Professional Documents

Culture Documents

Reverse Edm Collective Electrodes in Micro Ecm

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reverse Edm Collective Electrodes in Micro Ecm

Copyright:

Available Formats

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

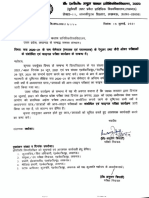

REVERSE EDM COLLECTIVE ELECTRODES

IN MICRO ECM

Sumit Kumar Singh1, Anil Chourasia2, Dr. Pankaj Agrawal3,

1,2

Research Scholar SATI Vidisha

3

Professor of SATI Vidisha

ABSTRACT

In micro ECM using ultra short pulses, the machining speed is not as fast as other processes. However, its productivity

can be increased by using collective electrodes for collective machining. In this study, collective electrodes were

fabricated by reverse EDM. By using the collective electrodes, micro hole array and grooves were machined and the

productivity was also increased. In micro ECM, the increase in machining time causes taper of structures. To prevent

taper, collective disk-type electrodes were introduced. By using dual disk-type electrodes, dual micro structures could be

machined without taper.

1.INTRODUCTION

Non-conventional machining processes like micro EDM and micro ECM are methods that machine materials by

scanning small tool electrodes along the toolpath. Because these methods can easily produce micro structures on

metallic workpieces without a mask, they are used to fabricate prototype micro products or micro molds. Since their

material removal rates are not as fast as other processes, these methods are difficult to apply in mass production[1].

However, their productivity can be increased by fabricating several electrodes and machining several holes or features

simultaneously. In ECM, since tool electrode wear is negligible, collective electrodes are much more effective than in

micro EDM. For fabricating collective electrodes, reverse EDM (REDM) was used[1]. REDM can machine collective

electrodes with various shapes easily. In this paper, the application of collective electrodes in micro ECM is

investigated. Using the collective electrodes, micro ECM is applied to hole array machining and micro milling.

2. FABRICATION OF COLLECTIVE ELECTRODES

2.1. Reverse EDM To machine collective electrodes by REDM, some holesare machined on a metal plate by EDM or

other machining processes. Then, the metal plate is attached on the XY stage, and a workpiece material for machining

micro electrodes is attached on the Z stage. The workpiece is fed down to the holes of the metal plate after applying

positive voltage to the workpiece. The workpiece material is machined by electrical discharge which occurs within

machining gap[2]. However, the regions which correspond to the holes are not machined. Finally, micro electrodes are

machined as many as the holes (figure 1).

Figure 1: Electrode fabrication by REDM.

2.2. Fabrication of triple micro electrodes Figure 2(a) shows the hole array, which is machined in the copper plate.

These holes were machined by using a micro electrode with 35 m diameter. Figure 2(b) shows the collective

electrodes, which were fabricated by REDM. Three micro electrodes of 35 m in diameter and 1.5 mm in length were

machined from abulk WC rod with a 300 m diameter. During the machining, the hole size increased from 45 m to

55 m. The radial machining gap was estimated to be about 10 m. Since the wear ratio is about 10 %, it was possible

to fabricate 1.5 mm long micro electrodes with only 200 m thick copper plate. During REDM, a short circuit between

Volume 3, Issue 10, October 2014

Page 342

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

the electrode and the workpiece occurred, causing a welding. In this experiment, by applying optimal capacitance, 650

pF, the welding could be avoided. At too high or too low capacitances, the welding occurred between the electrode and

the workpiece[4]. Since various features can be machined on a plate by micro EDM, several micro electrodes with

various shapes can be easily fabricated by REDM.

Figure 2: (a) micro holes for collective electrodes (copper, 55 m), (b) collective electrodes machined by REDM

(WC, 35 m, length 1.5 mm).

