Professional Documents

Culture Documents

锤执行器的枪支 PDF

Uploaded by

Jin SongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

锤执行器的枪支 PDF

Uploaded by

Jin SongCopyright:

Available Formats

United States Patent [191

[l 11

4,023,296

Frisoli

[45]

May 17,1977

[54] I-IAMMERACTUATORS FOR FIREARMS

[76] Inventor: David M. Frisoli, 2 Homestead

Road, Edison, NJ. 08817

[22] Filed:

Feb. 4, 1976

[21] Appl. No.: 655,000

[52]

[51]

[58]

US. Cl. .............................................. .. 42/69 B

Int. Cl.2 ....................................... .. F41C 19/00

Field of Search ..................... .. 42/69 B; 89/125 '

[56]

References Cited

FOREIGN PATENTS 0R APPLICATIONS

427,973

8/1911

France ............................. .. 42/69 B

Pn'mary Examiner-Stephen C. Bentley

Attorney, Agent, or Firm-Arthur L. Plevy

[57]

ABSTRACT

A hammer of a typical ?rearm is cocked at a point

about a threshold of equilibrium so that the hammer

may or may not move forward when the trigger mecha

nism is activated; means associated with the trigger

mechanism imparts an additional force to the hammer

to assure that the hammer will move toward the ?ring

pin upon activation of the trigger.

The invention has utility in all firearms employing a

hammer and trigger mechanism, but has particularly

utility in regard to automatic or semi-automatic weap

ons.

6 Claims, 3 Drawing Figures

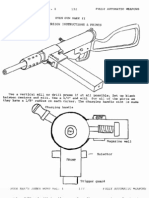

US. Patent

May 17, 1977

Sheet 1 of2

4,023,296

U.S. Patent

May 17, 1977

.5:

@Qom

v3

Sheet 2 of 2 _

4,023,296

4,023,296

Essentially, the hammer in such weapons is cocked so

that it is on the positive side of the null and exerts a

HAMMER ACTUATORS FOR FIREARMS

great force on the sear, which restrains the hammer

BACKGROUND OF THE INVENTION

from moving at this position. In such weapons, the sear

This invention relates to ?rearm triggering mecha 5 is highly polished and fabricated from a hard metal to

prevent wear due to the excessive force imposed

nisms and more particularly to a trigger mechanism for

a ?rearm capable of being activated with substantially ' thereon by the hammer. Such sears wear out relatively

fast, break and are subject to great forces and pressures

reduced trigger force.

in such weapons.

A major factor in determining the accuracy of a trig

ger actuated ?rearm resides in the users ability to 10 It is an object of this invention to provide an im

proved trigger mechanism for a ?rearm associated with

squeeze or release the trigger. A practical trigger in

reduced trigger pull and hence, capable of improved

most weapons requires a substantial pressure to ?re the

accuracy.

weapon. A typical manually operated bolt weapon

requires a user to impart about 2 to 3 pounds of force BRIEF DESCRIPTION OF PREFERRED

to activate the trigger, while an automatic weapon may

'

EMBODIMENT

require 3 to 5 pounds of force.

In a weapon of the type employing a hammer for

It can be easily ascertained that the user in imparting

striking

a projectile to be ?red when struck, the im

these forces via his trigger ?nger, will move or vibrate

provement therewith of apparatus for providing a ham

the weapon in doing so and this, of course, will ad

20 mer release, comprising means coupled to said hammer

versely affect the accuracy of his shot.

for positioning the same prior to release at a point near

Due to these and other considerations, there exists in

equilibrium wherein said hammer is restrained in said

the prior art, a mechanism typically referred to as a

position prior to the ?ring of said weapon, relatively

hair trigger. Such a mechanism does not require a

independent

of any associated mechanism and solely

large trigger force to ?re the weapon. These mecha

25 due to said position de?ning a condition of marginal

nisms are typically implemented by providing a very

stability and selective actuator means coupled to said

shallow recess on the hammer; which recess engages

with a mechanism coupled to the trigger. Hence, a

slight movement of the trigger removes the mechanism

from the notch, allowing the hammer to go forward to

strike the ?ring pin.

In a proper weapon, the hammer is usually cocked at

a full position on the positive side of a null, so that

hammer to impart a force thereto when selected in a

direction to cause said hammer to revert from said

condition of marginal stability to cause said hammer to

30 strike said projectile when said actuator means are

selected.

