Professional Documents

Culture Documents

Limited States Patent: Lngram

Uploaded by

Jin SongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Limited States Patent: Lngram

Uploaded by

Jin SongCopyright:

Available Formats

limited States Patent

[151

lngram

3,651,736

[451 Mar. 28, 11972

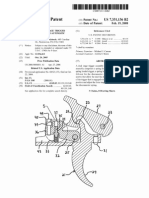

[54] BULT HANDLE AND PISTOL GRIP

MAGAZHNE FOR AN AUTOMATIC

lFlREARM

[72] Inventor:

Gordon B. Ingram, Studio City, Calif.

[73] Assignees: Michael H. Adair; lRosser S. Reeves, III,

c/o Tiderock Corporation, New York,

N.Y. , attorneysin-fact

[22] Filed:

3,276,323 10/1966

5/1967

3,318,192

Primary Examiner-Benjamin A. Borchelt

Assistant Examiner-Stephen C. Bentley

Attorney-Nolte & Nolte

[ 5 7]

Junell, 1969

Dieckmann ............................ ..89/ l 95

Miller et al ......................... ..89/l85 X

ABSTRACT

An automatic ?rearm comprises a frame, a receiver mounted

[21] Appl.No.: 832,083

on the frame, a barrel mounted on the receiver, a bolt

disposed in the receiver and telescopically movable relative to

the breech end of the barrel against the action of a recoil

[52] 11.8. C1. .................................... ..89/l32, 42/16, 89/1 K,

V

,7

'

"89/195

[51] Int. Cl ........................................................ ..F41d 11/02

[58] Field otSearch ................ ..42/7, 16.3, 72;89/27.3, 136,

89/132, 180,194,195, 197

References Cited

[56]

UNITED STATES PATENTS

710,660 10/1902

spring, the bolt being controlled by a sear which is movable in H 7

response to movement of the weapon trigger. A trigger guard

is mounted on the frame and disposed in enveloping relation

ship to the trigger and arranged with one end protruding in

wardly of the frame and adjacent the breech end of the barrel

so as to aid in guiding rounds of ammunition into the breech

end of the barrel. A bolt handle is movably mounted on the

bolt and arranged to extend through a longitudinal slot formed

in the receiver. The bolt handle is constructed so as to form a

Bennett et a1. ................. ..42/16.3 UX

locking relationship with enlarged ends of the longitudinal slot

when moved relative to the bolt and a sight passage is formed

786,099

3/1905

Clement . . . . . . . . . . . . . . . .

. . . ..89/l95 X

1,502,676

7/1924

Kewish ............. ..

....42/l6.3 UX

Reising.....

....42/l6.3 UX

in the outwardly protruding portion of the bolt handle which

allows sighting therethrough in line with the front and rear

. . . . . . ..89/l80

sights when the bolt handle is in an unlocked condition but

1,869,911

8/1932

2,297,693

l0/1942

2,424,194

3,039,366

7/1947

6/1962

Dicke . . . . . . . . . . . . .

Sampson et al.

............... ..42/72

lmthurn et al. ........................ ..42/7 X

precluding sighting when the bolt handle is in locked position.

7 Claims, 13 Drawing Figures

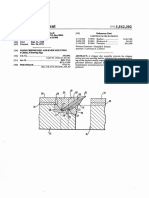

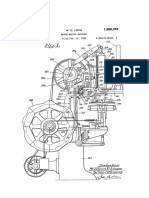

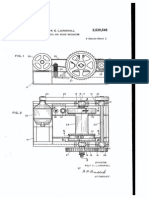

3,651,736

PATENTEHMAR 2 8 I972

SHEET 1 UF 3

I MW

MN

INVENTOR

GRDQN . ENGAM

ATTORNEY

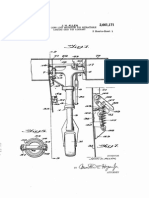

Pmmgnmzs 1972

3,651,736

SHEET 2 UF 3

57 I4

324$

30

2E

47

22

ATTORNEY

ll

3,651,736

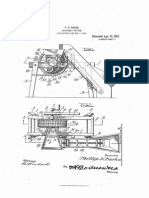

BOLT HANDLE AND PISTOL GRIP MAGAZINE FOR AN

AUTOMATIC FIREARM

Automatic weapons of the submachine gun type are some

times referred to as machine pistols and such weapons must be

light in weight and efficient in operation.

