Professional Documents

Culture Documents

United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1

Uploaded by

Jin SongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1

Uploaded by

Jin SongCopyright:

Available Formats

US 20100229446A1

(19) United States

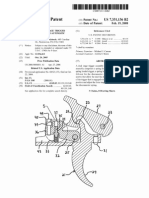

(12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1

IBARGUREN

(54)

(43) Pub. Date:

BREAK-ACTION FIREARM AND TRIGGER

Sep. 16, 2010

Related US. Application Data

MECHANISM

(60)

Provisional application No. 61/024,670, ?led on Jan.

30, 2008, provisional application No. 61/033,649,

_

(75) Inventor:

?led on Mar. 4, 2008.

Inigo Llzarralde IBARGUREN,

Publication Classi?cation

Bergara (ES)

(51)

Correspondence Address:

&

(2006.01)

F41A 3/58

(200601)

Ulsl

UEVA. PC

Int. Cl.

F41C 9/08

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ -

(57)

ABSTRACT

A ?rearm having a frame and a barrel pivotally mounted to the

frame, and further including a locking block pivotally

glgglgYUlgoAD SUITE 800

( )

mounted to the frame and movable between a ?rst position

(73) Assignee:

and a second position, Wherein in the ?rst position the locking

block engages the barrel to prevent pivotal motion thereof;

BLACKPOWDER PRODUCTS,

INC, Norcross, GA (U S)

and a trigger mechanism for a ?rearm having a neutral center

of gravity, the trigger member having a geometry that results

in an equal and/or symmetric distribution of its mass relative

to the pivot point of the trigger, Wherein impact caused by

(21) Appl' NO"

12/362184

dropping the ?rearm Will result in substantially equal appli

cation of forces on opposed sides of the trigger member,

(22)

Filed:

thereby reducing the likelihood of unintended discharge of

the ?rearm.

Jan. 29, 2009

12

22

60

50

52

/10

74

20

/ / 50

>

0

70

/

I

Q o,

76

44

74

52

72

40

42

Patent Application Publication

Sep. 16, 2010 Sheet 1 0f 10

76

US 2010/0229446 A1

Patent Application Publication

Sep. 16, 2010 Sheet 2 0f 10

US 2010/0229446 A1

Patent Application Publication

Sep. 16, 2010 Sheet 3 0f 10

US 2010/0229446 A1

42

72

Fig.

340

Patent Application Publication

Sep. 16, 2010 Sheet 4 0f 10

US 2010/0229446 A1

oE

@

mm

O

~

I QQ

Q

ocmwQ

mm

o

.,

cwmm

Qv

9wS

15

Patent Application Publication

Sep. 16, 2010 Sheet 5 0f 10

US 2010/0229446 A1

\

a 0

\W \

In

.210

LE

\~~\\

\\

\a

m,

Patent Application Publication

Sep. 16, 2010 Sheet 6 0f 10

55

US 2010/0229446 A1

Patent Application Publication

Sep. 16, 2010 Sheet 7 0f 10

US 2010/0229446 A1

Fig.

7

Patent Application Publication

Sep. 16, 2010 Sheet 10 0f 10

US 2010/0229446 A1

Sep. 16, 2010

US 2010/0229446 A1

BREAK-ACTION FIREARM AND TRIGGER

MECHANISM

?rearms. In general, the pivot point is located Wherever is

most convenient in terms of spatial ?tting of the trigger

mechanism and other components Within the gun frame, or at

CROSS-REFERENCE TO RELATED

APPLICATIONS

[0001] This application claims priority to US. Provisional

Patent Application Ser. No. 61/024,670, ?led Jan. 30, 2008,

and US. Provisional Patent Application Ser. No. 61/033,649,

?led Mar. 4, 2008, the entireties of Which applications are

hereby incorporated herein by reference,

TECHNICAL FIELD

[0002]

The present invention relates generally to the ?eld of

?rearms, and more particularly to an improved break-action

mechanism for providing access to the breech end of the

barrel of a ?rearm, to an improved trigger mechanism for a

?rearm, and to an improved ?rearm.

BACKGROUND OF THE INVENTION

[0003] In the use of various forms of ?rearms, it is desirable

to provide access to the breech end of the ?rearms barrel. For

example, in muZZle-loading ?rearms it is commonly neces

a position Whereby mechanical advantage may be improved.

As a result, the trigger is typically heavier on one side or the

other of the pivot pin (i.e., one side of the trigger body has a

greater mass than the other side).

[0009] Therefore, if a gun is dropped on the butt end, and

the trigger boW side of the trigger body (the part Where the

users ?nger puts pressure) is the heavier side, the inertia of

this heavier side can and often does overcome the strength of

the trigger return spring upon impact, causing the gun to ?re

unintentionally. Similarly, if a gun is dropped on the muZZle,

and the sear side of the trigger body (the portion of the trigger

body that is on the side opposite side of the pivot pin from the

boW) is heavier than the trigger boW side, the inertia can force

the trigger to disengage from the hammer or sear. Again, this

can cause the gun to ?re unintentionally.

