Professional Documents

Culture Documents

Us4522105 PDF

Uploaded by

Jin SongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us4522105 PDF

Uploaded by

Jin SongCopyright:

Available Formats

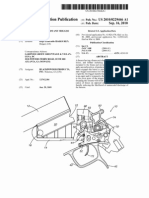

United States Patent [19]

[11]

Patent Number:

4,522,105

Atchisson

[45]

Date of Patent:

Jun. 11, 1985

[75]

[54]

2,365,142

2,361,519 12/1944

10/1944 Turner

Williams

Inventor:

SEMIAUTOMATIC

FIRING MECHANISM

FIREARMS

FOR

2,366,823

Ga.

Maxwell G. Atchisson, Doraville,

1/1945

Williams ..

3,942,410

3,651,736 3/1976

3/1972 Atchisson

Ingram

89/139

89/154 X

..

89/139

89/195 X

.. 89/139

[73] Assignee: SW Daniel, Inc., Atlanta, Ga.

[21] Appl- NO-i 501,705

J . 6 1983

[22] Filed:

n

.[|L_l555 12O0.1 ] FIUms..w ad0 s"nmm,.nI0.C

:13.

m

.

[56]

m8m" u"9 "un/.u.1"u5mm84, 91.mA9. 35.89,49 1124/3

References Cited

028492 @/16wn w

1 47. 1,/9 0.>,5

U.S. PATENT DOCUMENTS

4,421,009 12/1983 Castellano et al7

89/154

89/149 X

Primary Examiner-David H. Brown

Assistant ExaminerJohn E. Grif?ths

Attorney, Agent, or Firm-Jones & Askew

[57]

ABSTRACT

A semiautomatic ?ring mechanism for an autoloading

?rearm. A generally C-shaped hammer is pivotably

mounted behind a bolt, with a transversely-extending

sear piece located below the rearwardly-facing open

side of the hammer. The open ends of the hammer pro

vide ledges selectively engageable with primary and

89/139 X

2,090,340

2,136,396

659,507 10/1900

11/1938

8/1937 Savage

Browning

4,352,317 10/1982 Wilhelm

secondary sear surfaces on the sear piece.

., 89/148 X

89/195 X

12 Claims, 11 Drawing Figures

US. Patent Jun. 11,1985

Sheet 1 014

4,522,105

U.S. Patent Jun. 11, 1985

Sheet 2 of 4

4,522,105

US. Patent Jun. 11,1985

mm.2owQ33

@N#m

QM om

Sheet3of4

4,522,105

US. Patent Jun. 11, 1985

Sheet 4 of 4

4,522,105

4,522,105

FIRING MECHANISM FOR SEMIAUTOMATIC

in cocked or behind-cocked positions. The sear member

FIREARMS

is normally urged into a position where the primary sear

surface is engaged by the hammer incocked position.

FIELD OF INVENTION

This invention relates in general to ?rearms, and in

Stated in somewhat greater detail, the sear member

engages a pair of elongated members extending for

wardly within the frame of the gun, and slidably mov

able therein as the trigger is pulled or released. Sliding

rearward movement of the elongated members and the

particular relates to ?ring mechanisms intended for

semiautomatic ?rearms such as pistols or the like.

BACKGROUND OF THE INVENTION

associated sear member releases the hammer to effect

Firing mechanisms for ?rearms should meet a num

?ring, and the sear member thus is held in position for

ber of criteria. The ?ring mechanisms should be rela

tively lightweight so as not to add unnecessary weight

to the gun, and yet must also be sturdy and dependable.

Moreover, the number of component parts in the ?ring

mechanism should be minimized, and these parts prefer

ably should be easily formed without requiring undue

amounts of machining, so as to keep down the overall

cost of manufacturing and assemblying the ?rearm.

Still another criterion, particularly with so-called

automatic or autoloading semiautomatic-?ring ?re

arms which ?re a single round each time the trigger is

pulled, is a ?ring mechanism which cannot easily be

sear engaging surfaces of the hammer when positioned

engagement by the secondary sear-engaging hammer

15

element as long as the trigger remains pulled.

Accordingly, it is an object of the present invention

to provide an improved ?ring mechanism for ?rearms.

It is another object of the present invention to pro

vide a ?ring mechanism especially useful for hammer

?red semiautomatic ?rearms such as pistols or the like.

It is still another object of the present invention to

provide a ?ring mechanism for hammer-?red semiauto

matic pistols, and not readily convertible to full

automatic operation.

Other objects and advantages of the present invention

converted to full-automatic ?ring. A particular case in

point involves the Ingram pistol, a version of which is 25 will become more readily apparent from the following

description of a preferred embodiment.

disclosed in US. Pat. No. 3,651,736. The ?rearm as

disclosed in that patent is designed and intended for

BRIEF DESCRIPTION OF DRAWINGS

full-automatic ?ring, that is, the pistol automatically

reloads and ?res while the trigger is pulled, until all

rounds in the magazine are ?red. Although a semiauto

matic-?re version of this pistol has been produced, it is

nonetheless desirable to provide an improved semiauto

matic ?ring mechanism which ?ts within the basic

frame envelope of the pistol with minimum modi?ca

tions, which yields dependable hammer-?red operation

FIG. 1 is a pictorial view, shown partly broken away

for illustrative purposes, of a pistol equipped with a

?ring mechanism according to a preferred embodiment

of the present invention.

