Professional Documents

Culture Documents

Us4358986 PDF

Uploaded by

Jin SongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us4358986 PDF

Uploaded by

Jin SongCopyright:

Available Formats

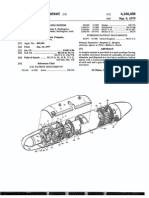

United States Patent [19]

[ll]

[45]

Giorgio

[54] RIFLE BOLT ASSEMBLIES

[76] Inventor:

Nov. 16, 1982

Attorney, Agent, or FirmEmory .L. Groff, Jr.

Charles Giorgio, 48 Justin St.,

Smith?eld, N.S.W, Australia

[57]

ABSTRACT

A ri?e having a body comprised of hingedly intercon

[21] Appl. No.: 183,163

nected lower and upper receivers, a trigger and hammer

assembly mounted in the lower receiver, a barrel ex

tending from one end of the upper receiver, an inte

grated bolt assembly removably mounted in the upper

receiver, the bolt assembly comprising a bolt carrier

[22] Filed:

Sep. 2, 1980

[30]

Foreign Application Priority Data

Sep. 11, 1979 [AU]

4,358,986

Australia ............................ .. PEO444

slidably mounted on two action rods joined at corre

[51]

Int. Cl.3 .............................................. .. F41D 5/04

sponding ?rst ends by an action plate, the action rods

[52]

US. Cl. ..................................... .. 89/142; 89/1 K;

being releasably supported at corresponding ends in the

[58]

Field of Search ........................ .. 89/1 K, 185, 199

89/185; 89/199; 89/128

ri?e body, a bolt slidably mounted in the bolt carrier, a

?ring pin slidably mounted in the bolt, compression

References Cited

springs between the action plate and the bolt carrier and

U.S. PATENT DOCUMENTS

retaining means on the action rods to retain the bolt

carrier on the action rods and retain the members of the

[56]

2,403,306

3,318,192

3,386,336

7/1946

5/1967

6/1968

Sampson et al. ............. ..... .. 89/199

Miller et al. ..... ..

89/199

Roy ..................................... .. 89/199

bolt assembly integrated so the bolt assembly can be

removed from the upper receiver as a complete unit.

Primary Examiner-Stephen C. Bentley

GGQ,

66

: U

m gl'unllllrllu

7 Claims, 5 Drawing Figures

emu-494%.

US. Patent

Nov. 16, 1982

Sheet 1 of 4v

4,358,986

mo. ,

US. Patent

Nov. 16, 1982

Sheet 2 of4

///////////

4,358,986

US Patent

Nov. 16, 1982

in.

mm

Sheet4 of4

4,358,986

4,358,986

the trigger 3 about pin 4 and has a limited arc of move

ment relative to the trigger 3 and is biased in a clock

RIFLE BOLT ASSEMBLIES

wise direction about pin 4 by a hidden spring. There is

a hammer 6 pivoted to the lower receiver about pin 7

This speci?cation describes improvements in ?re

arms. Speci?cally the improvements are directed to

and a torsion spring indicated 8 biases the hammer in a

clockwise direction. The hammer 6 has a ?rst lug 9 at its

lower end, an intermediate lug l0 and an upper lug 11.

Pivotally mounted at 12 is a sear, or automatic trigger,

providing a ?rearm which is versatile and easy to main

tain and operate.

The versatility will be apparent when it is understood

that the weapon can be used as a pistol or a rifle type

weapon and can be used as a single shot or an automatic

13 spring biased by torsion spring 14 against a multi

lobed cam 15 inside the lower receiver 1 and coupled to

a selector 16 which is illustrated in FIG. 1 in the single

?ring weapon. The versatility is further enhanced by

the use of a control element which when ?tted to the

weapon allows an automatic or semi-automatic ?re

shot position. The letter S indicates the safety non-?re

position for the selector l6 and the letter A indicates the

automatic ?re position.

pattern and when removed limits the weapon to single

shot. This is a major advantage as in many situations,

such as police actions and certain warfare situations, a

commanding officer can determine the mode of weapon

use and issue or withhold the control element depend

ing upon whether the men under his control should be

in a position to use automatic ?re patterns. In known 20

weapons the control over single shot (semi-automatic)

At the rear end of the lower receiver is a stock sup

port 17 to house a short stock 18, which is used when

the weapon is in the pistol form, or a full stock (not

shown). The stock is held in place by the screw 19.

There is a notch 20 in the support 17 for a purpose to be

described.

At the other end of the lower receiver there are two

arms 21 to receive a pivot pin 22 to pivotally secure a

or automatic ?re patterns rests solely with the user.