3. COLLECTIVE MACHINING

3.1. Micro hole array Figure 3 shows the micro hole array, which was machined by micro ECM. By using collective

electrodes, three holes were machined simultaneously. A total of 21 holes of 50 m in diameter were machined on a

100 m thick stainless steel plate. Pulses with 6.1 V amplitude, and 60 ns pulse on-time were applied in 0.1 M

H2SO4[4]. Since the total surface area was increased in the machining with collective electrodes, the current for each

hole was reduced and more machining time is required. The feedrate was 0.1 m/sec, which is half of the maximum

feedrate in the machining with a single electrode. However, since three holes were machined simultaneously, the

productivity of collective machining was 50 % higher than that of single machining[5]. More studies about the effect of

machining area on machining rate are required.

Figure 3: The micro holes which were machined with triple electrodes (304 SS with 100 m thickness, hole diameter:

about 50 m, 6.1 V, 60 ns pulse on-time, 1 s period).

3.2. Machining of collective structures Collective electrodes can be applied not only to the micro hole array machining,

but also to 3D micro structure machining. Figure 4 shows micro grooves which were machined by dual electrodes[8].

For betterflushing of electrolyte, material was machined layer-by-layer. For electrochemical milling, 6.0 V pulses of 60

ns duration were applied.

Volume 3, Issue 10, October 2014

Page 343

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

Figure 4: Dual grooves machined with dual electrodes (304 SS, 50 m width, 80 m depth, 6 V, 60 ns pulse on-time, 1

s period)

As shown in figure 4, the machining gap of initially machined layer is larger than that of lastly machined layer, which

causes taper. In ECM, the machining gap increases with the increase in the machining time. Since the machining time

for 3D structures is longer than that of micro hole machining, the increase in the machining gap can affect the

geometrical accuracy of 3D micro structures more severely. To prevent taper of structures, two different machining

conditions were applied in micro hole drilling and disk-type electrode was used [1, 2]. In this paper, for the collective

machining without taper, collective disk-type electrodes were machined by reverse EDM. The process for fabrication of

collective disk-type electrodes is shown in figure 5. The process of fabrication is similar to that ofcollective electrodes.

However, another hole array of the same size need to be machined. After machining collective electrodes, the electrodes

are inserted into the hole array. After inserting electrodes, the electrodes are machined by translating the plate

circularly. Then, the parts of electrodes around the plate are machined. By controlling the distance of circular

translation, the diameter of electrode neck is determine[9]d. Figure 6 shows dual disk-type electrodes and dual micro

columns which were machined with the dual disk-type electrodes. The two columns were machined simultaneously and

the taper shape was prevented. The width of columns is about 58 m and the height is 83 m.

Figure 5: The machining process for collective disk-type electrodes.

Volume 3, Issue 10, October 2014

Page 344

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

Figure 6: (a) dual disk-type electrodes (WC, 45 m disk diameter, 20 m neck diameter), (b) dual columns machined

with dual disk-type electrodes (304 SS, 58 m width, 83 m height, 6 V, 60 ns pulse on-time, 1 s period).

4. CONCLUSION

In micro ECM using ultra short pulses, the machining speed is not as fast as other processes. However, its productivity

can be increased by using collective electrodes for collective machining. In this study, collective electrodes were

fabricated by reverse[11] EDM. By using the collective electrodes, micro hole array and grooves were machined and the

productivity was also increased. In micro ECM, the increase in machining time causes taper of structures. To prevent

taper, collective disk-type electrodes were introduced. By using dual disk-type electrodes, dual micro structures could be

machined without taper.

REFERENCES

[1] Ahn, S. H., Ryu, S. H., Choi, D. K., Chu, C. N., 2004, Electrochemical Micro Drilling Using Ultra Short Pulses,

Prec. Eng., 28/2:129-134.

[2] Kim, B. H., Ryu, S. H., Choi, D. K., Chu, C. N., 2005, Micro Electrochemical Milling, J. Micromech. Microeng.,

15/1:124-129.

[3] D.C. Montgomery. 2009. Design and Analysis of Experiments, 7th Edition, Wiley.

[4] Rajurkar K.P., Levy G., Malshe A., Sundaram M.M., McGeough J., Hu X., Resnick R. and DeSilva A. 2006.

Micro and nano machining by electro-physical and chemical processes. Annals of the CIRP. 55(2): 643-666.