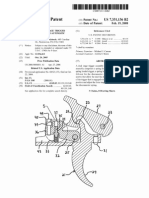

BRIEF DESCRIPTION OF FIGURES

when the hammer is released by the trigger, it will move

FIG. 1 is a partial structural side view of a trigger

rapidly toward the ?ring pin. In automatic weapons, the 35 actuator mechanism according to this invention.

hair trigger of the prior art cannot be used. This is so

FIG. 2 is a view similar to FIG. 1 depicting the release

as the shallow hammer notch and polished sear for

action of a triggering: mechanism according to this

restraining the hammer to enable hair trigger opera

invention.

tion, are much too critical and the weapon may ?re

FIG. 3 is a structural side view of another embodi

during automatic operation without using the trigger. 40 ment of a triggering mechanism particularly useful for

For example, an automatic weapon employing a hair

a single action weapon.

trigger mechanism may be ?red during bolt return or

DETAILED DESCRIPTION OF FIGURES

chambering of a fresh cartridge.

Thus, the hammer may inadvertently operate due to

Before proceeding with a detailed description, it is

the force of the bolt and thus ignite a cartridge without 45 noted that while the invention has particular utility in

trigger pull. This action will cause an automatic or

providing reduced pressure actuated trigger mecha

semi-automatic weapon to continuously ?re all rounds

nisms for automatic and semiautomatic weapons, the

without trigger pull and it is extremely undesirable,

concepts and structure have utility in single shot and

unsafe and unreliable.

other weapons, as well.

Furthermore, the hammer can also be released be 50 Referring to FIG. 1, there is shown a partial view of

fore the bolt is fully closed to cause a mis?re in a hair

the trigger mechanism of a weapon as a pistol, which

trigger weapon. These inadvertent operations can

may be of the semi-automatic type. As such, many

impose safety hazards on a user and are extremely

weapons operate accordingly and are designated as

dangerous and undesirable.

semi-automatic and so on. An example of such a

To prevent such problems, many prior art guns em 55 weapon may be had by reference to US. Pat. No.

3,866,516 by David M. Frisoli, the applicant herein and

ploy a hammer which is normally cocked almost at a

issued on Feb. 18, 1975 entitled SEMI-AUTOMATIC

null position, but slightly on the positive side. These

PISTOL EMPLOYING A PIVOTALLY, SLIDEABLE

weapons employ a polished sear which engages with a

MEMBER. This patent and US. Pat. No. 3,890,729

relatively deep hammer notch. The hammer in such

entitled PROJECTILE OR CARTRIDGE INJECTOR

weapons is prevented from reaching the null point or

FOR AUTOMATIC WEAPONS EMPLOYING MAG

going behind or on the negative side of the null, by a

AZINES issued on June 24, 1975 to said David Frisoli

mechanical stop which is positioned beneath the ham

mer on the receiver and located to allow the hammer to

generally describe certain common operating charac

engage the sear when cocked. Hence, when the trigger

teristics of such automatic and semi-automatic weap

is activated, the sear moves to free itself from the ham 65 ons.

Referring to FIG. 1, there is shown a trigger mecha~

mer notch, and the hammer once unrestrained, will

nism according to this invention which may be in

move forward due to the cocking of the same at the

positive side of the null.

cluded, for example, on a double action semi

4,023,296

automatic pistol 10. As indicated above, such pistols

may be of many variations and many calibers, as the

principles involved and the structure contemplated by

prior art stopping location is depicted by the dashed

this invention can be implemented in a great number of

for the stop 31, the hammer 11A can be pivoted be

yond the null point. This would cause the strut 14 to

lock the hammer so that it would not returnv at all upon

line 31A.

As one can ascertain from the Figure, if it were not

various ?reanns. For purposes of explanation, the pis

tol 10 is a semi-automatic pistol and hence, as indicated

above, would not accommodate a hair trigger due to

release of the sear 19. This is undesirable in prior art

the automatic operation of the pistol during ?ring and

guns, as a locked hammer would not release upon acti

recoil.

A typical hammer mechanism 11 is shown. The ham

mer has a relatively pointed extension 12, which con-_

vation of the trigger 21.