2

extend inwardly into the receiver 14. As is apparent from FIG.

9 the receiver 14 is supported at 14:: and at Mb by lateral por

tions of the trigger guard 7.

Front sight 15 is affixed in conventional manner to the for

ward end of receiver 14 and rear sight 16 is affixed by pins 17

According to this invention weight of the weapon is kept to

a minimum by constructing certain elements so that they per

form two or more functions. For example, the trigger guard of

and 18 to the frame 1.

A retractable stock 19 is mounted on a pair of rods 20

which are slidable into and out of the frame structure I.

this invention is arranged in such manner as to afford protec

Bolt 21 is slidably mounted within receiver 14 and is pro

tion for the outwardly protruding trigger and also so as to 10 vided with a cavity at its lower right hand portion as viewed in

function as guide means whereby rounds of ammunition are

FIG. 3 which is reciprocal relative to the breech portion 22 of

directed into the breech end of the gun barrel. According to

barrel 13. Bolt 21 is biased toward the right as viewed in FIG.

another feature of the invention, the bolt handle is arranged so

3 by recoil spring 23 which is disposed about rod 26. Rod 24 is

as to provide manual means for operating the bolt from its

affixed at its left hand end as viewed in FIG. 3 to the frame

15

closed to its open position and vice versa and in addition the

structure 1 and is received within a passage formed in bolt 21

bolt handle is movably mounted on the bolt so as to form a

so that the rod 23 is slidably related to bolt 21.

locking relationship with an enlarged end of the slot formed in

the receiver and in which the bolt handle is slidable. In addi- '

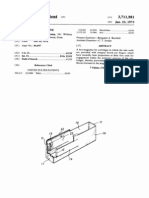

For the purpose of manually operating bolt 21 from its open

to its closediposition and viceversa, a manually operable han

tion, the bolt handle is provided with a sight path which ac

dle 25 is provided in accordance with one feature of this in

commodates the passage of liquid in alignment with the front 20 vention. Handle 25 is rotatable about its vertical axis and is

and rear sights when the bolt is unlocked but which precludes

held in a particular position by means of locking pin 26 which

sighting when the bolt is locked. In this manner a visual indica

is biased toward the left by a spring 27 and which seats within

tion of the locked and unlocked condition of the bolt is af

recesses formed on the sides of handle 25 such as are in

fordled.

dicated by the numerals 28 and 29. It will be understood that

25

For a better understanding of the invention reference may

recesses such as 28 and 29 are disposed about the periphery of

be had to the following detailed description taken in conjunc

handle 25 and preferably are four in number. Handle 25 ex

tion with the accompanying drawing in which

tends through slot 30 formed in the upper portion of receiver

14. Slot 30 is constructed with enlarged end portions 31 and

30 32.

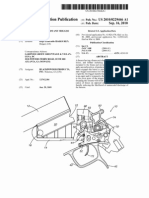

FIG. 2 is a top view of the gun shown in FIG. 1;

As is apparent from FIGS. 2A, 2B, 3A and 3B, the part of

FIGS. 2A and 2B are views taken along the line designated

handle 25 which is slidable within slot 30 is formed with a

2-2 in FIG. 2 and which respectively depict the bolt handle in

major axis and a minor axis so that when the major axis is

locked and unlocked condition;

disposed

in perpendicular relationship to slot 30 and with the

FIG. 3 is a side view partially sectioned and similar to FIG.