[0010]

Accordingly, a need for continuing improvement in

the ?eld has been recognized. It is to the provision of an

improved ?rearm, an improved break action mechanism, and

an improved trigger mechanism meeting these and other

needs that the present invention is primarily directed.

sary to access the breech end of the barrel to insert and remove

a percussion cap or primer for initiating the primary poWder

SUMMARY OF THE INVENTION

charge (typically blackpoWder, Pyrodex or other propellant).

In cartridge-type ?rearms, the cartridges are typically loaded

into a chamber in the breech end of the barrel.

[0004] Firearms using break-action mechanisms to provide

access to the breech end of the barrel are knoWn. Typically, a

hinge mechanism or pivot pin a?ixed to the frame of the

?rearm alloWs the muZZle end of the barrel to pivot doWnWard

and aWay from the rear stock and ?ring mechanism, causing

the breech end of the barrel to pivot upWard Where it is

exposed for easier access.

[0005] A knoWn break-action mechanism for muZZle-load

ing ?rearms includes a barrel locking and release mechanism

having a locking bolt slidably mounted to the barrel for

engaging a doWnWardly facing surface of the frame. A release

?nger extension of the trigger guard moves the locking block

out of engagement With the barrel to release the barrel locking

mechanism and permit pivoting of the barrel. Known break

action mechanisms for muZZle-loading ?rearms have also

included an intermediate pivoting latch member betWeen the

trigger and the hammer, for locking the hammer in a neutral or

half-cocked safety position.

[0006]

Previously knoWn break-action mechanisms have

been found to have a number of shortcomings. Undue com

plexity in a mechanism may lead to a lack of reliability and/or

safety, as Well as increased cost and a greater need for main

tenance and repairs.

[0007] Various trigger mechanisms for ?rearms are also

knoWn. Typically, a trigger body pivots about a pivot pin that

is coupled to the frame or other portion of the ?rearm, to

permit a user to manually release a hammer, ?ring pin, or

other ?ring mechanism, and thereby discharge the ?rearm. A

trigger boW or actuator portion of the trigger body is generally

con?gured for manipulation by the ?nger of a user to move

the trigger betWeen a forWard or ready position and a rear

[0011] In example embodiments, the present invention is a

?rearm having an improved break action mechanism. The

?rearm may take the form of a rifle, shotgun, handgun or the

like. In example forms, the ?rearm of the present invention is

a muZZle-loading ?rearm having a barrel With a closed breech

end including a nipple or other receiver for a primer or cap for

initiating the ?ring of the main charge of blackpoWder or

other propellant. In alternate embodiments, the ?rearm is a

breech-loading ?rearm such as a modern center-?re or rim

?re cartridge type ?rearm, or other form of break action

?rearm.

[0012] The barrel of such a ?rearm is pivotally mounted to

the frame of the gun to permit access to the breech end of the

barrel. A pivotally mounted trigger guard or other release

actuator actuates a release mechanism for selectively engag

ing and releasing a locking block With the barrel. The locking

block also serves to prevent opening or closing the break

action mechanism When the ?rearm is cocked, for improved

safety.

[0013]

In example forms, the ?rearm of the present inven

tion also includes a trigger mechanism having a trigger arm

that directly engages and releases the hammer, eliminating

the need for intermediate linkage elements, thereby reducing

complexity of the mechanism.

[0014] In one aspect, the present invention is a ?rearm

having a frame and a barrel pivotally mounted to the frame,

and further including a locking block pivotally mounted to the

frame and movable betWeen a ?rst position and a second

position, Wherein in the ?rst position the locking block

engages the barrel When the barrel is closed to prevent pivotal

motion thereof.

[0015] In another aspect, the invention is a barrel locking

mechanism for a break-action ?rearm, the barrel locking

mechanism including a barrel lug having a recess formed

Ward or ?ring position. A distal portion of the trigger body

selectively engages and releases the ?ring mechanism upon

manipulation of the actuator portion.

[0008] The speci?c location of the pivot pin on the trigger

therein, and further including a pivoting locking block selec

tively engagable and disengagable With the recess of the

body has heretofore been of little concern in the design of

barrel lug.

Sep. 16,2010

US 2010/0229446 A1

[0016] In another aspect, the invention is a trigger mecha

nism for a ?rearm, the trigger mechanism including a trigger

having an extension for direct engagement and release of a

hammer of the ?rearm.

[0017]

In further example embodiments, the present inven

tion is a ?rearm having an improved trigger mechanism. The

trigger mechanism of the present invention preferably

reduces the likelihood of unintentional discharge of a dropped

?rearm by providing a trigger body that is substantially

mechanism shoWn in FIG. 1, With the break action closed, the

barrel release mechanism engaged, and the trigger and ham

mer in the cocked position.

[0025] FIG. 5 is a schematic vieW shoWing the hammer of

the ?rearm of FIG. 1 in its cocked position, locking the barrel

release mechanism in its engaged state to prevent opening of

the break action When the ?rearm is cocked.

[0026] FIG. 6 is a schematic vieW shoWing the hammer in

its neutral position, freeing the barrel release mechanism to be

equally balanced (i.e., has substantially equal mass or

moment of inertia) on either side of the trigger pivot pin. In

disengaged for opening the break action.

this manner, if a gun is dropped and hits the ground in any

direction at all there is a substantially equal distribution of

release mechanism disengaged and blocking the hammer

mass or inertia on all sides of the pivot pin so that inertial

forces resulting on each side of the pivot point substantially

cancels out those resulting on the opposite side. This greatly

reduces the chance that the gun Will ?re accidentally. The

trigger mechanism of the present invention also includes a

trigger arm that directly engages and releases the hammer,

eliminating the need for intermediate linkage elements,

thereby reducing complexity of the mechanism.