Between the positive and negative positions is a cen

tral position of the hammer whereby it is at a point

ventionally engages a ?ring pin to ignite a cartridge

which can be referred to as a threshold of equilibrium.

during ?ring. The hammer is shown in a cocked posi

If the hammer were cocked at exactly this point, the

tion therefore depicting the weapon 10 in a ready to

plunger spring might cause it to go forward when the

?re state. This position of the hammer according to this

sear is released by the trigger or might cause it to lock.

invention, is extremely important as the hammer 11 is

The condition is sometimes referred to as conditional

positioned close to the equilibrium point or slightly on

or marginal stability.

the negative side of the equilibrium or null position of

In this invention, the hammer 11 is purposely cocked

the hammer assembly. What is meant by this will be

at this null point or equilibrium point or slightly nega

come clear when describing the remaining structure. 20 tive to the same. This causes, as indicated above, the

In many weapons, the hammer 11 is conventionally

hammer to be in a marginally locked position whereby

coupled to a strut 14. The strut 14 may be of an arcuate

it might not move at all when the sear 19 is released by

con?guration and is coupled to a hammer plunger

mechanism 15. The hammer plunger mechanism in

the trigger. This locking of the hammer 11 at the null is

accomplished via the strut 14 and the spring 17. It is

cludes a shaft 16 surrounded by a hammer spring 17; all 25 noted that if the hammer is, in fact, locked or at the

of which are enclosed in a retaining housing 18. Thus,

null, there is absolutely no pressure or relatively little

as shown for the position of the hammer 11, the spring

pressure exerted by the hammer 11 on the sear l9 and

17 is compressed due to the force exerted on the same,

the sear therefore acts merely as a blocking mechanism

via the strut 14 as coupled to the hammer 11.

to assure that the hammer will never spring forward, if

In a normal gun, the strut 14 and the spring retaining 30 the trigger is not activated.

housing 18 are aligned with respect to the receiving end

Hence, the sear 19 acts as a blocking mechanism,

of a gun so that at full cock, the hammer is set at a

rather than a release device as utilized in the prior art.

positive side of equilibrium. This, therefore assures that

Since in this position, there is no pressure on the sear,

the hammer will ?y forward when the trigger mecha

nism is accessed, as will be explained.

Also shown is a sear mechanism 19. The sear 19 is

coupled to a crossbar 20 which in turn is coupled to a

trigger mechanism 21. A trigger return spring 22 is

shown for returning the trigger to a quiescent condition

35

there is relatively little pressure on the trigger. There

fore, this invention contemplates the use, if desired, of

a deeper notch in the hammer, thus assuring more

intimate contact with the sear projection 23. The

deeper notch will prevent the gun from ?ring if

dropped and so on. Furthermore, the sear 19 does not

after it has been released by a user.

40 have to be polished, nor treated as hardened due to the

As can be seen from the ?gure, there is a dashed line

fact that there is relatively little pressure on the same.

representation of a hammer designated as 11A, which

Shown coupled to the sear 19 in this invention, is a

would be the location of a prior art hammer. To sim

crank 33 which will be freferred to as a hammer trip

plify matters, the operation of a conventional trigger is

as follows:

crank. The crank 33 in a double action gun is coupled

45 to the sear 19 and may be pivotally mounted at a pivot

When the prior art hammer as 11A is cocked, the

strut 14 compresses the hammer spring 17 and the

hammer is thus restrained in the position shown by the

point 34 on the frame of the gun. The stop 31 of the

gun 10 is positioned such that the hammer is allowed to

cock at the null point or slightly on the negative side of

sear 19. The sear 19 may include a notch 23 located

the null point.

'

thereon which sits in a notch on the hammer to assure 50 In this invention, as the trigger is pulled, the projec

that the hammer will not move forward until the trigger

21 is activated. As can be seen from the Figure, as the

trigger 21 is pressed or squeezed in the direction of the

tion 23 of sear 19 is removed from the hammer 11, as

in prior art guns. However, as indicated, the hammer,

being at null or slightly on the negative side of null, is

arrow 25, the crossbar 20 is pulled in the direction of

locked. The crank 33, during trigger pull, is accessed

arrow 26. The crossbar has a projecting end 20A which 55 by the notch 23, which pivots the crank so that the end

coacts with an aperture 27 located on the sear 19.

35 of the crank imparts a force to the strut 14. This

Thus, the crossbar pulls the sear free from the hammer

slight force unbalances the hammer and is in a direc

1 1A. This allows the hammer, due to the force stored in

tion to cause the hammer to revert from a condition of

the spring 17, to ?y towards the ?ring pin located about

marginal stability or revert from the negative side of the

area 30 and to therefore provide suf?cient energy to 60 null point to the positive side and thus, the hammer

drive the ?ring pin of the weapon causing it to ignite

11A ?ies forward to strike the ?ring pin, as conven

the cartridge in the chamber.

tional.