35 handle 25 disposed within the enlarged portion 31 or 32 of slot

1;

30, the bolt 21 is locked in position. Of course the bolt is

FIGS. 3A and 3B are views taken along the line designated

locked in its closed position when handle 25 is locked within

3-3 in FIG. 3 and depict respectively the bolt handle in

the enlarged portion 32 of slot 30. On the other hand, when

locked and unlocked positions;

FIG. 4 is an enlarged side view partially in section and which 40 the handle 25 is disposed in its locked position in enlarged

portion 31 of slot 30, the bolt is locked in its open position.

shows the bolt in its extreme open position ready for the initia

FIG. 1 is a side view of a sub-machine gun constructed ac

cording to the invention;

tion of a ?ring operation by the trigger;

FIG. 5 is a view similar to FIG. 4 but showing the bolt in an

With the bolt handle rotated to the unlocked position as

shown in FIGS. 2B and 3B, the bolt 21 is freely slidable from

left to right and vice versa.

Bolt handle 25 is provided with a sight passage 33 which al~

FIG. 6 is a view similar to FIGS. 4 and 5 but showing the 45

lows sighting along the front and rear sights 15 and 16 when

bolt in its closed firing position;

the bolt handle 25 is disposed in an unlocked position.

FIGS. 7 and 8 are enlarged views partially in section of the

On the other hand, when the bolt handle is arranged in

mechanism which depict the extractor and the ejector at the

intermediate position;

locked position, the sight passage in handle 25 is disposed in

beginning of an ejecting operation and at the completion

transverse relationship to the line of sight de?ned by from

thereof respectively and in which

50

sight 15 and rear sight 16 thereby affording a ready visual indi

FIG. 3 is a sectional view taken along the line 9--3 in FIG.

cation of the locked condition of the bolt.

For the purpose of securing the removable magazine 4 in

In the drawings the numeral 1 designates the frame struc

position within magazine housing 2, a rotatable latch 34 is

ture of the weapon to the bottom portion of which a magazine

housing designated by the numeral 2 is affixed. A hand 55 pivotally mounted on pin 35 within the hand grip portion 3 of

magazine housing 2. Furthermore latch 34 is biased in a

gripping portion 3 forms a part of magazine housing 2 and the

clockwise direction toward latching position by a compression

numeral 4 designates a conventional removable magazine

1.

structure.

spring 36 to cause the latching surface 37 of latch 34 to ride

underneath the latching surface 38 formed in magazine 4.

designated by the numeral 5. Trigger 5 is pivotally mounted on 60 Thus as shown in FIG. 3, the magazine 4 is held in its service

The trigger is of conventional construction and is

pin 6 secured to frame I in a manner well known in the art.

position.

The numeral 7 generally designates a trigger guard which is af

In order to remove magazine 4, manual pressure is applied

to projecting portion 39 of latch 34 to cause the latch to rotate

in a counterclockwise direction about pin 35. This action

fixed at one end to the frame 1 as by welding designated by the

numeral 8. Trigger guard 7 is provided at the other end with

an inwardly extending portion 9 which serves not only as a 65 releases latching surface 37 from latching surface 33 and al

lows the magazine 4 to be removed downwardly in conven'

portion of the trigger guard but which also serves as guide

tional fashion.

means whereby rounds of ammunition from the magazine 43

For the purpose of biasing ammunition rounds upwardly in

are directed into the breech end of the barrel. The numeral 10

a conventional manner, a spring 40 is provided which is of the

designates an intermediate portion of the trigger guard "i

which protrudes outwardly and functions in the conventional 70 compressional type and which functions in known manner as

is obvious from FIG. 3.

manner as a guard for trigger 5.

For controlling the operation of bolt 21 by means of trigger

In order to facilitate secure holding of the gun by the user, a

5, a scar 41 is provided with a latching surface 42 which en

strap 111 is mounted on bracket 12 to the frame of the weapon.

gages the lower right hand comer 43 of bolt 21 to hold the bolt

The barrel of the weapon is ?xedly mounted to the frame

and is designated by the numeral 13. Barrel 13 is arranged to 75 in its extreme left hand position. Sear 41 is pivotally mounted