[0018]

[0027]

FIG. 7 is a schematic vieW shoWing the barrel

from being cocked When the break action can be opened.

[0028] FIG. 8 is a ?rst perspective vieW of barrel release,

?ring and trigger mechanisms according to the example form

of the present invention shoWn in FIG. 1.

[0029] FIG. 9 is a second perspective vieW of the barrel

release, ?ring and trigger mechanisms according to the

example form of the present invention shoWn in FIG. 1.

[0030] FIG. 10 is a partial side vieW of the ?rearm shoWn in

FIG. 1.

In one aspect, the present invention is a ?rearm

including a trigger member pivotally mounted about a trigger

axis, Wherein the trigger member has a proximal portion on a

?rst side of the trigger axis and a distal portion on a second

side of the trigger axis opposite the ?rst side, and Wherein the

proximal portion has a Weight WP and the distal portion has a

Weight WD, and Wherein WP is approximately equal to WD.

[0019] In another aspect, the invention is a trigger member

for a ?rearm, the trigger member having a proximal portion

With a ?rst center of gravity spaced a distance DP from a

trigger axis, and a distal portion With a second center of

gravity spaced a distance DD from the trigger axis, and

Wherein DP*WP is approximately equal to DD*WD.

[0020] These and other aspects, features and advantages of

the invention Will be understood With reference to the draWing

?gures and detailed description herein, and Will be realiZed by

means of the various elements and combinations particularly

pointed out in the appended claims. It is to be understood that

DETAILED DESCRIPTION OF EXAMPLE

EMBODIMENTS

[0031]

The present invention may be understood more

readily by reference to the folloWing detailed description of

the invention taken in connection With the accompanying

draWing ?gures, Which form a part of this disclosure. It is to

be understood that this invention is not limited to the speci?c

devices, methods, conditions or parameters described and/or

shoWn herein, and that the terminology used herein is for the

purpose of describing particular embodiments by Way of

example only and is not intended to be limiting of the claimed

invention. Any and all patents and other publications identi

?ed in this speci?cation are incorporated by reference as

though fully set forth herein.

[0032] Also, as used in the speci?cation including the

appended claims, the singular forms a, an, and the

?rearm having a break-action barrel release and ?ring mecha

include the plural, and reference to a particular numerical

value includes at least that particular value, unless the context

clearly dictates otherWise. Ranges may be expressed herein as

from about or approximately one particular value and/or

to about or approximately another particular value.

When such a range is expressed, another embodiment

includes from the one particular value and/or to the other

particular value. Similarly, When values are expressed as

approximations, by use of the antecedent about, it Will be

understood that the particular value forms another embodi

nism according to example forms of the present invention,

ment.

shoWn With the break action closed, the barrel release mecha

nism engaged, and the trigger and hammer in the neutral

position, and also having a trigger mechanism according to an

like reference numbers represent corresponding parts

both the foregoing general description and the folloWing brief

description of the draWings and detailed description of the

invention are exemplary and explanatory of preferred

embodiments of the invention, and are not restrictive of the

invention, as claimed.

BRIEF DESCRIPTION OF THE DRAWINGS

[0021]

FIG. 1 is a side cutaWay vieW of a portion of a

example form of the present invention, shoWn With the trigger

and hammer in the neutral position.

[0022] FIG. 2 is another side cutaWay vieW of the ?rearm,

barrel release and ?ring mechanisms, and trigger mechanism

shoWn in FIG. 1, With the barrel release mechanism of the

?rearm in its released position.

[0023] FIG. 3 is another side cutaWay vieW of the ?rearm,

the barrel release and ?ring mechanisms, and the trigger

mechanism shoWn in FIG. 1, With the ?rearms break action

[0033]

With reference noW to the draWing ?gures, Wherein

throughout the several vieWs, FIGS. 1-10 shoW a break-action

?rearm 10 including barrel release and ?ring mechanisms

according to an example form of the present invention. The

?rearm 10 includes a barrel 12 that is pivotally mounted to a

frame 14 by a pivot pin or hinge mechanism 16. The barrel has

a front or muZZle end and a rear or breach end, in typical form.

In example embodiments, the ?rearm is a muZZle-loading

?rearm having a barrel With a ri?ed or smooth bore and a

closed breach end, With a ?ash hole extending through the

closed breech into the bore, and communicating With an

opened for access to the breech end of the barrel.

external nipple or receiver for accepting a primer or cap in

[0024] FIG. 4 is another side cutaWay vieW of the ?rearm,

the barrel release and ?ring mechanisms, and the trigger

typical form. Alternatively, the ?rearm of the present inven

tion can take the form of any other type of break action

Sep. 16,2010

US 2010/0229446 A1

?rearm, such as for example a ?rearm utilizing breech loaded

center-?re or rim-?re cartridges.