'

The reason that the prior art hammer 11A goes for

It is important to note that the hammer 11 as cocked,

ward once the sear is released, is that it has been

isextremely unstable at the equilibrium point and may

cocked at the positive side of a null position. The cock 65 ?y'forward before the crank 33 ever touches the strut

ing of the hammer is assured by means of a stop 31

under certain conditions. However, this is not undesir

which is located beneath the hammer and prevents the

able since the sear will block the hammer if the trigger

hammer from going beyond a positive null position. A

is not activated. However, if the hammer is cocked on

w.

4,023,296.

the negative side of equilibrium, thecrank 33._assures

activated by a crossbar 47 coupled to a trigger mecha

that the strut is accessed to cause the hammer to ?y

forward. In this manner, since there is no pressure

exerted by the. hammer on the sear 19, the trigger pull

nism, 48. The sear 49 is formed so that it has a projected

end closest to the hammer strut.42. When the trigger

48 is pulled back, the crossbar pushes a disconnector

can be practically. determined by the force exerted by

the sear return spring 36, which can. be on the order of p

less than an ounce.

pin 49, which inzturnrotates the sear causing the pro

jected end to eventually coact with the strut to force

the hammer past the null point towards the positive

It is thus ascertained that the cocking of the hammer

at equilibrium or slightly on the negative side of equi

librium virtually eliminates pressure on the sear, per

side. The hammer thus strikes the ?ring pin 50 with

increased velocity due to the increased compression of

the spring 44 because vof the full locked position of the

mitting activation of the hammer by negligible trigger

hammer.

pressure.

From the above ?gures and description, it could be

ascertained that there are many ways of accomplishing

The function and concept depicted in FIG. 1 is illus

trative only and it should be immediately apparent to . this setting of the hammer at equilibrium or at a null

those skilled in the art that there are a plurality of 15 positionand then to impart a force to the hammer or

mechanisms not disclosed which can afford the neces-

strut to assure that the hammer will coact with the

sary force to cause the hammer to revert from a condi

?ring pin only upon activation of the trigger and as

tion of marginal stability to a positive ?ring action.

such, one can- envision embodiments which might im

part the force directly to the hammer in an opposite

Thus, any device which imparts a force to a hammer

cocked as described is contemplated and is within the

scope and bounds of this invention.

20 direction tothat shown, or, for example, towards the

FIG. 2 is a schematic according to FIG. 1 showing the

or equivalent structure can be coupled directly to the

?ring pin. In a manually operated weapon, a trip crank

hammer trip crank 33 positively engaging the strut 14

during activation of the trigger 21.

trigger.

i As indicated above, it is a main desire of this inven

It can be ascertained again from FIG. 2 of the posi 25 tion to operate the hammer with any type of weapon at

tive action imparted by the mechanism to cause the

the point of equilibrium or slightly negative to that

hammer 11 to ?y forward.

.

point and then to imparta slight force directly to the

It is further noted that aside from the advantages

hammer or associated assembly to insure the positive

depicted above and relating to the elimination of pres

forward movement of the hammer under control of the

sure from the sear 19 and the substantial reduction in 30 triggering mechanism. In this manner, the apparatus

trigger pull, that there are other advantages associated

and structure can be employed on a great plurality of

with the mechanism described. Thus, it should be ap

weaponsand has, as indicated, particular utility in re

parent that due to the cocking of the hammer 11, the

gard to automatic and semi-automatic ?re arms.

spring 17 is further compressed or more compressed

It isalso noted that the manner in which the hammer

then it is in prior art devices. Since the hammer spring 35 is physically cocked, whether accomplished by the

17 stores potential energy which is converted to kinetic

movement of a barrel or other mechanism in a semi

energy by the hammer by further compressing the

automatic or automatic weapon or by a manual opera

spring, one can impart greater velocity to the hammer;

tion, is not pertinent to the operating characteristics of

thus assuring reliable cartridge ignition.

this invention, as long as the hammer as cocked is

Furthermore, the spring 17 is given more time to 40 caused to assume a rest position prior to ?ring at the

dissipate its energy and since there is a more efficient

null or equilibrium point or slightly negative thereto.

transfer of energy to the hammer, the operation of the

Hence, conventional means employed in existing weap

mechanism results in a hair trigger mode for an auto

ons of either automatically or manually cocking a ham

matic weapon, which eliminates all the disadvantages

mer are envisioned as being with the teachings of this

depicted above. The reliability is positively afforded by 45 invention.

the fact that the sear 19 functions as a blocking mecha

Many modi?cations and alternate embodiments

nism, rather than a release mechanism, but still enables

should be apparent to those skilled in the art and all

control of ?ring by the user, who must move the trigger

such structure is deemed to be encompassed within the

to ?re the weapon.

scope and breadth of the claims appended hereto.