[5] Se Hyun Ahna, Shi Hyoung Ryua, Deok Ki Choi and Chong Nam Chua. 2004. Electro-chemical micro drilling

using ultra short pulses. Precision Engineering. 28: 129-134.

[6] Munda J., Malapati M. and Bhattacharyya B. 2005. Experimental study on electrochemical micromachining.

Journal of Materials Processing Technology. 169: 485-492.

[7] Bhattacharyya B., Malapati M., Munda J. and Sarkar A. 2007. Influence of tool vibration on machining

performance in electrochemical micro-machining of copper. International Journal of Machine Tools and

Manufacture. 47(2): 335-342.

[8] Bhattacharyya B., Doloi B. and P.S. Sridhar. 2001. Electrochemical micro machining: new possibilities for micro

manufacturing. Journal of Material Processing Technology. 113: 301-305.

[9] Bhattacharyya B., Mitra S. and Boro A. K. 2002. Electrochemical Micromachining: New possibilities for

micromachining. Robotics and Computer integrated manufacturing. 18: 283-289.

[10] Bhattacharyya B, Muda J. Experimental investigation into electrochemical micromachining (EMM) process.

Journal of Materials Processing Technology2003;140(13):28791.

[11] Shin HS, KimBH, Chu CN. Analysis of the side gap resulting frommicro electro chemical machining with a

tungsten wire and ultrashort voltage pulses. Journal of Micromechanics and Microengineering 2008;18(7):16.

[12] Brett CMA, Brett AMO. Electrochemistry, principles,methods, and applications. New York: Oxford University

Press; 1993.

[13] International Union of Pure and Applied Chemistry. Compendium of chemical terminology. Blackwell Science;

1997.

[14] W. Natsu, T. Kunimi, and A. Terada Understanding ECM phenomenon using equivalent circuit for electrolyte

reaction. Proceeding of the Euspen 9th international conference, p. 491494.

Volume 3, Issue 10, October 2014

Page 345

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

[15] Rajurkar KP, Levy G,Malshe A, SundaramMM,McGeough J, Hu X, Resnick R, DeSilva A.Micro and

nanomachining by electro-physical and chemical processes.Annuals of the CIRP 2006;55(2):64366.

[16] Schuster R, Kirchner V, Allongue P, Ertl G. Electrochemical micromachining. Science 2000;289:98101.

[17] Masuzawa T, Okajima K, Taguchi T, Fujino M. EDM-Lathe for micromachining.CIRP Annals Manufacturing

Technology 2002;51(1):3558.

[18] Fan ZW, Hourng LW. The analysis and investigation on the micro pin fabrication by electrochemicalmachining.

International Journal ofMachine Tools and Manufacture 2009;49(78):65966.

[19] Choi SH, Ryu SH, Choi DK, Chu CN. Fabrication of WC micro-shaft using electrochemical etching. The

International Journal of Advanced Manufacturing Technology 2007;31(7):6827.

Volume 3, Issue 10, October 2014

Page 346

You might also like

- L460065397 TRG-001A 58x Trigger Conversion Module Instructions v2.5Document14 pagesL460065397 TRG-001A 58x Trigger Conversion Module Instructions v2.5matt_peacock_12No ratings yet

- Auto Repair Shop Business PlanDocument40 pagesAuto Repair Shop Business PlanBelinda100% (2)

- Guidance On Lineside Signal Aspect and Indication RequirementsDocument83 pagesGuidance On Lineside Signal Aspect and Indication Requirementsle5100kw100% (1)

- Curam Solution ArchitectureDocument30 pagesCuram Solution ArchitectureRrguyyalaNo ratings yet

- Apqp Pro 8.3 Process Development PlanningDocument7 pagesApqp Pro 8.3 Process Development PlanningMattNo ratings yet

- Effect of Current On EDMDocument58 pagesEffect of Current On EDMAli M. ElghawailNo ratings yet

- Electrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyFrom EverandElectrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyRating: 4 out of 5 stars4/5 (1)

- Failures in Excavator ArmsDocument8 pagesFailures in Excavator ArmsSonyAcerNo ratings yet

- Quay Wall Construction PDFDocument8 pagesQuay Wall Construction PDFdndudcNo ratings yet