[0034] FIGS. 1-3 show a sequence of operation of the barrel

there is no interference in pivoting the locking block from the

engaged or locked position to the disengaged or unlocked

position. Additionally, and as seen best With reference to FIG.

recess 22 in its distal face. A locking block 30 is pivotally

mounted about a pin a?ixed to the frame 14 of the ?rearm 10.

The locking block 30 has a free end extending aWay from its

7, the gun cannot be cocked When the barrel locking mecha

nism is disengaged (this could be caused by debris or corro

sion in the action, broken parts, or a number of other reasons),

because the lobe portion 34 of the locking block 30 interferes

With the arc of travel of the hammer extension portion 54. It is

important that the breech be fully locked When the ri?e is

?red, so preventing cocking of the hammer When the ri?e is

not properly locked provides an additional safety mechanism.

[0037] The ?rearm 10 further comprises a trigger mecha

nism providing direct engagement and release betWeen the

hammer 50 and a trigger member 70 that is pivotally coupled

to the frame 14 of the ?rearm. The trigger 70 preferably

pin connection, Which can sWing into engagement With the

comprises a unitary integral component including a loWer

barrel recess 22 to prevent the break action of the ?rearm from

actuator or how portion 72 for manipulation by the user to

move the trigger betWeen a forWard or ready position and a

rearWard or ?ring position, and an upper extension arm 74

having a notch or catch formed thereon. In the neutral position

locking mechanism according to an example form of the

present invention. FIG. 1 shoWs the break-action of the ?re

arm With the barrel closed, and the barrel locking mechanism

locked or engaged to prevent opening the barrel, FIG. 2 shoWs

the barrel locking mechanism unlocked or disengaged, With

the barrel closed but released to permit its opening. FIG. 3

shoWs the barrel locking mechanism unlocked or disengaged,

and the barrel open. A barrel lug 20 extending from the

underside of the barrel 12 includes a birds-mouth or angled

being opened (see FIGS. 1, 4, 5 & 6); and out of engagement

With the barrel recess to release the break action and permit it

to be opened (see FIGS. 2, 3 & 7). A torsion spring biases the

locking block 30 toWard its engaged position.

[0035] The ?rearm 10 further comprises a trigger guard 40

(FIGS. 1-3), a hammer block portion 56 of the hammer 50

40 includes a concavely curved cam surface 44, Which

engages a folloWer nub or protrusion 32 extending from one

engages the top face of the extension arm 74. In the cocked

position (FIG. 4), a sear surface 58 of the hammer 50 engages

the notch or catch of the extension arm 74. When the trigger

is actuated into its ?ring position, the sear surface 58 of the

hammer 50 releases from the notch or catch of the extension

arm 74, and the hammer is driven under the in?uence of the

or both sides of the locking block 30. The trigger guard 40

pivots about a guard axis 46 above the tang 42 and of toWard

the rearWard extent of the trigger guard. A coil or mousetrap

hammer spring to impact the ?ring pin 60 and discharge the

?rearm. A trigger spring 76 engages a spring arm portion of

the trigger 70 to bias the trigger toWard its ready position.

spring biases the trigger guard 40 toWard its closed position

(FIG. 1). Pivoting the trigger guard 40 from its closed position

mechanism of the present invention includes a neutral center

that is pivotally connected to the frame 14, and includes a

loWer extension ?nger or tang 42 for pivotally actuating the

trigger guard. An upper extension portion of the trigger guard

into its open position (FIGS. 2 & 3) engages the cam surface

[0038]

As seen best With reference to FIG. 2, the trigger

of gravity in Which the trigger pin or pivot axis 80 is located

44 doWnWardly along and against the protrusion 32, toggling

in relation to the trigger member 70 so that all sides of the

the locking block 30 from its engagedposition (FIG. 1) Where

it prevents the barrel from opening, into its disengaged posi

tion (FIGS. 2 & 3) Where it permits the barrel to be opened.

Returning the trigger guard 40 to its closed position alloWs the

mately the same Weight and/or moment of inertia. The center

locking block 30 to return to its engaged position.

[0036] FIGS. 4-7 demonstrate a safety mechanism

Whereby the barrel 12 of the ?rearm 10 cannot be opened or

closed When the ?rearm is cocked, and cannot be cocked

When the barrel locking mechanism is disengaged. A hammer

50 of the ?rearm is pivotally mounted to the frame 14, and

moves betWeen a forWard or ?ring position, a middle or

neutral position (FIGS. 2, 3 & 6), and a rearWard or cocked

position (FIGS. 4 & 5). In the forWard or ?ring position, a

strikerportion 52 of the hammer impacts a ?ring pin assembly

60, Which in turn impacts the primer or percussion cap to

discharge the ?rearm. A hammer spring biases the hammer 50

toWard the ?ring position. As seen best With reference to

FIGS. 4 and 5, When the hammer 50 is in its cocked position,

a hammer extension portion 54 of the hammer abuts against a

contact surface or lobe portion 34 of the locking block 30,

thereby locking the locking block in its engaged position. In

its engaged position, the locking block 30 is engaged Within

the barrel recess 22 to prevent a closed barrel from opening,

and also blocks the sWing of the barrel lug 20 to prevent an

open barrel from being closed. Thus, the barrel can not be

opened or closed When the hammer is cocked. Preventing the

gun from opening or closing When cocked can reduce the

likelihood of unintended discharge of the ?rearm. FIG. 6

shoWs the relationship of the same parts When the hammer 50

is uncocked and at rest in its neutral position. In this position,

trigger member (in relation to the pivot axis) have approxi

of gravity or center of inertia of the overall trigger member 70,

and/or of the trigger member and any operatively connected

components affecting movement of the trigger member, are

preferably coincident With or closely positioned in relation to

the pivot pin 80 or other axis of movement of the trigger body.