FIGS. 1, and 2 also disclose an adjustment mechanism 50 What is claimed is: '

39 which may be included so the user can accurately

1. In a weapon of the type including a hammer means

for striking a projectile, a sear for releasing said ham

nism 39 includes a set screw 38 which has one end

mer when said weapon is to be ?red, a trigger mecha

coupled to the retaining housing 18 to move the same

nism coupled to said sear and operative to remove the

in the direction shown by arrow 37 to therefore control 55 same from said hammer when said trigger is operated,

or adjust the equilibrium point or setting point for the

in combination therewith the improvement comprising

adjust the null position of the hammer 14. The mecha

hammer l1 and the strut 14 mechanism.

apparatus for substantially reducing the force neces

sary to operate said trigger, comprising:

Referring to FIG. 3, there is shown a triggering mech

anism according to this invention as implemented on a

a. ?rst means for cocking said hammer means prior

single action type semi-automatic pistol.

to ?ring of said weapon relatively at a null point for

restraining said hammer means at said null point to

A hammer 40 is shown cocked at null or slightly

negative to a null point as ascertained by a stop 41. The

hammer 40 is coupled to a strut 42 which again has one

end accessing a hammer plunger 43 to compress a

hammer spring 44 located in a hammer spring guide 45.

In the above con?guration, the hammer is also

cocked at the null point or at equilibrium and is con

ventionally restrained by a disconnector 46, which is

cause said hammer means to self-lock relatively

independent of said position of said sear, whereby

said hammer means de?ne a state of marginal sta

65

bility,

b. second means coupled to said sear and responsive

to said trigger when operative to impart a force to

said hammer means in a direction to alter said state

4,023,296

of marginal stability to cause said hammer to strike

said projectile when said trigger is operated, said

a. means coupled to said hammer for positioning the

same prior to release at a point near equilibrium

second means including a pivotally mounted crank

assembly having one end in proximity with said

hammer, said crank assembly pivotally mounted on

said sear to cause said crank assembly to impart a

force to said hammer suf?cient to alter said state of

wherein said hammer is restrained in said position

prior to the ?ring of said weapon, relatively inde

pendent of any associated mechanism and solely

due to said position as de?ning a condition of mar

marginal stability when said sear is operated by said

ginal stability,

trigger.

2. In a semi-automatic weapon of the type including 10

a hammer assembly for striking a ?ring pin when re

leased from a cocked position by actuating a trigger

mechanism coupled to a sear mechanism for exerting a

restraining force to oppose the motion of said hammer

until trigger activation, said hammer coupled to a strut

operative to compress a spring when said hammer is

cocked to provide energy to said hammer for striking

b. a moveable blocking means located in front of said

locked hammer to prevent movement of the same

towards said ?ring pin in a ?rst position and move

able in a second position to provide a free path for

said hammer,

c. selectable means coupled to said blocking means

said ?ring pin, the combination therewith, comprising:

a. ?rst means for cocking said hammer relatively

about a null point to compress said spring via said 20

strut to cause said hammer to lock via said spring

and strut at a position determinative of marginal

stability, whereby said sear has relatively little

force exerted thereon due to said locking of said

hammer, and

provement in combination therewith of apparatus for

providing a hammer release, comprising:

25

for moving the same to said second position, and

d. means coupled between said blocking means and

said hammer for imparting a force to said hammer

during movement of said blocking means to said

second position to cause said hammer to revert

from said condition of marginal stability to thereby

strike said projectile, said means including a crank

lever pivotally mounted on said blocking means

and having one end adapted to coact with said

hammer, said lever operative to activate said ham

mer when said blocking means moves to said sec

b. second means coupled to said sear and operative

ond position.

to impart a force on said hammer su?icient to

4. The hammer release according to claim 3 further

release the same from said condition of marginal.

including means mounted on said weapon and adapted

stability to cause said hammer to strike said ?ring

pin, said second means including a crank member 30 when adjusted to selectively vary the locking position

of said hammer about said null point.

pivotally mounted on said sear and having one end

5. The apparatus according to claim 3 wherein said

coacting with said strut to impart a force to said

weapon

is a semi-automatic pistol.

strut and hence, to said hammer to release the

6. The apparatus according to claim 3 wherein said

same from said condition of marginal stability.

a trigger mechanism.