A major structural advantage of the present weapon

tongue 23 of the upper receiver 24 to the lower receiver

over known weapons is that the bolt assembly is remov

1. In the lower receiver there are two transverse plates

able as a complete unit, this allows for replacement (if 25 25 and 26 to locate the upper end of a magazine 27. The

damaged) and cleaning (if dirty) in a simple and conve

magazine 27 has a longitudinal rib 28 to engage a locat

nient manner. Known weapons provide a bolt assembly

ing groove 29 to the plate 26. The magazine 27 is se

which is comprised of many parts arranged in such a

cured in the lower receiver by a spring loaded catch

way when the bolt. assembly is removed the user has a

comprising a plate 30 with a catch lug (not shown) to

collection of non interconnected components or com 30 project into the interior of the lower receiver 1 so as to

ponent groups which have to be re-assembled in the

be engageable in a hole 31 in the magazine 27. The catch

weapon after individual cleaning. The present invention

lug is disengaged from the hole 31 by laterally moving

has an advantage over such weapons particularly in a

night combat situation where there is no light to assist in

the catch plate 30 in the direction of the arrow by press

ing a button (not shown) on the obscured side of the

the stripping and re-assembling of the weapon.

35 lower receiver 1, FIG. 1.

The weapon of this invention has a ?ring rate, in

The upper receiver 24 comprises a tubular body 32 at

automatic mode, slower than that of current automatic

one end of which there is internally ?xed a barrel exten

weapons and provides less recoil and kick than

sion 33 with a bore threaded at 36 to receive the

known comparable weapons. This is achieved by design

threaded ?rst end 34 of a barrel 35. There are three

features which will be described. The weapon also pro 40 evenly spaced circular segments 37 projecting into the

vides a new form of rear sight which is simple and

bore of the barrel extension 33, they are separated by

effective.

three gaps 38. The rearward surfaces of the segments 37

The operational reliability of the weapon, as mea

are angled, see FIG. 4 and there are two adjacent bullet

sured by the frequencywith which components have to

ramps 39-40 in the two lowermost segments 37. The

be cleaned, is high in the present weapon due to the type 45 barrel extension 33 has a pair of action rod locating

of construction used for the gas cocking mechanism and

holes, 41, 42 see FIG. 4, hole 42 is counterbored. There

the bolt locking mechanism.

is also a bearing 43 for an operating rod.

In order that all of the foregoing developments may

The barrel 35 has a flash suppressor 44 at its other

be understood a presently preferred embodiment of the

end. Intermediate its ends the barrel 35 has an enlarged

invention will now be described with reference to the 50 portion 45 on which there is mounted a gas housing 46

accompanying drawings in which: '

positioned so as to place a port 35a in the barrel 35

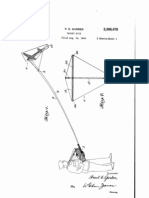

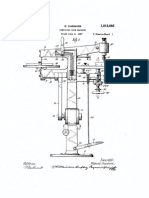

FIG. 1 is an exploded perspective view of the major

(which communicates with the bore thereof) in connec

tion with a passageway 47 in the gas housing 46 which

parts of a weapon according to the invention.

FIG. 2 is a cross-sectional view on the section line

2--2 of FIG. 1.

'

exits axially through a piston48. The gas housing 46

55 also provides a support for a front sight 49. The upper

FIG. 3 is a cross-sectional view on the section line

33 of FIG. 1.

FIG. 4 is a side view partly in section of portion of

the weapon of FIG. 1 at a cocking stage and

FIG. 5 is a view similar to FIG. 4 of the weapon at a 60

bullet loading stage.

receiver body 24 has at its other end a rear sight assem

bly 50 comprising a U bracket 51 with a transverse

adjusting screw 52 which engages with a sight block 53

on which there is rotatably mounted a sight member in

the form of a disc 54. The block 53 is moved laterally of

the weapon by means of the screw 52 for windage ad

justment. The disc 54 is rotated to one of three positions

so as to locate one of the three holes 55 in the disc 54 in

The weapon has a basic form comprising a lower

receiver 1 with an attached hand grip 2. In the lower

receiver 1 there is a trigger assembly which can be best

line with the front sight 49. The holes 55 in the disc 54

seen in FIGS. 4 and 5 and comprises a trigger 3 pivoted 65 are at different spacings from the axis of rotation of the

on a pin 4 and is biased in an anti-clockwise direction by

disc 54 to provide variations of rear sight height. Suit

a torsion spring indicated 5 around the pin 4. A latch

able detent means can be provided to releasably retain

member 3a is pivotally mounted on pin 4, it moves with

the disc 54 in a required location. Adjacent the U brack

4,358,986

cocking movement of hammer 6. When the trigger 3 is

ets 51 there is a slot 55a in the upper receiver in which

catch means is engaged to hold the upper and lower

released by the operator the catch lug 10 is released by

receivers in operative relationship. The upper receiver

24 is laterally stabilised by lugs 24a on the upper re

causes the trigger nose 86 to then engage the ?rst ham

the lip 88 and clockwise movement of the hammer

ceiver 24 which locate one to either side of the stock 5 mer lug 9, ready for the next bullet to be ?red. This

support 17.

Another component of the weapon is the bolt assem

bly, which is an integrated assembly of components able

to be removed as an assembly. It comprises a pair of -

action rods 56-56a held at one end in spaced relation

ship by an action plate 57 having a closure rib 58 and a

headed catch means 59 to engage in the slot 550 so as to

hold the upper and lower receivers in their operative

relationship.

Slidably mounted onthe rods 56-56ais a bolt carrier

single shot trigger-catch arrangement is well known

and is to be found on several weapons presently in use.

