Professional Documents

Culture Documents

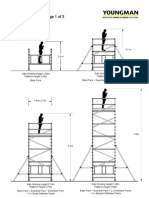

Standard Assembly Details

Uploaded by

Anonymous Tuahb8pZkCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Assembly Details

Uploaded by

Anonymous Tuahb8pZkCopyright:

Available Formats

CLADDED STAND ASSEMBLY INSTRUCTIONS

1. Delivery Of Stand

1.1

On receipt of the consignment check all the goods for general acceptable condition

and separate all items into their respective identities, i.e. frames, cell support

runners, front panels, rear panels, fasteners etc. A detailed parts list is enclosed for

a complete check of all items.

1.2

If any problems are found such as transit damage or apparently missing items,

please contact the Sales Department at the above number for assistance.

2. Preparation Of Stand Components

2.1

Each cladded stand unit comprises the following parts in varying quantities

dependent upon the specific rack type;

1.

2.

3.

4.

5.

6.

6.

7.

8.

9.

Support Frames

Runners (Cell Supports)

Insulating Runner Capping (when specified)

Tie-Bars (Diagonal Braces)

End Stand To Cladding Stand Of Brackets

Side Stand To Cladding Brackets ( > 2 Frames Only )

Front & Rear Panel(s)

End Panels

Roof Panel(s).

Kickstrips (when specified)

These parts are all identified on the enclosed exploded view drawing.

2.2

Prior to commencing assembly, ensure that all threaded fixing points are clear of

paint

2.3

Identify the relative ends of the cladding brackets. Sequences of four holes in line

are used to attach to the frame. One hole a distance of 45mm from the nearest end

indicates the top of the bracket. Bottom holes are located 15mm from their nearest

end.

2.3

Review drawing NIR3-2331 sheet 1 (attached) to achieve acceptable understanding

of the final stand assembly form. Note that this is a generic view and not specific to

the rack in question.

2.4

Fit the adjustable feet with their respective locknuts and washers and fully screw

them into the base of each support frame.

2.5

Attach the retractable handles supplied to the front cladding panels ensuring that

they open from the bottom when installed. The top of all panels can be identified by

a double folded edge that prevents them slipping off the cladding brackets when their

retaining screws are removed.

3. Assembly Of Stand

3.1

Loosely fix the 4 outside corner runners in place ensuring that no excess strain is

applied to the fixing point by the rack attempting to lean over.

3.2

Using the tie-bars, cladding brackets, relevant nylon spacers and M8 x 35 fixing

screws loosely attach the rear cladding brackets and tiebars ensuring that the top of

the bracket is located to the top of the rack. It is important to ensure that the cladding

brackets maintain a distance of 15mm from the frame leg. A selection of spacers of

both 15mm and 5mm thickness are supplied in adequate quantity to ensure this can

be achieved. Each Cladding bracket requires an earth cable to be located behind the

top fixing point for panel connection later. At the front right hand corner of the rack, it

is necessary to fit two earth cables, one of which is used for the roof panel.

3.3

Position the M8 threaded bar in the top channels of each frame ensuring that

approximately 60mm protrudes from the top of the channel. Fit the 45mm long

spacer over each threaded bar and lower the roof panel into place. At this point, the

roof panel will provide the effect of squaring up the rack assembly and the corner

runners and tiebars can now be tightened.

3.4

Fit the remaining runners in place and tighten.

3.5

Where runner capping material is supplied, fit in place over the runners.

3.6

Fit the cladding brackets to the front of the stand in the same manner as in 3.2 but in

all cases use 15mm spacers only.

3.7

Using the M8 Dome Nuts and Washers, fully fix the roof panel in place.

3.8

Unscrew the adjustable feet as necessary to level the stand. When correctly leveled

tighten the locknuts to secure the feet in their final position. It is essential that the

locknuts are tightened - failure to do this severely limits the load-bearing capacity of

the foot.

3.9

Working round the stand from the back, hang and secure each panel section in

place using the M6 x 16 Pozi Screws. Each side panel is fitted with two alternative

earth tags for connection to one earth cable previously fitted.

At this point, the stand should be fully assembled, stable and rigid. Battery bloc / cell

installation can be undertaken in accordance with the manufacturers guidelines.