- Auditing PSM SystemsDocument39 pagesAuditing PSM SystemsPradeep Nair100% (1)

- Aerospace Material Specification: Cloth, Glass, Finished, For Resin Laminates FSC 8305Document17 pagesAerospace Material Specification: Cloth, Glass, Finished, For Resin Laminates FSC 8305anilkumar100% (1)

- List of Steel Producer and Related AssociationsDocument2 pagesList of Steel Producer and Related Associationsbindu pathakNo ratings yet

- Chapter 15 Improving Service Quality and ProductivityDocument24 pagesChapter 15 Improving Service Quality and ProductivityKaalaivaani Narayanan50% (2)

- Engine Spare Parts Stock - 2Document8 pagesEngine Spare Parts Stock - 2Jahangir HosenNo ratings yet

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocument8 pagesDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocument8 pagesImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- EDM Guide: Electrical Discharge Machining Process ExplainedDocument8 pagesEDM Guide: Electrical Discharge Machining Process ExplainedAli HusinNo ratings yet

- Electrode CoatingDocument8 pagesElectrode CoatingSaurabh JainNo ratings yet

- Analysis On Fabrication of Micro-Tools by Micro-Electrochemical Machining ProcessDocument33 pagesAnalysis On Fabrication of Micro-Tools by Micro-Electrochemical Machining ProcessXu WeixingNo ratings yet

- A Study On The Machining of High-Aspect Ratio Micro-Structures Using micro-EDMDocument8 pagesA Study On The Machining of High-Aspect Ratio Micro-Structures Using micro-EDMPeeyushiRaghavNo ratings yet

- Development of Table Top Ultrasonic Assisted Sinking Micro Electrical Discharge Machining Set UpDocument19 pagesDevelopment of Table Top Ultrasonic Assisted Sinking Micro Electrical Discharge Machining Set UpPurece EugenNo ratings yet

- Finite Element Analysis of Wire Electrode On WEDM Process Using ANSYSDocument14 pagesFinite Element Analysis of Wire Electrode On WEDM Process Using ANSYSIJRASETPublicationsNo ratings yet

- COPEN-9 Full Paper Upload 77Document6 pagesCOPEN-9 Full Paper Upload 77aghosh704100% (1)

- Microelectronic Engineering: micro-EDM and ElectroformingDocument4 pagesMicroelectronic Engineering: micro-EDM and ElectroformingMariana Hernández PérezNo ratings yet

- Process Design and Development of Electromagnetic Shearing MachineDocument9 pagesProcess Design and Development of Electromagnetic Shearing MachineIJMERNo ratings yet

- Sabotin WCMNM Paper FinalDocument5 pagesSabotin WCMNM Paper Finaljoskov71No ratings yet

- Fabrication of MicrochannelDocument9 pagesFabrication of MicrochannelHarshit AgrahariNo ratings yet

- Ultrasonic and Electric Discharge Machining To Deep and Small Hole On Titanium AlloyDocument6 pagesUltrasonic and Electric Discharge Machining To Deep and Small Hole On Titanium AlloysatishmaanNo ratings yet

- Electromagnetic Forming - Hani Aziz AmeenDocument46 pagesElectromagnetic Forming - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Design and Simulation of Electrothermally Activated Bidirectional Microtweezer Using PMMA For Biomedical ApplicationsDocument4 pagesDesign and Simulation of Electrothermally Activated Bidirectional Microtweezer Using PMMA For Biomedical ApplicationstheijesNo ratings yet

- Journal of Materials Processing TechnologyDocument8 pagesJournal of Materials Processing TechnologyJaygopalj JayamohanNo ratings yet

- Micro ECM IndiaDocument8 pagesMicro ECM IndiagskrabalNo ratings yet

- Electrochemical Microfabrication LabDocument8 pagesElectrochemical Microfabrication LabJeevan GNo ratings yet

- 13 IjtimesDocument9 pages13 IjtimesMM GoudNo ratings yet

- Finishing of Micro-EDMed Surface Based On ScanningDocument6 pagesFinishing of Micro-EDMed Surface Based On ScanningOmkar DashNo ratings yet