3. In a weapon of the type employing a hammer for 35 selectable means includes

*

*

*

*

*

striking a projectile to be ?red when struck, the im

40

45

50

55

60

65

You might also like

- 螺栓枪口装步枪 PDFDocument7 pages螺栓枪口装步枪 PDFJin SongNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Document15 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Jin Song100% (1)

- Us965386 PDFDocument6 pagesUs965386 PDFJin SongNo ratings yet

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 pagesPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияNo ratings yet

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Document24 pagesUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongNo ratings yet

- 可调式双级触发机制半自动武器 PDFDocument12 pages可调式双级触发机制半自动武器 PDFJin SongNo ratings yet

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongNo ratings yet

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- Us 4407085Document5 pagesUs 4407085rte678No ratings yet

- Us 5117735Document14 pagesUs 5117735sdfsdf333No ratings yet

- F69FZ Cip 22lr ChamberDocument1 pageF69FZ Cip 22lr ChamberJorho JorhoNo ratings yet

- ListDocument40 pagesListCarlos Ramos100% (1)

- Steyr S40-A1Document63 pagesSteyr S40-A1AUGieDogie1No ratings yet

- Pistol Nickl Us1427966Document11 pagesPistol Nickl Us1427966cll1968No ratings yet

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pages1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongNo ratings yet

- HK Flat Bending JigDocument7 pagesHK Flat Bending JigRon WalshNo ratings yet

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- Ruger MKIIDocument1 pageRuger MKIIMike PapeNo ratings yet

- Handgun Safety Reference Owner'S Manual: International, IncDocument34 pagesHandgun Safety Reference Owner'S Manual: International, IncpreceptiveinquirerNo ratings yet

- Chimera ManualDocument12 pagesChimera ManualticocrazyNo ratings yet

- Ruger Mark IV Target Pistol Model# 40159 SpecsDocument2 pagesRuger Mark IV Target Pistol Model# 40159 SpecsAmmoLand Shooting Sports NewsNo ratings yet

- Revolver English PDFDocument1 pageRevolver English PDFmasinacrastura100% (2)

- Cetme Semi-Auto Sporter RifleDocument5 pagesCetme Semi-Auto Sporter RiflelordgwyddionNo ratings yet

- Manual FT 229 PaDocument26 pagesManual FT 229 PaGregoryNo ratings yet

- P22 USA ManualDocument17 pagesP22 USA ManualJoni WilliamsNo ratings yet

- KMR QRF MCMR: Bravo Company MFG®Document3 pagesKMR QRF MCMR: Bravo Company MFG®Matt KienertNo ratings yet

- Us 20060101695Document11 pagesUs 20060101695galak12001No ratings yet

- AMT BackupDocument12 pagesAMT BackupJustin100% (1)

- US Patent 4677897Document8 pagesUS Patent 4677897Mosin-NagantNo ratings yet

- Trigger Slap and Doubling Trouble ShootingDocument8 pagesTrigger Slap and Doubling Trouble ShootingAdam Hemsley100% (2)

- @VLNNR:: Beretta 3,021,763Document8 pages@VLNNR:: Beretta 3,021,763wererNo ratings yet

- Sub Machine Gun MGV 176 ManualDocument19 pagesSub Machine Gun MGV 176 ManualknockelfliesNo ratings yet

- The Glock-43Document4 pagesThe Glock-43Twobirds Flying PublicationsNo ratings yet

- Pump Shotgun: Instruction ManualDocument5 pagesPump Shotgun: Instruction ManualJustinNo ratings yet

- Instruction Manual PT 1911: Read Carefully Before Using Your FirearmDocument32 pagesInstruction Manual PT 1911: Read Carefully Before Using Your FirearmbrumbackicNo ratings yet

- The Beretta 950B Mustela PlasticoDocument35 pagesThe Beretta 950B Mustela Plasticohans landaNo ratings yet

- Rechambering ShotgunsDocument6 pagesRechambering ShotgunsZardoz1090No ratings yet

- Merged Document 4Document11 pagesMerged Document 4api-256434925No ratings yet

- Escort Instruction Manual GBDocument20 pagesEscort Instruction Manual GBJorge Andres Hartl100% (2)