The above is provided in order to ensure that assembly takes place in a tried and tested

manner. If anything is unclear, please dont hesitate to contact us on

Tel. : +44 (0) 1785 660700

Fax : +44 (0) 1785 661299

Email : support@nirvana-engineering.com

You might also like

- Design of Cold-Formed Steel Structures ASI PDFDocument104 pagesDesign of Cold-Formed Steel Structures ASI PDFgerrydimayugaNo ratings yet

- Engineering Standard Specification For Steam TracingDocument53 pagesEngineering Standard Specification For Steam Tracingkaruna346100% (1)

- Genie Switch GearDocument26 pagesGenie Switch GearDouglas KennedyNo ratings yet

- FE - FEBR Door Installation Instructions - 03-29-19 r1Document10 pagesFE - FEBR Door Installation Instructions - 03-29-19 r1Louis KiwaNo ratings yet

- Sliding DoorDocument12 pagesSliding Dooreusufiqbal100% (1)

- MW0JZE G3TXQ Broadband Hexagonal Beam Assembly Manual-18Document10 pagesMW0JZE G3TXQ Broadband Hexagonal Beam Assembly Manual-18Marcos MillerNo ratings yet

- ML700 Installation ManualDocument20 pagesML700 Installation ManualpelosyoNo ratings yet

- B&Q 8FT Trampoline PDFDocument22 pagesB&Q 8FT Trampoline PDFpaul_burger_100% (1)

- Kearney and Trecker Installation ManualDocument12 pagesKearney and Trecker Installation Manualaa987100% (1)

- Sand Slurry TestDocument5 pagesSand Slurry TestAnkit Singh100% (1)

- Adjustable-Beam Pallet Racking: Assembly GuideDocument12 pagesAdjustable-Beam Pallet Racking: Assembly GuideingenieroefNo ratings yet

- Elite Ezframe/Cinema235 & Sable Frame Series: Fixed Frame Projection ScreenDocument8 pagesElite Ezframe/Cinema235 & Sable Frame Series: Fixed Frame Projection ScreenWilliam K. McIntoshNo ratings yet

- Shield Assembly GuideDocument20 pagesShield Assembly GuideBrett DarbyNo ratings yet

- AQS-DOC020 (F) Type A Coanda Screen Installation Instructions1Document2 pagesAQS-DOC020 (F) Type A Coanda Screen Installation Instructions1barabatinaNo ratings yet

- NS114 Appendix E - Installation ManualDocument32 pagesNS114 Appendix E - Installation Manualpwills1234No ratings yet

- 2100d Installation GuideDocument20 pages2100d Installation GuideJazz TubaNo ratings yet

- Classic Inst Guide v10 - 4Document72 pagesClassic Inst Guide v10 - 4vins21No ratings yet

- Assembly and Service Instructions For Telescopic Steel CoversDocument8 pagesAssembly and Service Instructions For Telescopic Steel CoversĞőkuľ ŘãjNo ratings yet

- KTM 876 ManualDocument12 pagesKTM 876 ManualAle Stos GNo ratings yet

- 00704729-ITS1000M (Mini-Shelter) Quick Installation Guide (V100R002C02 - 01) HUAWEIDocument50 pages00704729-ITS1000M (Mini-Shelter) Quick Installation Guide (V100R002C02 - 01) HUAWEIchichofjsNo ratings yet

- Method Statement For Roofing Siding 2Document9 pagesMethod Statement For Roofing Siding 2mustafa100% (1)

- HOARDING Installation Guide: Manual HandlingDocument2 pagesHOARDING Installation Guide: Manual HandlingBasri Nor Mohd VIINo ratings yet

- Busway Installation & MaintenanceDocument18 pagesBusway Installation & Maintenanceminhtutran1983No ratings yet

- MP Tec Assembly Manual SnowflakeDocument12 pagesMP Tec Assembly Manual SnowflakeKarbonKaleNo ratings yet

- Epdesc 1Document6 pagesEpdesc 1Richard WardNo ratings yet

- Minimax DiagramsDocument10 pagesMinimax Diagramsmystery571No ratings yet

- Method Statement For Wall FormworkDocument2 pagesMethod Statement For Wall FormworkANILNo ratings yet

- Shingle Installation GuideDocument12 pagesShingle Installation GuideJefferson Mendieta100% (1)

- Amistco Mist Eliminator - Installation GuideDocument16 pagesAmistco Mist Eliminator - Installation GuidetmtoroNo ratings yet

- Chapter 1 - Shell PreparationDocument40 pagesChapter 1 - Shell PreparationEmanuel VidalNo ratings yet

- Installation Instructions: Model: RFMDocument11 pagesInstallation Instructions: Model: RFMmvelezg889706No ratings yet

