Professional Documents

Culture Documents

Sulfonates Fnweb

Uploaded by

GB ROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sulfonates Fnweb

Uploaded by

GB RCopyright:

Available Formats

Product Stewardship Summary

Sulfonates

Introduction

Table of Contents

The metallic salts of alkaryl sulfonic acids, commonly referred to as

sulfonates, belong to the class of lubricating oil additives known as

detergents. Unlike household detergents, these detergents are

specifically designed to be soluble in oil, and are insoluble in water.

Introduction

Description and Properties

Health Information

Environmental Information

Regulatory Information

Exposure Potential

Detergents are critical components of an engines lubricating oil,

providing protection whether its a lawn mower, car, or massive two story

marine diesel engine.

First, detergents provide a means for dissolving otherwise insoluble

metallic salts, like calcium or magnesium carbonate, in lubricating oil (see

manufacturing description below). As such they function like an antacid

for the engine, neutralizing corrosive combustion acids that would

otherwise dissolve key metal parts and eventually lead toengine failure.

Second, detergents prevent the buildup of harmful deposits on the rings

and in the grooves of the engine pistons. These deposits can cause the

rings of the piston to stick, causing potentially catastrophic liner wear,

which leads to loss of engine compression (power), poor emissions

quality and fuel economy, and eventually engine failure.

Description and Properties

Sulfonates appear as viscous amber liquids, and are insoluble in water.

They are denser than water, and as a consequence would sink if oured

into water. They have no appreciable odor. Per OSHA (Occupational

Safety and Health Administration US) guidelines they are not

considered flammable or combustible.

Page 1

Detergents are critical

components of an engines

lubricating oil.

To perform their everyday

functions as well as expected,

all their moving parts must be

powered and protected with

fuels and lubricants enhanced

by some of the most

technologically advanced

additives.

Product Stewardship Summary

Product Name Here (Header)

Detergents prevent the buildup of

harmful deposits on the rings and

in the grooves of the engine

pistons.

(

Figure 1. Chemical structure of a sulfonate contains critical parts.

Chemically sulfonates are made up of three parts a long hydrocarbon

tail which is responsible for their being soluble in lubricating oil; a polar

sulfonic acid head, which serves as a linking group to the third part, the

calcium carbonate base which is sequestered in the center of the

molecule. The amount of carbonate base present in the molecule is

tailored to the specific application for which the sulfonate is intended.

Figure 2. The heavy duty diesel piston is showing severe deposits due to

lack of sulfonates.

The detergent, or soap portion of the molecule (the long tail and polar

head) helps to clean engine deposits, especially on the piston ring and

lands. In the photograph above is depicted a piston showing how

carbonaceous deposits can build up without the correct selection of

detergent. To prevent this deposit build up, lubricating oils are formulated

with sulfonates that are high in soap content and relatively low in metallic

base. However there is still a need to neutralize harmful combustion

acids, so the solution is to use several different types of sulfonates, those

that are rich in soap to protect against engine deposits, and those that are

rich in metallic base to protect against corrosive wear from combustion

acids.

.

Health Information

Studies of sulfonates by the dermal, oral, and inhalation routes of

exposure indicate that these substances are low in acute toxicity by all

three routes of exposure. Signs of systemic toxicity occurred only at very

high dose levels that are much greater than typical human exposure.

Exposure via inhalation to the highest vapor concentration attainable did

not cause any deaths or signs of systemic toxicity.

Page 2

This summary is based on information as of January 2009.

Product Stewardship Summary

Product Name Here (Header)

Studies indicated that sulfonates generally have the potential to cause

only minimal irritation, and are not considered a potential irritant to the

skin or eyes according to current regulatory guidelines. Studies have

shown that sulfonates are skin sensitizers but when tested in human

patch tests, overbased sulfonates are not potential skin sensitizers.

The low volatility and low water

solubility of sulfonates limits the

potential for exposure, and

therefore risk, to people in the

workplace and consumers.

In studies, repeated exposures to sulfonates by the oral, dermal, and

inhalation routes of exposure caused reversible and non-life- threatening

systemic toxicity, low incidence of local skin injury at the site of

application, and local injury to the lungs, respectively. Evaluation of all the

data indicates that repeated-dose exposure to sulfonates demonstrates

low toxicity.

In vitro and in vivo studies have demonstrated that these substances lack

the potential to be genotoxic.

Environmental Information

At Chevron Oronite, we foster a culture grounded in operational

excellence and are conscientiously committed to protecting people and

the environment.