3,651,736

on pin 44 supported 'on frame ll. Sear 41 is biased in a

clockwise direction about pin 44 by means of compression

spring 45. A pin as is mounted on sear 411. and affords a sur

4

end of said barrel, a ?ring pin ?xedly positioned on a portion

of the bolt so located relative to the breech end of the barrel as

to come into contact with the free end of a cartridge of a

face for engagement by trigger 5. Thus in order to ?re the

weapon and with the parts disposed in the positions depicted

in FIG. 4, it is simply necessary manually to rotate trigger 5 in

round of ammunition in the breech end of the barrel upon

release of the bolt from its open position, recoil spring means

a clockwise direction about its pin 6. This action causes the

trigger 5 to rotate sear 41 in a counterclockwise direction

ing a trigger and sear movably mounted on said frame and

operable to release said bolt from its open position to initiate a

?ring operation, a magazine mounted on said frame with its

about pin 444 due to the engagement of trigger 5 with pin 46.

Rotation of sear 41 causes its latching surface 42 to disengage

the lower right hand latching surface 43 of bolt 21. When the

bolt is thus released, recoil spring 23 drives the bolt 21 toward

the right causing the round of ammunition designated Rl to

arranged to bias said bolt toward ?ring position, means includ

discharge portion adjacent the breech end of said barrel, a

trigger guard ?xedly mounted on said frame and having an in

termediate portion extending from said frame outwardly and

in enveloping relation to said trigger, said trigger guard being

slide upwardly and toward the right along guide portion 9 of

arranged with one end thereof disposed adjacent the discharge

15

trigger guard 7 as shown for example in F IG. 5. With round Rll

portion of said magazine and extending toward the breech end

seated within the breech portion 22 of barrel l3, ?ring pin 47

engages the cap portion of round Ril and ?res the round. The

of said barrel for guiding rounds of ammunition into the

breech end of said barrel prior to ?ring, and a bolt handle

projectile P11 proceeds outwardly toward the right in conven

tional fashion. .The pressure developed urges the cartridge

movably mounted on said bolt and protruding outwardly

through a longitudinal slot formed in said receiver, said slot

case (I'll toward the left which action drives the bolt Zll toward

the left against the action of recoil spring 23. Of course the

weapon continues to ?re automatically in known manner as

and said bolt handle being con?gured so as to prevent move

ment of said bolt relative to said receiver for'one position of

long as trigger 5 is depressed.

said bolt handle relative to said bolt and so as to accommodate

movement of said bolt relative to said receiver for another

Cartridge case such as Cl is extracted from the breech 22 of 25 position of said bolt handle relative to said bolt.

2. A ?rearm comprising a frame, a receiver mounted on said

the numeral 48. As the cartridge case such as Cl moves

frame, a barrel mounted on said receiver, a bolt mounted in

barrel 13 by an extractor designated for example in FIG. 7 by

toward the left in unison with the bolt 21, ejector pin 439

strikes the cartridge case C1 and drives the case downwardly

said receiver and telescopically movable relative to the breech

end of said barrel, recoil spring means arranged to bias said

and outwardly through the ejector opening 5t) formed in 30 bolt toward ?ring position, means including a trigger and sear

frame ll. This action is depicted in FIG. 8. Of course the ejec

movably mounted on said frame and operable to release said

tor pin 49 is disposed within a passageway 51 formed in bolt

bolt from its open position to initiate a ?ring operation, a

21 so that there is a slidable relationship between the bolt 21

magazine mounted on said frame with its discharge portion

and ejector pin 49 which pin is ?xed in position relative to

adjacent the breech end of said barrel, and a trigger guard ?x

frame ll. The extreme right hand end 52 of ejector pin 49 35 edly mounted on said frame and having an intermediate por

simply engages the lower side portion of cartridge case C11 and

tion extending from said frame outwardly and in enveloping

forces the case to swing out of contact with the jaws of the ex

tractor db.