- Selected Problems of Micro-Electrochemical Machining: Jerzy Kozak, Kamlakar P. Rajurkar, Yogesh MakkarDocument6 pagesSelected Problems of Micro-Electrochemical Machining: Jerzy Kozak, Kamlakar P. Rajurkar, Yogesh MakkarHusnainNo ratings yet

- Fabrication of Cylindrical Micro Tools by Micro Electrochemical Form Turning OperationDocument9 pagesFabrication of Cylindrical Micro Tools by Micro Electrochemical Form Turning OperationPrapto PraptNo ratings yet

- Precision Engineering: Ravinder Kumar, Inderdeep Singh TDocument7 pagesPrecision Engineering: Ravinder Kumar, Inderdeep Singh TAnonymous 5AmJ13mLkNo ratings yet

- Study of Process Parameter of Wire Electric Discharge Machining The ReviewDocument5 pagesStudy of Process Parameter of Wire Electric Discharge Machining The ReviewIAEME PublicationNo ratings yet

- Electrical Discharge MachiningDocument6 pagesElectrical Discharge MachiningzidaaanNo ratings yet

- Draft: Manufacturing of Ionic Polymer-Metal Composites (Ipmcs) That Can Actuate Into Complex CurvesDocument11 pagesDraft: Manufacturing of Ionic Polymer-Metal Composites (Ipmcs) That Can Actuate Into Complex CurvestoanthptNo ratings yet

- Reference: Diffusion Bonded EDM Electrode With Micro Holes For Jetting Dielectric Liquid, CIRP Annals - Manufacturing Technology, 2006Document11 pagesReference: Diffusion Bonded EDM Electrode With Micro Holes For Jetting Dielectric Liquid, CIRP Annals - Manufacturing Technology, 2006EdinNo ratings yet

- EDG Study Using Rotary Disk ElectrodeDocument9 pagesEDG Study Using Rotary Disk ElectrodeSarath ChandraNo ratings yet

- Electron Beam Welding of Micro-Housings With Dissimilar Metals For Electronic CircuitsDocument3 pagesElectron Beam Welding of Micro-Housings With Dissimilar Metals For Electronic CircuitsAbhishek KumarNo ratings yet

- Comparative Analysis of Mild Steel and Zirconium Oxide CoatingsDocument13 pagesComparative Analysis of Mild Steel and Zirconium Oxide Coatingsk eswariNo ratings yet

- Rapid Hybrid Tooling Based On CNC - and EDM-milling To Fabricate Lab-on-a-Chip SystemsDocument4 pagesRapid Hybrid Tooling Based On CNC - and EDM-milling To Fabricate Lab-on-a-Chip SystemsthanhphucphanNo ratings yet

- M.tech ProjectDocument7 pagesM.tech ProjectNOMAN KASHIFNo ratings yet

- Wire EDM ProcessDocument10 pagesWire EDM Processgargi.gangwar.ecelliitkgpNo ratings yet

- Improved Electrical Discharge Machine (EDM) Servomechanism Controller For Machining Micro PitsDocument6 pagesImproved Electrical Discharge Machine (EDM) Servomechanism Controller For Machining Micro PitsKevin WellsNo ratings yet

- Design and Simulation of Bidirectional In-Plane Chevron Beam MicrotweezerDocument7 pagesDesign and Simulation of Bidirectional In-Plane Chevron Beam MicrotweezerParvulescu CatalinNo ratings yet

- Literature ReviewDocument34 pagesLiterature ReviewMuhammad WaleedNo ratings yet

- A Study On The Performance of Copper-Graphite As Tool Material in Micromachining by Micro Electro Discharge MachiningDocument4 pagesA Study On The Performance of Copper-Graphite As Tool Material in Micromachining by Micro Electro Discharge MachiningMuhammad Aamir HayatNo ratings yet

- MEMS Piezoelectric Power Generator ArrayDocument5 pagesMEMS Piezoelectric Power Generator ArrayWilliam AndrianNo ratings yet