Sulfonates are not expected to undergo hydrolysis, photolysis, or

microbial degradation based on their chemistry, test data and predictive

modeling. Additionally due to their low vapor pressure and low water

solubility, they are more likely to partition into soil and sediment than into

air and water. Based on current data, sulfonates are unlikely to

bioaccumulate in the environment.

Sulfonates are not toxic to aquatic organisms based on a number of

studies.

In the event of a spill of a product containing sulfonates, stop the source

of the release if you can do it without risk. The Material Safety Data Sheet

for the product contains suggested spill response and clean-up

procedures. As appropriate (or required) report spills to local authorities.

In the USA the US Coast Guard can be reached at 1-800-424-8802 and

Chemtrec at 1-800-424-9300.

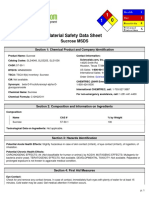

Regulatory Information

Requirements may exist that govern the manufacture, importation, sale,

transportation, use, and/or disposal of sulfonates or products containing

them. These requirements may vary by jurisdiction. For more information,

consult the relevant Material Safety Data Sheet (MSDS).

Exposure Potential

Sulfonates are not expected to

undergo hydrolysis, photolysis,

or microbial degradation based

on their chemistry, test data

and predictive modeling.

The low volatility and low water solubility of sulfonates limits the potential

for exposure, and therefore risk, to people in the workplace and

consumers. Indirect exposure to these chemicals via the environment is

likely to be negligible. Also, exposure to these substances during normal

lubricant use is low because they comprise only a fraction of the final

lubricant oil product.

Page 3

This summary is based on information as of January 2009.

Product Stewardship Summary

Product Name Here (Header)

Manufacturing of sulfonates generally occurs in dedicated closed systems

with proper engineering controls, thereby minimizing potential exposure.

Solid waste is either incinerated or recycled and therefore there is no

significant release to the environment. Waste water is treated before

release to a sewer or other appropriate system. Workers in manufacturing

plants, including those in sample analysis, blending, maintenance, and

cleaning and those involved in transportation are well trained in their

particular operations and wear appropriate personal protection

equipment, e.g. safety glasses, chemical resistant gloves, etc.

Sulfonates have no appreciable

odor.

Professional mechanics, service station attendants, and other skilled

workers that are frequently involved with oil changes use personal

protective equipment and hygiene practices that reduce potential

exposure to lubricant oils. Consumers have potential for exposure to

small amounts of these substances due to the possibility of skin contact

with fresh lubricant oils that can occur during crankcase oil changes or

periodic oil top off. There may also be infrequent, trivial inhalation

exposure to aerosols/vapor if top-off is conducted before the engine has

cooled. However, do-it-yourself consumer exposure is likely to be

relatively infrequent. In summary, there is minimal potential for exposure

of the consumer to sulfonates.

Disclaimer

Responsible Care Contact Information

Although the information on this Internet Web site and document are

presented in good faith and believed to be correct, Chevron Oronite Co.

LLC makes no representations or warranties of any kind, either express

or implied, regarding this information or the products to which this

information refers, including as to their completeness, accuracy,

merchantability, fitness for a particular purpose or otherwise.

Chevron Oronite Company LLC

Global Responsible Care Manager

6001 Bollinger Canyon Road

San Ramon, CA 94583-2324

Readers are advised to make their own determination as to the

suitability of any products for their purposes prior to use. In no event will

Chevron Oronite Co. LLC be responsible for damages of any nature

whatsoever resulting from the use of or reliance upon any of this

information or the product to which this information refers.

www.oronitegoes.com

Chevron Oronite Co. LLC makes no commitment to update or correct any

information that appears on the Internet or on the World-Wide Web server.

Page 4

This summary is based on information as of January 2009.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lutensol TO 12 SdsDocument13 pagesLutensol TO 12 SdsGülşah Özkula DemirakNo ratings yet

- Ensure A Safe Workplace Task-1Document11 pagesEnsure A Safe Workplace Task-1ibrahim MoustafaNo ratings yet

- Msds HCL 0,1 NDocument6 pagesMsds HCL 0,1 NRinie Aeryn Nayndine'netzzNo ratings yet

- All FormulaeDocument20 pagesAll FormulaeGB RNo ratings yet

- 10th Maths Centum Coaching Team Question Paper 4Document6 pages10th Maths Centum Coaching Team Question Paper 4GB RNo ratings yet

- GlutathioneDocument21 pagesGlutathioneGB R100% (1)