The stock 19 as explained above is retractably mounted on

relation to said trigger, said trigger guard being arranged with

one end thereof extending inwardly into the interior portion of

- said frame through an opening formed therein and disposed

the frame 1 by virtue of the slidable relationship of rods 20 40 somewhat to the rear of the breech end of said barrel and said

with the frame ll. Rods 20 are provided with a pair of notches

one end of said trigger guard being con?gured to de?ne an up

which cooperate with manually controlled transversely

disposed locking rods. For example, outwardly protruding

wardly inclined path for guiding rounds of ammunition into

the breech end of said barrel prior to ?ring.

manually engageable pin 53 is engageable with transversely

3. A ?rearm according to claim 2 wherein the other end of

disposed locking rods 54 and 55 which cooperate with a trans 45 said trigger guard is ?xedly mounted on said frame immediate

verse notch formed in rods 20. Rods 5d and 55 together with

the manually operable element 53 are biased downwardly by

compression spring 56 which is mounted within manually

operable element 53. Spring 56 at its upper end is seated

ly forward of said trigger.

'

4. A ?rearm comprising a frame, a receiver mounted on said

frame, a barrel mounted on said receiver, a bolt mounted in

said receiver and telescopically movable relative to the breech

end of said barrel, recoil spring means arranged to bias said

bolt toward ?ring position, means including a trigger and sear

movably mounted on said frame and operable to release said

bolt from its open position to initiate a ?ring operation, a

3, upward pressure on manually operable release element 53 55 magazine mounted on said frame with its discharge portion

elevates the transversely disposed locking rods 54 and 55 and

adjacent the breech end of said barrel, and a trigger guard ?x

causes those rods to disengage the notches formed in rods 24)

edly mounted on said frame and having an intermediate por

against plate 57 secured at its forward and rear portions to

transversely disposed rods 58 and 59 which are mounted at

their ends in ?xed relationship on frame structure ll. Thus with

the stock 19 disposed in its retracted position as shown in HG.

and allows the rods 20 to be withdrawn toward the left. When

tion extending from said frame outwardly and in enveloping

the right hand notch of rods 2%} (not shown) engages the

relation to said trigger, said trigger guard being arranged with

downwardly biased locking rods 54 and 55, the stock 119 is 60 one end thereof disposed adjacent the discharge portion of

locked in its outwardly extended position. in this position the

said magazine and extending toward the breech end of said

weapon may be ?red by resting the stock 19 against the

barrel for guiding rounds of ammunition into the breech end

shoulder, hip, chest or the like of the user. in order to retract

of said barrel prior to ?ring and said one end of said trigger

the stock 19, the element 53 is pushed upwardly and the stock

guard being provided with lateral portions for engaging lower

pushed inwardly into the locking position shown in FIG. 3.

65 parts of said receiver and for affording support therefor.

Safety element 60 is movable by pin 6H manually in a trans

5. A ?rearm comprising a frame, a receiver mounted on said

verse direction about pin 62 as a center so as to engage the

frame, a barrel mounted on said receiver, a bolt mounted in

sear 4311 at the rear thereof thereby to prevent bolt releasing

said receiver and telescopically movable relative to the breech

end of said barrel, recoil spring means arranged to bias said

bolt toward ?ring position, a bolt handle movably mounted on

movement of the sear.

The embodiments of the invention in which an exclusive

property or privilege is claimed are de?ned as follows:

i claim:

ll. A firearm comprising a frame, a receiver mounted on said

frame, a barrel mounted on said receiver, a bolt mounted in

said bolt and protruding outwardly through a longitudinal slot

formed in said receiver, said slot and said bolt handle being

con?gured so as to prevent movement of said bolt relative to

said receiver for one position of said bolt handle relative to

said receiver and telescopically movable relative to the breech 75 said bolt and so as to accommodate movement of said bolt

3,651,736

relative to said receiver for another position of said bolt handle relative to said bolt, and a sight passage being formed in

said bolt handle and arranged to accommodate sighting when

said bolt handle is disposed in unlocked condition but not

6. A ?rearm according to claim 5, further comprising at

least one sight aligned with the bolt handle.

7- A ?rearm according to claim 5' further comprising from

and rear sights aligned withthe bolt handle

when said bolt handle is in a bolt locking position.