The automatic ?re mode will be described later.

The operation of the bolt assembly depends on cock

ing the weapon. Means for manual cocking is provided

andthis comprises the tubular support 78 with a cock

ing handle 79 housed and guided by slot 80 in one half

81 of a two piece hand grip 81-82 which is uni?ed by

screws 83. The parts 81-82 clamp around the front end

ofthe'upp'er receiverand about the gas housing 46. The ' " '

cocking handle is urged into contact with the end 84 of

60 in which there is slidably mounted a ?ring pin striker

61 the sliding movement of which is limited by shoul

ders 63 and a pin 64 passing through the bolt carrier 60.

A cylindrical bolt 62 is slidably mounted in the bolt

handle 79 to the handle part 81, housed within the hand

carrier 60. The bolt 62 has an axial bore 65 and at one 20

Operation of the bolt assembly as is follows. By pull

ing the cocking handle 79 towards the stock support 17

end a head 66 with three lobes 66a. Slidably mounted in

the bore 62 there is a rod 67 with a head 68 at one end

' which lies adjacent striker 61. The bore 65 is of reduced

slot 80 by tension spring 85, connecting the cooking

grip assembly.

the bolt carrier 60 is pushed back by tube 78 to com

press the springs 60a. As this occurs a cam face 89 on

the underface of the bolt carrier 60 engages the top of

diameter as it passes through the head 66 and a ?ring pin

69 in the other end of rod 67 is slidably supported in the 25 the hammer and pivots the hammer against the resis

tance of spring 8 to engage the nose 86 of the trigger 3

reduced diameter portion of bore 65. A compression

with the ?rst lug 9 to retain the hammer cocked. This

spring 70 encircling pin 67 between head 68 and shoul

enables a bullet to be urged, by spring means of known

der 62a on bolt 62 and urges the head 68 into contact

type in the magazine 22, into a position where it can be

with striker 61 and retains the ?ring pin 69 clear of the

?oor of a recess 74 in the bolt head 66.

removed by the advancing bolt in the next ?ring opera

bolt 62 and it engages in a cam track 73 in the bolt

carrier. The recess 74 in the end of the bolt head 66 is

tion and urged up ramp 39 or 40 of the barrel extension

and into the barrel bore. At this time the recess 74 and

the cartridge case rim grip 75 at the front of the bolt

central and has an associated spring loaded ?nger 75 of

head 66 will have engaged the rear end of the cartridge

There is a cam pin 72 projecting radially from the

known type to grip the rim of a cartridge case and in the 35 case. As the bolt assembly continues to move forward

the three lobes 66a of the bolt head 66 pass through the

case of a spent cartridge to withdraw it from the barrel

gaps 38 between the segments 37 of the barrel extension

bore. There is also an ejector pin 75a of known type in

33 and enter an unthreaded portion 90 of the bore of the

the recess 74 which ejects a spent cartridge case

barrel extension 33, to drive the bullet hard home in the

through an elongated aperture 76 in the upper receiver

24 as the bolt carrier 60 retracts to a position where the 40 barrel 35 and the pin and cam 72-73 are in the relation

ship illustrated in FIG. 1. The bolt carrier 60 can still

cartridge case is free from lateral restraint. The bolt

continue to move longitudinally relative to the bolt 62

carrier 60 is retained on the action rods 56-56a by a

under the in?uence of the springs 60a until the front end

circlip 77 on action rod 56a against which it is thrust by

of the carrier 60 rests against the barrel extension 33.

springs 600 on rods 56-56a.

The bolt assembly is mounted in the upper receiver 45 l

by sliding it into the upper receiver body 32 so that the

The relative longitudinal movement between the bolt

carrier 60 andthe bolt 62 causes the pin 72 to run along

cam 73 and the bolt 62 to turn so that the lobes 66a lying

in a plane behind the segments 37 move to a position

rods 56-56a engage respectively in a tubular member 78

in hole 41 in the barrel extension 33 and in hole 42 in the

barrel extension 33 with the circlip 77 in the counter

bore of hole 42. The headed catch 59 engages in the vslot 50

55a and serves to guide the closing rib 58 as it is urged

behind the segments 37 thereby locking the bolt 62

by springs 600 into the notch 20.

Prior to detailing the operation of the bolt assembly

the trigger mechanism will be described. The following

bolt head 66 locked behind it. By squeezing the trigger

spring 8, by the rearward movement of the bolt carrier

charged along the barrel bore by the gas. Automatic

against axial movement. About 30 of rotation is re

quired for locking.

