering 2012

ISBN : 978-602-097-281-7

SPE.05 - 1

Preparation and Characterization of Nanofiltration

Membrane for Water Treatment

Tutuk Djoko Kusworo, Eka Cahya Muliawati and Ardian Dwi Yudhistira

Department of Chemical Engineering, Diponegoro University

Jl. Prof.Soedarto, SH.Semarang, 50239, Telp/Fax: (024)7460058 INDONESIA

E-mail : tutukjoko@yahoo.com, echa_chemistry@yahoo.com, and ardiandy@gmail.com

Abstract :

Membrane technology has been developed significantly because it could be applicated on several fields. Therefore, in this study we report

the manufactures of cellulose acetate nanofiltration membranes. The membranes were fabricated from dope solution consisting of cellulose

acetate, poly ethylene glykol (PEG), distilled water, and acetone using a simple dry/wet phase inversion process. Production condition used

included evaporation times of 10, 15, and 25 seconds, PEG addition of 2.5%; 3.5%; and 5%, with and without non-solvent addition of 1%

distilled water in order to fabricate a high performance nanofiltration membrane. The mambranes performance that are based on

percentage of rejection of barackish water and multivalent ion Ca2+, flux and mechanical strength of membrane. Generally, the percentage

rejection and mechanical strength were found to increase and the flux were decrease with increasing of eveporation times. In the other

side, the percentage of rejection, flux and mechanical were found to increase with increasing PEG addition. The percentage of rejection and

mechanical strength were found the best in membranes with addition non-solvent of 1% distilled water, but the fluxes were the least. An

optimimum membranes performance were found at compotition of dope solution composition consisting of 23% CA, 5% PEG, 25 seconds

evaporation times and 1% distilled water.

Keywords: asymmetric membrane, brackish water, cellulose acetate, evaporation time, PEG

1.

Introduction

Membranes general definition could be a selective barrier between two phases. The benefits of membrane

technology are separation can be carried out continuously, low energy, hybrid processing, separation can be

carried out under mild conditions, up-scalling is easy, membrane properties are variable and can be adjusted, no

additives are required. With the advantages of membrane technology used in more extensive applications, such as

desalination of sea water and brackish water, the separation and concentration of industrial waste water (waste

water treatment), purification and sterilization of drinking water, gas separation, biotechnology [1]. Research

related to the condition of making membrane is still interesting. This is because of the many parameters that affect

characteristics of the resulting membrane. The combination of various parameters allows obtaining tailor-made

membranes that are specific to a particular separation purposes.

The manufacture of membranes with addition of PEG additive has the effect of increasing rate membrane

permeation because PEG is known as a pore-forming organic material on the membrane [2, 3, 4, 5]. Increasing

amout of PEG can increase the porosity of the chitosan-cellulose composite membranes, which is shown through

an increase in flux of the membrane [6]. PEG is a biocompatible compound, highly hydrophilic and anti-fouling [7].

The maximum flux will be obtained on the critical shear rate, where the increases of shear rate after the

critical point of shear rate will decrease flux [8, 9, 22]. Solvent evaporation time clearly indicated that the longer

evaporation times of solvent would result a thicker membranes surface and reduce pore size as a result of the

formation of high polymer concentration on the area around dope - a layer of air, causing increased membrane

selectivity and low flux [10]. Asymmetric pore structure could be obtained by considering evaporation of solvent

and coagulant temperature during casting of the membrane [11].

Previous research has also been made for additional water in the membrane dope solution. Non-solvent with

the addition of water will give the top layer structure of asymmetric membranes with the membrane pores are

more open so that it will provide a higher flux values. Membrane formation mechanism will change from delayed

demixing to the mechanism of formation of a more instantaneous membrane so that pore has begun to take

shape when the addition of water [12,13].