- RPD Build - Red Neck EngineerDocument6 pagesRPD Build - Red Neck EngineerDale Wade50% (2)

- JERICHO Manual 08 011 08 15 00 PDFDocument74 pagesJERICHO Manual 08 011 08 15 00 PDFAlberto AmbiNo ratings yet

- 级触发自动武器 PDFDocument15 pages级触发自动武器 PDFJin SongNo ratings yet

- Tanfoglio Thor Single Shot PistolDocument20 pagesTanfoglio Thor Single Shot PistolAndrew Gates100% (1)

- America's Rifle - The ARDocument15 pagesAmerica's Rifle - The ARlsilva171No ratings yet

- Mossberg Brownie Barrel PDFDocument1 pageMossberg Brownie Barrel PDFCarlos sandoval100% (2)

- CZ 805bren A1Document19 pagesCZ 805bren A1deckahmNo ratings yet

- CZ 75 P 07 Duty BrochureDocument2 pagesCZ 75 P 07 Duty BrochureGustavo Salas100% (1)

- Thompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866Document28 pagesThompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866johndone100% (1)

- Savage 187JDocument1 pageSavage 187Jspanky6276100% (1)

- H&K Field Stripping NewDocument53 pagesH&K Field Stripping Newkcluer8No ratings yet

- Ruger 22-45 Bolt Dis AssemblyDocument3 pagesRuger 22-45 Bolt Dis Assemblyapi-3840428100% (3)

- M76 Sporter Rifle ManualDocument12 pagesM76 Sporter Rifle Manualdebugster100% (1)

- STEN / 76: 9mm Sub Machine Gun SuppressorDocument6 pagesSTEN / 76: 9mm Sub Machine Gun SuppressorIngo QuanderNo ratings yet

- Instruction Manual Slavia 634 enDocument14 pagesInstruction Manual Slavia 634 enzeniek50% (2)

- Colt Peacemaker 22Document5 pagesColt Peacemaker 22Justin100% (3)

- Armscor - Squires Bingham 20 ManualDocument9 pagesArmscor - Squires Bingham 20 Manualmceldridge50% (2)

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.From EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Rating: 5 out of 5 stars5/5 (1)

- (GUNSMITHING) Sten Submachine Gun WWIIDocument7 pages(GUNSMITHING) Sten Submachine Gun WWIIMago Invisivel100% (10)

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDocument6 pages偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongNo ratings yet

- 枪炮声抑制器 PDFDocument11 pages枪炮声抑制器 PDFJin SongNo ratings yet

- 撞针选择的枪 PDFDocument9 pages撞针选择的枪 PDFJin SongNo ratings yet

- 安装装置,枪支消声器 PDFDocument28 pages安装装置,枪支消声器 PDFJin Song100% (1)

- 级触发自动武器 PDFDocument15 pages级触发自动武器 PDFJin SongNo ratings yet

- 块化插入触发器的方法和装置5 PDFDocument23 pages块化插入触发器的方法和装置5 PDFJin SongNo ratings yet

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pages1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,069,602 B2Document13 pagesUlllted States Patent (10) Patent N0.: US 8,069,602 B2Jin Song100% (1)

- Us4467698 PDFDocument11 pagesUs4467698 PDFJin Song100% (1)

- 可调式双级触发机制半自动武器 PDFDocument12 pages可调式双级触发机制半自动武器 PDFJin SongNo ratings yet

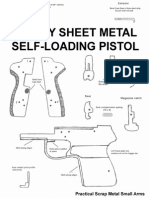

- The DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFDocument15 pagesThe DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFgunpdfs93% (121)

- Us4854065 PDFDocument7 pagesUs4854065 PDFJin SongNo ratings yet

- Us7946069 PDFDocument15 pagesUs7946069 PDFJin SongNo ratings yet

- Us6308609 PDFDocument18 pagesUs6308609 PDFJin SongNo ratings yet

- Us6418655 PDFDocument17 pagesUs6418655 PDFJin SongNo ratings yet

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongNo ratings yet

- Us4522106 PDFDocument13 pagesUs4522106 PDFJin Song100% (1)

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- Us5274939 PDFDocument7 pagesUs5274939 PDFJin SongNo ratings yet

- Us7676976 PDFDocument35 pagesUs7676976 PDFJin SongNo ratings yet

- Us4358986 PDFDocument9 pagesUs4358986 PDFJin SongNo ratings yet

- Limited States Patent: LngramDocument7 pagesLimited States Patent: LngramJin SongNo ratings yet