15

25

30

35

'40

45

50

55

60

65

75

"

You might also like

- Black Diamond ManualDocument72 pagesBlack Diamond ManualDale Hannum67% (3)

- Owen Sub Machine Gun PatentDocument11 pagesOwen Sub Machine Gun PatentBallistics67% (3)

- (GUNSMITHING) Sten Submachine Gun WWIIDocument7 pages(GUNSMITHING) Sten Submachine Gun WWIIMago Invisivel100% (10)

- The DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFDocument15 pagesThe DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFgunpdfs93% (121)

- Crosman 160 Factory Service ManualDocument9 pagesCrosman 160 Factory Service ManualCKJJ55@hotmail.cm75% (4)

- Maintain Armored Vehicle TurretDocument120 pagesMaintain Armored Vehicle TurretKamerad Les50% (2)

- 45 Automatic, The - NRA American Rifleman Reprint - OcrDocument28 pages45 Automatic, The - NRA American Rifleman Reprint - Ocrmaxi29999100% (5)

- Beretta Px4 Storm: 17Document9 pagesBeretta Px4 Storm: 17John Newberry100% (1)

- Practical Pathology of Gunshot Wounds: J. Scott Denton, MD Adrienne Segovia, MD James A. Filkins, MD, JD, PHDDocument7 pagesPractical Pathology of Gunshot Wounds: J. Scott Denton, MD Adrienne Segovia, MD James A. Filkins, MD, JD, PHDdwee_RNSNo ratings yet

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Document16 pagesSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongNo ratings yet

- United States Patent 1191: MasuyamaDocument7 pagesUnited States Patent 1191: MasuyamaAbdullah AljabriNo ratings yet

- Oct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Document5 pagesOct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Юрий РуденкоNo ratings yet

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pages1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongNo ratings yet

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- Us965386 PDFDocument6 pagesUs965386 PDFJin SongNo ratings yet

- Us4854065 PDFDocument7 pagesUs4854065 PDFJin SongNo ratings yet

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- Us 3706152Document7 pagesUs 3706152rte678No ratings yet

- Us 4407085Document5 pagesUs 4407085rte678No ratings yet

- H.M. Sprague's Folding Pistol Patent from 1912Document4 pagesH.M. Sprague's Folding Pistol Patent from 1912djsfNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- Us 5117735Document14 pagesUs 5117735sdfsdf333No ratings yet

- Us4358986 PDFDocument9 pagesUs4358986 PDFJin SongNo ratings yet

- Benet Mercie BreechDocument13 pagesBenet Mercie BreechAnonymous htRZ5zTMgNo ratings yet

- Jan. 4, L 1966 T. W. Spack 3,227,148Document6 pagesJan. 4, L 1966 T. W. Spack 3,227,148MainAvelNo ratings yet

- ??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Document7 pages??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Слэйтер Строительная компания100% (1)

- Adjustable Handles for Riding or Walking Behind Lawn MowerDocument4 pagesAdjustable Handles for Riding or Walking Behind Lawn Mowerraseks1No ratings yet

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- Viewfinder ProjectDocument4 pagesViewfinder ProjectAndrei PoseaNo ratings yet

- Nov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Document6 pagesNov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Jin SongNo ratings yet

- United States PatentDocument5 pagesUnited States PatentJagannathan ArumugamNo ratings yet

- 3/ Z7 VZMZM/ZZ : V. Holek 2,216,412Document3 pages3/ Z7 VZMZM/ZZ : V. Holek 2,216,412wererNo ratings yet

- M2 HB Bolt Side Change US2529391Document4 pagesM2 HB Bolt Side Change US2529391apoorva singhNo ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- ZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Document5 pagesZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Edikan AkpanNo ratings yet

- Title - Wood Chipper Disc and Knife MountingDocument5 pagesTitle - Wood Chipper Disc and Knife Mountingمحمد عبدالدايمNo ratings yet

- Dec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Document8 pagesDec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Rezicky ImamNo ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- United States Patent (191: SeecampDocument4 pagesUnited States Patent (191: Seecamp9aszerfNo ratings yet