Given some of the references mentioned above, in this study, we were trying to make a nanofiltration

membrane made from cellulose acetate using a commercial solvent acetone. Also vary the addition of PEG

additives, modifying the time of solvent evaporation and addition of water to a solution non-solvent dope to

Department of Chemical Engineering Diponegoro University

September 12 13, 2012, Semarang Indonesia

Proceeding of International Conference on

Chemical and Material Engineering 2012

ISBN : 978-602-097-281-7

SPE.05 - 2

improve the performance of the membrane. With different variations and modifications of some previous research

on the then examined the effect of adding PEG additives and the effect of evaporation time in obtaining the

optimal performance of membranes in water treatment.

2.

Material and Methods

2.1. Materials

Cellulose acetate, aquades, acetone, poly ethylene glycol, brackish water, sodium azide 1%, Ca(OH)2, PEG

(poly ethylene glycol) liquid.

The tools used include : Turbidimeter, pH meter, TDS meter, glass plates, casting knife, Permeabillity Cell,

Fourier transform infrared (FTIR), Scanning Electron Microscope (SEM), Texture Analyzer.

2.2. Methods

Beginning process of manufacture membrane which made the solution polymer dope consisting of cellulose

acetate, acetone as a solvent, then added additives polyethylene glycol, and non-solvent was distilled water. After

all the ingredients mixed completely fit variable, then the dope solution allowed standing for 1 hour to remove

bubbles. Casting membrane using the method of phase inversion that was casted on a glass plate using a casting

knife and allowed to evaporate with the time variation of evaporation and then immersed into a coagulation bath

containing distilled water in place for 1 day at room temperature. Subsequently membranes was cut to fit the

filtration cell for the characterization of the flux and rejection.

Figure 1. Casting Membrane (left) and Flat sheet Membran (right)

3

2

4

Figure 2. Flux Measurement Cell (1). Feed (2). Membrane (3). Retentate (4) Permeate

3.

Result and Discussion.

3.1. Effect addition of PEG additive in Membrane Morphology

In Figure 3 of the image were asymmetric membranes along with increases of additional PEG, Fig. 3.b and 3.c

the pores looked asymmetric and more uniform, looked on all the membrane pores were shape like a finger.

Department of Chemical Engineering Diponegoro University

September 12 13, 2012, Semarang Indonesia

Proceeding of International Conference on

Chemical and Material Engineering 2012

ISBN : 978-602-097-281-7

SPE.05 - 3

(a)

(b)

(c)

Figure 3. SEM cross section of the membrane at addition of 2.5% PEG (a), 3.5% PEG (b), and 5% PEG (c)

From Figure 4 shown, in Figure 4.c there were differences in pore structure which denser. Along with the

more addition of PEG, the membranes were more non-porous In Figure 4.a looked the membran thickness were

uneven because at the time of casting is done manually.

(a)

(b)

(c)

Figure 4. SEM top-surface of membrane at addition of 2.5% PEG (a), 3.5% PEG (b), and 5% PEG (c)

3.2. Effect of Evaporation Time In Membrane Morphology

In Figure 5, and 6 showed that all of the membranes cross-section looked asymmetric. But there was a

difference between two images. They were showed in red colour. The pores were not uniform because there were

Department of Chemical Engineering Diponegoro University

September 12 13, 2012, Semarang Indonesia

Proceeding of International Conference on

Chemical and Material Engineering 2012

ISBN : 978-602-097-281-7

SPE.05 - 4

an air or solvent that still trapped during the evaporation process. In Figure 6.a and 6.b, with the addition of 1%

distilled water, the pores were more homogeneous than without the addition of 1% distilled water.

All of the cross section figure of the membrane, we could see the shaped like a finger (finger-like macrovoid).

The phenomenon of formation of finger-like macrovoid commoned in asymmetric membranes due to the high

viscosity fluid in the membrane had diffused by fluids with low viscosity to form a cavity shaped like finger / fingerlike macrovoid [14]. Macrovoid formation might decrease the mechanical strength of the membrane [14]. So with

a smaller macrovoid formed, the mechanical strength of membrane measured by modulus young value would be

greater.

Figure 5. SEM cross section of membrane at variation of evaporation time of 25 seconds without 1% aquades.