- Us3276323 PDFDocument7 pagesUs3276323 PDFJin SongNo ratings yet

- Nov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Document6 pagesNov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Jin SongNo ratings yet

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Document16 pagesSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongNo ratings yet

- UD150L-40E Ope M501-E053GDocument164 pagesUD150L-40E Ope M501-E053GMahmoud Mady100% (3)

- South Asia On ShortwaveDocument15 pagesSouth Asia On ShortwaveKasi XswlNo ratings yet

- Man D28Document44 pagesMan D28Jorge Barradas Osorno100% (1)

- Sin EncoderDocument6 pagesSin Encoderboynew87No ratings yet

- Practical Application of Pervious Concrete - Mix Designs That Are WorkableDocument20 pagesPractical Application of Pervious Concrete - Mix Designs That Are WorkablePJ FlexirNo ratings yet

- OGC-FIC-004-I-Cable Insulation Resistance-Field Installation ChecklistDocument2 pagesOGC-FIC-004-I-Cable Insulation Resistance-Field Installation ChecklistTaylorNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- Systemd CheatsheetDocument1 pageSystemd Cheatsheetzaffa11No ratings yet

- Power SteeringDocument31 pagesPower SteeringpeskeirasNo ratings yet

- Kategori Kompeten Penjaga Jentera Elektrik STDocument9 pagesKategori Kompeten Penjaga Jentera Elektrik STAbun ParadoxsNo ratings yet

- Vacuum Distillation (Ok)Document112 pagesVacuum Distillation (Ok)Ahmed Mohamed Khalil100% (1)

- C SB453H8A Sanyo 5.5TR CompressorDocument14 pagesC SB453H8A Sanyo 5.5TR CompressorHarsh Vani AroraNo ratings yet

- 2016 GME Steel ProductsDocument16 pages2016 GME Steel ProductsMarco Dos Santos NevesNo ratings yet

- Is 2571-1970Document27 pagesIs 2571-1970Deboline MitraNo ratings yet

- Drying Kinetics and Characteristic Drying Curve of Lightly Salted Sardine (Sardinella Aurita)Document8 pagesDrying Kinetics and Characteristic Drying Curve of Lightly Salted Sardine (Sardinella Aurita)Nguyen Thu HaNo ratings yet

- WG1AR5 Chapter08 FINAL PDFDocument82 pagesWG1AR5 Chapter08 FINAL PDFMariel YarrodNo ratings yet

- Network Protocol TutorialDocument43 pagesNetwork Protocol TutorialGiovanni RadiciNo ratings yet

- Settling Tank DecantDocument23 pagesSettling Tank Decantjvan migvelNo ratings yet

- WISKA Cable Glands and Junction Boxes English PDFDocument216 pagesWISKA Cable Glands and Junction Boxes English PDFtony6868No ratings yet

- Presentation 1Document8 pagesPresentation 1JACKMAAAANo ratings yet

- Uh X PDFDocument20 pagesUh X PDFRepresentaciones y Distribuciones FAL100% (1)

- Non Vital BleachingDocument19 pagesNon Vital BleachingPriyabrat Pattanaik100% (1)

- Security For VPNs With IPsec Configuration Guide - 15.2MTDocument166 pagesSecurity For VPNs With IPsec Configuration Guide - 15.2MTAnonymous fIXhrYSmNo ratings yet

- Epoxylite TSA 220 - TDS - 2008Document3 pagesEpoxylite TSA 220 - TDS - 2008Anonymous sAmJfcVNo ratings yet

- Chemistry Lab 2 Flame TestsDocument7 pagesChemistry Lab 2 Flame Testshpcoutinho36No ratings yet

- Oxygen Booster ManualDocument27 pagesOxygen Booster ManualAldo Tolaba Quiroga100% (3)

- Section 2 Airwothiness of Civil Aviation RequirementsDocument21 pagesSection 2 Airwothiness of Civil Aviation Requirementssuryaame67% (3)

- MGT6153.E1 Summer 2012 Multiple-Choice Exercise 1 - Answer KeyDocument14 pagesMGT6153.E1 Summer 2012 Multiple-Choice Exercise 1 - Answer Keyxbinhx100% (1)

- 6 Energy Calculation: UDEC Version 4.0Document28 pages6 Energy Calculation: UDEC Version 4.0Rakshit MishraNo ratings yet

- Converção de AçosDocument16 pagesConverção de Açoshelton dziedzicNo ratings yet