- April 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965Document4 pagesApril 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965fgrt490No ratings yet

- Foldable Boat FlierDocument5 pagesFoldable Boat FlierRakeshNo ratings yet

- Us 1401667Document11 pagesUs 1401667kissaNo ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- Mannlicher Us1008162Document6 pagesMannlicher Us1008162cll1968No ratings yet

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduNo ratings yet

- US3173686 (Coin-Op Kiddie Ride)Document8 pagesUS3173686 (Coin-Op Kiddie Ride)ENo ratings yet

- Automatic Firearm: Original Filled July 31, 1923Document30 pagesAutomatic Firearm: Original Filled July 31, 1923Jay MasonNo ratings yet

- Pocket Lighter Patent from 1936 Describes Zippo DesignDocument3 pagesPocket Lighter Patent from 1936 Describes Zippo DesignRakeshNo ratings yet

- M1-M14 Conversion US3362095Document3 pagesM1-M14 Conversion US3362095apoorva singhNo ratings yet

- Us4467698 PDFDocument11 pagesUs4467698 PDFJin Song100% (1)

- Pistol Nickl Us1427966Document11 pagesPistol Nickl Us1427966cll1968No ratings yet

- US2128620 - Bending MachineDocument5 pagesUS2128620 - Bending MachinedevheadbotNo ratings yet

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDocument7 pagesCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Document7 pages"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNo ratings yet

- Thompson Proto US1425810Document4 pagesThompson Proto US1425810apoorva singhNo ratings yet

- A Single ShontgunDocument3 pagesA Single ShontgunyuehanNo ratings yet

- Us2297693 PDFDocument8 pagesUs2297693 PDFJin SongNo ratings yet

- US2755738 Rocket Fuze 3.5 Inch Rocket M404 PatentDocument3 pagesUS2755738 Rocket Fuze 3.5 Inch Rocket M404 Patentrichardwb1No ratings yet

- Nov. 22, 1932. W. D. Lpps. 1888,353Document12 pagesNov. 22, 1932. W. D. Lpps. 1888,353AGUAVIVANJNo ratings yet

- Us1446763 PDFDocument7 pagesUs1446763 PDFJin SongNo ratings yet

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Document12 pagesL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniNo ratings yet

- Anti-Aircraft Fire Control Device (1937)Document10 pagesAnti-Aircraft Fire Control Device (1937)CAP History LibraryNo ratings yet

- Mannlicher Us1166913Document6 pagesMannlicher Us1166913cll1968No ratings yet

- GB657382ADocument4 pagesGB657382AOctav IanNo ratings yet

- A Neolithic Ceremonial Complex in Galloway: Excavations at Dunragit and Droughduil, 1999–2002From EverandA Neolithic Ceremonial Complex in Galloway: Excavations at Dunragit and Droughduil, 1999–2002No ratings yet

- 撞针选择的枪 PDFDocument9 pages撞针选择的枪 PDFJin SongNo ratings yet

- 可调式双级触发机制半自动武器 PDFDocument12 pages可调式双级触发机制半自动武器 PDFJin SongNo ratings yet

- 锤执行器的枪支 PDFDocument7 pages锤执行器的枪支 PDFJin SongNo ratings yet

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDocument6 pages偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongNo ratings yet

- 螺栓枪口装步枪 PDFDocument7 pages螺栓枪口装步枪 PDFJin SongNo ratings yet

- 枪炮声抑制器 PDFDocument11 pages枪炮声抑制器 PDFJin SongNo ratings yet

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Document24 pagesUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongNo ratings yet

- 块化插入触发器的方法和装置5 PDFDocument23 pages块化插入触发器的方法和装置5 PDFJin SongNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,069,602 B2Document13 pagesUlllted States Patent (10) Patent N0.: US 8,069,602 B2Jin Song100% (1)

- 级触发自动武器 PDFDocument15 pages级触发自动武器 PDFJin SongNo ratings yet

- 安装装置,枪支消声器 PDFDocument28 pages安装装置,枪支消声器 PDFJin Song100% (1)