The bullet is now hard home in the barrel 35 with the

3 the nose 86 disengages the lug 9 and the hammer 6 hits

description will be followed with reference to FIGS. 4 55 the striker 61 which drives the ?ring pin 69 into the

recess 74 of the bolt head 66 and into the end of the

and 5. With the selector 16 set for single shot, the trig

cartridge to detonate the charge therein. Gas is gener

ger nose 86 is engaged with the hammer ?rst lug 9 when

ated and the projectile portion of the bullet is dis

the hammer is cooked, against the action of its biasing

60. Because of the speed with which the hammer is 60 recocking of the trigger with associated ejection of the

spent cartridge and reloading with a new bullet now

cooked the user is unable to release the trigger 3 quickly

takes place. Recocking can be achieved automatically

enough after a shot is ?red to enable the trigger nose 86

by using some of the gas generated in the barrel when

to re-engage the hammer ?rst lug 9 on the next cocking

the bullet is ?red. The gas is channelled through port

cycle. For this reason a latch means is provided to pre

vent hammer forward movement a second time. It com 65 350 and passageway 47 to the piston 48 which is housed

in one end of a movable three piece cylinder-plunger

prises a latch member 3a pivoted on pin 4 and which,

assembly. There is a cylinder part 90 which is a sliding

when the trigger is held depressed, is in a position to

?t, with ample clearance for reasons to be described, on

allow a lip 88 to engage the second hammer lug 10 on a

4,358,986

the piston 48. There is a link member 91 and an operat

ing rod 92 around which there is a spring 93. The rod 92

is slidably housed in hole 43 in the barrel extension 33

and end engages the bolt carrier 60. A portion of the gas

generated in the barrel at ?ring is bled through piston 48

into cylinder 90 to move it and components 91 and 92,

The remaining aspect of the gun is the conversion

from a single shot (semi-automatic) weapon to a fully

automatic weapon. This is achieved by inter-action

between pegs 95 on the under face of the bolt carrier 60

and lugs 99 on a slide 96. The slide 96 is located between

wall 98 of the upper receiver 24 with one long side

and as rod 92 rests on the bolt carrier 60 the bolt carrier

below a runner bar 97 on the under face of the bolt

60 is pushed back against its springs 60a. It will be seen

carrier 60 and its other long side below bar 94. Theslide

includes a cutout 100 in which is located the end 101 of

that the cam track 73 has a straight section 94 thus the

?rst part of the backward movement of the bolt carrier M 0 the sear blade 102. In operation the selector 16 is posi

tioned for automatic (position A) this positions a selec

60 does not rotate the bolt 62. This is purposely done to

tor cam to prevent latch member 3a engaging the ham

allow the pressure of the gas in the barrel bore resulting

mer lug 10 and also positions the end 103 of the blade

from the ?ring of the bullet to drop to at least the level

102 of the sear 13 so it can engage the hammer lug 11 as

where the gas pressure is below that suf?cient to expand

the case into binding contact with the barrel bore. If 15 the hammer is cocked by the returning bolt carrier 60.

When the bolt carrier 60 moves in a cocking operation

cartridge case removal is attempted whilst it is ex

the pegs 95 retreat from engagement with the lugs 99 on

panded by excess pressure the rim could be ripped off

the slide 96 and the sear spring causes the end 101 of the

leaving a spent case in the path of the next bullet. The

sear blade 102 to bear on the part 104 of slide 96 to move

gas pressure is also designed to co-act with designed

the slide toward the action plate 57. The scar 13 takes

masses of the moving parts and the strength of the

lated effects of gas pressure, spring strength and moving

up a position (as determined by the selector cam) such

that as the cocking of the hammer takes place the end

101 of the sear 13 engages the hammer lug 11. On the

components.

mer advance. When the trigger 3 is depressed it re

springs 60a to obtain a return (cocking action) speed

slower than would otherwise be the case. The interre

return of the bolt carrier 60 under the influence of its

masses builds into the weapon a predetermined ?ring

25 springs 60a the pegs 95 pass over the slide 96 until they

rate, lessens wear and allows greater control of the

engage the lugs 99. This occurs instantaneously after

weapon because the reaction forces to ?ring forces is

the

bullet is hard home and the bolt has been rotated and

small. The ?t between the cylinder 90 and piston 48 is

locked.

The slide 96 is then moved with the bolt carrier

intentionally slack to allow blow_by of gas, this blows

60 for a very small distance and the slide part 104

away burnt powder to atmosphere which powder

catches the upper sear blade end 101 to disengage the

might otherwise accumulate in the piston and cylinder.

sear blade end 103 from the hammer lug 11. At this

Such accumulation would necessitate, and does necessi

stage if the trigger is not depressed the trigger nose 86

tate in some known weapons, frequent cleaning of these

will engage the hammer lug 9 preventing further ham

The pin cam arrangement 72-73 rotates the bolt 62 as 35 moves the trigger nose 86 from the hammer lug 9 and

the bolt carrier continues to move and this release the

the hammer hits the striker 61. The gas cocking action

interengaging lobes 66a and segments 37. The large arc

of rotation of about 30 to disengage the lobes and seg

for each successive ?ring takes place as described

above. With the trigger still depressed the only hammer

lug operating is the lug 11 and with the lower end 103

ments is also a factor in slowing down the ?ring rate of

the weapon. The gas energy exerted on the rod 92 hurls 40 of the sear blade. This engagement is automatically

the bolt carrier 60 and its associated bolt 62 after un

tripped by the plate 96 (as described above) as long as

locking rotation, rearwardly. The energy imparted by

the trigger is held depressed and continuous ?ring will

the gas is taken up in overcoming the inertia of the mass

of the bolt carrier assembly and by the work done in

compressing its springs 60a. During the return move

ment of the bolt carrier the used cartridge is withdrawn

continue.