FIG. 2 is an exploded view showing certain ones of

the elements from FIG. 1.

35

FIG. 3 is a partial section view of the gun shown in

with an economy and simplicity of ?ring mechanism

components, and which is not readily convertible to

FIG. 1, showing the gun cocked and with the safety on.

full-automatic ?ring without substantially rebuilding

that the hammer is forward and the trigger is pulled.

the gun.

SUMMARY OF INVENTION

Stated in general terms, the ?ring mechanism of the

FIG. 4 is a vertical section view as in FIG. 3, except

FIG. 5 is a section view as in FIG. 3, except that the

trigger remains pulled and the hammer is held by the

secondary sear surface.

FIG. 6 is a vertical section view of the bolt insert in

the disclosed embodiment.

FIG. 7 is a section view taken along line 7-7 of FIG.

present invention includes a hammer selectably held in

cocked position, or released for ?ring, by selective en

gagement with a sear extending between two confront 45

2, showing details of the trigger bar.

ing sear-engaging surfaces associated with the hammer.

_ FIG. 8 is a pictorial view showing the ?ring mecha

The sear member includes a primary sear surface and a

secondary sear surface, and these sear surfaces may

selectably be engaged by corresponding sear-engaging

surfaces associated with the hammer. The primary sear

surface holds the hammer cocked, and the primary sear

surface becomes disengaged from the hammer when the

nism of the preferred embodiment, with the trigger

pulled and the hammer held by the secondary sear.

FIG. 9 is a pictorial view of the ?ring mechanism

shown in FIG. 8, with the trigger released and the ham

mer held in cocked position by the primary sear.

FIG. 10 is a plan view of the hammer in the disclosed

embodiment.

trigger is pulled. If the trigger remains pulled as the

hammer is returned to the cocked position by rearward

FIG. 11 is a section view taken along line 11 of FIG.

bolt travel upon ?ring the gun, the other sear-engaging 55

2.

surface associated with the hammer engages the second

ary sear surface, retaining the hammer behind cocked

DESCRIPTION OF PREFERRED EMBODIMENT

position and preventing the hammer from striking the

Turning ?rst to FIG. 1, a ?ring mechanism according

?ring pin as the bolt moves forward to chamber a new

round. When the trigger is released, the hammer returns 60 to the disclosed embodiment of the present invention is

disposed in a pistol shown generally at 15. The pistol

to engagement with the primary sear surface of the sear

member, in cocked position.

has a frame including a lower receiver 16 and an upper

receiver 17, each of which is fabricated from sheet

Stated somewhat more particularly, the present ?ring

metal as known to those skilled in the art. A hand grip

mechanism includes a hammer having a pair of mutually

spaced apart elements, ?anking the sear member ex 65 18 extends downwardly from the lower receiver 16, and

tending in the space between elements. The primary

the hand grip includes a receptacle for receiving a con

and secondary sear surfaces are on opposite sides of the

ventional cartridge-feeding magazine 19. A trigger

sear member, closely spaced apart from corresponding

guard 20 is mounted immediately in front of the hand

4,522,105

grip 18, and the ?nger-engaging portion 21 of a trigger

22 extends within the trigger guard.

The piston 15 has a barrel 25 extending forwardly

from the front end of the upper receiver 17, and the

inner end of the barrel terminates in a breech end 26

(FIG. 3) chambered to receive a cartridge of appropri

ate caliber. A bolt body 27 is slidably mounted within

the upper receiver 17, and the bolt body carries a cylin

drical bolt insert 28 within a hemispherical recess 29

formed in the underside of the bolt body. Another re

cess 30 (FIG. 2) is formed in the underside of the bolt

body 27 adjacent the front end thereof, permitting the

bolt body to slide back and forth over the rear portion

of the barrel.

The bolt body 27 is biased forwardly by the recoil

spring 33 telescopically received over the recoil rod 34,

which slidably extends into the longitudinal recoil rod

hole 35 formed in the bolt body 27. The back end of the

the bolt body 27 and the bolt insert 28 move back within

the receiver. A ?xed ejector pin 64 slidably extends

through a mating longitudinal hole 65 in the bolt insert

28. The forward end of the ejector pin 64 is located

within the upper receiver so that cartridges are ejected

through the ejection port 66 of the bolt body 27 during

rearward travel of the bolt body. It will be understood

that the right side of the upper receiver 17, shown cut

away in FIG. 1, is provided with an ejection port lo

cated to be aligned with the ejection port 66 of the bolt

body as cartridge ejection occurs.

The back end 4811 of the ?ring pin 48 protrudes be

hind the back of the bolt body 27 as best seen in FIG. 3,

in position to be struck by the forward surface 70 of the

hammer 71. The hammer 71, as best seen in FIG. 10, is

a generally C-shaped member having a body 72 termi

nating in two ends 73, 74 curved inwardly to confront

each other across an open space 75. The hammer ends

recoil rod 34 abuts the back wall 36 of the lower re

73 and 74 of the C-shaped hammer are spaced apart

ceiver 16.