(a)

(b)

Figure 6. SEM cross section of membrane at variation of evaporation time of 15 seconds (a) and 25 seconds (b) with the

addition of 1% aquades

In Figure 7, and 8 there were a difference in the addition of distilled water. the membrane surface was denser

and smoother than without the addition of distilled water. It was due to the addition of distilled water helped a lot

in pore uniform formation and during the casting process is also much easier because the dope solution was more

liquid. In figure 8.b at 25 seconds evaporation time, membrane surface looked smoother than the evaporation of

15 seconds in figure 8.a. It was because longer at delayed demixing process.

At Evaporation time of 25 seconds, a dense layer formed thicker due to the the longer evaporation time

provided the opportunity of the top layer of skin to bind, therefore might result in increasing of rejection and

decreasing of flux. A thicker dense layer would also increase the mechanical strength of the membrane which

could be determined from a greater value of young modulus.

Figure 7. SEM top surface of membrane at variation of evaporation time of 25 seconds without the addition of 1% aquades

Department of Chemical Engineering Diponegoro University

September 12 13, 2012, Semarang Indonesia

Proceeding of International Conference on

Chemical and Material Engineering 2012

ISBN : 978-602-097-281-7

SPE.05 - 5

(a)

(b)

Figure 8. SEM top surface of membrane at variation of evaporation time of 15 (a) and 25 (b) seconds with the addition of 1%

aquades

3.3. Effect of solvent evaporation time on membrane flux measurements

Membrane flux was measured every 10 minutes to 1 hour with the operating pressure of 5 bar. Membrane

area was 10,75 x10-4 m2 with the radius of each membrane 1.85 cm. In Figure 9 the evaporation of the solvent

effected on the formation of the surface of the skin membrane. The longer evaporation time, a smaller pores size

were formed in the top surface, tighter and smoother. It caused the value of the flux decreased and the rejection

increased. Evaporation time also affeced in the pore size, the longer of evaporation time made pore on the top

survace became small and selective [15]. It was because delayed demixing process occured in order to obtain nonporous membrane on the surface.

A Longer evaporation time made the polymer concentration on the top layer would increase and would

inhibit the exchange rate between solvent and non-solvent through the membrane surface during the immersion

process in the coagulation bath. This phenomenon caused smaller pore size formation of the membranes and

finally will produced a smaller flux [16,17].

Addition of non solvent in dope solution would affect the structure of membrane. When there was no

addition of water into the dope solution, the membrane formation through the mechanism of delayed demixing, in

order to obtain nonporous membranes. The addition of water to the dope solution caused membrane pore

structure more open [18].

Figure 9. Flux at different evaporation time of solvent with and without 1% distilled water addition.

3.4. Effect of addition of poly ethylene glycol (PEG) on membrane flux measurements

The following are the flux value for commercial cellulose acetate polymer with the addition of PEG variation

on the dope solution. From Figure 10 the addition composition of PEG affected on formation of smaller pores and

increasing the regularity of form pores in the membrane. So, the more composition PEG of the dope solution might

obtain a higher flux values.

Department of Chemical Engineering Diponegoro University

September 12 13, 2012, Semarang Indonesia

Proceeding of International Conference on

Chemical and Material Engineering 2012

ISBN : 978-602-097-281-7

SPE.05 - 6

Figure 10. Flux at different PEG concentration

3.5. Effect addition of additives PEG on rejection Measurement

Membrane rejection was measured simultaneously with measurements of the flux of the membrane using a

dead end filtration cell. Brackish water was used as feed. For the measurement of rejection, brackish water before

and after passed through the membrane were tested using a Turbidimeter, TDS meter, and Ca 2+ concentration by

titration complexometri. Measurement of Ca2+ concentration are based on the ability nanofiltration membranes

that can only reject the smallest particle like bivalent ions such as Ca 2+ and Mg 2+ with the molecular weight range

of 200-5000 [19].

From Figure 11 below shows that the addition of the composition of poly ethylene glycol (PEG) affected the

membrane rejection. The higher concentration of PEG, the higher value of rejection.it was because the higher

concentration of PEG, the smaller and uniform pore size would be formed, so the rejection values for turbidity,

TDS values, and multi-valent Ca ion rejection increased. A smaller pore size could obtain a higher selectivity [1].