For example, in the depicted embodiment, the mass of the

trigger boW portion 72 of the trigger member 70, Which lies on

a ?rst (loWer) side of the trigger mechanisms pivot axis 80,

times the distance betWeen that ?rst or proximal portion of the

trigger bodys center of gravity (CGP) and the pivot axis, is

equal to or approximately equal to (i.e., Within about

5%- l 0%) the mass of the opposed upper portion ofthe trigger

member (comprising the upper extension arm 74 and the

spring arm 76), Which lies opposite the trigger boW portion on

a second or opposed side of the pivot axis, times the distance

betWeen that second or distal portion of the trigger bodys

center of gravity (CGD) and the pivot axis. Additionally, a line

draWn betWeen the center of gravity (CGP) of the proximal

portion of the trigger member 70 and the center of gravity

(CGD) of the distal portion of the trigger member preferably

passes through or immediately adjacent the trigger pivot axis

80, With the centers of gravity CGP, CGD approximately

equidistant from the pivot axis. In this manner, the trigger

member 70 has a geometry that results in an equal and/or

symmetric distribution of its mass about the pivot point 80 of

the trigger. As such, if the gun is dropped and hits the ground

in any direction at all, there is equal or approximately equal

(e.g., Within the ability of the trigger return springs ability to

Sep. 16,2010

US 2010/0229446 A1

resist unintentional discharge) inertia on all sides of the pivot

pin so that every side affected cancels out the effect of the

opposite side. This greatly reduces the chance that the gun

10. The ?rearm of claim 7, further comprising a hammer

movable betWeen a neutral position and a cocked position,

and Wherein the locking block can not be moved out of the

Will ?re accidentally.

?rst position When the hammer is cocked.

[0039] While the invention has been described With refer

ence to preferred and example embodiments, it Will be under

stood by those skilled in the art that a variety of modi?cations,

additions and deletions are Within the scope of the invention,

as de?ned by the folloWing claims.

What is claimed is:

1. A ?rearm comprising:

a frame;

a barrel pivotally mounted to the frame, the barrel having a

breech end and a muZZle end;

a trigger pivotally mounted relative to the frame about a

trigger axis, the trigger comprising a proximal portion

on a ?rst side of the trigger axis and a distal portion on a

second side of the trigger axis opposite the ?rst side, and

Wherein the proximal portion has a Weight WP and the

distal portion has a Weight WD, and Wherein WP is

approximately equal to WD;

a locking block pivotally mounted to the frame and mov

able betWeen a ?rst position and a second position,

Wherein in the ?rst position the locking block engages

the barrel When closed to prevent pivotal motion thereof,

and in the second position the locking block is disen

gaged from the barrel to alloW pivotal motion of the

barrel relative to the frame; and

a trigger guard having a loop portion for shielding the

trigger, a forWard portion extending toWard the muZZle

end, and a rearWard portion extending aWay from the

muZZle end, the trigger guard being pivotally mounted to

the frame about a guard axis located toWard the rearWard

portion, the trigger guard having a cam surface for actu

ating the locking block to move betWeen its ?rst position

and its second position upon pivotal movement of the

trigger guard.

11. The ?rearm of claim 10, Wherein the ?rearm can not be

cocked When the locking block is not in the ?rst position.

12. The ?rearm of claim 10, Wherein the barrel of the

?rearm can not be opened or closed When the ?rearm is

cocked.

13. A ?rearm comprising a trigger member pivotally

mounted about a trigger axis, Wherein the trigger member

comprises a proximal portion on a ?rst side of the trigger axis

and a distal portion on a second side of the trigger axis

opposite the ?rst side, and Wherein the proximal portion has a

Weight WP and the distal portion has a Weight WD, and

Wherein WP is approximately equal to WD.

14. The ?rearm of claim 13, Wherein WP is betWeen 0.90

WD to 1.10 WD.

15. The ?rearm of claim 13, Wherein the proximal portion

has a ?rst center of gravity spaced a distance DP from the

trigger axis, and the distal portion has a second center of

gravity spaced a distance DD from the trigger axis, and

Wherein DPXWP is approximately equal to DDXWD.

16. The ?rearm of claim 16, Wherein a line draWn betWeen

the ?rst and second centers of gravity crosses at or near the

trigger axis.

17. The ?rearm of claim 13, comprising a muZZle-loading

?rearm.

18. The ?rearm of claim 13, Wherein the trigger member

further comprises an extension for direct engagement and

release of a hammer of the ?rearm.

19. A ?rearm comprising:

a trigger movable betWeen a ready position and a ?ring

2. The ?rearm of claim 1, comprising a muZZle-loading

?rearm Wherein the breech end of the barrel is closed.