20 from the hammer body 72 so that the hammer ends

The bolt insert 28 is removably retained in the bolt

receiving recess 29 of the bolt body 27 by the bolt insert

pin 40, which extends through the transverse opening

41 in the bolt insert and through aligned mating open

de?ne respective ledge surfaces 76, 77 facing inwardly

toward the inside of the hammer body. The outside

surface 70 of the hammer body 72 is the forementioned

forward surface for striking the back end 480 of the

ings 42 in each side of the bolt body recess 29. The bolt 25 ?ring pin.

insert 28 thus is ?xed to the bolt body 27 and travels

A hollow hammer axle 80 extends outwardly from

back and forward with the bolt body. A bolt actuating

both sides of a ?rst end 81 of the hammer 71. The exte

handle 43 (FIG. 1) is attached to the top of the bolt

rior surface at the ends of the hammer axle form the

body 27, and extends outwardly through the slot 44 in

reduced radii 80a which keep the sear assembly from

the top of the upper receiver 17.

moving upward, as described below. The hammer axle

It will be understood that the front face 47 of the bolt

80 may be machined as an integral unitary part of the

insert 28 is con?gured to ?t the head of the particular

hammer 71, or alternatively may be separately formed

cartridge for which the pistol 15 is chambered. It should

as a tubular member secured in a hole at the ?rst end 81

also be understood that different models of a particular

of the hammer. In either case, a bearing hole extends

pistol may be chambered for cartridges of different 35 through the hammer axle 80 and the hammer, and the

calibers, in which case the bolt body 27 may be a uni

hammer pivots on the hammer pin 82 (FIG. 2) extend

versal bolt body con?gured for use in such guns of

ing through the opening in the hammer axle. It will be

different calibers. Where the bolt body 27 is a universal

understood that the hammer pin 82, in the assembled

bolt body, it will be understood that a different bolt

pistol 15, is secured in aligned openings on each side of

insert 28 con?gured for the particular caliber must be

the lower receiver 16, to mount the hammer 71 for

?tted in the universal bolt body in the manner described

pivotable movement below and behind the bolt body

above.

27, in the forward position shown in FIGS. 4 and 5.

Turning to FIG. 6, it is seen that the bolt insert 28

A double torsion hammer spring 84 urges the ham

carries a ?oating ?ring pin 48 received for reciprocal

mer 71 to the forward position shown in FIG. 4. The

movement within the ?ring pin hole 49 longitudinally 45 hammer spring 84 includes a pair of legs 85 which lie

extending through the bolt insert. The ?ring pin 48

includes a rear portion 50 of diameter suf?cient for a

smooth sliding ?t within the enlarged-diameter portion

51 of the ?ring pin hole 49. A transverse notch 52 is

formed across part of the ?ring pin enlarged portion 50,

against the inside bottom surface 93 of the lower re

ceiver l6, and also includes a free loop 87 which en

gages the body 72 of the hammer 71 within the inside

flat surface 88 adjacent the rear hook-shaped end 74 of

50 the hammer.

and the bolt insert pin 40 (which retains the bolt insert

28 in the bolt body 27) extends through the notch 52 in

the ?ring pin. The width of the bolt insert pin 40 is less

a pair of laterally spaced-apart parallel rails 92 slidably

than the corresponding dimension of the ?ring pin

notch 52, thus retaining the ?ring pin for a limited ex

55 A cross member 94 is secured to the upper sides of the

tent of longitudinal movement within the bolt insert 28.

rails 92 adjacent the back ends of the rails, and this cross

Situated below the hammer 71 in the lower receiver

16 is the sear assembly 91. The sear assembly 91 includes

resting on the bottom plate 93 of the lower receiver 16.

A ?ring pin spring 53 surrounds the shank portion 54 of

member maintains the spaced-apart arrangement of the

the ?ring pin, in front of the enlarged portion 50, and

rails. A pair of spaced-apart tangs 95 project rearwardly

the ?ring pin spring urges the ?ring pin rearwardly so

from the back of the cross member 94, with the tangs

that the back end of the ?ring pin protrudes behind the 60 not being directly behind the rails 92. The spacing be

back end 58 of the bolt insert. When the ?ring pin is

tween the rails 92 is somewhat less than that of the tangs

struck by the hammer as described below, the ?ring pin

95, placing the rails in from the adjacent sides of the

travels forwardly within the bolt insert and the forward

end 59 of the ?ring pin emerges from the ?ring pin hole

lower receiver 16 for clearing of the radii along each

side of the lower receiver. The front ends of separate

60 in the front face 47 of the bolt insert. In this manner, 65 compression coil sear springs 96 ?t over the outer ends

a chambered round is ?red.

of the tangs 95, and the back end of each sear spring

The bolt insert 28 carries an extractor 63 of conven

engages the back wall 36 of the lower receiver 16. With

tional design, to extract cartridges from the breech as

the ?ring mechanism assembled as shown in FIG. 1, the

4,522,105

sear springs 96 are maintained in compression and urge

the sear assembly 91 forwardly within the lower re

ceiver. Each reduced radius 800 of the hammer axle 80

rests just above the top surface of a corresponding rail

92, as shown in FIG. 1, and the reduced radii thus keeps

the rails from moving upwardly within the lower re

thus representing the safety on position shown in

and relative locations of the confronting surfaces 122

and 123 of the hammer, the sear bridge can pass through

the space 75 as explained below.

The forward face 116 of the sear bridge 115 is sloped

71, pivoting the hammer rearwardly about the hammer

the magazine 19, and slidably ?t beneath the ?ngers 100

the sear forward surface 116, the sear springs 96 move

FIG. 3.