To limit the movement of the slide 96 in a forward

45 direction there is a hook end 105 which engages in a

notch 106 in the lower wall 98 of the upper receiver. To

limit it in the opposite direction the outer end 107 of

cocked. The energy stored in the springs 600 due to the

hook 105 abuts the inner face 108 of the stock support

rearward motion of the bolt carrier 60 is expended in

17. It will be understood that the movement of slide 96

the next ?ring operation by returning the bolt carrier 60 50 is quite small. A notch 109 in the bottom of the action

toward the barrel extension 33 and in removing a bullet

plate is provided to accommodate the body of hook 105.

from the magazine 27 along a ramp 39 or 40 into the

It will be noted from FIG. 2 that the cam 89 is in the

barrel bore where it is retained by the relocked bolt

form of a rib and that the slide lugs 99 and the pegs 95

head 66. The weapon is now ready for a further single

are located to either side of the cam 89.

shot to be ?red.

55

The weapon can be readily changed from automatic

and ejected (as previously described) and the hammer is

The manner of removing a round of ammunition from

to single shot (semi-automatic) by positioning the selec

the magazine 27 is best seen in FIG. 3 which also shows

tor 16 and removing the plate 96. The plate 96 may be

a guide bar 94 ?xed to the inside of the upper receiver

left installed however and the selector merely moved to

24. The purpose of the bar 94 is to prevent premature

single shot.

rotation of the bolt 62 in thebolt carrier 60 in a bullet 60

The hook 105 may be replaced by an upturned lug

loading operation. There is a tendency to premature

rotation of the bolt 62 because of the eccentric engage

110 (see inset).

The foregoing description clearly illustrates the oper

ment of an edge of a lobe of head with a cartridge

case as it is withdrawn from the magazine 27 by the

ation of the weapon, its several novel features and ex

advancing bolt assembly. The track 94 drops away

adjacent the barrel extension 33 leaving the pin 72 free

to be moved by the cam 73 and so permit the required

cam action necessary to turn the bolt 62.

plains the advantages hereinbefore identi?ed.

65

I claim:

1. A ri?e comprising a lower receiver and an elon

gated tubular upper receiver in operative overlying

relationship; a barrel assembly mounted in and project

4,358,986

ing from a ?rst end of the upper receiver; a trigger and

face of the bolt carrier and an inner surface of the upper

hammer assembly mounted in the lower receiver; an

opening in the upper receiver to allow a ?ring pin strik

receiver, a ?rst operating face on the slide engageable

by striker means on the bolt carrier as the bolt carrier

ing hammer of the hammer assembly to project into the

nears the ends of a movement towards the barrel assem

upper receiver; a bolt assembly comprising a bolt car

bly, a second operating face on the slide engaged by the

upper face of the sear plate; the positioning of the com

rier, two parallel action rods demountably supported

longitudinally in the upper receiver in a plane parallel to

the plane occupied by the axis of the bore of the barrel

assembly, bearing means in the bolt carrier slidably

engaging the action rods, a bolt slidably and part rotat

ably mounted in the bolt carrier and projecting from

one end thereof with the axis of sliding movement

aligned with the axis of the bore of the barrel assembly

ponents being such that on a rearward movement of the

bolt carrier away from the barrel assembly in automatic

operation of the ri?e the striker means moves away

from the slide ?rst operating face thereby allowing the

sear plate biasing spring to move the slide in the same

direction through engagement of the sear plate upper

face with the slide second operating face and allowing

engagement of the hammer top lug with the sear lower

and with a head lockable in a recess in said barrel assem

bly, a ?ring pin assembly axially slidably mounted in the

face as the hammer cocking cam face of the bolt carrier

bolt and projecting from the other end of the bolt car

rier, an action plate interconnecting the ends of the

rotates the hammer against its spring bias; movement of

the bolt carrier in the opposite direction resulting in said

striker means engaging the slide ?rst operating face to

action rods adjacent said other end of the bolt carrier,

compression springs on the action rods interposed be

move the slide towards the barrel assembly and rotate

tween said other end of the bolt carrier and the action 20 the sear plate against the bias of its spring to disengage

the sear lower face from the hammer upper lug allow

plate; characterised by retaining means on one action

ing the hammer to rotate and strike the ?ring pin in the

rod located between said one end of the bolt carrier and

bolt assembly.

the other end of said one action rod to retain the bolt

carrier on the action rods and thereby integrate the bolt

3. A ri?e as claimed in claim 2 wherein, the bolt

carrier and the action rods enabling that integrated 25 carrier underface includes a cam track to cock the ham

assembly to be removed as a complete unit from the

ri?e, releasable catch means to lock the upper and lower

mer.

receivers in operative overlying relationship, said catch

generally rectangular ring and said ?rst operating face

4. A ri?e as claimed in claim 2 wherein, the slide is a

comprises spaced upstanding lug means at one narrow

means including a lug on said action plate and a recess

in the lower receiver urged into engagement by the 30 end of the slide and said second operating face is a

tongue in the plane of the slide and projecting inwardly

compression springs on the action rods, said action rods

into the open central portion of the slide from the other

being supported in the upper receiver by said catch

narrow end of the slide, and wherein the striker means

means and by support means in the barrel assembly

is two pegs one to either side of the cam track to engage

engaged by said other ends of said action rods, said

support means including a manually operable cocking 35 the slide lugs.