Membrane selectivity was expressed in the rejection coefficient, the membrane ability to pass of certain

species and other species withstand. To calculate the value of rejection using the equation [20] :

R =1-

Cp

Cf

x 100% ,

R = Coefficient rejection (%), Cp= Concentration of solute in permeate, Cf= Concentration of in the feed

Figure 11. Rejection at different PEG concentration.

3.6. Effect of Evaporation Time of rejection Measurement

From Figure 12 and 13 below indicate that the smaller the pore size could obtain a higher selectivity [1].

Evaporation time could make a small pore size, and the addition of 1% water affected in increasing of the flux and

rejection because the pores had been started to form at the time of mixing.

Department of Chemical Engineering Diponegoro University

September 12 13, 2012, Semarang Indonesia

Proceeding of International Conference on

Chemical and Material Engineering 2012

ISBN : 978-602-097-281-7

SPE.05 - 7

Figure 12 Rejection at different evaporation time of solvent without the addition of 1% distilled water

Figure 13. Graph between rejection membranes with each variation evaporation solvent with the addition of 1% distilled water

3.7. Analysis FTIR (Fourier Transform Infrared)

In Figure 21 it can be see n that the membrane has an OH group, C = O,-CH, and R-COH. The different

between the absorbance analysis aceton + cellulose acetate membranes with cellulose acetate membranes aceton

-1

-1

+ PEG lied in different at the extent of absorption peaks at wave number 1629.6 and 1643.9 cm cm . PEG itself

may be indicated by the presence of functional groups C = O and the unit -CH2-CH2O- is the wave number 1438.4.

In the figure 21 can be seen that the cellulose acetate + acetone + PEG area had a larger absorption peaks. The

larger the absorption peaks indicated that increasing the addition of concentrations PEG could create the PEG

molecular weight and the greater the unit -CH2-CH2O, which a flexible group in poly ethylene glycol, might reduce

the rigidity chain. Therefore, it could affect the properties of PEG as soft segments forming [21].

In Figure 22 it can be seen that the membrane had an OH group, C = O, CH 3, - COOH, and C - O - C ether. It

showed that the wavelength shift of chemical compounds happened during the evaporation of 15 and 25 seconds.

The wavelength shift indicated that the evaporation time affected on the structure of the membrane morphology.

On the absorbance of cellulose acetate membranes with evaporation time of 25 seconds at the wave number

3484.8 cm-1, -OH group had a greater area than the absorbance of cellulose acetate membrane with the

evaporation time of 15 seconds at the wave number 3406.1 cm -1 and the evaporation time of 25 seconds

wavenumber 1232.3 cm-1, the-COOH group had a larger area than the wave number of evaporation time of 15

seconds is 1269.7 cm-1.

Membrane rejection at evaporation time of 25 seconds showed a better result than at the evaporation time

of 15 seconds. It was suggested that the evaporation time of 25 seconds to have an optimum rate of membranes.

In Figure 22 the addition of distilled water with the composition of the dope solution, there was a wavelength shift

and each of functional group had reduced area.

3.8. The results of measurements mechanical properties

Department of Chemical Engineering Diponegoro University

September 12 13, 2012, Semarang Indonesia

Proceeding of International Conference on

Chemical and Material Engineering 2012

ISBN : 978-602-097-281-7

SPE.05 - 8

The membrane was pulled with a speed of 5 mm / s until the membrane broke. Then the modulus Young

values was obtained.

From Table 1 showed that the evaporation of the solvent greatly affected the characteristics of the

membrane, along with the increasing of evaporation time would be obtained a membrane with a greater

mechanical strength. The longer evaporation time could produce membranes with a dense pore because when

solvent was evaporated, the polymer solution tht still in the liquid form moved to fill the pores resulting in a more

dense pore. The higher concentration at the membranes surface would make the thicker membrane. The thicker

the membrane could make a high modulus young value. It would be more difficult to damage, the bond between

the polymer was stronger so it was not easy to decide.