One end 73 of the hammer 71 has a beveled or other

wise acutely-angled lower surface 122 which, in assem

bly, confronts the forward face 116 of the sear bridge

115. Similarly, the back end 74 of the hammer has a

ceiver.

beveled or otherwise acutely-angled lower surface 123

The cross member 94 of the sear assembly 91 includes

confronting the rear face 117 of the sear bridge 115,

a sear bridge 115 located above and between the rails

when the hammer is moved back to the cocked position.

92. The scar cross member 94 is located in relation to 10 The angled surfaces 122 and 123 of the hammer 71 are

contiguous with the corresponding ledges 76 and 77, at

the hammer 71 so that the sear bridge 115 is substan

the respective ends of the hammer.

tially aligned with the open space 75 at the back of the

The operation of the above-described ?rearm is now

hammer when in cocked position, as seen in FIGS. 1, 8,

discussed, with particular emphasis on the ?ring mecha

and 9. As will become apparent, the front-to-back di

mension of the sear bridge 115 is approximately the 15 nism. The ?rearm is cocked in the usual manner, by

pulling back the operating lever 43 to slide back the bolt

same as the distance 75 between ends 73 and 74 of the body 27 and the bolt insert 28. The rearwardly-travel

hammer. Because of the angled faces on the front and

ing bolt engages the forward surface 70 of the hammer

back faces of the sear bridge, together with the angles

pin 82. The back end of the bolt insert 28 is tapered on

the underside as shown at 31, FIG. 6, and the back end

48a of the ?ring pin 48 is beveled at 48b, to provide

camrning surfaces for engaging the hammer. As rear

backwardly from bottom to top as best seen in FIG. 11.

ward travel of the bolt assembly continues, the hammer

The rear face 117 of the sear bridge is sloped forwardly

from bottom to top, causing the sear bridge to have 25 71 pivots back until the angled surface 122 at the ?rst

end 73 of the hammer engages the beveled forward

approximately the cross-shape of a trapezoid. As is

surface 116 on the sear bridge 115. The scar bridge 115,

explained below, the bottom surface 118 adjacent the

and thus the entire sear assembly 91, is cammed rear

front face of the sear bridge 115 comprises the primary

wardly as the hammer surface 122 engages and tra

sear surface, and the bottom surface 119 adjacent the

verses the forward face 116 of the sear bridge. As the

rear face 117 comprises the secondary sear surface.

hammer surface 122 moves beyond the lower edge of

The sear rails 92 extend forwardly on both sides of

the sear assembly forward, placing the primary sear

which prevent upward movement of the rails. The front

surface 118 of the sear bridge 115 in engagement above

end of each sear rail 92 has an undercut notch 100, best 35 the ledge 76 at the ?rst end 73 of the hammer 71. The

seen in FIG. 2 in front of the magazine, to receive the

hammer is now cocked, held in that position by engage

complementary projections 101 of the trigger bar 102.

The trigger bar 102, which in the disclosed embodiment

is a separate element from the sear rails 92, slidably rests

on the bottom plate 93 of the lower receiver, as best

seen in FIGS. 3-5.

The trigger bar 102 in assembly is mounted immedi

ately in back of the trigger 22, FIG. 3, and the forward

bias of the sear springs 96 urge the front side 103 of the

ment of the ledge 76 with the primary sear surface 118.

This condition is shown in FIGS. 3 and 9. The beveled

surface 123 at the back of the hammer is located so as

not to contact the confronting rear face 117 of the sear

bridge when the hammer pivots back no further than

the cocked position illustrated in FIG. 3.

When the trigger 22 is pulled, the sear assembly 91

moves back until the sear bridge 115 disengages the

trigger bar against the back 94 of the trigger. The front 45 ledge 76 of the hammer. The hammer now falls under

side of the trigger bar 102 preferably includes a beveled

power of the hammer spring 84, striking the back end

surface 104, best seen in FIG. 7, extending part-way

48a of the ?ring pin as shown in FIG. 4 and causing a

down from the top of the trigger bar, thereby de?ning

chambered round (if present) to be tired. This ?ring

a narrowed trigger-engaging front side 103 providing a

produces blowback movement of the bolt insert and

more precise feel to the ?ring mechanism.

bolt body, repeating the cocking procedure described

The trigger 22 is pivotably mounted on the trigger

above.

pin 107 in conventional manner. Pulling the ?nger en

If the trigger 22 remains pulled during the-cocking

gaging portion 21 of the trigger 22 thus pivots the trig

procedure, it will be understood that the primary sear

ger to move back the trigger bar 102 and the rest of the

surface 118 on the sear bridge 115 remains back and out

rest of the sear assembly 91, in opposition to the sear 55 of possible engagement with the forward ledge 76 on

springs 96.

the hammer. In that case, the rear surface 117 of the sear

A tang 108 extends from the front side of the trigger

22, located immediately above the safety member 109.