5. A ri?e as claimed in claim 4 including, a down

rod slidably housed in a bearing in the barrel assembly,

turned travel limiting hooked lug at said other end of

an axial bearing in a ?rst end of the cooking rod to

slidably receive said other action rod, a cocking handle

on the cocking rod and biasing means to bias the cock

ing rod in a direction away from the bolt carrier.

2. A ri?e as claimed in claim 1 in which the trigger

face of the upper receiver.

6. A ri?e as claimed in claim 1 wherein the bolt head

has three lobes, said recess in the barrel assembly in

and hammer assembly includes a trigger pivotally

cludes three lugs separated by three gaps through

the slide to engage over the other end of the lowermost

which the bolt lobes can pass and the degree of rotation

of the bolt is such as to lock said three lobes behind said

?rst direction, the hammer being mounted in the lower

,

receiver and spring biassed in a direction opposite to the 45 three lugs.

mounted in the lower receiver and spring biassed in a

7. A rifle as claimed in claim 1 wherein the bolt is

rotated by interengaged cam and peg means on the bolt

and the bolt carrier and said cam includes a ramped

?rst direction, an upper lug on the hammer; a hammer

cocking cam face on the bolt carrier; a sear plate pivot

ally housed in the lower receiver and spring biased in

portion to rotate the bolt and a straight portion parallel

said ?rst direction and including an upper face and a

lower face and an arm; variable cam means in the lower 50 to the axial movement of the bolt to provide axial move

ment of the bolt carrier relative to the bolt prior to the

receiver engageable by the sear plate arm to position the

rotation of the bolt in an unlocking movement of the

sear plate in an operative or an inoperative position for

bolt head in the recess of the barrel assembly.

automatic or single shot ri?e operation respectively; a

*

removable slide slidably located between the undersur

55

65

You might also like

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- Us 4407085Document5 pagesUs 4407085rte678No ratings yet

- Nun M.: BC BM 0000Document12 pagesNun M.: BC BM 0000shdhsjkNo ratings yet

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- Toy Derringer Handgun Firing Mechanism PDFDocument5 pagesToy Derringer Handgun Firing Mechanism PDFyuehan0% (1)

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- Us 3706152Document7 pagesUs 3706152rte678No ratings yet

- Oct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Document5 pagesOct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Юрий РуденкоNo ratings yet

- Us 5117735Document14 pagesUs 5117735sdfsdf333No ratings yet

- 撞针选择的枪 PDFDocument9 pages撞针选择的枪 PDFJin SongNo ratings yet

- Us2550873 PDFDocument4 pagesUs2550873 PDFHéglison MarquesNo ratings yet

- Us4467698 PDFDocument11 pagesUs4467698 PDFJin Song100% (1)

- United States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashDocument7 pagesUnited States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashSandeep SNo ratings yet

- Us965386 PDFDocument6 pagesUs965386 PDFJin SongNo ratings yet

- Us 4407085Document5 pagesUs 4407085Слэйтер Строительная компанияNo ratings yet

- Post 6 36083 SA Repeating DerringerDocument18 pagesPost 6 36083 SA Repeating Derringerbadlabmouse0% (1)

- US Patent 4677897Document8 pagesUS Patent 4677897Mosin-NagantNo ratings yet

- Limited States Patent: LngramDocument7 pagesLimited States Patent: LngramJin SongNo ratings yet

- 8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336Document9 pages8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336tyrer567899No ratings yet

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pages@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNo ratings yet

- M1-M14 Conversion US3362095Document3 pagesM1-M14 Conversion US3362095apoorva singhNo ratings yet

- US2755738 Rocket Fuze 3.5 Inch Rocket M404 PatentDocument3 pagesUS2755738 Rocket Fuze 3.5 Inch Rocket M404 Patentrichardwb1No ratings yet

- Jan. 4, L 1966 T. W. Spack 3,227,148Document6 pagesJan. 4, L 1966 T. W. Spack 3,227,148MainAvelNo ratings yet

- Owen Sub Machine Gun PatentDocument11 pagesOwen Sub Machine Gun PatentBallistics67% (3)

- Thomosmm Donnell: T. M. McdonnellDocument3 pagesThomosmm Donnell: T. M. Mcdonnelledef345No ratings yet

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- Colt 1911 ManualDocument14 pagesColt 1911 ManualLouis Neri100% (11)

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Document16 pagesSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongNo ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- Us 3960084Document3 pagesUs 3960084rte678No ratings yet

- Sling GunDocument7 pagesSling GunMinh100% (1)

- MMM-@U: H. M. SpragueDocument4 pagesMMM-@U: H. M. SpraguedjsfNo ratings yet

- Benelli B76 US3893369Document4 pagesBenelli B76 US3893369apoorva singhNo ratings yet