- Us7676976 PDFDocument35 pagesUs7676976 PDFJin SongNo ratings yet

- Us7946069 PDFDocument15 pagesUs7946069 PDFJin SongNo ratings yet

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Document15 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Jin Song100% (1)

- Us6418655 PDFDocument17 pagesUs6418655 PDFJin SongNo ratings yet

- Us6308609 PDFDocument18 pagesUs6308609 PDFJin SongNo ratings yet

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- Us5274939 PDFDocument7 pagesUs5274939 PDFJin SongNo ratings yet

- Us4358986 PDFDocument9 pagesUs4358986 PDFJin SongNo ratings yet

- Us4854065 PDFDocument7 pagesUs4854065 PDFJin SongNo ratings yet

- Us4467698 PDFDocument11 pagesUs4467698 PDFJin Song100% (1)

- Nov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Document6 pagesNov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Jin SongNo ratings yet

- Us4522106 PDFDocument13 pagesUs4522106 PDFJin Song100% (1)

- Us3276323 PDFDocument7 pagesUs3276323 PDFJin SongNo ratings yet

- Base Weapon Design DMDocument36 pagesBase Weapon Design DMBrenda Robles100% (3)

- BaikalDocument63 pagesBaikalSAIFNo ratings yet

- M Lok Modular Accessory System Owners Manual2Document11 pagesM Lok Modular Accessory System Owners Manual2bahriun syahriNo ratings yet

- Forensic Ballistics 5Document8 pagesForensic Ballistics 5johnpaulacostaNo ratings yet

- BHP Trigger JobDocument8 pagesBHP Trigger Jobssnvet100% (3)

- Instruction Manual For Magnum Research's MLR-1722 RifleDocument15 pagesInstruction Manual For Magnum Research's MLR-1722 RifleYamveaNo ratings yet

- BA STEYR EVO 10 enDocument26 pagesBA STEYR EVO 10 enAnwar AnwarNo ratings yet

- Manual Colt M4 M16 22 Rimfire 10R11Document32 pagesManual Colt M4 M16 22 Rimfire 10R11Mike Cannady0% (1)

- Ryobi RLT254CDSO User ManualDocument48 pagesRyobi RLT254CDSO User ManualPaul WilsonNo ratings yet

- MGS 916 Catalog FinalDocument13 pagesMGS 916 Catalog FinalFrank MeekerNo ratings yet

- Pistol Shooting Technique GuideDocument11 pagesPistol Shooting Technique Guidemladen1858948No ratings yet

- Zastava m57 M70a ENDocument16 pagesZastava m57 M70a ENmarcial ponceNo ratings yet

- Uncle Mikes 235431-2014 CatalogDocument32 pagesUncle Mikes 235431-2014 CatalogAdrian KozelNo ratings yet

- Gen4 ENDocument20 pagesGen4 ENjessebearNo ratings yet

- HK MP5Document126 pagesHK MP5Adri Mas Mola100% (1)

- 1911manual 5Document64 pages1911manual 5jackNo ratings yet

- Beretta 92A1 & 96A1 User ManualDocument88 pagesBeretta 92A1 & 96A1 User Manualtroutn222No ratings yet

- Rotary Hammer ManualDocument12 pagesRotary Hammer Manualt_sebi20039559No ratings yet

- FDASDocument22 pagesFDASAly Bueser67% (3)

- Sako S20Document32 pagesSako S20OneMAN TwoWHEELSNo ratings yet

- M4 Carbine Instruction/Safety ManualDocument52 pagesM4 Carbine Instruction/Safety ManualTaKTiKiLLNo ratings yet

- CZ USA 2017 Product CatalogDocument81 pagesCZ USA 2017 Product CatalogMario Lopez100% (1)

- TECHNICAL MANUAL - Shortguns, All Types PDFDocument258 pagesTECHNICAL MANUAL - Shortguns, All Types PDFTien Nguyen Van100% (1)

- Measurelab User ManualDocument25 pagesMeasurelab User ManualMohamed MohamedNo ratings yet