The safety member 109 is mounted for selective rotation

by the operating lever 110 located on the outside of the

beveled surface 123 at the back end 74 of the hammer,

lower receiver, and one side of the safety member in

cludes a release notch 111 positioned below the tang 108

on the trigger. The release notch 111 receives the trig

assembly 91 against the remaining trigger-pulling force,

piece is positioned for camming engagement by the

after the hammer pivots back beyond the cocked posi

tion. This camming engagement between the hammer

surface 123 and the sear bridge cams forwardly the sear

and this force immediately moves the sear assembly

rearwardly to engage the rear ledge 77 of the hammer

normal ?ring action as illustrated in FIGS. 4 and 5. 65 by the secondary sear surface 119 at the back side of the

Rotating the operating lever 110 one-half turn places

sear bridge 115. The hammer 71 thus remains held in the

ger tang 108 when the trigger is pulled, thus permitting

the solid portion 112 of the safety member immediately

below the tang 108, blocking trigger movement and

secondary-sear position shown in FIGS. 5 and 8, as the

bolt assembly travels forward under power of the recoil

4,522,105

8

to the ?rst position, thereby maintaining said ham

mer means ready to pivot to the ?ring position

spring 33. When the trigger is released, the sear bridge

115 moves forwardly to disengage the secondary sear

surface 119 from the hammer and position the primary

when said sear means next is moved to the second

sear surface 118 to engage the forward ledge 76 of the

position.

hammer, in the cocked position shown in FIG. 3. The

hammer thus pivots forwardly a relatively short

amount, determined by the relative angular-engage

2. The ?ring mechanism as in claim 1, further com

prising:

trigger means operative to move said sear means from

ment positions of primary and secondary sear surfaces

with the respective ledges on the hammer. It can be

particularly seen from FIG. 10 that the primary sear

said ?rst position to said second position when

pulled; and

means operative to return said sear means to said ?rst

engaging forward ledge 76 of the hammer is angularly

depressed by a slight amount relative to the secondary

position when said trigger means is released.

3. The ?ring mechanism as in claim 1, wherein:

sear-engaging ledge 77, with reference to the pivot axis

said sear means includes a sear member having said

of the hammer.

It will thus be seen that the ?ring mechanism as dis

?rst and second sear surfaces; and

said sear member enters said opening in said hammer

closed herein is relatively straightforward in design and

means as the hammer means is moved to the

operation, and is con?gured to ?t within the con?nes of

cocked position, so that said primary and second

ary sear surfaces respectively confront said pri

mary and secondary sear engaging surfaces.

4. The ?ring mechanism as in claim 1, wherein said

a hand gun or the like. The secondary sear arrangement

retains the hammer from forward movement while the

trigger remains pulled, preventing accidental second

?res which might result if the hammer were allowed to

follow the bolt forward after loading a new round. It

will also be seen that the present ?ring mechanism is not

sear means is disposed for movement on a linear path

readily or easily convertible to full-automatic ?ring, and

any such conversion would require substantial redesign 2

and reconstruction of the ?ring mechanism.

It will also be understood that the foregoing relates

only to a preferred embodiment of the present inven

tion, and that numerous modi?cations and alterations

may be made therein without departing from the spirit

resilient means urging said sear means to said ?rst

position whereat said hammer means is retained

cocked; and

position.

1. Firing mechanism for a ?rearm, comprising:

6. The ?ring mechanism as in claim 5, wherein:

hammer means movable along a path including a

said sear means comprises a sear member extending

?ring position and a cooked position;

transverse to said path of travel of the sear means;

said primary and secondary sear surfaces being on

opposite sides of said sear member; and

means biasing said hammer means for pivotal move

ment toward the ?ring position;

said hammer means having ?rst and second confront

said hammer means opening receives said sear mem

ing surfaces de?ning an opening in the hammer

means, and having primary and secondary sear

engaging surfaces, said primary sear engaging sur

ber when the hammer means is cocked, so that said

primary and secondary sear engaging surfaces of

the hammer means respectively confront the pri

face adjacent said ?rst confronting surface, said

mary and secondary sear surfaces of said sear mem

secondary sear engaging surface adjacent said sec

45

ary sear engaging surfaces positioned in mutually

spaced apart relation across said opening;

sear means disposed between said primary and sec

ondary sear engaging surfaces, and selectably mov

able between a ?rst position and a second position;

said sear means having a primary sear surface located

for engagement by said primary sear engaging

surface as said hammer means is moved to the

cocked position, so as to retain the hammer means

in the cooked position when the sear means is in 55

said ?rst position;

?rst and second positions; and further comprising

said second position in opposition to said resilient

means, so as to disengage said primary sear surface

and allow said hammer means to move to the ?ring

claims.

I claim:

said sear means having a secondary sear surface lo

sear means is movable on a straight path between said

trigger means operative to move said sear means to

and scope of the invention as de?ned in the following

ond confronting surface, said primary and second

between said ?rst and second positions.

5. The ?ring mechanism as in claim 1, wherein said

ber.

7. The ?ring mechanism as in claim 6, wherein:

said sear means further comprises elongated means

operatively associated with said sear member and

extending to a location forwardly of the sear mem

ber; and

said trigger means when pulled being operable to

move said elongated means back, thereby moving

said sear member to said second position and thus

disengaging said primary sear surface from said

hammer means.

8. Apparatus as in claim 7, wherein:

said elongated means comprises a pair of elongated

rails extending forwardly from spaced apart loca

cated for engagement by said secondary sear en

gaging surface as said hammer means is pivoted

beyond the cocked position, with said sear means

moved to said second position so that the primary

tions on said sear member, so that said hammer

means can move into the space between said rails

sear engaging surface cannot engage the sear

trigger engaging means bridging said elongated rails

means, thereby retaining the hammer means behind

the cocked position; and

said primary and secondary sear surfaces being lo

forwardly of said hammer means.