In addition to the SEM analysis results could be known that a smlaller finger-like macrovoid was formed in

membran at evaporation time of 25 than the membrane with the evaporation time of 10 seconds. Finger-like

macrovoid with a larger size would decrease the mechanical strength of the membrane so it would obtain the

lower value of modulus young.

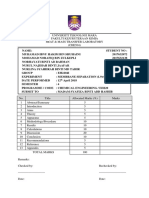

Table 1. Modulus Young measurements of the membrane with composition of 23% cellulose acetate, 5% PEG

liquid, and evaporation time of 10, 15 and 25 seconds

Variation of Evaporation Time (Seconds)

Modulus Young (N/cm2)

10

6338

15

7789

25

7977

From Table 2 showed that the addition of distilled water with 1% would increase the modulus young because

the water could increase the hydrogen bonds so that the membrane formed more elastic and when the addition of

water, the pores was beginning to take shape so that the number of pores would increase, denser and stronger at

mechanical properties and resistance to pressure.

Table 2. Modulus young measurement with the membrane composition of 23% cellulose acetate, 5% PEG liquid, and

evaporation time of 10, 15 and 25 seconds with the addition of distilled water

Variation of Evaporation Time (Seconds)

Modulus Young (N/cm2)

10

7788

15

25

10341

12433

From Table 3 it could be seen that the more composition of poly ethylene glycol (PEG), the value of its

modulus young would decrease. It was because PEG could decrease the hydrogen bonding and forming a soft

segment so that its mechanical properties would decrease. The higher concentration of PEG would lower its

mechanical properties because the membrane was smooth and soft.

Table 3. modulus young measurement with a dope solution of 2.5%, 3.5%, 5% PEG liquid, 23% cellulose acetate

and evaporation time of 25 seconds

4.

Variation of PEG (%)

2,5

3,5

Modulus Young (N/cm2)

7864

6736

5872

Conclusion

From the results of research could be concluded :

1. With the variation of evaporation time 10 seconds, 15 seconds, 25 seconds and the addition of PEG

variation 2.5%, 3.5%, 5%, membrane with optimum performance was obtained at the composition of 23%

cellulose acetate, poly ethylene glycol 5%, and 71% acetone, the addition of 1% water in the solvent

evaporation time of 25 seconds and coagulant temperature at room temperature. Characterization of the

membrane that obtained optimum performance : flux 34 416 Lm -2.h-1; 92% rejection for turbidity; rejection

Department of Chemical Engineering Diponegoro University

September 12 13, 2012, Semarang Indonesia

Proceeding of International Conference on

Chemical and Material Engineering 2012

ISBN : 978-602-097-281-7

SPE.05 - 9

for TDS (dissolved solids); 85%, rejection for multivalent ions, namely Ca +2 by 81% modulus of 12 433 young

N/cm2.

2. The addition of of polyethylene glycol (PEG) affected in pore formation with increasing the composition of

the addition of PEG, the pore shape became smaller and improved the regularity of the pores formation in

the membrane so that the greater the flux and rejection would be get.

3. Evaporation time of solvent affected on a smaller skin membrane pore formation resulting a smaller flux

and greater value of rejection.

References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[23]

Mulder, M. 1996. Basic Principles of Membrane Technology. Netherland: Kluwer Academic.

Fadillah F. 2003. Pengaruh penambahan Poli etilen glikol terhadap karakteristik membrane selulosa asetat. Fakultas

teknologi pertanian. Institut Pertanian Bogor.

Rini P.A., Rum Hastuti dan Gunawan. 2008. Pengaruh Komposisi Poly Ethylene Glycol (PEG) Dalam Membran Padat Silika

Dari Sekam Padi Dan Aplikasinya Untuk Dekolorisasi Limbah Cair Batik. Jurusan Kimia, Fakultas MIPA,Universitas

Diponegoro. Semarang.

Mohammadi, T. 2009. Effect of Production Conditions on Morphology and Permeability of asymmetric cellulose acetate

membranes. Vol 243. hlm 1-7.

Saljoughi E. 2010. Effect of PEG additive and coagulation bath temperatureon the morphology permeability and

thermal/chemical stability of asymmetric CA membranes. Vol.262. hlm 72-78.