3. The ?rearm of claim 1, further comprising a hammer

position, the trigger comprising an actuator portion for

movable betWeen a neutral position and a cocked position,

a hammer movable betWeen a neutral position, a cocked

and Wherein the locking block is locked in the ?rst position

When the hammer is cocked.

4. The ?rearm of claim 3, Wherein the hammer can not be

cocked When the locking block is not in the ?rst position.

5. The ?rearm of claim 1, Wherein the barrel of the ?rearm

can not be opened or closed When the ?rearm is cocked.

6. The ?rearm of claim 1, further comprising a hammer,

and Wherein the trigger further comprises an extension for

direct engagement and release of the hammer

7. A ?rearm comprising:

a frame;

a barrel pivotally mounted to the frame; and

a locking block pivotally mounted to the frame and mov

able betWeen a ?rst position and a second position,

manipulation by a user, and an extension arm having a

top face and a notch formed therein; and

position and a discharge position, the hammer compris

ing a hammer block portion and a sear surface;

Wherein the hammer block portion of the hammer engages

the top face of the trigger extension arm When the trigger

is in the ready position and the hammer is in the neutral

position, to prevent the hammer from moving to the

discharge position; and

Wherein the sear surface of the hammer engages the notch

of the trigger extension arm When the trigger is in the

ready position and the hammer is in the cocked position;

and

Wherein the hammer is released to the discharge position

When the trigger is moved to the ?ring position.

20. The ?rearm of claim 19, Wherein the trigger further

Wherein in the ?rst position the locking block engages

the barrel When closed to prevent pivotal motion thereof.

8. The ?rearm of claim 7, further comprising a trigger

guard, the trigger guard comprising a cam surface for moving

the locking block betWeen the ?rst position and the second

prises a trigger spring in engagement With the spring arm of

the trigger to bias the trigger toWard the ready position.

21. The ?rearm of claim 19, comprising a muZZle-loading

position.

?rearm.

9. The ?rearm of claim 7, comprising a muZZle-loading

?rearm.

comprises a spring arm, and Wherein the ?rearm further com

You might also like

- 锤执行器的枪支 PDFDocument7 pages锤执行器的枪支 PDFJin SongNo ratings yet

- 螺栓枪口装步枪 PDFDocument7 pages螺栓枪口装步枪 PDFJin SongNo ratings yet

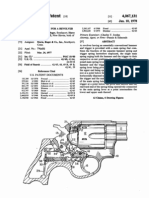

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- EP2369289A1Document10 pagesEP2369289A1awe234No ratings yet

- 可调式双级触发机制半自动武器 PDFDocument12 pages可调式双级触发机制半自动武器 PDFJin SongNo ratings yet

- Cetme Semi-Auto Sporter RifleDocument5 pagesCetme Semi-Auto Sporter RiflelordgwyddionNo ratings yet

- Us965386 PDFDocument6 pagesUs965386 PDFJin SongNo ratings yet

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 pagesPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияNo ratings yet

- Escort Instruction Manual GBDocument20 pagesEscort Instruction Manual GBJorge Andres Hartl100% (2)

- Ruger Mark IDocument7 pagesRuger Mark IAdam OrionNo ratings yet

- Steyr S40-A1Document63 pagesSteyr S40-A1AUGieDogie1No ratings yet

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- Mauser Model 45 ENGLISH PDFDocument19 pagesMauser Model 45 ENGLISH PDFIM_JohnnyV100% (1)

- ' Aug. 5, 1930. B. A. Revelli: Filed April' 22, 192sDocument4 pages' Aug. 5, 1930. B. A. Revelli: Filed April' 22, 192sЮрий РуденкоNo ratings yet

- Sub Machine Gun MGV 176 ManualDocument19 pagesSub Machine Gun MGV 176 ManualknockelfliesNo ratings yet

- Cobra BigBoreDerringer Manual PDFDocument40 pagesCobra BigBoreDerringer Manual PDFandrey33% (3)

- Us 4407085Document5 pagesUs 4407085rte678No ratings yet

- Evanix Tactical Sniper Owners ManualDocument16 pagesEvanix Tactical Sniper Owners ManualDavid DeMack II100% (1)

- Tanfoglio Thor Single Shot PistolDocument20 pagesTanfoglio Thor Single Shot PistolAndrew Gates100% (1)

- KMR QRF MCMR: Bravo Company MFG®Document3 pagesKMR QRF MCMR: Bravo Company MFG®Matt KienertNo ratings yet

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pages1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongNo ratings yet

- Post 6 38604 Reifgraber AutoDocument14 pagesPost 6 38604 Reifgraber AutoAoolf ManNo ratings yet

- Cetme: Special Purpose Assault MACHINEGUN 5.56x45Document24 pagesCetme: Special Purpose Assault MACHINEGUN 5.56x45Jon MorenoNo ratings yet

- Mossberg Brownie barrel dimensionsDocument1 pageMossberg Brownie barrel dimensionsCarlos sandoval100% (2)

- Revolver English PDFDocument1 pageRevolver English PDFmasinacrastura100% (2)

- AK47 Variation ChartDocument50 pagesAK47 Variation ChartNester Tovar100% (3)

- Valmet M-88Document12 pagesValmet M-88aki009No ratings yet

- GSG MP40 - 9x19 - America PDFDocument20 pagesGSG MP40 - 9x19 - America PDFeric100% (1)