9. Apparatus as in claim 8, wherein:

said resilient means urging said sear means comprises

cated on said sear means so that said hammer means

a pair of compression springs aligned with said pair

pivots to be retained at the cocked position by said

of elongated rails so as to urge said trigger engag

ing means toward said trigger means.

primary sear surface when the sear means returns

without interference; and

4,522,105

10. In a ?ring mechanism for a ?rearm having a

position; and

frame, bolt means supported in the frame for limited

travel, and a ?ring pin associated with the bolt means,

a secondary sear surface on said sear member to en

the improvements comprising:

gage the other of said ledges when the hammer is

pivoted behind the cooked position while said sear

means is moved to said second position in response

sear means disposed in the frame below the bolt

means for travel along a linear path;

to pulling said trigger,

means urging said sear means to a ?rst position on

whereby said sear member moves from said other

said path;

ledge to said one ledge as said trigger is released,

a trigger selectably operative to move said sear means

permitting said hammer to return to engagement at

to a second position on said path, in opposition to

the cocked position.

said urging means;

11. The ?ring mechanism as in claim 10, wherein:

a hammer pivotably mounted in the frame for move

ment between a cocked position and a ?ring posi

tion;

said sear member is a cross member transversely ex

15

means resiliently biasing said hammer for movement

engaging said sear member and extending for~

wardly within the frame toward said trigger,

said hammer having a ?rst surface and a second sur

whereby said elongated members and said trans

face confronting each other and de?ning an open~

ing in the hammer, and having a ?rst ledge and a

second ledge, said ?rst ledge adjacent said ?rst

verse sear member slide back within said frame

along said linear path when said trigger is pulled, so

as to disengage said primary sear surface from the

confronting surface and said second ledge adjacent

confronting ledge on said hammer.

said second confronting surface, said ?rst and sec

ond ledges positioned in mutually spaced apart

tending within said frame substantially behind the

pivotal axis of said hammer; and

said sear means includes a pair of elongated members

toward the ?ring position;

relation across said opening in which said sear

means extends as the hammer is in the cocked posi

10

cocked position while said sear means is at said ?rst

25

12. The ?ring mechanism as in claim 11, wherein:

said hammer is located above said elongated mem

bers; and further comprising:

tiOn;

said sear means including a sear member located to be

received in said opening between said ledges when 30

the hammer is in cocked position;

a primary sear surface on said sear member to engage

one of said ledges and retain said hammer in

means operatively associated with said hammer and

de?ning at least one radius surface engaging and

preventing upward movement of at least one of

said elongated members,

said radius surface not impeding said sliding move

ment of the elongated members.

*

35

40

45

55

60

65

=l<

You might also like

- R4A3 Rifle PresentationDocument63 pagesR4A3 Rifle PresentationJames Garma Navalta94% (16)

- KMR QRF MCMR: Bravo Company MFG®Document3 pagesKMR QRF MCMR: Bravo Company MFG®Matt KienertNo ratings yet

- Practical Guide to the Operational Use of the PPS-43 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunNo ratings yet

- Practical Guide to the Operational Use of the PPSh-41 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPSh-41 Submachine GunRating: 5 out of 5 stars5/5 (2)

- (GUNSMITHING) Sten Submachine Gun WWIIDocument7 pages(GUNSMITHING) Sten Submachine Gun WWIIMago Invisivel100% (10)

- The DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFDocument15 pagesThe DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFgunpdfs93% (121)

- Small Arms: A Firearms Expansion For Twilight 2000 4 EditionDocument40 pagesSmall Arms: A Firearms Expansion For Twilight 2000 4 EditionKarl Punu100% (12)

- Heckler and Koch MP7: The Replacement ForDocument4 pagesHeckler and Koch MP7: The Replacement Foryan indra prasthaNo ratings yet

- Gas OperatedDocument5 pagesGas OperatedZararian Ali0% (1)

- V3 ECM Tutorial v1.0Document40 pagesV3 ECM Tutorial v1.0lmkkilo3No ratings yet

- Carl Gustav m45Document18 pagesCarl Gustav m45lobosolitariobe100% (2)

- Walther P22 USA ManualDocument17 pagesWalther P22 USA Manualhwroark100% (3)

- M1911 PistolDocument14 pagesM1911 Pistolblowmeasshole19110% (1)

- Sa 80Document12 pagesSa 80jinnah14364No ratings yet

- Handgun Firing Mechanism with Independent Sear ReleaseDocument5 pagesHandgun Firing Mechanism with Independent Sear Releaseyuehan0% (1)

- US Patent 4677897Document8 pagesUS Patent 4677897Mosin-NagantNo ratings yet

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- 锤执行器的枪支 PDFDocument7 pages锤执行器的枪支 PDFJin SongNo ratings yet

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- MAX1045 ManualDocument13 pagesMAX1045 Manualbrowar444100% (1)

- FN FAL Gas Block Conversion InfoDocument2 pagesFN FAL Gas Block Conversion InfoAdam HemsleyNo ratings yet

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 pagesPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияNo ratings yet

- A MAC History LessonDocument11 pagesA MAC History Lessonlopezm93No ratings yet

- EP2369289A1Document10 pagesEP2369289A1awe234No ratings yet

- Firearm Bolt Locking Mechanism Patent SummaryDocument9 pagesFirearm Bolt Locking Mechanism Patent Summaryapoorva singhNo ratings yet