- Prepositions of Time: At, On, and In: English Grammar and Exercises For ESL LearnersDocument2 pagesPrepositions of Time: At, On, and In: English Grammar and Exercises For ESL LearnersGB RNo ratings yet

- Video 70 3654168076Document4 pagesVideo 70 3654168076GB RNo ratings yet

- Straight Line EquationDocument20 pagesStraight Line EquationGB RNo ratings yet

- Can Store Large Amount of Data in Its Storage Place For Feature Use. Computer Can Keep All Information We Need Written On Paper in Files in An Enormous Task. Once You Have Gone Through The TediousDocument1 pageCan Store Large Amount of Data in Its Storage Place For Feature Use. Computer Can Keep All Information We Need Written On Paper in Files in An Enormous Task. Once You Have Gone Through The TediousGB RNo ratings yet

- Transfer Factor CardioDocument2 pagesTransfer Factor CardioGB R100% (1)

- MSDS Freon R.22 DupontDocument8 pagesMSDS Freon R.22 DupontMahameru RayaNo ratings yet

- Jotashield PrimerDocument3 pagesJotashield PrimerNonie NNo ratings yet

- SHE ManualDocument221 pagesSHE ManualNellyUSA100% (1)

- Jubiliant MSDSDocument12 pagesJubiliant MSDShimanshushah871006No ratings yet

- 3M - Scotch Brand 1607 Heavy Duty Contact CleanerDocument7 pages3M - Scotch Brand 1607 Heavy Duty Contact Cleanerjaredf@jfelectric.comNo ratings yet

- MSDS TMCSDocument4 pagesMSDS TMCSimjohnphanNo ratings yet

- Silwet Adjuvants SAG Antifoams: Inventing PossibilitiesDocument12 pagesSilwet Adjuvants SAG Antifoams: Inventing PossibilitiesPongthip PesachpinankulNo ratings yet

- Vam Tech Sheet DowDocument2 pagesVam Tech Sheet DowManju Lata KapurNo ratings yet

- Painting Procedure - Rev.1Document30 pagesPainting Procedure - Rev.1didi sudiNo ratings yet

- MethylalDocument12 pagesMethylalWhitley RichardsNo ratings yet

- (+) - 5fluorodeoxyuridine MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pages(+) - 5fluorodeoxyuridine MSDS: Section 1: Chemical Product and Company IdentificationShelley HernandezNo ratings yet

- Sukrosa PDFDocument5 pagesSukrosa PDFSilvi TatianNo ratings yet

- Material Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument7 pagesMaterial Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingJessik CerónNo ratings yet

- Quick Start Guide Smartpower Solutions en 88540Document20 pagesQuick Start Guide Smartpower Solutions en 88540majd ibrahimNo ratings yet

- SDS US English FLUOROCARBON+GEL+875L-MSDocument7 pagesSDS US English FLUOROCARBON+GEL+875L-MSLizeth MejíaNo ratings yet

- SDS Protan Ventiflex Ducting Material 6298FR and 6698FR v.2.0 - ENGDocument3 pagesSDS Protan Ventiflex Ducting Material 6298FR and 6698FR v.2.0 - ENGTom HightNo ratings yet

- Eriochrome Black T Msds PDFDocument2 pagesEriochrome Black T Msds PDFDonaldNo ratings yet

- Candidate Report - SAMPLEDocument10 pagesCandidate Report - SAMPLEaitzaz561No ratings yet

- 6025 EPICON T-500 Rev (1504)Document2 pages6025 EPICON T-500 Rev (1504)UMUTNo ratings yet

- Supplier Quality ToolkitDocument5 pagesSupplier Quality ToolkitJosué PérezNo ratings yet

- Dosing Pump BTB4Document54 pagesDosing Pump BTB4Ci ReNo ratings yet

- H&S in The Home Care Enviornment - Lap - 301Document93 pagesH&S in The Home Care Enviornment - Lap - 301Jafar KhanNo ratings yet

- Combustible MetalsDocument7 pagesCombustible Metalsgh0stj0k3rNo ratings yet

- Eonspill 257 MailDocument6 pagesEonspill 257 MailBilal B.SNo ratings yet

- 海尔 PC+ABS NH-9012 MSDSDocument5 pages海尔 PC+ABS NH-9012 MSDSkatolokchokNo ratings yet

- Basf 9665 Conipur M 865 Z enDocument3 pagesBasf 9665 Conipur M 865 Z enMarijana JukicNo ratings yet

- Industrial Safety OutlineDocument16 pagesIndustrial Safety Outlinermallik1972No ratings yet