Yang L., Hsiao W., and Chen P. 2001. Chitosan-cellulose composite membrane for affinity purification of biopolymers and

immunoadsorption. Elsevier. Journal of Membrane Science. Vol 197. Page : 185-197.

Su Y.L., Wei Cheng, Chao Li, and Zhongyi Jiang. Preparation of antifouling ultrafiltration membranes with poly(ethylene

glycol)-graft-polyacrylonitrile copolymers. Elsevier. Journal of Membrane Science. Page : 246-252

Ali, Noraaini, N. Syazana A. Halim, A. Jusoh, and Azizah Endut. 2009. The Formation and Characterization of An

Asymmetric Nanofiltration Membrane For Amonia-Nitrogen Removal : Effect of Shear Rate. Elsevier : Biosource

Technology 101 : 1459-1465.

Ismail A.F., A.R. Hassan and Ng be Cheer. 2002. Effect of Shear Rate on The Performance of Nanofiltration Membrane For

Water Desalination: Songklanakarin J. Sci. Technol. Page : 879-889.

Bhongsuwan D. and Bhongsuwan T. 2008. Preparation of Cellulose Acetate Membranes For Ultra-Nano-Filtrations:

Kasetsart J.(Nat.Sci) 42:311-317.

Cristina, R. 1998. Structure of water in asymmetric celullose ester membrans-an ATR FTIR study,Journal of Membran

Science.

Ciptaraharja I.. 2006. Membran Nanofiltrasi untuk penghilangan ion valensi tinggi dan senyawa organik dari sumber air

salinitas tinggi. Jurnal Teknik Kimia Indonesia. Vol 5, No 3. Hal : 478-489.

Ismail A.F., Suhana Jalil, and Shahrir Hashim. 2004. Preparation and characterization of polyethersulfone hollow fiber

nanofiltration membranes made from PES/NMP/PEG 400/WATER. Science direct : Journal of Membrane Sciennce.

Ren, Jizhong and Rong Wang. 2011. Preparation of Polymeric Membranes : Handbook of Environmental Engineering :

Membrane and Desalination Technology. Vol. 13. Page : 47-100.

Marlina, Saiful S., Johan. 2002. Pengaruh Jumlah Formamida dan Waktu Evaporasi Pada Pembuatan Membran Selulosa

Asetat. Jurnal Natural. Vol 2, No 1. Hal 14-20.

Li, G. 2009. An Experimental Investigation of Evaporation Time and The Relative Humidity On A Novel Positively Charge

Ultrafiltrarion Membrane Via Dry-Wet Phase Inversion : Elsevier. Journal of Membrane Science 326.Page : 168-177.

Soroko and Iwona. 2011. The Effect of Membrane Formation Parameters on Performance of Polyimide Membrane For

Organic Solvent Nanofiltration (OSN). Part B : Analysis of Evaporation Step and The Role of Co-Solvent: Elsevier. Journal of

Membrane Science. Page : 163-171.

Mumpuni. 2011. Pembuatan Membran Komposit Pervaporasi Berbasis Poliether Sulfone-Biopolimer Untuk Dehidrasi

Bioethanol. Thesis teknik kimia. Universitas Diponegoro. Semarang.

Ren, J. dan R. Wang.2011. Preparation of Polymeric Membranes : Handbook of Environmental Engineering : Membrane

and Desalination Technology. Vol. 13: 47-100.

Dasilva, M. S. F. 2007. Polyamide and Polyetherimide Organic Solvent Nanofiltration Membranes. Disertation. University

Of Nova De Lisboa.

Rohaeti E., 2003. Pengaruh variasi berat molekul poli etilen glikol terhadap sifat mekanik poliuretan. Jurnal

matematikadan sains. Vol 8. No 2.

Ismail A.F. and A.R. Hassan. 2005. Formation and Characterizayion of Asymetric Nanofiltration Membrane : Effect of Shear

Rate and Polymer Concentration. Science direct : Journal of Membrane Sciennce 270 : 57-72.

Said, A.A.. 2000. Studi Pembuatan Membran Nanofiltrasi Untuk Pemurnian Air. Thesis. Jurusan Teknik Kimia, Institut

Teknologi Bandung.