- Sig MP46 MP48 Operation ManualDocument4 pagesSig MP46 MP48 Operation ManualohcockNo ratings yet

- Cetme/HK Flat Bending Jig for AR-15 Lower Receiver BendsDocument7 pagesCetme/HK Flat Bending Jig for AR-15 Lower Receiver BendsRon WalshNo ratings yet

- Sub Machine Gun MGV 176 ManualDocument19 pagesSub Machine Gun MGV 176 ManualknockelfliesNo ratings yet

- Sten Plans The Sten MkiiDocument28 pagesSten Plans The Sten MkiiJohn FindleyNo ratings yet

- A 518298Document19 pagesA 518298browar444No ratings yet

- AMT LightningDocument9 pagesAMT LightningJustinNo ratings yet

- Symbol of Violence, War and Culture: Chapter OneDocument10 pagesSymbol of Violence, War and Culture: Chapter OneMister BurdsNo ratings yet

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Document24 pagesUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongNo ratings yet

- AMT BackupDocument12 pagesAMT BackupJustin100% (1)

- W mp40Document7 pagesW mp40Антон ЗахаровNo ratings yet

- ' Aug. 5, 1930. B. A. Revelli: Filed April' 22, 192sDocument4 pages' Aug. 5, 1930. B. A. Revelli: Filed April' 22, 192sЮрий РуденкоNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Document15 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Jin Song100% (1)

- RSTA Muzzle Brake / Flash Suppressor Mount Installation ManualDocument2 pagesRSTA Muzzle Brake / Flash Suppressor Mount Installation ManualGriffin Armament Suppressors0% (1)

- Home N Ew Arrivals C Loseouts Schem Atics Sell Your PartsDocument2 pagesHome N Ew Arrivals C Loseouts Schem Atics Sell Your Partstwinscrewcanoe100% (1)

- Yugo M24 47 DisassemblyDocument30 pagesYugo M24 47 Disassemblyziehenbenzin100% (1)

- CZ 92 Instruction Manual GuideDocument0 pagesCZ 92 Instruction Manual Guideab212amisar0% (1)

- H&K Field Stripping NewDocument53 pagesH&K Field Stripping Newkcluer8No ratings yet

- Dec. 22, 1953 R. T. Catlin Etal: AmmunitionDocument4 pagesDec. 22, 1953 R. T. Catlin Etal: Ammunitionkahj juliNo ratings yet

- Uzi Carbine Fixed Stock InstallationDocument4 pagesUzi Carbine Fixed Stock Installationelvergonzalez1No ratings yet

- The 10mm Automatic - by Chuck HawksDocument2 pagesThe 10mm Automatic - by Chuck Hawksblowmeasshole1911No ratings yet

- Breda M1937 machine gun overview: caliber, weight, barrel length, rate of fireDocument3 pagesBreda M1937 machine gun overview: caliber, weight, barrel length, rate of firefmspecialist100% (1)

- Puma M1887 Lever Shotgun ManualDocument24 pagesPuma M1887 Lever Shotgun Manualesporadico123100% (1)

- GSG MP40 - 9x19 - America PDFDocument20 pagesGSG MP40 - 9x19 - America PDFeric100% (1)

- 5 Olympic - Whitney - Wolverine PDFDocument16 pages5 Olympic - Whitney - Wolverine PDFrico oliverNo ratings yet

- Chimera ManualDocument12 pagesChimera ManualticocrazyNo ratings yet

- MAS-38 Submachine Gun FranceDocument4 pagesMAS-38 Submachine Gun Franceblowmeasshole1911No ratings yet

- Tel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Document4 pagesTel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Radim KadlecNo ratings yet

- AK Trigger Modification GuideDocument6 pagesAK Trigger Modification GuideAdam Hemsley100% (1)

- Pump Shotgun: Instruction ManualDocument5 pagesPump Shotgun: Instruction ManualJustinNo ratings yet

- P64 ManualDocument15 pagesP64 ManualRobert OgburnNo ratings yet

- Hugo Schmeisser German Weapons InventorDocument4 pagesHugo Schmeisser German Weapons Inventorblowmeasshole1911No ratings yet

- MAC .45 ACP Receiver & Mag HousingDocument3 pagesMAC .45 ACP Receiver & Mag Housingbrowar444No ratings yet

- Build a semi-auto RPD rifle from a parts kitDocument6 pagesBuild a semi-auto RPD rifle from a parts kitDale Wade50% (2)

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesFrom EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesNo ratings yet

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- Practical Guide to the Operational Use of the UZI Submachine GunFrom EverandPractical Guide to the Operational Use of the UZI Submachine GunNo ratings yet

- 枪炮声抑制器 PDFDocument11 pages枪炮声抑制器 PDFJin SongNo ratings yet

- 安装装置,枪支消声器 PDFDocument28 pages安装装置,枪支消声器 PDFJin Song100% (1)

- 撞针选择的枪 PDFDocument9 pages撞针选择的枪 PDFJin SongNo ratings yet

- Us7946069 PDFDocument15 pagesUs7946069 PDFJin SongNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,069,602 B2Document13 pagesUlllted States Patent (10) Patent N0.: US 8,069,602 B2Jin Song100% (1)

- 螺栓枪口装步枪 PDFDocument7 pages螺栓枪口装步枪 PDFJin SongNo ratings yet

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDocument6 pages偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongNo ratings yet