- Sig MP46 MP48 Operation ManualDocument4 pagesSig MP46 MP48 Operation ManualohcockNo ratings yet

- Vepr Bullet Guide IntstallDocument2 pagesVepr Bullet Guide IntstallTawnee Rae HallNo ratings yet

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Document24 pagesUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongNo ratings yet

- CZ 92 Instruction Manual GuideDocument0 pagesCZ 92 Instruction Manual Guideab212amisar0% (1)

- STG 43 ManualDocument23 pagesSTG 43 ManualDavid NashNo ratings yet

- Build a semi-auto RPD rifle from a parts kitDocument6 pagesBuild a semi-auto RPD rifle from a parts kitDale Wade50% (2)

- Product Instructions - Flat Bending Jig InstructionsDocument34 pagesProduct Instructions - Flat Bending Jig InstructionsDale WadeNo ratings yet

- US Patent 4677897Document8 pagesUS Patent 4677897Mosin-NagantNo ratings yet

- P22 USA ManualDocument17 pagesP22 USA ManualJoni WilliamsNo ratings yet

- Cetme/HK Flat Bending Jig for AR-15 Lower Receiver BendsDocument7 pagesCetme/HK Flat Bending Jig for AR-15 Lower Receiver BendsRon WalshNo ratings yet

- C 96 BroomhandledisassemblyDocument56 pagesC 96 BroomhandledisassemblyKristjan ReinoNo ratings yet

- JERICHO Manual 08 011 08 15 00 PDFDocument74 pagesJERICHO Manual 08 011 08 15 00 PDFAlberto AmbiNo ratings yet

- Colt Peacemaker 22Document5 pagesColt Peacemaker 22Justin100% (3)

- 5 8366 PDFDocument68 pages5 8366 PDFguillermoNo ratings yet

- P64 ManualDocument15 pagesP64 ManualRobert OgburnNo ratings yet

- Firing Mechanism For A RevolverDocument9 pagesFiring Mechanism For A RevolverjonybravominiNo ratings yet

- H&K Field Stripping NewDocument53 pagesH&K Field Stripping Newkcluer8No ratings yet

- Pistol Nickl Us1427966Document11 pagesPistol Nickl Us1427966cll1968No ratings yet

- Dokumen - Tips Colt m1911 Frame BlueprintsDocument9 pagesDokumen - Tips Colt m1911 Frame BlueprintsRaul AlvarezNo ratings yet

- Tel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Document4 pagesTel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Radim KadlecNo ratings yet

- 9mm BSP Machine Gun: Legal NoteDocument29 pages9mm BSP Machine Gun: Legal NoteLeonBackupsNo ratings yet

- Ruger Mark IV Tactical Spec SheetDocument1 pageRuger Mark IV Tactical Spec SheetAmmoLand Shooting Sports NewsNo ratings yet

- Ammo TM ExtractDocument6 pagesAmmo TM ExtractNester TovarNo ratings yet

- Puma M1887 Lever Shotgun ManualDocument24 pagesPuma M1887 Lever Shotgun Manualesporadico123100% (1)

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Altrimanuali Documento 23Document27 pagesAltrimanuali Documento 23Wesley Maia100% (2)

- Kalashnikov AK74 Assault RifleDocument49 pagesKalashnikov AK74 Assault RifleJustin LeeNo ratings yet

- Practical Guide to the Operational Use of the PPS-43 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunNo ratings yet

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesFrom EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesNo ratings yet

- Practical Guide to the Operational Use of the PPSh-41 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPSh-41 Submachine GunRating: 5 out of 5 stars5/5 (2)

- 撞针选择的枪 PDFDocument9 pages撞针选择的枪 PDFJin SongNo ratings yet

- 可调式双级触发机制半自动武器 PDFDocument12 pages可调式双级触发机制半自动武器 PDFJin SongNo ratings yet

- (GUNSMITHING) Sten Submachine Gun WWIIDocument7 pages(GUNSMITHING) Sten Submachine Gun WWIIMago Invisivel100% (10)

- 枪炮声抑制器 PDFDocument11 pages枪炮声抑制器 PDFJin SongNo ratings yet

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Document24 pagesUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongNo ratings yet

- 级触发自动武器 PDFDocument15 pages级触发自动武器 PDFJin SongNo ratings yet

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDocument6 pages偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongNo ratings yet

- 安装装置,枪支消声器 PDFDocument28 pages安装装置,枪支消声器 PDFJin Song100% (1)

- 块化插入触发器的方法和装置5 PDFDocument23 pages块化插入触发器的方法和装置5 PDFJin SongNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,069,602 B2Document13 pagesUlllted States Patent (10) Patent N0.: US 8,069,602 B2Jin Song100% (1)

- Us5274939 PDFDocument7 pagesUs5274939 PDFJin SongNo ratings yet

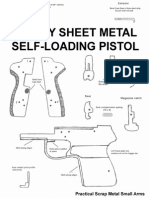

- The DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFDocument15 pagesThe DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFgunpdfs93% (121)

- Us7946069 PDFDocument15 pagesUs7946069 PDFJin SongNo ratings yet

- Us6308609 PDFDocument18 pagesUs6308609 PDFJin SongNo ratings yet

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pages1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongNo ratings yet