- PSL500Document4 pagesPSL500Eduardo CastañedaNo ratings yet

- VA Trenchduct - : Full, Intermittent, or BottomlessDocument4 pagesVA Trenchduct - : Full, Intermittent, or BottomlessAl AlxNo ratings yet

- Westbury C10, C20 InstalltionDocument2 pagesWestbury C10, C20 InstalltionKristen AlfredNo ratings yet

- Xr5 JK 2021 VersionDocument18 pagesXr5 JK 2021 VersionLuis CuberoNo ratings yet

- Manual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)Document15 pagesManual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)victoranticonajicaro100% (1)

- Conlift Concrete Lifting SystemsDocument24 pagesConlift Concrete Lifting Systemsyyanan1118No ratings yet

- HAB 1 End To End Assembly 11-07-11Document32 pagesHAB 1 End To End Assembly 11-07-11Wamae Kangethe0% (1)

- AN-T80003 Trusted System Mechanical Build 01Document6 pagesAN-T80003 Trusted System Mechanical Build 01Houssam BahriNo ratings yet

- Installation, Operation & Maintenance Manual: Hisaka Works, LTDDocument48 pagesInstallation, Operation & Maintenance Manual: Hisaka Works, LTDmadodandembeNo ratings yet

- Manual - AR4 Travel TrackDocument22 pagesManual - AR4 Travel TrackKshitijNo ratings yet

- Standard Assembly Guidenew 2Document27 pagesStandard Assembly Guidenew 2tylerchase.caNo ratings yet

- Manual ISO SPEEDDocument16 pagesManual ISO SPEEDBernardo RatiaNo ratings yet

- Ivc Single Faced Sluice Gate Valve Valvula de CompuertaDocument14 pagesIvc Single Faced Sluice Gate Valve Valvula de CompuertaSurendra ReddyNo ratings yet

- Danley Insert Plate ArmourMate BrochureDocument12 pagesDanley Insert Plate ArmourMate BrochuresuvraNo ratings yet

- 052876-005 Patio Awning Installation ManualDocument8 pages052876-005 Patio Awning Installation ManualStacy OneillNo ratings yet

- 1.0 Work Methodology 1.1 Installation of Doors Manufacturer 1.1.1 Materials and ToolsDocument4 pages1.0 Work Methodology 1.1 Installation of Doors Manufacturer 1.1.1 Materials and ToolsmustafaNo ratings yet

- Goalrilla Basketball Goal Anchor Kit Manual-B2309Document10 pagesGoalrilla Basketball Goal Anchor Kit Manual-B2309tally3tallyNo ratings yet

- IG de Reno Mattresses InstallationDocument2 pagesIG de Reno Mattresses InstallationSílvio GonçalvesNo ratings yet

- ManualDocument9 pagesManualbheigh5054100% (1)

- Ultra Slim TV Wall Mount: Installation InstructionsDocument4 pagesUltra Slim TV Wall Mount: Installation InstructionsMạnh HùngNo ratings yet

- Tank Erection Manual 2010Document17 pagesTank Erection Manual 2010kaijuNo ratings yet

- Wynnster Mercury 9Document1 pageWynnster Mercury 9groomlake99No ratings yet

- 601 Car Frame Installations R1Document16 pages601 Car Frame Installations R1bhupiisterNo ratings yet

- RCM - Rs 07 Rack System Assembly - IIDocument2 pagesRCM - Rs 07 Rack System Assembly - IIfkNo ratings yet

- Router Table FenceDocument11 pagesRouter Table Fenceleo100% (2)

- Acson AHU O&M ManualDocument13 pagesAcson AHU O&M ManualKamran AhmedNo ratings yet

- Procedures For The Assembly and DisassemDocument5 pagesProcedures For The Assembly and Disassemعلي الزغلNo ratings yet

- EJB, Style C Model M82 Series Junction Boxes IF 931: Installation & Maintenance InformationDocument12 pagesEJB, Style C Model M82 Series Junction Boxes IF 931: Installation & Maintenance InformationAriel Paniagua VillenuevaNo ratings yet

- TH 3 MKDocument20 pagesTH 3 MKAdrianoAmadorNo ratings yet

- CMU InstallationDocument3 pagesCMU InstallationBenard MangaliNo ratings yet

- Family Handyman Ultimate Organizing SolutionsFrom EverandFamily Handyman Ultimate Organizing SolutionsRating: 5 out of 5 stars5/5 (2)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Guide To Forms of SeperationDocument32 pagesGuide To Forms of SeperationHồ ThànhNo ratings yet