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Document24 pagesUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongNo ratings yet

- 可调式双级触发机制半自动武器 PDFDocument12 pages可调式双级触发机制半自动武器 PDFJin SongNo ratings yet

- Us7676976 PDFDocument35 pagesUs7676976 PDFJin SongNo ratings yet

- 块化插入触发器的方法和装置5 PDFDocument23 pages块化插入触发器的方法和装置5 PDFJin SongNo ratings yet

- 级触发自动武器 PDFDocument15 pages级触发自动武器 PDFJin SongNo ratings yet

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pages1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongNo ratings yet

- Us5274939 PDFDocument7 pagesUs5274939 PDFJin SongNo ratings yet

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongNo ratings yet

- Us6308609 PDFDocument18 pagesUs6308609 PDFJin SongNo ratings yet

- Us4854065 PDFDocument7 pagesUs4854065 PDFJin SongNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Document15 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Jin Song100% (1)

- Us6418655 PDFDocument17 pagesUs6418655 PDFJin SongNo ratings yet

- Us4522106 PDFDocument13 pagesUs4522106 PDFJin Song100% (1)

- Us4467698 PDFDocument11 pagesUs4467698 PDFJin Song100% (1)

- Us4358986 PDFDocument9 pagesUs4358986 PDFJin SongNo ratings yet

- Limited States Patent: LngramDocument7 pagesLimited States Patent: LngramJin SongNo ratings yet

- Us3276323 PDFDocument7 pagesUs3276323 PDFJin SongNo ratings yet

- Nov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Document6 pagesNov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Jin SongNo ratings yet

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Document16 pagesSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongNo ratings yet

- Sig P250 ManualDocument68 pagesSig P250 ManualMichael KovalNo ratings yet

- Ruger New 2010 Catalog (LCR and LCP)Document7 pagesRuger New 2010 Catalog (LCR and LCP)rreyesa2001No ratings yet

- 2015 Ruger CatalogDocument64 pages2015 Ruger CatalogStephen CookNo ratings yet

- Manual Desert EagleDocument54 pagesManual Desert EagleGaiaNo ratings yet

- UZI PRO Pistol Operator Manual 08 011 05 09 30 - 1Document60 pagesUZI PRO Pistol Operator Manual 08 011 05 09 30 - 1Ricardo C TorresNo ratings yet

- Cemte C Rifle ManualDocument46 pagesCemte C Rifle Manualholescreek100% (1)

- Smallbore Prone Shooting VOL2Document46 pagesSmallbore Prone Shooting VOL2jimdigrizNo ratings yet

- Nigcoy 8 Ecomig Arms and Ammunition HoldingDocument7 pagesNigcoy 8 Ecomig Arms and Ammunition HoldingWisdom AbrahamNo ratings yet

- MP 40 Submachine Gun (NAZI Germany)Document9 pagesMP 40 Submachine Gun (NAZI Germany)blowmeasshole1911No ratings yet

- Ruger CarbineDocument36 pagesRuger CarbinePAULO RIBEIRONo ratings yet

- Twilight 2000 - Assault Rifles 01Document210 pagesTwilight 2000 - Assault Rifles 01Robert Rome100% (1)

- Directory Introhistgun PDFDocument101 pagesDirectory Introhistgun PDFN.R. Jenzen-Jones100% (1)

- Gilboa Catalog 2012Document12 pagesGilboa Catalog 2012PredatorBDU.comNo ratings yet

- N0v-14, 1967 A. C. Warner Etal 3,352,046: Defensive Weapon and Cartridge Theref orDocument12 pagesN0v-14, 1967 A. C. Warner Etal 3,352,046: Defensive Weapon and Cartridge Theref orЮрий РуденкоNo ratings yet

- UUSA 2023 CatalogDocument60 pagesUUSA 2023 Catalogverjo360No ratings yet

- 2011 FNH USA COMMERCIAL CatalogDocument64 pages2011 FNH USA COMMERCIAL CatalogMario LopezNo ratings yet

- US7849623 Rolling Block Trigger PDFDocument25 pagesUS7849623 Rolling Block Trigger PDFE MakinenNo ratings yet

- XQ50 / LRF XQ50: Reticle CatalogueDocument13 pagesXQ50 / LRF XQ50: Reticle CatalogueВладимир ШведNo ratings yet

- GLOCK'S G48 MOS - Perfection Got Better.Document4 pagesGLOCK'S G48 MOS - Perfection Got Better.Twobirds Flying PublicationsNo ratings yet

- German K98 ManualDocument20 pagesGerman K98 ManualPatrician1100% (3)

- Tentative Requirement of Rfi For Items For 2016-17Document24 pagesTentative Requirement of Rfi For Items For 2016-17RajeshKumarSahuNo ratings yet

- MG42 Machine Gun (NAZI)Document9 pagesMG42 Machine Gun (NAZI)blowmeasshole1911No ratings yet

- KAC Civilian Catalog 2012Document28 pagesKAC Civilian Catalog 2012solsysNo ratings yet

- Firearms Green BookDocument31 pagesFirearms Green Bookthelie020No ratings yet

- 2011 Rossi CatalogDocument32 pages2011 Rossi CatalogguiarqNo ratings yet

- Firearms ClassificationDocument3 pagesFirearms ClassificationJohn Francis Arellano BatohanonNo ratings yet