- Us6418655 PDFDocument17 pagesUs6418655 PDFJin SongNo ratings yet

- Us7676976 PDFDocument35 pagesUs7676976 PDFJin SongNo ratings yet

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongNo ratings yet

- Us4854065 PDFDocument7 pagesUs4854065 PDFJin SongNo ratings yet

- Us4522106 PDFDocument13 pagesUs4522106 PDFJin Song100% (1)

- Us4358986 PDFDocument9 pagesUs4358986 PDFJin SongNo ratings yet

- Us4467698 PDFDocument11 pagesUs4467698 PDFJin Song100% (1)

- Us3276323 PDFDocument7 pagesUs3276323 PDFJin SongNo ratings yet

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Document16 pagesSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongNo ratings yet

- Limited States Patent: LngramDocument7 pagesLimited States Patent: LngramJin SongNo ratings yet

- Nov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Document6 pagesNov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Jin SongNo ratings yet

- Mil STD 636Document79 pagesMil STD 636Carlos AntonioNo ratings yet

- Criminalistics Compilation Notes - 2Document215 pagesCriminalistics Compilation Notes - 2Ldrrmo IpilNo ratings yet

- Rule Book 3 FitaDocument42 pagesRule Book 3 Fitas27j06No ratings yet

- Five Rivers Auctions January 2014 Hand Gun CatalogDocument39 pagesFive Rivers Auctions January 2014 Hand Gun Catalogewood1999No ratings yet

- List of Firearms Before The 20th Century - WikipediaDocument34 pagesList of Firearms Before The 20th Century - WikipediarodairishmaeNo ratings yet

- CyberPunk 2020 - Source - Solo of Fortune II (CP3361) (MQ Scan)Document98 pagesCyberPunk 2020 - Source - Solo of Fortune II (CP3361) (MQ Scan)Gergő Tóth88% (8)

- Army Vehicles EquipmentDocument35 pagesArmy Vehicles Equipmentapi-26808978100% (3)

- Tikka T3X Tac A1 Accessories & Spare Parts CatalogueDocument17 pagesTikka T3X Tac A1 Accessories & Spare Parts CatalogueIonutMircea100% (1)

- Calibers and their effectivenessDocument3 pagesCalibers and their effectivenessMaverick' ChurchNo ratings yet

- 9 LINER REPAIR RECOVERY REQUESTDocument1 page9 LINER REPAIR RECOVERY REQUESTKerry WeiNo ratings yet

- PP 90Document13 pagesPP 90Rob slaatsNo ratings yet

- La Longue Carabine Fallout Wiki FandomDocument1 pageLa Longue Carabine Fallout Wiki FandomGiancarlo Farias dos SantosNo ratings yet

- Threads For Lee Enfield Rifle PDFDocument3 pagesThreads For Lee Enfield Rifle PDFIvan DuncanNo ratings yet

- Unit 7 - MarksmanshipDocument82 pagesUnit 7 - Marksmanshipsca0808100% (1)

- Production Information For Military Versions of The Model 1911 Handgun MFG From 1912 To 1945Document10 pagesProduction Information For Military Versions of The Model 1911 Handgun MFG From 1912 To 1945blowmeasshole1911No ratings yet

- 2012 Noveske CatalogDocument26 pages2012 Noveske CatalogMario LopezNo ratings yet

- Destiny 2 Massive Breakdown Weapon Stats Spreadsheet PDFDocument22 pagesDestiny 2 Massive Breakdown Weapon Stats Spreadsheet PDFjwickwickNo ratings yet

- T2K Infantry WeaponsDocument107 pagesT2K Infantry WeaponsLesbian E-Girl67% (3)

- Dust Warfare Unit CardsDocument15 pagesDust Warfare Unit CardsLes Shorey100% (2)

- 5.7x28 Hand LoadsDocument4 pages5.7x28 Hand LoadsK Scott Wyatt100% (1)

- Fast Change BarrelDocument2 pagesFast Change BarrelMago Invisivel100% (1)

- AirgunningDocument61 pagesAirgunningRajeev DudiNo ratings yet

- Rationalization in Ballistics and Questioned DocumentsDocument123 pagesRationalization in Ballistics and Questioned DocumentsGina Cambongga33% (3)

- TARDY & GODWIN v. Hogan, Et. Al. - 4th Circuit Appeals Ruling en BancDocument116 pagesTARDY & GODWIN v. Hogan, Et. Al. - 4th Circuit Appeals Ruling en BancGrant Stern100% (1)

- Pisto Shot AnalysisDocument1 pagePisto Shot Analysisapi-3695814No ratings yet

- 2012 HK Product CatalogDocument15 pages2012 HK Product CatalogPredatorBDU.com100% (1)

- Sako S20Document32 pagesSako S20OneMAN TwoWHEELSNo ratings yet

- Naval Postgraduate School Monterey, CaliforniaDocument109 pagesNaval Postgraduate School Monterey, CaliforniaMarcelo MartinezNo ratings yet

- D585D Gustloff Volkssturmgewehr VG 1 5 Rifle GermanyDocument2 pagesD585D Gustloff Volkssturmgewehr VG 1 5 Rifle GermanyKurt100% (1)