- Belt Fed BAR (Belgium) US2136512Document4 pagesBelt Fed BAR (Belgium) US2136512apoorva singhNo ratings yet

- Us 4676137Document6 pagesUs 4676137fghdfjerNo ratings yet

- Arts5.: in RunDocument4 pagesArts5.: in RunMuzammil AmirNo ratings yet

- Berthier Us1446635Document12 pagesBerthier Us1446635cll19680% (1)

- SA VZ 58 High Cap Rifle Instructions Manual PDFDocument43 pagesSA VZ 58 High Cap Rifle Instructions Manual PDFMonteiro Antonio100% (1)

- Usa TB-23-7-1 1942Document25 pagesUsa TB-23-7-1 1942Dennis KlinemanNo ratings yet

- Nov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Document6 pagesNov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Jin SongNo ratings yet

- Target Kite (1944)Document7 pagesTarget Kite (1944)CAP History LibraryNo ratings yet

- US1507881Document3 pagesUS1507881Lawrence RyperNo ratings yet

- Us 4207797Document7 pagesUs 4207797fghdfjerNo ratings yet

- April 10, 1956 C. L. Fender 2,741,146Document4 pagesApril 10, 1956 C. L. Fender 2,741,146David DonosoNo ratings yet

- Us4854065 PDFDocument7 pagesUs4854065 PDFJin SongNo ratings yet

- Us 6357155Document5 pagesUs 6357155edef345No ratings yet

- Filed Sept. 8, l942Document4 pagesFiled Sept. 8, l942HaithemNo ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Err-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695Document3 pagesErr-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695RakeshNo ratings yet

- US Army Operator's Manual For The AK-47 Assault Rifle: 203d Military Intelligence BattalionDocument33 pagesUS Army Operator's Manual For The AK-47 Assault Rifle: 203d Military Intelligence BattalionAlexis DragonNo ratings yet

- Us 4689908Document6 pagesUs 4689908djsfNo ratings yet

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDocument7 pagesCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitNo ratings yet

- United States Patent (19) : HoenigDocument5 pagesUnited States Patent (19) : HoenigminiselNo ratings yet

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Document12 pagesL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- Post 6 38604 Reifgraber AutoDocument14 pagesPost 6 38604 Reifgraber AutoAoolf ManNo ratings yet

- United States Patent 1111 3,595,128Document9 pagesUnited States Patent 1111 3,595,128rte678No ratings yet

- Aug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1Document4 pagesAug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1raseks1No ratings yet

- 枪炮声抑制器 PDFDocument11 pages枪炮声抑制器 PDFJin SongNo ratings yet

- (GUNSMITHING) Sten Submachine Gun WWIIDocument7 pages(GUNSMITHING) Sten Submachine Gun WWIIMago Invisivel100% (10)

- 撞针选择的枪 PDFDocument9 pages撞针选择的枪 PDFJin SongNo ratings yet

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Document24 pagesUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongNo ratings yet

- 螺栓枪口装步枪 PDFDocument7 pages螺栓枪口装步枪 PDFJin SongNo ratings yet

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDocument6 pages偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongNo ratings yet

- 块化插入触发器的方法和装置5 PDFDocument23 pages块化插入触发器的方法和装置5 PDFJin SongNo ratings yet

- 安装装置,枪支消声器 PDFDocument28 pages安装装置,枪支消声器 PDFJin Song100% (1)

- Us5274939 PDFDocument7 pagesUs5274939 PDFJin SongNo ratings yet

- 可调式双级触发机制半自动武器 PDFDocument12 pages可调式双级触发机制半自动武器 PDFJin SongNo ratings yet

- 锤执行器的枪支 PDFDocument7 pages锤执行器的枪支 PDFJin SongNo ratings yet

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pages1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,069,602 B2Document13 pagesUlllted States Patent (10) Patent N0.: US 8,069,602 B2Jin Song100% (1)

- 级触发自动武器 PDFDocument15 pages级触发自动武器 PDFJin SongNo ratings yet

- The DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFDocument15 pagesThe DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFgunpdfs93% (122)

- Us7946069 PDFDocument15 pagesUs7946069 PDFJin SongNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Document15 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Jin Song100% (1)

- Us6418655 PDFDocument17 pagesUs6418655 PDFJin SongNo ratings yet

- Us7676976 PDFDocument35 pagesUs7676976 PDFJin SongNo ratings yet

- Us4522106 PDFDocument13 pagesUs4522106 PDFJin Song100% (1)

- Us6308609 PDFDocument18 pagesUs6308609 PDFJin SongNo ratings yet

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongNo ratings yet

- Us4854065 PDFDocument7 pagesUs4854065 PDFJin SongNo ratings yet

- Us3276323 PDFDocument7 pagesUs3276323 PDFJin SongNo ratings yet

- Nov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Document6 pagesNov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Jin SongNo ratings yet

- Us4467698 PDFDocument11 pagesUs4467698 PDFJin Song100% (1)

- Limited States Patent: LngramDocument7 pagesLimited States Patent: LngramJin SongNo ratings yet