- Induction Heating Process Design Using Comsol Multiphysics Software Version 42aDocument4 pagesInduction Heating Process Design Using Comsol Multiphysics Software Version 42areaktorenergiNo ratings yet

- EDM MachineDocument15 pagesEDM MachinePanosNo ratings yet

- A Study On Electrochemical Machining Performance Analysis of Shape Memory Alloy With Electrolyte and ElectrodeDocument5 pagesA Study On Electrochemical Machining Performance Analysis of Shape Memory Alloy With Electrolyte and ElectrodeSankalp BhatiyaNo ratings yet

- Influence of EDM Process Parameters in Deep Hole Drilling of Inconel 718Document11 pagesInfluence of EDM Process Parameters in Deep Hole Drilling of Inconel 718Pranes RainaNo ratings yet

- IIT Kharagpur: 1.1 Introduction To Electron Beam WeldingDocument16 pagesIIT Kharagpur: 1.1 Introduction To Electron Beam Weldingrajaraji33No ratings yet

- Microelectromechanical Systems Vibration Powered Electromagnetic Generator For Wireless Sensor ApplicationsDocument7 pagesMicroelectromechanical Systems Vibration Powered Electromagnetic Generator For Wireless Sensor ApplicationskhodabandelouNo ratings yet

- 15 ThreePhase Common ModeDocument12 pages15 ThreePhase Common ModeEzeldeen AgoryNo ratings yet

- A Low Cost Electrochemical Metal 3D Printer - ManuscriptDocument12 pagesA Low Cost Electrochemical Metal 3D Printer - ManuscriptAsmo DyneNo ratings yet

- Analytical Modeling of Hybrid CMOS-SET Based Moore and Mealy Logical CircuitDocument7 pagesAnalytical Modeling of Hybrid CMOS-SET Based Moore and Mealy Logical CircuitInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Electrochemical Discharge Machining Process: Anjali V. KulkarniDocument6 pagesElectrochemical Discharge Machining Process: Anjali V. KulkarniAjay kumar chaudharyNo ratings yet

- Title: MEMS Wideband Vibrational Energy HarvestingDocument5 pagesTitle: MEMS Wideband Vibrational Energy Harvestingbudhaditya royNo ratings yet

- Manufacture_of_a_Home-Made_Spot_Welding_Machine_frDocument4 pagesManufacture_of_a_Home-Made_Spot_Welding_Machine_frkimtuan835958549964No ratings yet

- Design and Construction of A Welding Machine With A Variable Current SelectorDocument11 pagesDesign and Construction of A Welding Machine With A Variable Current SelectorluiscercadoNo ratings yet

- WIRE-EDM PROCESS EXPLAINEDDocument13 pagesWIRE-EDM PROCESS EXPLAINEDSwez RatanNo ratings yet

- Investigating Effects of Process Variables On MRR in EDM by Using Taguchi Parameter Design ApproachDocument6 pagesInvestigating Effects of Process Variables On MRR in EDM by Using Taguchi Parameter Design ApproachPujara ManishNo ratings yet

- jmm8 2 025007Document8 pagesjmm8 2 025007rasoulNo ratings yet

- Electron Beam Welding: Author's: A. Leonard Pawan, A. Antony Ajay, K. Manjunath, S .Yuvaraj PandiDocument11 pagesElectron Beam Welding: Author's: A. Leonard Pawan, A. Antony Ajay, K. Manjunath, S .Yuvaraj PandiLeonard PawanNo ratings yet

- Electrical Discharge Machining: Jump To Navigation Jump To SearchDocument17 pagesElectrical Discharge Machining: Jump To Navigation Jump To SearchPanosNo ratings yet

- A Critical Review On Optimization of WEDM Process Using Taguchi ArrayDocument6 pagesA Critical Review On Optimization of WEDM Process Using Taguchi ArrayIJRASETPublicationsNo ratings yet

- Electrochemical Machining ReviewDocument5 pagesElectrochemical Machining ReviewBasavaraj HosurNo ratings yet