- ACS800 GeneralDocument14 pagesACS800 GeneralAnonymous AMQMyB2EbNo ratings yet

- NEXTSTATION Turbo Color Capacitor ReplacementDocument8 pagesNEXTSTATION Turbo Color Capacitor ReplacementPiotr TwareckiNo ratings yet

- Evaluation of The Degree Conversion of Dental Composite Nanoparticles As An Effect On The Variation of Initial Temperature TreatmentDocument4 pagesEvaluation of The Degree Conversion of Dental Composite Nanoparticles As An Effect On The Variation of Initial Temperature TreatmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Chocolate Industry Final Presentation - NestleDocument19 pagesChocolate Industry Final Presentation - NestleJohn J. OrtolanoNo ratings yet

- ASME B31 - Standards of Pressure PipingDocument3 pagesASME B31 - Standards of Pressure PipingRachit OzaNo ratings yet

- Rotary Drum SpecsDocument16 pagesRotary Drum SpecsArrianne Jaye MataNo ratings yet

- Is-950 Water Tender, Type BDocument19 pagesIs-950 Water Tender, Type BCharls JamesNo ratings yet

- Project ChemistryDocument18 pagesProject ChemistryA MNo ratings yet

- M.tech Ise (2021-23) - List of Topics For PresentationDocument2 pagesM.tech Ise (2021-23) - List of Topics For PresentationAmarnath Reddy RagipindiNo ratings yet

- ME 231 Montazami Whharris 9-10-18 SOLUTIONDocument4 pagesME 231 Montazami Whharris 9-10-18 SOLUTIONEduardo Perez UriegasNo ratings yet

- MagnaflocDocument3 pagesMagnaflocfrancsanchezNo ratings yet

- Wa320 5Document228 pagesWa320 5Felipe Naxo Becerra Arriagada50% (2)

- C POL Resin PropertiesDocument2 pagesC POL Resin PropertiesSAURABH MODINo ratings yet

- DPC: Novel Fabric Made by Water Hyacinth (Eichornia PolyesterDocument7 pagesDPC: Novel Fabric Made by Water Hyacinth (Eichornia PolyesterRhian PanaganeNo ratings yet

- 5.1 Combustion of OilDocument6 pages5.1 Combustion of Oilkcp1986No ratings yet

- Hydronic Cooling - OikosDocument5 pagesHydronic Cooling - OikosShashank JainNo ratings yet

- Future Readymix - Original: K150 K200 Q Cost Q Cost 0.190 3.990 0.190 4.275 0.734 5.072 0.598 0.150 0.678 1.356 2 0.360Document10 pagesFuture Readymix - Original: K150 K200 Q Cost Q Cost 0.190 3.990 0.190 4.275 0.734 5.072 0.598 0.150 0.678 1.356 2 0.360Mohammed Abd ElazizNo ratings yet

- GCSBSP-200 GCSBSP-150 GCSBSP-201: TURBO Steam Master Professional Iron Plancha Profesional Steam Master Con TURBODocument2 pagesGCSBSP-200 GCSBSP-150 GCSBSP-201: TURBO Steam Master Professional Iron Plancha Profesional Steam Master Con TURBOKickingEdgarAllenPoeNo ratings yet

- Thermostability of PVC and Related Chlorinated Polymers: Application Bulletin 205/2 eDocument3 pagesThermostability of PVC and Related Chlorinated Polymers: Application Bulletin 205/2 eAnas ImdadNo ratings yet

- Literature Review Ema CpdicDocument5 pagesLiterature Review Ema CpdicHemavathy RtNo ratings yet

- DSFDocument3 pagesDSFJose Maria SantosNo ratings yet

- Boys Book of Steam EnginesDocument282 pagesBoys Book of Steam Enginesmardukzek100% (6)

- Unit 10 Thermogravimetric AnalysisDocument24 pagesUnit 10 Thermogravimetric Analysismaidhily83% (6)

- Section 05505 METAL FABRICATIONS PDFDocument13 pagesSection 05505 METAL FABRICATIONS PDFIm ChinithNo ratings yet

- Geography Form 3 Week 2 Lesson 1 Study PackDocument8 pagesGeography Form 3 Week 2 Lesson 1 Study PackIss MeNo ratings yet

- NSC 200-250/D271DC4-ADV: Technical DataDocument3 pagesNSC 200-250/D271DC4-ADV: Technical DatajtorerocNo ratings yet