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Document16 pagesSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongNo ratings yet

- The Implementing Rules and Regulations For The Comprehensive Firearms and Ammunition Regulation ActDocument45 pagesThe Implementing Rules and Regulations For The Comprehensive Firearms and Ammunition Regulation ActJasNo ratings yet

- Psl-54 Rifle: Cal 7.62X54RDocument14 pagesPsl-54 Rifle: Cal 7.62X54RMohamed Almasri100% (2)

- TitanfallDocument26 pagesTitanfallnateNo ratings yet

- Sniper Elite ManualDocument31 pagesSniper Elite Manualshrekdj88% (8)

- Begun and Held in Metro Manila, On Monday, The Twenty-Third Day of July, Two Thousand TwelveDocument8 pagesBegun and Held in Metro Manila, On Monday, The Twenty-Third Day of July, Two Thousand TwelveGerald HernandezNo ratings yet

- Fosc-Chapter-1-3 4Document10 pagesFosc-Chapter-1-3 4buddy helpsNo ratings yet

- ATF Proposed Changes To Exempting Armor Piercing AmmoDocument17 pagesATF Proposed Changes To Exempting Armor Piercing AmmoGuns.comNo ratings yet

- U.S. Rifle 7.62MM, Ml4 AND M14E2: FMM WasmmoDocument27 pagesU.S. Rifle 7.62MM, Ml4 AND M14E2: FMM Wasmmopetcali24No ratings yet

- Steyr Mannlicher - Army Universal Assault Rifle "Steyr" Semi-Automatic AUG Cal.5,56 (.223)Document44 pagesSteyr Mannlicher - Army Universal Assault Rifle "Steyr" Semi-Automatic AUG Cal.5,56 (.223)YamveaNo ratings yet

- Brothers in Arms - Road To Hill 30 - 2005 - UbisoftDocument18 pagesBrothers in Arms - Road To Hill 30 - 2005 - UbisoftWanderson PereiraNo ratings yet

- Principle of Small ArmsDocument19 pagesPrinciple of Small Armsdharmendra singhNo ratings yet

- Sig551 A1minimanual Pn1512024 Rev1hrDocument100 pagesSig551 A1minimanual Pn1512024 Rev1hrIbis12No ratings yet

- Firearms and HistoryDocument11 pagesFirearms and HistoryEARL DOLIGASNo ratings yet

- Army Universal Assault Rifle Steyr Semi Automatic Aug Cal 5-56-223 MM Nato ManualDocument44 pagesArmy Universal Assault Rifle Steyr Semi Automatic Aug Cal 5-56-223 MM Nato Manualchevy-usa-1No ratings yet

- Polytechnic University of The Philippines Rotc Unit: Anonas Street, Sta. Mesa, ManilaDocument3 pagesPolytechnic University of The Philippines Rotc Unit: Anonas Street, Sta. Mesa, ManilaAngelica RoseNo ratings yet

- JERICHO Manual 08 011 08 15 00 PDFDocument74 pagesJERICHO Manual 08 011 08 15 00 PDFAlberto AmbiNo ratings yet

- FTM Student Handbook and Study GuideDocument130 pagesFTM Student Handbook and Study GuideScott CNo ratings yet

- Dark Heresy EquipmentDocument52 pagesDark Heresy EquipmentToni Linden50% (2)

- Yllana Bay View College: Balangasan District Pagadian CityDocument8 pagesYllana Bay View College: Balangasan District Pagadian CityElla BanlasanNo ratings yet

- ch3Document62 pagesch3leadazideNo ratings yet

- The M1 GarandDocument2 pagesThe M1 Garandidontknowusers (idontknowusers)No ratings yet

- ANCHETAAADocument79 pagesANCHETAAAGUILAY, KEVIN MARK F.No ratings yet

- TM - 9 1005 222 12 - 17mar1969Document67 pagesTM - 9 1005 222 12 - 17mar1969lobosolitariobe100% (1)

- Detail Specification, Rifle, 5.56 Millimeter, m1641 Mil-Dtl-32309Document57 pagesDetail Specification, Rifle, 5.56 Millimeter, m1641 Mil-Dtl-32309cjnjr1No ratings yet

- ps4 Master Mod Operation Instructions v1Document2 pagesps4 Master Mod Operation Instructions v1api-254342543No ratings yet

- 1996 National Firearms AgreementDocument15 pages1996 National Firearms AgreementJockNo ratings yet

- Midterm Examination: # 51 N. Bacalso Ave., Sambag 1, Cebu City Tel No.: (032) 383-6586Document4 pagesMidterm Examination: # 51 N. Bacalso Ave., Sambag 1, Cebu City Tel No.: (032) 383-6586Vin SabNo ratings yet

- ASLSK TutorialDocument206 pagesASLSK Tutorialrgarcp2348100% (7)

- WWII Historical Reenactment Society Jun 2010Document28 pagesWWII Historical Reenactment Society Jun 2010CAP History LibraryNo ratings yet

- 2012 FNH USA Commercial CatalogDocument72 pages2012 FNH USA Commercial CatalogMario LopezNo ratings yet