- VLSI Fabrication and CharacterizationDocument40 pagesVLSI Fabrication and CharacterizationKarthik RamasamyNo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Mexican Innovation System: A System's Dynamics PerspectiveDocument12 pagesThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocument10 pagesStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Soil Stabilization of Road by Using Spent WashDocument7 pagesSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Advanced Load Flow Study and Stability Analysis of A Real Time SystemDocument8 pagesAdvanced Load Flow Study and Stability Analysis of A Real Time SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Digital Record For Privacy and Security in Internet of ThingsDocument10 pagesA Digital Record For Privacy and Security in Internet of ThingsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Impact of Effective Communication To Enhance Management SkillsDocument6 pagesThe Impact of Effective Communication To Enhance Management SkillsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Deep Learning Based Assistant For The Visually ImpairedDocument11 pagesA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Document10 pagesA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Performance of Short Transmission Line Using Mathematical MethodDocument8 pagesPerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Challenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19Document10 pagesChallenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocument9 pagesSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocument9 pagesAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Secured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpDocument12 pagesSecured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Predicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsDocument10 pagesPredicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Reuse and Salvage For Gear Train and Gear Shafts On 3500 Series and C175 EnginesDocument58 pagesReuse and Salvage For Gear Train and Gear Shafts On 3500 Series and C175 Enginesma.powersourceNo ratings yet

- Avresumefall 2018 MechtimesDocument1 pageAvresumefall 2018 Mechtimesapi-294245259No ratings yet

- Ebm-Papst 6318 - 19HPU Server - Round Fan 6318 - 19HPU - PCHubDocument2 pagesEbm-Papst 6318 - 19HPU Server - Round Fan 6318 - 19HPU - PCHubBruno NascimentoNo ratings yet

- PRJ-BUL-05-2019 v2 - Work Group Supervisor Roles and AccountabilitiesDocument3 pagesPRJ-BUL-05-2019 v2 - Work Group Supervisor Roles and AccountabilitiesCK TangNo ratings yet

- Mehak Industries: Quality Assurance Plan For Logitudinal/Circumferential Welded M.S. PipeDocument1 pageMehak Industries: Quality Assurance Plan For Logitudinal/Circumferential Welded M.S. PipeSadiq ShakilNo ratings yet

- BTech 2nd Sem Exam TimetableDocument104 pagesBTech 2nd Sem Exam TimetableGaurav SinghNo ratings yet

- Hindalco Industries LTD, Mahan Aluminium Facility / Process Change ManagementDocument2 pagesHindalco Industries LTD, Mahan Aluminium Facility / Process Change Managementravi singhNo ratings yet

- Housekeeping MaterialDocument12 pagesHousekeeping MaterialDevesh TripathiNo ratings yet

- Vishay SPECTROL Part Number Replacement PCN SF 141 2014 PDFDocument9 pagesVishay SPECTROL Part Number Replacement PCN SF 141 2014 PDFAnonymous g1Uh7kzLvbNo ratings yet

- Sop For Package Integrity - Leak TestDocument4 pagesSop For Package Integrity - Leak TestMusyoka UrbanusNo ratings yet

- Stretch Film Technical Specification: 1 Product DescriptionDocument4 pagesStretch Film Technical Specification: 1 Product DescriptionAbd Alkarim MohamedNo ratings yet

- Dometic SMDocument50 pagesDometic SMZoran ProkicNo ratings yet

- Nalgene Plastics Tech Guide 0209Document64 pagesNalgene Plastics Tech Guide 0209bkorecNo ratings yet

- GPS QualificationsDocument8 pagesGPS Qualificationsozzy75No ratings yet

- How the World Bank Built an Enterprise TaxonomyDocument28 pagesHow the World Bank Built an Enterprise TaxonomyChiKita Tinitana100% (1)

- Technology and Safety of Marine SystemsDocument335 pagesTechnology and Safety of Marine SystemsJorge SilvaNo ratings yet

- Gangway Tower Preservation Procedure On SiteDocument4 pagesGangway Tower Preservation Procedure On SiteSalim Mohd RazNo ratings yet

- Richland Technologies 5th Anniversary Press ReleaseDocument2 pagesRichland Technologies 5th Anniversary Press Releaseadam_simpson9021No ratings yet