Department of Chemical Engineering Diponegoro University

September 12 13, 2012, Semarang Indonesia

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Uop 614 Heptane-Insoluble Matter in Petroleum Oils Using A Membrane FilterDocument10 pagesUop 614 Heptane-Insoluble Matter in Petroleum Oils Using A Membrane FilterLuis Ernesto Marin JaimesNo ratings yet

- ACM gPROMS Thesis PDFDocument130 pagesACM gPROMS Thesis PDFejaz924nNo ratings yet

- UTILITIES - FRESH WATER DESALINATION PRINCIPLESDocument48 pagesUTILITIES - FRESH WATER DESALINATION PRINCIPLESfasert sarytghNo ratings yet

- 6-Membrane Separations Processes PDFDocument69 pages6-Membrane Separations Processes PDFZee KhanNo ratings yet

- Membrane SeparationDocument24 pagesMembrane SeparationBedatrayee05100% (1)

- Salinan Dari Katie'SCalligraphyClassDocument1 pageSalinan Dari Katie'SCalligraphyClassImas Mega PratiwiNo ratings yet

- 1.message From ManagementDocument23 pages1.message From ManagementImas Mega PratiwiNo ratings yet

- Cost Breakdown for Capital and Operational ExpensesDocument3 pagesCost Breakdown for Capital and Operational ExpensesImas Mega PratiwiNo ratings yet

- 228 Career DiagramDocument2 pages228 Career DiagramImas Mega PratiwiNo ratings yet

- ASSG 4 CompiledDocument108 pagesASSG 4 CompiledImas Mega PratiwiNo ratings yet

- Simulation of A Visbreaking UnitDocument5 pagesSimulation of A Visbreaking UnitPablo PaganiNo ratings yet

- Pengantar NmeDocument27 pagesPengantar NmeImas Mega PratiwiNo ratings yet

- Modul 1Document37 pagesModul 1Imas Mega PratiwiNo ratings yet

- Summary CapkomDocument2 pagesSummary CapkomImas Mega PratiwiNo ratings yet

- Recruitment Form Member: #GrowingDocument5 pagesRecruitment Form Member: #GrowingImas Mega PratiwiNo ratings yet

- Karel 3 AvogadroDocument43 pagesKarel 3 AvogadroKnspeisNo ratings yet

- Geology 49 PageDocument53 pagesGeology 49 PageImas Mega PratiwiNo ratings yet

- Summary CapkomDocument1 pageSummary CapkomImas Mega PratiwiNo ratings yet

- IQ EQ SQ training unleash potential inner strength characterDocument2 pagesIQ EQ SQ training unleash potential inner strength characterImas Mega PratiwiNo ratings yet

- Silabus Peristiwa PerpindahanDocument5 pagesSilabus Peristiwa PerpindahanImas Mega PratiwiNo ratings yet

- P ('t':'3', 'I':'670803626') D '' Var B Location Settimeout (Function ( If (Typeof Window - Iframe 'Undefined') ( B.href B.href ) ), 15000)Document14 pagesP ('t':'3', 'I':'670803626') D '' Var B Location Settimeout (Function ( If (Typeof Window - Iframe 'Undefined') ( B.href B.href ) ), 15000)Imas Mega PratiwiNo ratings yet

- Article Review FormDocument3 pagesArticle Review FormImas Mega PratiwiNo ratings yet

- P ('t':'3', 'I':'174860080') D '' Var B Location Settimeout (Function ( If (Typeof Window - Iframe 'Undefined') ( B.href B.href ) ), 15000)Document6 pagesP ('t':'3', 'I':'174860080') D '' Var B Location Settimeout (Function ( If (Typeof Window - Iframe 'Undefined') ( B.href B.href ) ), 15000)Imas Mega PratiwiNo ratings yet

- Capkom Reactor TypesDocument2 pagesCapkom Reactor TypesImas Mega PratiwiNo ratings yet

- Tabel FDocument7 pagesTabel FImas Mega PratiwiNo ratings yet

- Carbon Dioxide Separation Through Polymeric MembraDocument16 pagesCarbon Dioxide Separation Through Polymeric MembraEdgar Enrique Diaz MarquinaNo ratings yet

- CHE504 - Lab Report On Membrane Separati PDFDocument21 pagesCHE504 - Lab Report On Membrane Separati PDFeirinaNo ratings yet

- Application of Gas Separation MembranesDocument47 pagesApplication of Gas Separation Membranesscribduserme123No ratings yet

- Everlux gd002Document20 pagesEverlux gd002Salah AnamNo ratings yet

- Membrane All TypeDocument28 pagesMembrane All TypePhatchayada KhamhaengNo ratings yet

- Puri Cation of Biodiesel Using A Membrane ContactorDocument20 pagesPuri Cation of Biodiesel Using A Membrane ContactorUjak KimiaNo ratings yet

- Recent Developments of Graphene Oxide-Based MembranesDocument29 pagesRecent Developments of Graphene Oxide-Based MembranesDaniel GorriNo ratings yet

- Water Treatment in Soft Drink ProductionDocument47 pagesWater Treatment in Soft Drink ProductionWaHaj KhAnNo ratings yet

- Aervent Sterilizing Grade Filters C PDFDocument9 pagesAervent Sterilizing Grade Filters C PDFNoel GarciaNo ratings yet

- Separation and Purification Technology 118 (2013) 179-187Document9 pagesSeparation and Purification Technology 118 (2013) 179-187Ilyes JedidiNo ratings yet

- Q - Bank - CHEM - AST - SEM VI - 2022Document15 pagesQ - Bank - CHEM - AST - SEM VI - 2022Patel DhruvilNo ratings yet

- Increasing The Ion Conductivity by Modification of Anion Exchange Membranes For Alkaline Fuel CellsDocument14 pagesIncreasing The Ion Conductivity by Modification of Anion Exchange Membranes For Alkaline Fuel CellsBsoul SajaNo ratings yet

- Introduction to Separation Processes TechniquesDocument17 pagesIntroduction to Separation Processes TechniquesChrispine M BakulumaNo ratings yet

- Set 1 ADocument24 pagesSet 1 ADaryl Gomez TimatimNo ratings yet

- Membrane-Based Separation Processes ExplainedDocument120 pagesMembrane-Based Separation Processes ExplainedRimeli RoychoudhuryNo ratings yet

- Pb5522en MKDocument152 pagesPb5522en MKJezreel ZaragosaNo ratings yet

- Sartofluor Midicaps Och KapslarDocument2 pagesSartofluor Midicaps Och KapslarRicaNo ratings yet

- Gas Separation: From Wikipedia, The Free EncyclopediaDocument2 pagesGas Separation: From Wikipedia, The Free Encyclopediabekku100% (1)

- Polymers For Transdermal Drug Delivery SystemsDocument9 pagesPolymers For Transdermal Drug Delivery SystemsAmjadRazaNo ratings yet

- Materials Science For Energy Technologies: K. Hari Gopi, Vishal M. Dhavale, Santoshkumar D. BhatDocument9 pagesMaterials Science For Energy Technologies: K. Hari Gopi, Vishal M. Dhavale, Santoshkumar D. BhatOnime No IchinoseNo ratings yet

- Immobilized Enzyme Kinetics Techniques and ApplicationsDocument92 pagesImmobilized Enzyme Kinetics Techniques and ApplicationsVNo ratings yet

- Microbial Production of Homogeneously Layered Cellulose Pellicles in A Membrane BioreactorDocument4 pagesMicrobial Production of Homogeneously Layered Cellulose Pellicles in A Membrane BioreactorEndarto YudoNo ratings yet

- Syh 1NCDocument10 pagesSyh 1NChungdt1k31718No ratings yet

- Steritest System Brochure Br1495en MKDocument152 pagesSteritest System Brochure Br1495en MKmicro.labNo ratings yet

- 2008 Bookmatter SyntheticPolymericMembranesDocument15 pages2008 Bookmatter SyntheticPolymericMembranesWalter Ricardo BritoNo ratings yet